Refrigeration system used in infrared receiver

An infrared detector and refrigeration system technology, applied in household refrigeration devices, refrigerators, refrigeration components, etc., can solve the problems of short refrigeration time, poor refrigeration effect, and inability to meet the use requirements of high-precision infrared detectors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

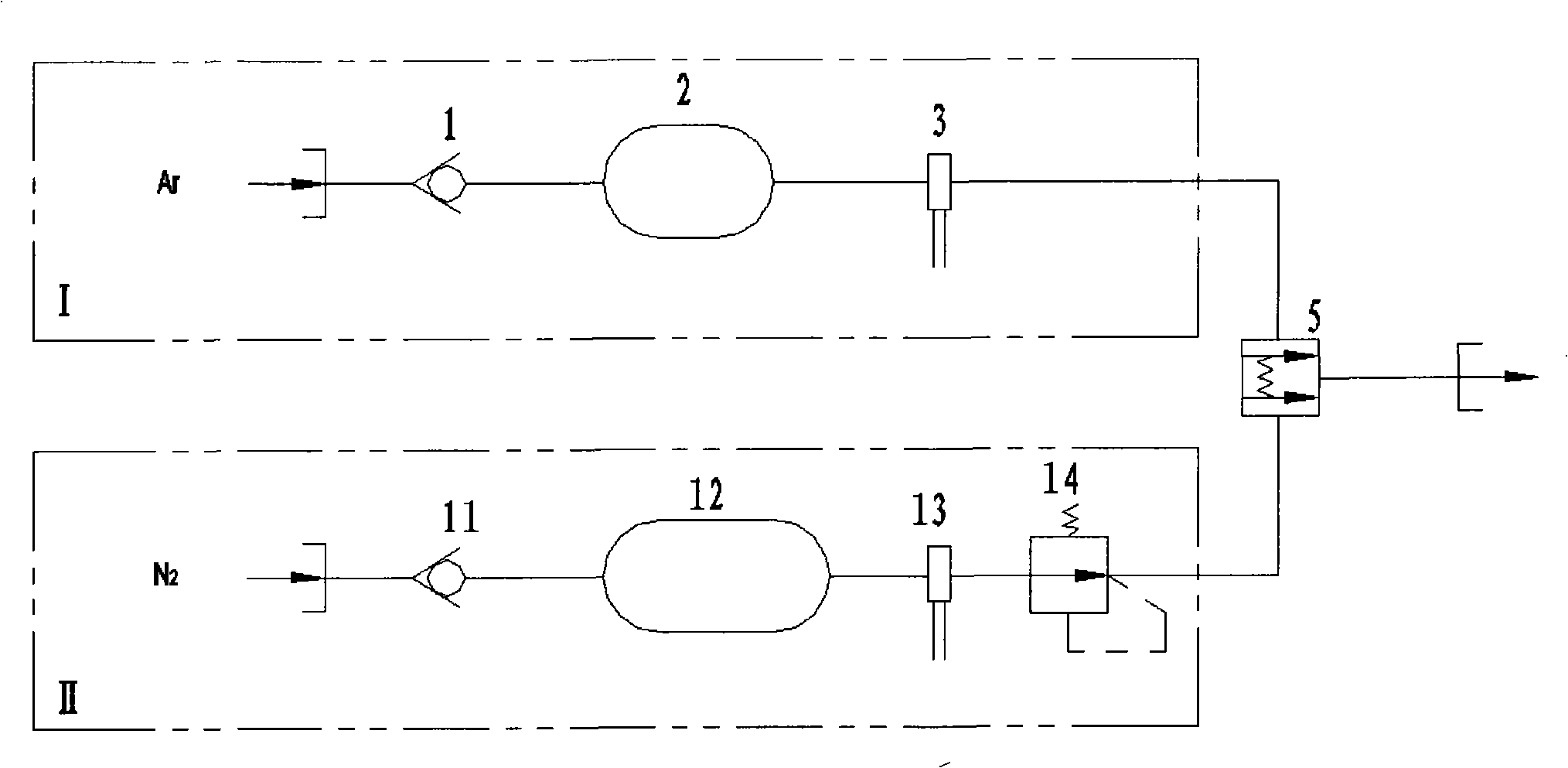

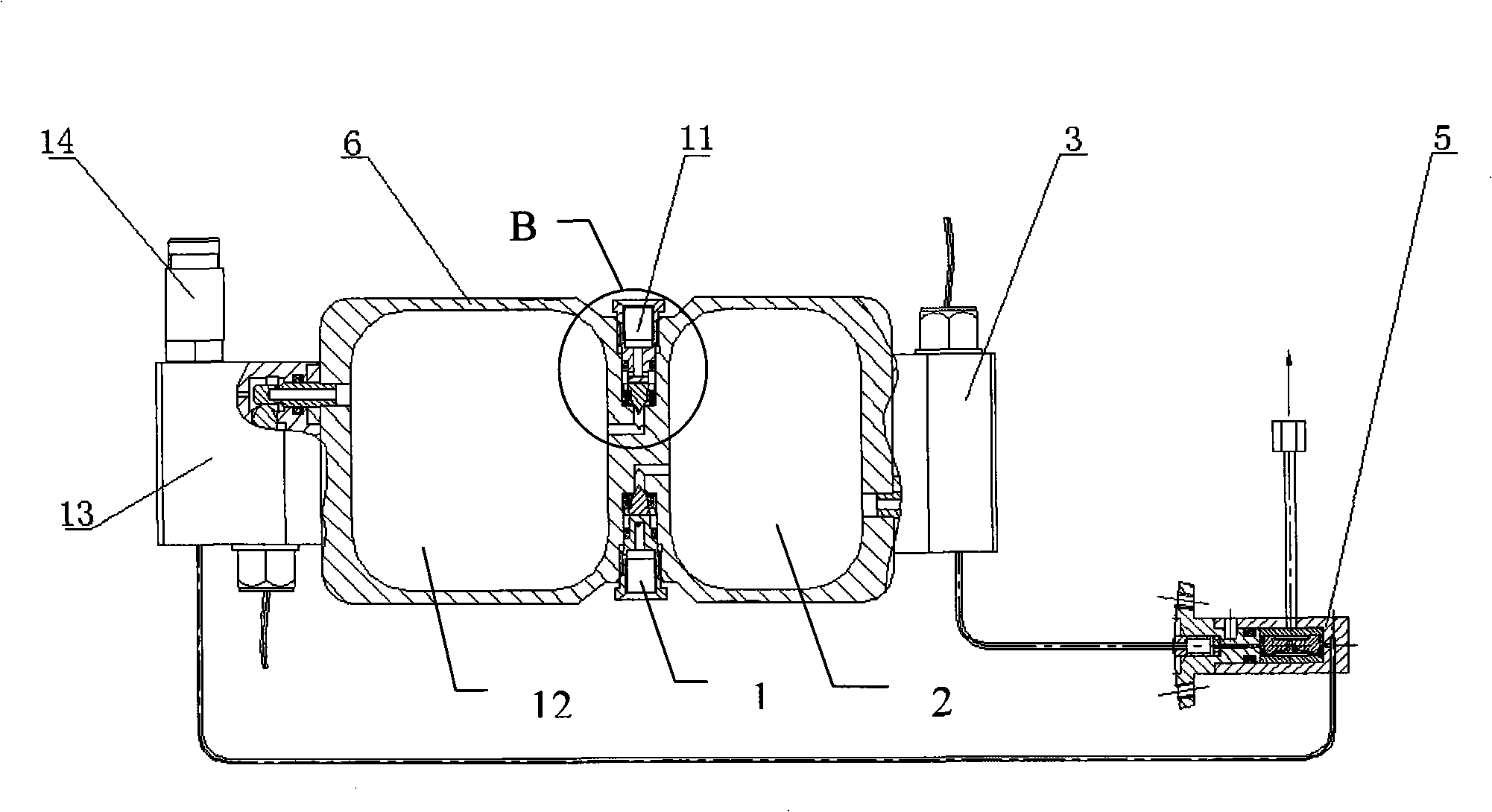

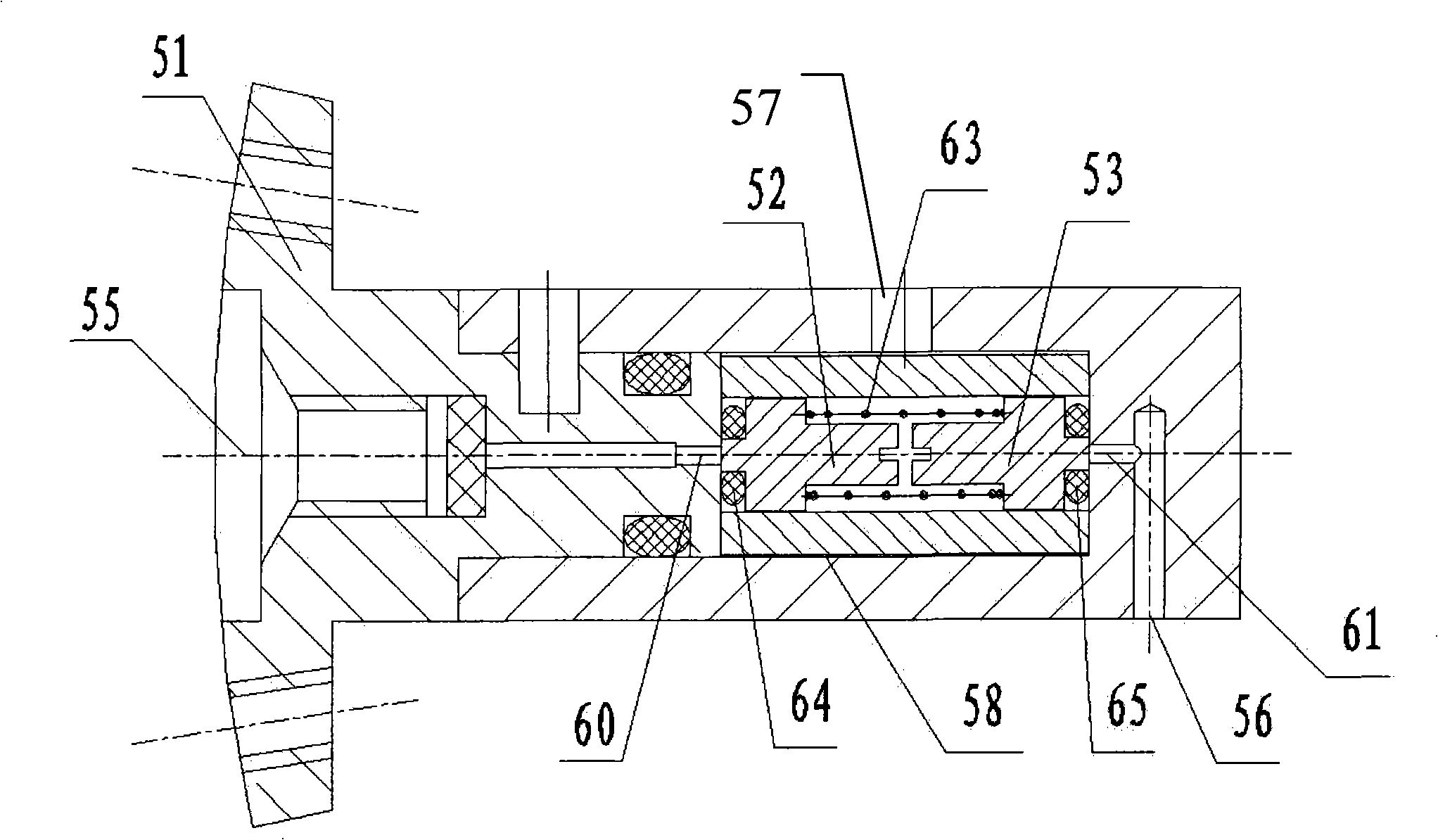

[0021] Figure 1~6 The refrigeration system for infrared detectors shown in the present invention includes a gas storage bottle 6, which has two mutually independent first gas storage chambers 2 and second gas outlet chambers 12, the first gas storage chamber 2 and the second gas outlet chamber. The gas storage chamber 12 is respectively provided with an air inlet and an air outlet. The air inlets of the two gas storage chambers are respectively sealed and fixed with inflatable check valves 1 and 11, and the gas outlet of the first gas storage chamber 2 is fixedly installed. There is a first electric explosion opening valve 3 that controls the discharge of gas in the first gas storage chamber 2, and a valve that controls the discharge of gas in the second gas storage chamber 12 is fixedly installed at the gas outlet of the second gas storage chamber 12. The second electric explosion opens the valve 3, and a pressure relief valve 14 is communicated with the second electric expl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com