Core cooling system of pipe extruding mould

A technology of extrusion die and cooling system, applied in the field of cooling system for the core of pipe extrusion die, can solve the problems that the inner wall of the extrusion pipe cannot be cooled, the extrusion efficiency cannot be effectively improved, and the production cost is high, and the cost is low and the installation is convenient. , and the effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solutions and advantages of the present invention clearer, below in conjunction with embodiment and accompanying drawing, the present invention is described in further detail:

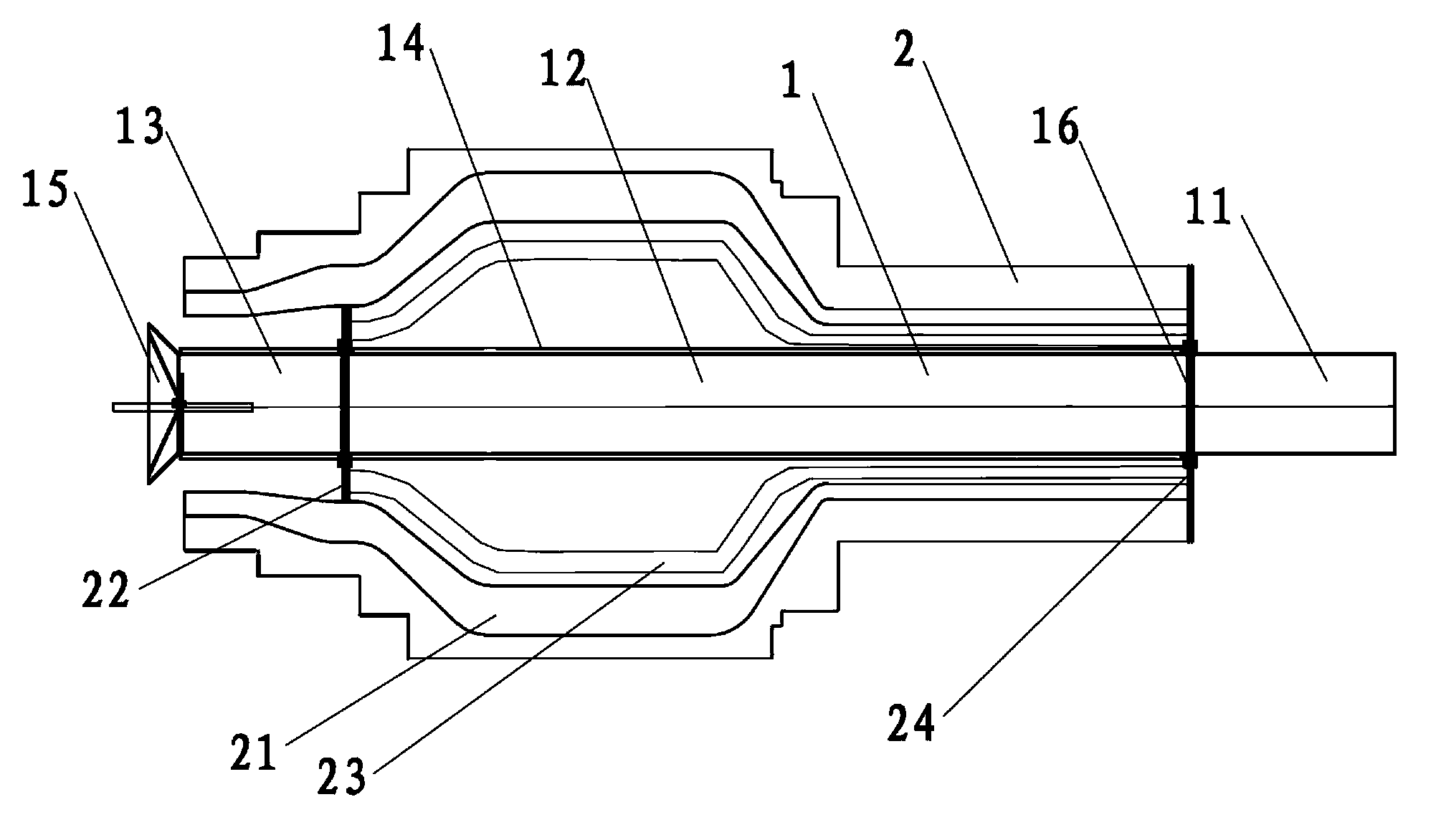

[0024] figure 1 The structure of the pipe extrusion die core cooling system provided by the present invention is schematically shown. As shown in the figure, the pipe extrusion die core cooling system includes a core mold 2 arranged inside the extrusion die, and on the core mold There are mutually independent extrusion channels 21 and a central cavity, and a cold air pipe 1 is pierced in the central cavity; wherein the cold air pipe 1 includes an air inlet tube 11, an intermediate air tube 12 and an air outlet tube 13, so The air inlet cylinder 11 protrudes from the outside of the mandrel; a heat insulating layer 14 is provided on the outer wall of the middle air cylinder 12; a cooling passage 23 is also provided at a position close to the extrusion passag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com