Patents

Literature

81results about How to "Short cooling time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

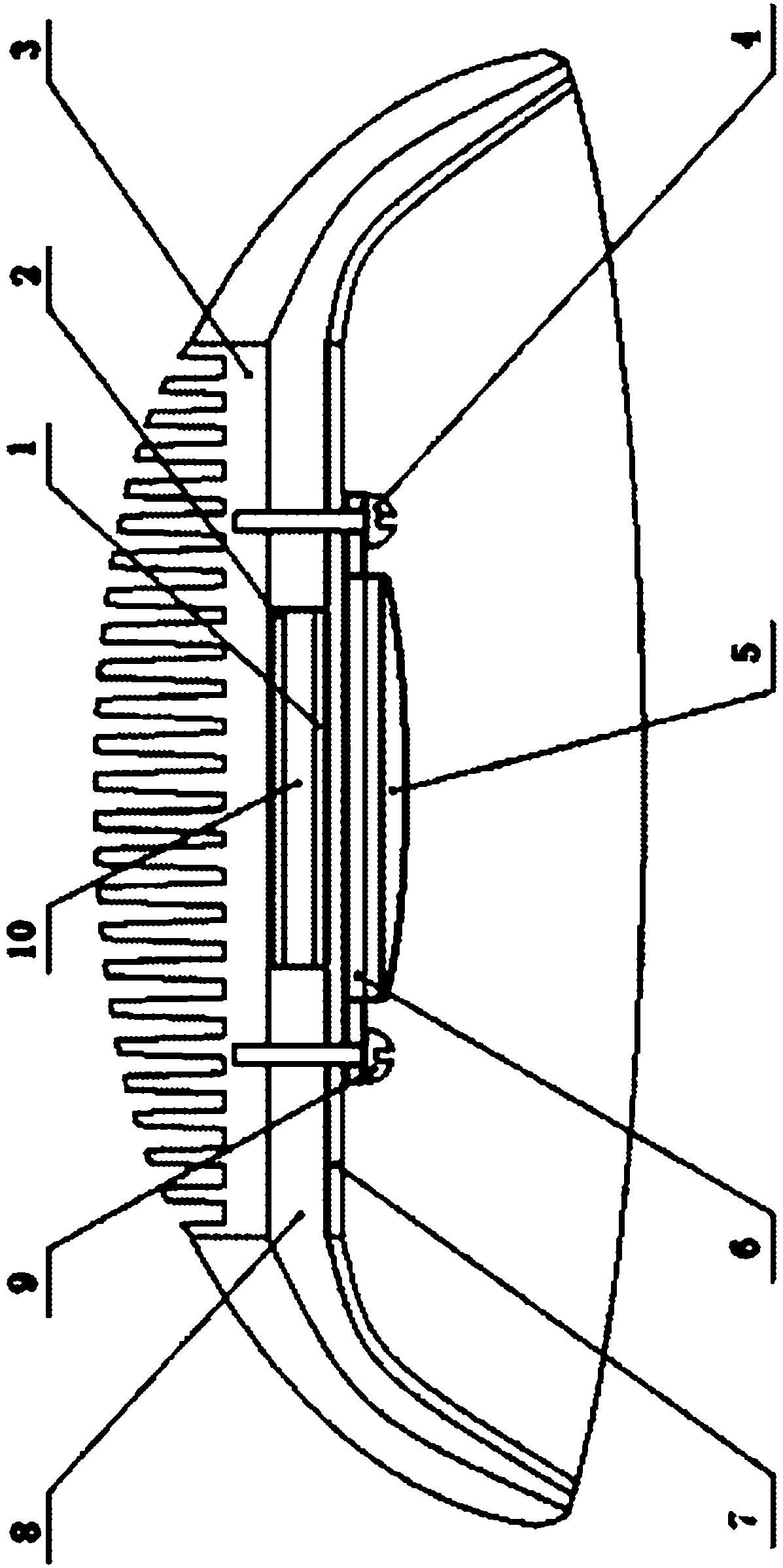

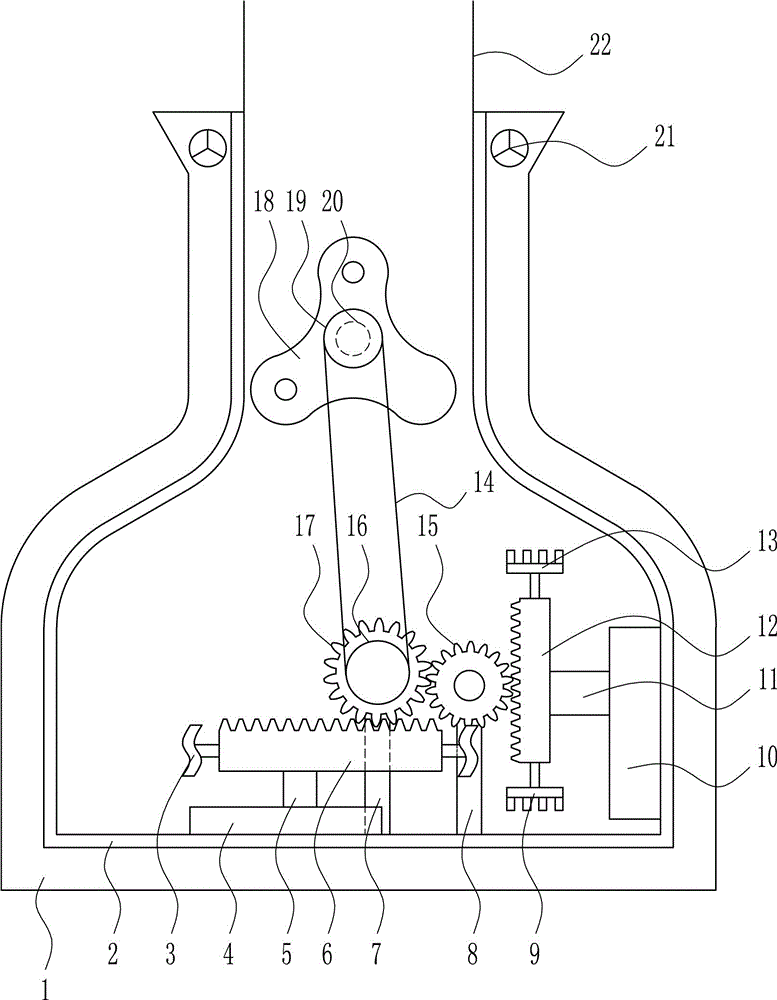

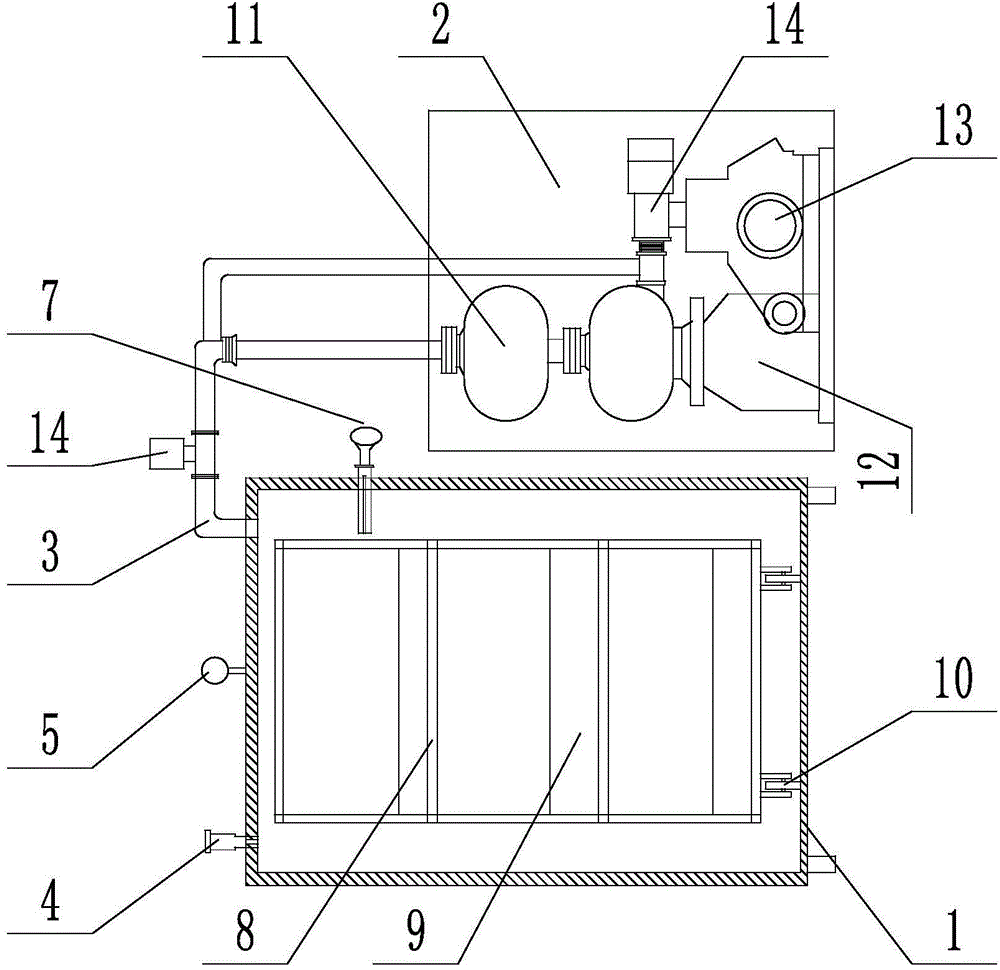

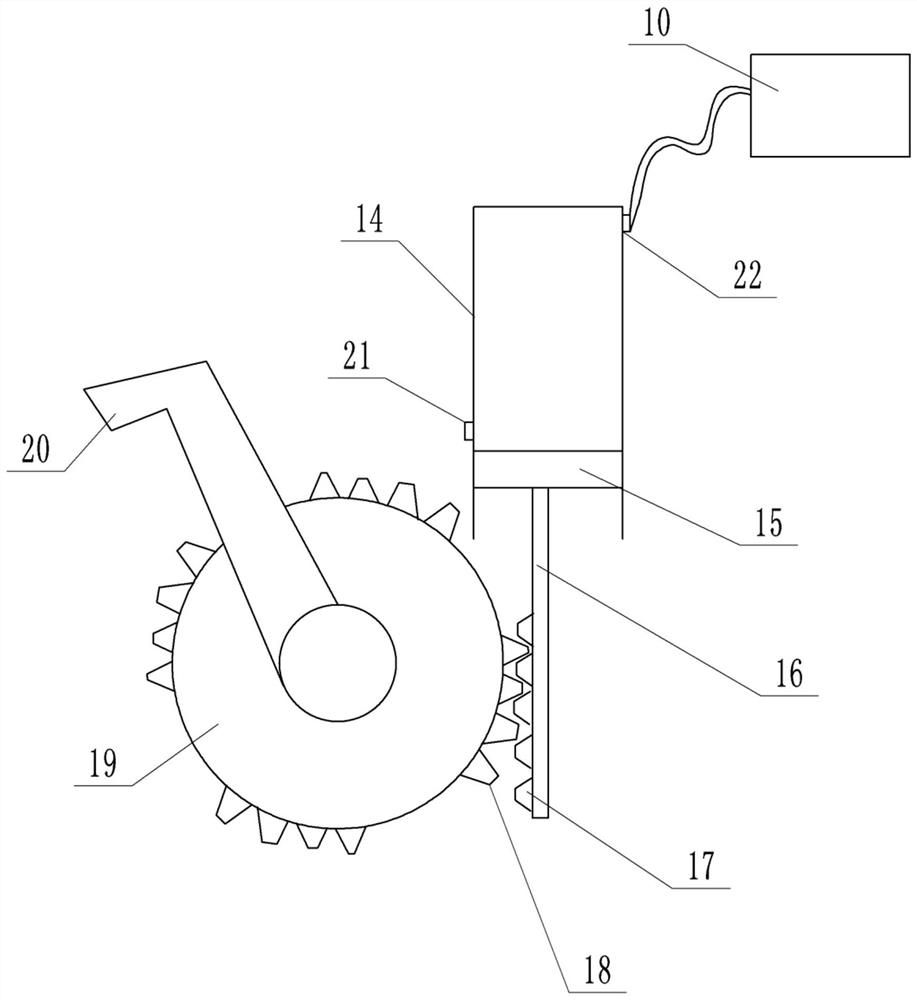

Automobile injection mold

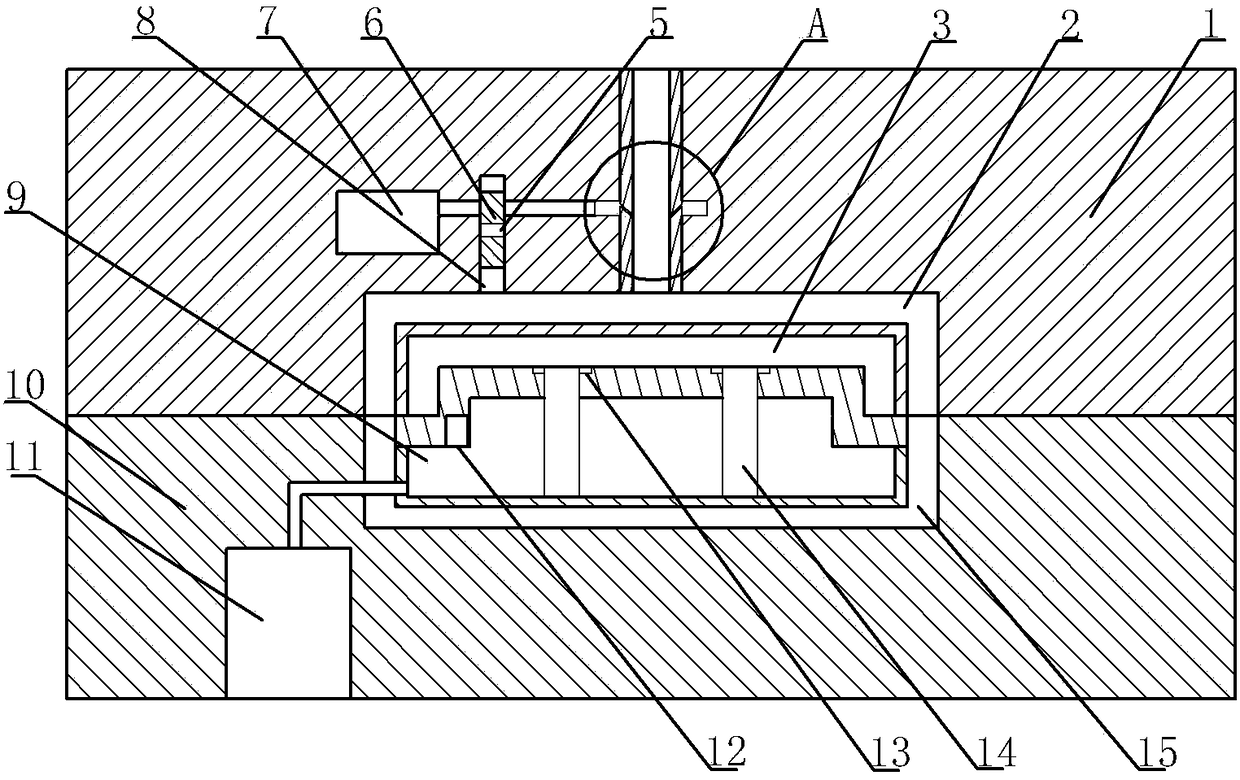

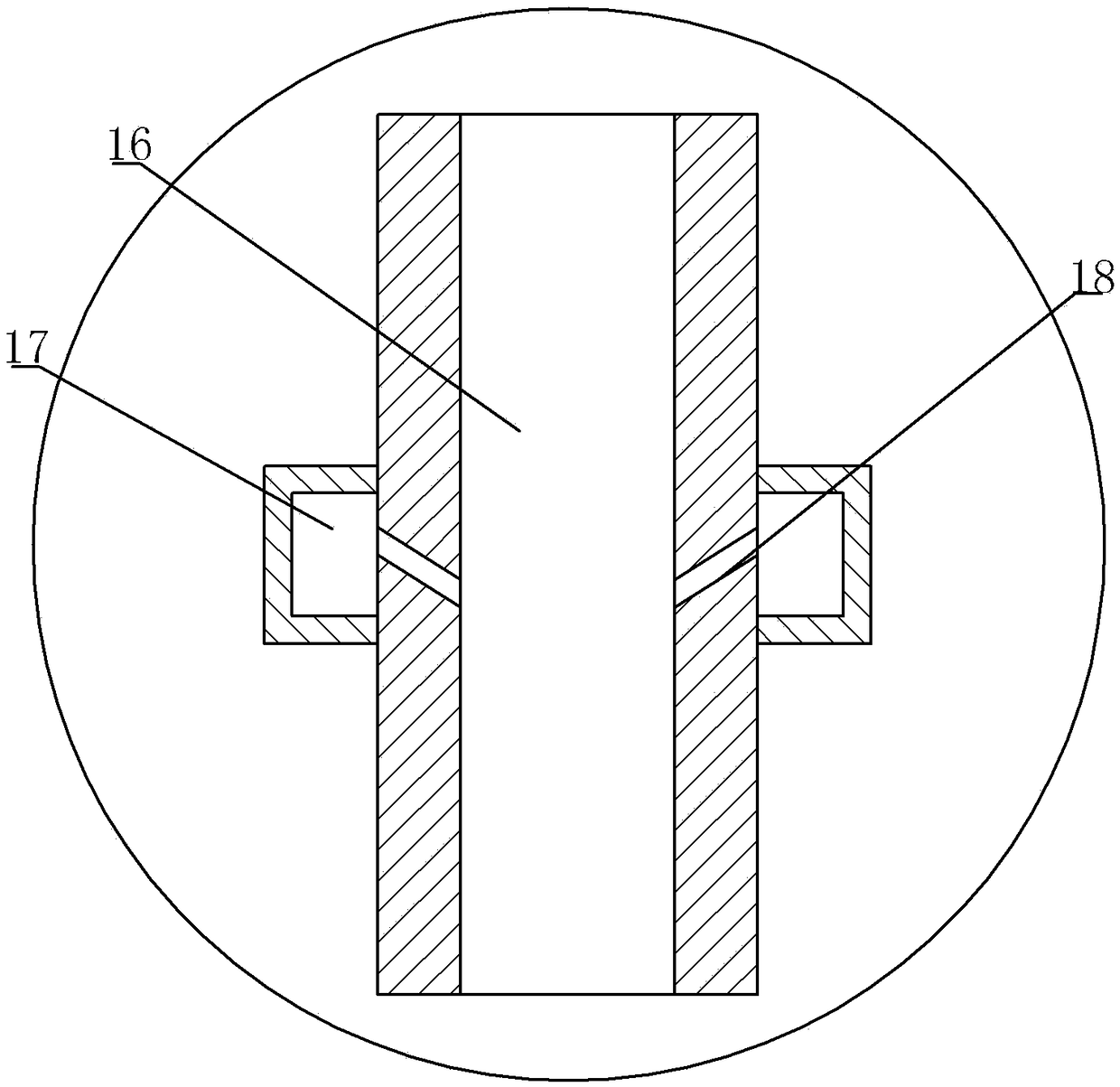

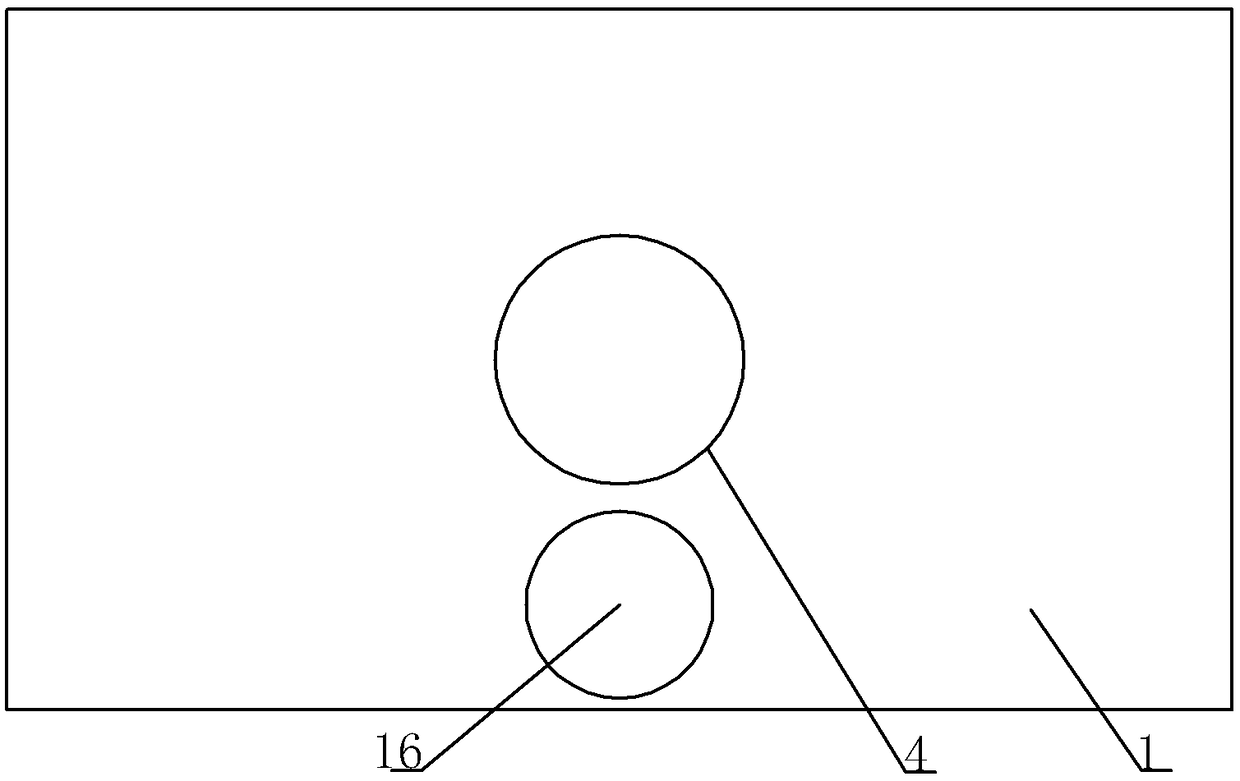

The invention relates to the technical field of mold machining, and discloses an automobile injection mold. The automobile injection mold comprises an upper mold and a lower mold. The upper mold is aconcave mold, and the lower mold is a convex mold. When the upper mold and the lower mold are clamped, a closed molding cavity is formed between the upper mold and the lower mold. An injection moldingchannel and a gas channel are arranged on the concave mold. An annular cavity is formed in the periphery of the gas channel. A gas outlet communicating with the annular cavity is formed in the gas channel. The gas outlet inclines downwards and faces the interior of the gas channel. A high-pressure gas cavity communicating with the annular cavity is formed in one side of the gas channel. A slidingblock is arranged between the high-pressure gas cavity and the gas channel and provided with a connector. A gas bag is arranged below the sliding block. An upper cooling channel communicates with thegas channel. The convex part of the convex mold comprises a balance cavity and a sliding plate. The sliding plate is in sliding connection with the convex mold and closes the balance cavity. A pressure reduction valve is fixed to the sliding plate. A limiting block is arranged on the sliding plate. A high-pressure gas pump and a lower cooling channel are arranged in the convex mold. The high-pressure gas pump communicates with the balance cavity. According to the automobile injection mold, plastic melt in the molding cavity can be fast cooled, and the mold molding efficiency can be improved.

Owner:CHONGQING YINSHENG MOLD

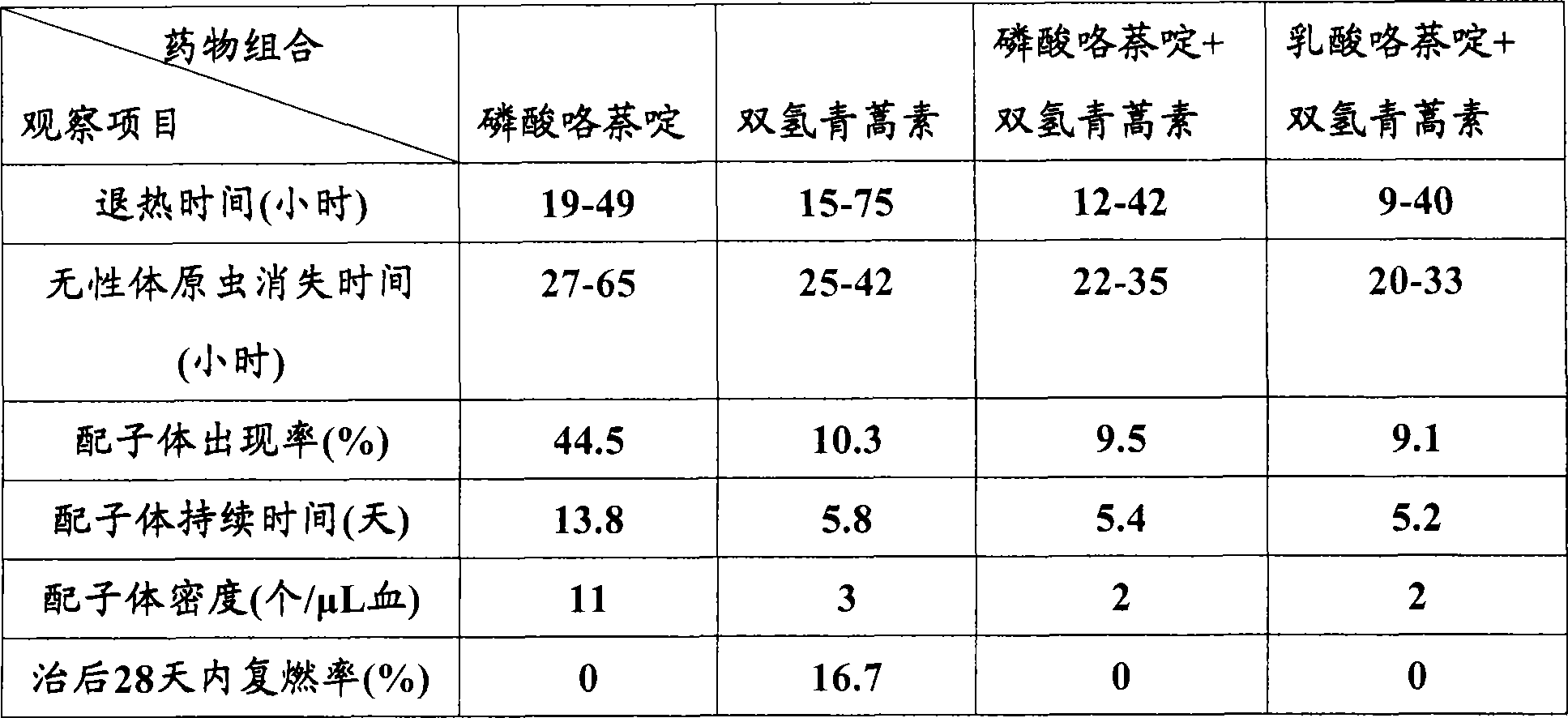

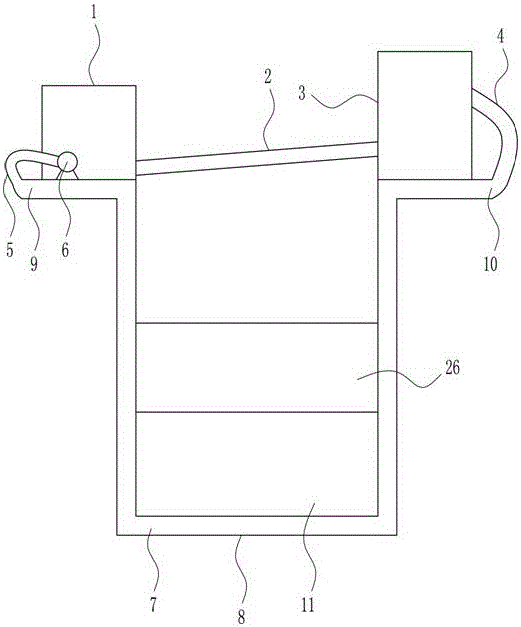

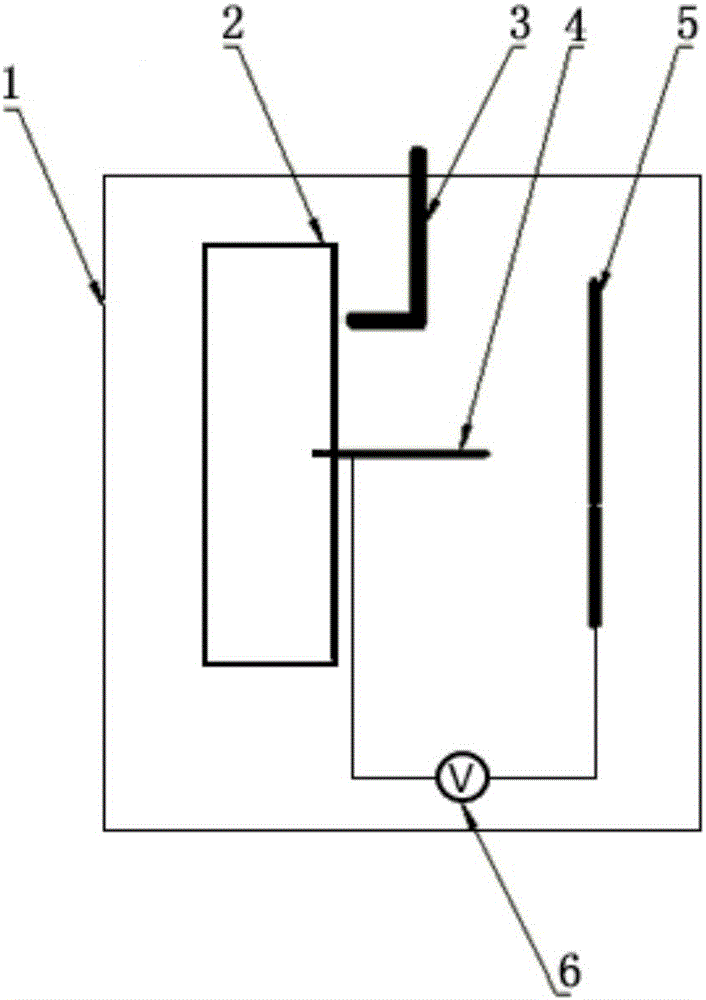

Single-linked low-temperature low-confining-pressure triaxial creep testing apparatus

InactiveCN104634666ANo need to worry about validityStable air pressureMaterial strength using tensile/compressive forcesGas cylinderAxial pressure

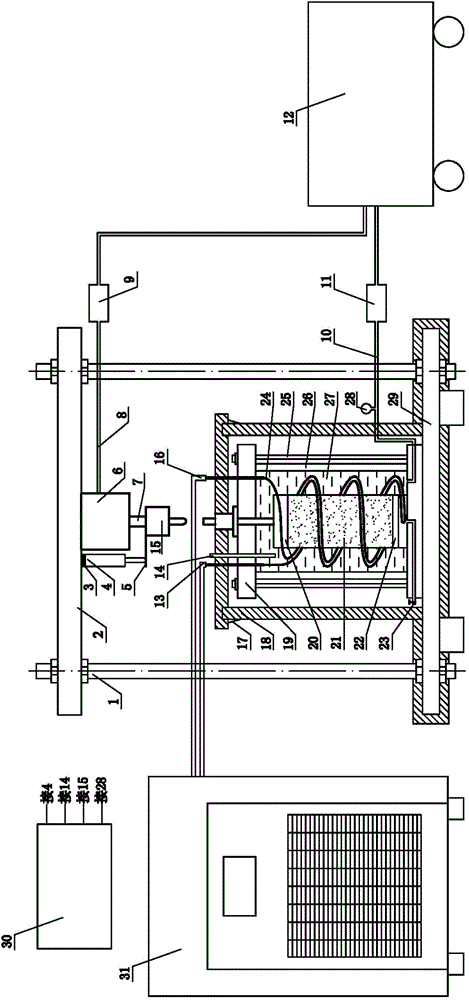

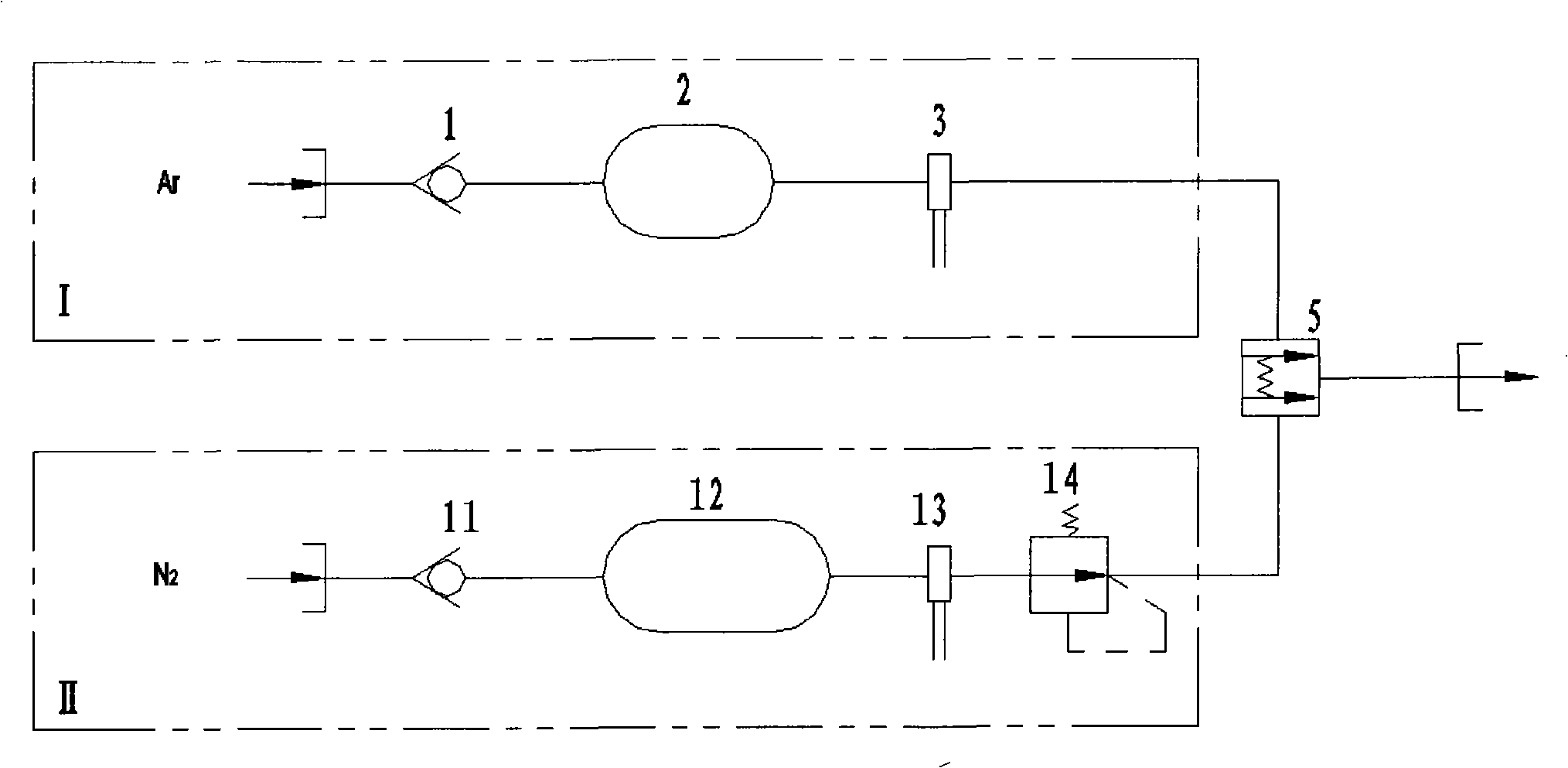

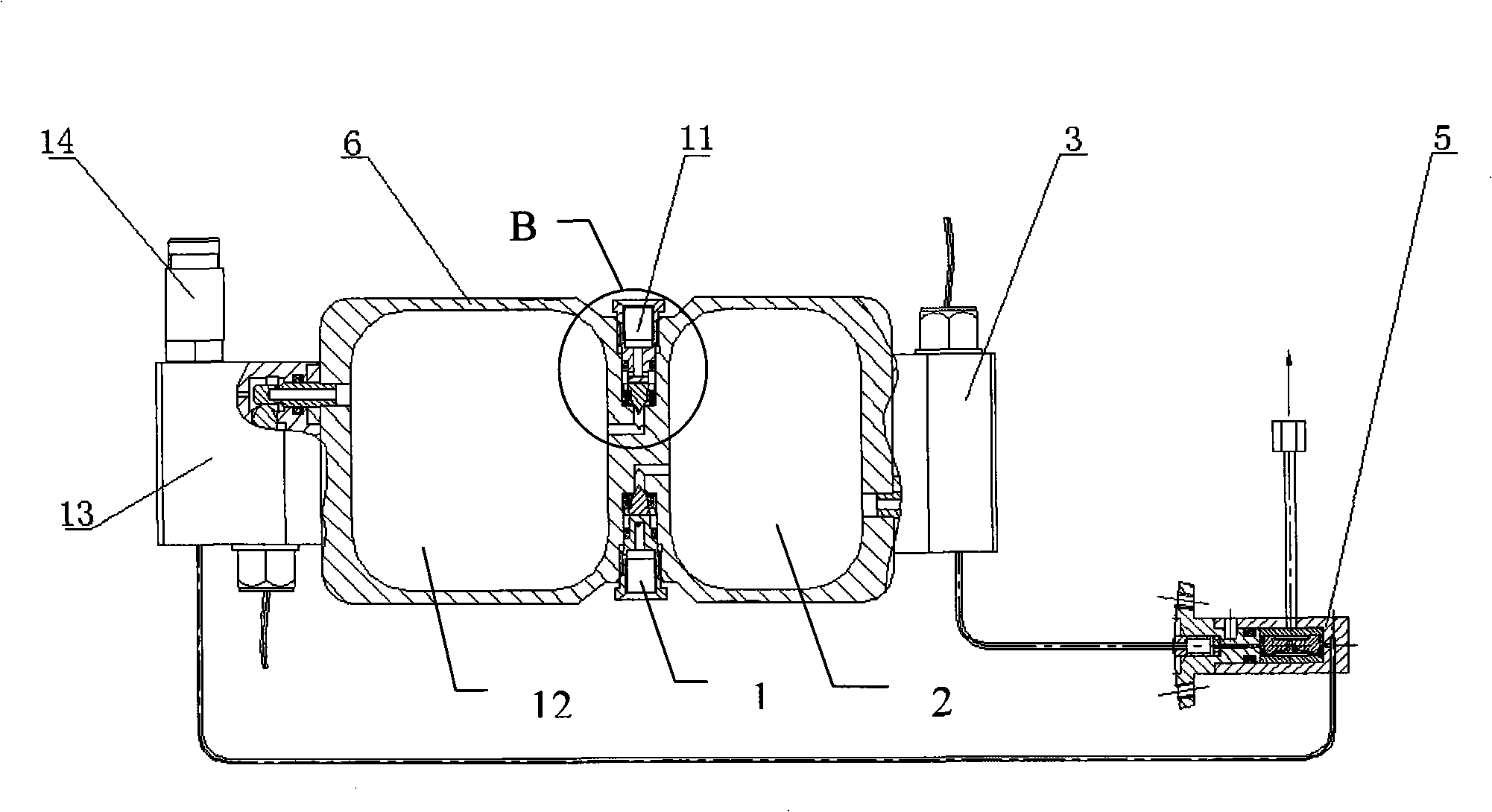

The invention discloses a single-linked low-temperature low-confining-pressure triaxial creep testing apparatus, and relates to the field of civil engineering material testing instruments. By adopting the creep testing apparatus, the problem of imperfect frozen soil creep tests under small stress and small confining pressure at present can be solved. A technical scheme adopted by the single-linked low-temperature low-confining-pressure triaxial creep testing apparatus is as follows: the single-linked low-temperature low-confining-pressure triaxial creep testing apparatus mainly comprises a host, a pressure chamber, a pneumatic servo system, an automatic data acquisition system and an automatic temperature control system, wherein a gas cylinder is fixedly arranged at the lower part of a reaction frame of the host, an axial load sensor is fixedly arranged at the lower part of a force transfer rod of the gas cylinder, a displacement sensor is fixedly arranged between the reaction frame and the gas cylinder, a double-helical copper pipe connected with the automatic temperature control system is arranged inside the pressure chamber, a temperature sensor is arranged on a top cover of the pressure chamber, the axial pressure and confining pressure of the pressure chamber are controlled by an axial pressure regulator and a confining pressure regulator of the pneumatic servo system, a confining pressure sensor is arranged at a confining pressure pipeline at the bottom end of the pressure chamber, and a heat preservation tank is arranged at the outer part of the pressure chamber. The single-linked low-temperature low-confining-pressure triaxial creep testing apparatus disclosed by the invention can be applied to uniaxial or triaxial creep tests of frozen soil under low temperature and low confining pressure and uniaxial or triaxial creep tests under normal temperature and low confining pressure.

Owner:HARBIN INST OF TECH

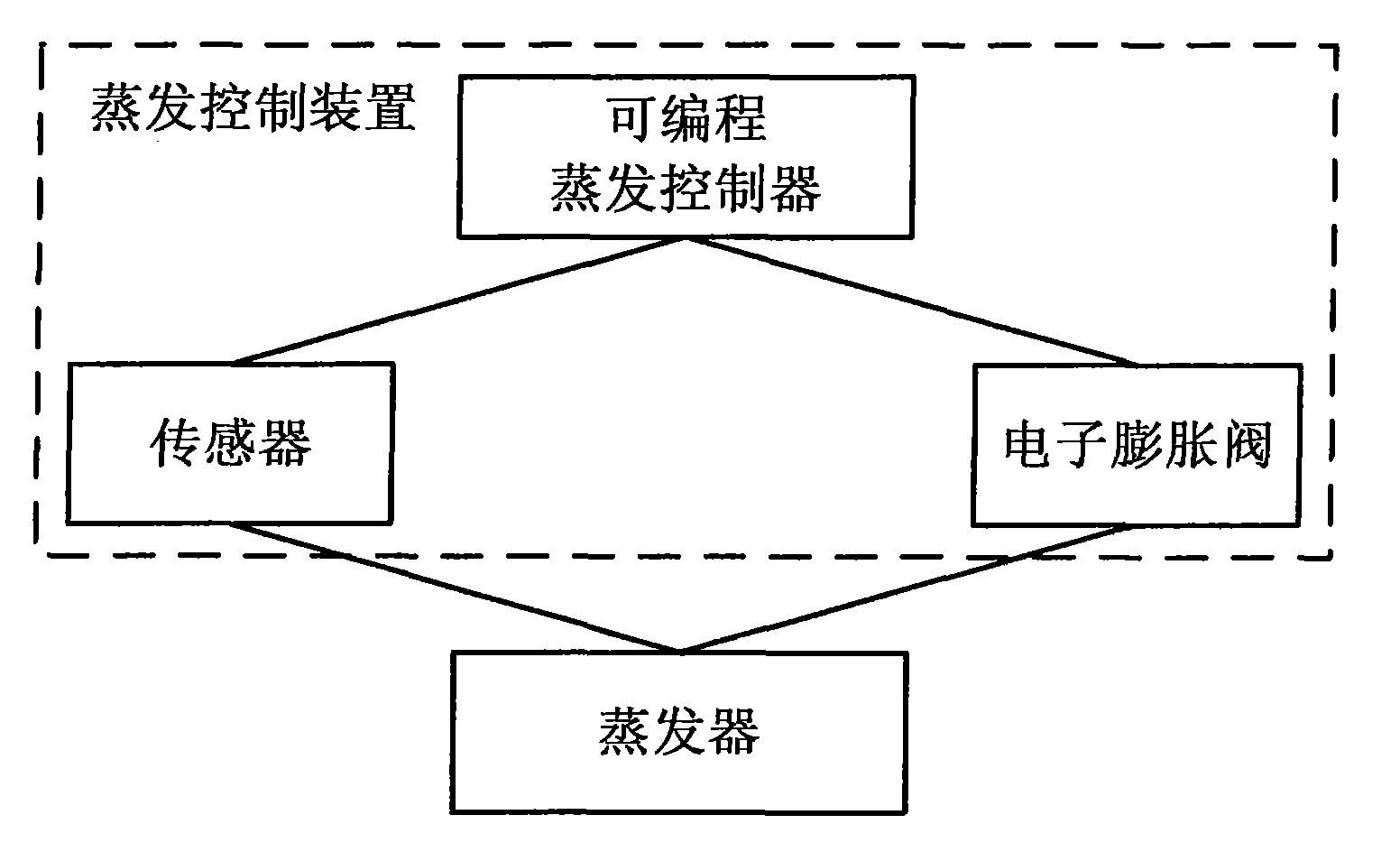

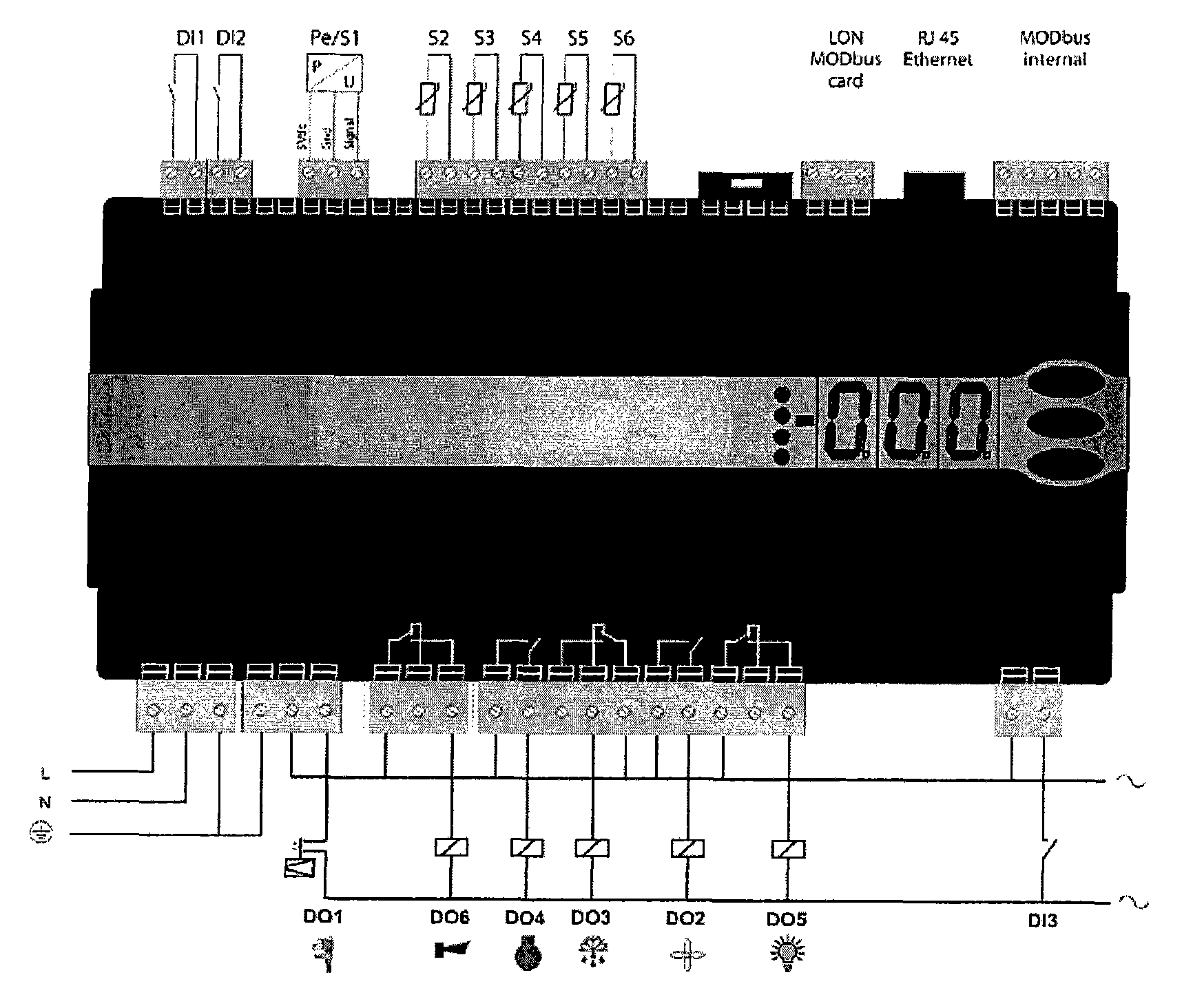

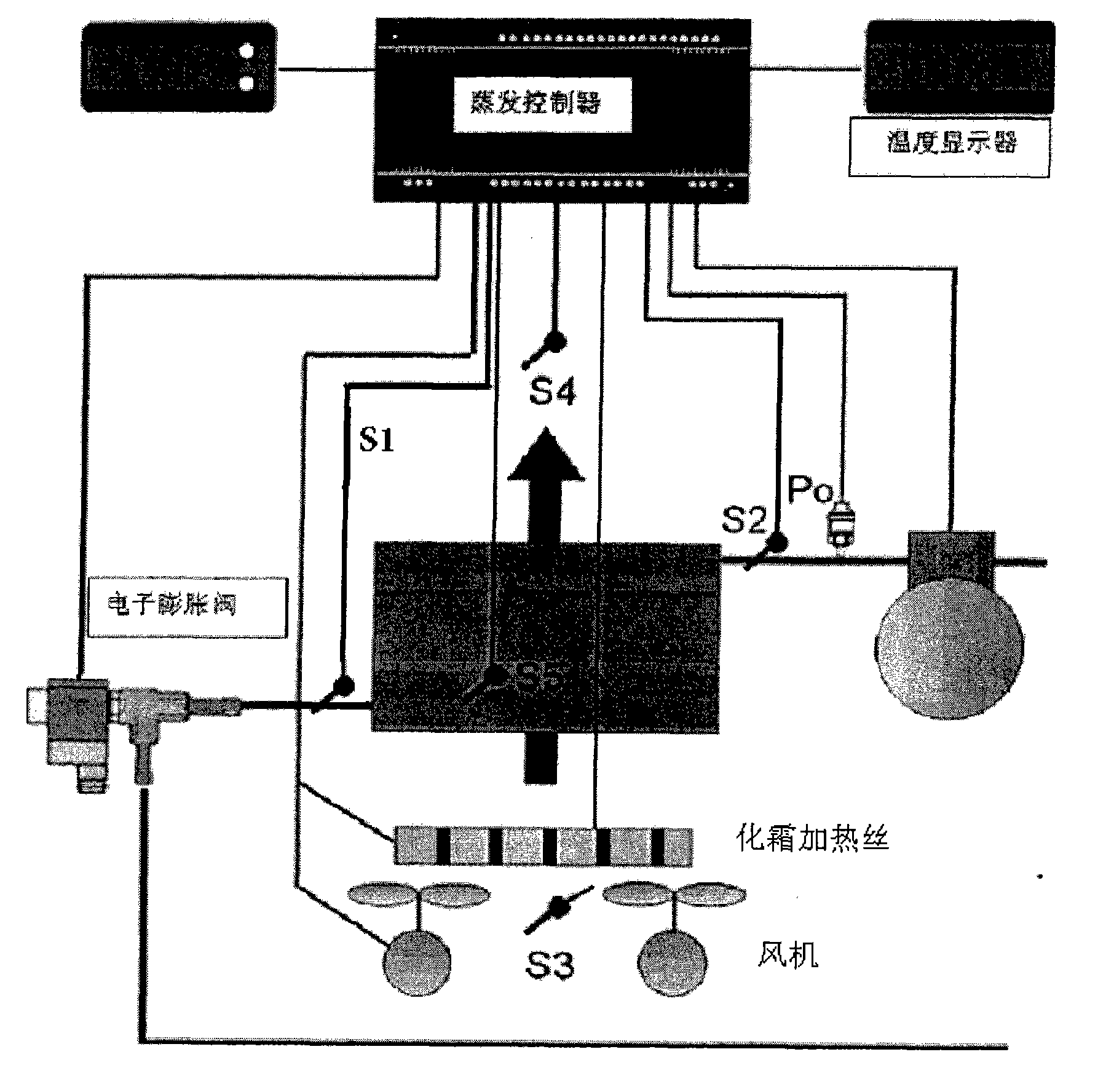

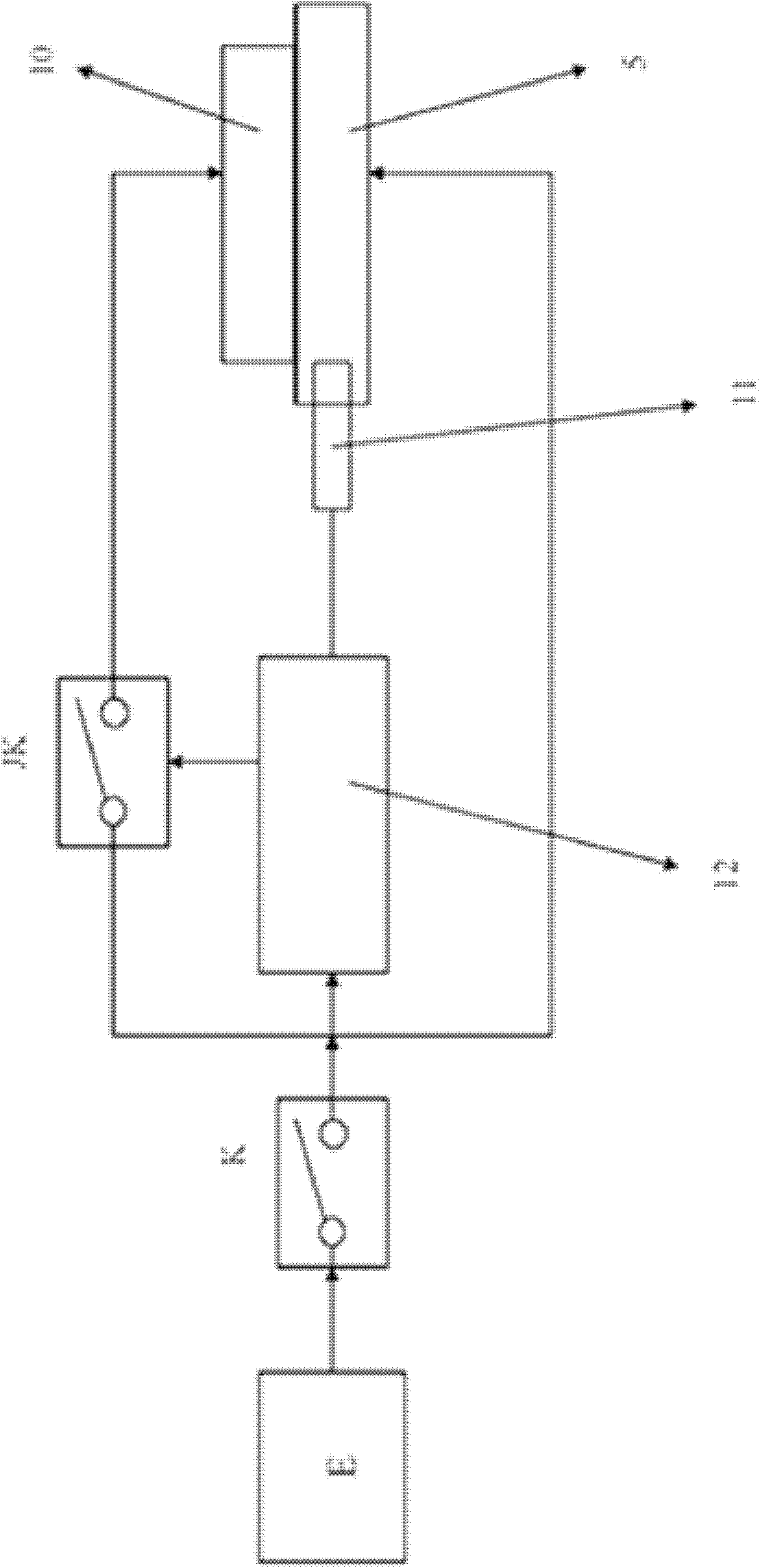

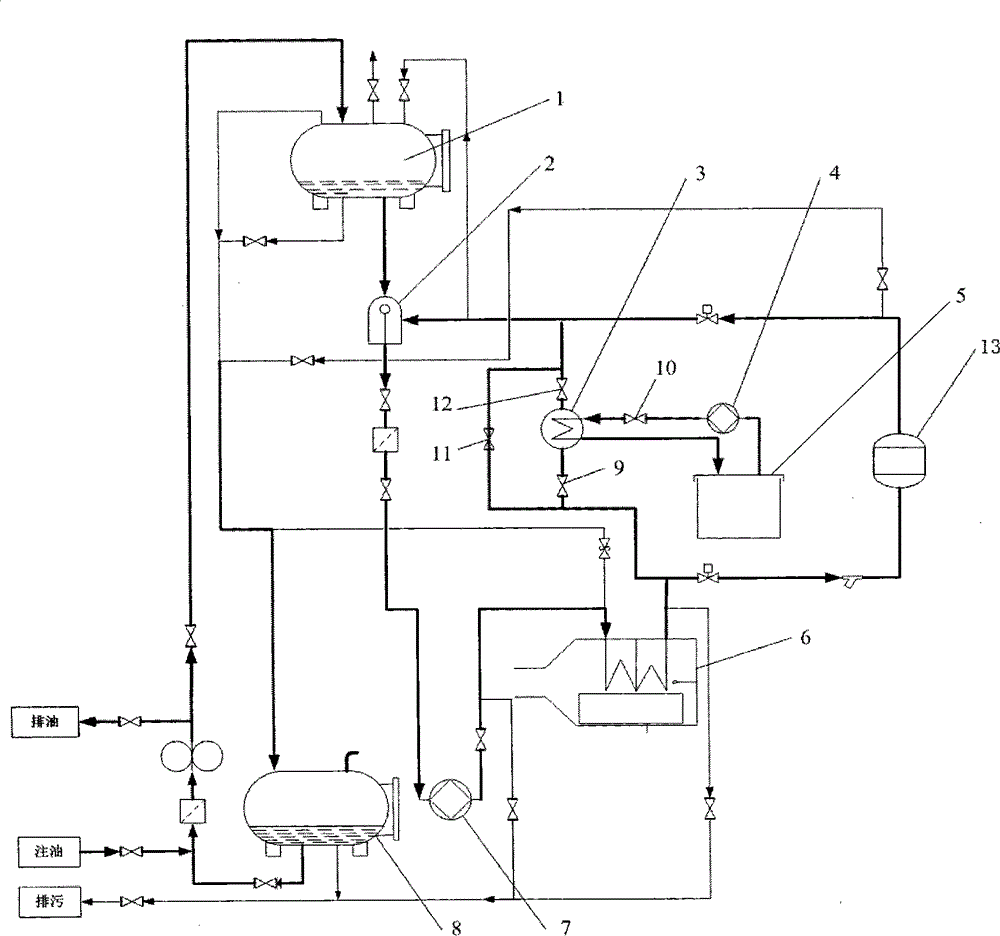

Evaporation control device used in refrigerating system

InactiveCN102116550APrecisely adjust the amount of refrigerantSmall temperature fluctuationsRefrigeration safety arrangementProgrammable logic controllerEvaporation

The invention discloses an evaporation control device used in a refrigerating system, comprising a programmable evaporation controller, an electronic expansion valve and a sensor, wherein, the programmable evaporation controller is connected with the electronic expansion valve, and is connected with an evaporator through the sensor; and the electronic expansion valve is arranged on a refrigerant input pipeline of the evaporator; the sensor is used for detecting the temperature and the pressure in the evaporator, and outputting the detected temperature and pressure signals to the programmable evaporation controller; the programmable evaporation controller is used for receiving the detected temperature and pressure signals detected by the sensor; the opening and closing of the electronic expansion valve as well as the opening time and the opening of the electronic expansion valve are controlled according to the signals; and the electronic expansion valve is used for controlling the amount of the refrigerant entering into the evaporator under the control of the programmable evaporation controller, thus realizing the accurate control on the temperature in the evaporator. By utilizing the evaporation control device provided by the invention, the accurate control on the temperature and the pressure is realized, the reaction sensitivity is improved, and the energy consumption is lowered.

Owner:DANFOSS SHANGHAI AUTOMATIC CONTROLS

Moisture loss prevention method during cut flower vacuum precooling course

InactiveCN1602658AShort cooling timeUniform coolingFlower preserving apparatusWater depletionCut flowers

This invention provides a way to preserve water from the flowers un the process of vacuum pro-coldness when cut flowers. The factory is put the tidied flowers stem into the container with enough liquor. Ensure that the stem is under liquor. Put the probe into the liquor in the same time, and then put the container with flowers into the vacuum jug. Start the vacuum pump to depress the air pressure, accommodate the temperature to the required standard, close the vacuum pump, and then recover to normal pressure. This way can decrease the depletion of flowers in transport decreased water depletion, solved the problem of long distance transport. Promote the development of flowers commerce in our nation and other nations.

Owner:CHINA AGRI UNIV

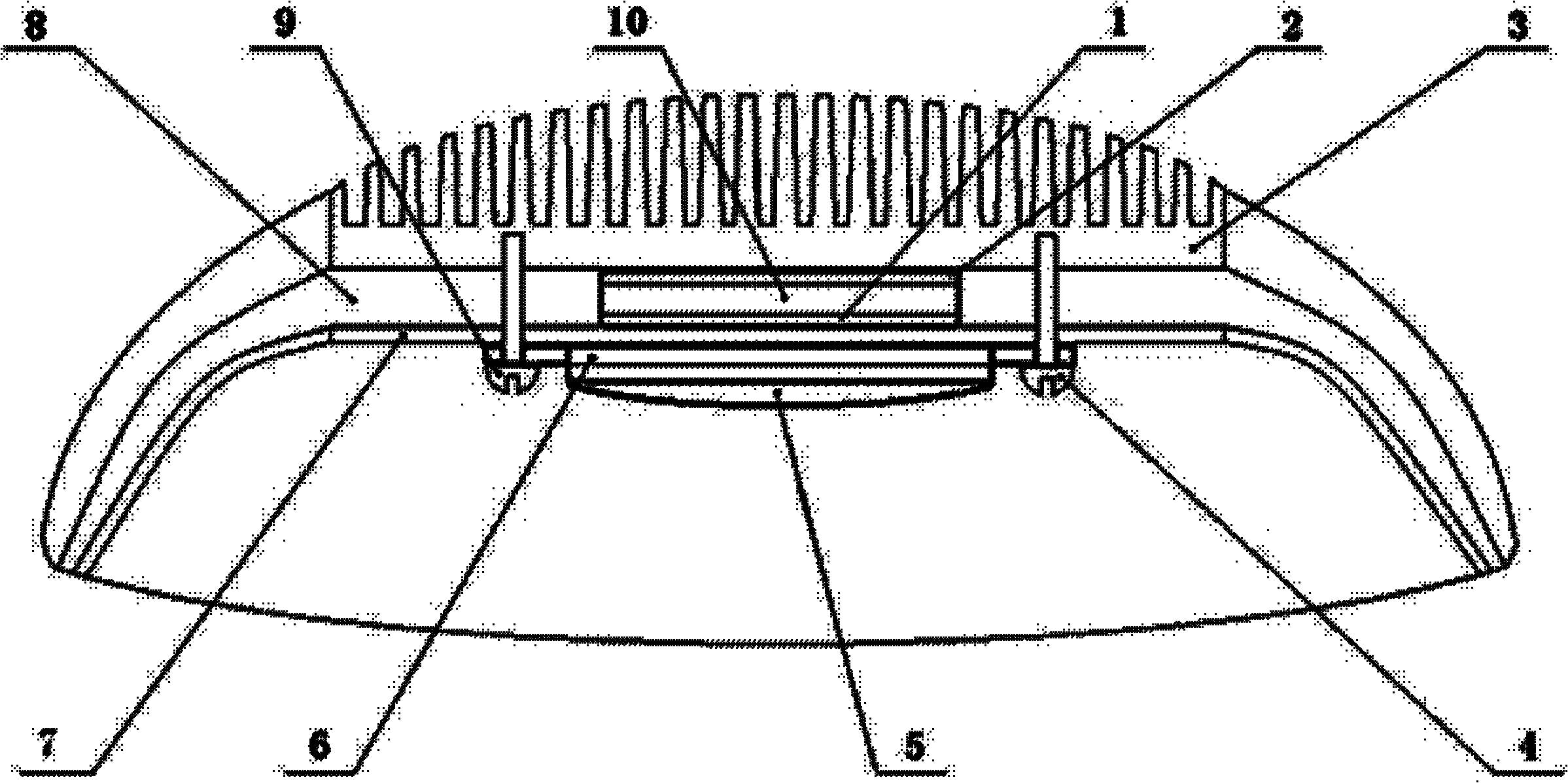

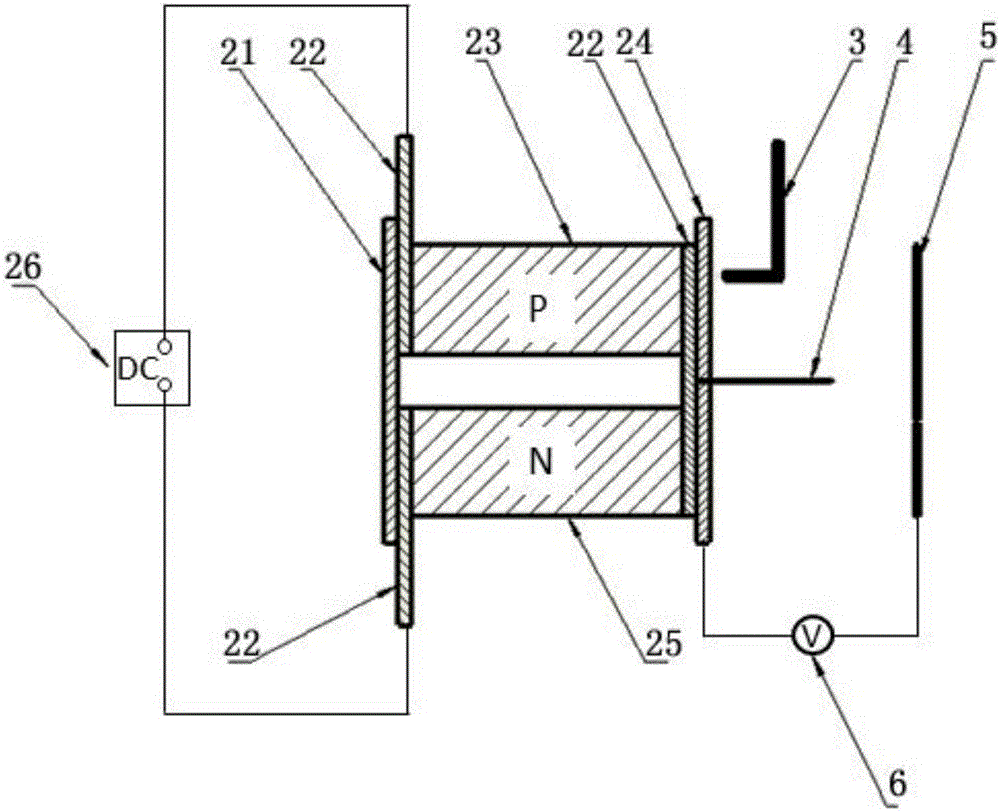

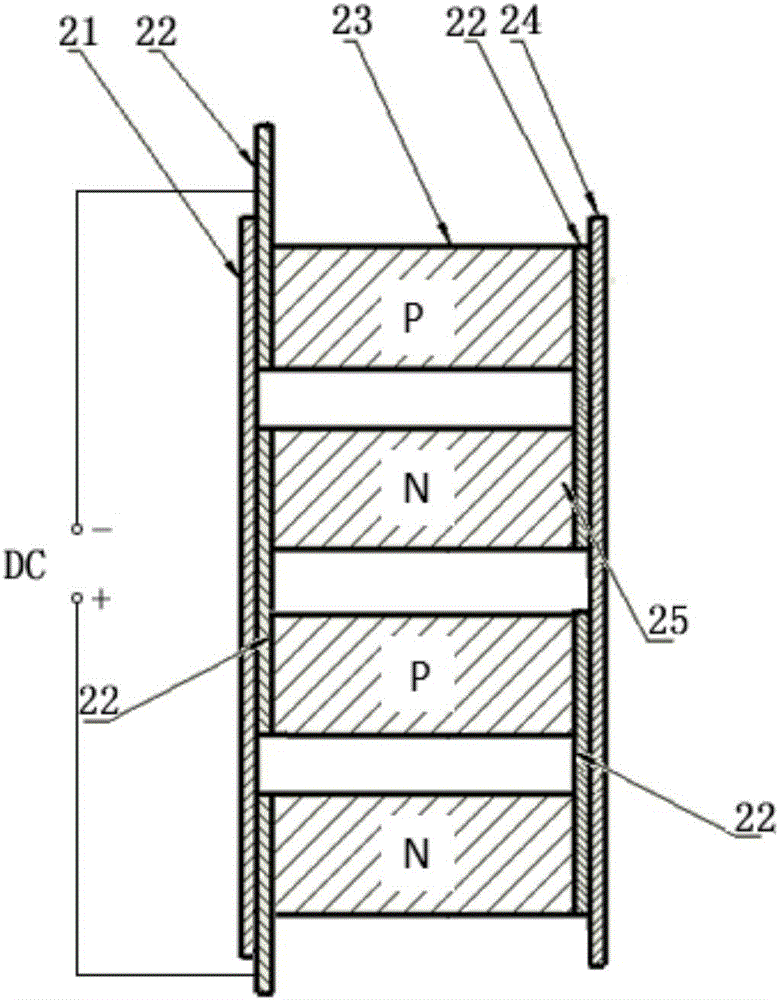

Semiconductor refrigeration high-power LED lamp

InactiveCN102252200ASimple structureReduce volumePoint-like light sourceLighting heating/cooling arrangementsJunction temperatureWorking temperature

The invention discloses a semiconductor refrigeration high-power LED lamp, aiming at solving the junction temperature problem of a high-power LED lamp. The technical scheme adopted by the invention is as follows: a cold end of a semiconductor refrigeration sheet is connected with a module baseplate of a high-power LED module via a cold end metal sheet; a temperature sensor is mounted on or near the module baseplate, the temperature sensor is in electric connection with an upper-lower limit temperature control circuit, a temperature control switch in electric connection with the semiconductor refrigeration sheet is in electric connection with the upper-lower limit temperature control circuit, and a power supply is connected with the temperature control switch, the upper-lower limit temperature control circuit and the high-power LED module through a power supply switch respectively; the module baseplate, the cold end metal sheet and a radiator are connected together by a plurality of heat insulation bolts; and heat insulation materials are filled on the periphery of the semiconductor refrigeration sheet and between the radiator and the cold end metal sheet. According to the semiconductor refrigeration high-power LED lamp, the semiconductor refrigeration sheet is used for cooling actively and forcibly; the working temperature of the high-power LED module is reduced to below 40 degrees centigrade; and the luminous efficiency of the high-power LED is enhanced to the greatest limit.

Owner:卢会水 +2

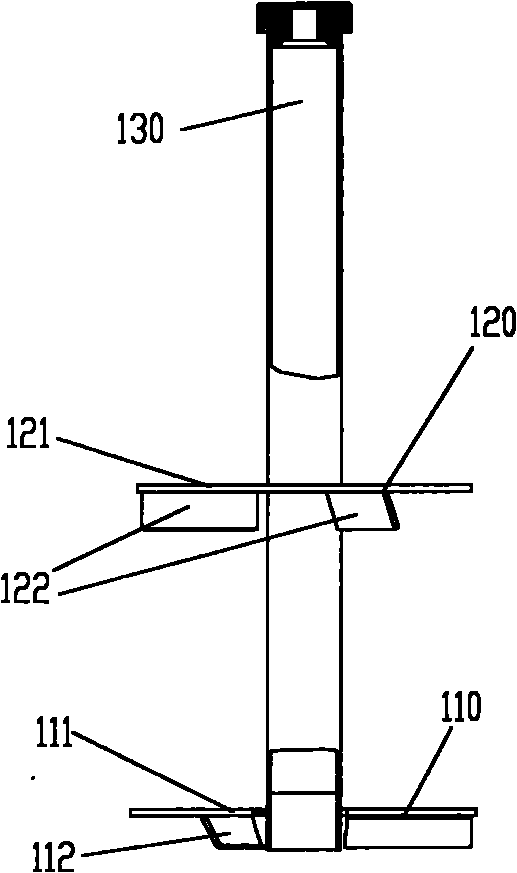

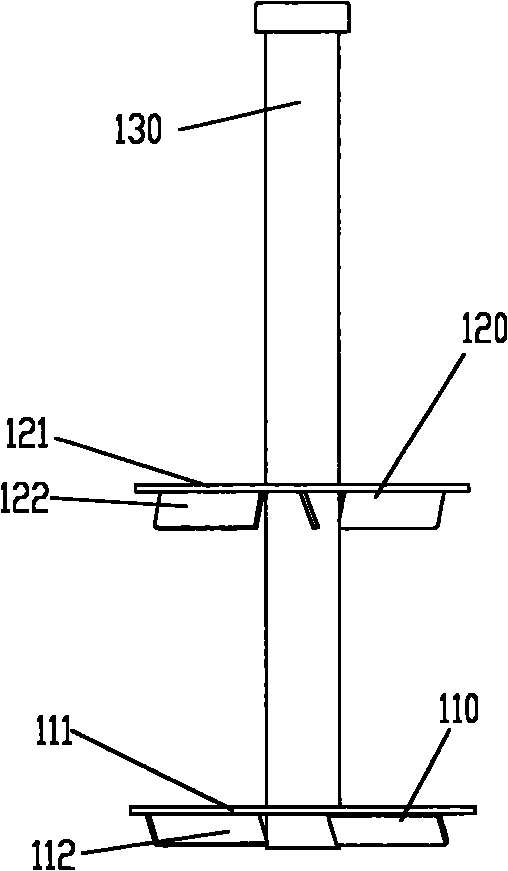

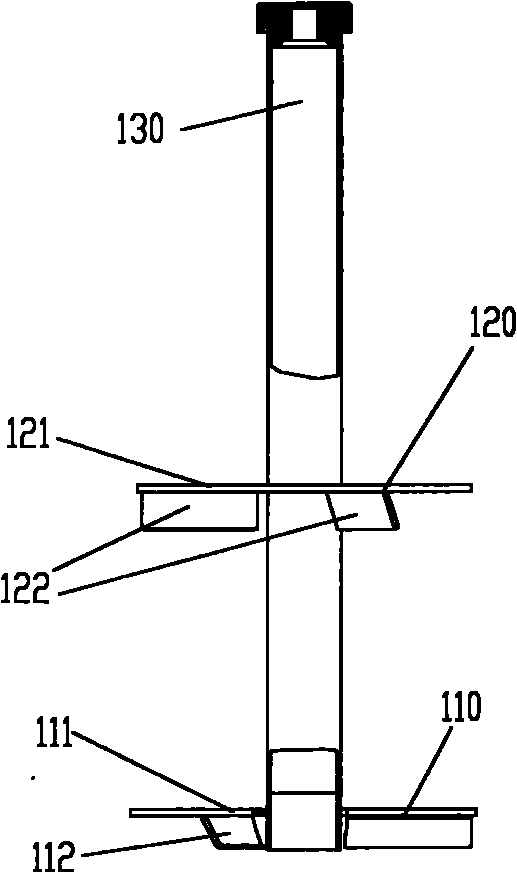

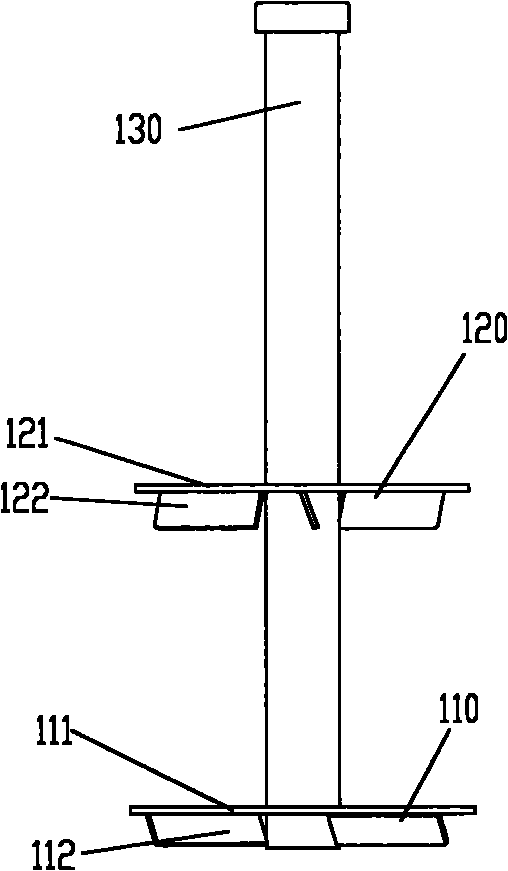

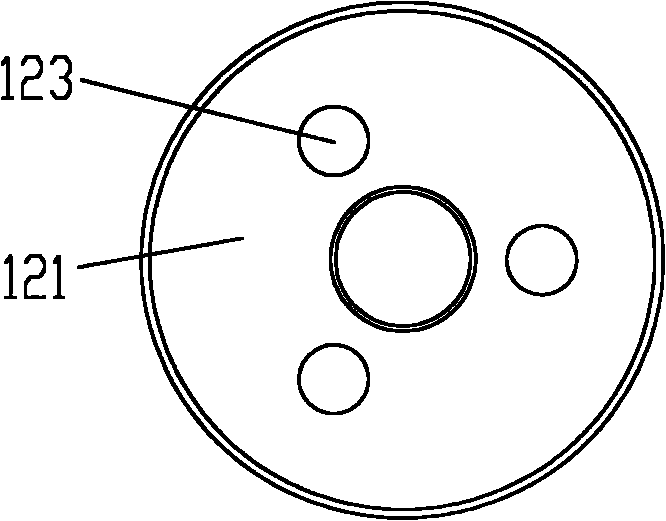

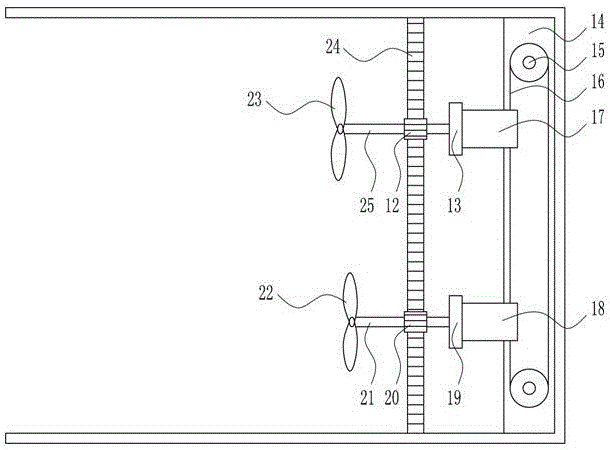

Stirring shaft, homogenizing and aging machine and sterilizing, homogenizing and aging integrated machine

The invention discloses a stirring shaft for stirring ice cream pulp, which comprises a transmission shaft and a lower stirring device arranged at the lower end of the transmission shaft, wherein the lower stirring device comprises a lower stirring body vertically arranged on the transmission shaft and a lower stirring blade arranged on the lower end face of the lower stirring body; an upper stirring device is also arranged on the transmission shaft; and the upper stirring device comprises an upper stirring body vertically arranged on the transmission shaft and an upper stirring blade arranged on the lower end face of the upper stirring body. The invention also discloses a homogenizing and aging machine and a sterilizing, homogenizing and aging integrated machine provided with the stirring shaft. The stirring shaft can prevent the slurry from forming a material layer on the cylinder wall of a cylinder body of the homogenizing and aging machine or the sterilizing, homogenizing and aging integrated machine. The homogenizing and aging machine or the sterilizing, homogenizing and aging integrated machine adopting the stirring shaft has the advantages of strong refrigerating capability, short refrigerating time, long service life, low energy consumption and low cost.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +1

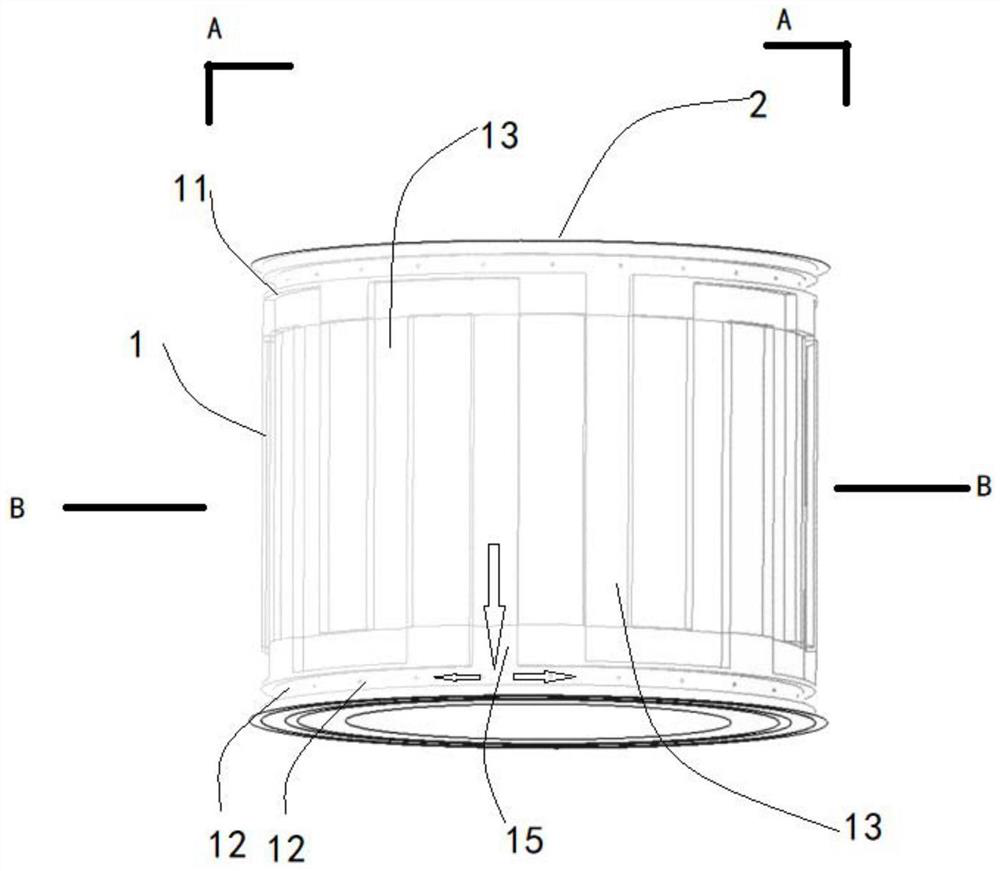

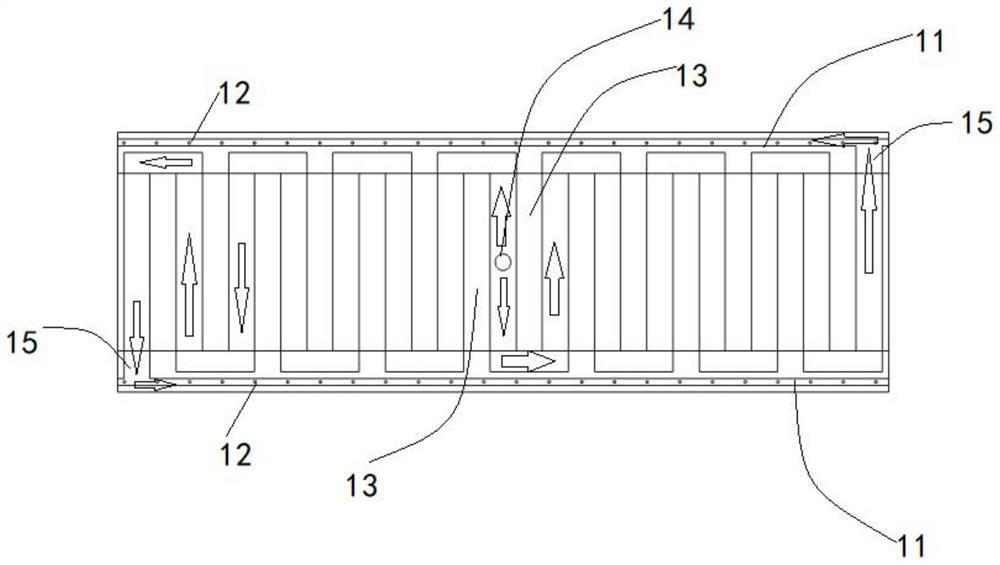

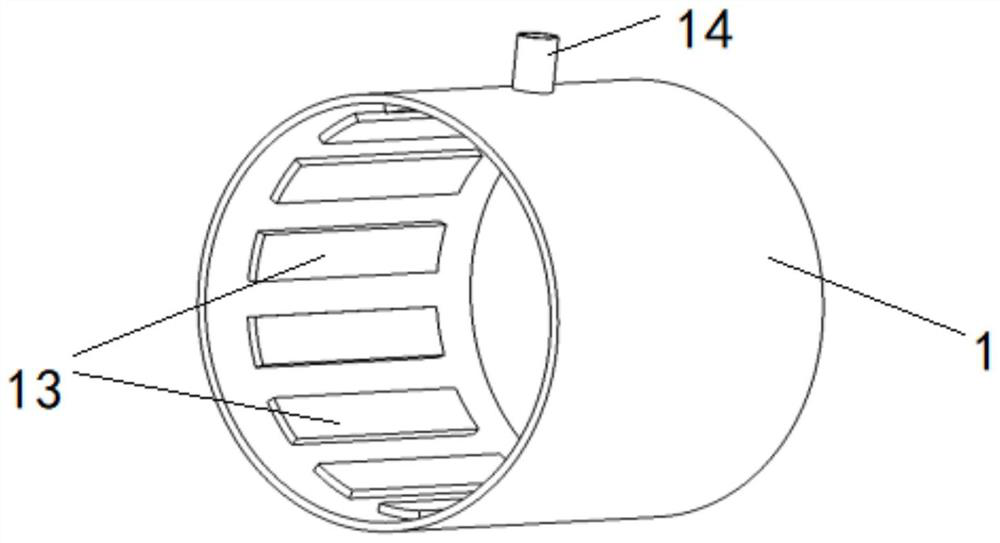

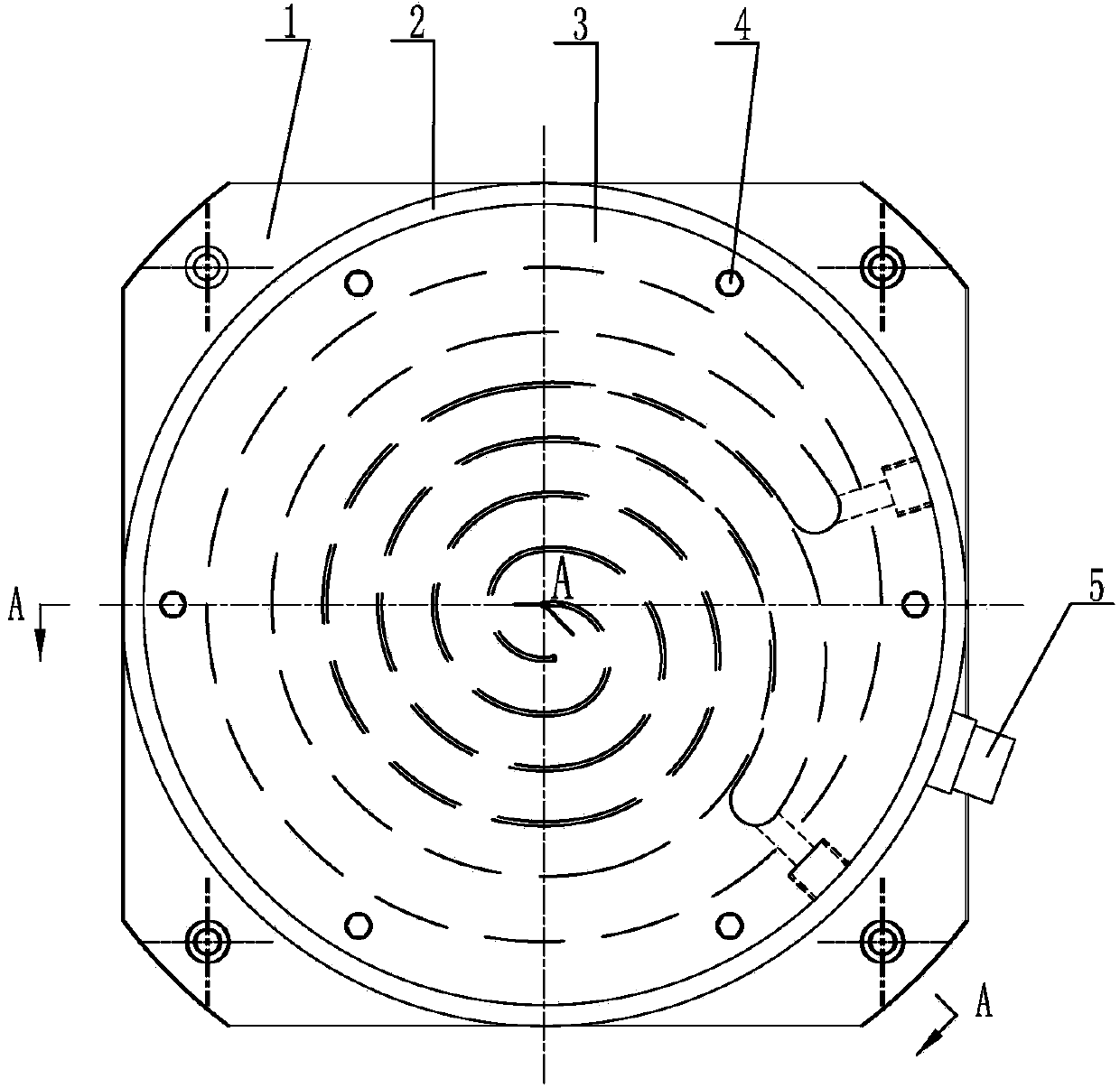

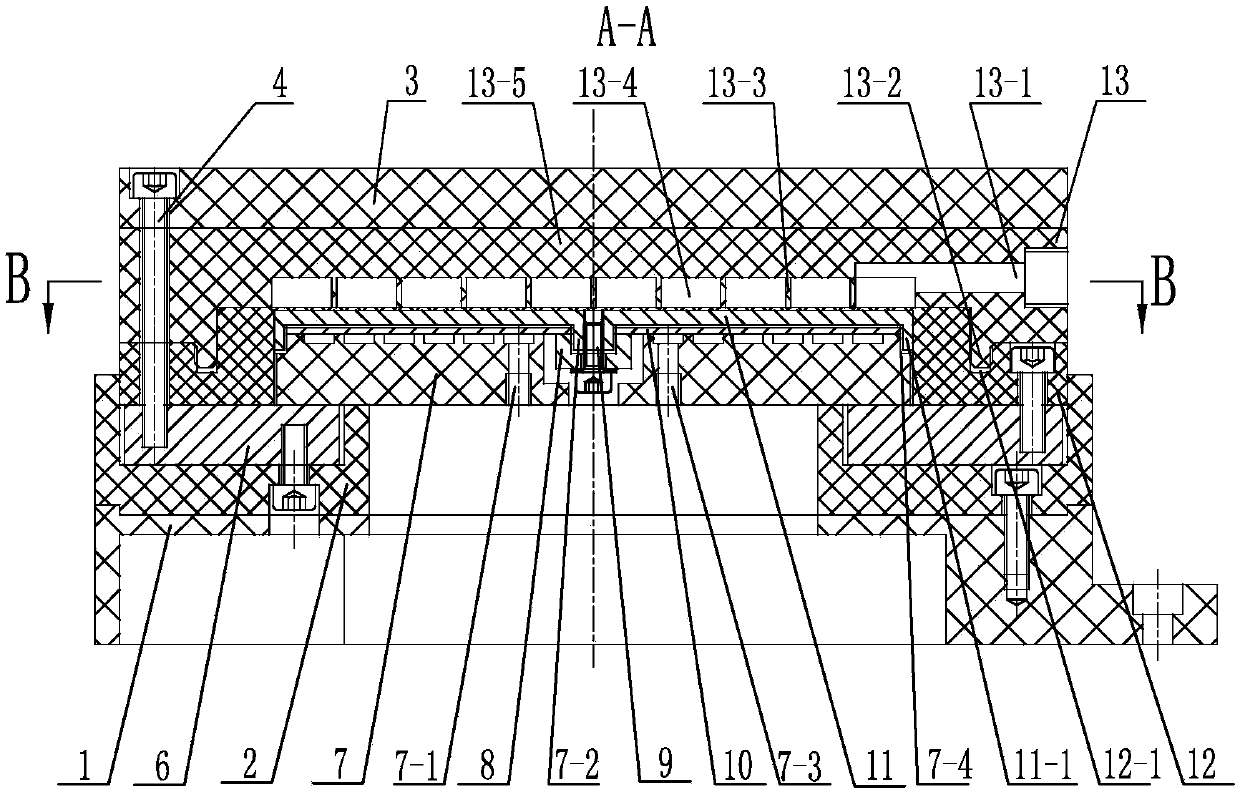

Cooling structure and method of driving motor, oil-cooled motor and automobile

PendingCN113612351AImprove cooling efficiencyIncrease the heat exchange areaCooling/ventillation arrangementNew energyElectric machinery

The invention discloses a cooling structure of a driving motor, belongs to the technical field of motor cooling structures, and solves the technical problem that: the service performance of an automobile is reduced due to low heat exchange efficiency between cooling liquid and a stator of a structure in the prior art. The cooling structure is suitable for cooling a stator of a new energy automobile, the driving motor comprises a casing, an inner cavity is defined by the casing to install a stator iron core and an oil injection ring, a cooling oil way is arranged in an area defined by the oil injection ring, the casing and the stator iron core, cooling liquid can flow through the stator iron core and the oil injection ring, and at least the stator core can be cooled. The invention also discloses a driving motor cooling method designed by taking the cooling structure as a unit, an oil-cooled motor and an automobile. Functions of the driving motor are perfected, and the requirement of people for high heat exchange efficiency of the cooling liquid and the stator is met.

Owner:LEADRIVE TECH (SHANGHAI) CO LTD

Stirring shaft, homogenizing and aging machine and sterilizing, homogenizing and aging integrated machine

InactiveCN102048015BImprove cooling effectShort cooling timeFrozen sweetsDrive shaftPulp and paper industry

The invention discloses a stirring shaft for stirring ice cream pulp, which comprises a transmission shaft and a lower stirring device arranged at the lower end of the transmission shaft, wherein the lower stirring device comprises a lower stirring body vertically arranged on the transmission shaft and a lower stirring blade arranged on the lower end face of the lower stirring body; an upper stirring device is also arranged on the transmission shaft; and the upper stirring device comprises an upper stirring body vertically arranged on the transmission shaft and an upper stirring blade arranged on the lower end face of the upper stirring body. The invention also discloses a homogenizing and aging machine and a sterilizing, homogenizing and aging integrated machine provided with the stirring shaft. The stirring shaft can prevent the slurry from forming a material layer on the cylinder wall of a cylinder body of the homogenizing and aging machine or the sterilizing, homogenizing and aging integrated machine. The homogenizing and aging machine or the sterilizing, homogenizing and aging integrated machine adopting the stirring shaft has the advantages of strong refrigerating capability, short refrigerating time, long service life, low energy consumption and low cost.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +1

Cooling method for superconducting magnet of superconducting circular accelerator

InactiveCN107481831AMeet cooling requirementsReduce consumptionSuperconducting magnets/coilsLiquid nitrogen coolingSuperconducting Coils

The invention belongs to the field of superconducting circular accelerators, and provides a cooling method for a superconducting magnet of a superconducting circular accelerator in order to solve the problems that in China, the existing cooling methods for superconducting magnets are complex in procedure and large in time consumption for cooling and the like. The cooling method includes the steps of (1) vacuumizing the superconducting magnet; (2) conducting liquid nitrogen refrigeration on the superconducting magnet, and meanwhile adjusting length of a pulling rod of the superconducting magnet in a radial direction; (3) exhausting liquid nitrogen and vacuumizing the superconducting magnet; (4) conducting liquid helium refrigeration on the superconducting magnet to complete cooling. The cooling method for the superconducting magnet of the superconducting circular accelerator adopts a two-segment cooling mode including a liquid nitrogen cooling process and a liquid helium cooling process; the cooling procedures are designed reasonably, the cooling time is short, the operation is convenient, and the cooling method can effectively reduce consumption amount of the liquid nitrogen and the liquid helium on the premise of meeting the cooling demands for superconducting coils.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

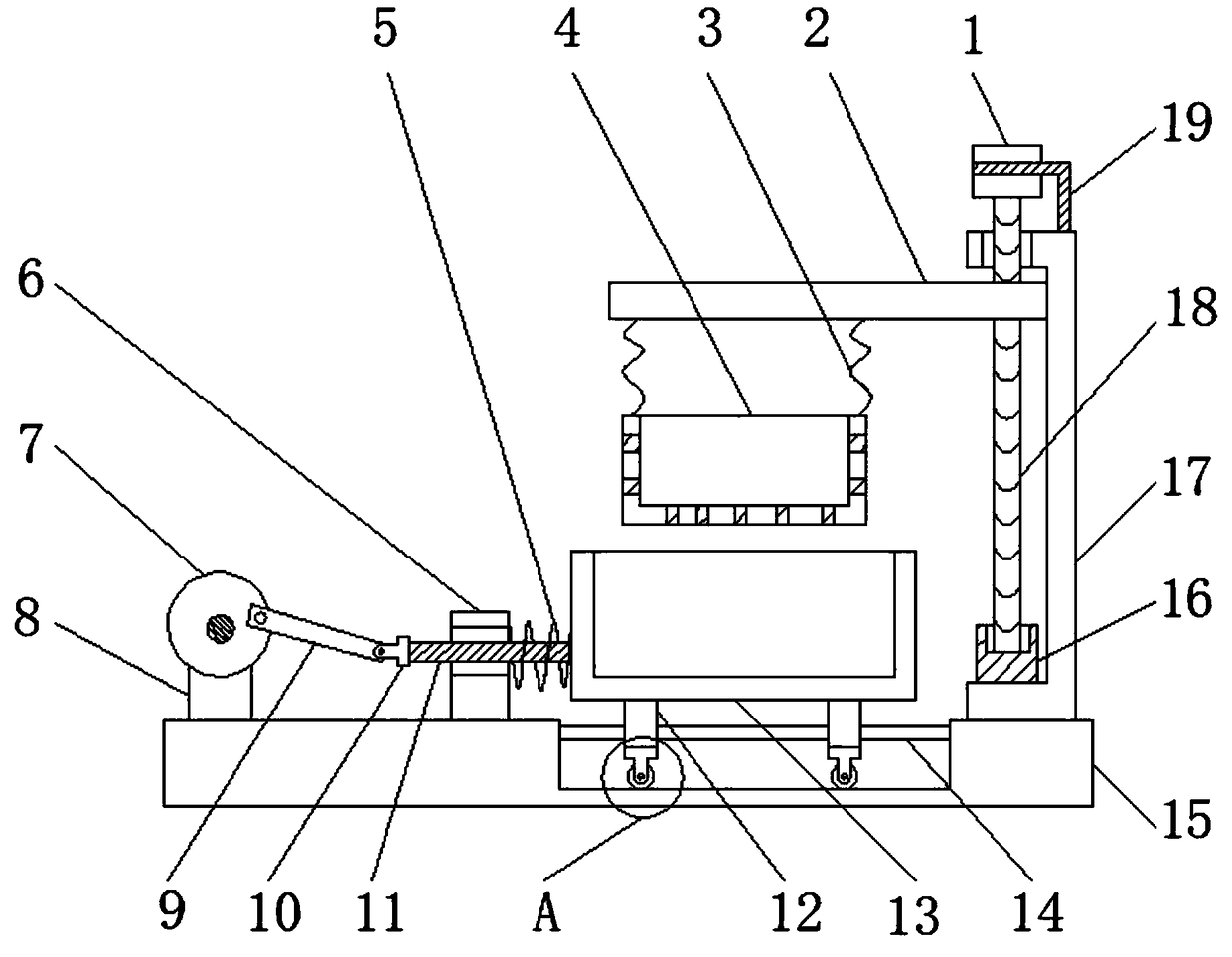

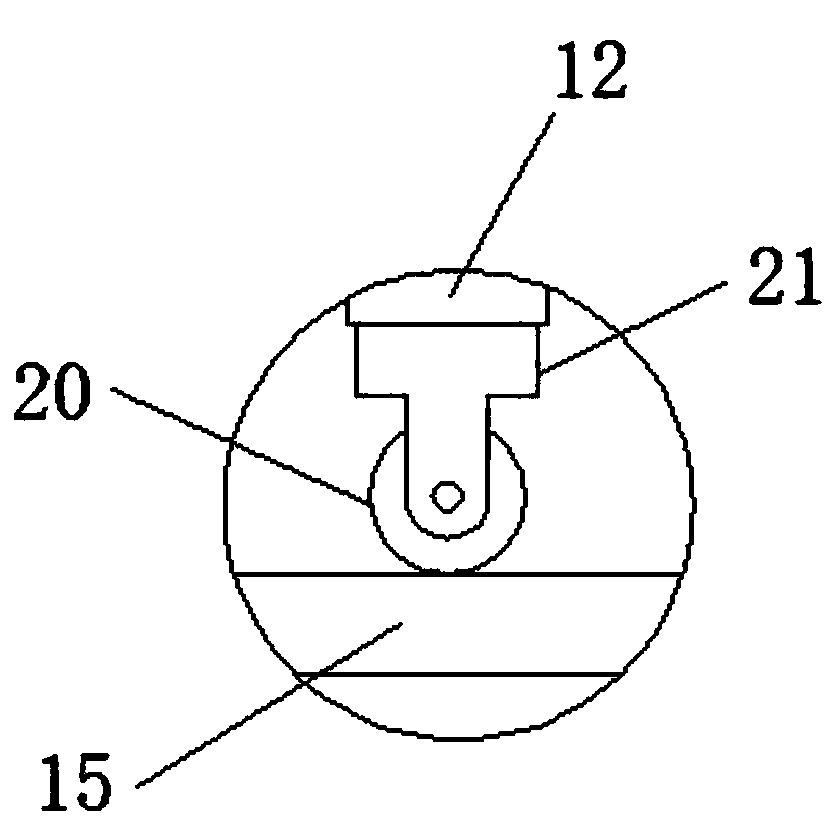

Quick safety cooling device for organic heat transfer material heater of heat source simulation system

The invention belongs to the field of vehicle engineering and discloses a quick safety cooling device for an organic heat transfer material heater of a heat source simulation system. The quick safety cooling device comprises a cooler, a cooling water pump, a cooling water tank, a front cooler valve, a water channel valve, a main loop valve and a rear cooler valve, wherein the main return valve is arranged on a main loop of the heat source simulation system, the cooler is in parallel connection with the main loop valve, the front cooler valve and the rear cooler valve are arranged at an oil inlet and an oil outlet of the cooler respectively, a water outlet of the cooling water tank is connected with a water inlet of the cooler through the cooling water pump, a water outlet of the cooler is connected with a water return opening of the cooling water tank, and the water channel valve is arranged on a connecting pipeline between the water outlet of the cooling water tank and the water inlet of the cooler and is in parallel connection with a tester. The quick safety cooling device has the advantages that by the aid of an open-type heat exchange mode, the problem that time for cooling the organic heat transfer material heater is long is solved, potential safety hazards during cooling of the organic heat transfer material heater are overcome, and accordingly, safety protection and energy conservation are achieved for the system.

Owner:CHINA NORTH VEHICLE RES INST

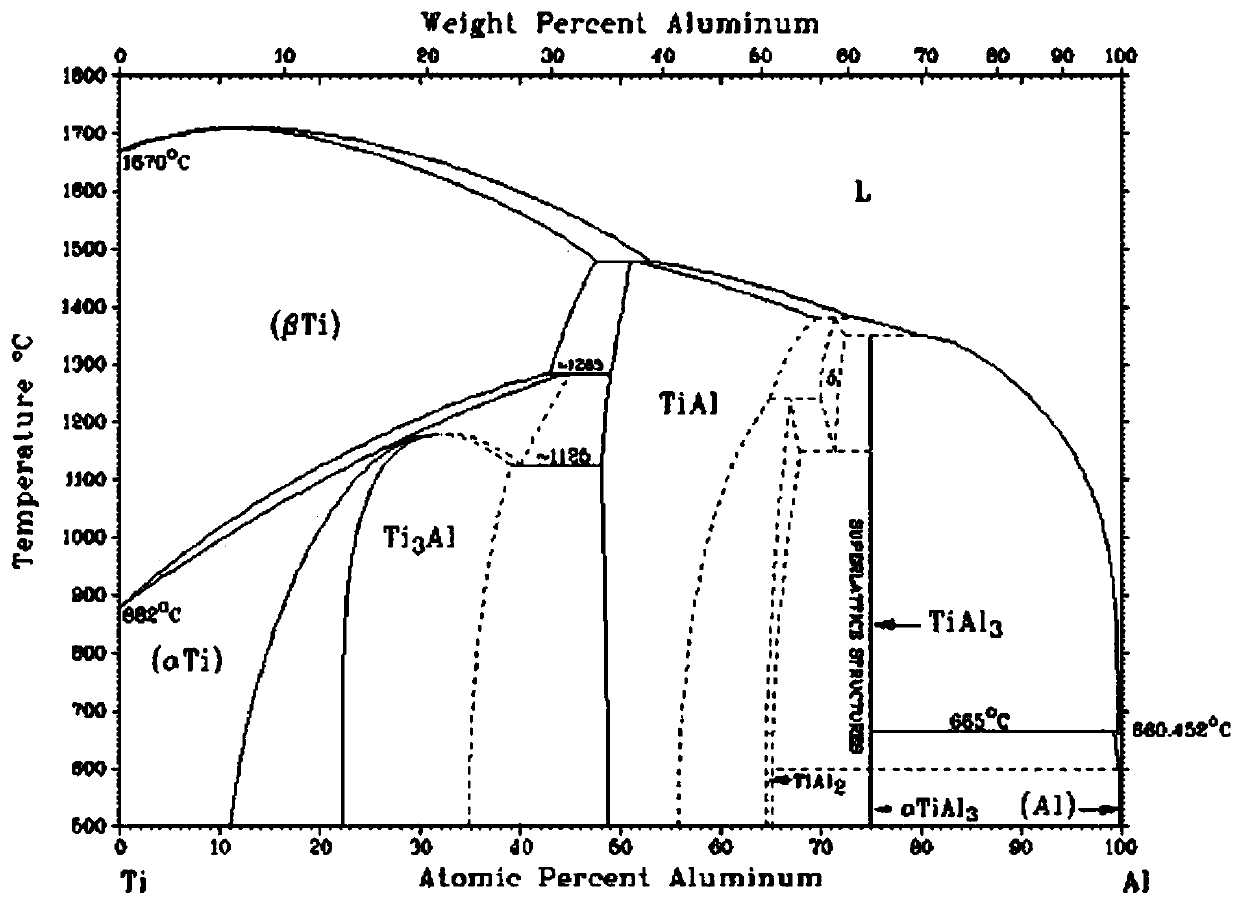

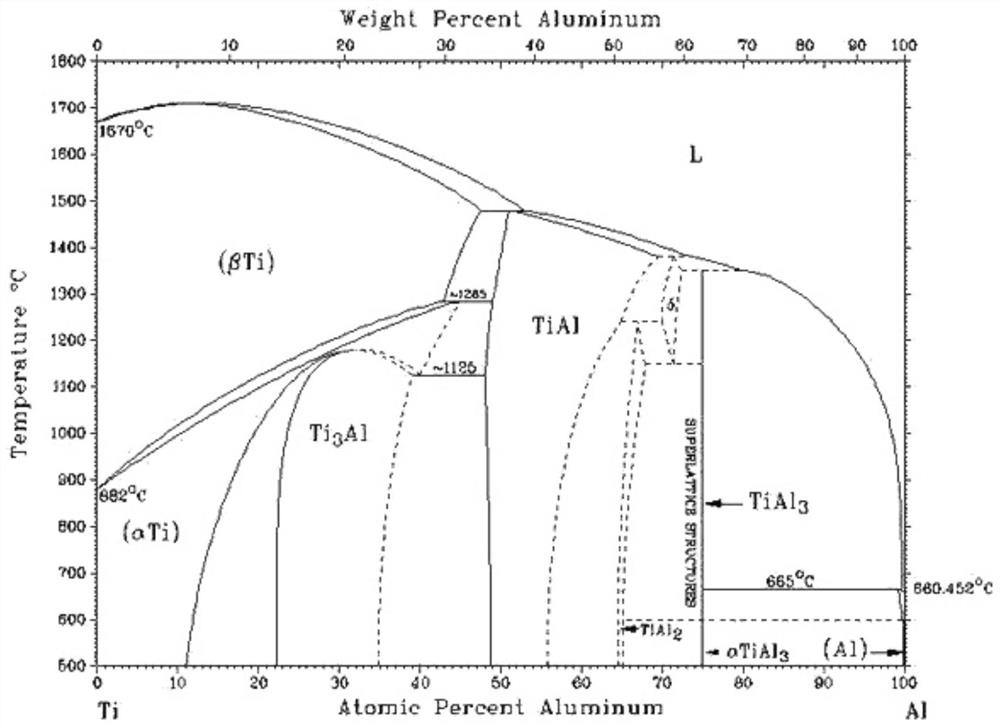

Preparation method of titanium-aluminum alloy target material

ActiveCN111101105AReduce manufacturing costSimple production process controlTransportation and packagingMetal-working apparatusTitaniumHot isostatic pressing

The invention discloses a preparation method of a titanium-aluminum alloy target material. The preparation method comprises a powder mixing step, a filling step, a cold isostatic pressing step, a welding sheath degassing step, a hot isostatic pressing step, a slitting step, an alloying diffusion heat treatment step and a machining finishing step. The preparation method is simple in control, low inprocessing cost and high in processing efficiency.

Owner:东莞市欧莱溅射靶材有限公司

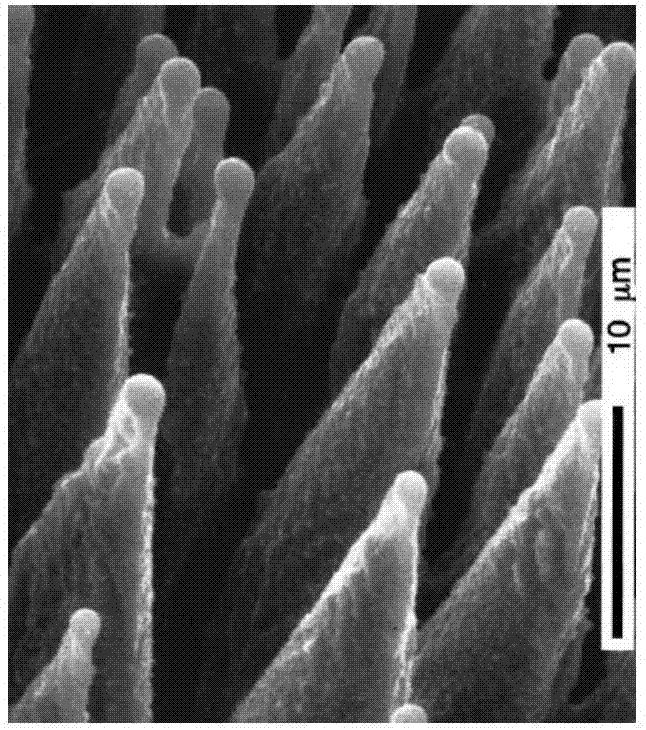

Returning light processing device

InactiveCN107069399AMeet application needsNo vibrationActive medium shape and constructionLaser cooling arrangementsWater coolingRefrigeration

The invention relates to a returning light processing device. The returning light processing device comprises a semiconductor refrigeration module, a black silicon structure absorption surface, a mechanical framework, an optical fiber clamp and an optical fiber. The mechanical framework is the framework of the returning light processing device and the internal of the mechanical framework is of a hollowed column structure; the black silicon structure absorption surface is arranged on the bottom surface of the hollow column structure of the mechanical framework; the semiconductor refrigeration module is arranged on the outer wall of the black silicon structure absorption surface; the outer side of the mechanical frame has the optical fiber clamp; the mechanical framework is integrated with the optical fiber clamp; and the optical fiber clamp clamps the tail end of the optical fiber. The returning light processing device does not need water cooling and air-cooled protection, can perform collection processing of returning light under hectowatt and satisfies application needs of a big power optical fiber laser.

Owner:CHINA WEAPON EQUIP RES INST

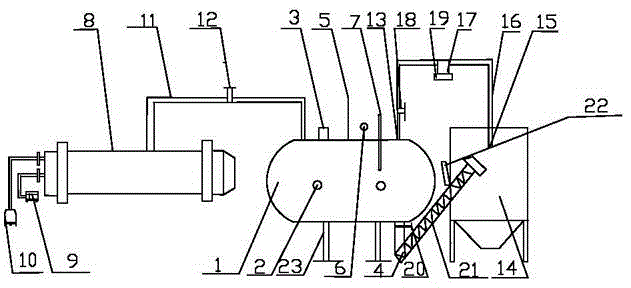

Mushroom wood powder fast sterilization device and sterilization method

ActiveCN104958770AEvenly heatedEasy to fixHeatHorticultureEnvironmental engineeringMechanical engineering

The invention relates to a mushroom wood powder fast sterilization device and sterilization method. The mushroom wood powder fast sterilization device comprises a sterilization kettle and a cooling temperature reducing device, wherein the sterilization kettle comprises a sterilization kettle body, a steam air inlet formed in the sterilization kettle body, a feeding opening formed in the upper end of the sterilization kettle body, a discharging opening formed in the lower end of the sterilization kettle body and a stirrer arranged in the sterilization kettle body; an air outlet pipeline is arranged on the sterilization kettle body; the other end of the air outlet pipeline is communicated with the cooling temperature reducing device; an air outlet valve is arranged on the air outlet pipeline; the steam air inlet is communicated with an outside steam pipeline. The mushroom wood powder fast sterilization device has the advantages that the structure is simple; the sterilization kettle body is pressurized through steam; the mushroom wood powder is directly heated by steam; the temperature and the pressure are high; the effect of fast and thorough sterilization is achieved. The sterilization method is simple, can be easily understood, and can be easily mastered, the technical requirements are low, the sterilization speed is high, the temperature reducing time is short, and the sterilization effect is good.

Owner:翔天科技股份有限公司

Thick film heater

The invention relates to a thick film heater. The thick film heater comprises a thick film heating disk, a heating disk pressing block, a heat conduction disk and a heating pool, wherein the heating disk pressing block is arranged on the lower portion of the thick film heating disk, the heat conduction disk and the heating pool are arranged on the top of the thick film heating disk, a gas groove is formed in the surface, making contact with the thick film heating disk, of the heating disk pressing block, a gas inlet connector and a gas outlet connector formed in the heating disk pressing block are communicated with the gas groove, the heating pool which is made of fluoroplastic or is provided with a fluoroplastic layer is provided with a pool cover and a flow guide plate, the flow guide plate on the heating pool is attached to the heat conduction disk, a cavity of the heating pool is divided by the flow guide plate to form a surrounding liquid flow channel, a liquid inlet connector and a liquid outlet connector are formed in the heating pool, and are communicated with the liquid flow channel, a first temperature sensor which is used for detecting the temperature of outlet liquid is installed on the side, with the liquid outlet connector, of the heating pool, the detection end of the first temperature sensor is arranged in the liquid flow channel, and a second temperature sensor is installed on the heat conduction disk. According to the thick film heater, the temperature of the liquid can be controlled conveniently, rapidly and accurately, operation is reliable, cleaning efficiency is improved, and maintenance is convenient.

Owner:CHANGZHOU RUIZE MICROELECTRONICS

Refrigeration system used in infrared receiver

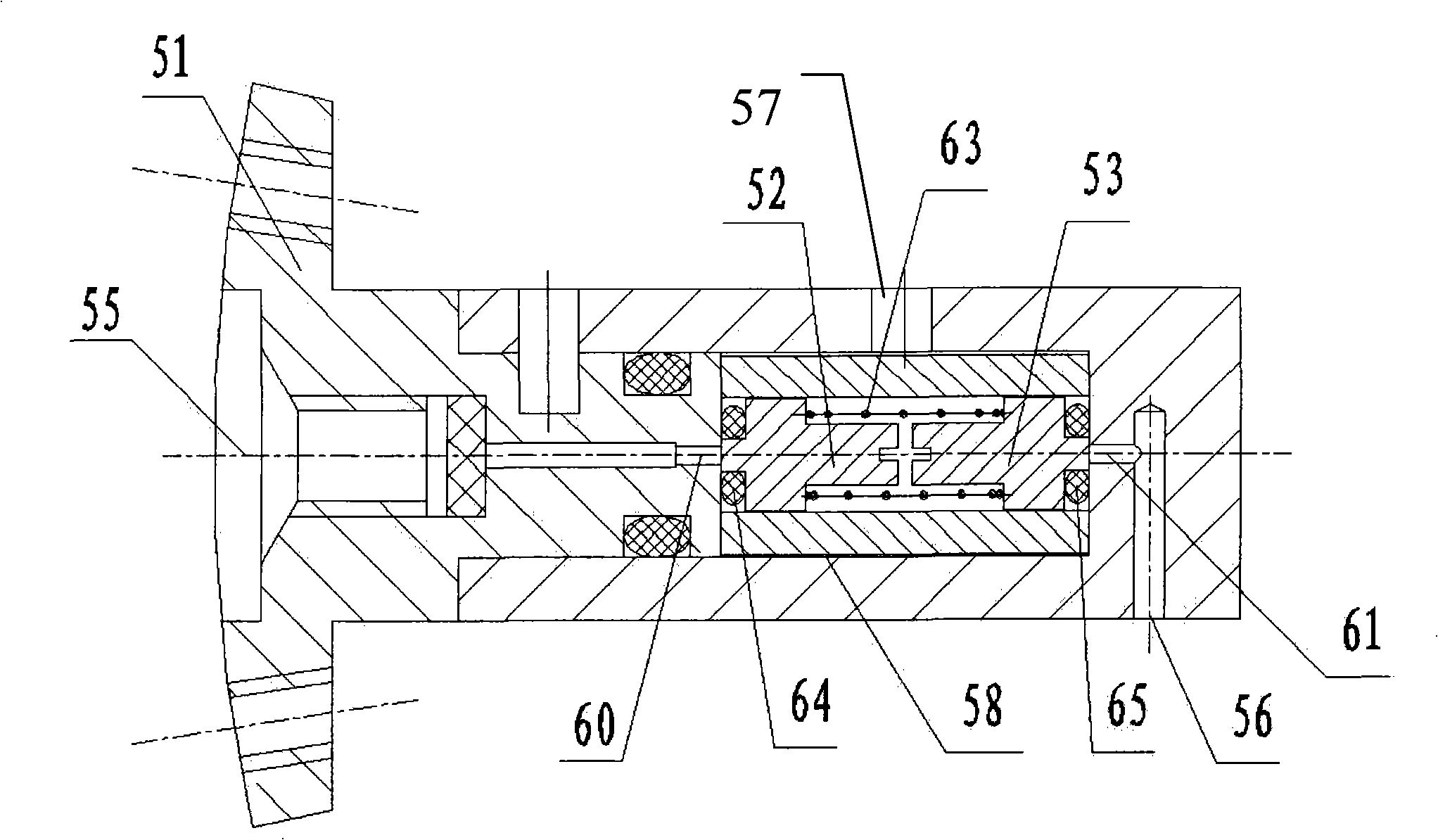

ActiveCN101526290AIncrease in sizeAvoid poor coolingDomestic cooling apparatusFluid circulation arrangementElectricityGas cylinder

The invention relates to a refrigeration system used in an infrared receiver, which comprises a gas tank and a valve used for controlling the efflux of gas in the gas tank; wherein the gas tank is internally provided with a first gas storage cavity and a second storage cavity which are mutual independence and both provided with air inlets and air outlets; the two air inlets are both sealed and provided with a gas charging retaining valve; and the two air outlets are both provided with the valves used for controlling the efflux of the gas in the gas tank; the valves are electrical explosion opening valves which comprise a first electrical explosion opening valve and a second electrical explosion opening valve; the first electrical explosion opening valve is communicated with the first gas storage cavity; and the second electrical explosion opening valve is communicated with the second gas storage cavity; the air outlet of the second electrical explosion opening valve is communicated with a reducing valve, the air outlet of the reducing valve and the air outlet of the first electrical explosion opening valve are both communicated with different air inlets of a gas circuit diverter valve. The refrigeration system adopts bipolar refrigeration, has long refrigeration time and good refrigeration effect and meets the operating requirements for the infrared receiver with the high precision.

Owner:CAMA LUOYANG GAS SUPPLY

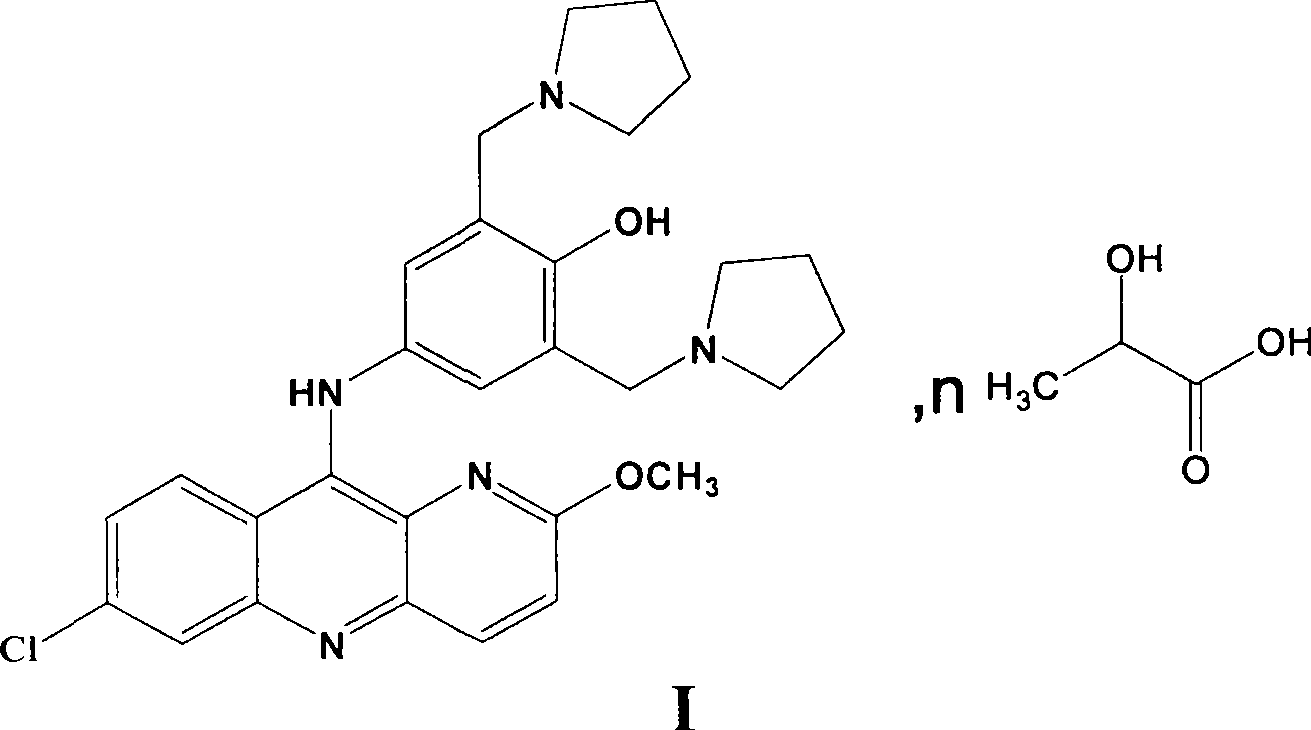

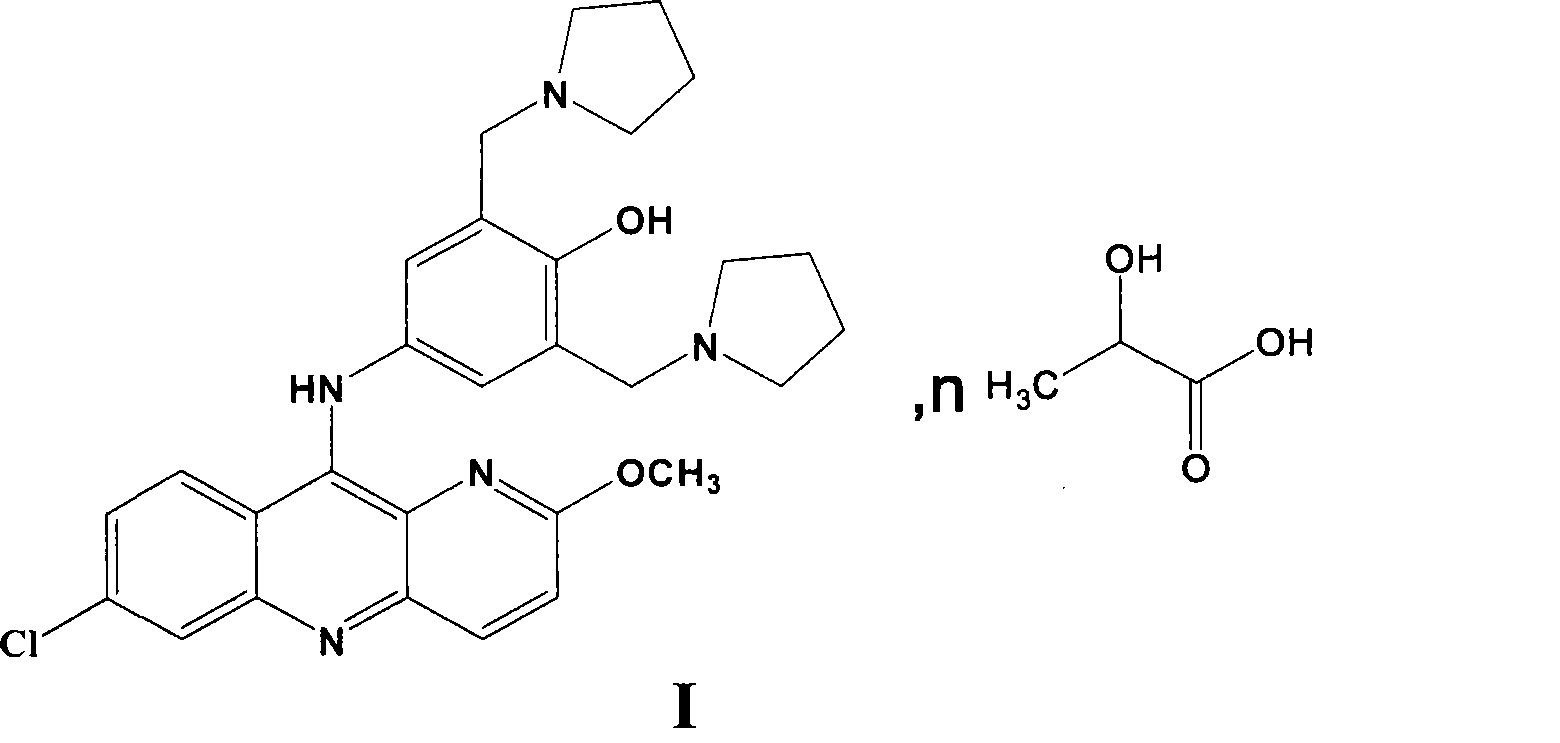

Lact-pyrondridin and its pharmaceutical composition

InactiveCN101544638AImprove bioavailabilityReduce dosageOrganic active ingredientsOrganic chemistryPharmaceutical drugCombinatorial chemistry

The invention provides lact-pyrondridin and its pharmaceutical composition, more specificly, the invention provides compound of formula I, wherein n is 1 to 4, or its solvate, crystal type, amorphous material. The invention also provides a pharmaceutical composition comprising compound of formula I, compound pharmaceutical combination comprising compound of formula I and arteannuin analog, medicine kit product comprising compound of formula I and arteannuin analog, and uses of the compound of formula I, pharmaceutical composition or compound pharmaceutical combination in preparing medicine for prevention and / or cure for the malaria. The compound of formula I possesses higher bioavailability and synergistic effect with arteannuin analog.

Owner:CHONGQING TONGTIAN PHARMA

Inoculation method for mushroom wood flour liquid strains

ActiveCN104956919ANot easy to mixPollution rotten rod rate is lowCultivating equipmentsMushroom cultivationPunchingInoculation methods

The invention relates to an inoculation method for mushroom wood flour liquid strains. The inoculation method comprises the following operation steps that 1, mushroom wood flour is transferred into a sterilization tank to be sterilized and cooled to 17 DEG C to 30 DEG C; 2, the sterilized and cooled mushroom wood flour is transferred into an inoculation tank, the liquid strains are added to the sterilized and cooled mushroom wood flour in the inoculation tank to be fully stirred till the strains and the mushroom wood flour are mixed evenly, feed liquid obtained after even mixing is thrown into a storage tank, sterile air is pumped into the storage tank, and still standing is carried out for 1-48 hours; 3, after still standing is finished, the feed liquid obtained after even mixing in the step 2 is bagged, and bags are transferred into a fungus culture chamber for mycelium culture. According to the method, even inoculation is achieved, infectious microbe is not prone to being mixed in the strains, manual punching is not needed, operation is easy, the workload is small, and large-scale industrial production can be achieved.

Owner:蕈康堂生物科技股份有限公司

Cooling device for processing paint stripping-free jointing clamps of enameled wires

The invention relates to a cooling device, in particular to a cooling device for paint stripping-free jointing clamps of enameled wires. The technical problem to be solved by the present invention is to provide a short-time consumed cooling device for paint stripping-free jointing clamps. In order to solve the above-mentioned technical problems, the invention provides a cooling device for paint stripping-free jointing clamps comprises a water tank, a first water pipe, a cooling tank, a water outlet pipe, a water pump, a cooling groove, and a heat radiator. The cooling groove is provided with a cavity, the rear end of the top of the cavity is provided with a water inlet, the front end of the top of the cavity is provided with a water outlet, the rear side of the top of the cooling groove is provided with the water tank, the water pump is arranged at the bottom of the water tank and provided with the water outlet pipe penetrating the rear wall of the water tank. The cooling device has the advantages of short time-consuming, simple structure and simple operation, and the first heat sink and the second heat sink can be dissipated when the electric winder is operated.

Owner:WUXI JIANGSU WEIFENG PRINTING MACHINE

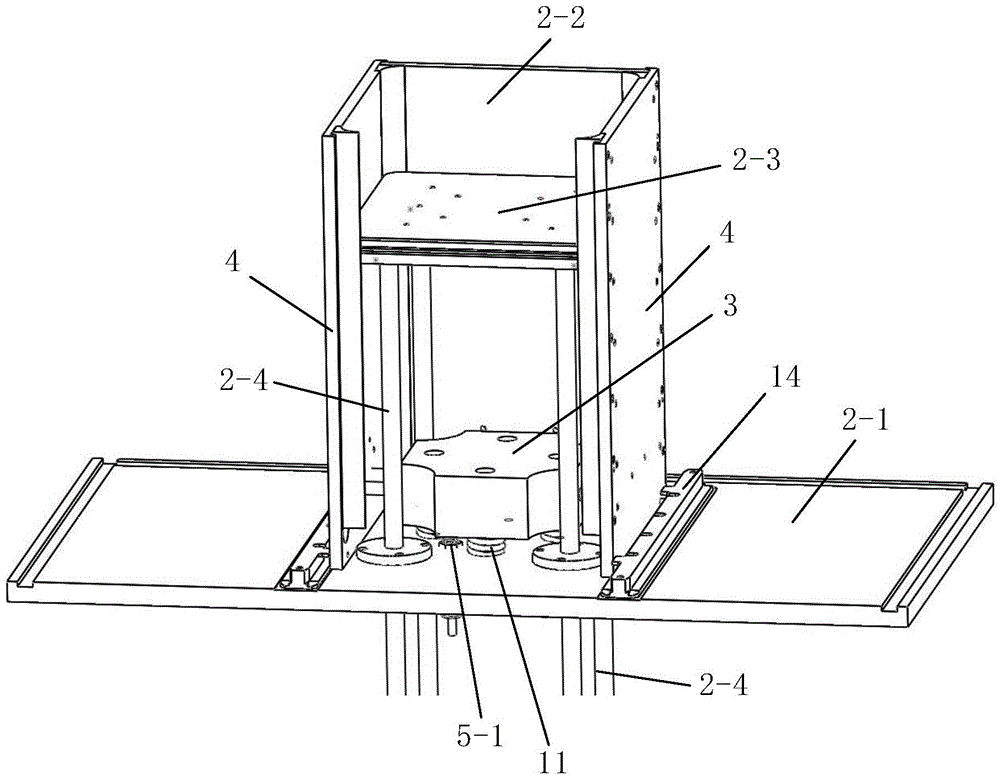

Cooling device of electron beam selective melting forming equipment

ActiveCN105642897ACompact structureEasy to assemble and disassembleAdditive manufacturing apparatusIncreasing energy efficiencyWork performanceElectron

The invention discloses a cooling device of electron beam selective melting forming equipment. The cooling device comprises a circulating air cooling device for cooling an electron beam selective melting forming chamber and a control device for controlling the circulating air cooling device, wherein the electron beam selective melting forming chamber comprises a forming chamber bottom wall, a forming cabin, a forming bottom plate and a lifting mechanism; the circulating air cooling device comprises a cooling air supplying device, a cooling block, two cooling side plates and a height detection unit; the cooling block is horizontally arranged above the forming chamber bottom wall and located in the forming cabin, and two cooling side plates are two side plates in the forming cabin; an in-plate cooling air runner is arranged in the cooling side plate, and an air inlet side cooling air runner, an air outlet side cooling air runner and an inter-side plate cooling air runner are arranged in the cooling block. The cooling device disclosed by the invention is simple in structure, reasonable in design, reliable in working performance, fast in cooling rate, good in use effect and capable of effectively solving the problem that the formed parts are low in powder pile cooling rate.

Owner:西安赛隆增材技术股份有限公司

Cable cooling structure

InactiveCN106298065AImprove cooling effectShort cooling timeInsulating conductors/cablesWater storage tankCooling effect

The invention discloses a cable cooling structure. The cable cooling structure comprises a box body and a water tank, wherein the box body is positioned in the water tank; openings are formed in the middle parts of two parallel side walls of the box body respectively, and center lines of the openings are overlapped; a water blocking box is arranged on the outer side of each opening; first round holes are formed in the side walls, opposite to the openings, of the water blocking boxes; V-shaped openings are formed below the first round holes; spraying devices are arranged on the inner sides of the openings and are fixedly welded on the side wall of the box body; third round holes are formed in the side walls, opposite to the openings, of the spraying devices; one nozzle is fixed on each of the upper part and the lower part of each spraying device; a sensor is arranged at the tail end of the box body; and the sensor is used for measuring the temperature of a cable and metering the length of the cable. According to the cable cooling structure, the nozzles simultaneously spray water to the cable, the surface of the whole cable can be well in contact with cooling water to perform heat exchange, the cooling effect is good, and the cooling time is short; furthermore, the quality of products is ensured, and meanwhile, water flowing into the water tank enters a water storage tank, so that the water can be recycled, and the energy source is saved.

Owner:安徽顺驰电缆股份有限公司

Water cooling device for aluminum alloy production

The invention belongs to the technical field of aluminum alloy production equipment, and particularly relates to a water cooling device for aluminum alloy production. The water cooling device comprises a bottom plate, wherein a groove is formed in the upper end of the bottom plate, a sliding rod is fixedly connected between opposite side walls in the groove, two sliding blocks are arranged on thesliding rod in a sliding mode, a moving device is arranged at the lower ends of the sliding blocks, a cooling groove is fixedly connected to the upper ends of the two sliding blocks, a storage basketis arranged above the cooling groove, a plurality of through holes are formed in the storage basket, a fixing block and a second servo motor are sequentially arranged on one side of the cooling groove, and the fixing block and the second servo motor are fixedly connected with the bottom plate. The water cooling device is novel in structure; and the mechanical operation in the cooling process of aluminum alloy is achieved through a simple structure, a large amount of manpower is saved, the cooling time is short, and the efficiency is high.

Owner:NANJING JIAMING DIE CASTING FACTORY

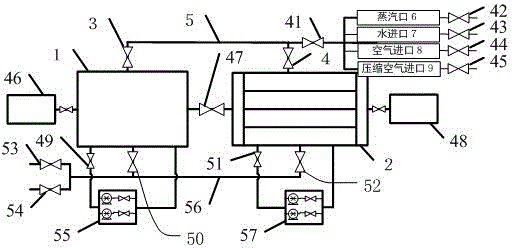

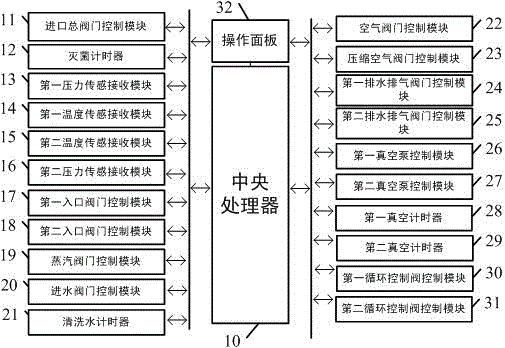

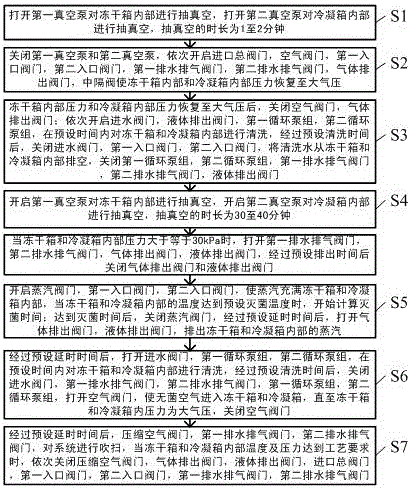

Freeze dryer on-line cleaning and sterilization system and method

ActiveCN106492240AAchieve cleaningImprove convenienceHollow article cleaningLavatory sanitoryExhaust valveFreeze-drying

The invention provides a freeze dryer on-line cleaning and sterilization system including a controller, a freeze-drying box and a condensation box; a freeze-drying box inlet and a condensation box inlet are both connected with an inlet pipeline, an inlet group of the inlet pipeline is provided with an inlet master valve, a steam port is provided with a steam valve, a water inlet is provided with a water inlet valve, an air inlet is provided with an air valve, and a compressed air inlet is provided with a compressed air valve; the freeze-drying box is provided with a freeze-drying box drainage and exhaust port, and the freeze-drying box drainage and exhaust port is provided with a first drainage and exhaust valve; the condensation box is provided with a condensation box drainage and exhaust port, and the condensation box drainage and exhaust port is provided with a second drainage and exhaust valve; the freeze-drying box drainage and exhaust port and the condensation box drainage and exhaust port are both connected with a drainage and exhaust pipeline. The system adopts a cleaning and sterilization method, can realize the on-line cleaning and on-line sterilization of a freeze dryer, also has shorter cooling time than that of the prior art, and realizes the convenience of production. The purposes of saving energy and reducing consumption are achieved.

Owner:SHANDONG TAIBANG BIOLOGICAL PROD CO LTD

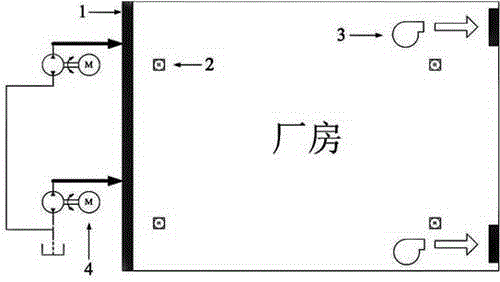

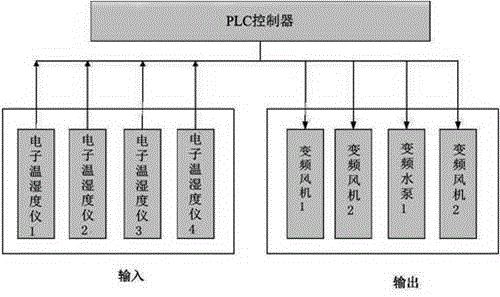

Intelligent fan and water curtain temperature control system

InactiveCN105240975ARealize automatic controlImprove the status quo of uncontrollable temperatureMechanical apparatusSpace heating and ventilation safety systemsTemperature controlAutomatic control

An intelligent fan and water curtain temperature control system comprises a water curtain, electronic temperature and humidity meters, frequency-convertible exhaust fans, frequency-convertible water pumps and a PLC control circuit. The water curtain is arranged on the entrance of a factory, and the bottom of the water curtain is connected to a water tank through a conveying pipe and the frequency-convertible water pumps. The electronic temperature and humidity meters are arranged on the four corners needing cooling in the factory. The frequency-convertible exhaust fans are arranged on the ventilation openings of the factory. The electronic temperature and humidity meters are connected with the frequency-convertible exhaust fans and the frequency-convertible water pumps through the PLC control circuit. Compared with the prior art, the intelligent fan and water curtain temperature control system has the advantages that automatic temperature control is achieved, the control accuracy is high, the cooling time is short, the problem that the temperature of the cooling water curtain cannot be controlled in the past is solved, air flow with constant temperature is obtained, and the work environment is improved for workshop workers and equipment.

Owner:WUJIANG CSG GLASS CO LTD

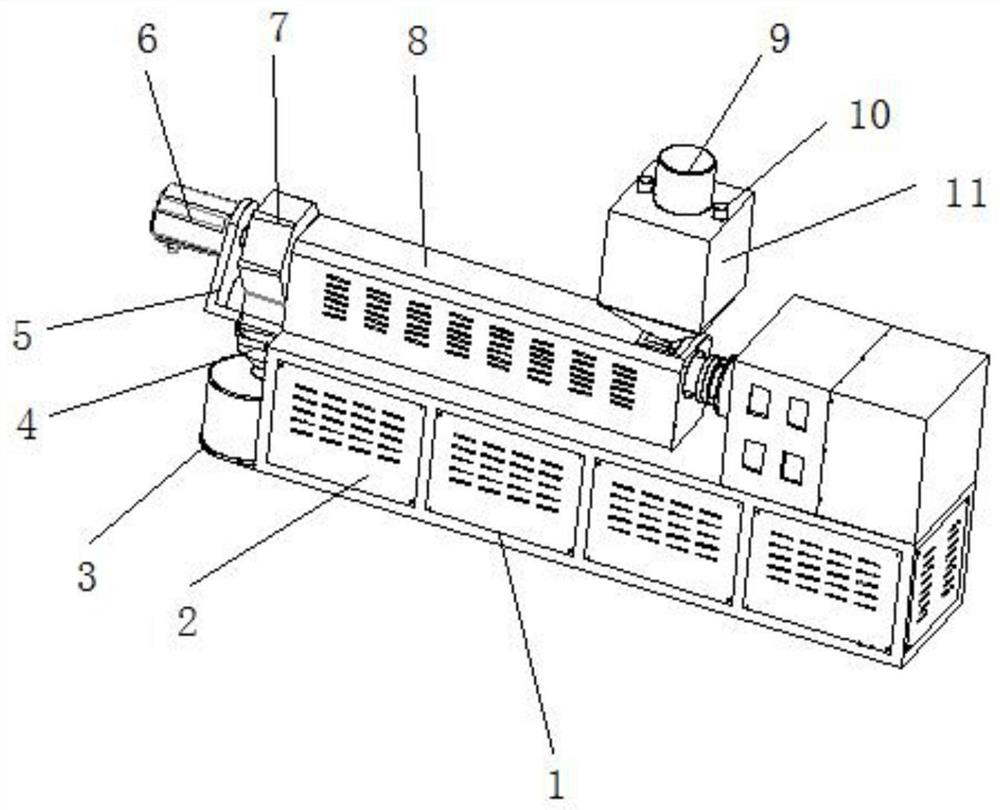

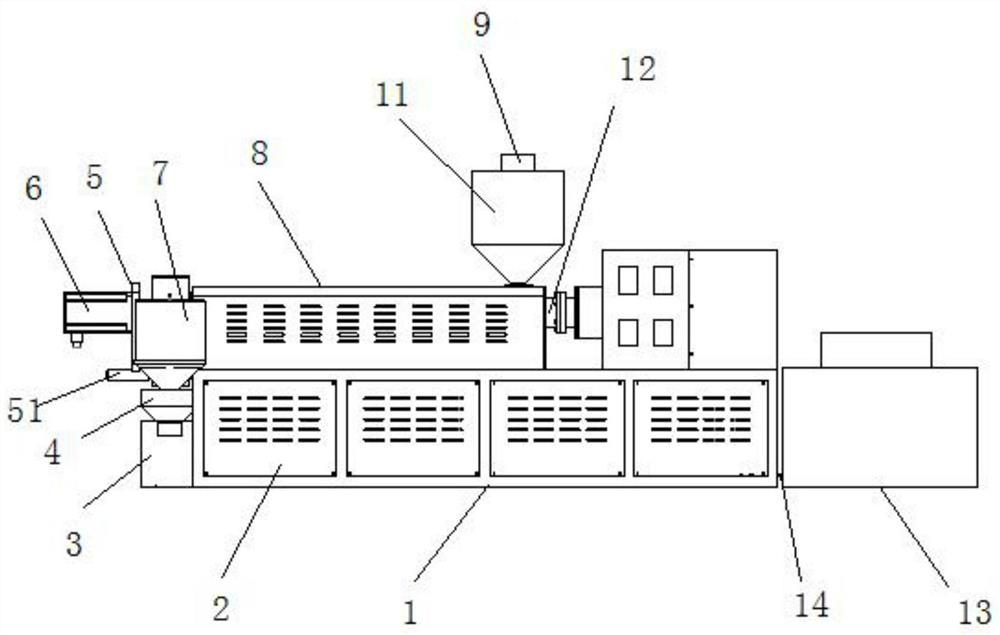

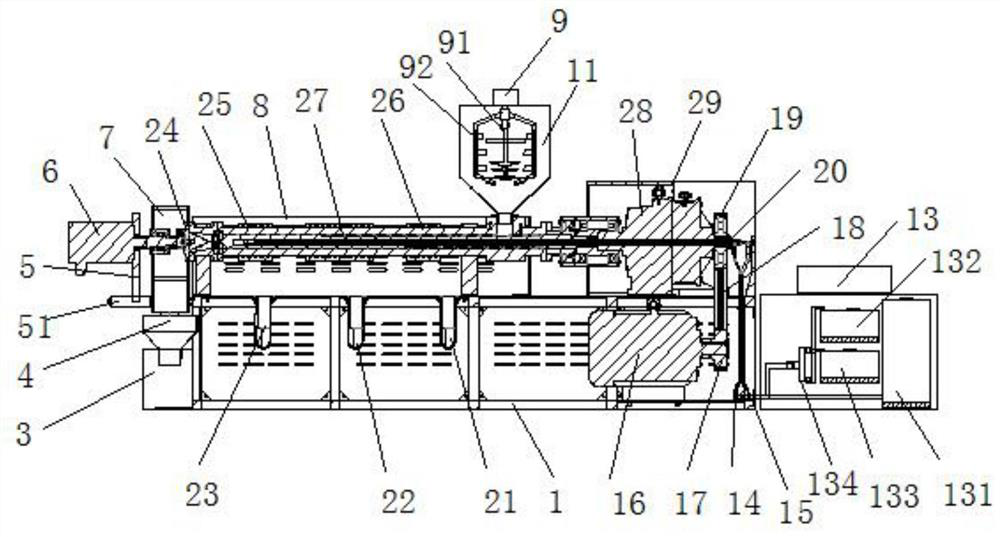

A plastic extruder with adjustable extrusion barrel temperature

The invention discloses a plastic extruder with adjustable extruding barrel temperature. An outer protective cover is fixed on the surface of the frame, and the extruding barrel is horizontally erected inside the outer protective cover. Several cast aluminum heating sleeves are fixedly arranged on the arc side of the outer protective cover, and a feeding chamber is fixedly arranged at one end of the outer protective cover, and the discharge port of the feeding chamber passes through the outer protective cover and is arranged on the extruding cylinder. On the feeding port, a cooling pipe is fixed inside the cavity of the rotating shaft inside the extrusion barrel, and a temperature control box is installed on one side of the frame. By setting a stirring mechanism in the feeding chamber, the The plastic is stirred by the stirring mechanism in the feeding chamber, so that the mixing of the plastic raw materials is more uniform, and the extrusion quality of the extrusion barrel is improved. The adjustment of the temperature of the plastic raw material in the barrel makes the heating and cooling effects of the barrel more prominent.

Owner:ANHUI TENGYUE ALUMINUM PLASTIC

Auxiliary cooling device for fuel oil

ActiveCN106839813AImprove cooling effectSpeed up coolingDirect contact heat exchangersEngineeringFuel oil

The invention relates to a cooling device and especially relates to an auxiliary cooling device for fuel oil. The technical problem to be solved by the invention is to provide the auxiliary cooling device for fuel oil with low cooling time consumption. In order to solve the technical problem, the auxiliary cooling device for fuel oil, provided by the invention, comprises a vent pipe, a cooling box, an S-shaped radiating fin, a first slide rail, a first slide block, a first rack, a first support rod, a second support rod, a first radiating fin and a second slide rail; fans are arranged on left and right sides above the vent pipe; a rotating motor is arranged on a rear wall in the cooling box; a cap-shaped block is arranged on the front side of the rotating motor; a small belt pulley is arranged on the front side of the cap-shaped block; and the second slide rail is arranged under a right wall in the cooling box. The auxiliary cooling device for fuel oil can achieve the effects of high cooling speed of the fuel oil, simple structure and simple operation.

Owner:天津国科医疗科技发展有限公司

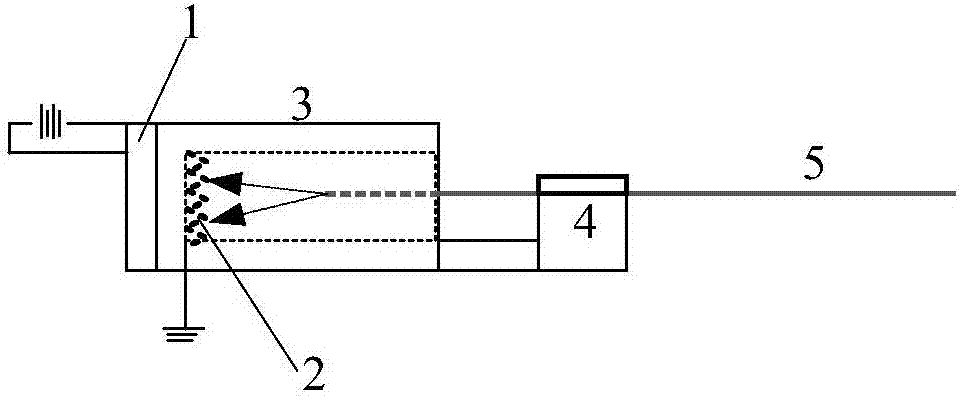

Ion source and ion mobility spectrometer

PendingCN106442695AReduce power consumptionReduce demandMaterial analysis by electric/magnetic meansIon sources/gunsWater vaporHigh pressure

The invention belongs to the technical field of ion mobility spectrometry and provides an ion source and an ion mobility spectrometer. The ion source comprises a sample feeding tube, a condensation needle, a cooling component, a counter electrode plate and a high-voltage power source. The sample feeding tube is used for guiding a sample mixed in water vapor; the cooling component is connected with one end of the condensation needle and used for cooling the condensation needle to enable the sample in the water vapor to condense on the condensation needle; the high-voltage power source forms an electric field between the condensation needle and the counter electrode plate to break liquid drops condensed at the other end of the condensation needle into ionized mist moving towards the counter electrode plate. Compared with a traditional ion source, the ion source has advantages of low sample quantity, low required voltage and low power consumption.

Owner:SUZHOU WEIMU INTELLIGENT SYST CO LTD

A kind of preparation method of titanium-aluminum alloy target

ActiveCN111101105BReduce manufacturing costSimple production process controlTransportation and packagingMetal-working apparatusProcessing costHeat treated

The invention discloses a method for preparing a titanium-aluminum alloy target, which comprises a powder mixing step, a filling step, a cold isostatic pressing step, a welding sheath degassing step, a hot isostatic pressing step, a cutting step, and alloying diffusion A heat treatment step and a machining finishing step. The preparation method of the invention has the advantages of simple control, low processing cost and high processing efficiency.

Owner:东莞市欧莱溅射靶材有限公司

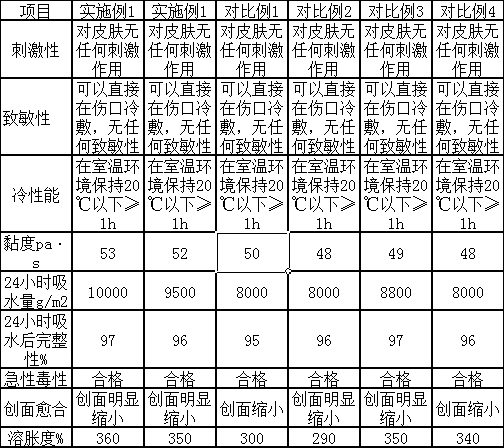

Medical cooling polymer hydrogel cold therapy patch

InactiveCN109700879AGood surface feelImprove hydrophilicityHydroxy compound active ingredientsAntipyreticPolymer scienceTherapeutic effect

The present invention discloses a medical cooling polymer hydrogel cold therapy patch and belongs to the technical field of medical polymer materials. The medical cooling polymer hydrogel cold therapypatch is mainly prepared from the following raw materials: polyphosphazene, selenium dioxide, silk fibroin, purple sweet potato powder, calcium chloride, xanthan gum, purified water, methylpyridine,polyethylene glycol, methyl iodide, sodium carboxymethyl cellulose, PVA, sodium tetraborate, sodium hydroxide, polypropylene glycol and a mixture of traditional Chinese medicines. The anti-aging hydrogel cold therapy patch is simple in preparation technology, suitable in gel strength and long in duration of cold compress curative effects, an ideal cold compress patch product, and suitable for large-scale production applications. A hydrogel layer combines traditional hydrogel cold compress and calcium chloride cold compress, and is good in auxiliary treatment effects, free of any side effects and easy to use.

Owner:余标

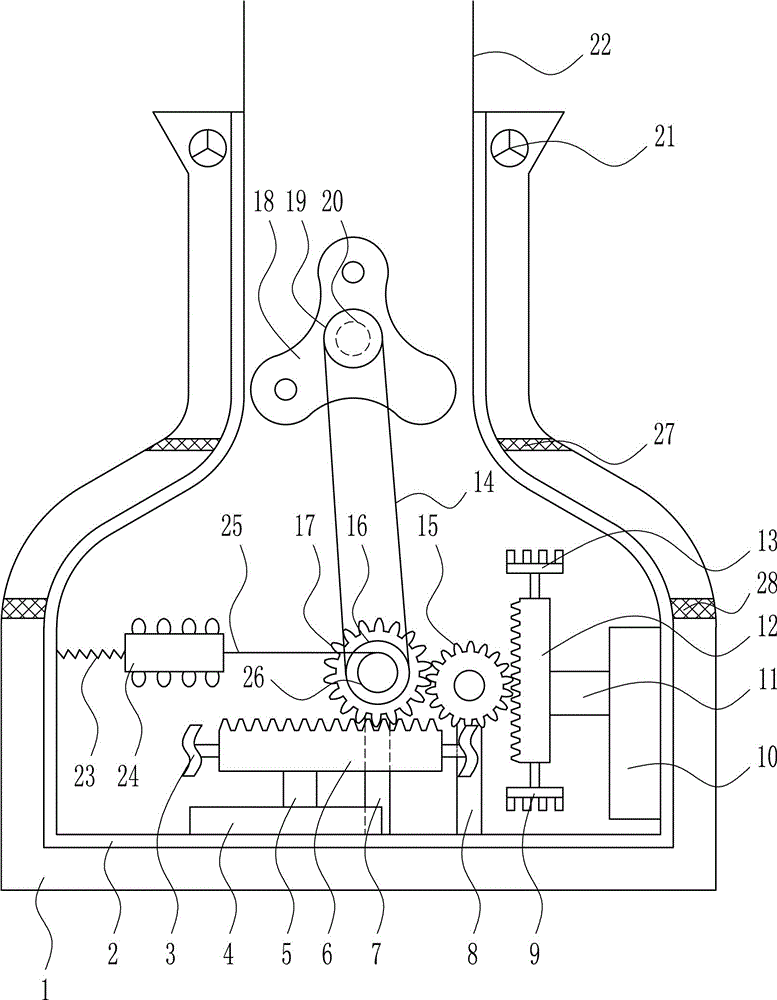

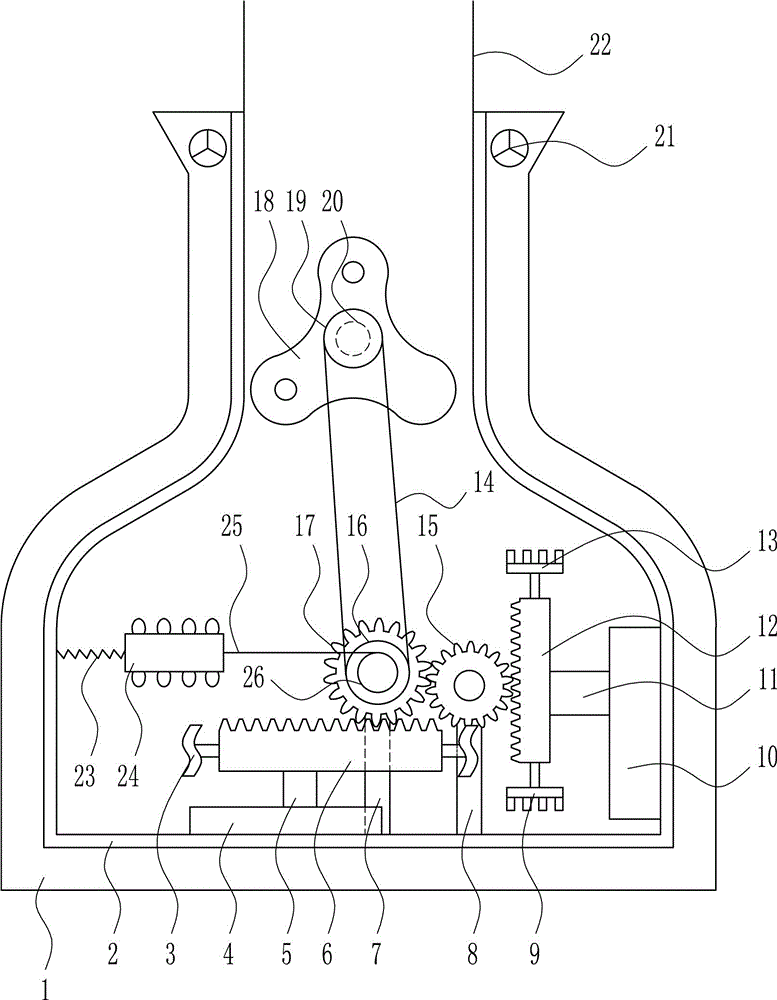

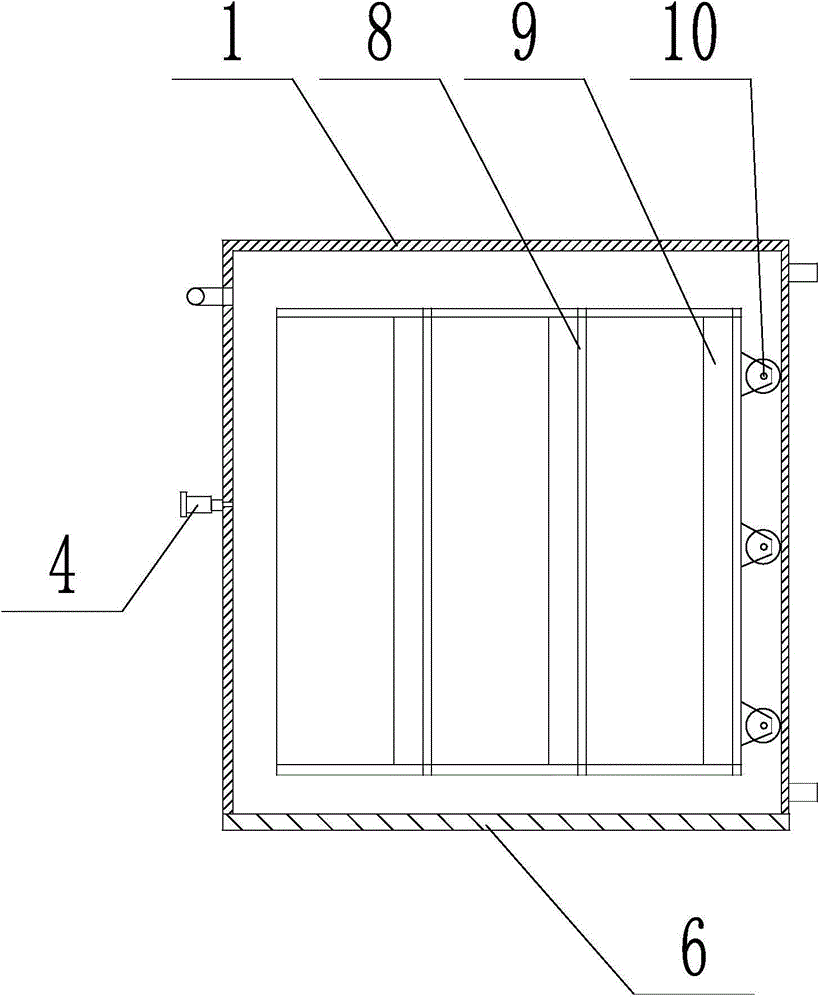

A vacuum cooling machine

The present invention discloses a vacuum cooling machine and the characteristics of the vacuum cooling machine are as follows: a box body and a vacuum cooling unit are connected via an air exhaust pipe, a deflating valve and a vacuum meter are installed on the top of the cabinet, an airproof gate is provide at one side of the box body, a temperature sensor is installed on the right wall of the box body, shelves are arranged inside the box body, good trays are provided on the shelves, and two truckles are provided at the lower end of the shelves. The vacuum cooling unit includes two condensers, a roots pump, a water-ring pump and a vacuum solenoid valve. The roots pump is connected to the bottom of the condensers, the water-ring pump is connected to the right side of the roots pump, and the vacuum solenoid valve is connected to the top of the water-ring pump. The beneficial effects of the vacuum cooling machine are as follows: the vacuum cooling machine has fast cooling speed, short cooling time and uniform temperatures, can avoid biochemical reactions and biological fermentation and ensure a long-term preservation of food, has small occupied area, does not produce any pollutants during the running process, and is safe and hygienic.

Owner:ZHUCHENG YOUBANG IND & TRADE CO LTD

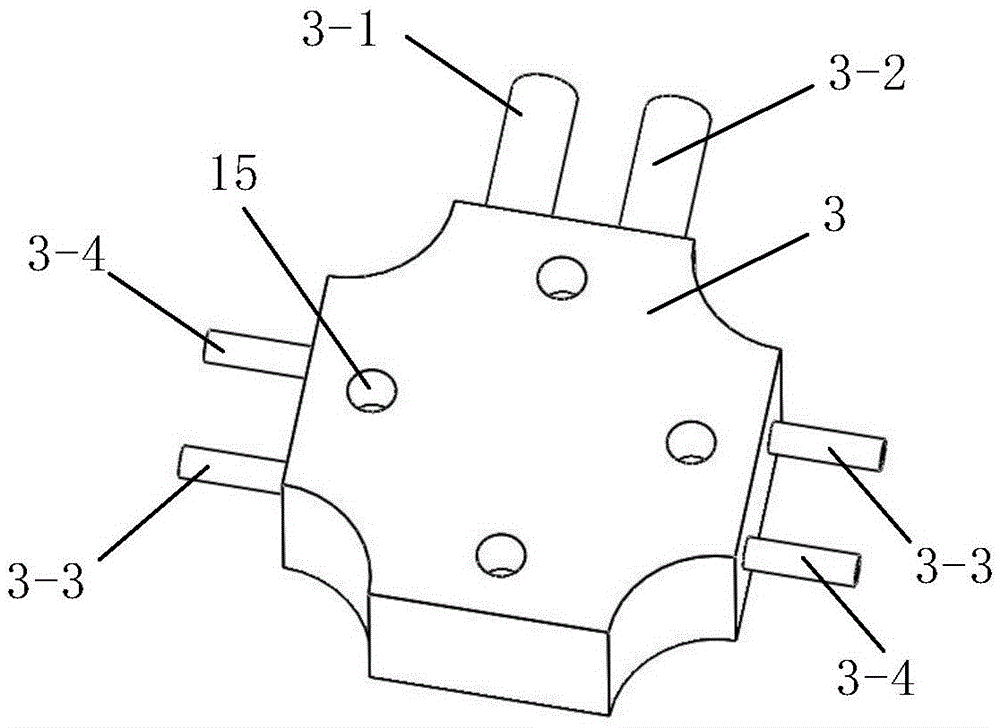

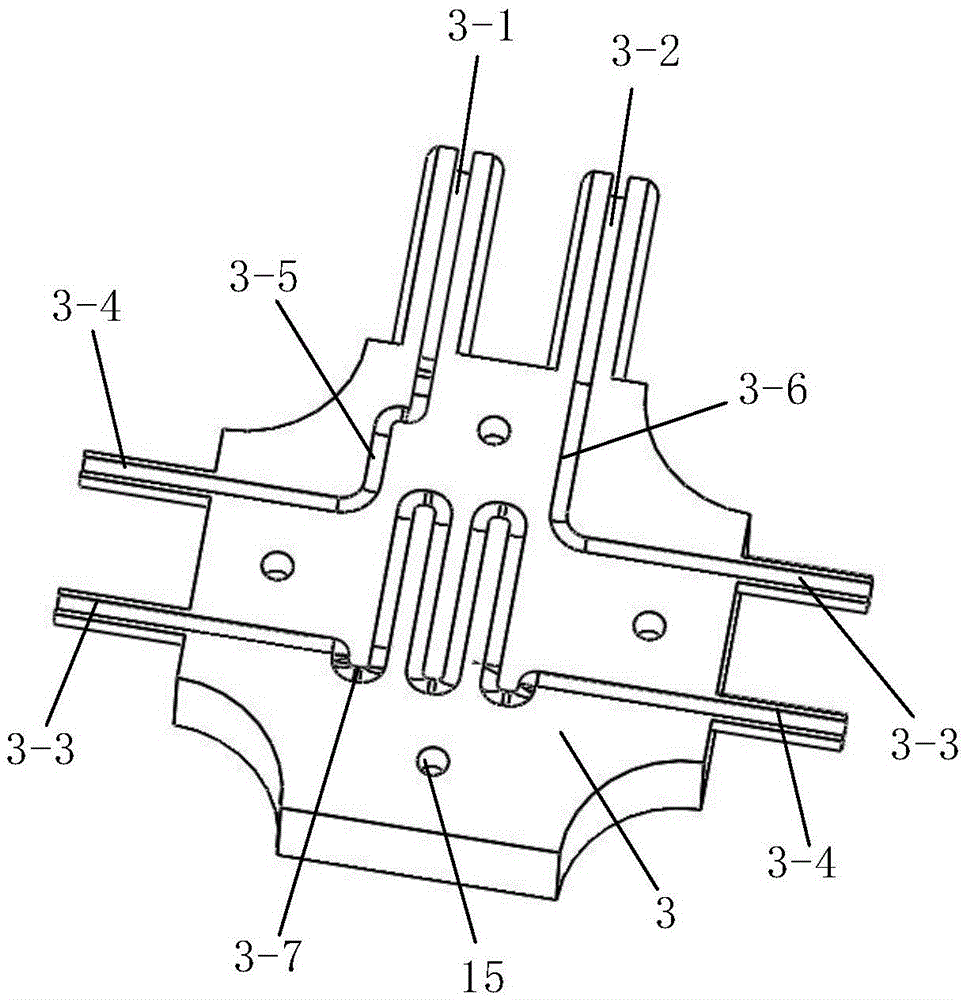

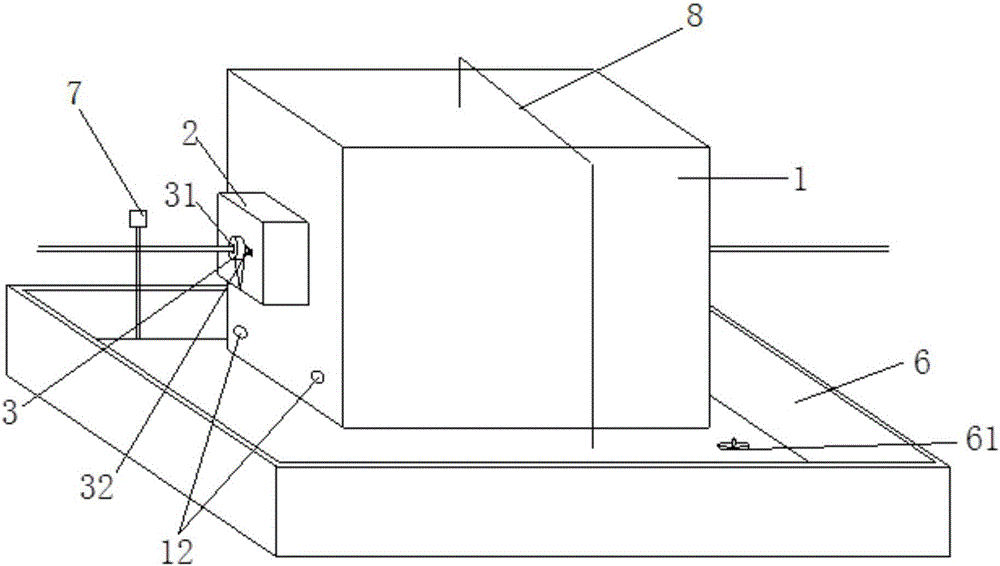

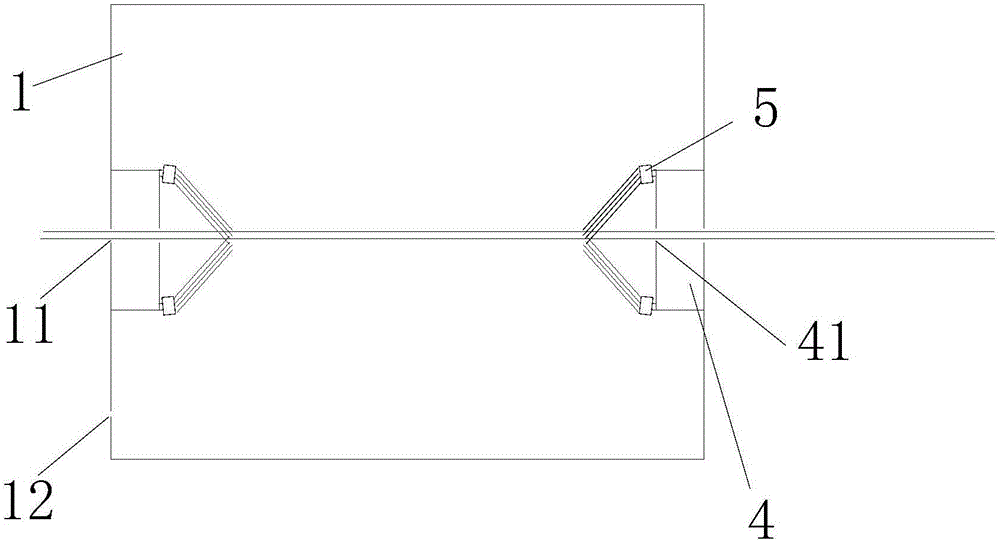

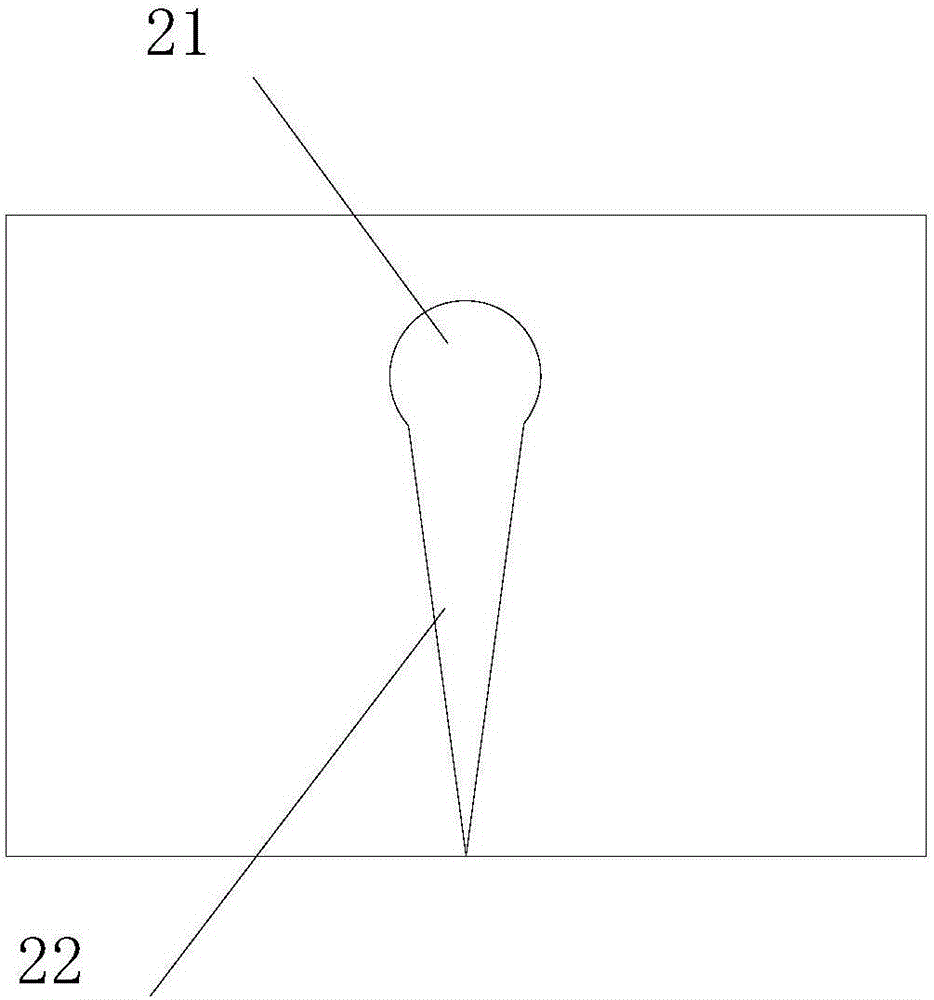

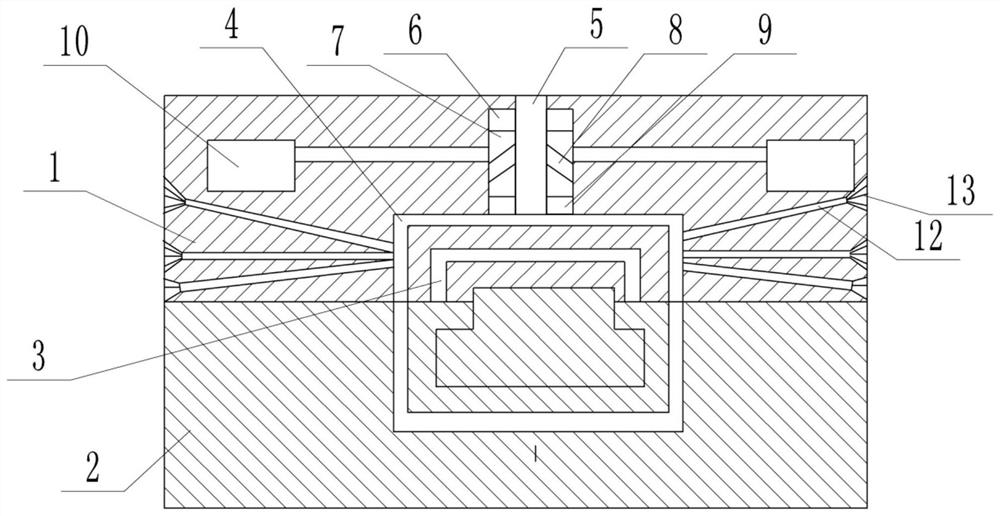

Automobile die

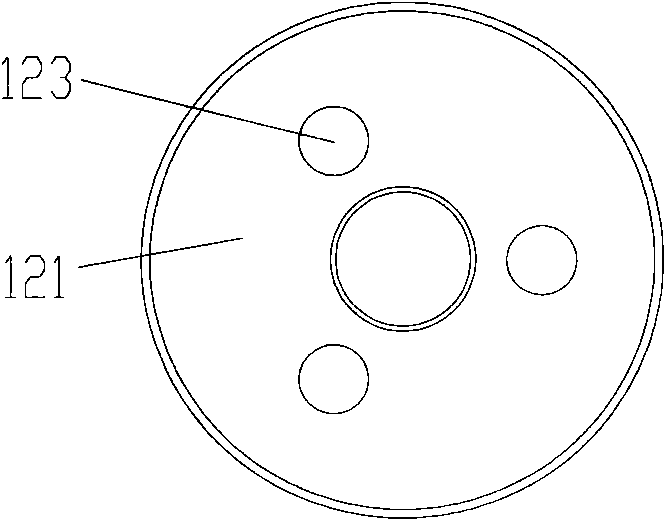

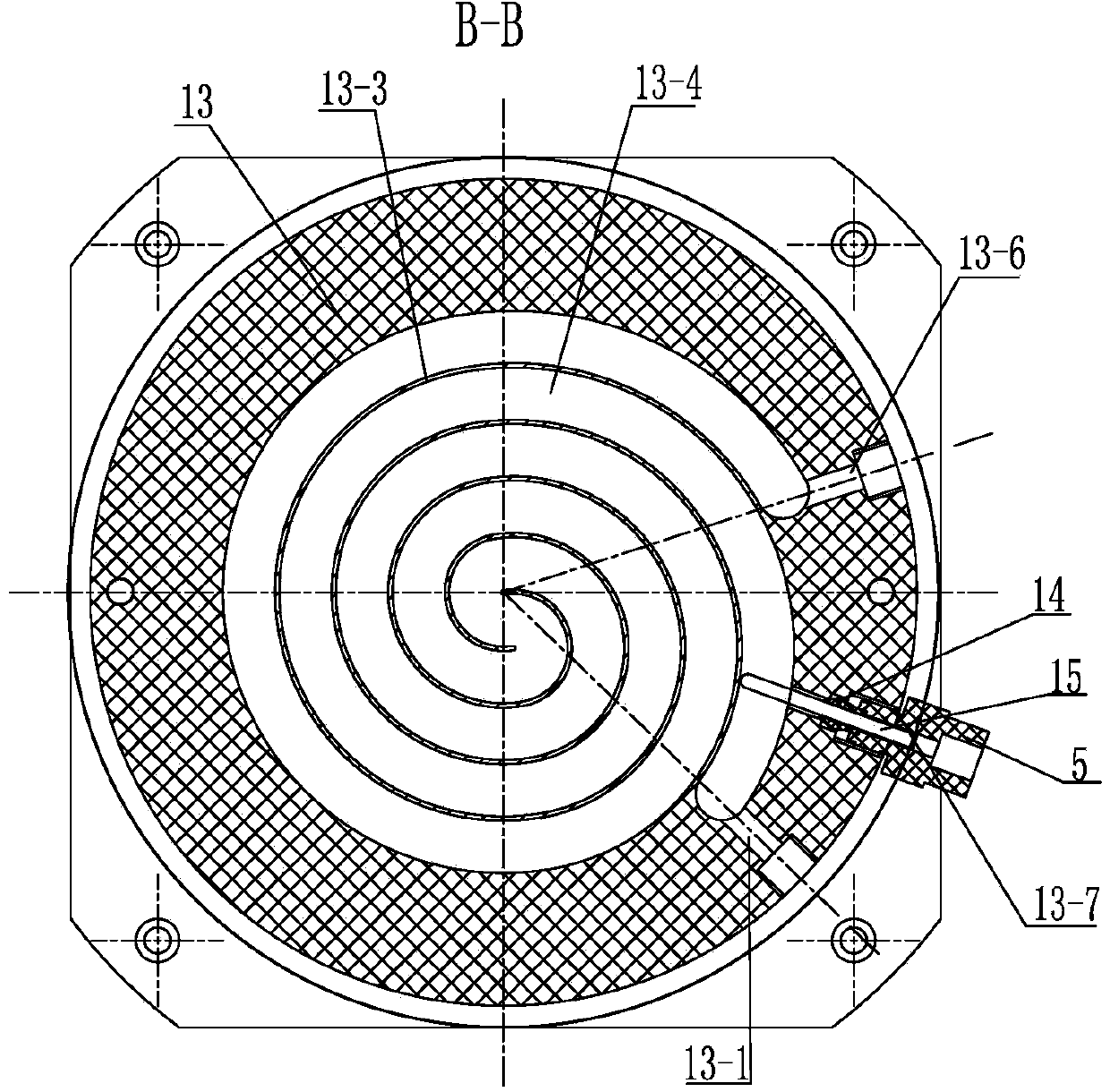

ActiveCN112318822ARealize the function of injection moldingIncrease flow rateDomestic articlesEngineeringMechanical engineering

The invention discloses an automobile die. The automobile die comprises an upper die body and a lower die body, wherein a closed forming cavity is formed between the upper die body and the lower die body when the upper die body and the lower die body are clamped, an injection molding channel and an air channel are formed in the upper die body, the injection molding channel communicates with the forming cavity, a heat conduction channel is formed in the upper die body and wraps the forming cavity, the air channel communicates with the heat conduction channel, symmetrical openings are formed inthe inner wall of the air channel, symmetrical adjusting sliding grooves are formed in the two sides of the outer wall of the air channel, symmetrical through openings are formed in the two sides of the side wall of each adjusting sliding groove, the bottoms of the adjusting sliding grooves abut against the heat conduction channel, air bags are arranged in the adjusting sliding grooves, sliding blocks are arranged on the air bags, inclined openings are formed in the middles of the two sliding blocks, and two high-pressure cavities and air pipes connected with the output ends of the high-pressure cavities respectively are arranged on the upper die body. According to the scheme, the cooling time is short, the efficiency is high, water can be saved, and the cost is reduced.

Owner:太仓金钟电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com