Multi-layer coextrusion blown-film die

A multi-layer co-extrusion and machine head technology, which is applied in the field of multi-layer co-extrusion blown film head, can solve the problems of large volume, difficulty, and aggravated sealing of the lower part of the machine head, and achieve the risk of material denaturation, peak cutting, valley filling, Reduce the degree of unequal exclusion and protect the effect of extrusion pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

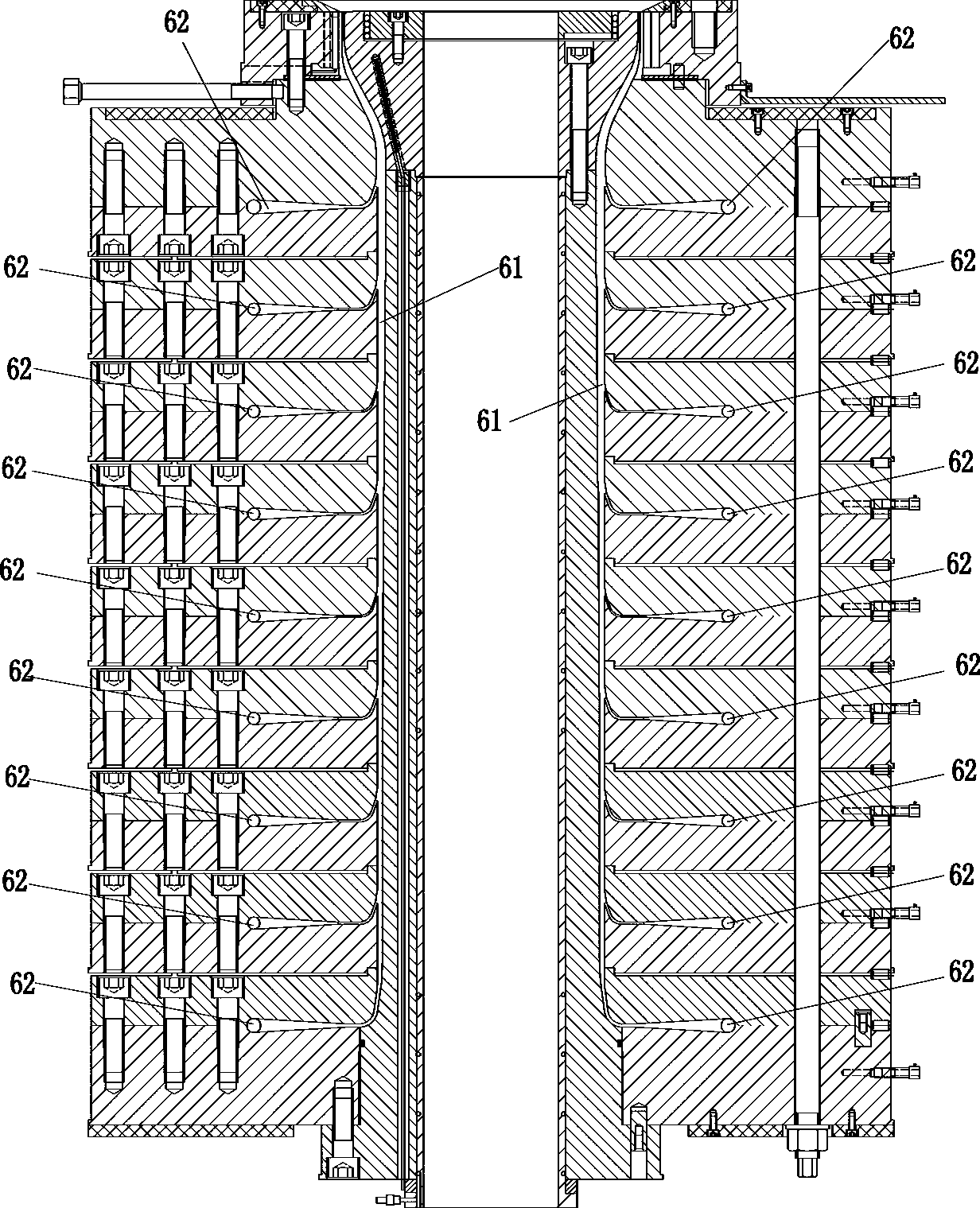

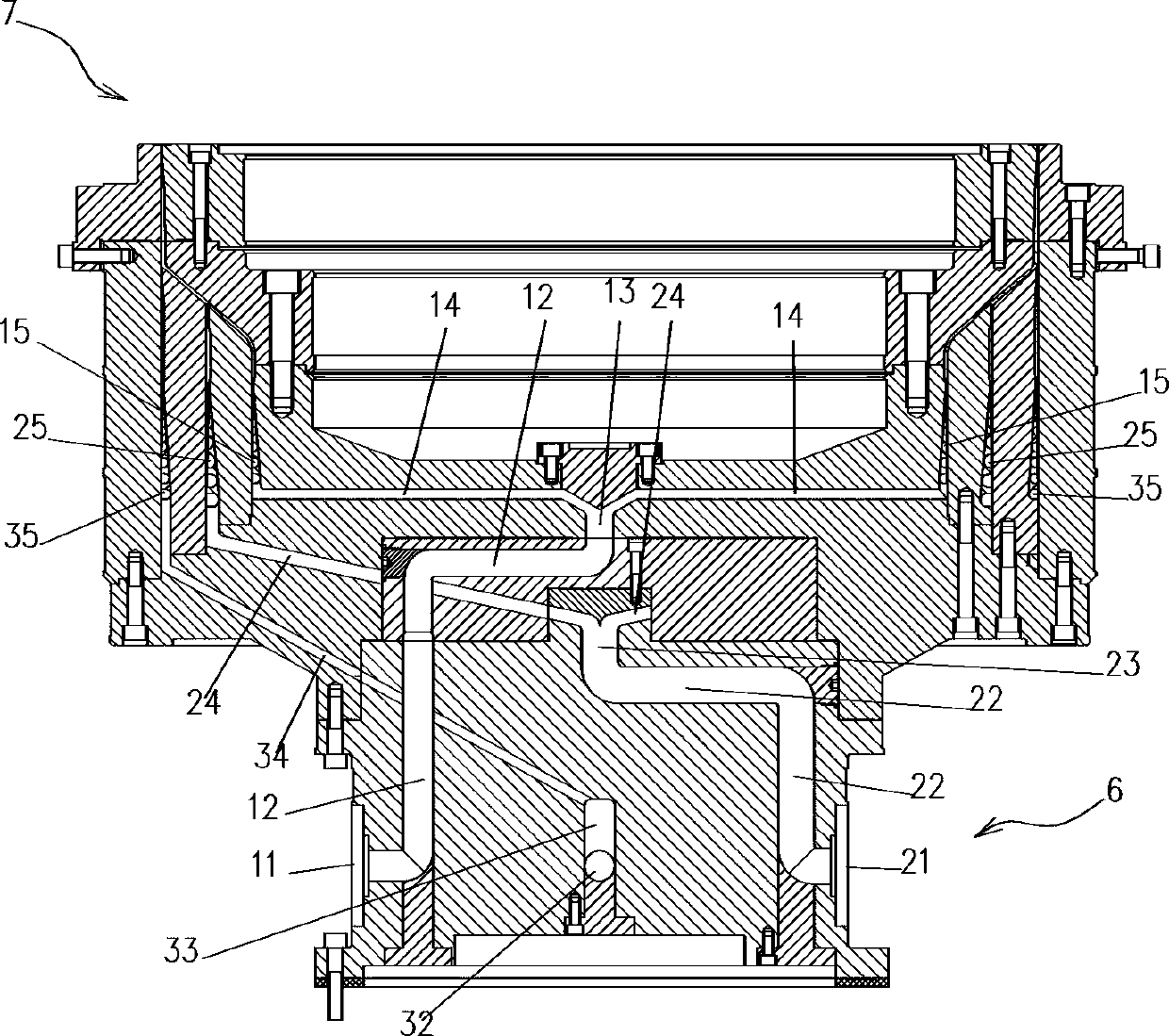

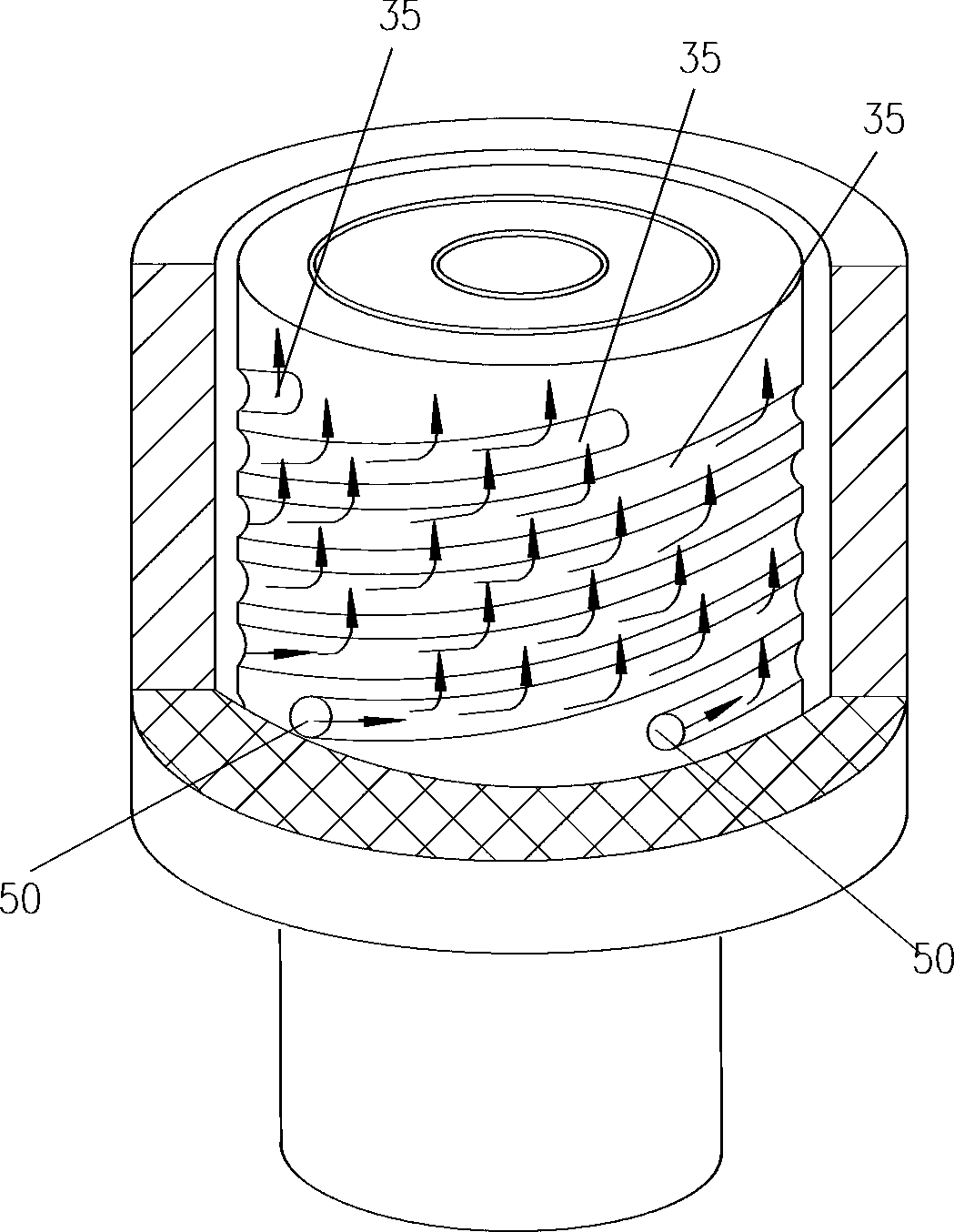

[0054] Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 The multi-layer co-extrusion blown film head shown is a five-layer co-extrusion blown film head, including five sets of material flow channel systems, each set of material flow channel systems is used to guide the flow of a corresponding layer of material; each A set of material flow channel system includes a material inlet, an eccentric main channel, a central main channel, multiple radial branch channels, and multiple spiral flow channels;

[0055] Specifically, the first set of material flow channel system includes a feed inlet 11, an eccentric main channel 12, a central main channel 13, a plurality of radial branch channels 14, and a plurality of spiral flow channels 15, such as Figure 7 , Figure 14 , Figure 19 As shown; the second set of material flow channel system includes a feed inlet 21, an eccentric main channel 22, a central main channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com