A plastic extruder with adjustable extrusion barrel temperature

A technology of a plastic extruder and an extrusion cylinder, which is applied in the field of plastic processing, can solve the problems of a single cooling fan, low efficiency, and long cooling processing time of the extrusion cylinder, so as to achieve a short cooling processing time, improve the extrusion quality, and reduce the cooling effect. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

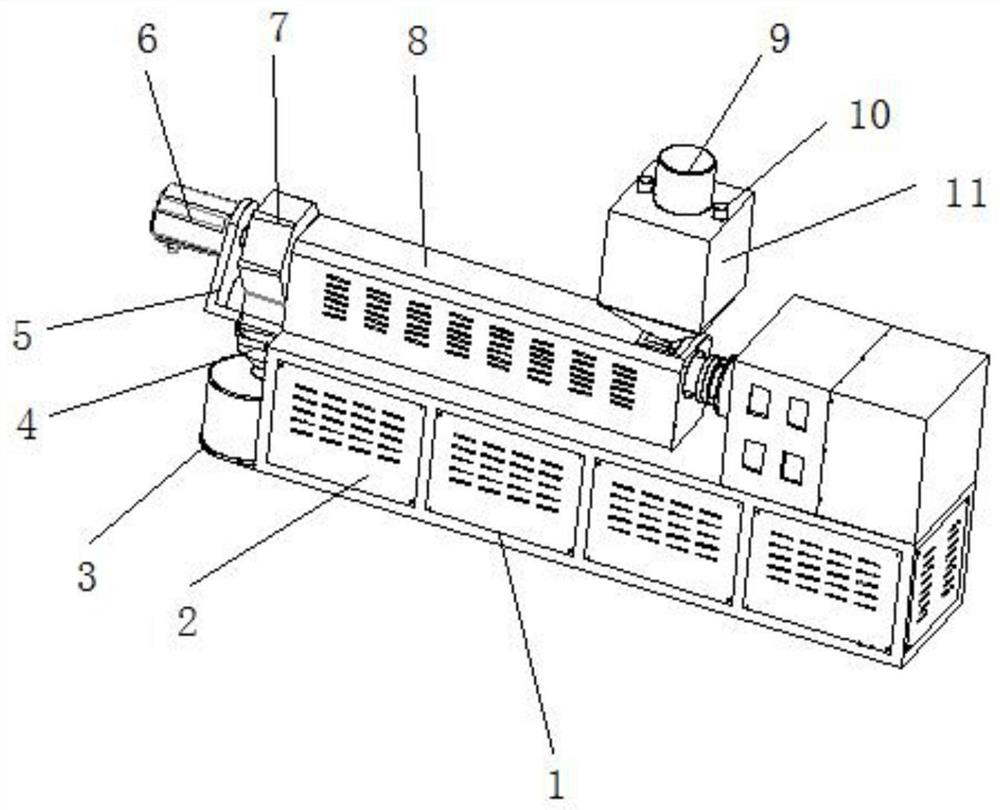

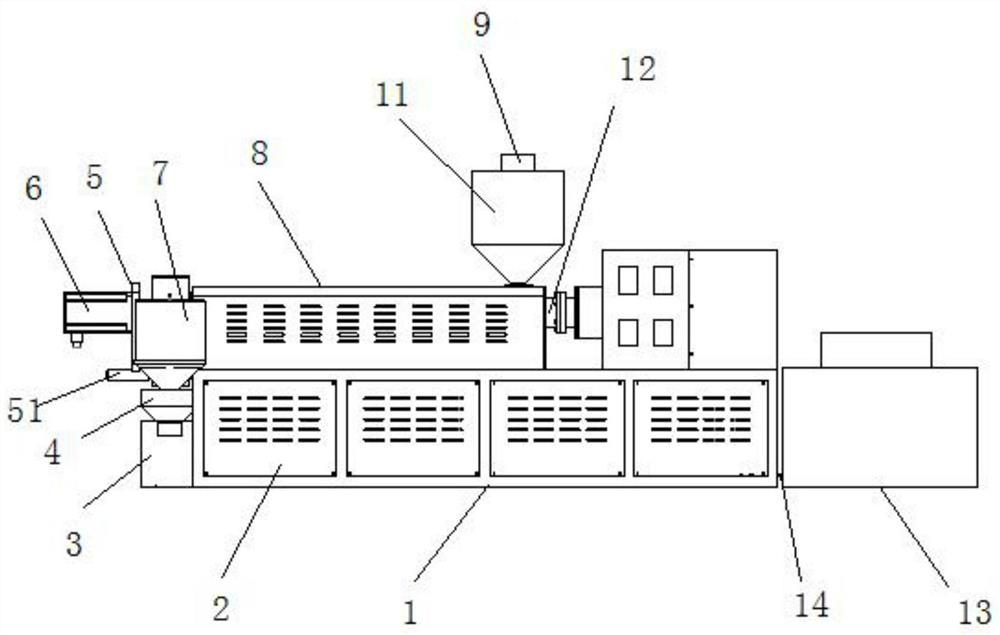

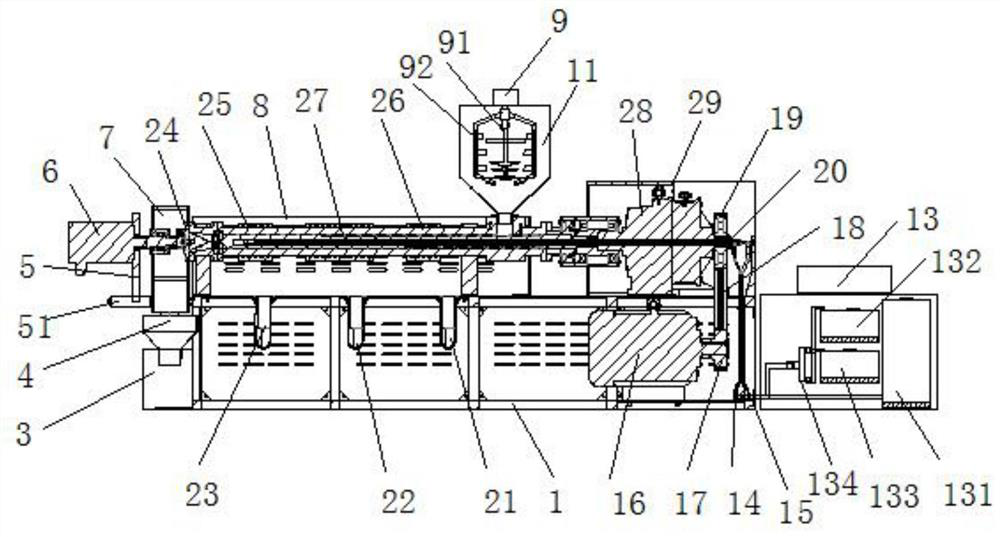

[0033] See Figure 1 ~ 7In the embodiment of the present invention, a plastic extruder at which an extruded cylinder temperature is adjustable, including a frame 1, and a rectangular square frame structure composed of a plurality of gear rods, and the long square frame structure is made of three The small frame is composed, and the heat sink 2 is provided on both sides of the three small frames, and the surface of the frame 1 is provided with an outer shield 8, and one end of the frame 1 is provided with a mount 29, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com