Patents

Literature

99results about How to "Improve extrusion quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

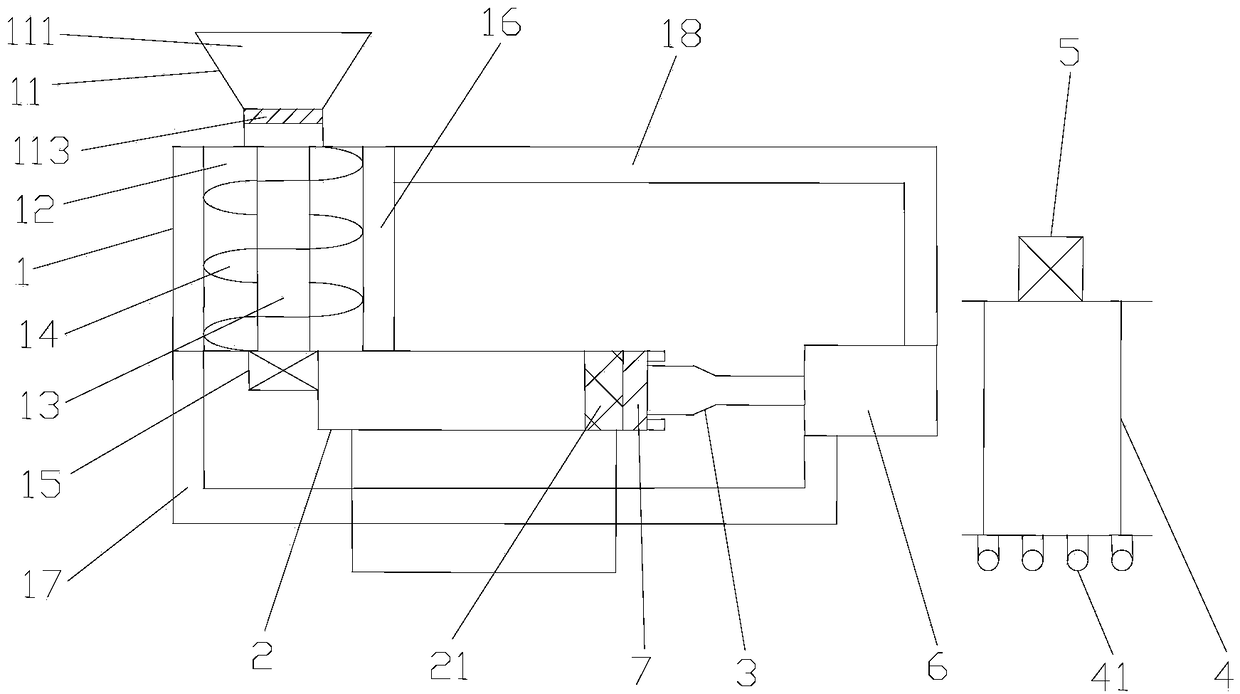

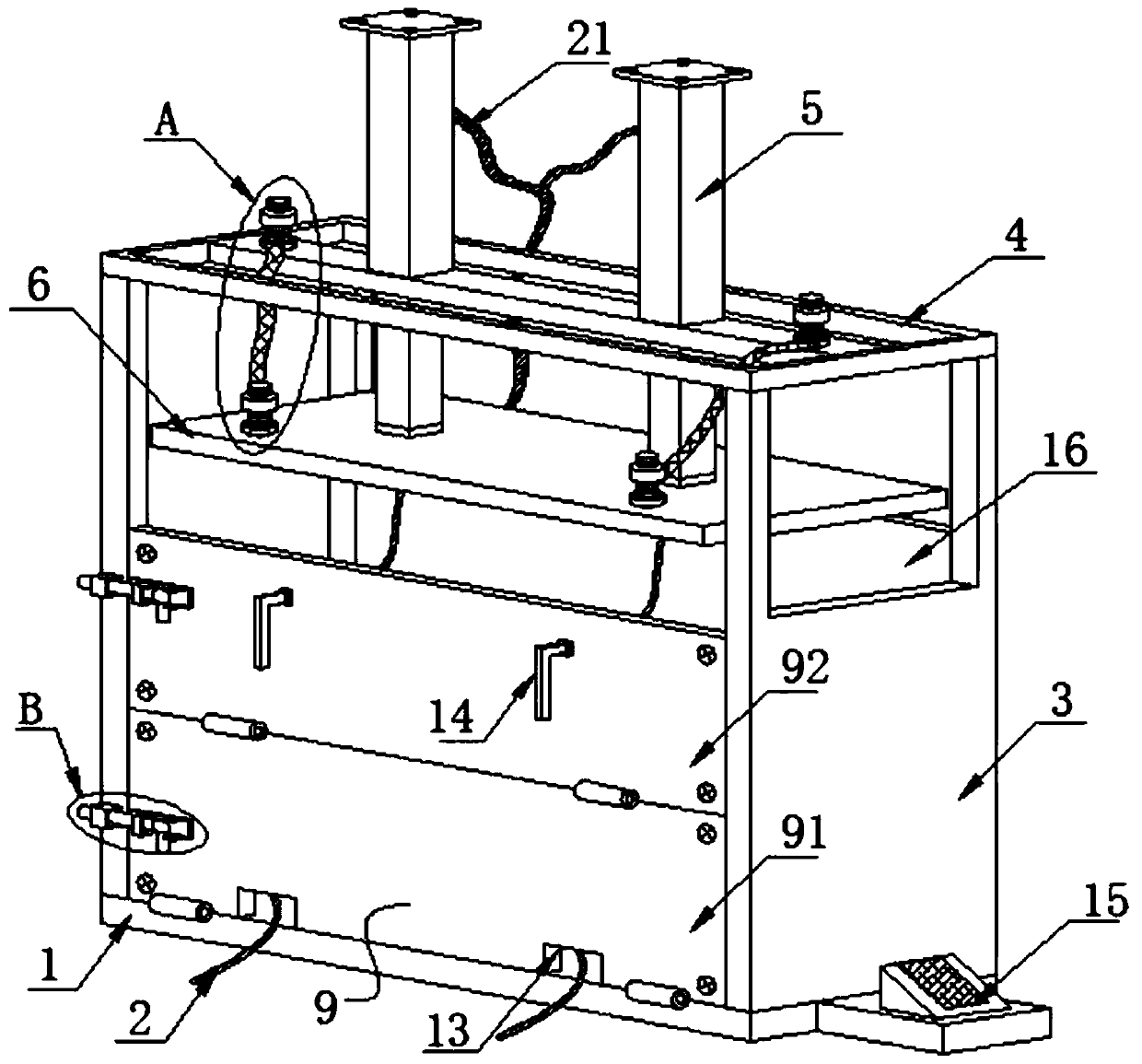

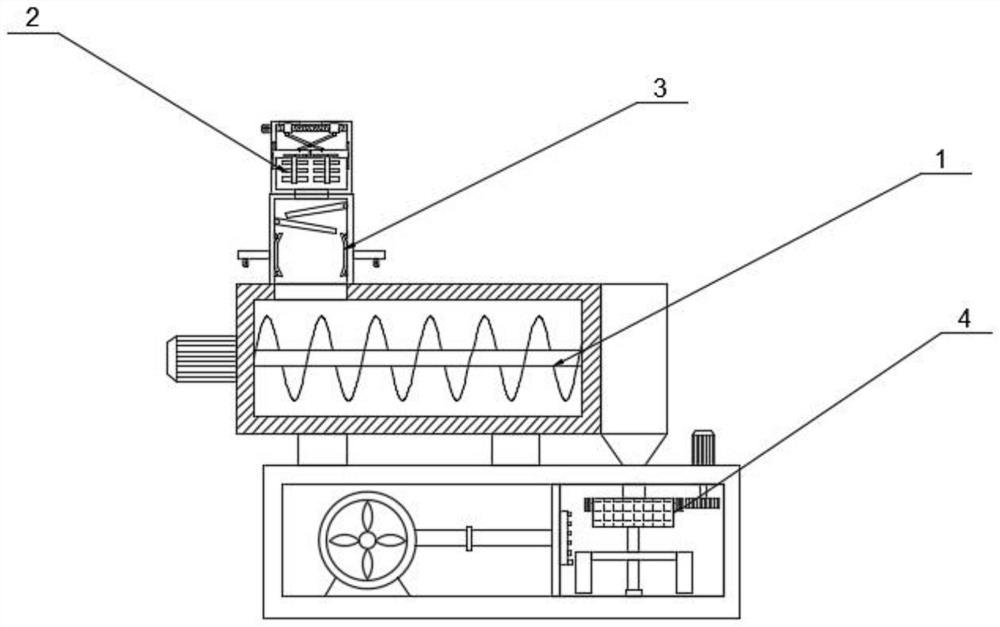

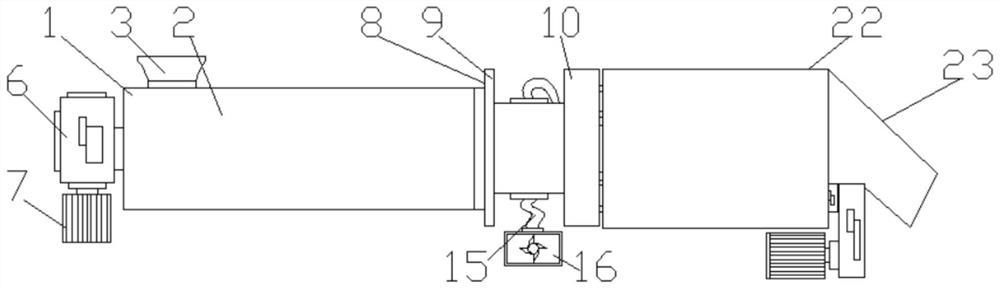

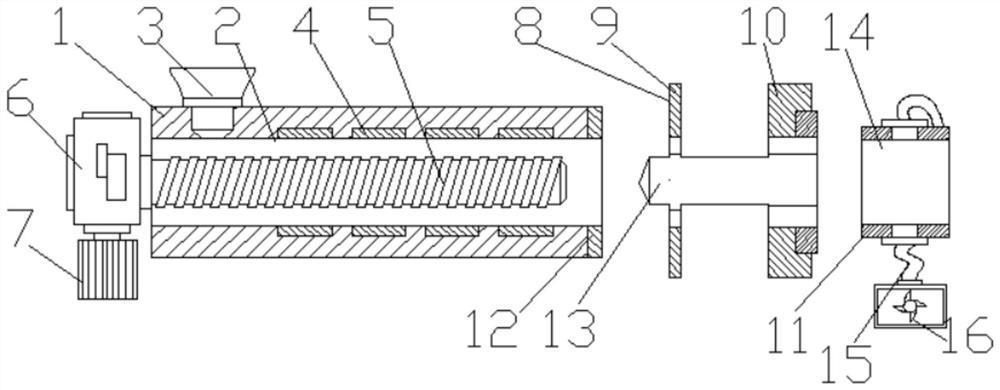

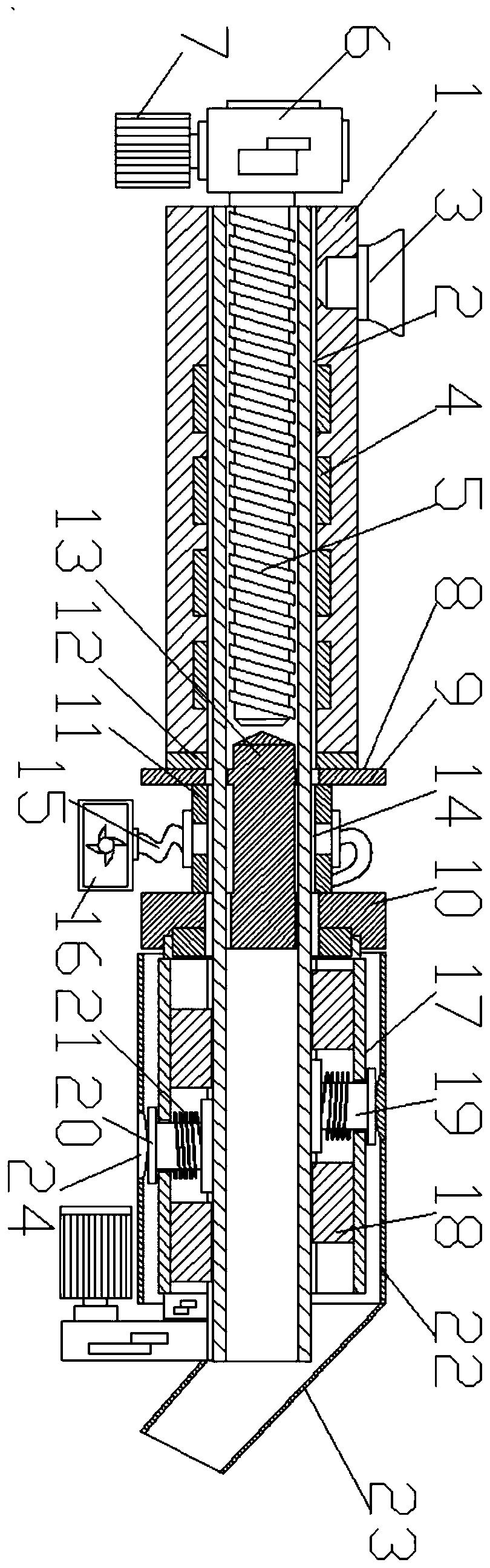

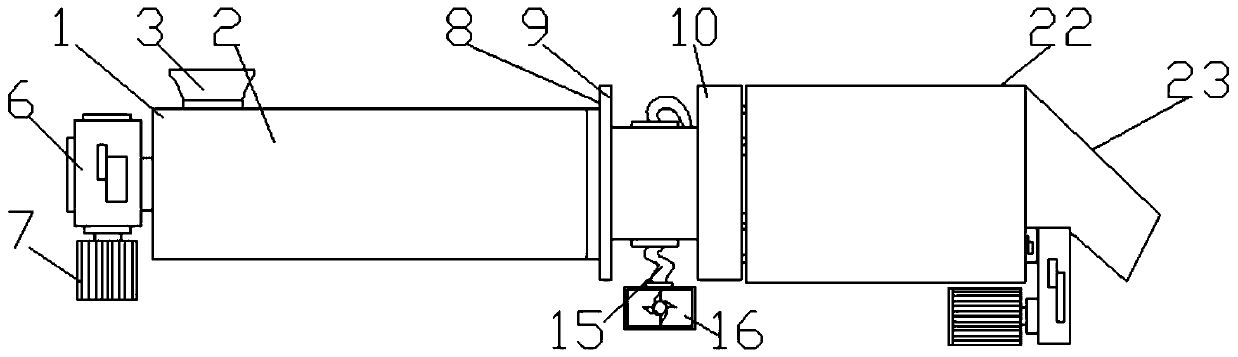

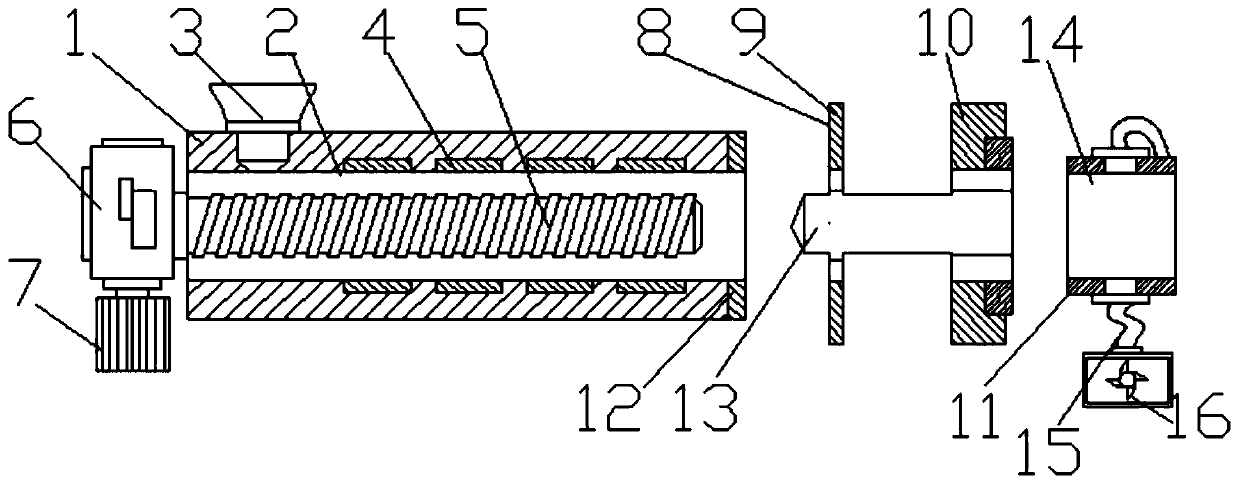

Efficient feed processing device and method

InactiveCN110063512AImprove processing efficiencyImprove processing qualityFeeding-stuffTransportation and packagingUv disinfectionEngineering

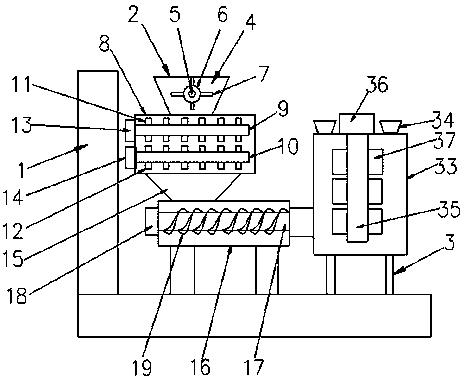

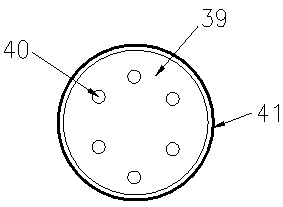

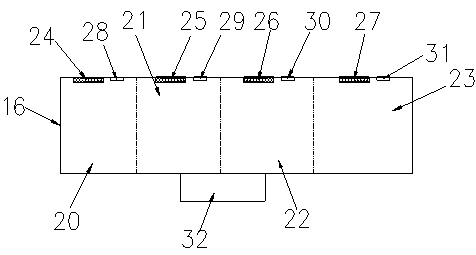

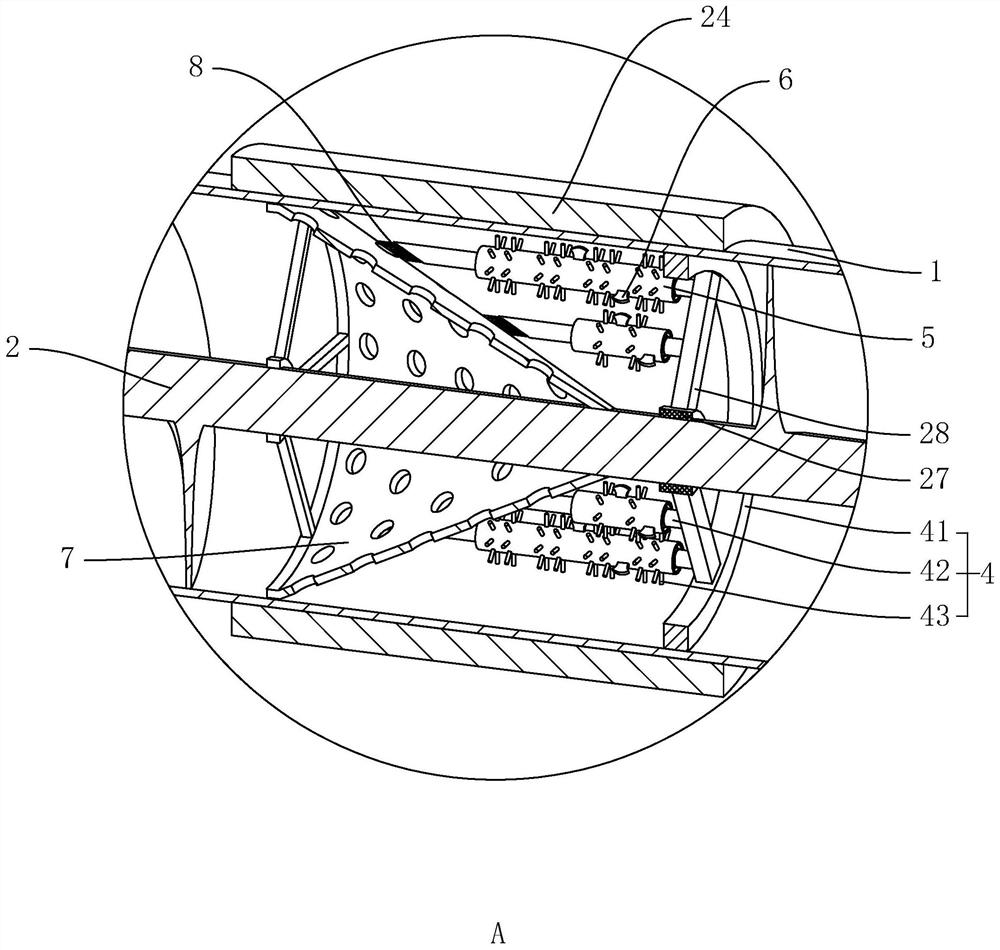

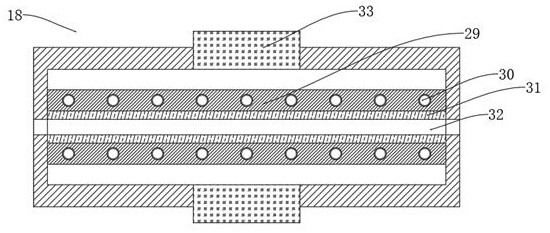

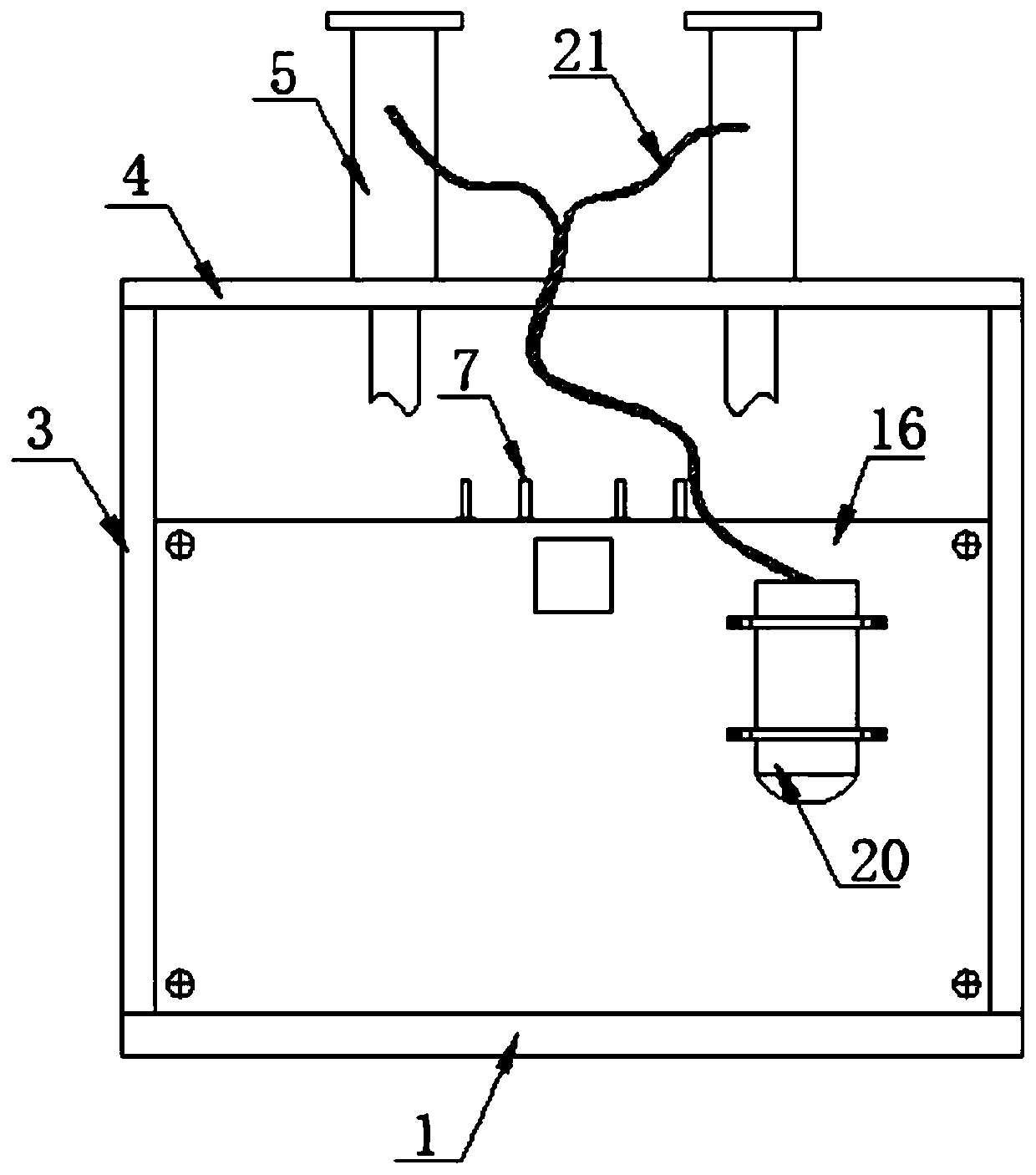

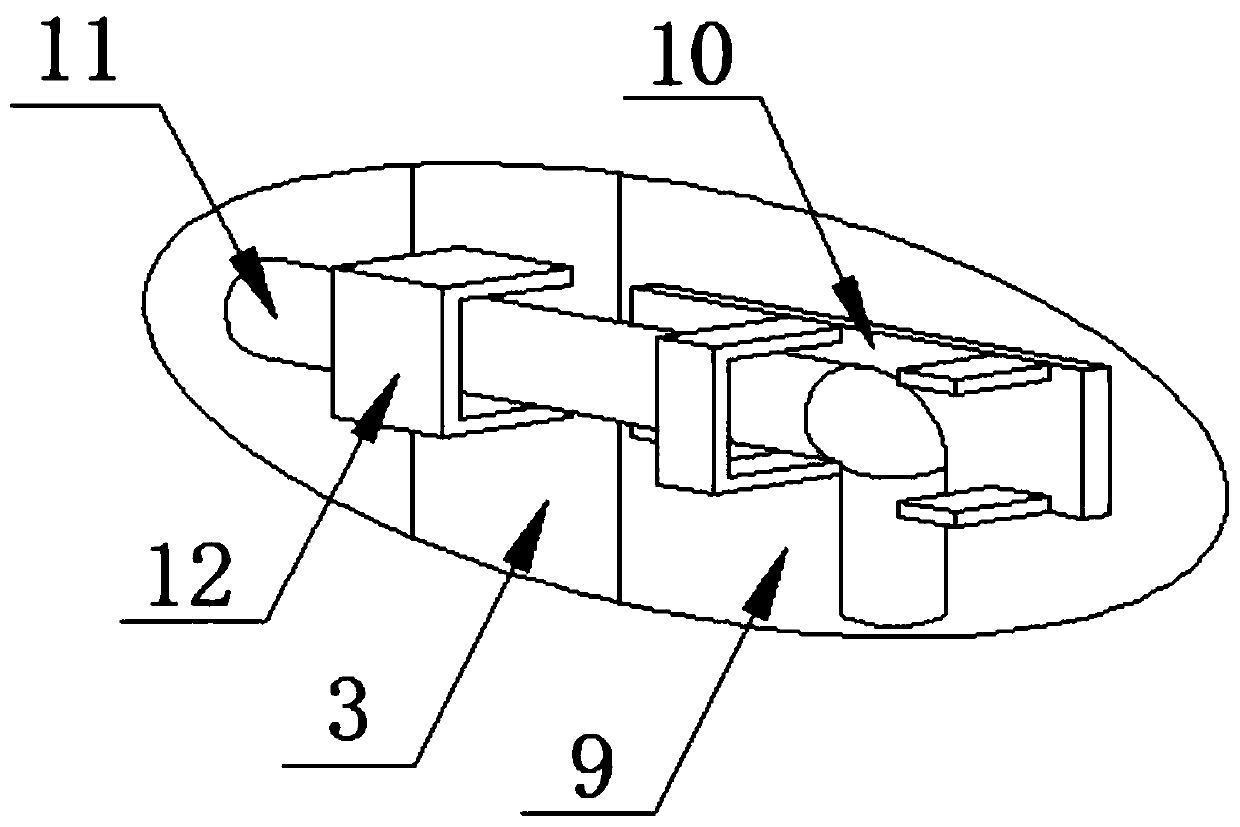

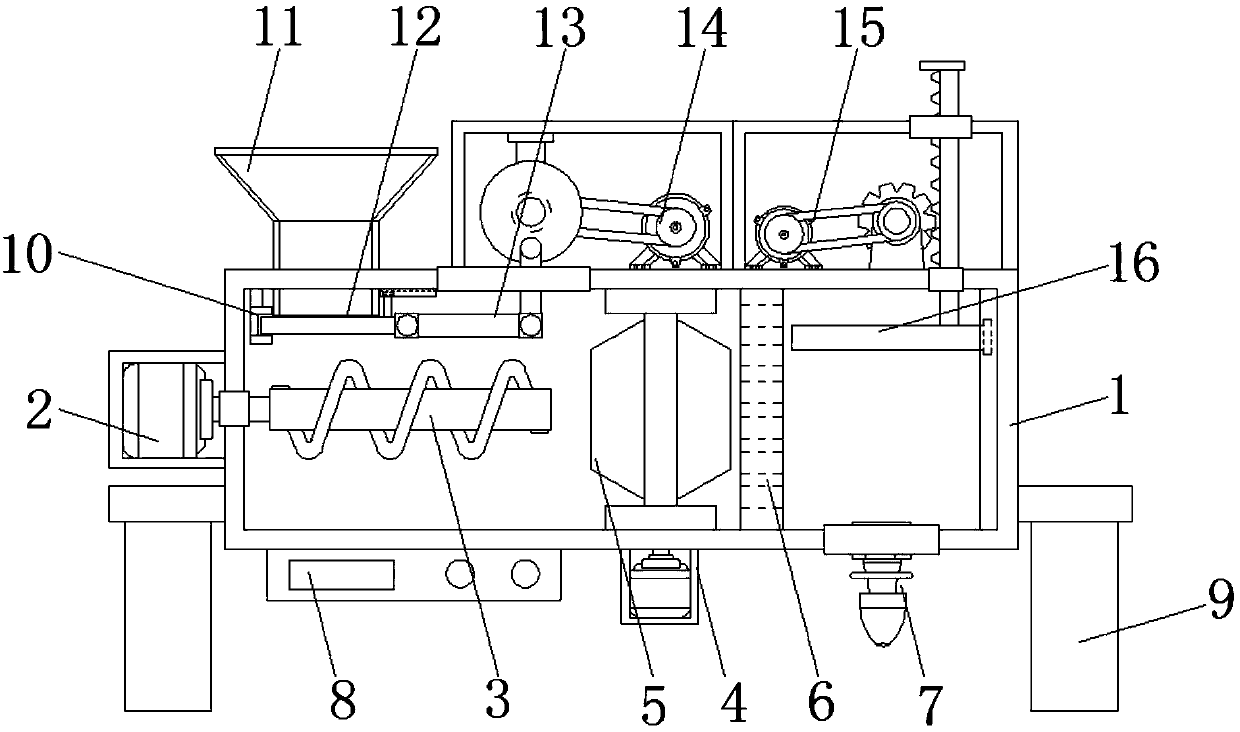

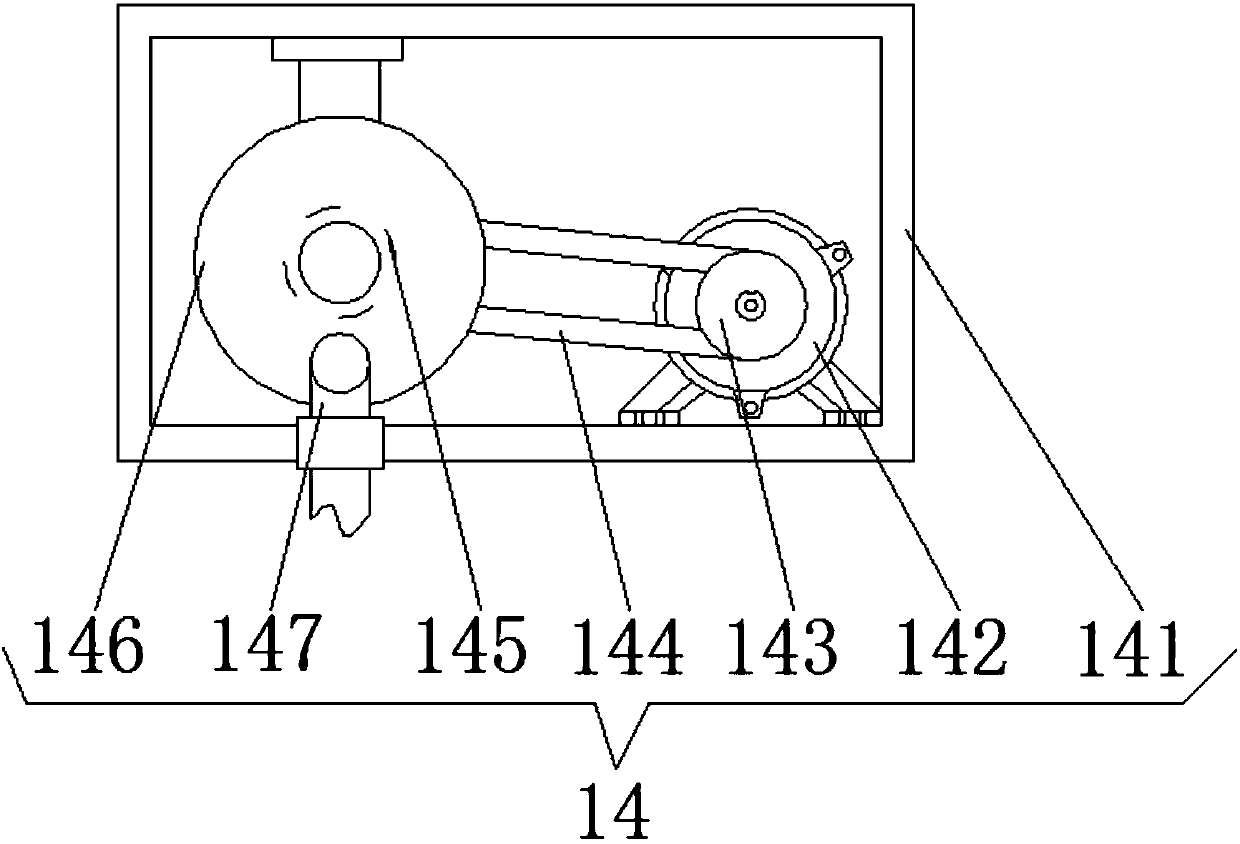

The invention discloses an efficient feed processing device and method. The device includes an L-shaped bracket, a crushing mechanism, an extrusion mechanism and a mixing mechanism are installed on the L-shaped bracket, a storage bin is installed on the upper portion of the crushing mechanism, the extrusion mechanism is installed on the lower portion of the crushing mechanism, the crushing mechanism is communicated with the extrusion mechanism, the stirring mechanism is installed on one side of the extrusion mechanism, and a recycling box is installed on the lower portion of the stirring mechanism. To-be-processed raw materials are mixed in the storage bin and then fed in the crushing mechanism for uniform crushing, the crushed materials are heated and extruded in the extrusion mechanism,and the extruded materials enter the stirring mechanism and then are mixed and stirred with an additive and finally discharged into the recycling box for ultraviolet disinfection. The structural design is novel, crushing, extrusion, stirring and disinfection of feed can be achieved, the feed processing efficiency and quality can be improved, and the labor intensity of workers is reduced.

Owner:王春梅

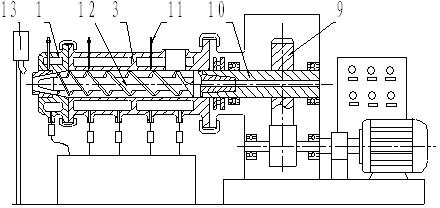

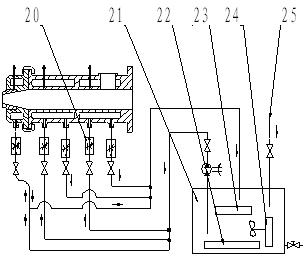

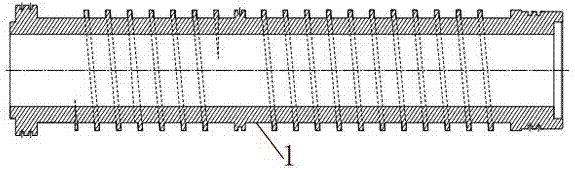

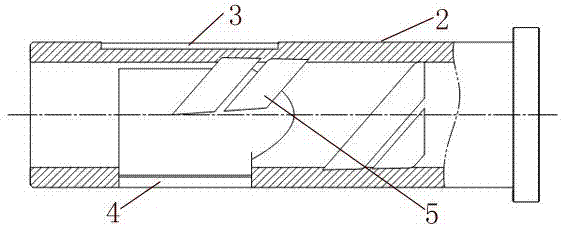

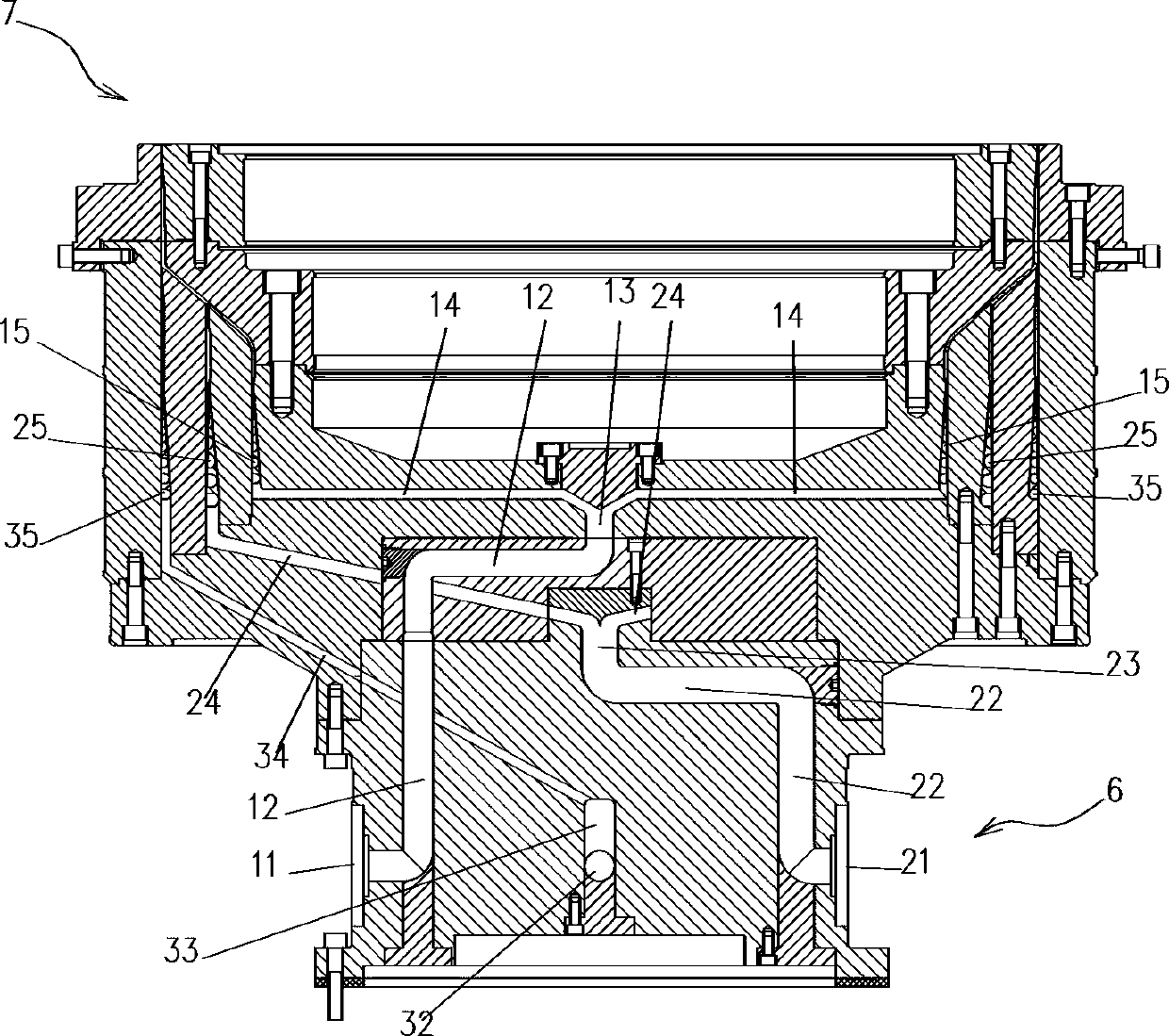

Experimental machine for testing extrusion properties of rubber

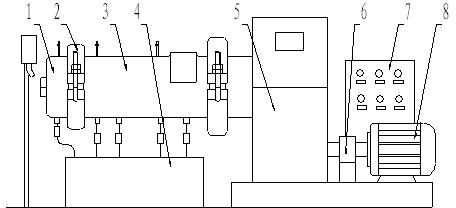

The invention provides an experimental machine for testing extrusion properties of rubber. The experimental machine for testing extrusion properties of rubber comprises a machine head, a machine body, a transmission mechanism, screws, a temperature control device and a control system. The control system comprises temperature thermocouples arranged on the machine body. The experimental machine for testing extrusion properties of rubber is characterized in that the screws have at least two helical structures; the tails of the screws are removably connected to a main transmission shaft of the transmission mechanism; and the control system also comprises an infrared temperature and speed detection device arranged on a rubber outlet of the machine head, and a torque sensing device arranged on an output shaft of a motor. The experimental machine for testing extrusion properties of rubber can realize comprehensive testing of extrusion performances of rubber prepared according to different formulas, provides reasonable and accurate technical conditions for actual production, improves the quality of rubber materials and rubber products, reduces energy consumption, and provides the basis for designing of various rubber extruders. The temperature control device has a simple structure, is convenient for control, and reduces a loss and a cost.

Owner:QINGDAO UNIV OF SCI & TECH

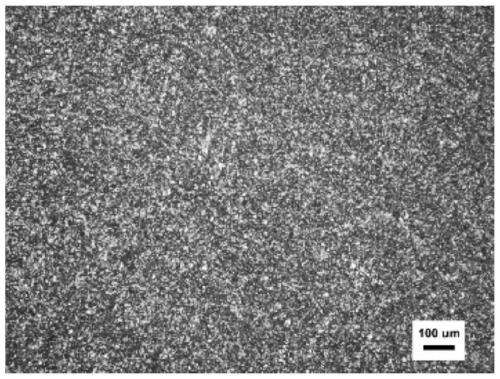

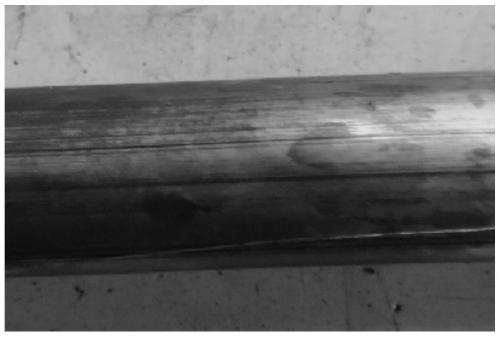

Preparation method for large-length welding spot-free copper-chromium-zirconium contact wire

ActiveCN111519116APlay brokenPlay a role in deformationConductive materialMetal/alloy conductorsTemperature controlCopper

The invention relates to a preparation method for a large-length welding spot-free copper-chromium-zirconium contact wire. The copper-chromium-zirconium is prepared from 0.7 to 1.2 weight percent of Cr, 0.05 to 0.15 weight percent of Zr, and the balance of Cu and unavoidable impurities. The preparation method is characterized by comprising the following process flows of (1) casting, namely, preparing a copper-chromium-zirconium wire blank by an upcast continuous casting method, wherein the diameter of the wire blank is 25 to 35 mm; (2) performing cold machining, namely, performing cold machining with the deformation amount of 35 to 70 percent on the copper-chromium-zirconium wire blank; and (3) performing annealing treatment, namely, performing annealing treatment on the wire blank subjected to the cold machining, wherein the temperature is controlled to be 600 to 800 DEG C and the heat preservation time is 1 to 5 hours, and cooling the wire blank along with a furnace. According to thepreparation method for the large-length welding spot-free copper-chromium-zirconium contact wire, uniformity of a contact wire structure and fineness of crystal particles are ensured by setting a process flow and setting each process flow parameter, so that the large-length welding spot-free copper-chromium-zirconium contact wire can be prepared.

Owner:JINTIAN COPPER GROUP CORP NINGBO

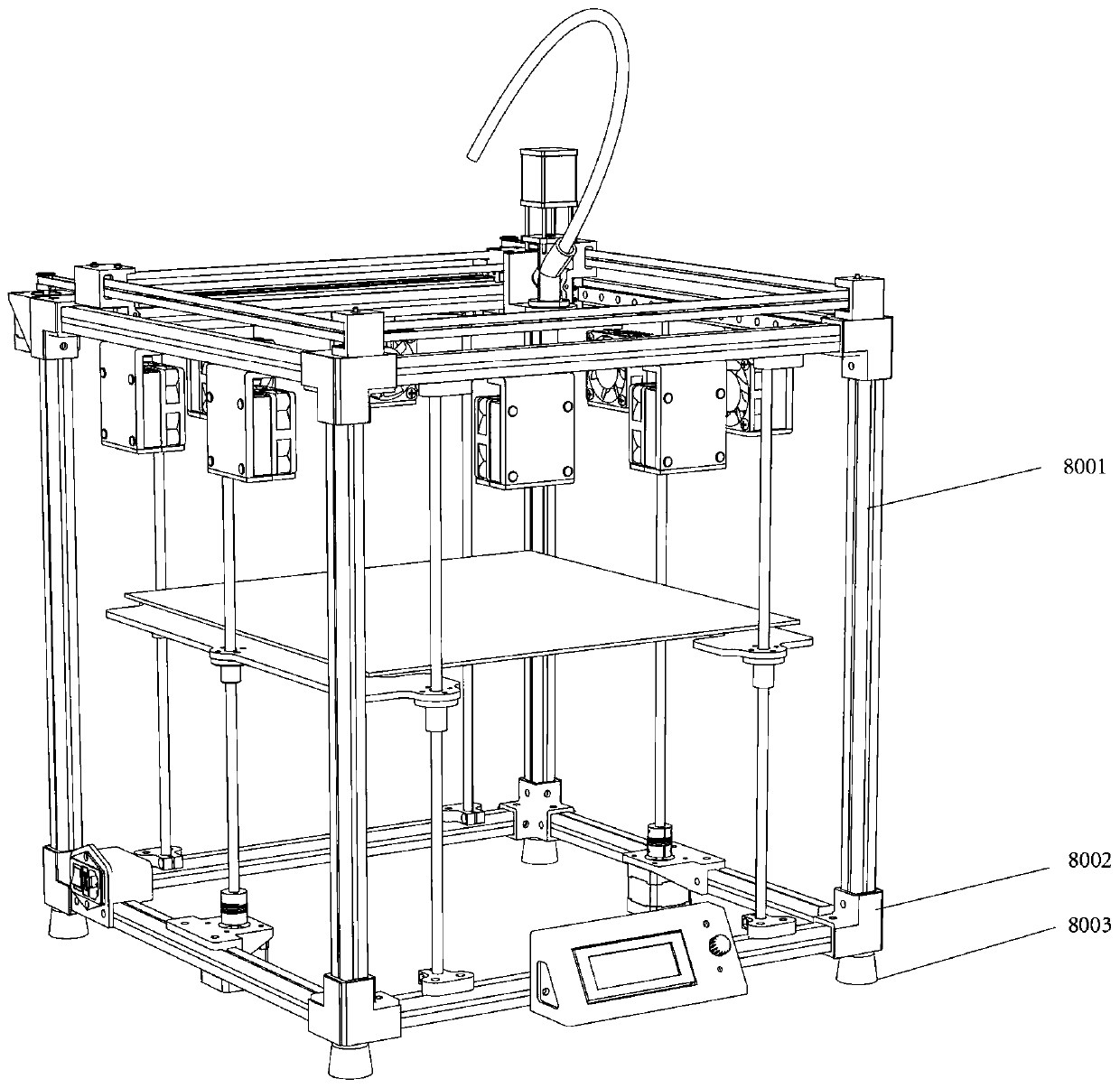

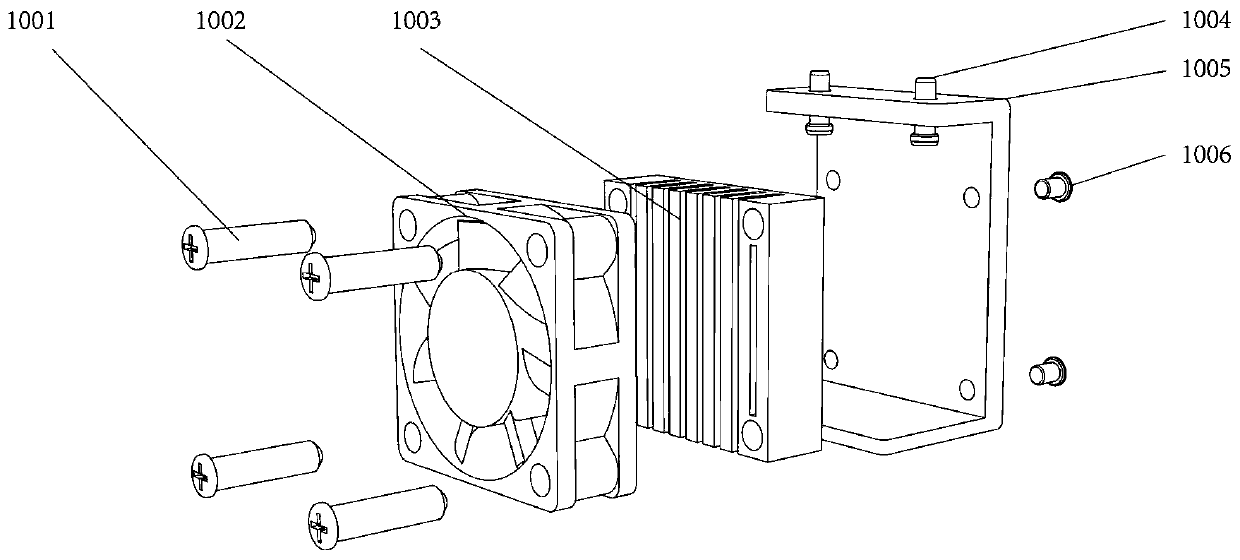

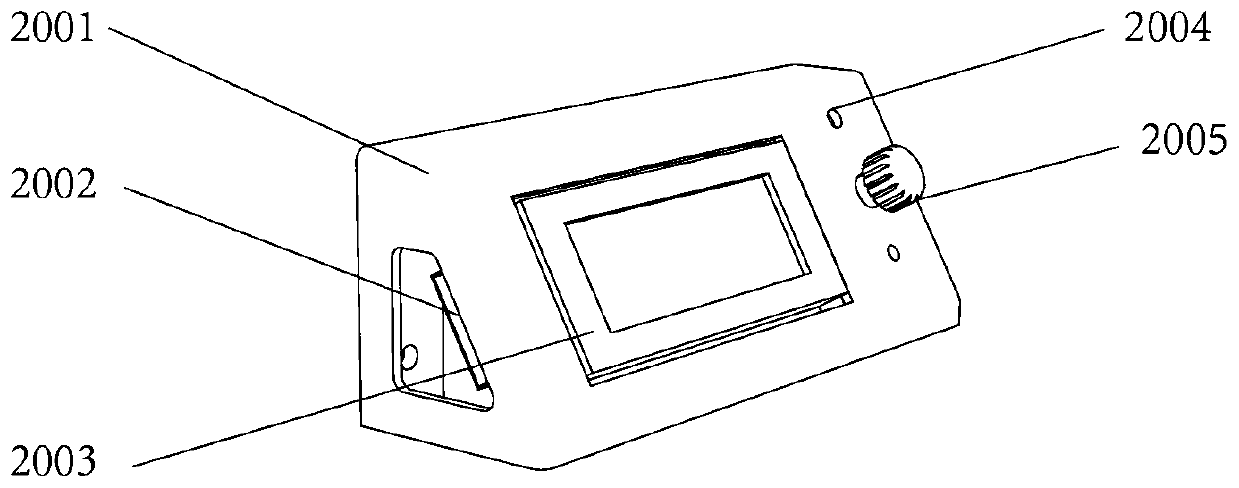

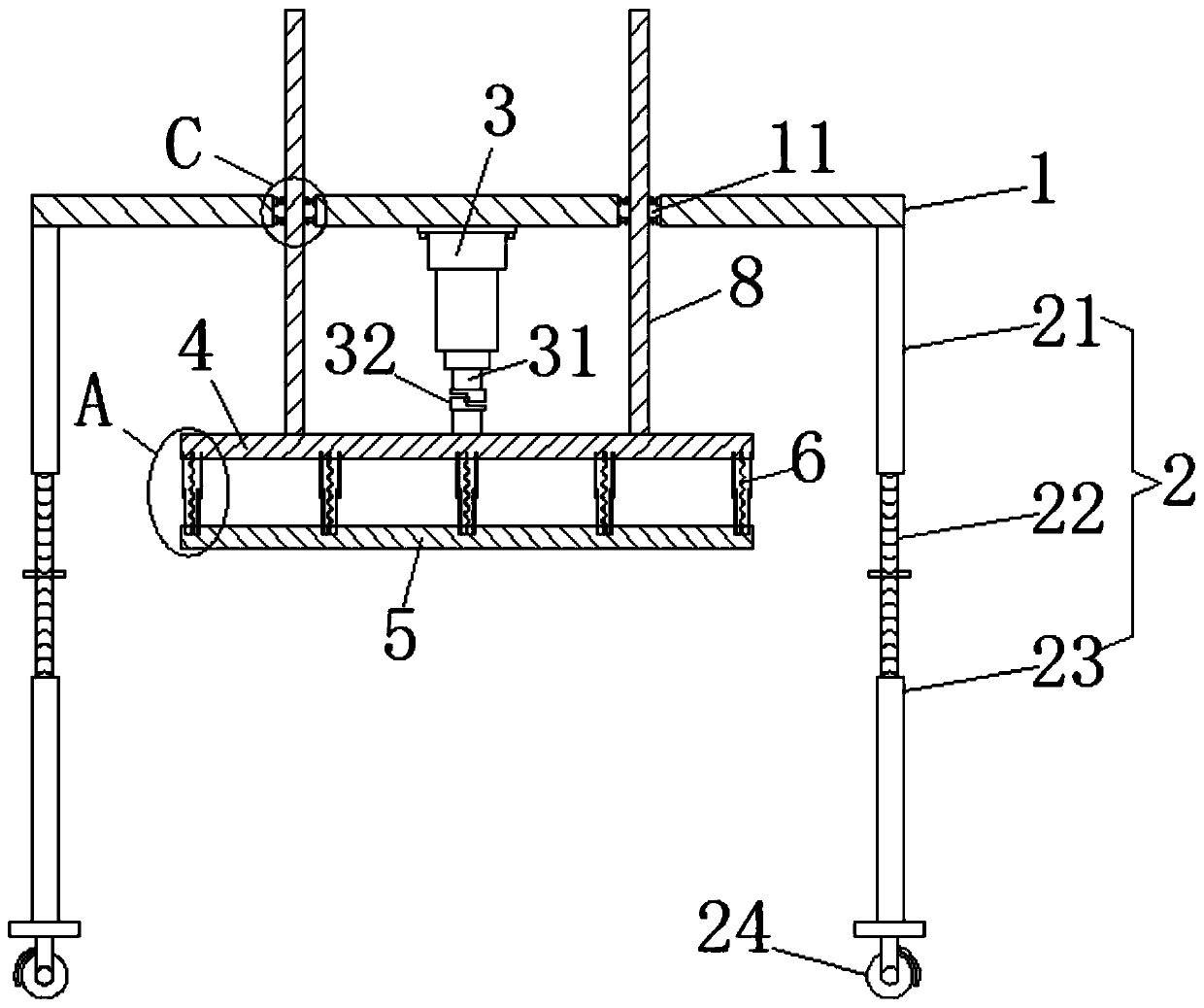

3D ceramic printing device drying by virtue of heating fan

InactiveCN110815494AEffective reinforcementTake away evenlyCeramic shaping apparatusComposite materialHeat transfer

The invention discloses a 3D ceramic printing device drying by virtue of a heating fan. The 3D ceramic printing device drying by virtue of the heating fan comprises a main frame, a printing platform,a ceramic printing device and a heating fan device, wherein the printing platform is capable of lifting along Z axis in the main frame; the ceramic printing device is capable of moving along X axis and Y axis on the upper part of the main frame; the ceramic printing device comprises a printing needle head; and the printing needle head is arranged on an air blowing path of the heating fan device. According to the technical scheme, water in a 3D ceramic printing part is slowly and uniformly removed by virtue of a hot air fluid; influence on the structure of the 3D ceramic printing part is avoided due to no direct touch of the heating fan device with the ceramic printing part; and the heating fan device is high in heating speed, efficiency and heat transfer, sensitive in response to a controldevice, high in controllability, compact in structure, light in weight, and capable of dissipating a part of water of a ceramic paste in a short time to achieve a solidification effect.

Owner:HUNAN UNIV +1

Processing method of fibers for grid type purse net fishing net

ActiveCN106192049AImprove compositionGood spinnabilityClimate change adaptationArtificial filament heat treatmentCarbon blackWollastonite

The invention provides a processing method of fibers for a grid type purse net fishing net. The processing method is characterized by comprising the following steps: pre-mixing UHMWPE (Ultrahigh Molecular Weight Polyethylene) powder, silicone powder, nano silicon dioxide, HDPE (High-density Polyethylene) powder, a nano titanium dioxide silver-loaded antibacterial agent, an antioxidant B225, hydroxystearic acid, nano-grade diatomite, nano-grade white carbon black, nano-grade wollastonite and an ethylene-vinyl acetate copolymer, which are weighed according to a formula, and pouring the mixture into a high-speed kneading pot and carrying out high-speed kneading to obtain a UHMWPE modified material; fusing and extruding the UHMWPE modified material through a double-screw-rod extruder; fusing and extruding an extruded product from a spinneret hole through a metering pump which is additionally arranged on a double-screw-rod outlet; cooling, pre-stretching and hotly setting extruded freshly formed filaments and winding a fiber bundle through a fiber winding machine which utilizes a torque motor; dividing the fiber bundle into fibers through a fiber dividing machine, so as to obtain the fibers for the grid type purse net fishing net.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

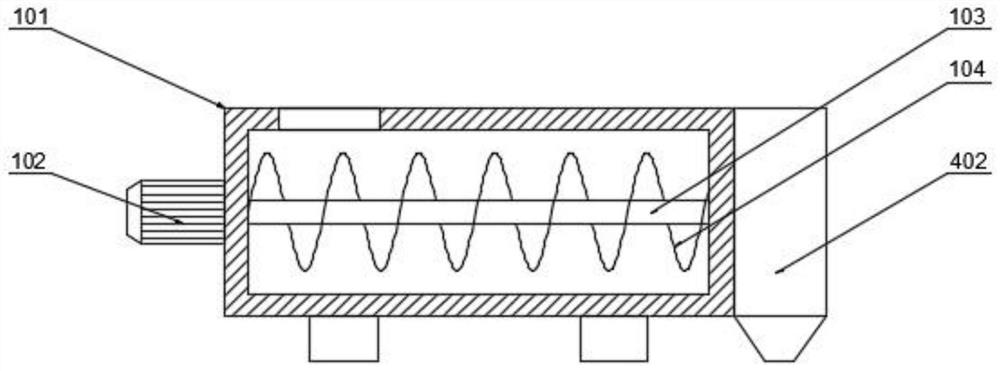

Cable extruding machine with preheating

PendingCN108831634AReasonable structureSave resourcesApparatus for heat treatmentInsulating conductors/cablesHelical blade

The invention provides a cable extruding machine with preheating, which comprises a feeding device, an extruding device, an extruding die head, a take-up roller, a variable frequency motor and a cooling device, wherein the bottom of the feeding device is connected with the extruding device, the right side of the extruding device is connected with the extruding die head, the right side of the extruding die head is connected with the cooling device, the take-up roller is installed at the right side of the cooling device, the take-up roller is connected with the variable frequency motor, the feeding device includes a feeding port, a feeding shell, a heating pipe, a helical blade, a rotating motor, a preheating shell, a water inlet pipe and a water outlet pipe, and the feeding port includes afunnel-shaped shell, guide slots and a buffer sheet. Preheating is performed on plastic particles, and the extruding efficiency is improved.

Owner:ZHEJIANG QINSHAN CABLE

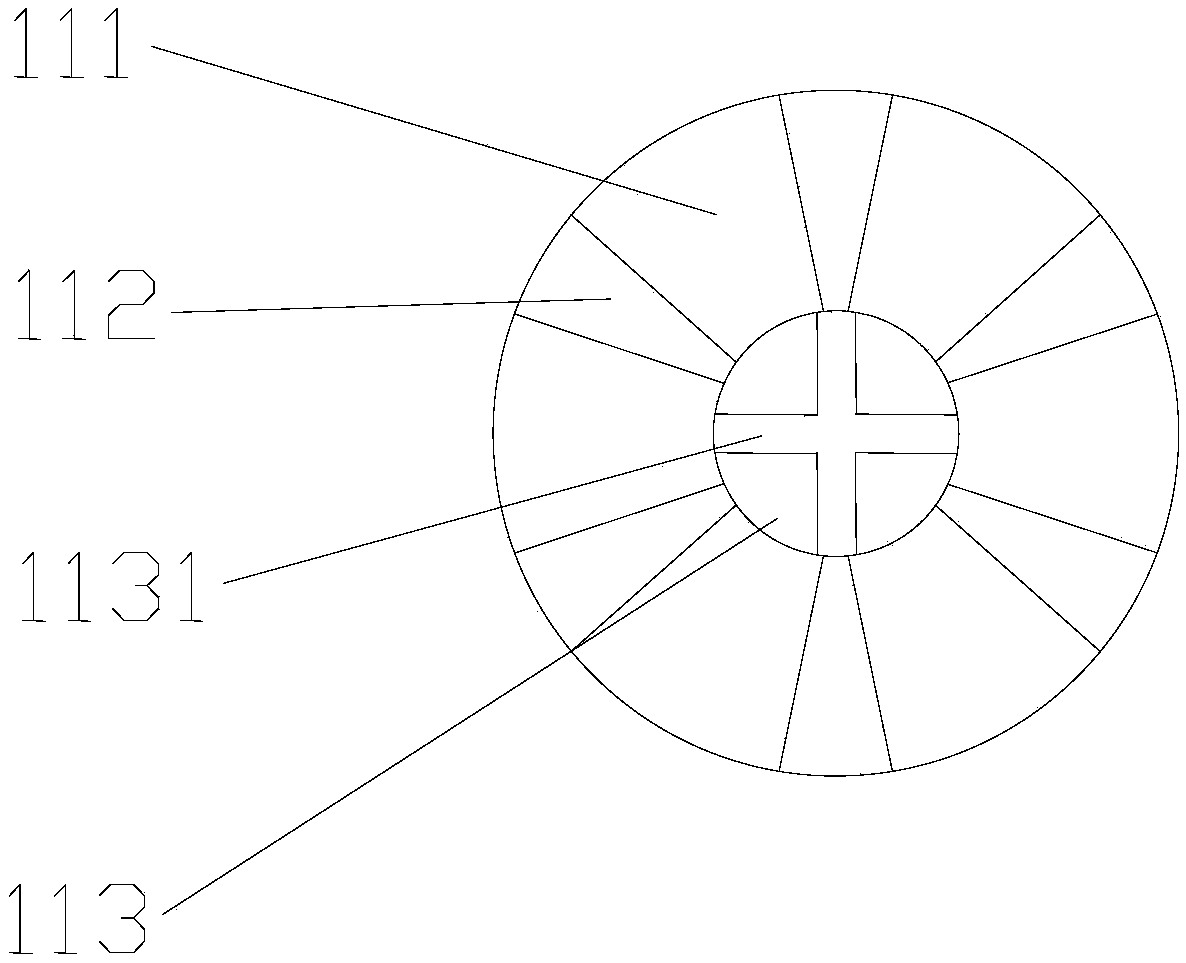

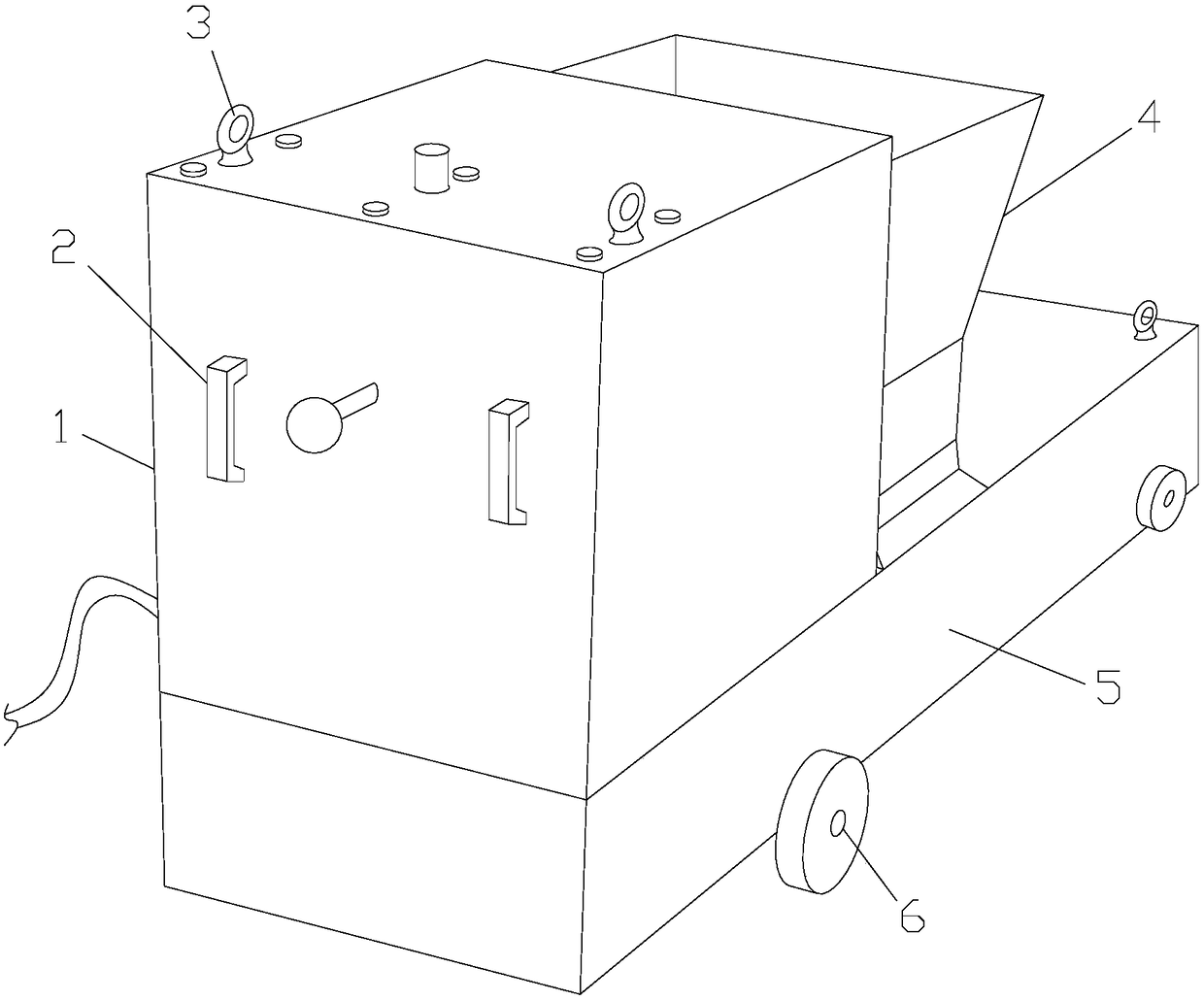

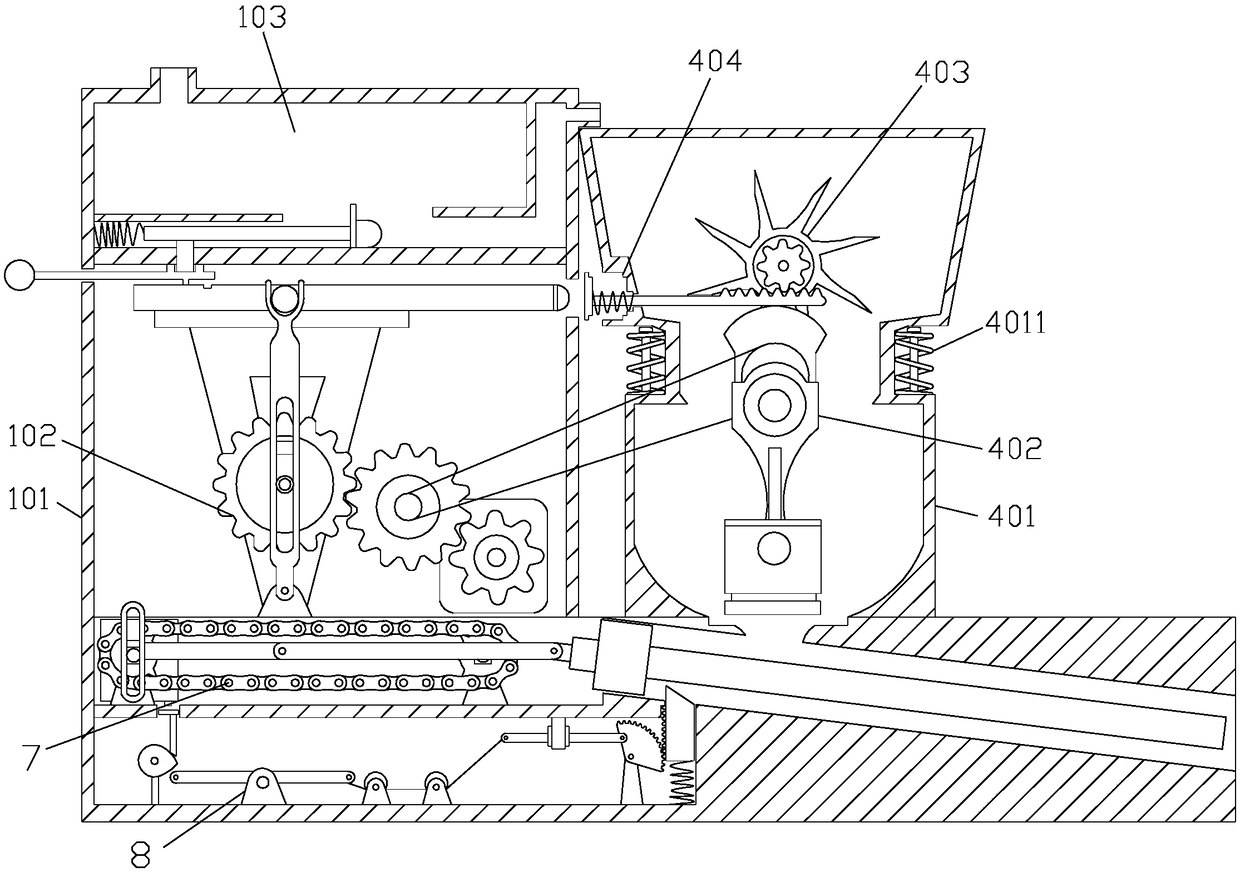

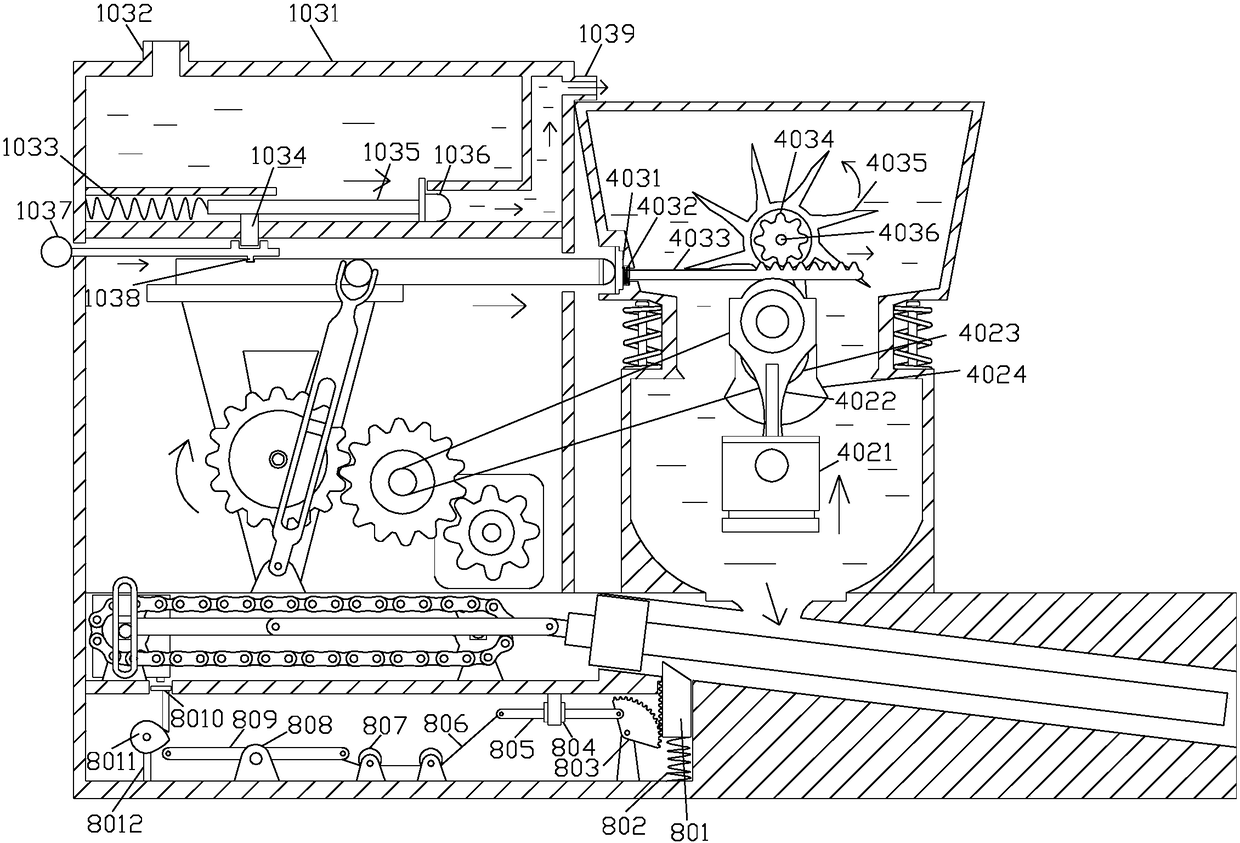

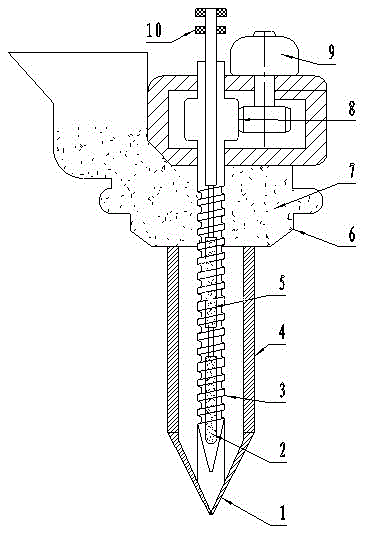

Concrete grape trellis rod pushing and squeezing former

ActiveCN108327045AControl the amount of water injectedAvoid damageMouldsFeeding arrangmentsMoving frameControl rod

The invention discloses a concrete grape trellis rod pushing and squeezing former which structurally comprises a pushing and squeezing former, a pushing handle, a lifting ring, a hopper, a moving frame, a tyre, a pushing device and a triggering mechanism. In order to improve a stirring effect, accomplish automatic pushing after squeezing forming, and conveniently add water during stirring, according to the concrete grape trellis rod pushing and squeezing former, a drive mechanism is arranged in the pushing and squeezing former; a stirring effect is improved through a stirring device; the squeezing efficiency and the quality are improved through a squeezing mechanism; the water injection rate of a water injection device can be controlled through a water injection control rod, so that concrete is prevented from being solidified during stirring due to excessive drying so as to be prevented from damaging a machine; and the pushing device can be used for automatically pushing through the triggering mechanism, so that the labor intensity is reduced, and the structure is stable.

Owner:襄阳金美科林农业开发有限公司

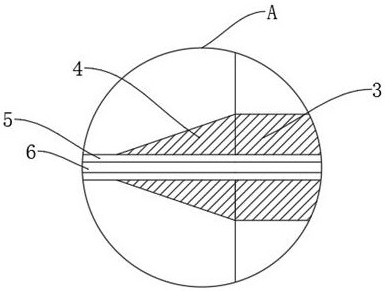

Feed guide type rubber extruding machine swivel nut

InactiveCN103587101AImprove extrusion qualityIncrease glue outputRubber materialMechanical engineering

The invention discloses a feed guide type rubber extruding machine swivel nut which comprises a front swivel nut and a rear swivel nut, wherein the front swivel nut and the rear swivel nut are movably connected with each other; a feeding opening and a feeding section are arranged on the rear swivel nut; a conical inner thread large-lead spiral groove is formed in an inner hole between the feeding opening and the feeding section. Through the adoption of the conical inner thread large-lead spiral groove, the radial friction to a rubber material when being rotated in the feeding opening and the feeding section along with a screw rod is increased, so that the rubber material can be rapidly changed into linear forwarding from rotation at the feeding section, the feeding opening is enabled to hold the material sufficiently and stably, the rubber material is sufficiently plasticized, particularly the rubber material is prevented from sliding at the feeding opening when the rotation speed of the screw rod is increased, the situation that the rubber material is not sufficiently held at the feeding opening before improvement is completed, the extrusion quality and the rubber yield of the screw rod are greatly improved, and the production capacity is greatly improved; moreover the feed guide type rubber extruding machine swivel nut has the characteristics that the structure is reasonable, the rubber guide speed is fast, the rubber raw material application range is large, and the extrusion efficiency is high.

Owner:JIANGSU MEIDIAN ELECTRICAL MACHINERY TECH

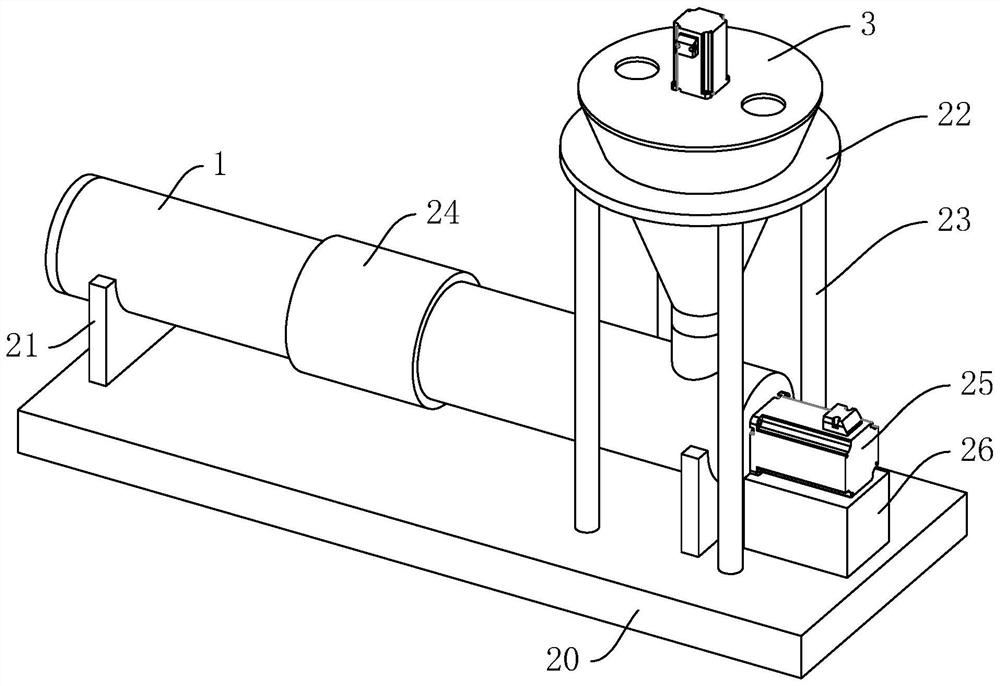

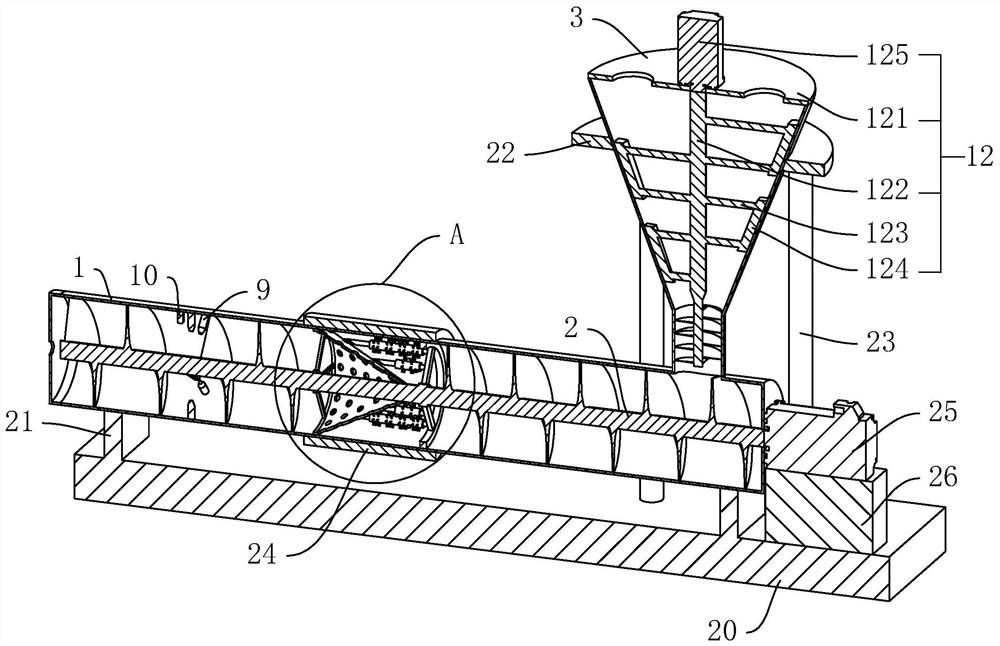

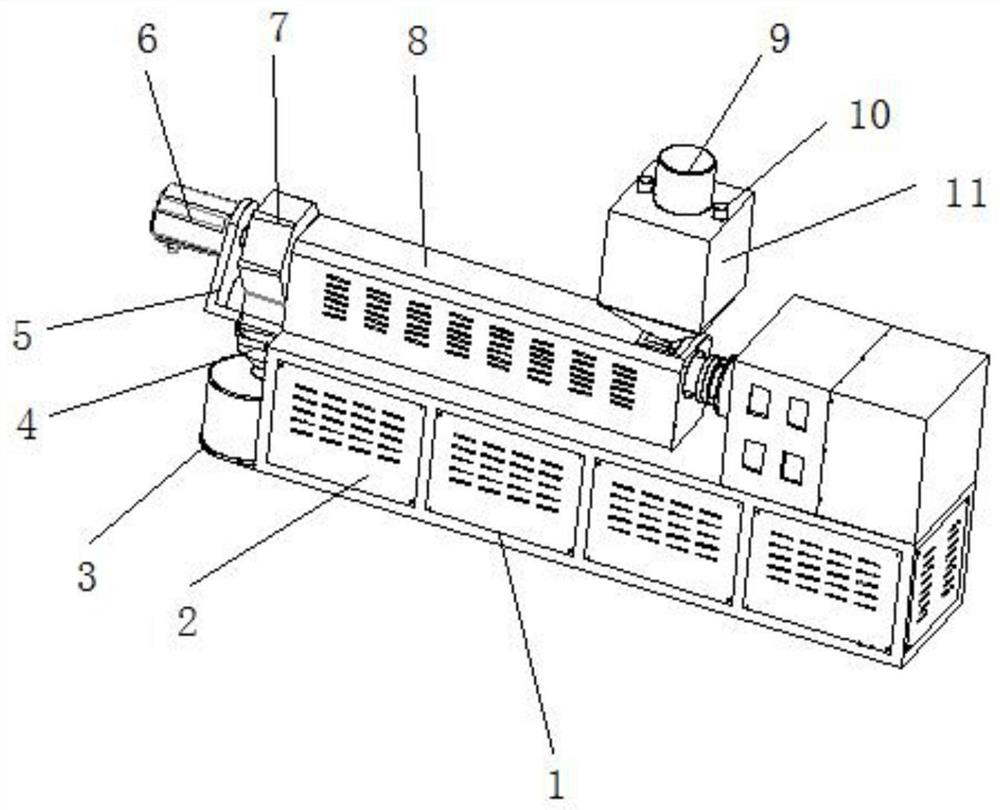

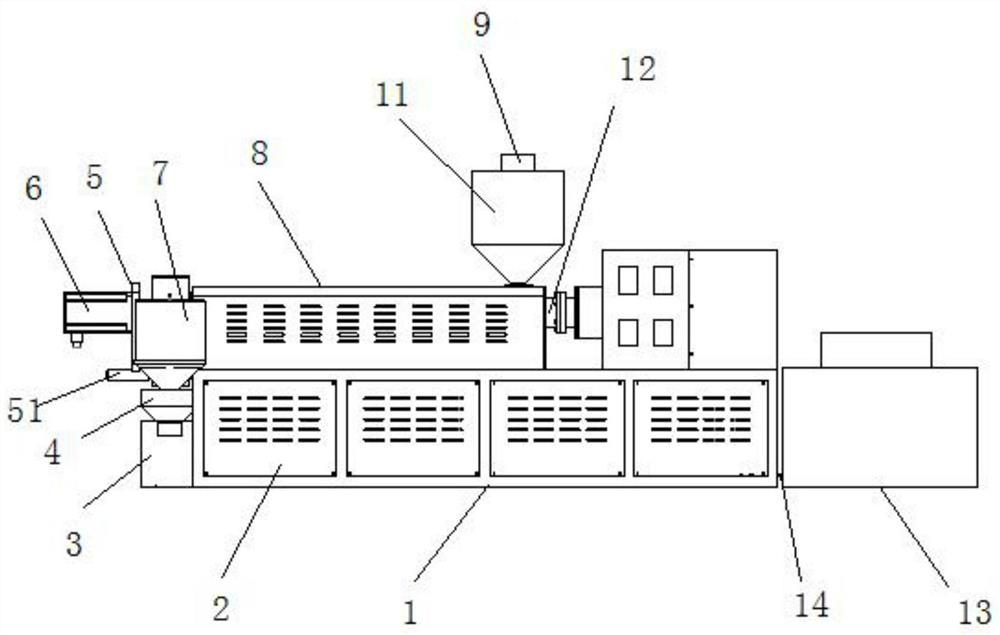

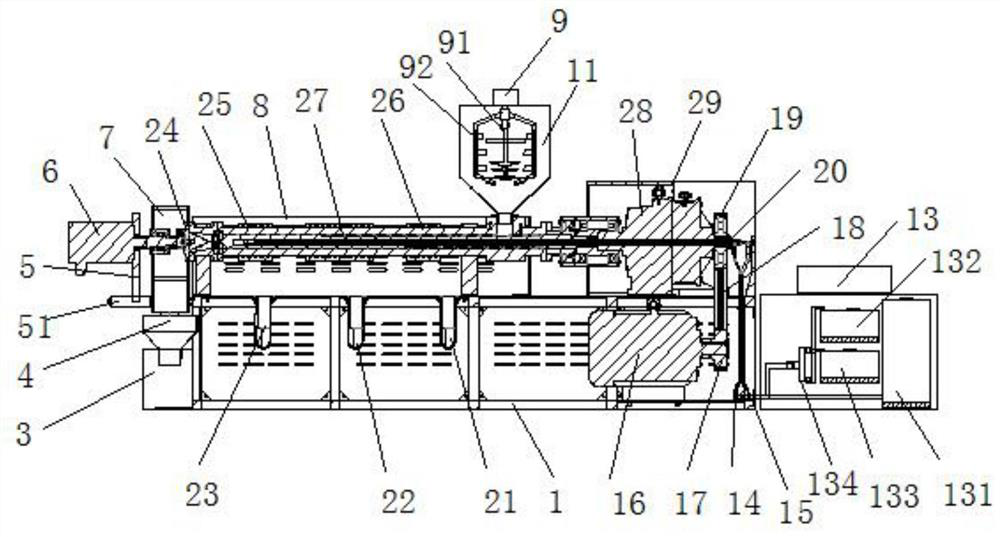

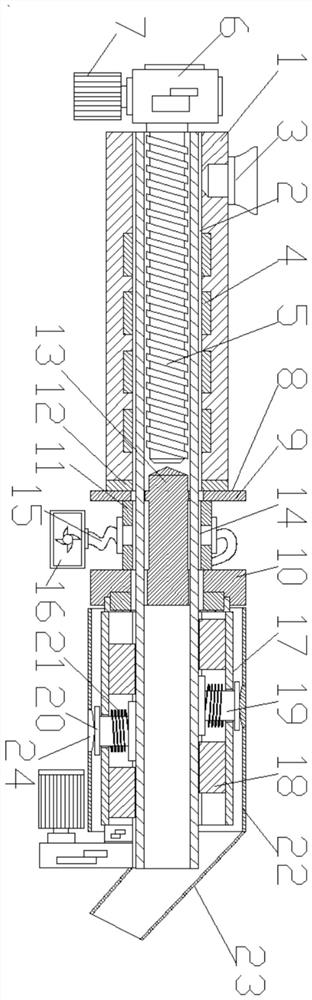

Extruder used for sea island composite wire production

ActiveCN111748862AHeating evenlyImprove the mixing effectSpinning solution de-aeratingSpinning head liquid feederEngineeringMechanical engineering

The invention relates to the technical field of composite wire production equipment, in particular to an extruder used for sea island composite wire production. The extruder comprises a conveying shell, a conveying screw rotationally arranged in the length direction of the conveying shell and a feeding hopper arranged in the length direction of the conveying shell and communicating with the conveying shell. A stirring assembly is arranged at the position, located in a heating area, in the conveying shell. The stirring assembly comprises a stirring circular ring fixedly arranged on the outer side wall of the conveying screw, multiple stirring shafts arranged on the side, away from the feeding hopper, of the stirring circular ring and auxiliary shafts arranged on the outer side walls of thecircumferences of the stirring shafts. The extruder has the effects that the material mixing uniformity is effectively improved, the temperature differences of various positions of materials are reduced, and the material extrusion quality is improved.

Owner:兴惠化纤集团有限公司

Polytetrafluoroethylene extrusion tube forming equipment

The invention discloses polytetrafluoroethylene extrusion tube forming equipment, and relates to the technical field of polytetrafluoroethylene extrusion tubes. The equipment aims to solve the problemthat existing extrusion tubes are low in strength right after extrusion, deformation is easily caused by external actions and the extrusion quality is affected. An extrusion nose is installed at oneend of an extrusion cylinder barrel; a cylinder barrel core bar is arranged inside the extrusion cylinder barrel; an outer mold core seat is arranged on the inside the extrusion nose; an outer mold core is arranged on the inside of the outer mold core seat; an inner mold core is arranged on the inside of the outer mold core; a sealing barrel cover is arranged at the upper end of the extrusion cylinder barrel; a plunger push plate is installed on the inside of the extrusion cylinder barrel; a multistage air cylinder is arranged at one end of the plunger push plate; a fixed frame is installed onthe outer part of the multistage air cylinder; the fixed frame and the multistage air cylinder are positioned on the outer part of the extrusion cylinder barrel; the multistage air cylinder and the fixed frame are connected with the extrusion cylinder barrel via screws; and sealing clamp rings are arranged on the outer part of the extrusion cylinder barrel and of the extrusion nose.

Owner:泰州市光明电子材料有限公司

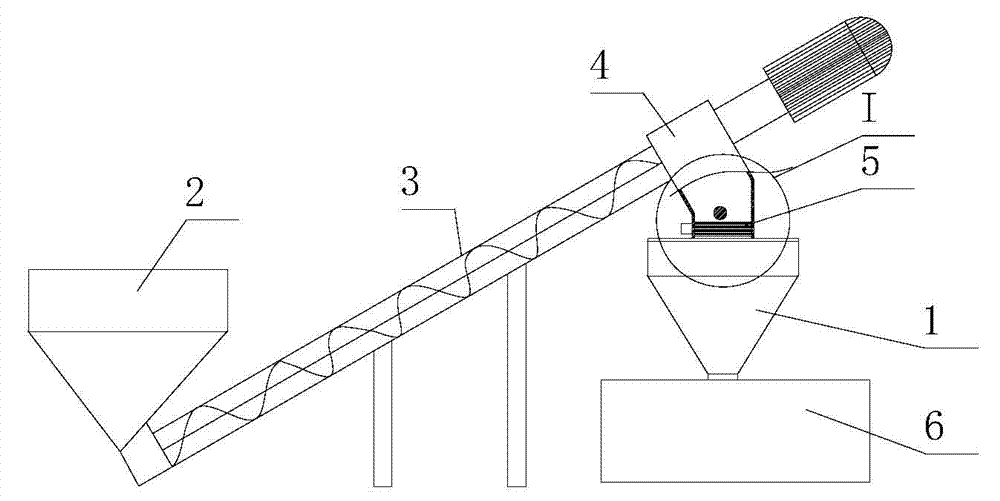

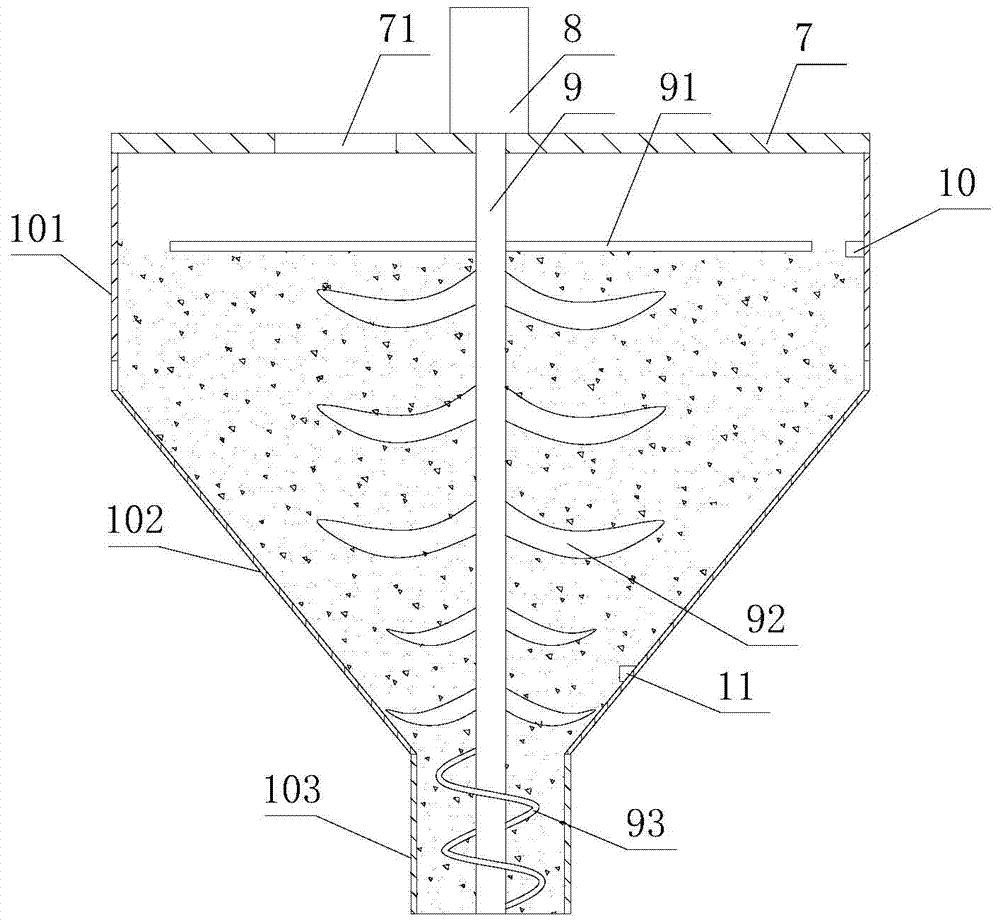

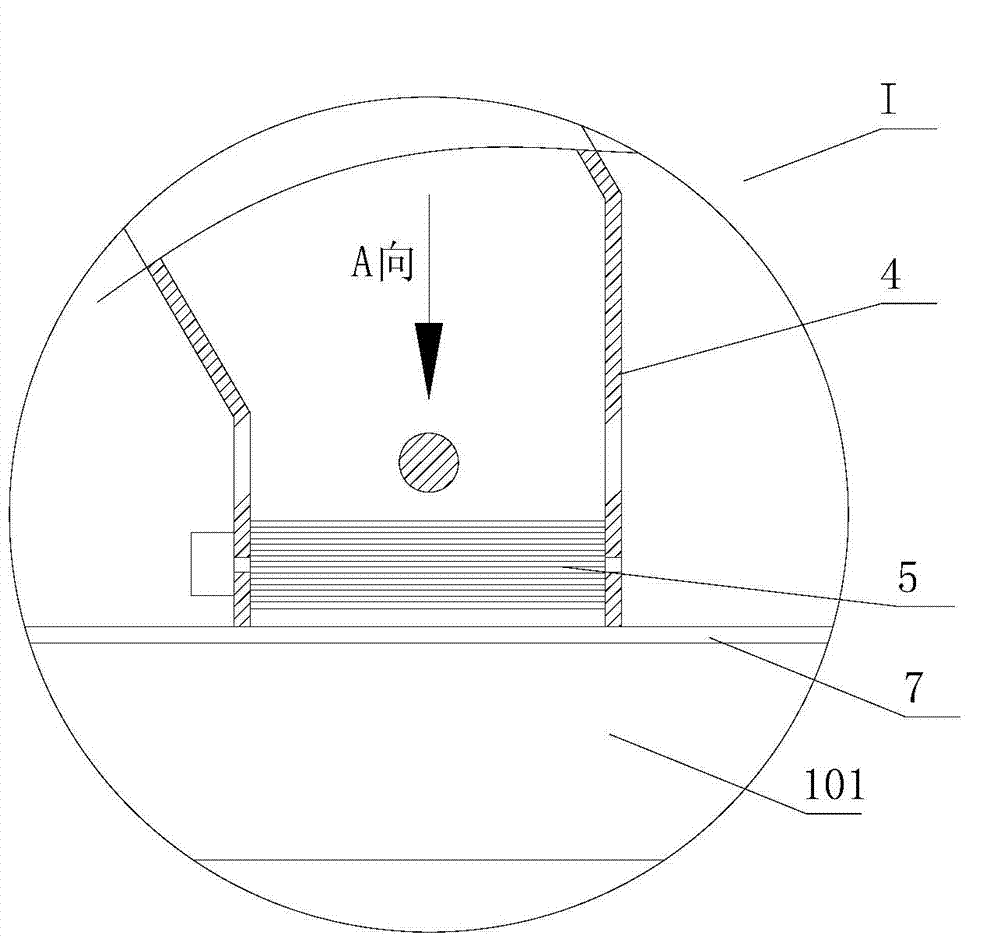

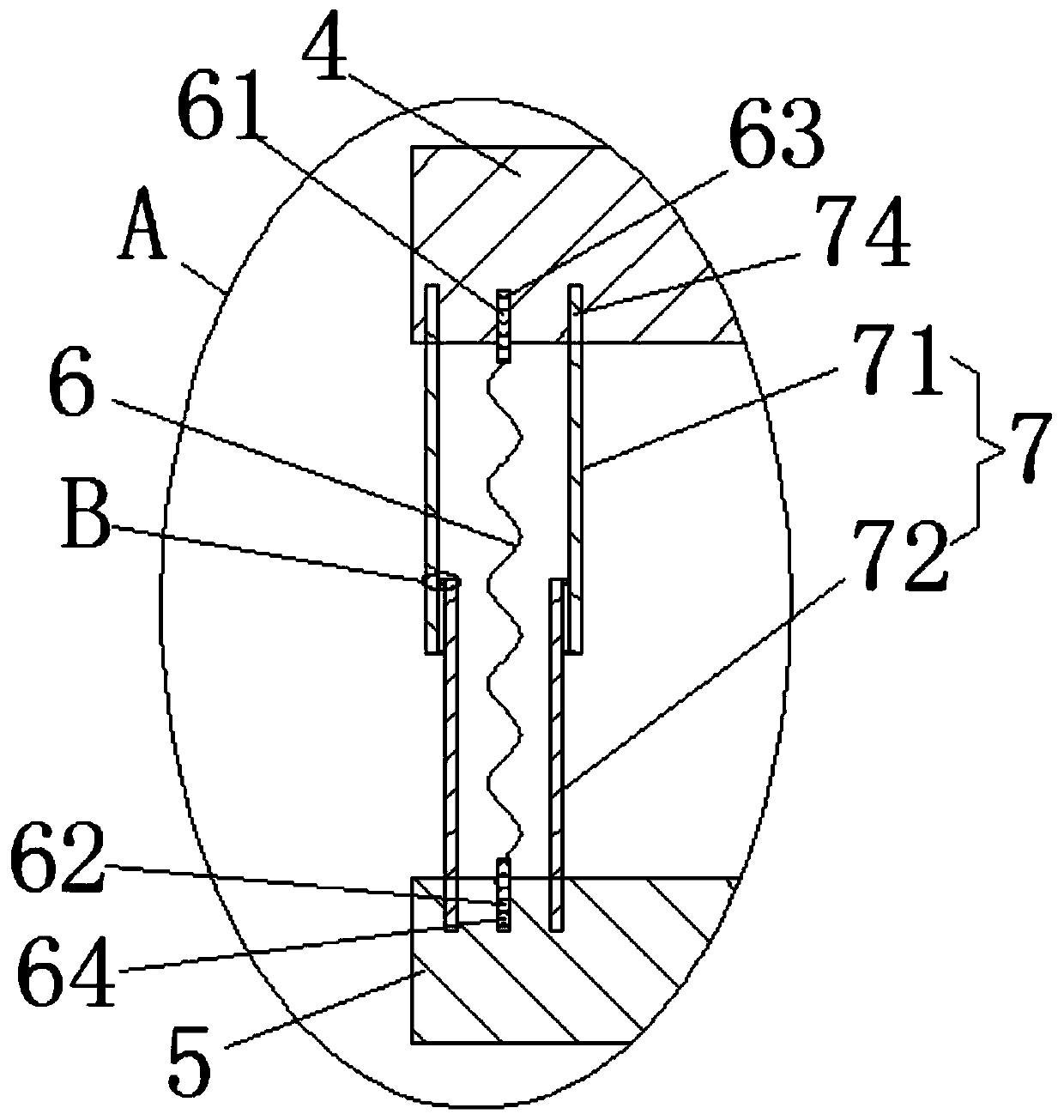

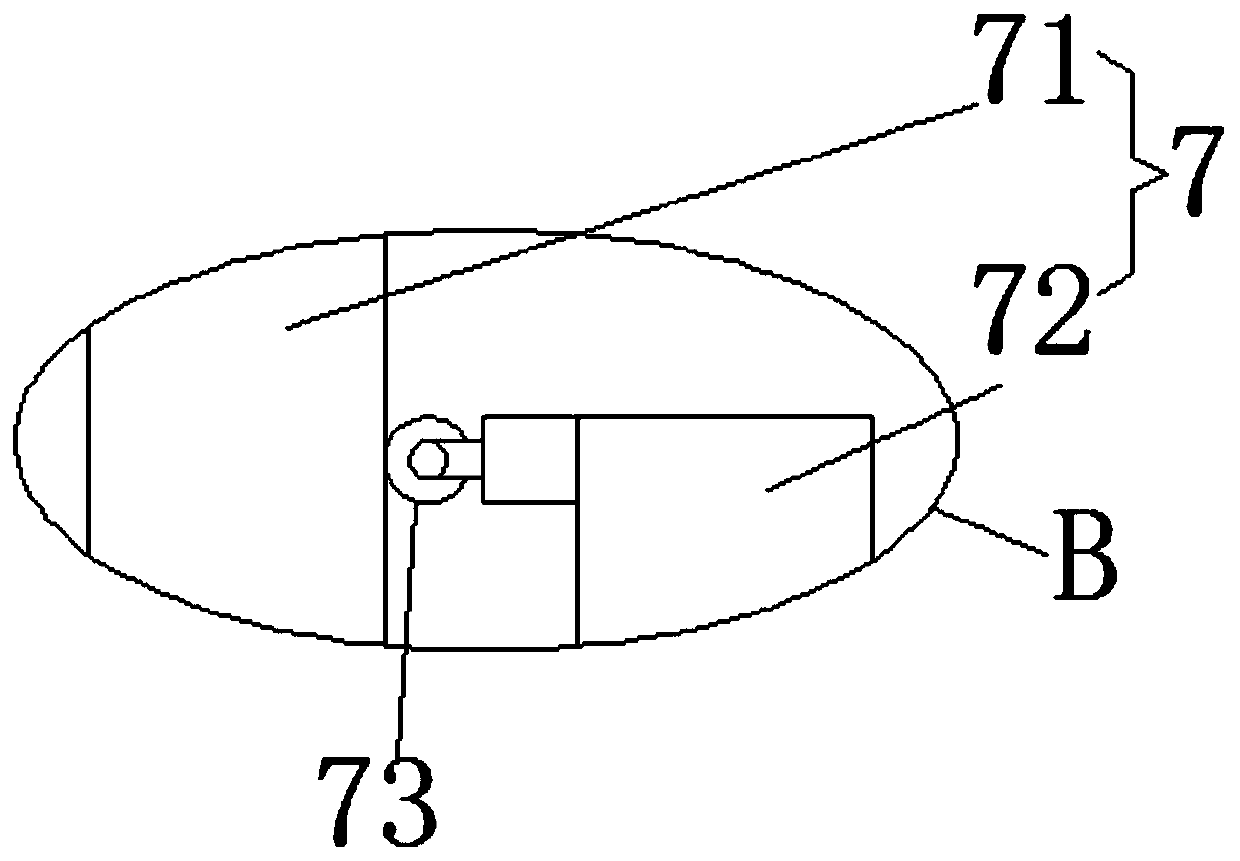

Loading device of extruder

The invention discloses a loading device of an extruder. The loading device comprises a feeding hopper, a material storage box and a spiral loading mechanism which is connected between the feeding hopper and the material storage box, wherein one end of the spiral loading mechanism is arranged on the bottom of the material storage box; the other end of the spiral loading mechanism is arranged above the feeding hopper; a discharging tube is connected between a spiral conveying mechanism and the feeding hopper; two crushing devices are arranged in a cross manner in the discharging tube, wherein one crushing device is arranged above the other crushing device; each crushing device comprises a first roller and a second roller which are engaged with each other, wherein the first roller and the second roller are arranged at the same height and are rotatably connected with the discharging tube, and one end of the first roller is connected with a drive device; bristles are arranged inside the discharging tube; and the bristles are matched with the first rollers and the second rollers. The loading device of the extruder disclosed by the invention can be used for crushing materials, and is beneficial to extrusion forming of materials in the extruder.

Owner:昆山市华浦塑业有限公司

3D printing chocolate nozzle

InactiveCN104686765AAdjust speedUniform and stable extrusion effectCocoaInsulation layerElectric machinery

The present invention relates to a 3D printing chocolate nozzle. A screw material sending rod is arranged in an extrusion head, and an end heater, a front end heater and a heater conducting ring are arranged in the material feed sending rod which is connected with a material sending electric motor by material sending rod driving cogs. By arranging the end heater and the front end heater in the screw material sending rod, the 3D printing chocolate nozzle can achieve a more uniform and stable extrusion effect, and by installing an insulation layer outer the extrusion head, the nozzle can control and further reduce the temperature difference. The material sending electric motor uses material sending rod driving cogs to drive the screw material sending rod to continuously send the chocolate particles from a hopper into the nozzle, and the chocolates can be stably extruded by the extrusion head. By adjusting the rotation rate of the material sending electric motor, the nozzle can achieve different printing effects.

Owner:CHONGQING YUNLIAN TECH

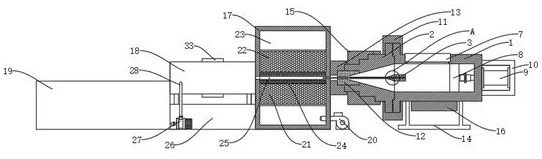

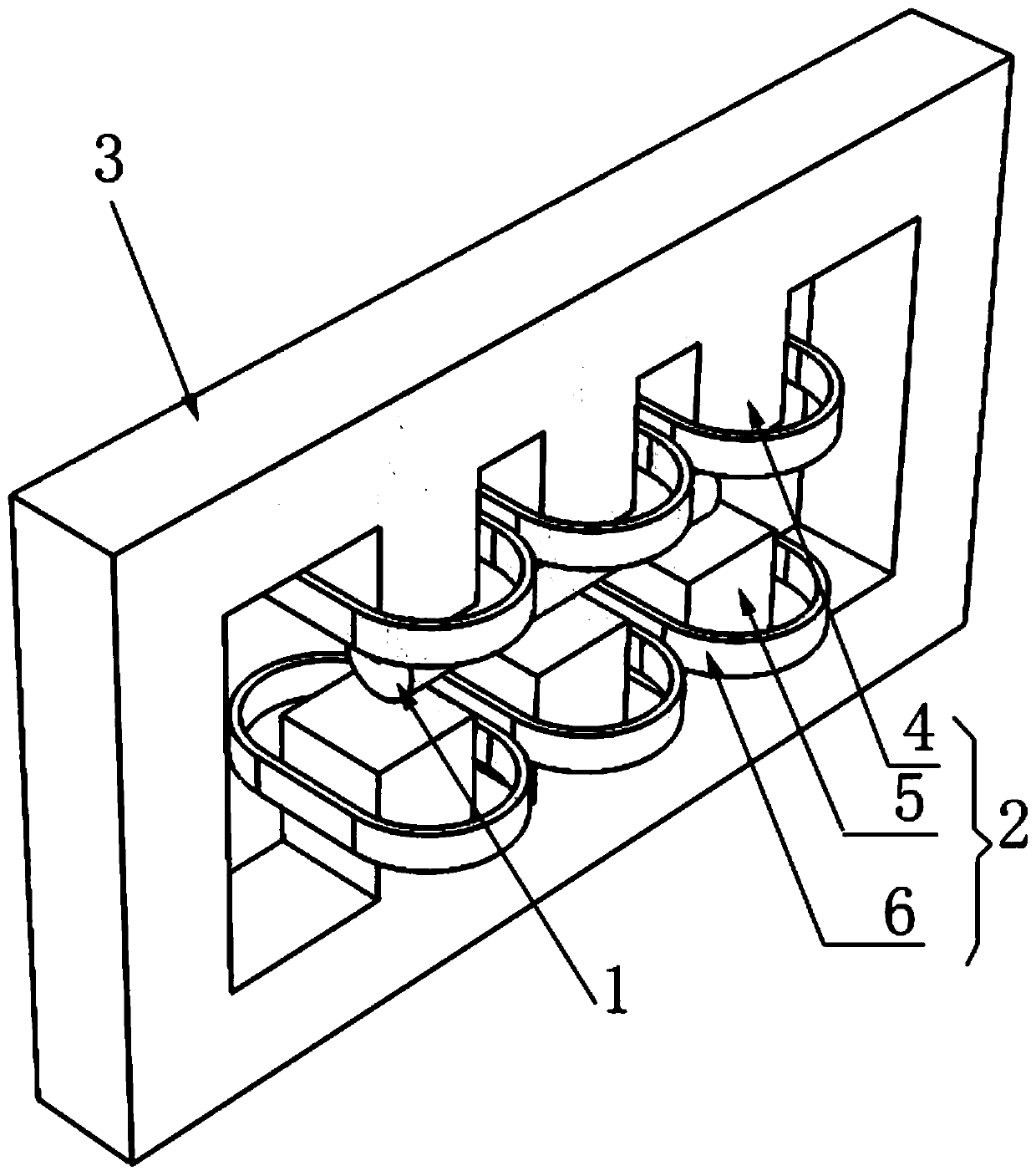

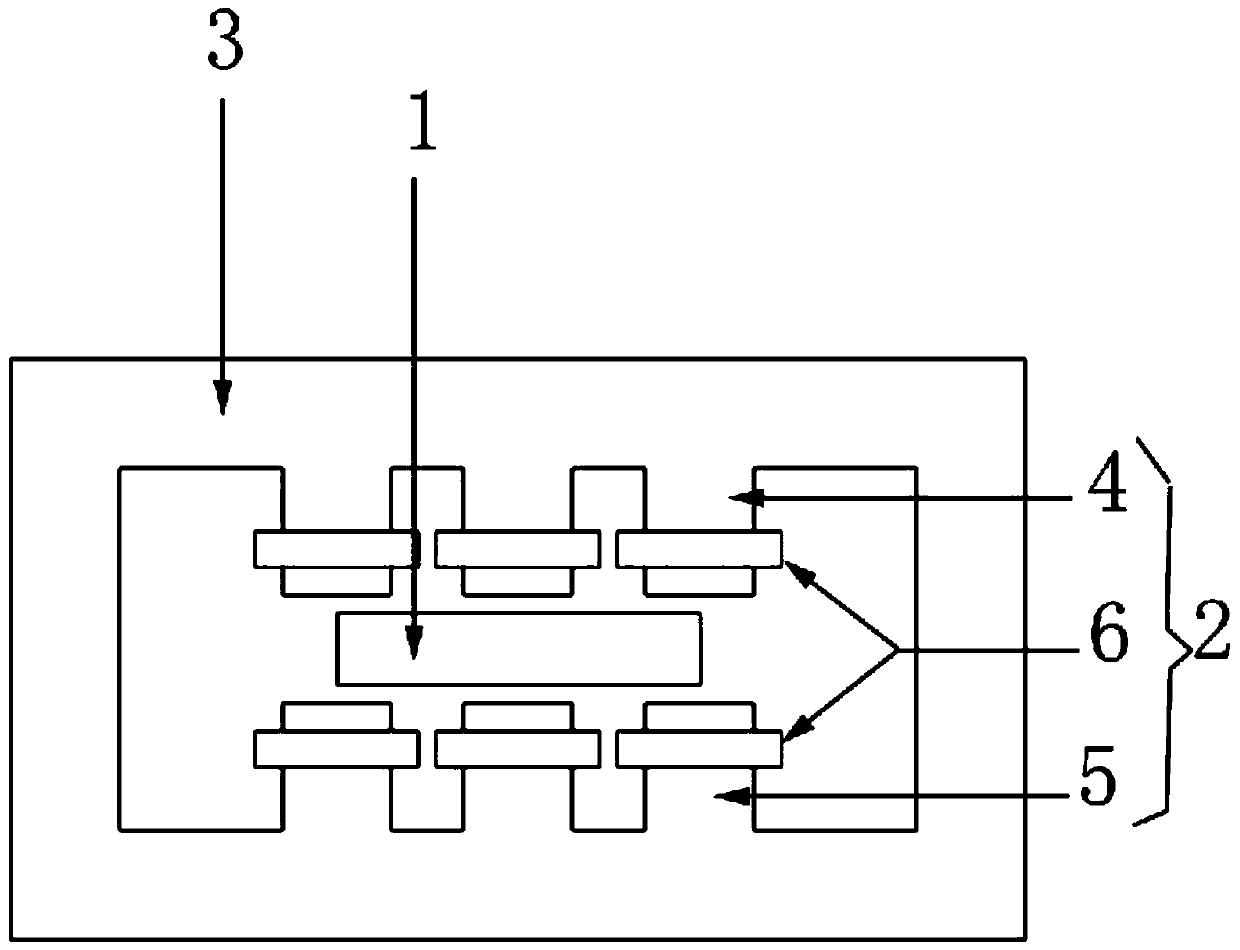

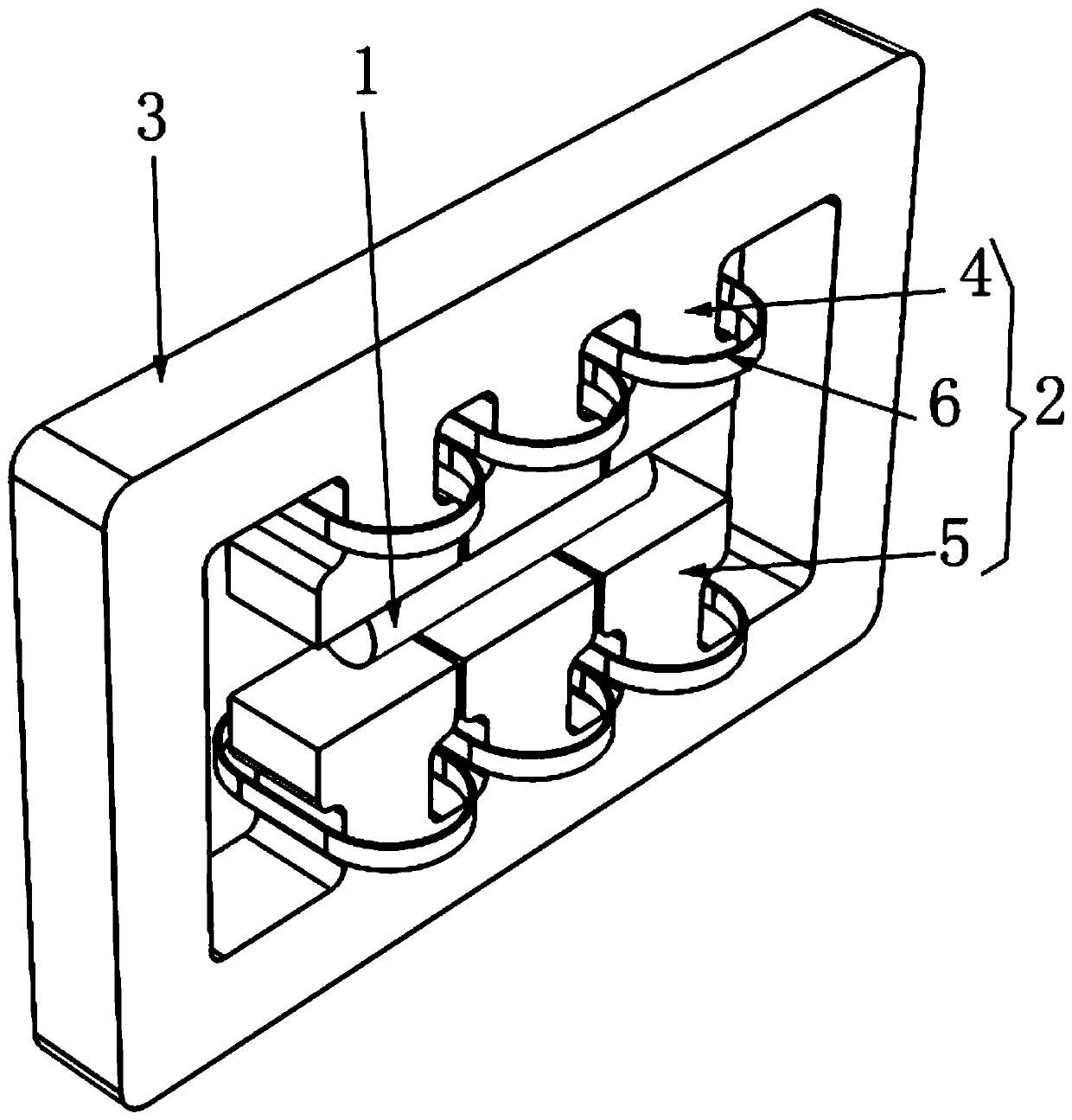

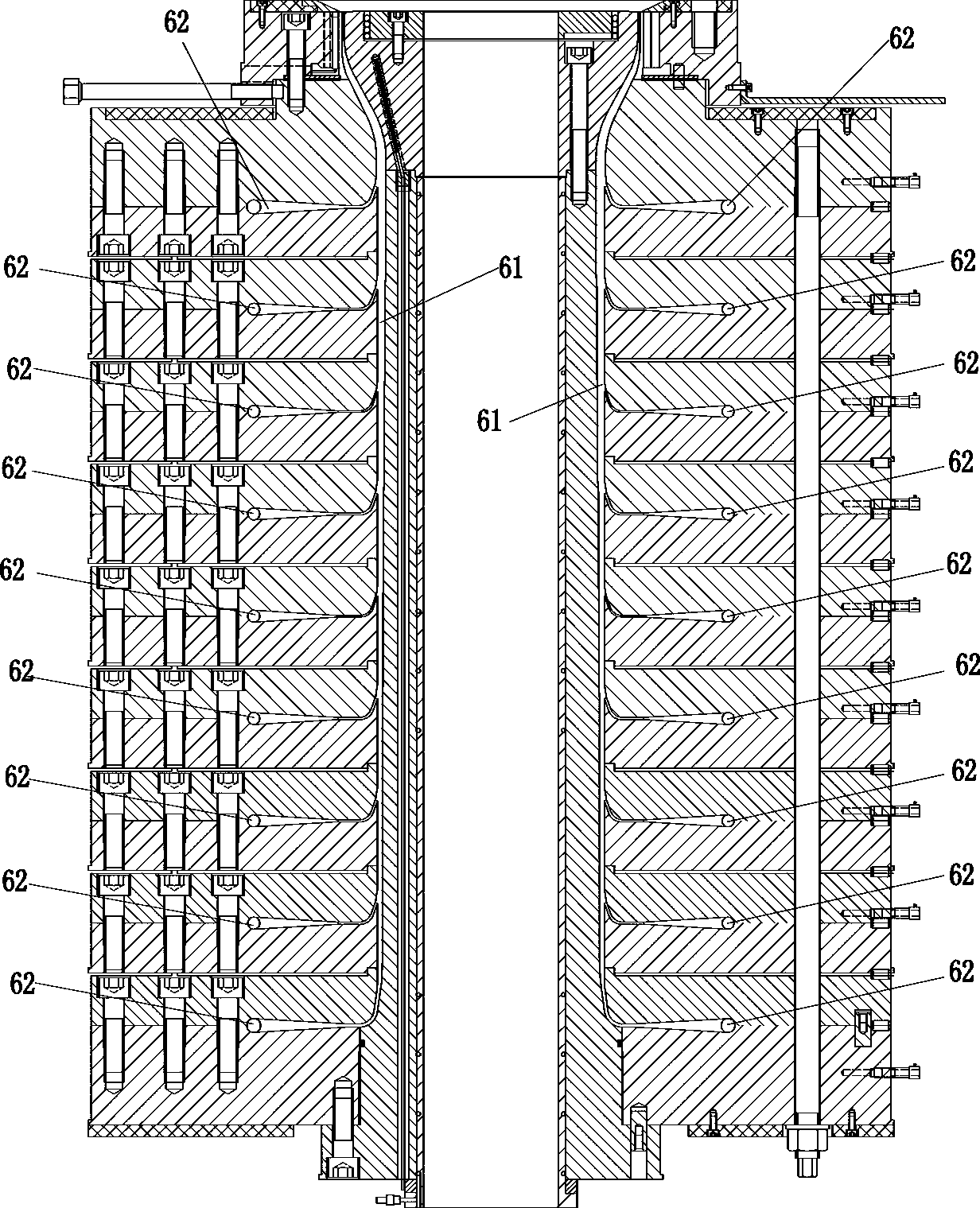

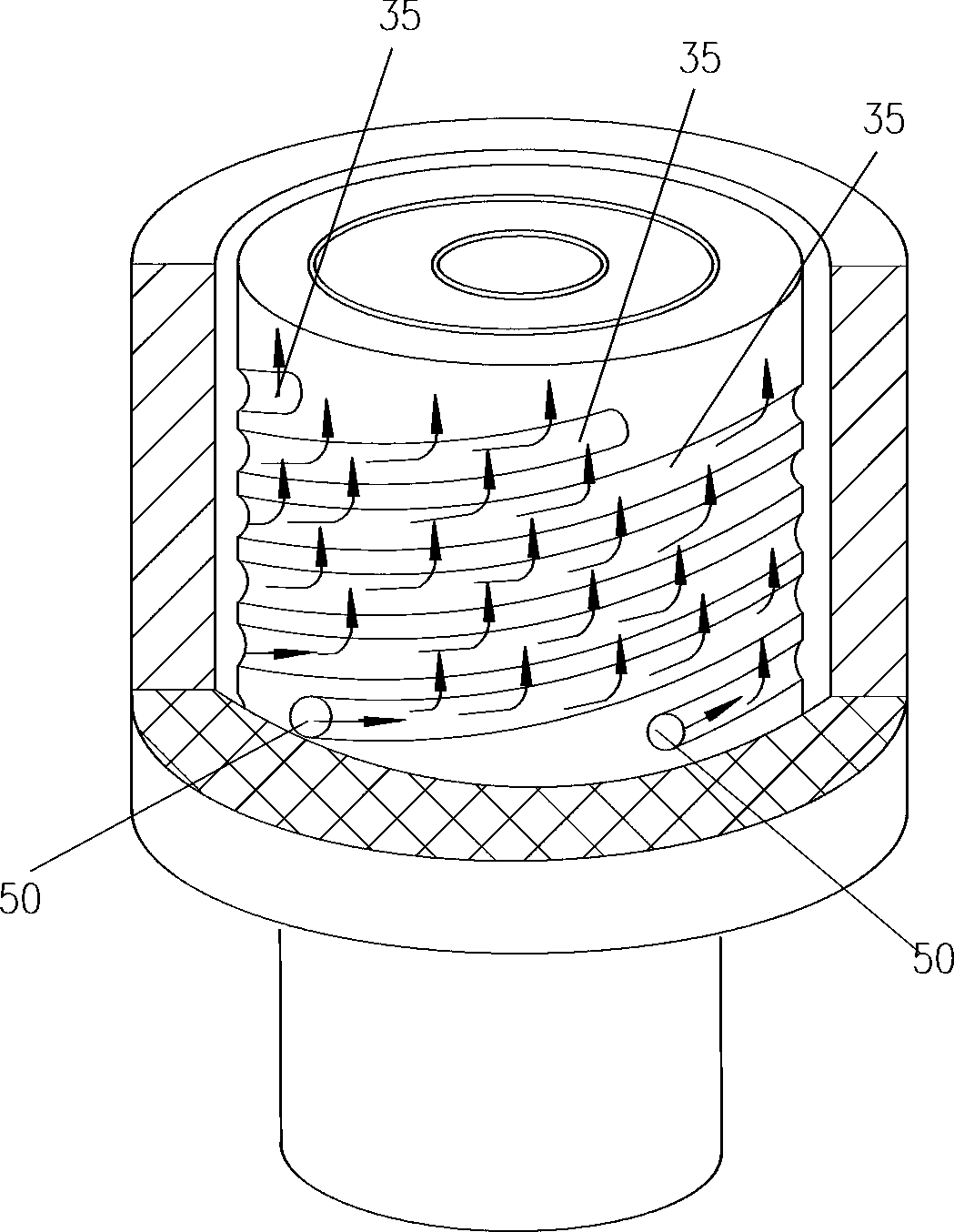

Multifunctional direct current induction heater structure capable of achieving gradient heating and uniform heating

InactiveCN110193528AUniform heating effectAvoid defects such as microcracksSymmetric axisMicro cracks

The invention provides a multifunctional direct current induction heater structure capable of achieving gradient heating and uniform heating, and belongs to the technical field of direct current induction heaters. The multifunctional direct current induction heater structure capable of achieving gradient heating and uniform heating comprises a plurality of induction heating parts which are arranged side by side in the axial direction of a metal rod to be heated; each induction heating part comprises a first heating column and a second heating column which protrude from an iron core; the firstheating column and the second heating column are mutually symmetric with respect to the central axis of the metal rod to be heated as the symmetric axis; and a magnet exciting coil is further arrangedon the iron core. The multifunctional direct current induction heater structure has simple structure, can change the magnetic field distribution of the heating region as long as the electric currentsize is adjusted, and can achieve the uniform heating and gradient heating of the metal rod; a certain temperature gradient is formed in the axial direction of the metal rod, so that the high temperature end takes the lead in entering an extruding machine; the deformation heat increases the temperature of a low temperature part of the metal rod, thus, an isothermal extrusion effect is formed in the entire extrusion process, the occurrence of defects such as microcracks inside the metal rod can be avoided, and the extrusion quality of the metal rod is improved.

Owner:BEIJING JIAOTONG UNIV

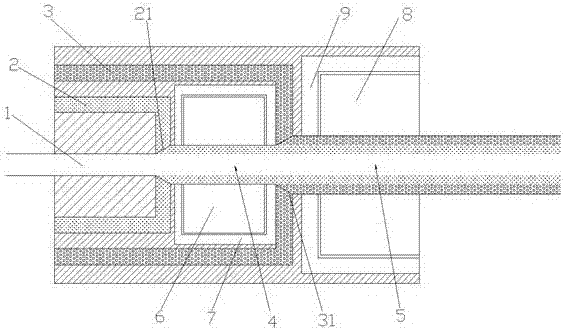

Mould for cable extruding equipment

PendingCN107225746AAvoid compromising qualityAvoid lowering the temperatureCoatingsMolten stateLiquid nitrogen cooling

The invention discloses a mould for cable extruding equipment. The mould comprises a cable hole, an inner coating layer feeding channel and an outer coating layer feeding channel which are sequentially arranged from inside to outside, wherein a first extruding mould cavity and a second extruding mould cavity are sequentially arranged behind the cable hole; the cable hole communicates with the first extruding mould cavity; the first extruding mould cavity communicates with the second extruding mould cavity; and a liquid nitrogen cooling room is arranged outside each of the two extruding mould cavities. According to the mould for the cable extruding equipment disclosed by the invention, the liquid nitrogen cooling rooms and vacuum heat-insulating layers can quickly cool cables which complete inner coating layer coating and outer coating layer coating, the liquid nitrogen cooling rooms are prevented from reducing temperatures of molten-state coating layer materials in the coating layer feeding channels to damage the state of the molten-state coating layer materials, and quality of the cable coating layers is prevented from being affected, so that once extrusion forming is realized, and the good extruding quality is achieved.

Owner:JIANGSU DONGFANG CABLE MATERIAL

Gluing device for plywood processing

The invention discloses a gluing device for plywood processing, which includes a base and four support feet, wherein support pillars are mounted on both sides of the outer wall at the top of the base;a rectangular groove is formed in the outer wall of the top of each support pillar; a same horizontally placed screw rod is rotationally connected onto the inner walls at the two ends of each rectangular groove; sliding blocks are rotationally connected with the peripheral outer walls of the two screw rods through threads; a same fixing plate is mounted at the top outer walls of the two sliding blocks; a limiting groove is formed in the top outer wall of each fixing plate; a motor is mounted on the outer wall at one end of each support pillar; the output shaft of the motor is fixedly connected with the outer wall at one end of each screw rod; connecting plates are mounted on the outer walls on the two sides of the base. According to the invention, the motors, the support pillars, the screw rods, the sliding blocks and the fixing plate are arranged, the plywood to be subjected press fitting is stored, and then is moved to be position below a protective frame, following-up extrusion isfacilitated, and workload of staff is reduced.

Owner:湖北天莱木业有限公司

Compression device for bonding for soundboard frame of piano

The invention discloses a compression device for bonding for a soundboard frame of a piano. The compression device for bonding for the soundboard frame of the piano comprises a rectangular top plate, wherein self-locking universal wheels are rotationally installed at the four corners of the lower end surface of the rectangular top plate through telescopic adjustment support legs separately; a cylinder is fixedly installed at the middle part of the lower end surface of the rectangular top plate through a bolt; a circular rod is welded to the lower end of a piston rod of the cylinder; the lower end of the circular rod is welded to the middle part of the upper end surface of a rectangular transversal plate; a pressure sensor is installed at the middle part of the circular rod; an extrusion plate is installed below the rectangular transversal plate through springs; a telescopic pipe is arranged outside each spring in a sleeving mode; and the upper end and the lower end of each telescopic pipe are detachably connected with the lower end surface of the rectangular transversal plate and the upper end surface of the extrusion plate separately. According to the scheme, the soundboard frame can be compressed in one process, so that high working efficiency is achieved; and the extrusion strength and extrusion time for the soundboard frame can be set according to the actual need, and the pressure of the extrusion plate on the soundboard frame is gradually increased, so that improvement for the extrusion quality for the soundboard frame is benefited, and damage to the soundboard frame is prevented.

Owner:河南教育学院

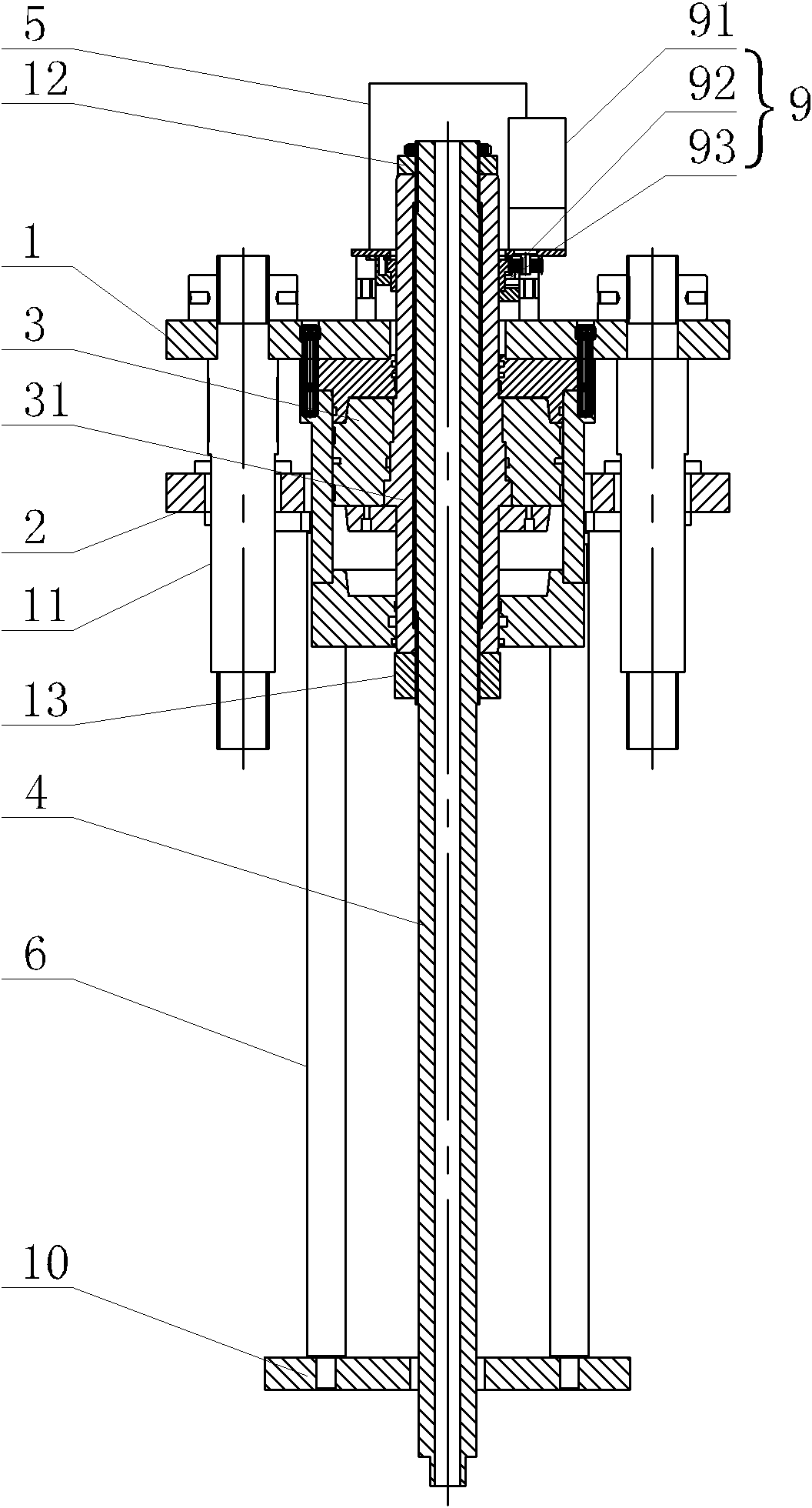

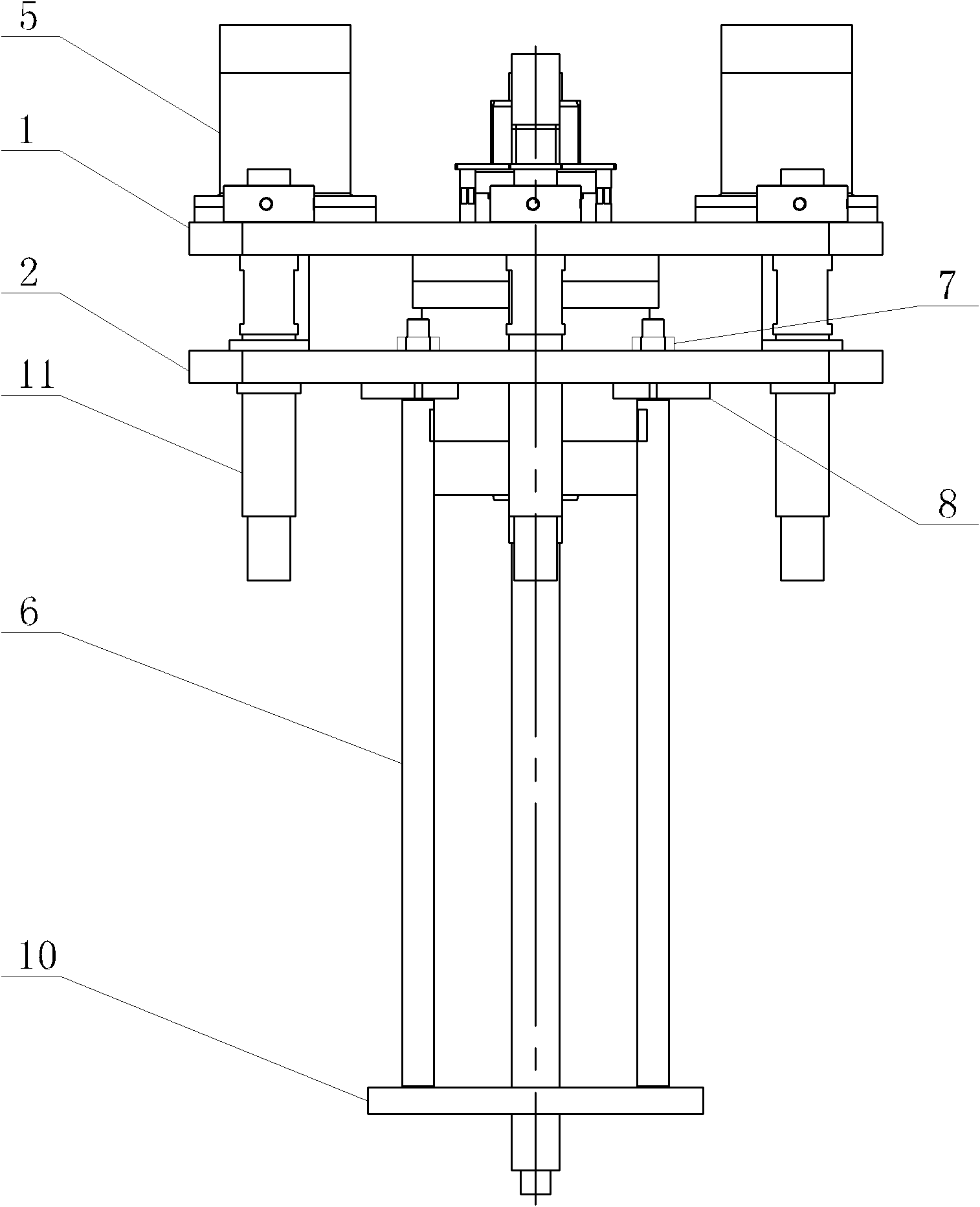

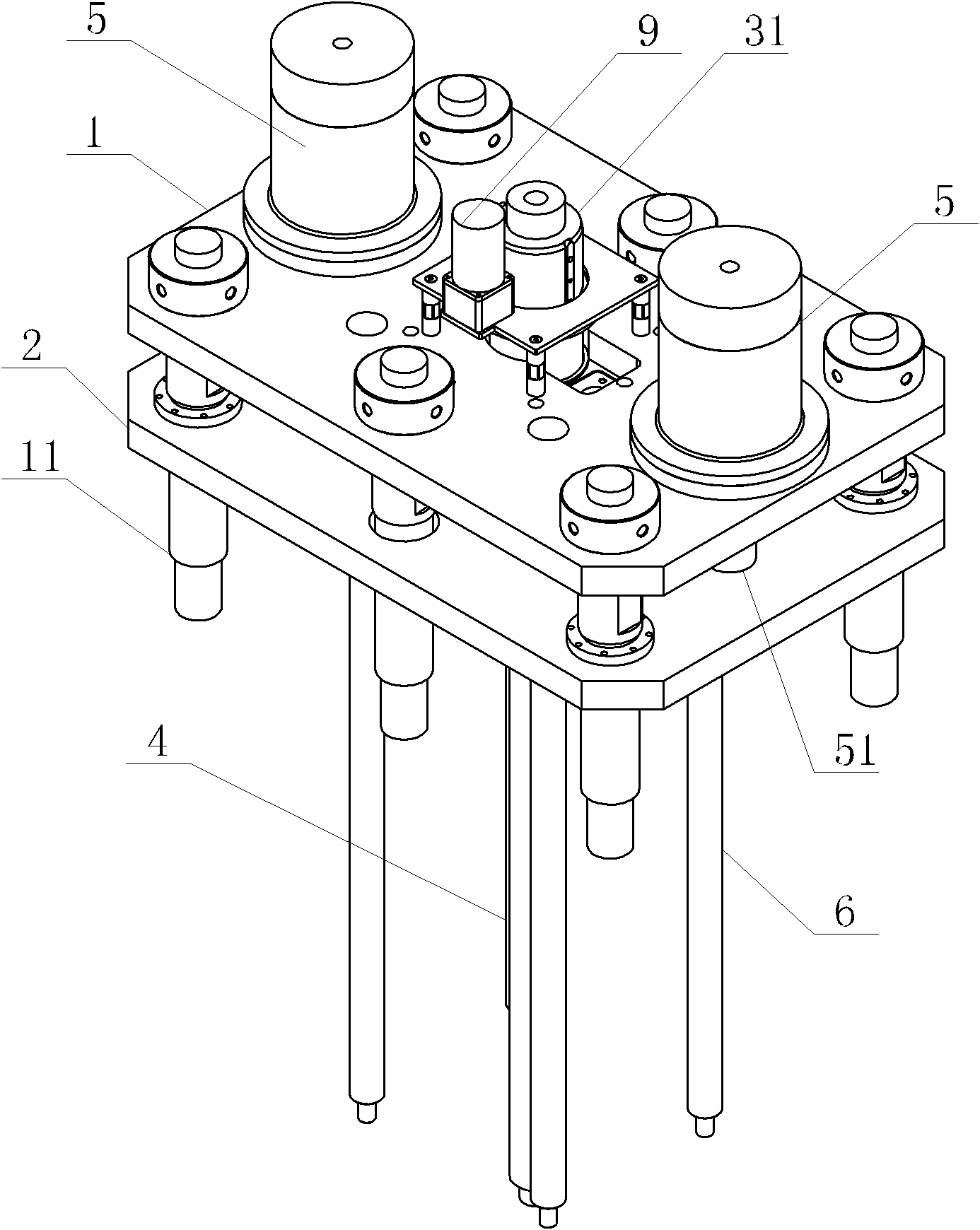

Ejection and secondary extrusion device

The invention belongs to the technical field of extrusion forming machines and particularly relates to an ejection and secondary extrusion device for use in combination of a metal extrusion forming machine. The ejection and secondary extrusion device comprises an upper mounting plate and a lower driving plate, wherein the upper mounting plate is provided with an extrusion cylinder which passes through the center of the lower driving plate; the piston rod of the extrusion cylinder is a hollow piston; a secondary extrusion rod with a central through hole is inserted into the hollow piston rod; the hollow piston rod is fixedly connected with the secondary extrusion rod; the upper mounting plate is also provided with a stamping ejection device which comprises an ejection cylinder fixed on the upper mounting plate; the piston rod of the ejection cylinder is fixedly connected with the lower driving plate; and n ejection connecting rod is arranged at the bottom of the driving plate and is connected with an ejection connecting rod for demolding. The ejection and secondary extrusion device can realize secondary supplementation and provide an ejecting force in stamping and demolding effectively, can improve material performance effectively, and is convenient in stamping and demolding, compact in structure and convenient in installation and maintenance.

Owner:山东八零特种电缆有限公司

Composite co-extrusion tubular plastic lamp shade extrusion die

The invention discloses a composite co-extrusion tubular plastic lamp shade extrusion die, comprising an opening template, a bus plate, a transition plate and a die body. The composite co-extrusion tubular plastic lamp shade extrusion die is characterized by also comprising a locating pin, a core rod, a small screw and a plurality of long screws, wherein a main runner penetrating from left to right is arranged among the opening template, the bus plate, the transition plate and the die body; an outer thread is formed on the external circle surface of the right part of the die body; a main feeding hole is formed in the right end of an inner hole of the die body; a bypass feeding hole and a bypass runner are formed in the bus plate; a round hole and an end face runner are formed in the opening template; the end face runner comprises two branch runners which are symmetrically arranged; two symmetrical grooves are formed in the core rod; one end of the end face runner is communicated with the round hole of the opening template, and the other end of the end face runner is communicated with the bypass runner. The tubular plastic lamp shade disclosed by the invention is good in light transmittance in one half part while is light-tight in the other half part, and is beautiful in appearance and low in cost.

Owner:HUBEI ANXIN PLASTIC MOLDS

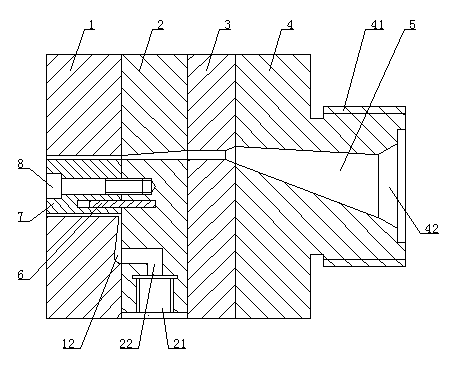

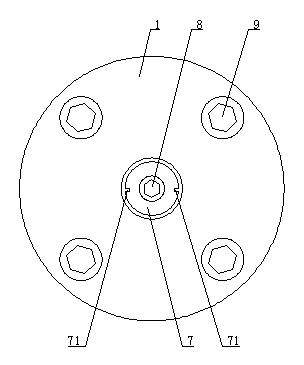

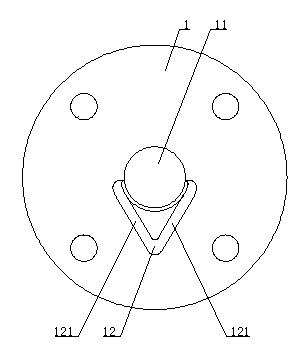

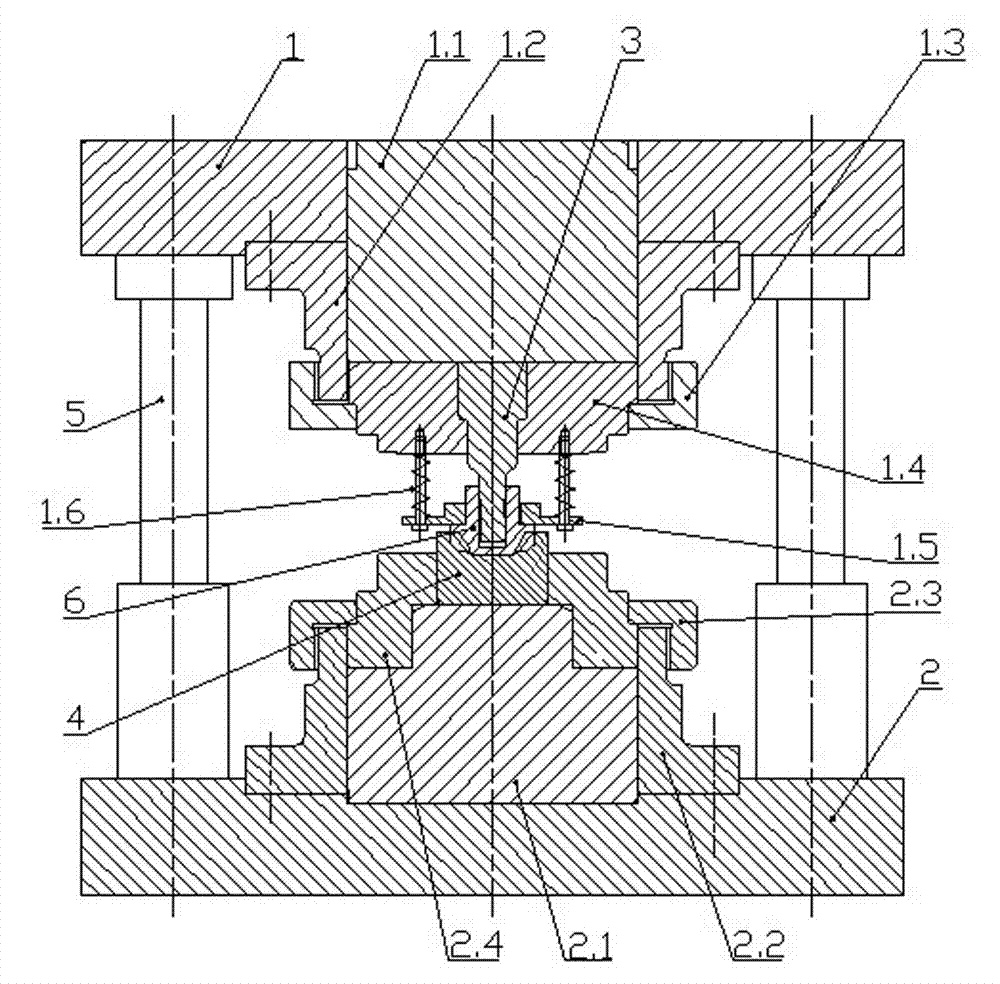

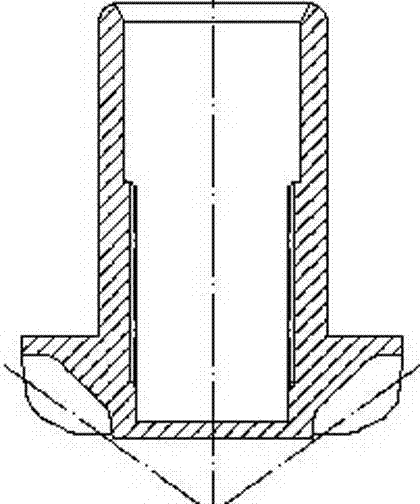

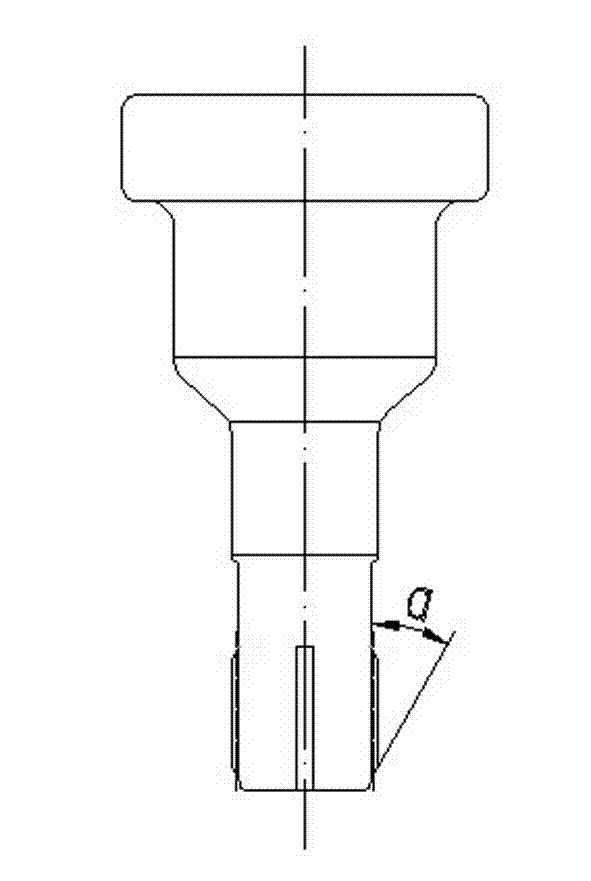

Cold extrusion mold for blind hole inner spline

InactiveCN103691753AImprove extrusion qualityIncrease productivityExtrusion diesMaterials scienceCushion

The invention discloses a cold extrusion mold for a blind hole inner spline. The cold extrusion mold for the blind hole inner spline comprises an upper mold and a lower mold, wherein the upper mold and the lower mold are connected through guide sliding posts to form a mold frame; an upper cushion block, an upper mold seat and an upper locking ring are positioned and installed on the upper mold by taking an upper mold plate and an upper positioning sleeve as carriers; a bottom cushion block, a base and a lower locking ring are positioned and installed on the lower mold by taking a bottom plate and a lower positioning sleeve as carriers; a mold head which extends out downward is positioned and installed on the upper mold seat of the upper mold; an elastic top consisting of a ring and a spring is fixedly connected with the bottom surface of the upper mold seat by taking the mold head a center; a toothed mold is positioned and installed on a base of the lower mold; the toothed mold with an upward mold cavity is coaxial with the mold head. The blind hold inner spline is formed by cold extrusion; the process is advanced; the structure is reasonable; the extrusion quality is high; moreover, the production efficiency is high. The cold extrusion mold for the blind hole inner spline is suitable for machining blind hole inner splines in all specifications.

Owner:JIANGSU AIRSHIP GEAR

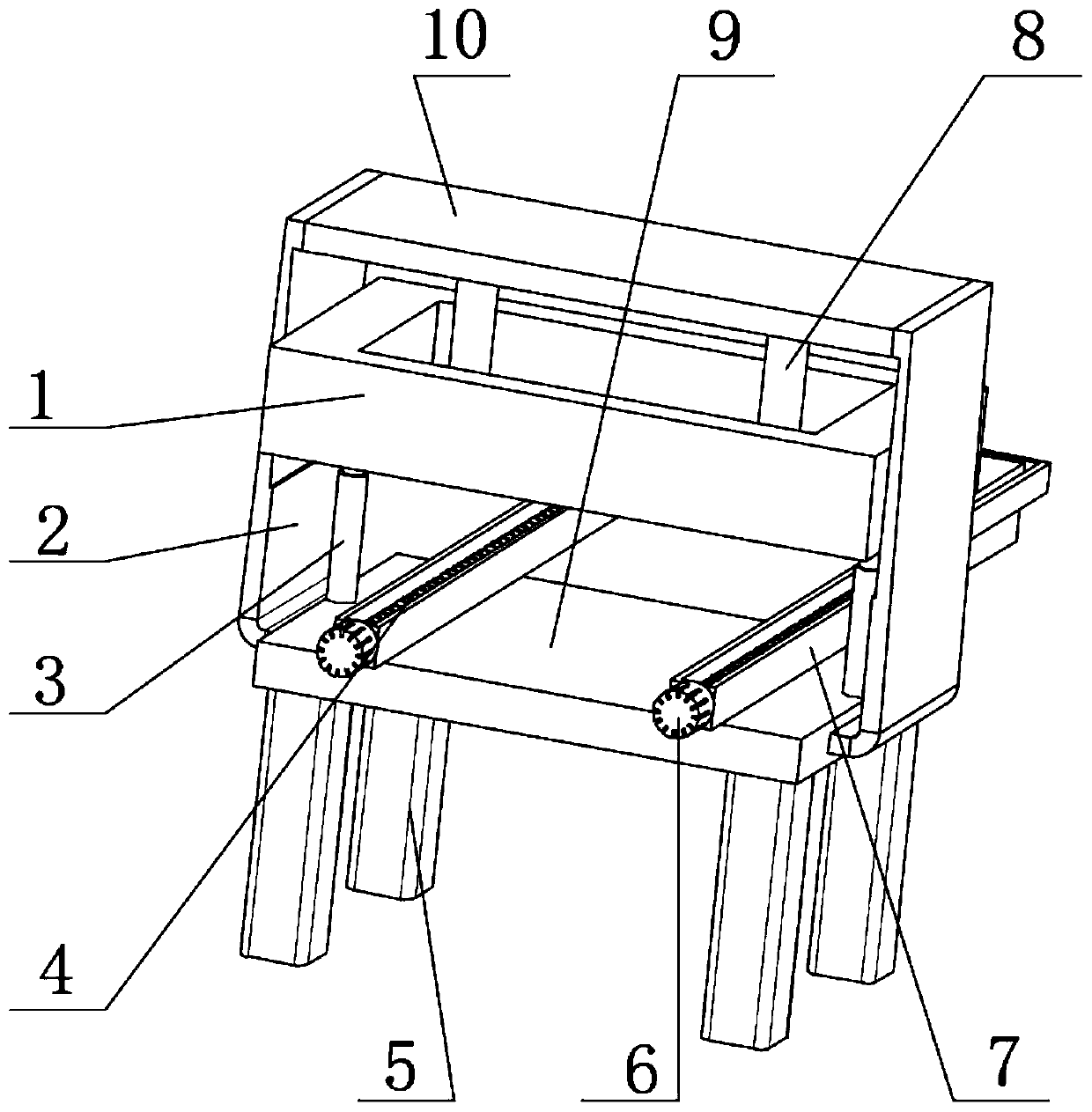

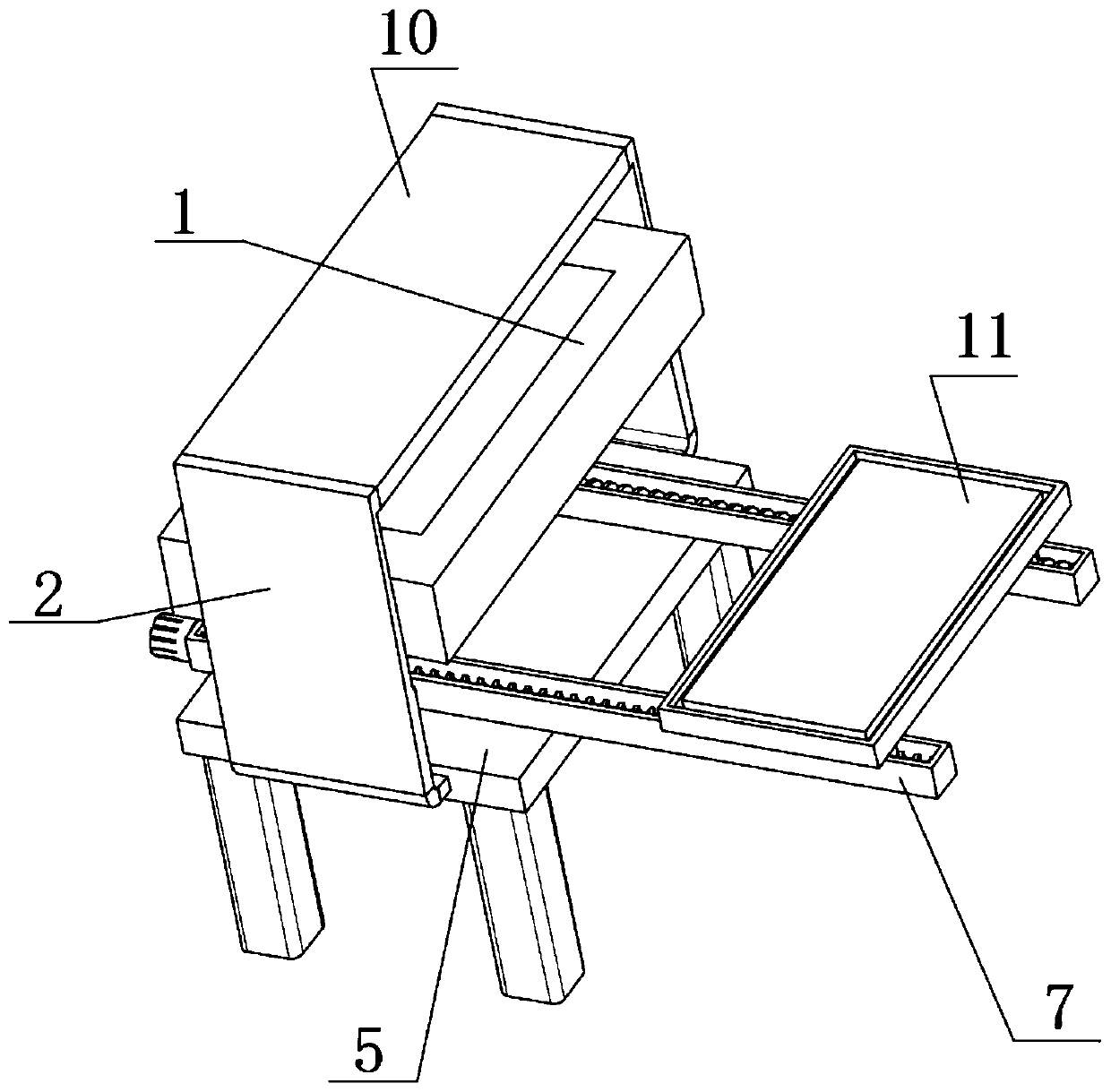

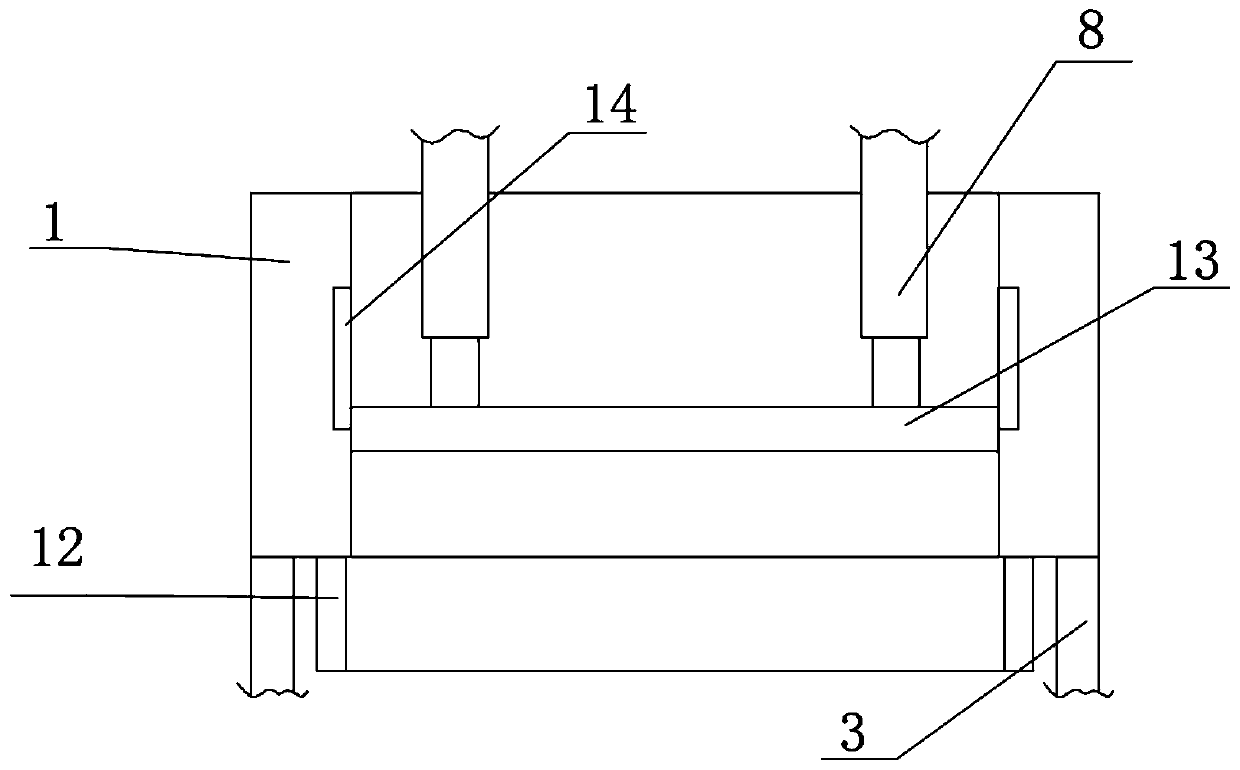

Semi-automatic tobacco leaf graded bundling machine and tobacco leaf bundling method

PendingCN110663989ASimple and efficient operationSave human effortTobacco preparationAgricultural engineeringEngineering

The invention discloses a semi-automatic tobacco leaf graded bundling machine. The semi-automatic tobacco leaf graded bundling machine comprises a base and a tobacco leaf fixing rope; both sides of the top of the base are fixedly connected with support frames; the tops of the support frames are fixedly connected with equipment mounting frames; electric cylinders are fixedly mounted at both sides of the tops of the equipment mounting frames by connection blocks; and the bottom ends of the electric cylinders run through the equipment mounting frames and extend to the bottoms of the equipment mounting frames. The invention relates to the technical field of tobacco leaf machining. According to the semi-automatic tobacco leaf graded bundling machine, when tobacco leaves are packaged, the tobacco leaves only need to be placed in equipment and then a pedal control part is stepped to carry out squeezing on the tobacco leaves; the semi-automatic tobacco leaf graded bundling machine is simple and convenient to operate; a great amount of labor is saved; when tobacco is squeezed, the fixing rope is laid in advance, so that tobacco bundling efficiency is improved to a great degree and an operator can easily bundle and release the tobacco leaves in the bundling process; and the machine is lightweight, occupies a small space and is convenient to carry. The invention further provides a tobaccoleaf bundling method.

Owner:桐城市阳光塑业有限公司

Separated type plastic extruding machine convenient to use

The invention discloses a separated type plastic extruding machine convenient to use. The separated type plastic extruding machine comprises an outer frame; a first motor is fixedly connected to the left side of the outer frame; one end of an output shaft of the first motor penetrates through the outer frame and extends into the interior of the outer frame; a stirring rod is fixedly connected to the end, located in the outer frame, of the first motor; a second motor is fixedly connected to the bottom of the outer frame; and one end of an output shaft of the second motor penetrates through theouter frame and extends into the interior of the outer frame. The invention relates to the technical field of plastic extruding machines. According to the separated type plastic extruding machine convenient to use, the purpose of increasing the heating and melting rate can be achieved, the working efficiency can be improved, the waste of time can be reduced, people can use the machine conveniently, meanwhile, energy can be saved, melted raw materials can be conveniently extruded, the extrusion quality can be improved, processing can be guaranteed, the raw materials can be convenient to enter,intermittent feeding can be realized, melting can be facilitated, plastic extruding can be facilitated, meanwhile, the stability of a device can be improved, and the service life of the device can beprolonged.

Owner:李庭裕

Kitchen waste resource utilization biological treatment method

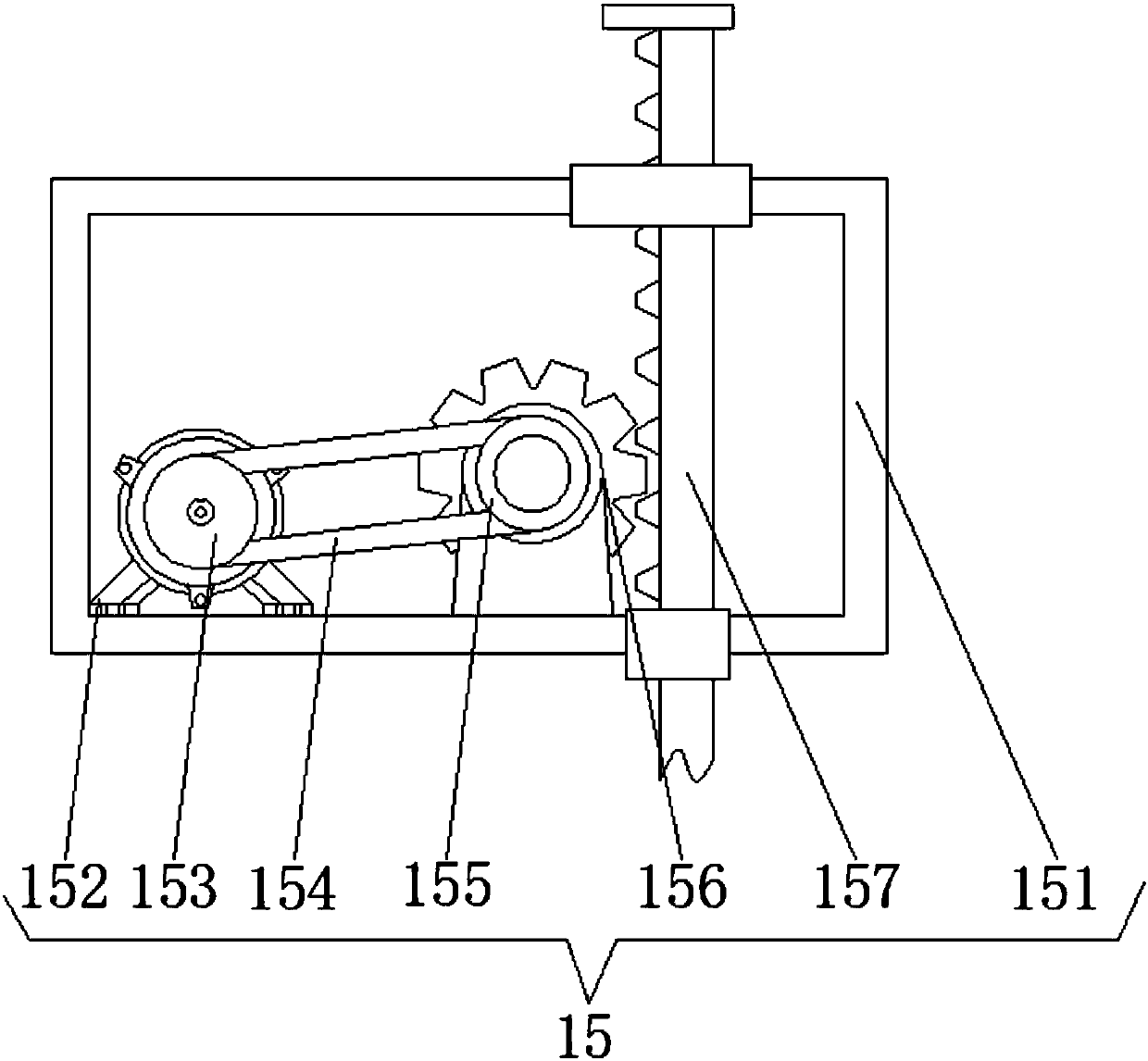

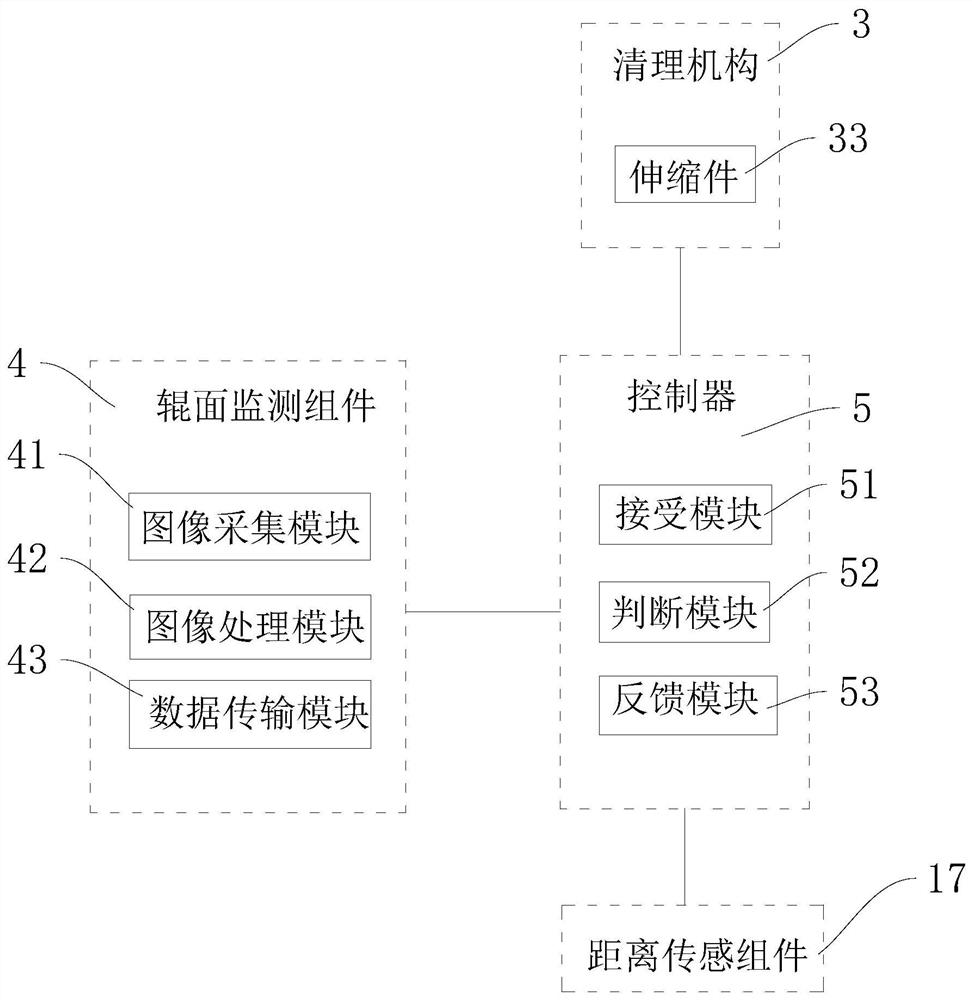

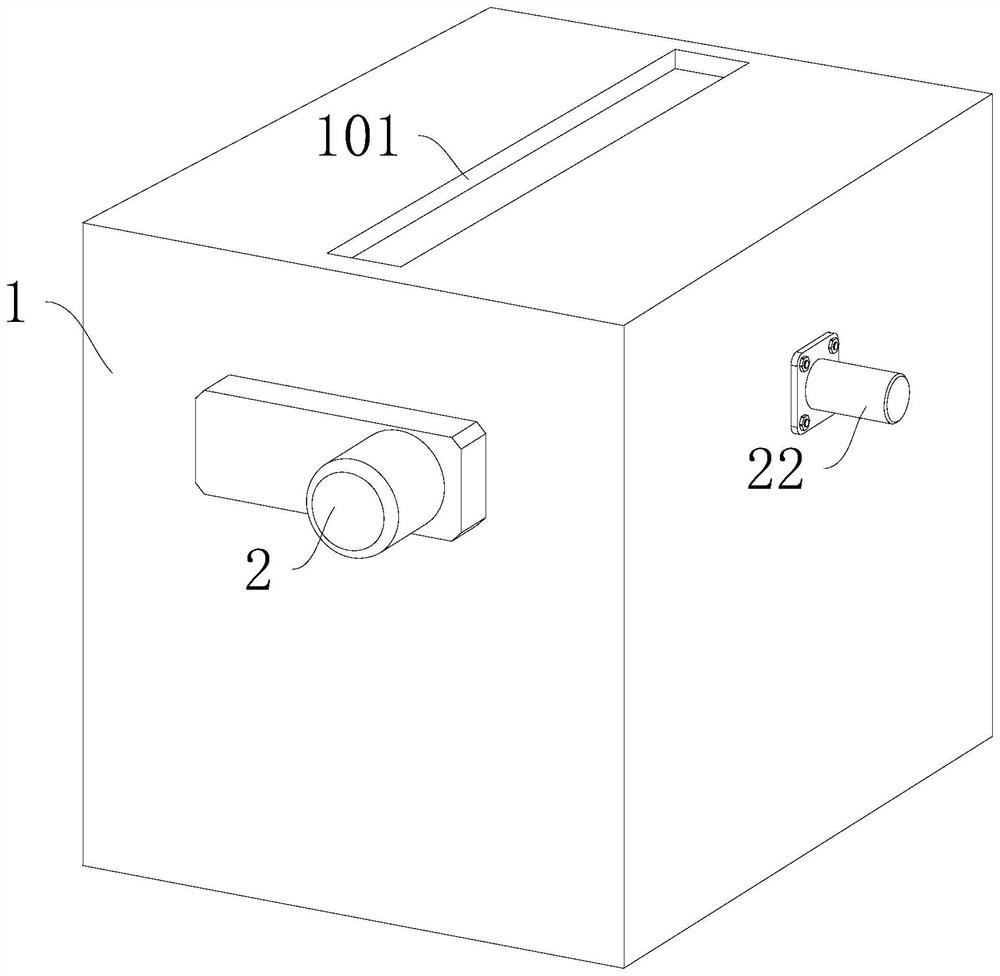

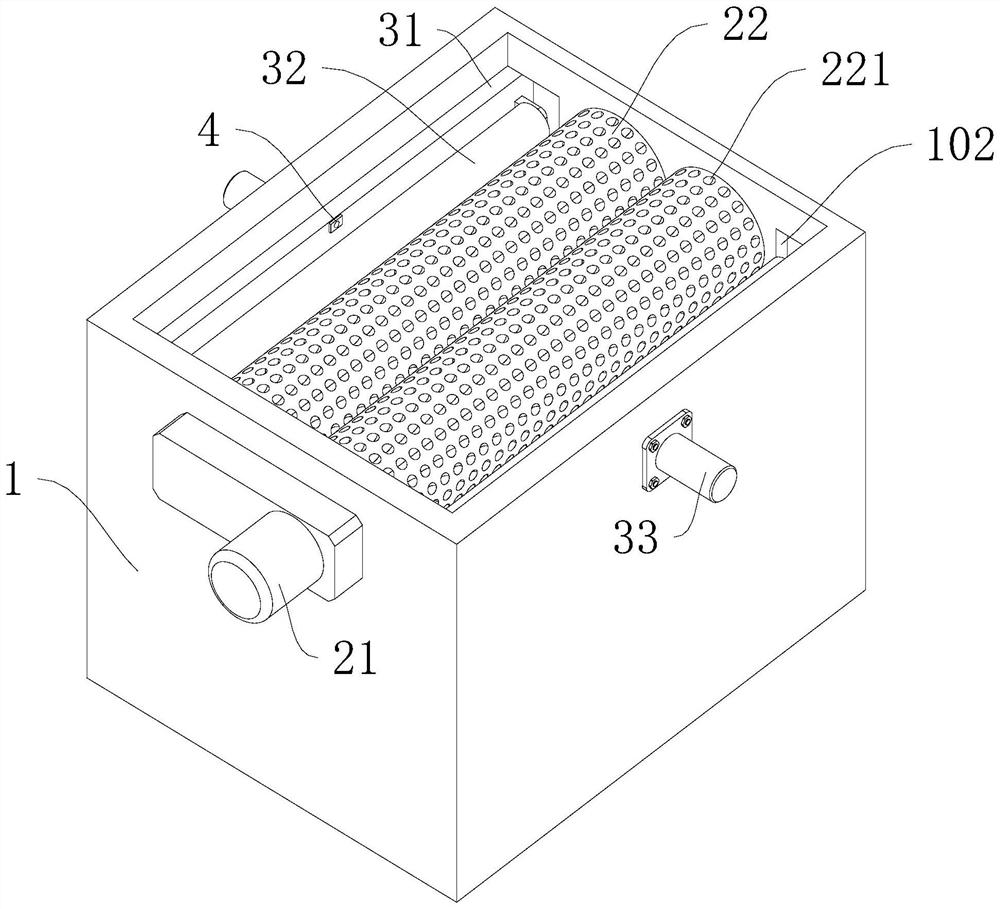

ActiveCN113510960AAvoid wear and tearEasy to cleanSievingSolid waste disposalElectric machineryProcess engineering

The invention relates to a kitchen waste resource utilization biological treatment method which adopts granulation equipment. The granulation equipment comprises a granulation box, an extrusion mechanism, cleaning mechanisms, a roller surface monitoring assembly and a controller. The extrusion mechanism comprises an extrusion motor and two extrusion rollers. The tangent position of the two extrusion rollers is located below a feeding port of the granulation box. Each cleaning mechanism corresponds to one extrusion roller and is used for cleaning the roller surface of the extrusion roller. Each cleaning mechanism comprises a mounting plate, a brush and a telescopic piece. The brushes are fixed on the mounting plates, and the mounting plates are arranged in the granulation box and can move to enable the brushes to be in contact with or separated from the roller surfaces of the extrusion rollers. The telescopic pieces are fixed on the granulation box and are used for driving the mounting plates to move. According to the kitchen waste resource utilization biological treatment method, the surfaces of the extrusion rollers can be cleaned in good time, residual materials on the surfaces of the extrusion rollers are removed, the yield of extruded particles is increased, and the situation that the extrusion rollers are subjected to long-time friction, and consequently the granulation effect is reduced can be avoided.

Owner:安徽坤健生物科技有限公司

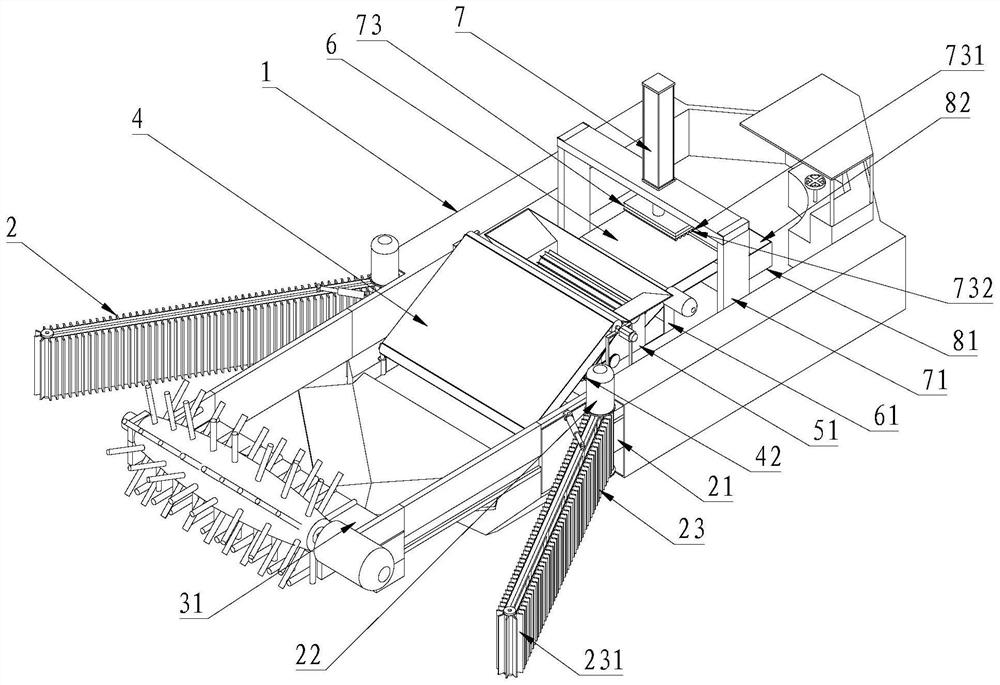

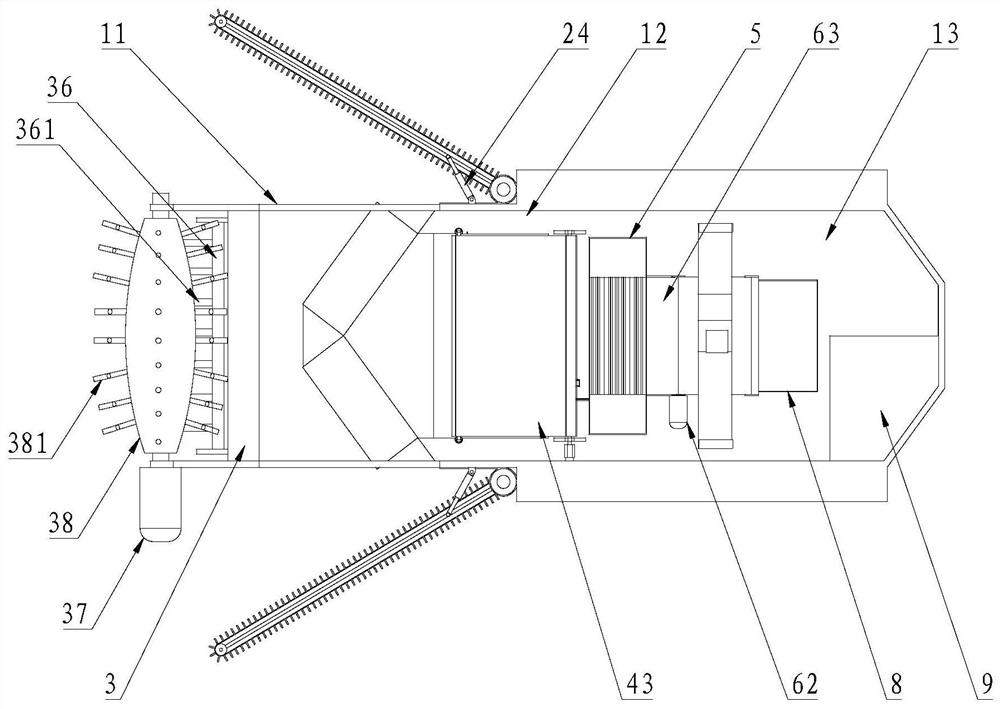

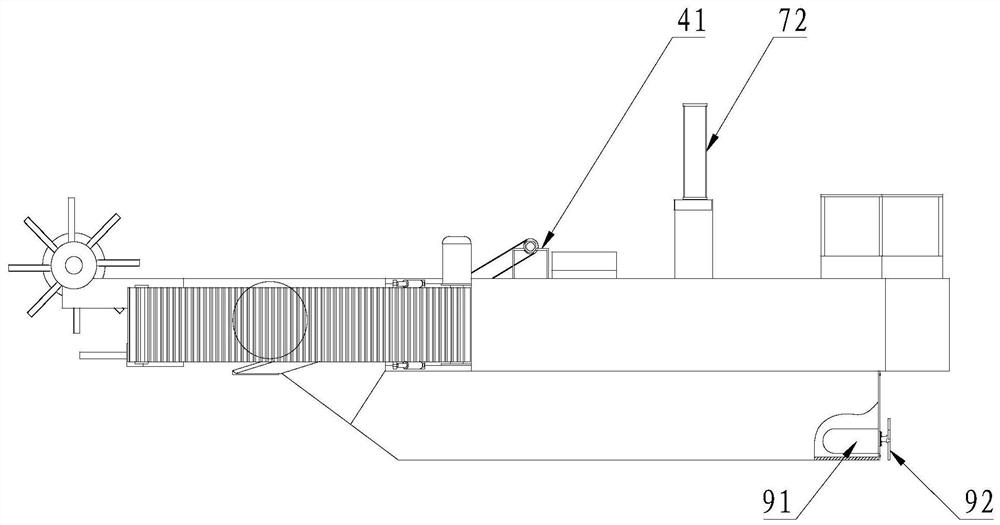

An automatic cleaning device for river crab breeding aquatic plants

ActiveCN112136485BImprove cutting effectImprove the effect of cutting and millingWater cleaningWaterborne vesselsHydraulic cylinderDrive motor

The present invention relates to the technical field of aquaculture, in particular to an automatic cleaning device for river crab culture aquatic plants, the cutting mechanism includes a second mounting frame, a second motor, a rack and pinion assembly, an upper blade and a lower blade; the first conveying mechanism It includes a third mounting frame, a third motor and a second conveyor belt; the cutting and grinding mechanism includes a fourth mounting frame, a first box body, a fourth motor, a first cutting roller, a second cutting roller, a fifth motor, a A grinding roller and a second grinding roller; the second conveying mechanism includes a fifth mounting frame, a sixth motor and a third conveyor belt; the extrusion mechanism includes a sixth mounting frame, a hydraulic cylinder and a pressing plate; the recycling The mechanism includes a seventh mounting frame and a receiving trough; the driving mechanism includes a driving motor and a propeller. Compared with the traditional way of manually cleaning aquatic plants, the device for automatically cleaning aquatic plants for river crab cultivation in the present invention improves the cleaning effect and recycling rate of aquatic plants.

Owner:武夷学院

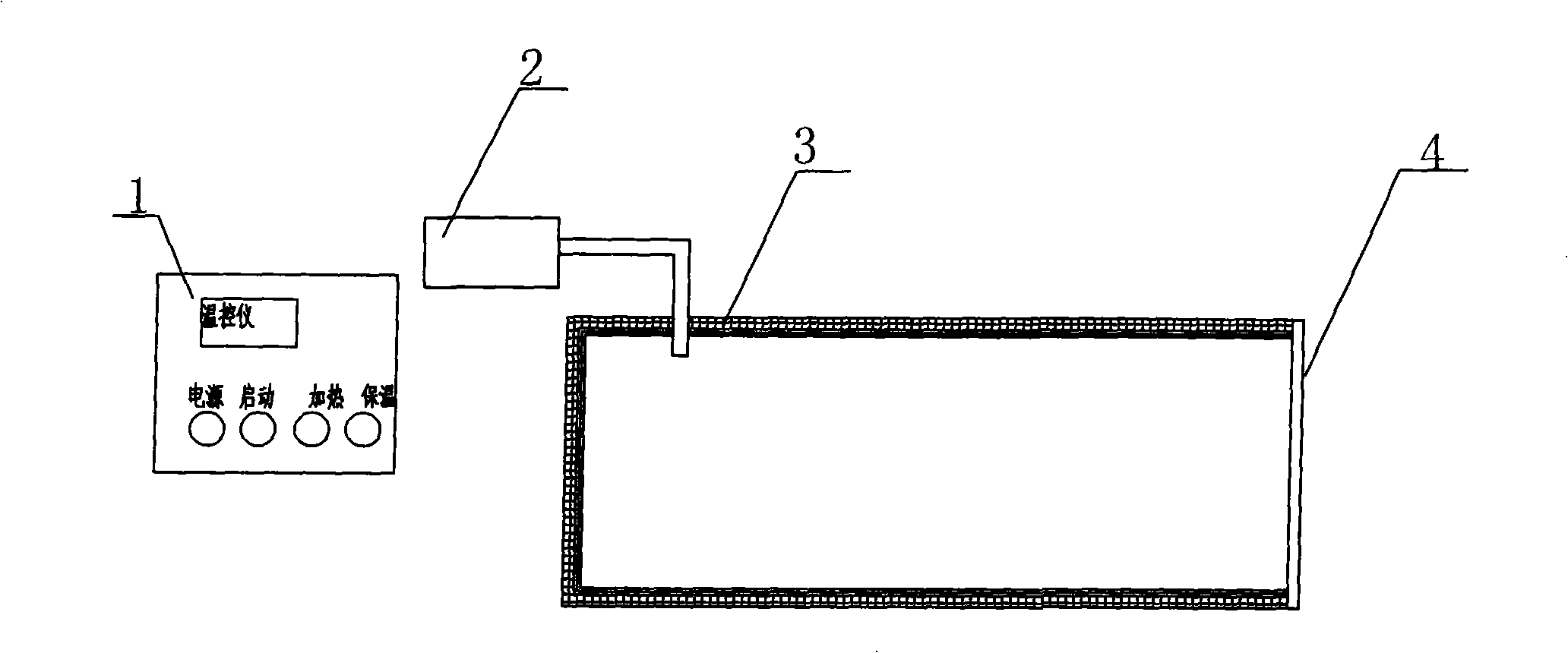

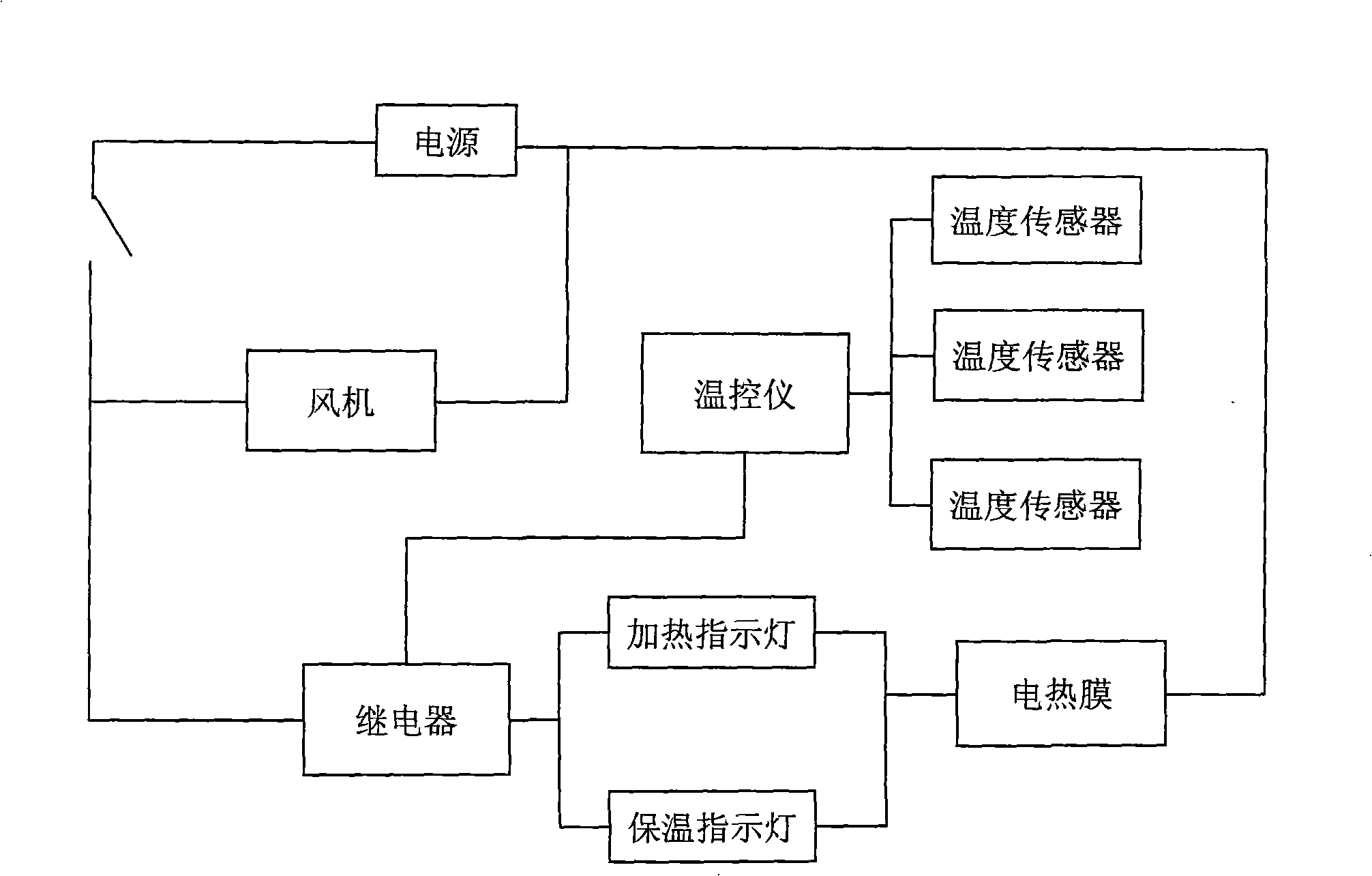

Die heating device of tyre rubber extruding machine

InactiveCN101407106AImprove extrusion qualityGood preheating effectTyresAir cycleTemperature control

The invention discloses a tire profile rubber extruder die heating device. The heating device comprises a box body and a temperature controller. One end of the box body is provided with an openable box door. An insulated heat preservation layer is clamped between an inner surface board and an outer surface board of the box board. An electrical heating wire or film is arranged between the inner surface board and the insulated heat preservation layer. The electrical heating wire or film is connected with a relay. The temperature controller comprises a temperature control apparatus and a relay which are arranged in an operation box and 2 to 5 temperature sensors which are arranged in the box and connected with a signal end of the temperature control apparatus. The operation box has a power switch and a heating indication lamp. A die is placed in the box, a temperature is set on the temperature control apparatus, the electrical heating wire or film is powered to carry out electric heating and the heating indication lamp turns on. When the temperature rises to a preset value, the temperature control apparatus sends a signal to the relay and the electrical heating wire or film stops heating. The die heating device also has a fan with a wind outlet inserted into the box body to promote air circulation and achieve a consistent temperature in the box body. The die heating device has good pre-heating effect, is particularly applicable to giant tire production for heating, can automatically control temperature, and is convenient in operation, simple in structure and low in cost.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

Multi-layer coextrusion blown-film die

The invention relates to a multi-layer coextrusion blown-film die which comprises N sets of material runner systems. Each set of material runner system comprises a feed inlet, an eccentric main runner, a center main runner, multiple radial sub-runners, and multiple spiral runners. Except for the material runner system on the innermost layer, each radial sub-runner of each of the rest sets of material runner systems comprises a section of radial sub-runner telecentric section, a section of radial sub-runner vertical section and a section of radial sub-runner pericenter section; the number of the radial sub-runner vertical sections of the whole die is totally 8x(N-1); the horizontal distances from the 8x(N-1) radial sub-runner vertical sections to the central axes of the die are equal; and the vertical position of the center main runner of the material runner system on the outermost layer is higher than the center main runner of the material runner system on the middlemost layer. According to the multi-layer coextrusion blown-film die provided by the invention, the diameter of the lower part is small, and a most suitable scheme of one-to-one corresponding combination between the spiral runners and the center main runners can be flexibly selected optimally.

Owner:GUANGDONG JINMING MACHINERY

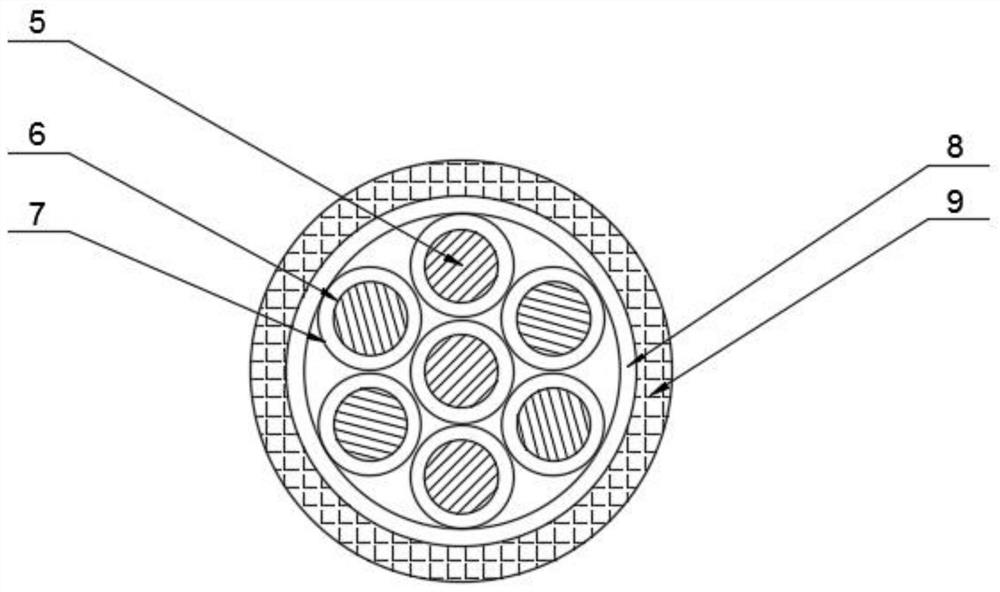

Cross-linked polyethylene insulated halogen-free low-smoke fire-resistant control cable

InactiveCN112164492AImprove fire resistanceImprove securityPlastic/resin/waxes insulatorsInsulated cablesGlass fiberPolymer science

The invention discloses a cross-linked polyethylene insulated halogen-free low-smoke fire-resistant control cable, which comprises conductors, fire-resistant mica layers, insulating layers, a beltinglayer and a sheath layer. The conductors are wrapped with the fire-resistant mica layers, the fire-resistant mica layers are wrapped with the insulating layers, and the conductors, the fire-resistantmica layers and the insulating layers form insulating wire cores; a plurality of insulating wire cores are mutually twisted into a bundle to form a cable core, the cable core is wrapped by a wrappingtape layer, and the wrapping tape layer is wrapped by a sheath layer. Each conductor is composed of annealed copper wires, and each fireproof mica layer is formed by wrapping a mica tape. The insulating layer is made of cross-linked polyethylene, the wrapping tape layer is formed by wrapping an alkali-free glass fiber tape, and the sheath layer is made of halogen-free flame-retardant polyolefin. By adopting the crosslinked polyethylene as the material of the insulating layer, the fire resistance of the cable can be greatly improved while the insulativity is ensured, so that the safety of the cable is improved, and the application range of the cable is expanded.

Owner:ANHUI HAINA CABLE GRP

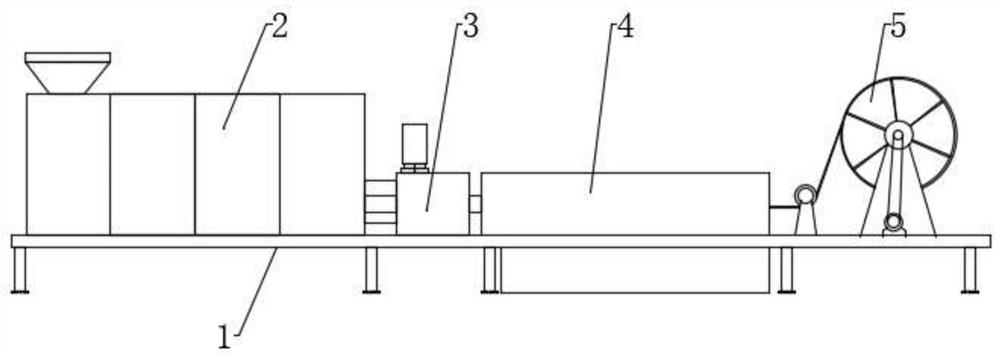

Soluble teflon processing device and processing technology thereof

The invention discloses a soluble teflon processing device and a processing technology thereof. The soluble teflon processing device comprises an extruder, a mold outlet of the extruder is connected with a vacuum mold, the output end of the vacuum mold is connected with a water tank, and the other side of the water tank is provided with a take-up machine; the soluble teflon processing device further comprises a machine frame used for bearing the extruder, the vacuum mold, the water tank and the take-up machine; and a multi-stage temperature control structure is arranged on the extruder, and the temperature of the multi-stage temperature control structure is distributed from low to high in the output direction of the extruder. The soluble teflon processing device and the processing technology thereof have the beneficial effects that sectional temperature control is adopted in the extruder, so that the decomposition phenomenon caused by too fast local temperature rise when soluble polytetrafluoroethylene is heated is avoided, and the stability of the extrusion process is improved; and the high extrusion temperature is adopted, the viscosity of the soluble polytetrafluoroethylene is reduced, the critical shear rate of the soluble polytetrafluoroethylene is increased, the phenomena of rough surface, no gloss or layering are eliminated in the extrusion process, and the extrusion quality of the soluble polytetrafluoroethylene is improved.

Owner:DONGGUAN GODDESS ELECTRONICS

A plastic extruder with adjustable extrusion barrel temperature

The invention discloses a plastic extruder with adjustable extruding barrel temperature. An outer protective cover is fixed on the surface of the frame, and the extruding barrel is horizontally erected inside the outer protective cover. Several cast aluminum heating sleeves are fixedly arranged on the arc side of the outer protective cover, and a feeding chamber is fixedly arranged at one end of the outer protective cover, and the discharge port of the feeding chamber passes through the outer protective cover and is arranged on the extruding cylinder. On the feeding port, a cooling pipe is fixed inside the cavity of the rotating shaft inside the extrusion barrel, and a temperature control box is installed on one side of the frame. By setting a stirring mechanism in the feeding chamber, the The plastic is stirred by the stirring mechanism in the feeding chamber, so that the mixing of the plastic raw materials is more uniform, and the extrusion quality of the extrusion barrel is improved. The adjustment of the temperature of the plastic raw material in the barrel makes the heating and cooling effects of the barrel more prominent.

Owner:ANHUI TENGYUE ALUMINUM PLASTIC

A high temperature resistant cable extruder

The invention discloses a high temperature resistant cable extruder, which comprises an extruding cylinder box, a plastic fixing device and a rotating discharge cylinder. The middle part of the extruding cylinder box is provided with a through cavity, and the top of the left end of the extruded cylinder box is opened with a The material inlet communicates with the through cavity, and several installation grooves are opened inside the extruded barrel box, and the cavity wall of the material inlet is fixedly connected with the outer end surface of the hopper. The invention uses a heater to heat the barrel wall to soften the raw material, so that the propulsion screw rotates to push the raw material into the molding device, and the fan sends the cold air flow through the cold plastic plate to the cold flow chamber, so that the material is rapidly cooled and shaped , the overall efficiency of extrusion is greatly improved, and the life loss of the extruder under long-term high-temperature operation is reduced; in addition, the automatic discharge delivery function is realized by rotating the discharge cylinder, and the sliding structure of the rotating arc plate and the push plate reduces In the process of material processing, the heat cannot be dissipated due to blockage, which reduces the service life of the extruder and improves the heat resistance.

Owner:安徽华上电缆科技有限公司

High-temperature-resistant cable plastic extruding machine

The invention discloses a high-temperature-resistant cable plastic extruding machine which comprises a plastic extruding barrel box, a fixed plastic device and a rotary discharging barrel. A through cavity is formed in the middle of the plastic extruding barrel box, a feeding opening is formed in the top of the left end of the plastic extruding barrel box to communicate with the through cavity, multiple mounting grooves are formed in the plastic extruding barrel box, and the cavity wall of the feeding opening is fixedly connected with the outer end face of a hopper. The barrel wall is heated through heaters to soften raw materials, a propelling screw rotates to carry out plastic extruding forming on the raw materials and push the raw materials into the fixed plastic device, cold airflow istransmitted into a cold flow cavity by a fan through a cold plastic plate, the materials are quickly cooled and shaped, the plastic extruding efficiency is overall improved greatly and lift shortening of the plastic extruding machine under long-time high temperature work is reduced; and in addition, the functions of automatic discharging and transmitting are achieved through the rotary discharging barrel, through the rotating sliding structure of arc plates and propelling plates, the problems that heat cannot be dissipated due to blocking in the material processing process, and the service life of the plastic extruding machine is shortened are reduced, and heat resistant performance is improved.

Owner:安徽华上电缆科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com