Multifunctional direct current induction heater structure capable of achieving gradient heating and uniform heating

A technology of uniform heating and DC induction, applied in the field of multifunctional DC induction heater structure, can solve the problems of inconvenient adjustment distance, micro-cracks in molded products, affecting product quality, etc., to avoid defects such as internal micro-cracks and improve extrusion. The effect of pressure quality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

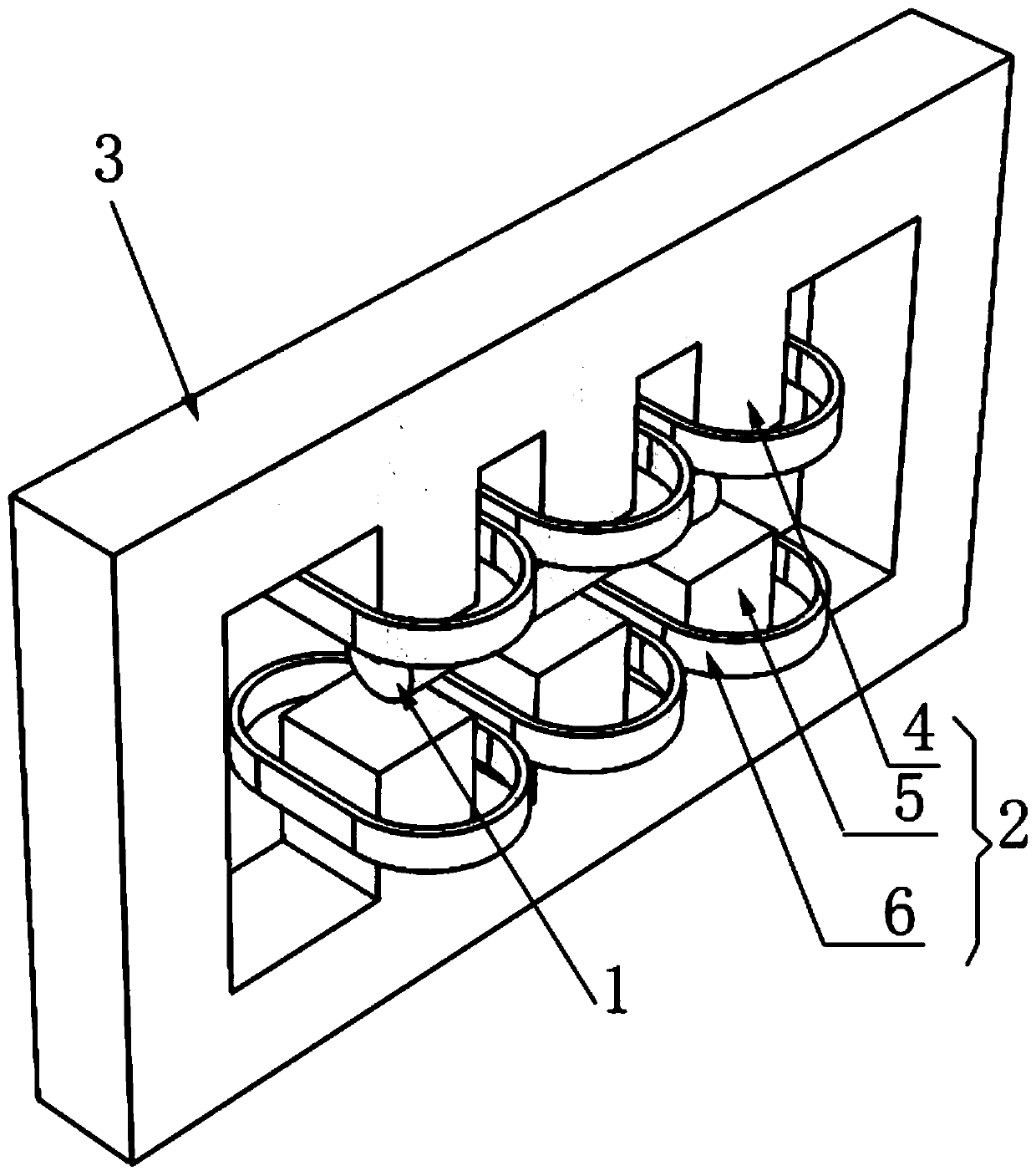

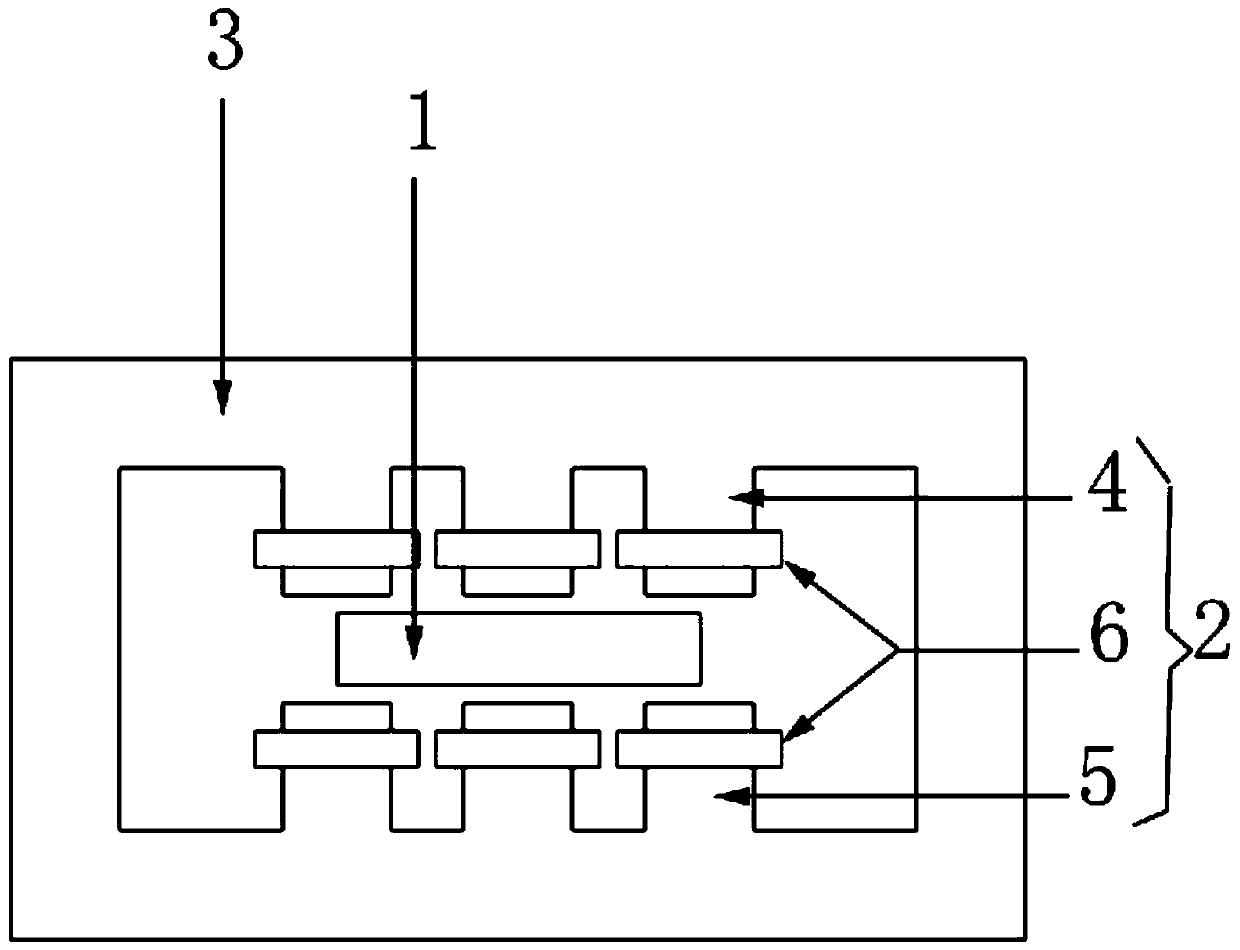

[0042] Such as Figure 1 to Figure 2 As shown, Embodiment 1 of the present invention provides a multifunctional DC induction heater structure that can realize gradient heating and uniform heating, including:

[0043] A plurality of induction heating parts 2 arranged side by side along the axial direction of the metal rod 1 to be heated;

[0044] The induction heating part 2 includes a first heating column 4 and a second heating column 5 protruding from an iron core 3, and the first heating column 4 and the second heating column 5 are centered on the metal rod 1 to be heated. The axes are symmetrical with each other; the first heating column 4 and the second heating column 5 are both provided with an excitation coil 6.

[0045] The iron core 3 is made of a ferromagnetic material with high magnetic permeability, so that a larger core air gap central magnetic field can be obtained.

[0046] The iron core 3 is an integrally made rectangular frame shape. The first heating column 4 and the...

Embodiment 2

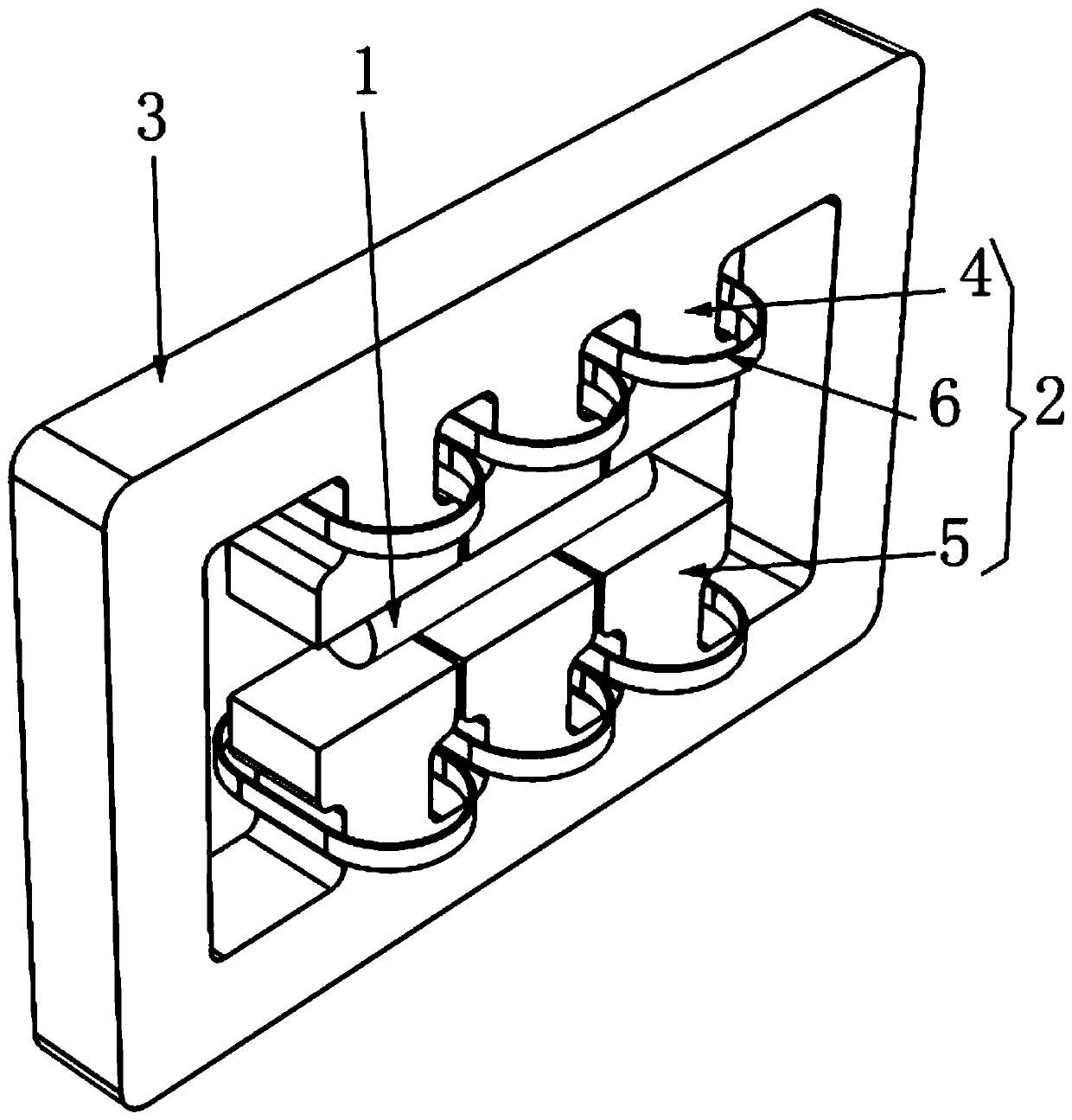

[0056] Such as Figure 3 to Figure 4 As shown, Embodiment 2 of the present invention provides a multifunctional DC induction heater structure that can realize gradient heating and uniform heating, including:

[0057] A plurality of induction heating parts 2 arranged side by side along the axial direction of the metal rod 1 to be heated;

[0058] The induction heating part 2 includes a first heating column 4 and a second heating column 5 protruding from an iron core 3, and the first heating column 4 and the second heating column 5 are centered on the metal rod 1 to be heated. The axes are symmetrical with each other; the first heating column 4 and the second heating column 5 are both provided with an excitation coil 6.

[0059] The iron core 3 is made of a ferromagnetic material with high magnetic permeability, so that a larger core air gap central magnetic field can be obtained.

[0060] The iron core 3 is an integrally made rectangular frame shape. The first heating column 4 and th...

Embodiment 3

[0071] Such as Figure 7 As shown, Embodiment 3 of the present invention provides a multifunctional DC induction heater structure that can realize gradient heating and uniform heating, including:

[0072] A plurality of induction heating parts 2 arranged side by side along the axial direction of the metal rod 1 to be heated;

[0073] The induction heating part 2 includes a first heating column 4 and a second heating column 5 protruding from an iron core 3, and the first heating column 4 and the second heating column 5 are centered on the metal rod 1 to be heated. The axes are symmetrical with each other; the first heating column 4 and the second heating column 5 are both provided with an excitation coil 6.

[0074] The iron core 3 is made of a ferromagnetic material with high magnetic permeability, so that a larger core air gap central magnetic field can be obtained.

[0075] The iron core 3 is formed by combining a plurality of C-shaped frames in parallel, and the opening directions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com