Cooling device of electron beam selective melting forming equipment

A technology of selective melting and cooling device, applied in the field of additive manufacturing, can solve the problem of slow cooling rate of powder pile cooling of formed parts, and achieve the effects of increasing cooling contact area, good use effect and shortening cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

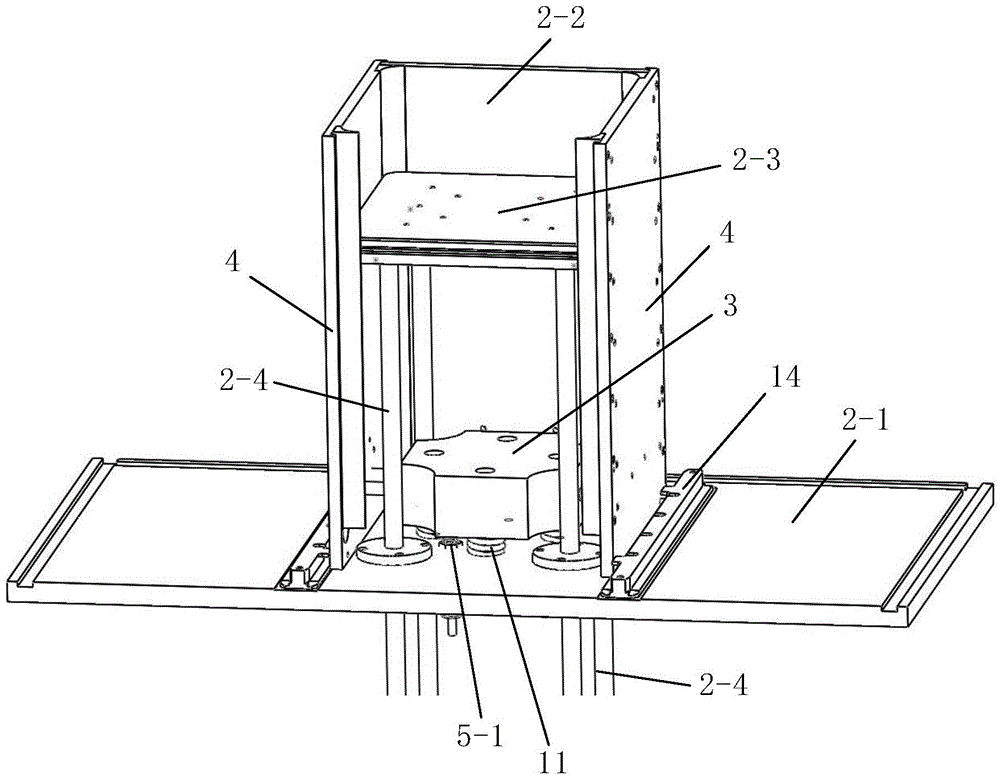

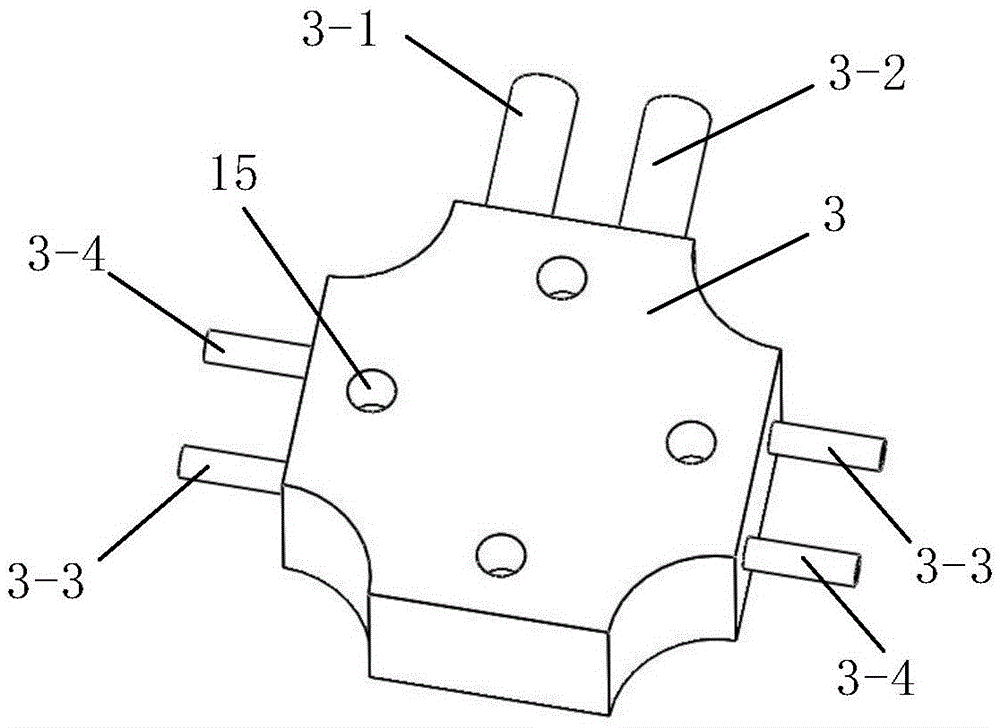

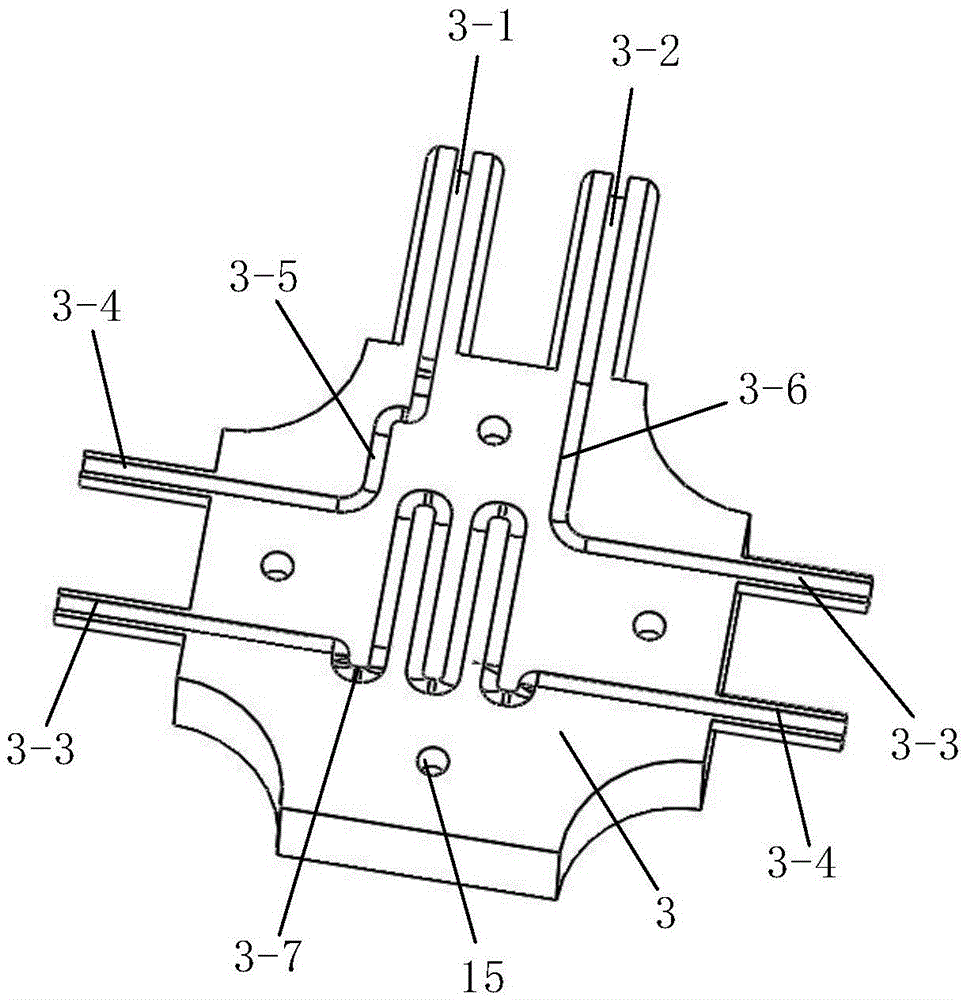

[0048] like figure 1 , Figure 9 As shown, the present invention includes a circulating air cooling device for cooling the electron beam selective melting forming chamber (that is, inside the electron beam selective melting forming chamber) and a control device 1 for controlling the circulating air cooling device. The melting and forming chamber includes a forming chamber bottom wall 2-1, a forming chamber 2-2 installed on the forming chamber bottom wall 2-1, and a body that is installed in the forming chamber 2-2 and can move up and down in the forming chamber 2-2. The forming base plate 2-3 and the lifting mechanism that drives the forming base plate 2-3 to move up and down, the forming bin 2-2 is arranged vertically, and the forming base plate 2-3 is arranged horizontally and installed on the lifting mechanism ; The forming bottom plate 2-3 is rectangular, and the forming chamber 2-2 is in the shape of a quadrangular column and is formed by splicing four side plates respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com