Patents

Literature

34results about How to "Simple production process control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

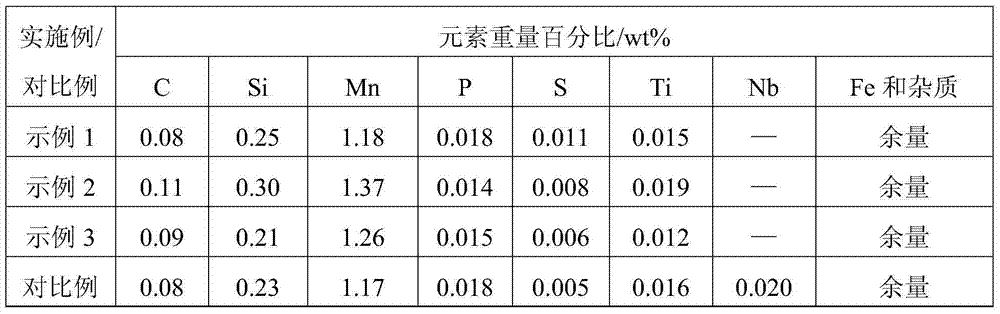

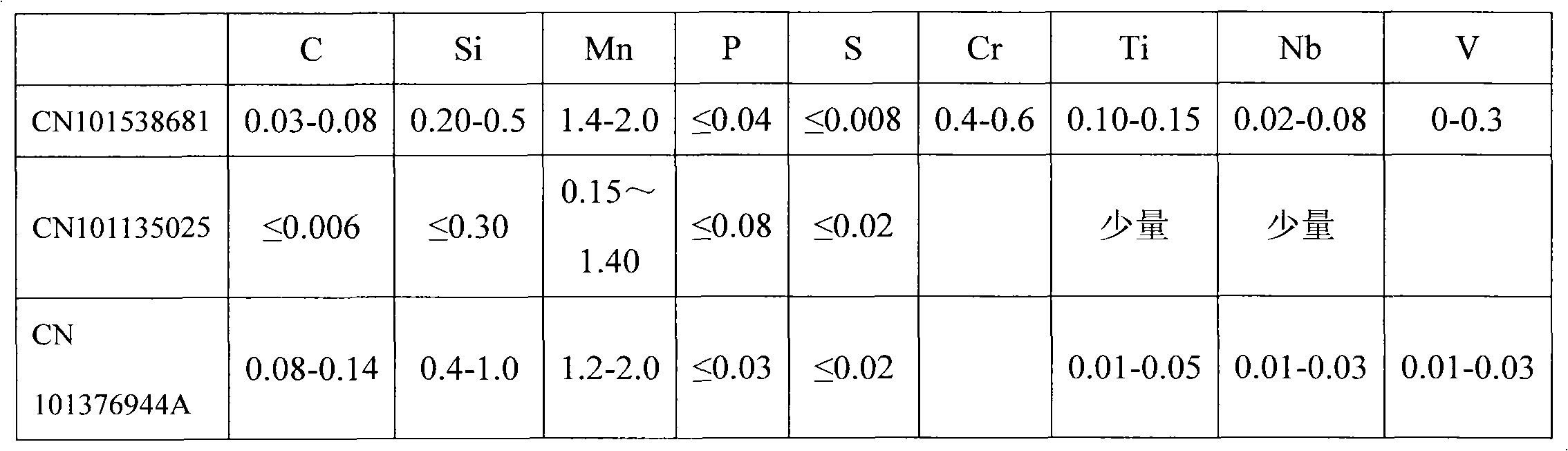

Production method of low-cost X52 pipeline steel and pipeline steel

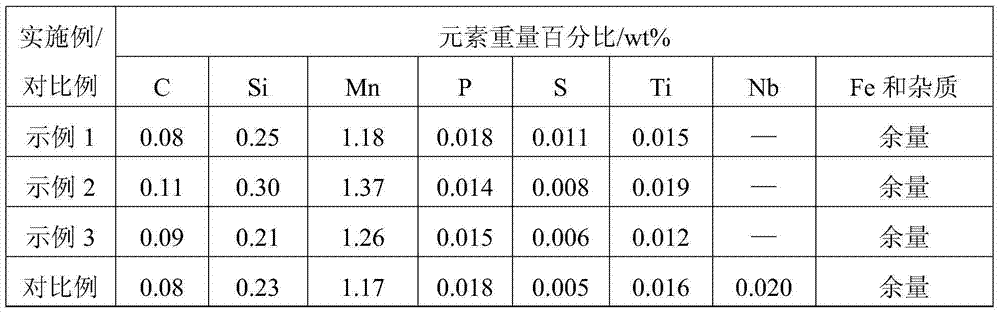

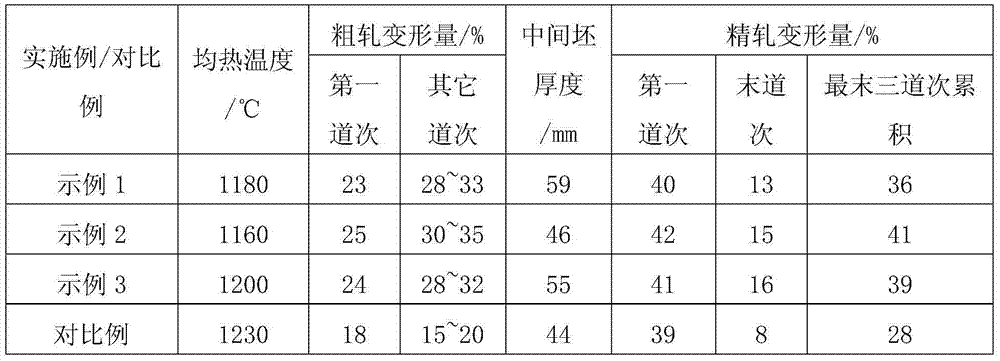

The invention provides a production method of a low-cost X52 pipeline steel and a pipeline steel. The production method comprises the following steps: desulphurization, converter smelting and continuous casting are conducted on molten iron to prepare a pipeline steel continuous casting billet; the pipeline steel continuous casting billet is soaked to be at 1160-1200 DEG C, and roughly rolled for 3-7 times by a roughing mill to obtain an intermediate billet; the intermediate billet is finely rolled for 4-7 times by a finishing mill; the finely-rolled pipeline steel is quickly cooled to be at 550-610 DEG C at the cooling speed of 50-100 DEG C / s, and is rolled to obtain a pipeline steel finished product. No Nb is added to the low-cost X52 pipeline steel. Through the adoption of the production method of the low-cost X52 pipeline steel, the production cost of the X52 pipeline steel can be lowered, the production technique control is easy, and the adaptability is high.

Owner:攀钢集团西昌钢钒有限公司 +1

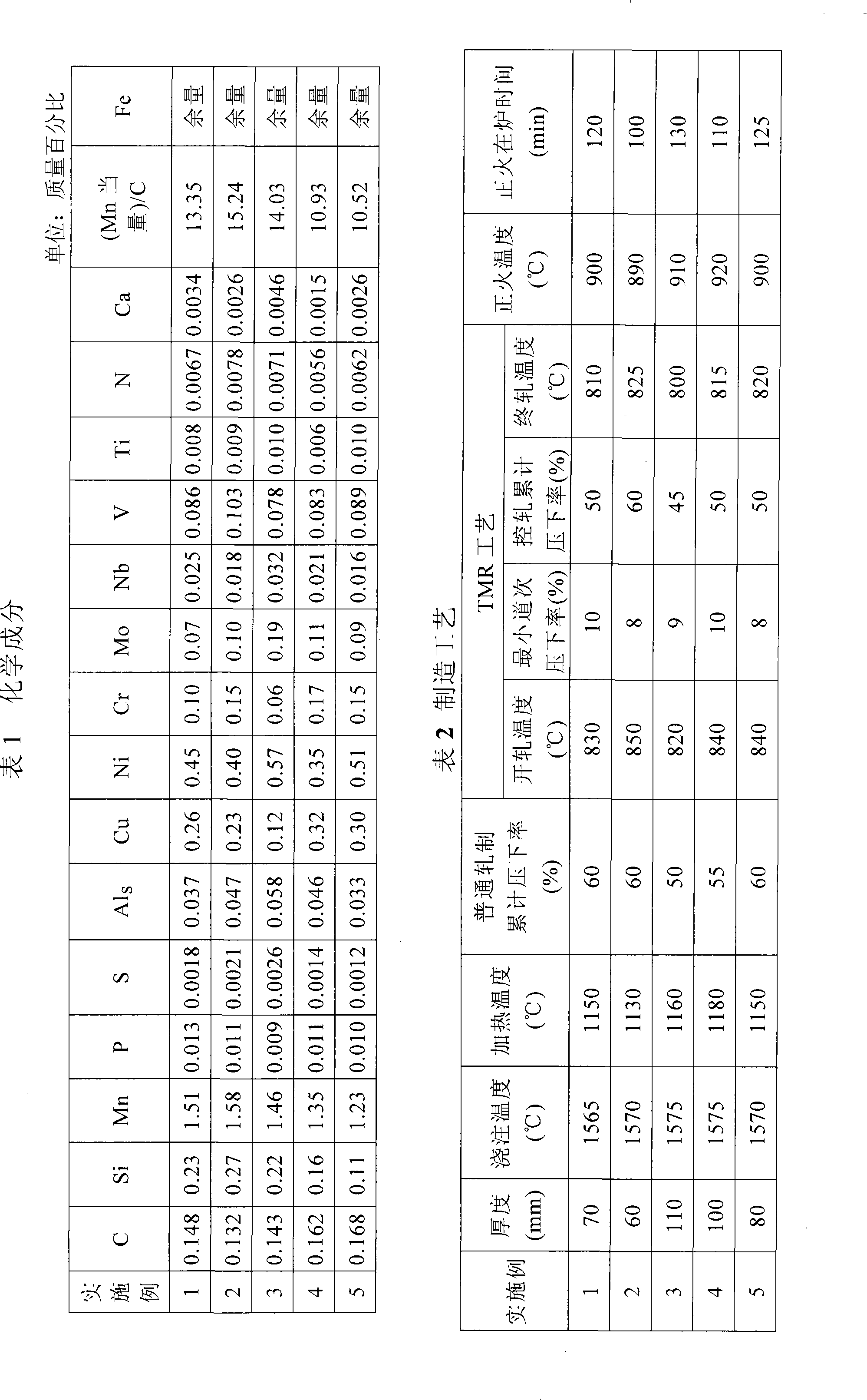

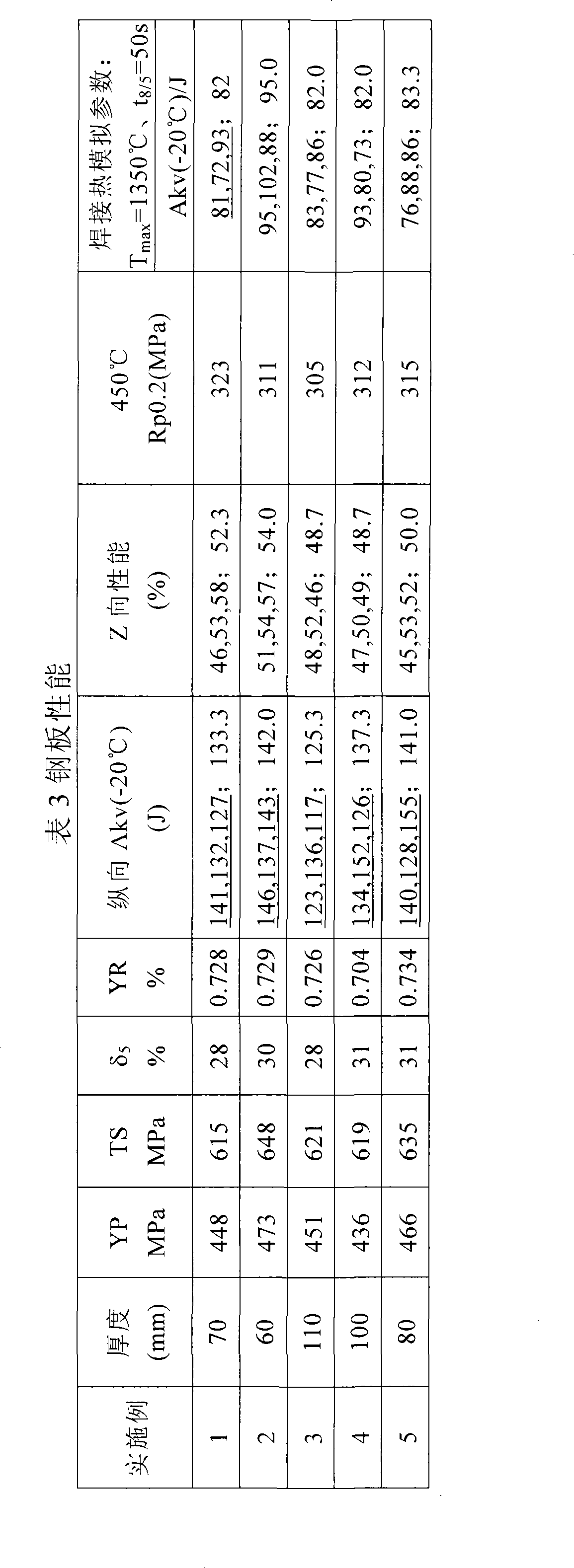

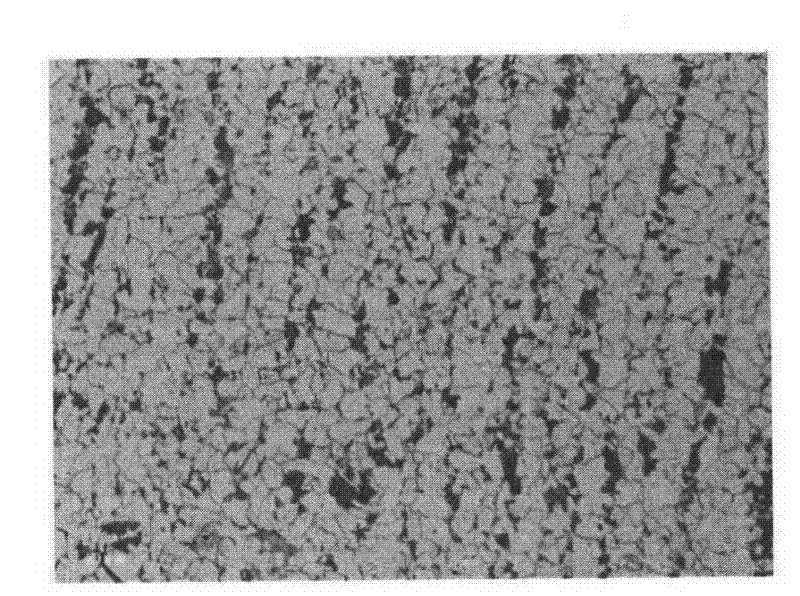

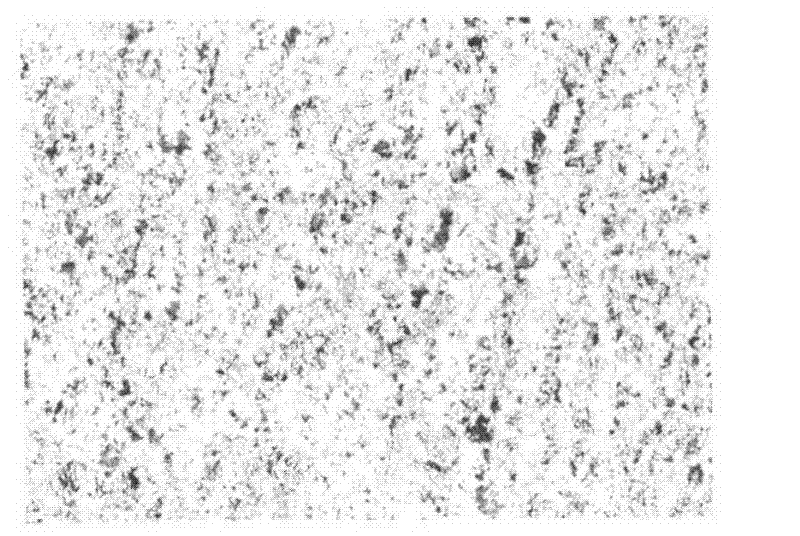

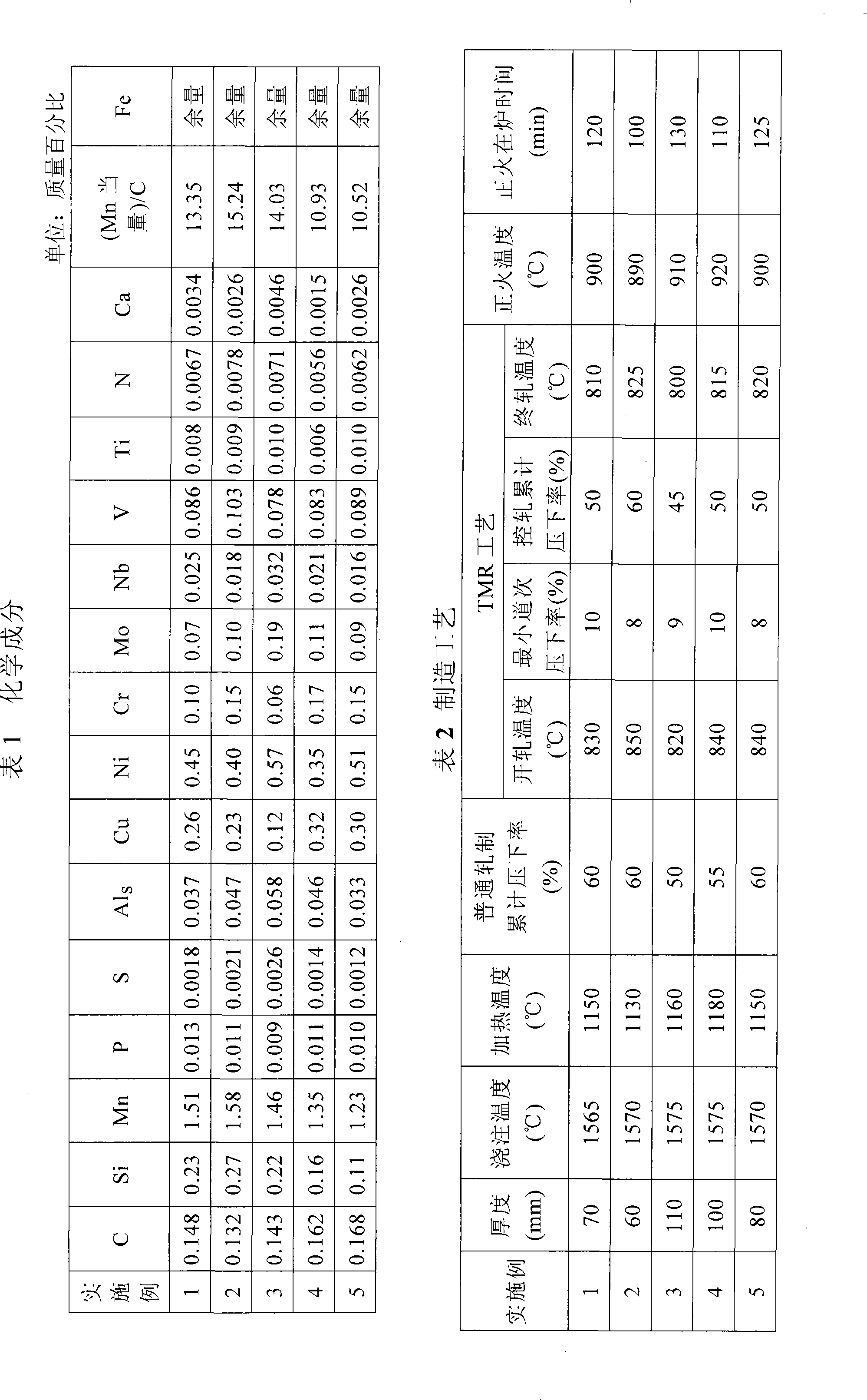

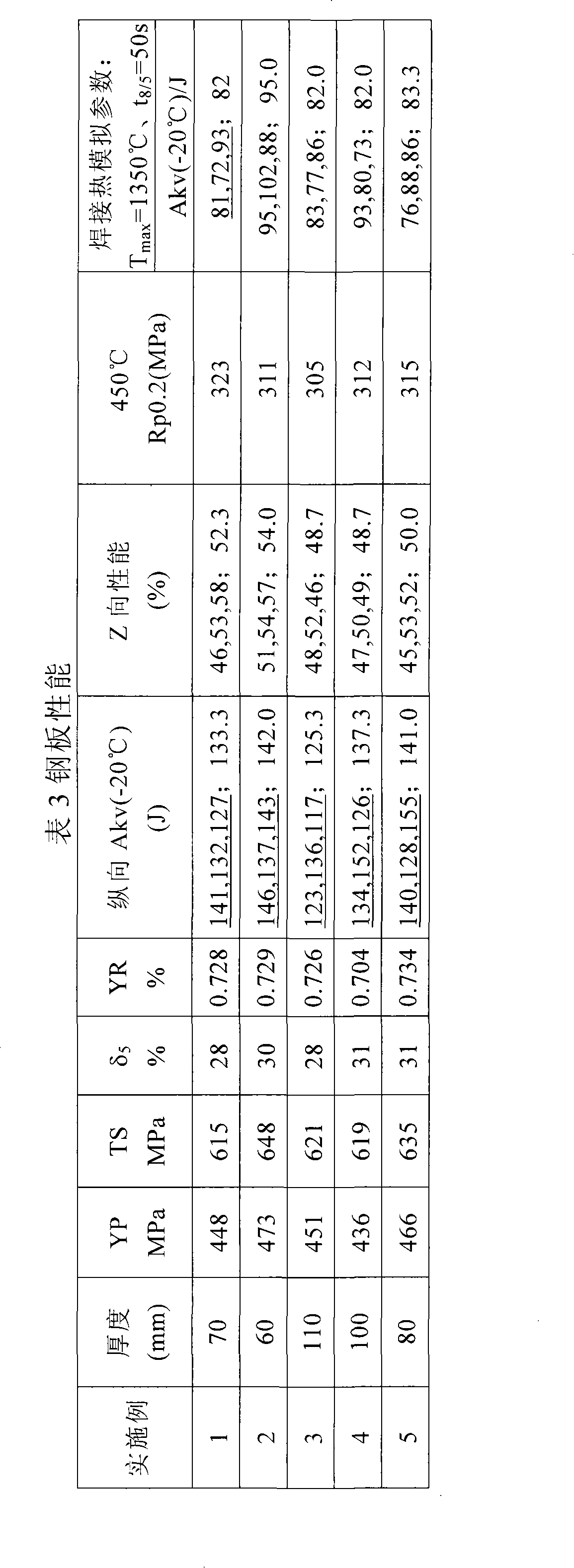

Super-thick steel plate with obdurability matching and excellent high-temperature performance and manufacturing method thereof

ActiveCN101613840AExcellent fatigue and creep resistanceExcellent resistance to temper embrittlementFurnace typesMetal rolling arrangementsEquivalent weightHeat treated

The invention relates to a super-thick steel plate with obdurability matching and excellent high-temperature performance and a manufacturing method thereof. The method comprises the following steps: adopting a component system of low alloy steel with medium C, high Mn and medium N as a basis; properly improving the acid soluble Als content in the steel and controlling the range of the content; controlling the ratio of Mn equivalent weight to C to between 10 and 20; alloying Cu, Ni, Cr, Mo and V; performing Nb and ultromicro Ti treatment, wherein the ratio of Nb to Ti is more than or equal to 1.50; performing Ca treatment, wherein the ratio of Ca to S is between 1.00 and 3.00; and optimizing the process of controlled rolling and subsequent heat treatment, thus the super-thick steel plate obtains excellent obdurability matching, exhaustion creep resistance, temper embrittlement resistance and welding manufacturability, in particular to excellent exhaustion creep resistance for a welding joint, and is particularly suitable to serve as a heat resistant pressure vessel body.

Owner:BAOSHAN IRON & STEEL CO LTD

Steel plate for ship structure and manufacture method thereof

InactiveCN102212750AReasonable chemical composition designSimple production process controlSteel platesSheet steel

The invention discloses a steel plate for a ship structure and a manufacture method thereof. The steel plate for the ship structure comprises the following chemical components in percentage by weight: 0.10%-0.16% of C, 0.20%-0.45% of Si, 1.25%-1.55% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.020%-0.050% of Nb, 0.010%-0.020% of Ti, 0.030%-0.070% of V, 0.20%-0.40% of Ni, 0.015%-0.050% of Als, and the balance of Fe and unavoidable impurities, wherein Als is aluminum soluble in acid. According to the invention, the steel plate can be used for ships or offshore oil platforms; the steel plate is simple in component design and good and steady in performance and also has a good welding performance; and simultaneously, a preparation process is simple and is easy to operate.

Owner:LAIWU IRON & STEEL GRP

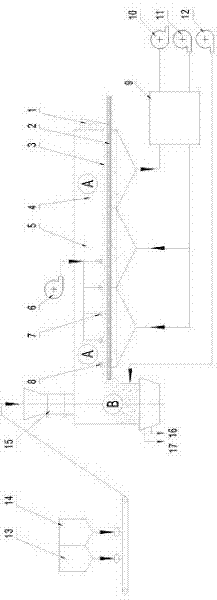

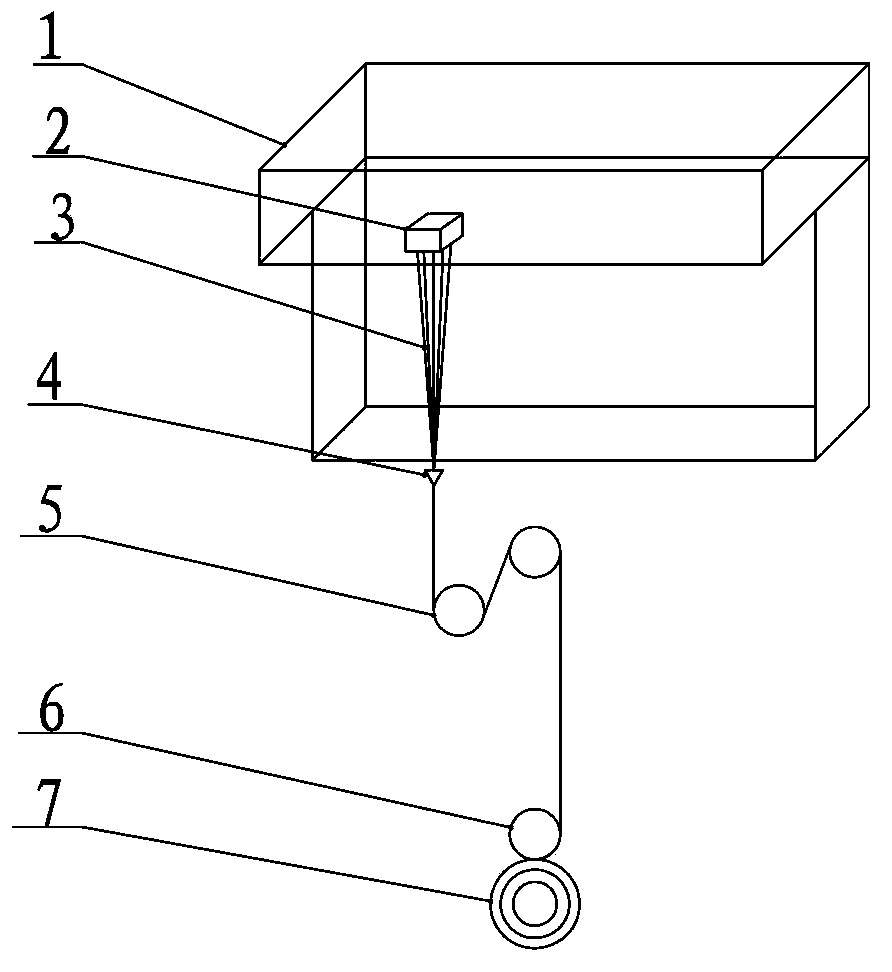

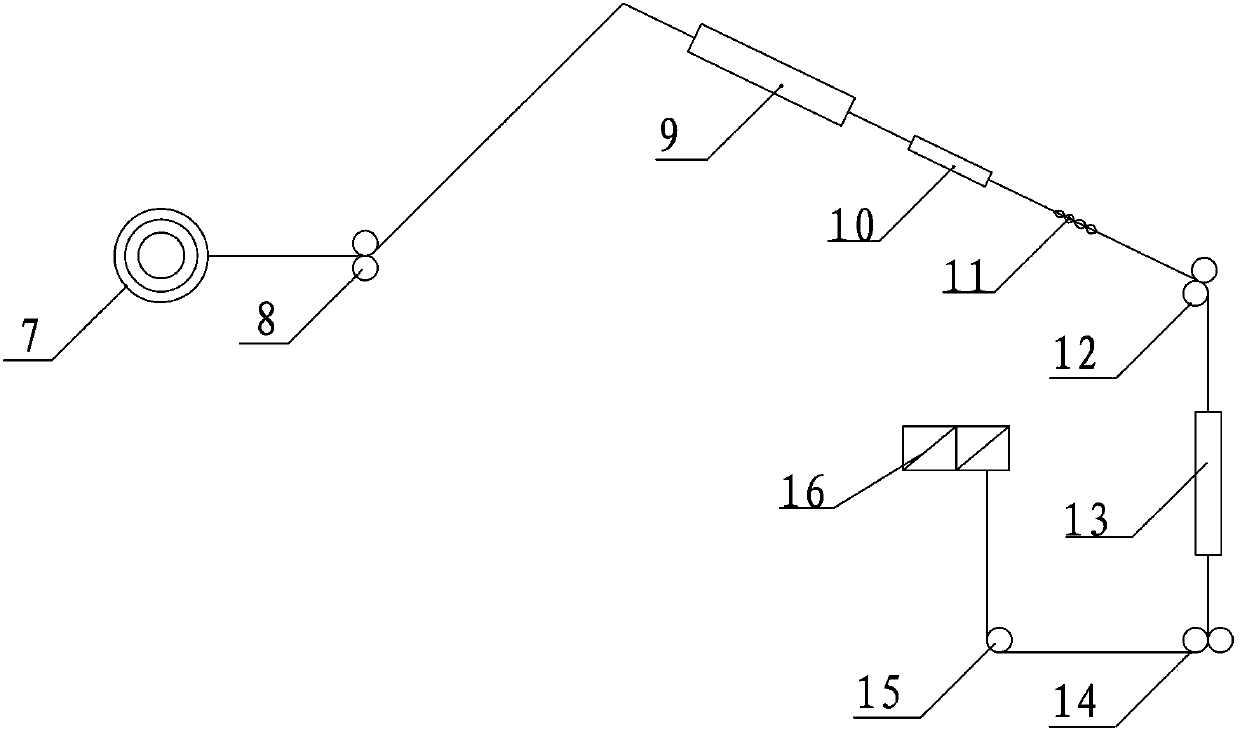

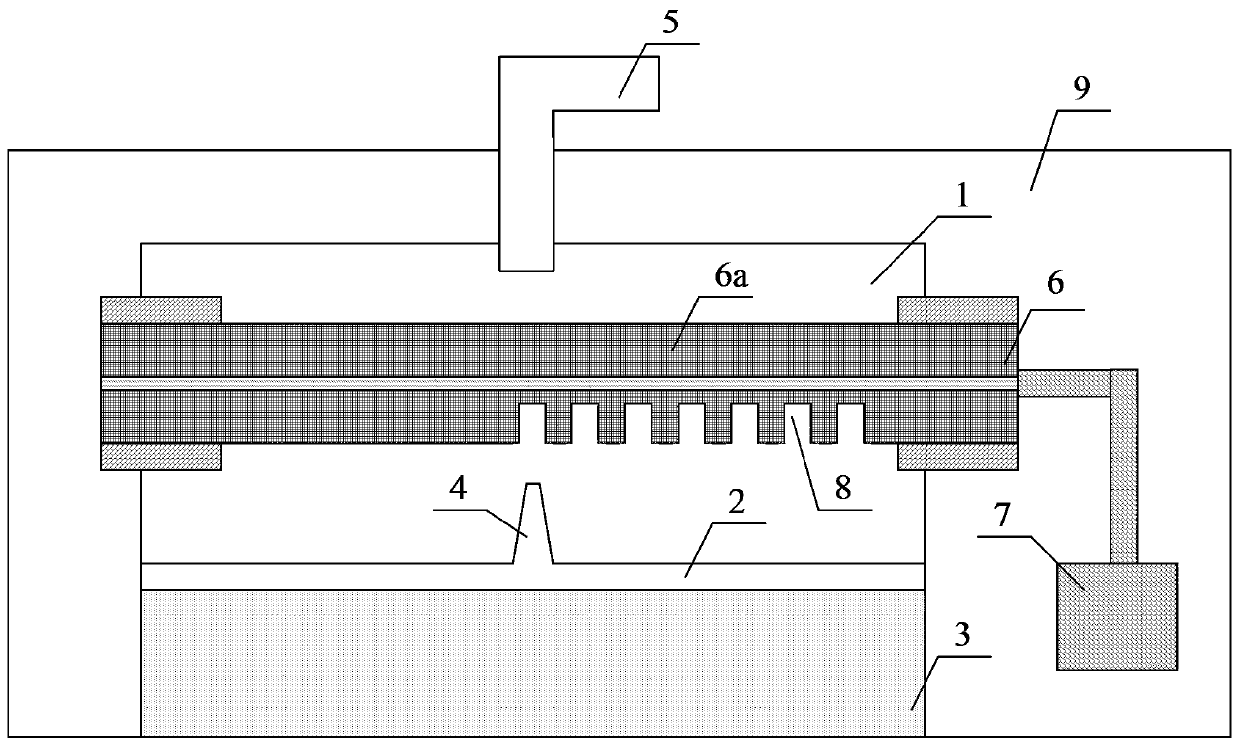

Continued ironmaking device based on melting reduction

The invention relates to a continued ironmaking device based on melting reduction of iron oxide containing carbon iron oxide balling (blocks). In the invention, the device is a continued ironmaking device based on melting reduction and can carry out continual tapping by pre-reducing furnace burden (3) through continually adding the furnace burden (3), extracting air, preheating, blasting and carrying out downstream roasting, and directly conveying the pre-reduced furnace burden (3) into a smelting-separating furnace (B) for continuous smelting-separation; a preheat area (4), a roasting area (5) and the smelting-separation areas behind the preheat area and the roasting area form a connected hearth; a combustion-supporting burner (8) and a secondary tuyere (7) are arranged also; preferably, the high-temperature coat gas generated in the smelting-separation area is subjected to secondary combustion in a pre-reduced furnace (A) for preheating and roasting the furnace burden (3); then the furnace burden (3) is discharged into the smelting-separation area for the further reduction, carburization and melting to separate the slag and iron; in the preheated area (4), the fuse passes through a bed of material to directly heat the furnace burden (3), and then the fuse enters a heat exchanging device (9) and a fuse process system; and a fan blasts the cool air below the bed into a hearth bottom (2) through the heat exchange device (9). The device has the advantages of short flow, reduced energy consumption, low carbon emission, low production cost, simple equipment, less occupied space, less investment and short building period.

Owner:李振洪

Ultra-thick high temperature-resistant steel for pressure vessel and preparation method thereof

ActiveCN102094150AProportion design is reasonableIncrease productivityTemperature control deviceMetal rolling arrangementsChemical compositionMetallurgy

The invention relates to an ultra-thick high temperature-resistant steel for a pressure vessel and a preparation method thereof. After smelting and refining, the steel is subjected to continuous casting, hot rolling, normalizing and tempering. The steel comprises the following controlled chemical components in percentage by mass: 0.08-0.15% of C, 0.15-0.40% of Si, 0.40-0.70% of Mn, 0.90-1.20% of Cr, 0.15-0.30% of V, 0.25-0.35% of Mo, at most 0.025% of P, at most 0.010% of S and the balance of Fe and inevitable inclusions. The preparation method provided by the invention comprises the steps of smelting, heating, rough rolling, finish rolling, normalizing and tempering. The invention has the characteristics of appropriate design and proportion of the chemical components, simple manufacturing process, large thickness dimension (80mm), good heat resistance, stable product performance and the like.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

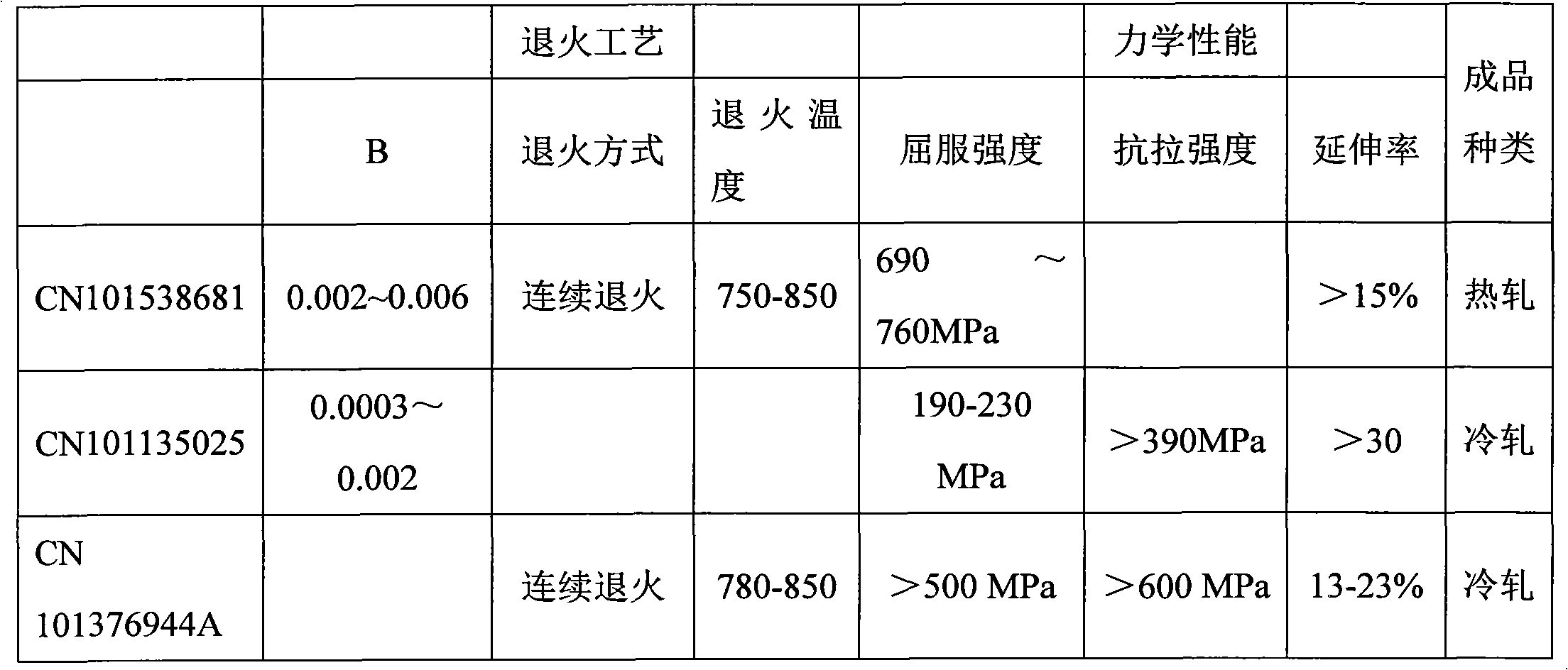

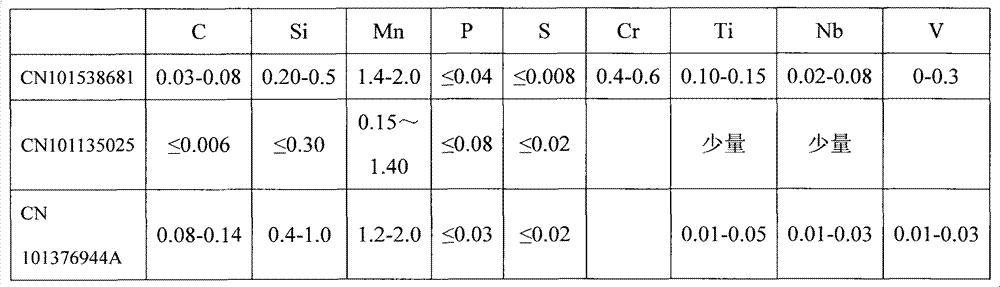

High-strength cold-rolled steel sheet with yield strength level of 700MPa and manufacturing method thereof

InactiveCN101956139AHigh standardAbundant resourcesFurnace typesHeat treatment furnacesSheet steelMolten steel

The invention provides a high-strength cold-rolled steel sheet with the yield strength level of 700MPa and a manufacturing method thereof. The method comprises a thin stab casting and rolling flow, a cold rolling flow, an annealing flow, a finishing flow and the like. Refined molten steel comprises the following main chemical components: 0.03 to 0.07 weight percent of C, less than or equal to 0.35 weight percent of Si, 0.40 to 2.0 weight percent of Mn, less than or equal to 0.020 weight percent of P, less than or equal to 0.010 weight percent of S, 0.25 to 0.80 weight percent of Cr, 0.06 to 0.25 weight percent of Ti and the balance of Fe and inevitable residual elements. In the annealing process, the steel is annealed in a hood-type annealing furnace in the temperature range of 500 DEG C to an A1 transition point. The manufactured high-strength cold-rolled steel sheet with the yield strength level of 700MPa has the advantages of low alloy element cost, single component, the yield strength of higher than 700MPa, the elongation rate of over 5 percent, high machinability and the like.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Preparation method of light mullite brick

The invention relates to a preparation method of a light mullite brick, belonging to the field of refractory material. The light mullite brick consists of main material and filler, the main material contains the following raw materials by weight percent: 20-50 wt% of kaolin, 15-35 wt% of fine powder of calcined coal gangue and 20-50 wt% of fine powder of recycled material, and the filler contains the following raw materials by weight percent: 15-61 wt% of coal dust, 3-28 wt% of polystyrene globule, 8-30 wt% of sawdust and 5-32 wt% of waste paper pulp. The raw materials are simple in category and low in costs. The preparation method adopts the optimum scheme applying the filler, so the production process is simpler and easier to control. The coal dust and the paper pulp are added, so the cost of the fuel is reduced, and the service performance of the finished light mullite brick is ensured. The light mullite brick prepared through the method reaches the minimum volume density of 0.4g / cm<3> and the average compressive strength of being equal to or above 1.2 MPa, and the heat conductivity coefficient of the light mullite brick under at 350 DEG C is less than 0.15w / m.k.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

Production method of ammonium iodide

ActiveCN1751998ALow requirements for production equipmentSimple production process controlAmmonium halidesDicarbonateIodine

A process for preparing ammonium iodide from iodine, Fe powder, and dicarbonate includes such steps as preparing ferrous iodide, reaction between ferrous iodide and dicarbonate to obtain ferrous carbonate, ammonium iodide, CO2 and water, separating ammonium iodide, removing SO4 radical, filtering, concentracting, and crystallizing. Its advantage is low corrosion to productive apparatus.

Owner:自贡市金典化工有限公司

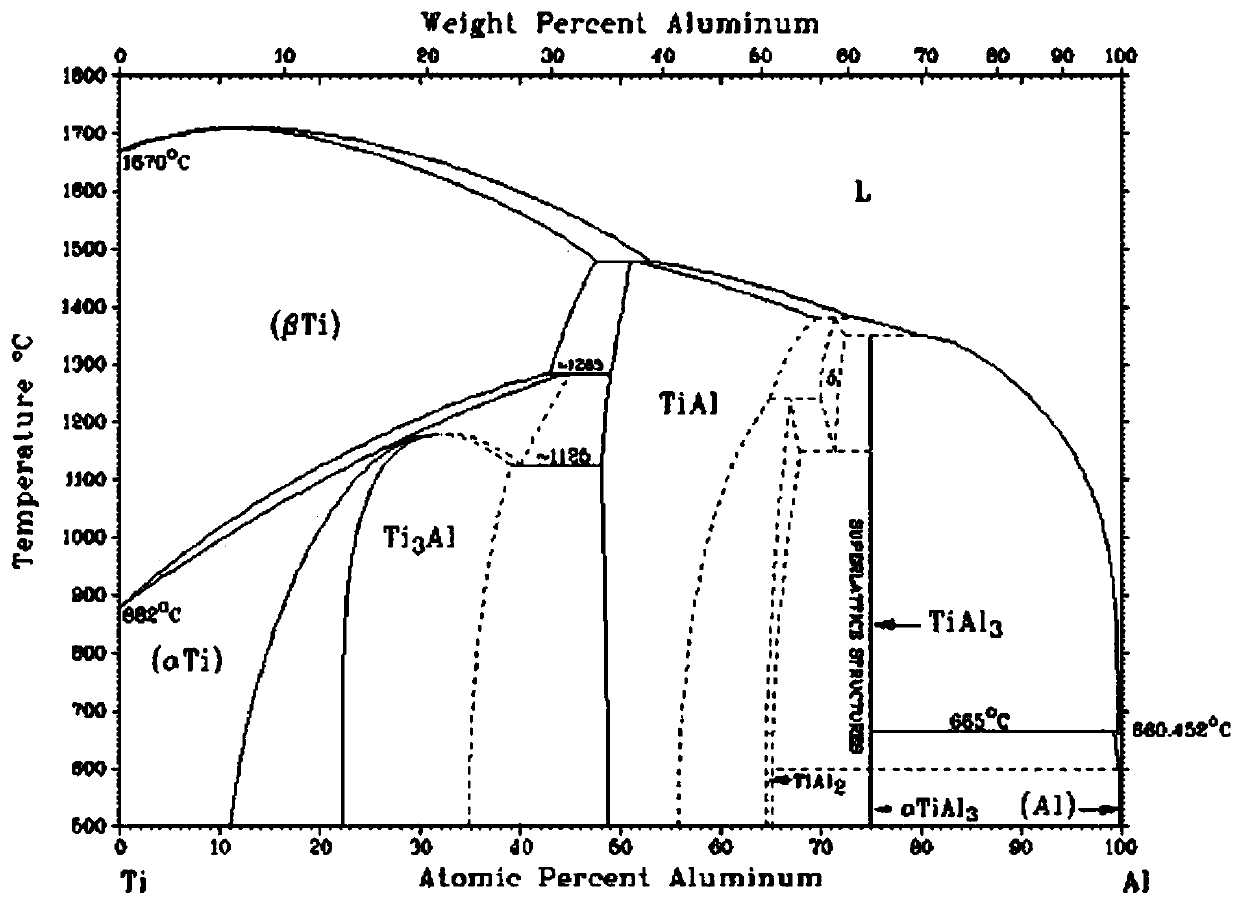

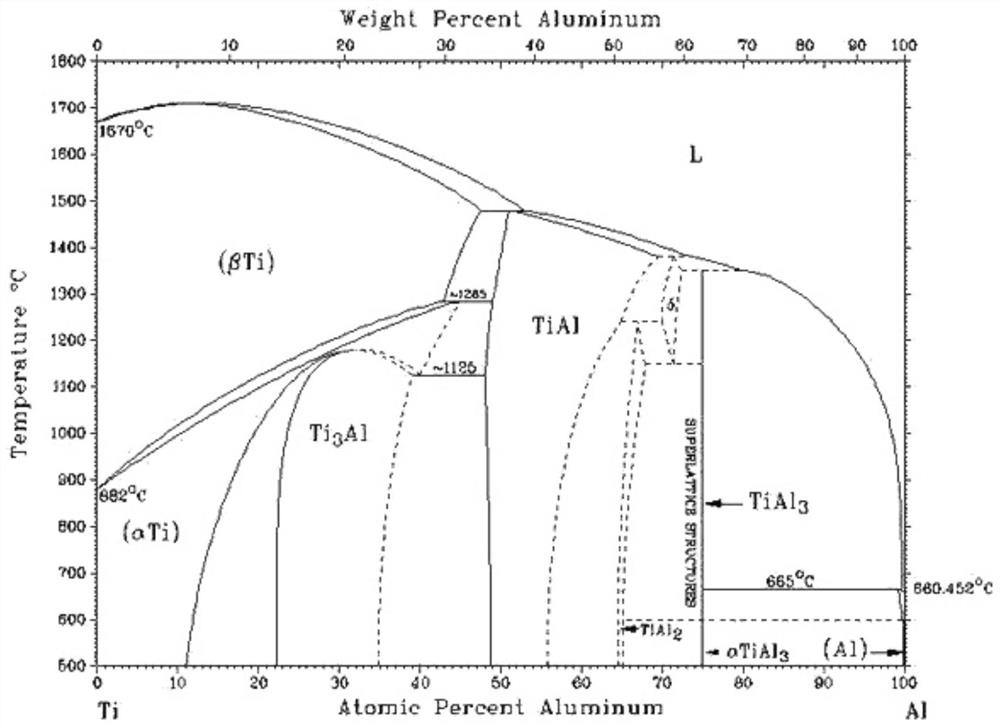

Preparation method of titanium-aluminum alloy target material

ActiveCN111101105AReduce manufacturing costSimple production process controlTransportation and packagingMetal-working apparatusTitaniumHot isostatic pressing

The invention discloses a preparation method of a titanium-aluminum alloy target material. The preparation method comprises a powder mixing step, a filling step, a cold isostatic pressing step, a welding sheath degassing step, a hot isostatic pressing step, a slitting step, an alloying diffusion heat treatment step and a machining finishing step. The preparation method is simple in control, low inprocessing cost and high in processing efficiency.

Owner:东莞市欧莱溅射靶材有限公司

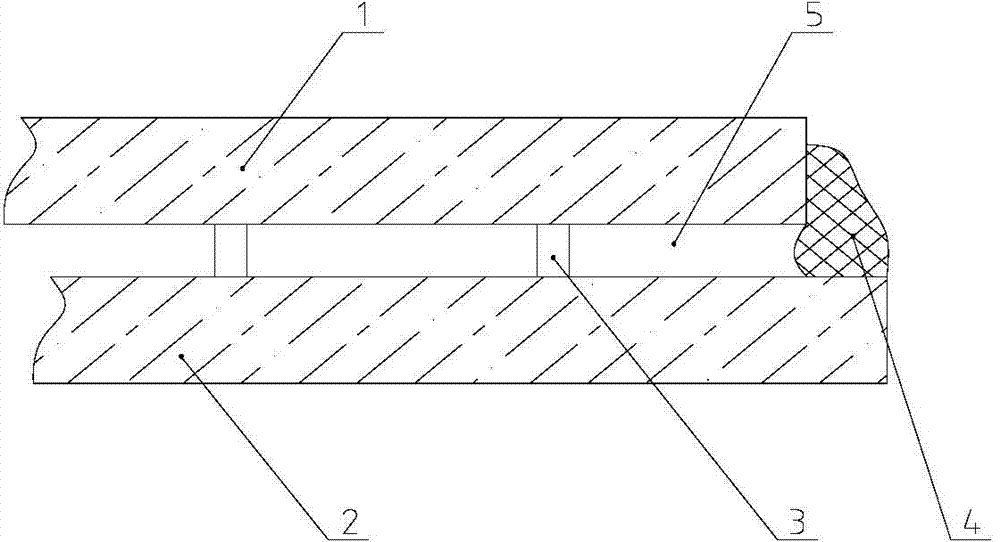

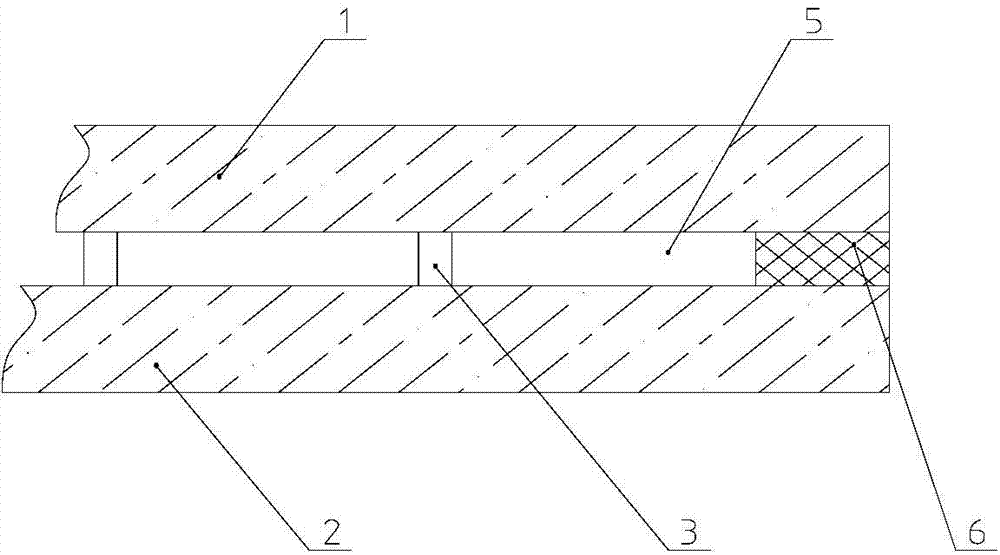

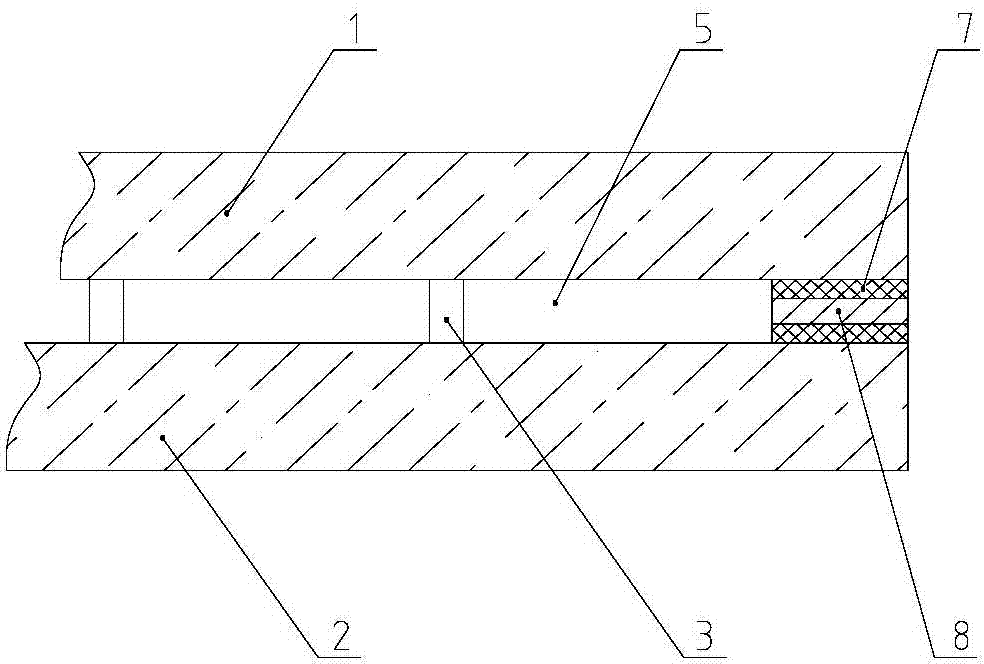

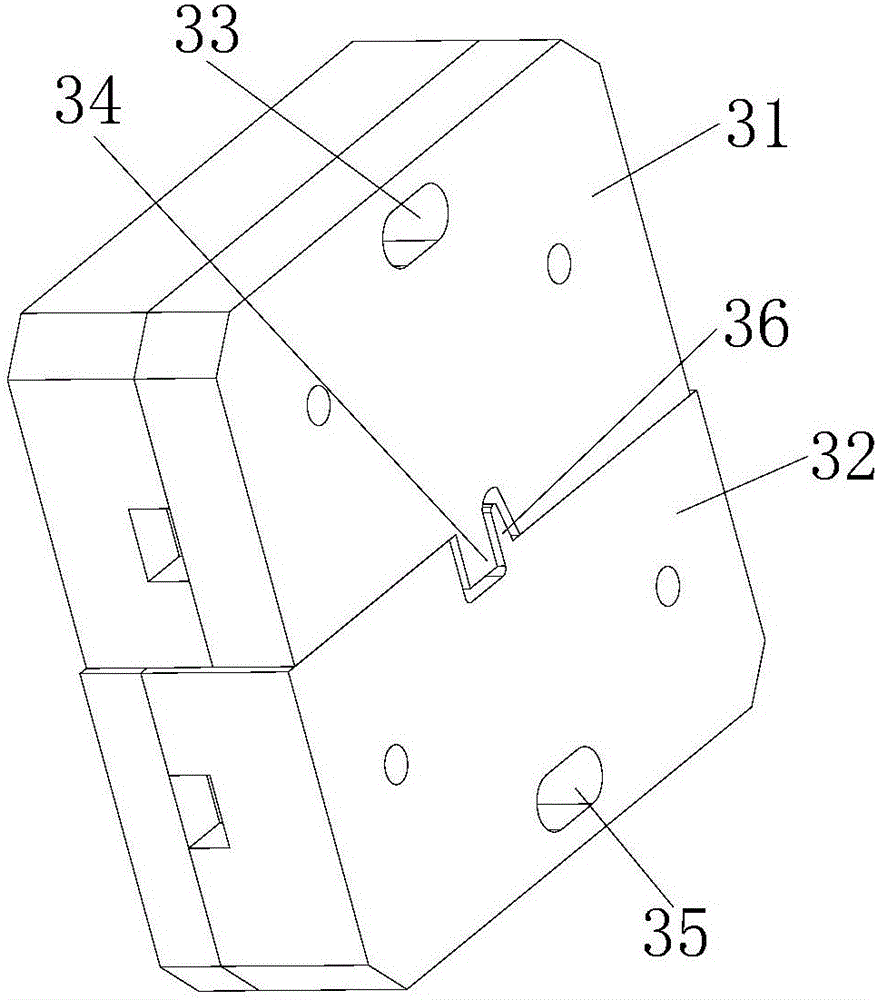

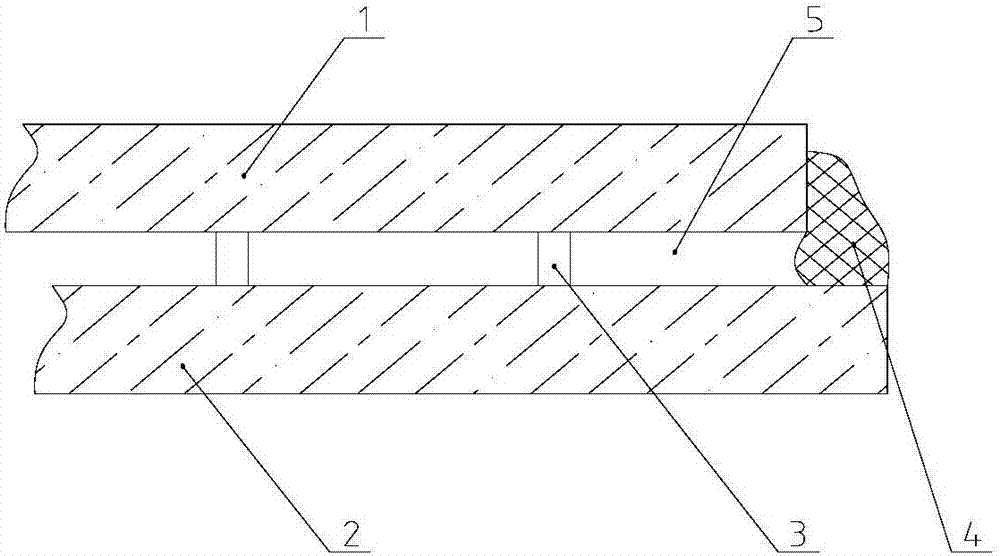

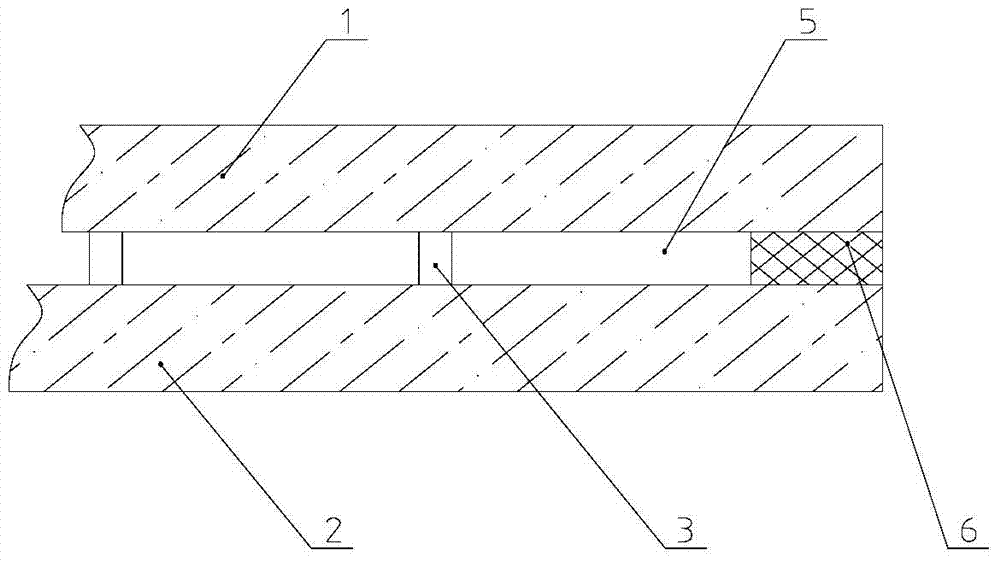

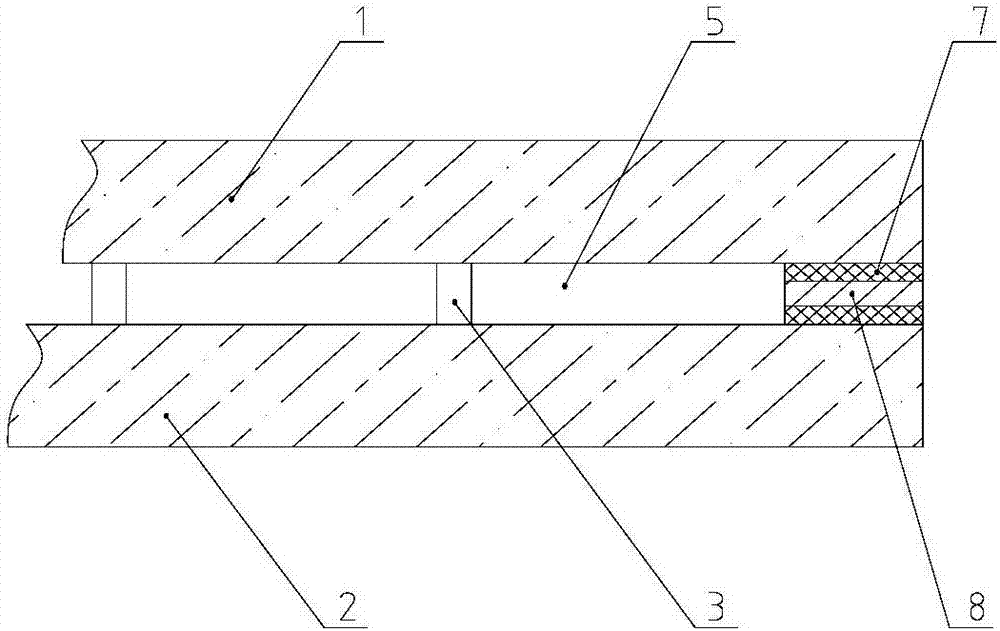

Vacuum glass sealing and connecting structure, semi-finished product of vacuum glass sealing and connecting structure, and sealing and connecting method of vacuum glass sealing and connecting structure

The invention provides a vacuum glass sealing and connecting structure, a semi-finished product of the vacuum glass sealing and connecting structure, and a sealing and connecting method of the vacuum glass sealing and connecting structure. According to the sealing and connecting method, one surface of a metal strap material is coated with a glass powder slurry, and the surface is bonded with the peripheral surface, to be sealed and connected, of each glass plate; connection as a whole body is realized via heating melting; and the metal strap material on the adjacent glass plates is laminated, and is connected as a whole body via connection and airtight welding. According to the vacuum glass sealing and connecting structure, the periphery surface, to be sealed and connected, of each glass plate is connected with the metal strap material via glass powder slurry heating melting, so that the metal strap material on the adjacent glass plates is laminated, and is connected and subjected to airtight welding According to the vacuum glass sealing and connecting structure, infiltrating characteristics of the glass powder slurry and bonding performance under fusion states are used fully; easy welding characteristics of metal material is used fully; and flow line production of vacuum glass with tempered glass and semi-tempered glass is realized.

Owner:LUOYANG NORTHGLASS TECH +1

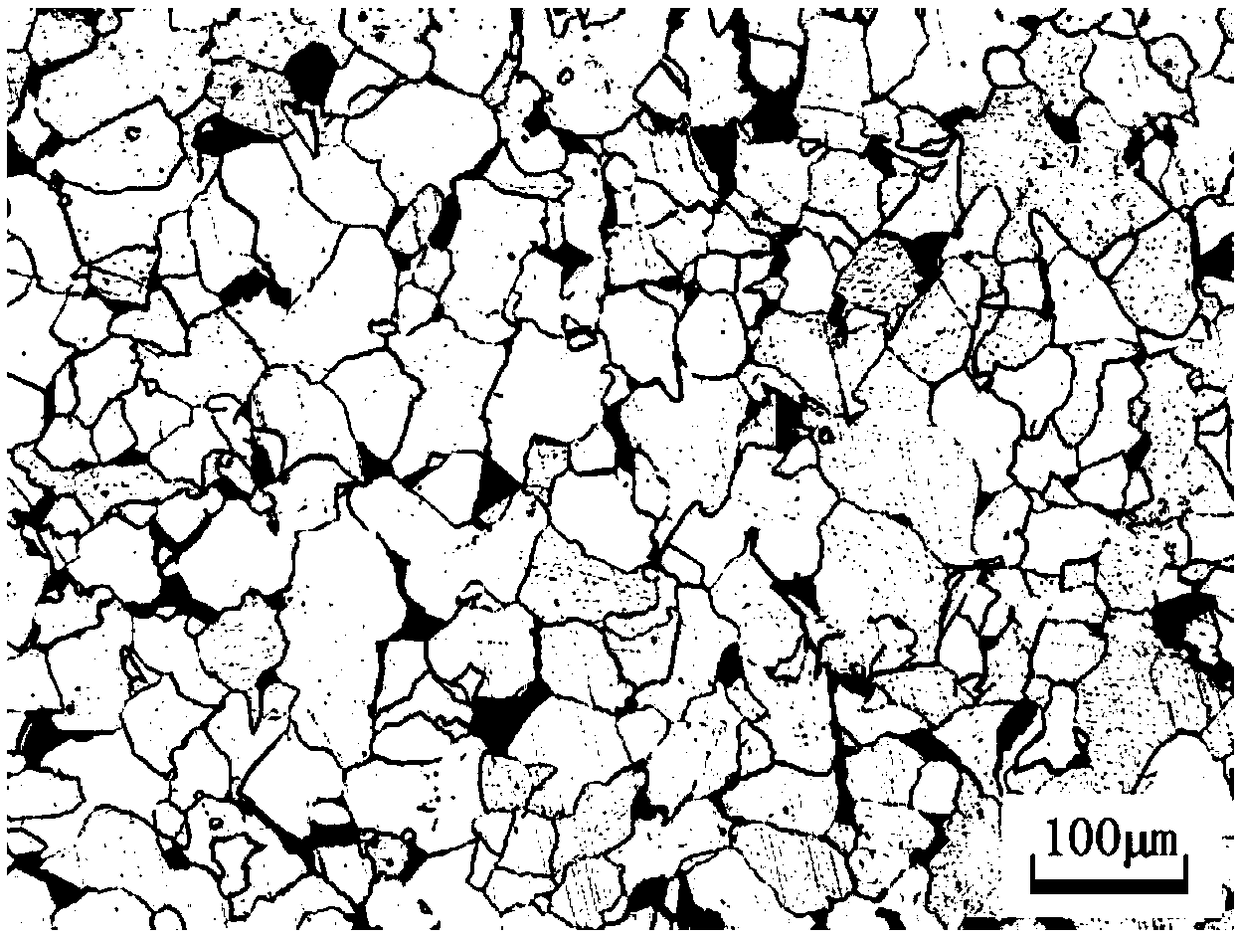

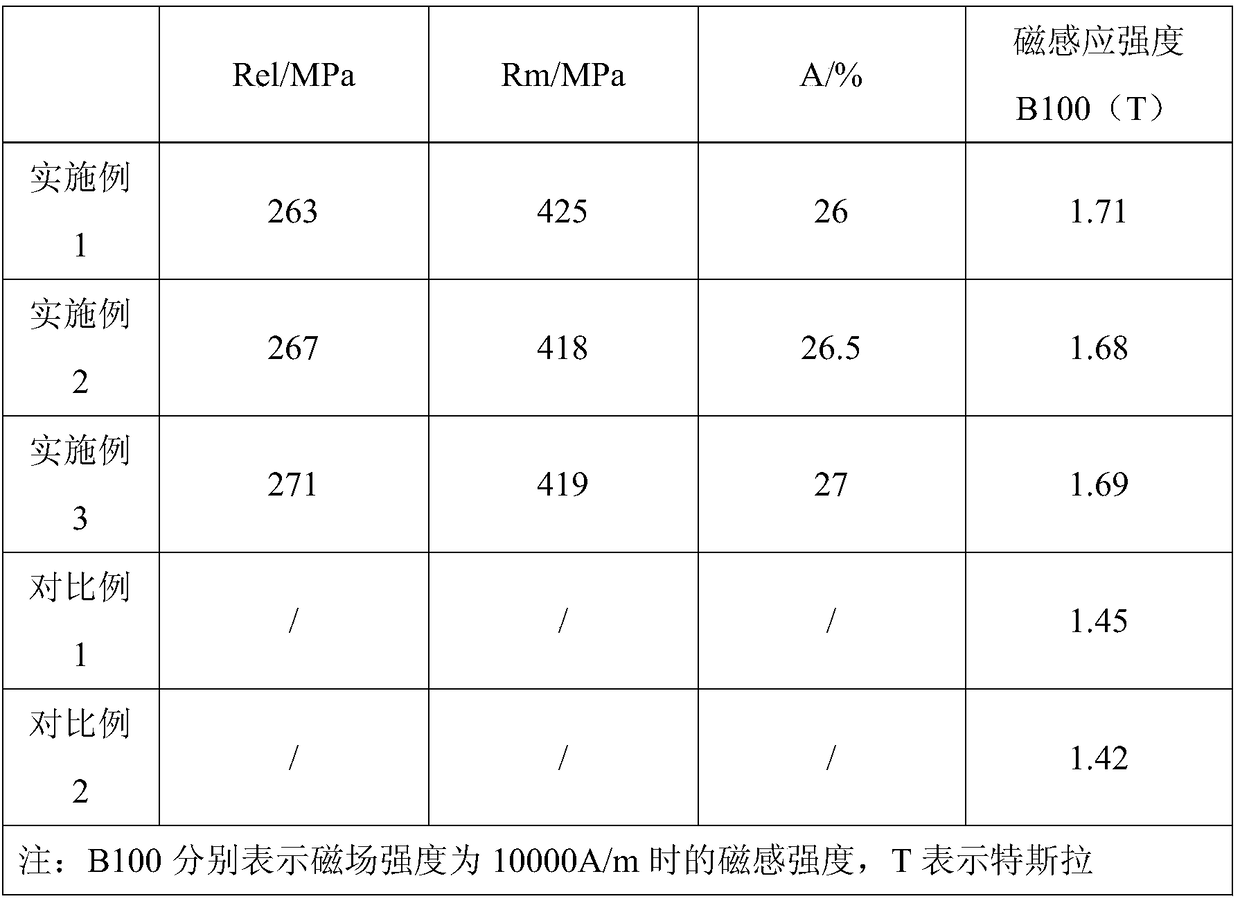

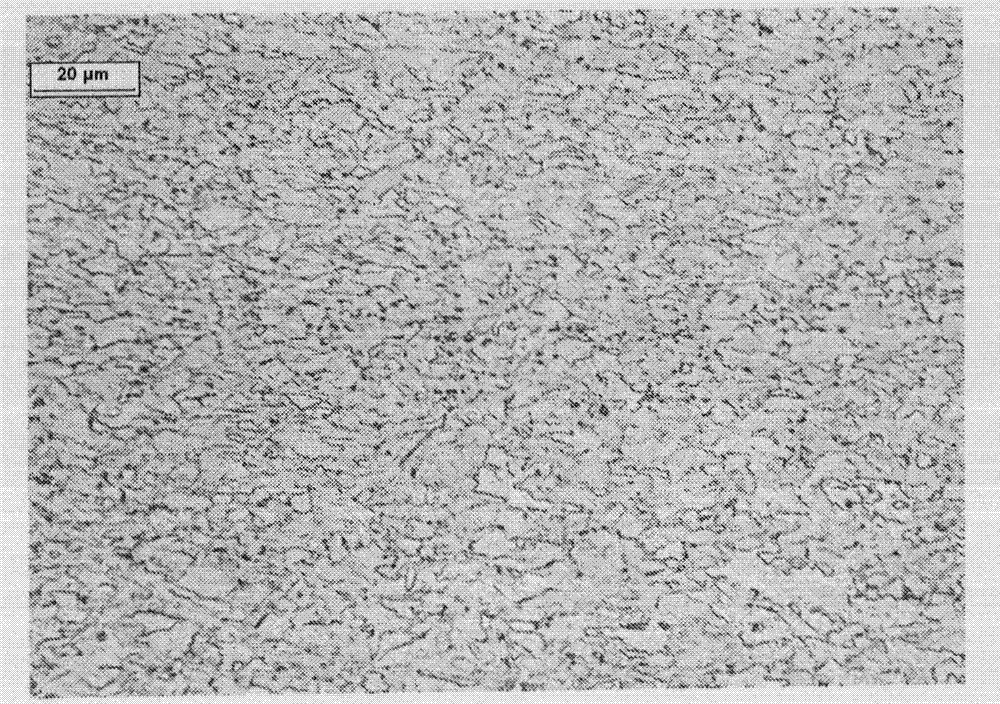

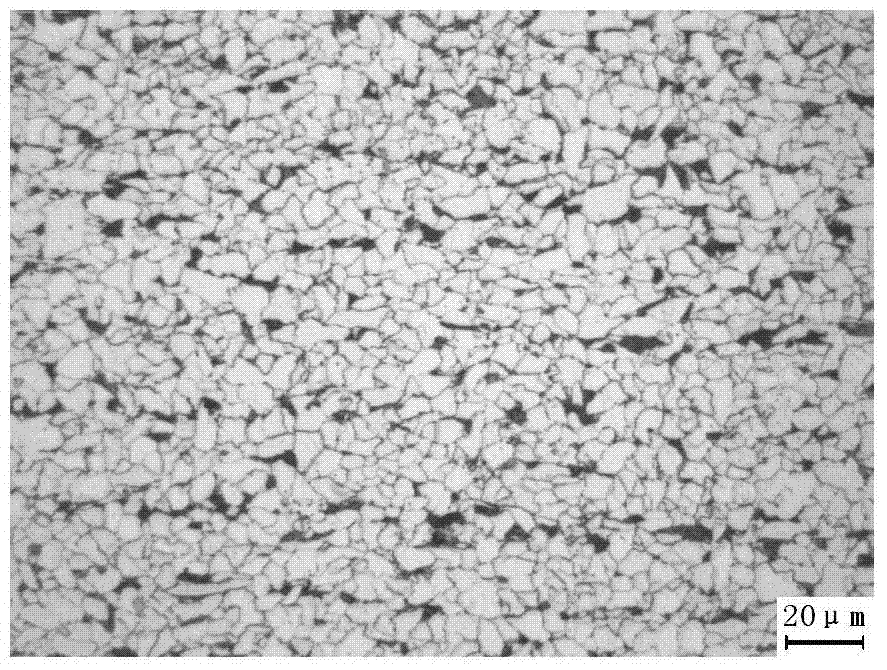

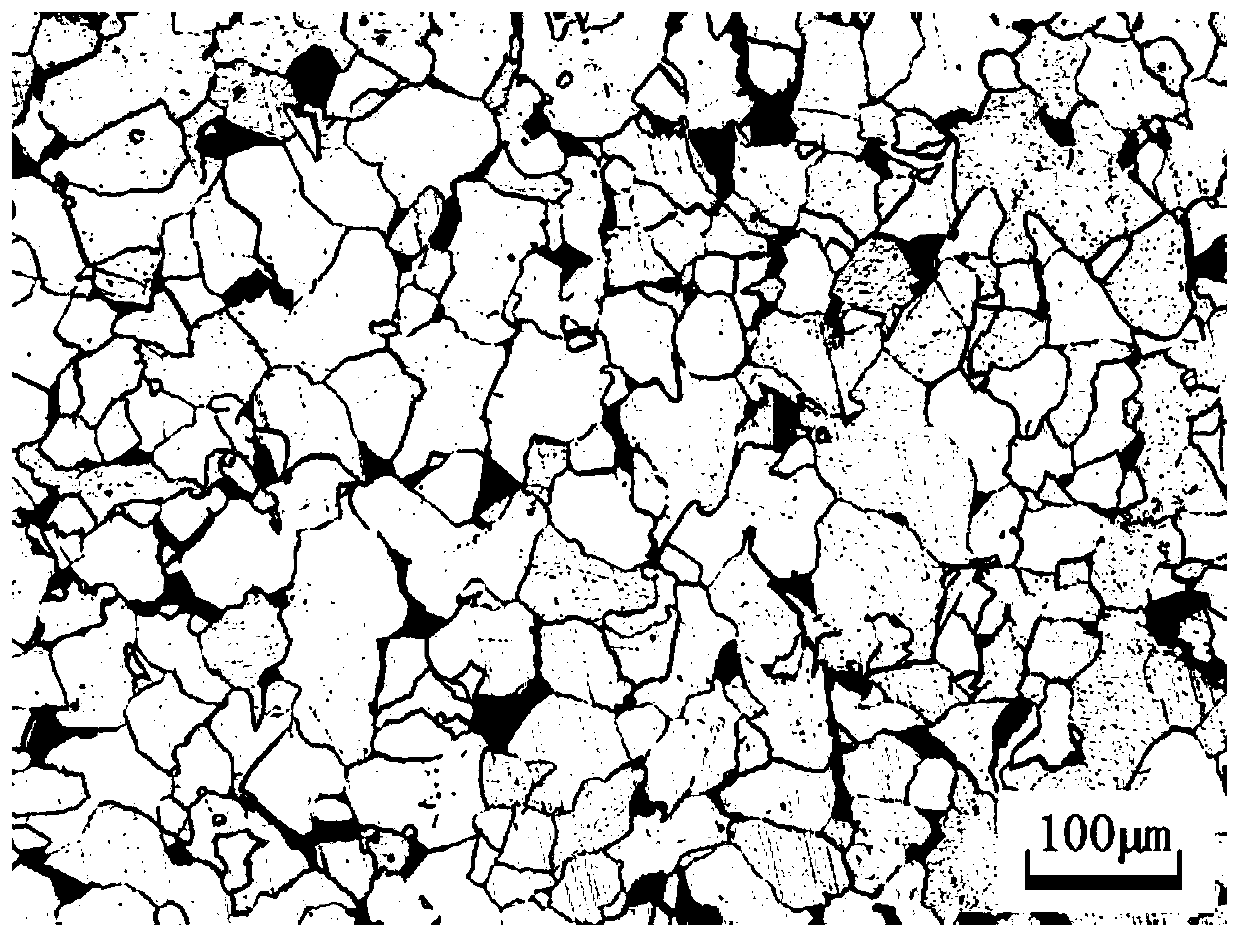

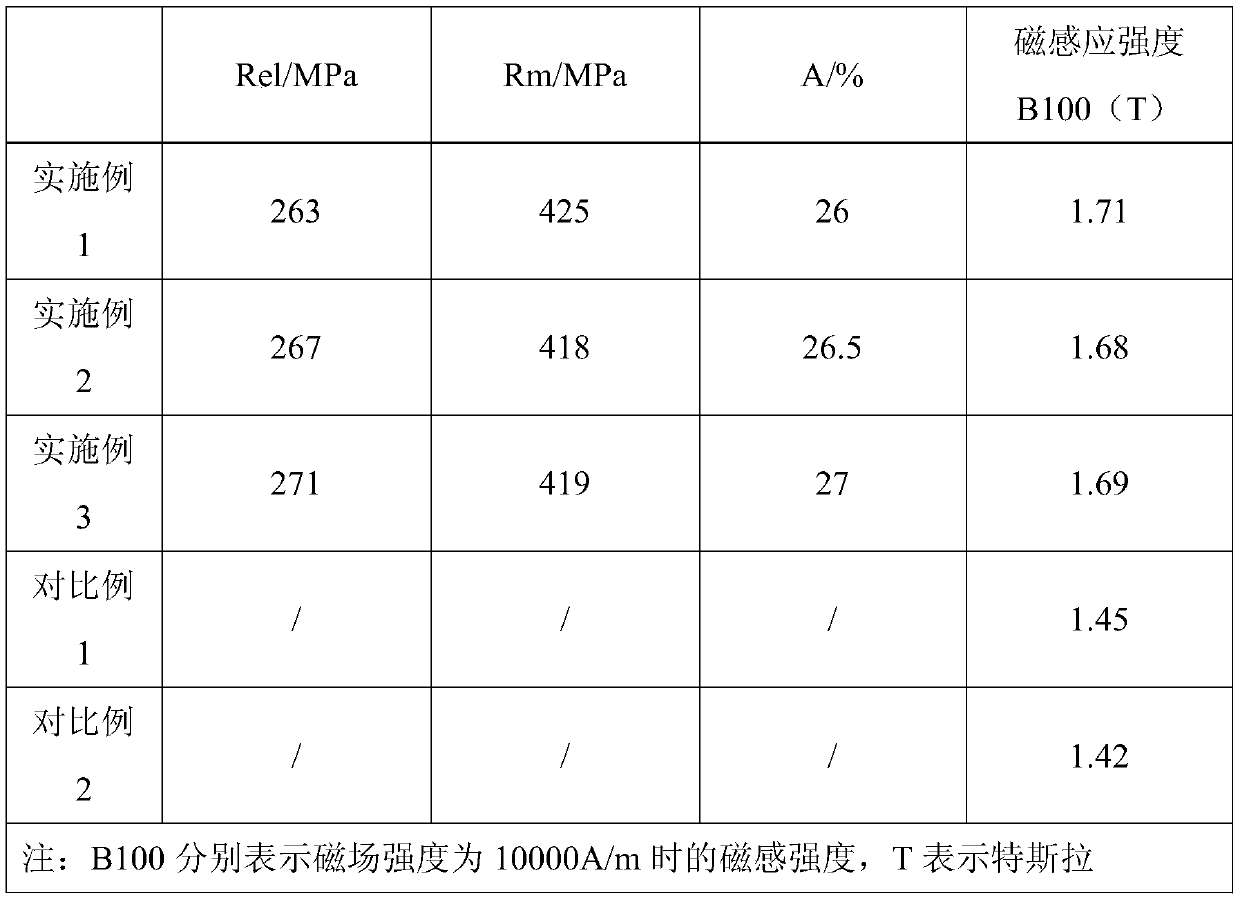

F-shaped steel for magnetic levitation rails with high magnetic flux density and production method thereof

The invention discloses F-shaped steel for magnetic levitation rails with high magnetic flux density and a production method thereof. The F-shaped steel contains the following components by weight percent: 0.04-0.07% of C, 0.08-0.20% of Si, 0.5-0.8% of Mn, less than or equal to 0.015% of P, less than or equal to 0.015% of S, 0.015-0.030% of Nb, 0.03-0.05% of Als and the balance of Fe and impurityelements. According to the invention, the F-shaped steel for magnetic levitation rails with high magnetic flux density and excellent mechanical properties is acquired in the manner of designing steelcomponents, controlling quantity and size of impurity grains in the steel-making process and supplementing by high-temperature quick rolling so as to solidly dissolve alloying elements in steel and accelerate quick growth of crystal grains. According to the invention, the magnetic flux density of F-shaped steel is greatly increased and is 15% higher than that of present F-shaped steel.

Owner:武汉钢铁有限公司

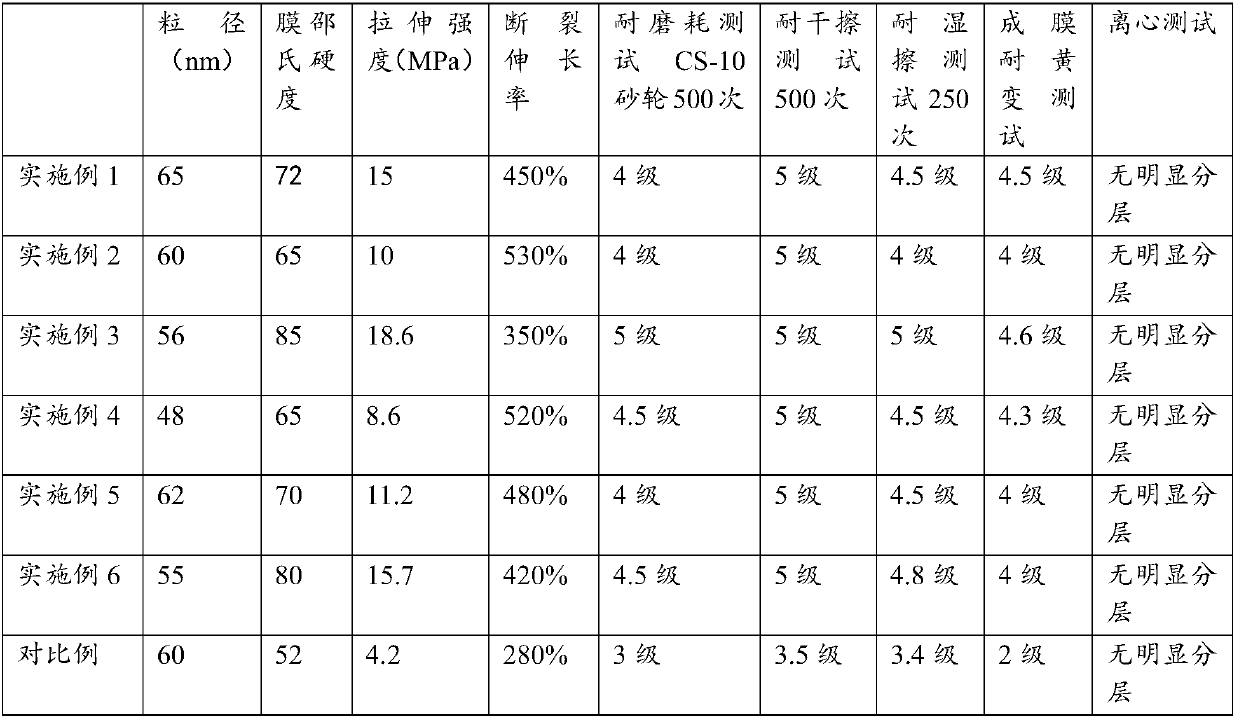

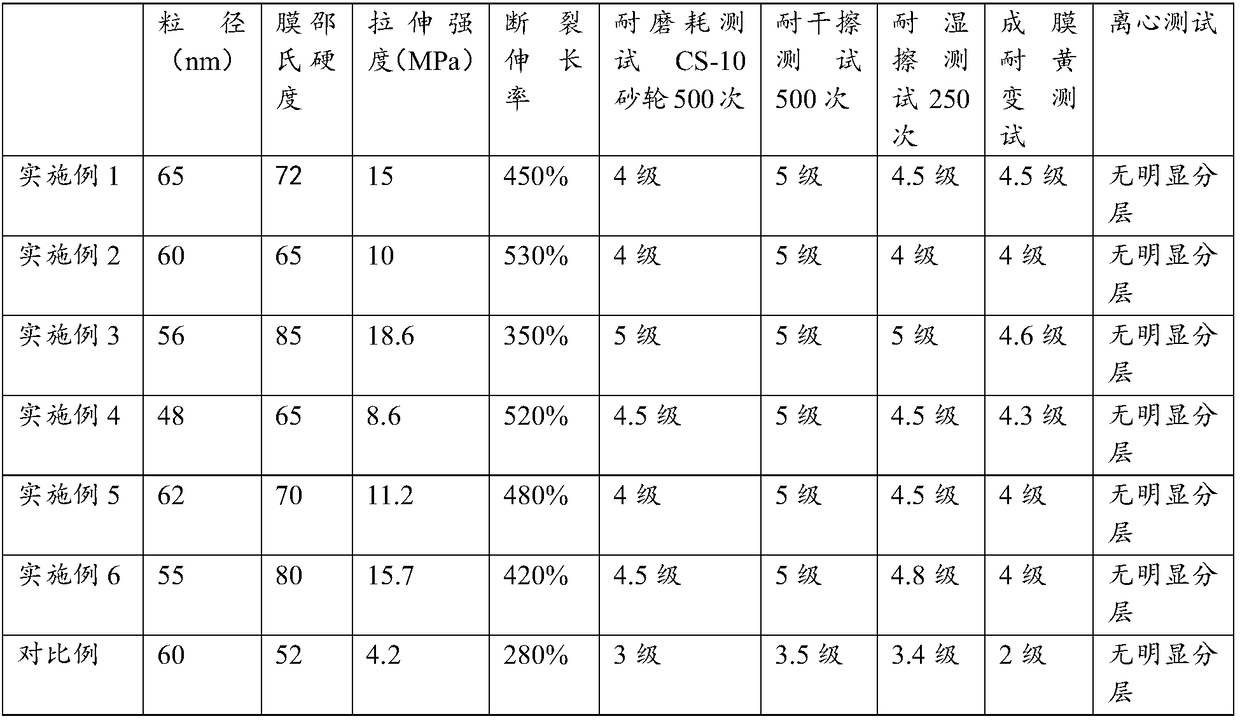

Waterborne polyurethane and preparation method and application thereof

ActiveCN107857869AIncrease softnessDoes not affect viscosityPolyurea/polyurethane coatingsLeather surface finishingHydrophilic monomerCross-link

The invention relates to the field of macromolecular materials and particularly relates to waterborne polyurethane and a preparation method and application thereof. The preparation method comprises the steps: subjecting an HDI trimer or IPDI trimer to a polymerization reaction with polyethylene glycol, then, subjecting the product to a reaction with hexamethylene diisocyanate or isophorone diisocyanate so as to form an isocyanate terminated tri-functionality polymer, and regulating the viscosity of the isocyanate terminated tri-functionality polymer with acetone; subjecting HDI or IPDI to a reaction with a binary alcoholic monomer and a hydrophilic monomer so as to obtain a linear aqueous polyurethane prepolymer, and regulating the viscosity of the linear aqueous polyurethane prepolymer with acetone; subjecting the isocyanate terminated tri-functionality polymer and the linear aqueous polyurethane prepolymer to a cross-linking reaction under the action of a chain extender, and removingthe acetone, thereby obtaining the waterborne polyurethane. After the waterborne polyurethane prepared by the preparation method forms a film, the softness is relatively good, finished, compliant andsoft surface touch feeling of leather is achieved, and meanwhile, the physical properties are relatively good.

Owner:达威水基聚氨酯(上海)有限公司

Method for preparation of light wall material

InactiveCN101116999AReduce dosageReduce moisture contentMouldsMixing operation control apparatusFoaming agentSlurry

The invention provides a manufacturing method of light wall material, according to the invention, 30-50 shares of portland cement, 2-5 shares of fibre, 60-100 shares of perlite, 10-20 shares of powder coal ash, 1-4 shares of additive and 50-100 shares of water should be mixed and stirred evenly as material slurry, 4-14 shares of vesicant should be put in, the slurry should be stirred evenly and poured in moulds, then be solidified, ejected and maintained to form the light wall material. The invention is characterized in easy getting of the material from market, especially for the adopting of Portland cement, which is capable of being gotten expediently anywhere, thereby reducing the cost greatly.

Owner:钱周炯

High-strength cold-rolled steel sheet with yield strength level of 700MPa and manufacturing method thereof

InactiveCN101956139BAbundant resourcesLow priceFurnace typesHeat treatment furnacesSheet steelMolten steel

The invention provides a high-strength cold-rolled steel sheet with the yield strength level of 700MPa and a manufacturing method thereof. The method comprises a thin stab casting and rolling flow, a cold rolling flow, an annealing flow, a finishing flow and the like. Refined molten steel comprises the following main chemical components: 0.03 to 0.07 weight percent of C, less than or equal to 0.35 weight percent of Si, 0.40 to 2.0 weight percent of Mn, less than or equal to 0.020 weight percent of P, less than or equal to 0.010 weight percent of S, 0.25 to 0.80 weight percent of Cr, 0.06 to 0.25 weight percent of Ti and the balance of Fe and inevitable residual elements. In the annealing process, the steel is annealed in a hood-type annealing furnace in the temperature range of 500 DEG C to an A1 transition point. The manufactured high-strength cold-rolled steel sheet with the yield strength level of 700MPa has the advantages of low alloy element cost, single component, the yield strength of higher than 700MPa, the elongation rate of over 5 percent, high machinability and the like.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

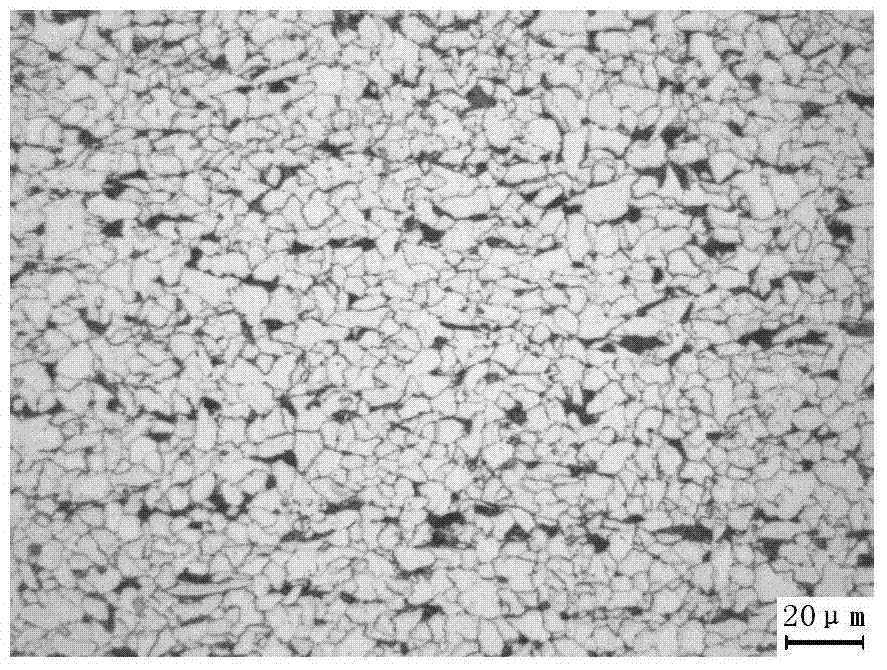

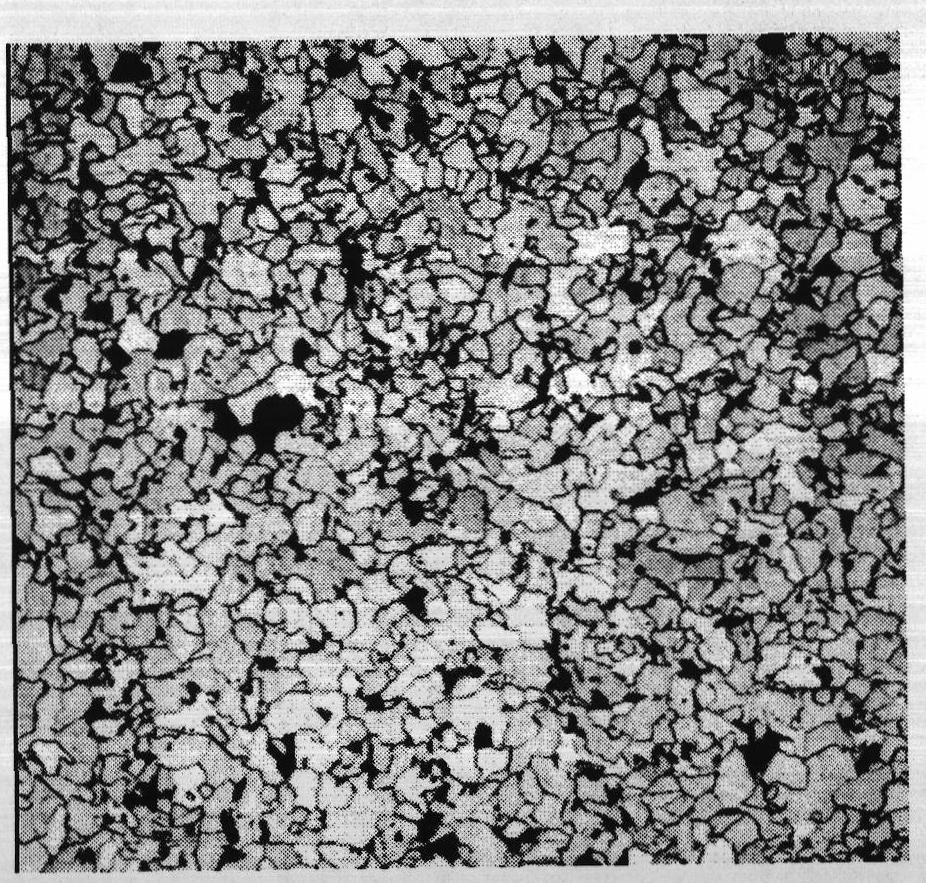

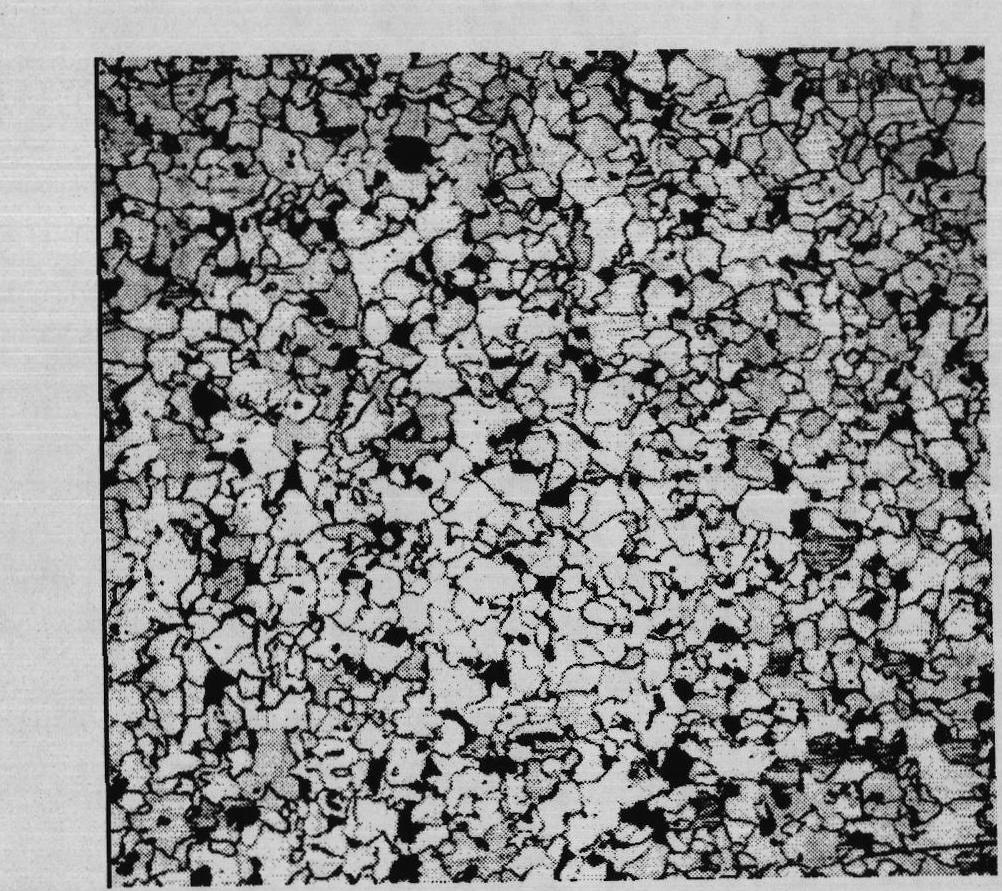

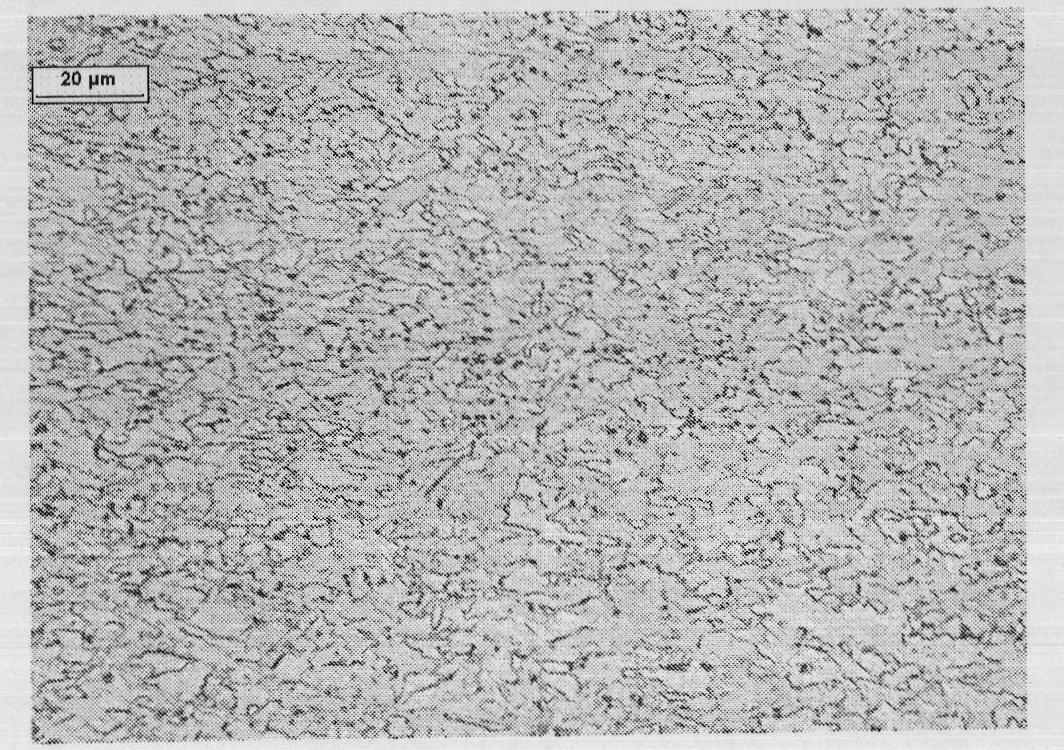

A high-strength hot-rolled steel strip with reduced manganese and improved band structure and its manufacturing method

The invention discloses a high-strength hot rolled steel strip with improved zonal structure by manganese reduction and a manufacturing method thereof. The high-strength hot rolled steel strip comprises the following chemical components in percentage by weight: 0.14-0.17% of C, 0.15-0.35% of Si, 0.40-0.60% of Mn, at most 0.020% of P, at most 0.010% of S, 0.040-0.060% of Ti and 0.020-0.040% of Alt. The manufacturing method comprises the following steps: 1) smelting and continuous casting: smelting molten steel according to preset components, and casting into a continuous casting blank; 2) rolling: the heating temperature is controlled at 1240-1280 DEG C, the holding time is greater than or equal to 180 minutes, the finishing temperature of the recrystallization zone is greater than or equal to 1020 DEG C, and the finishing temperature of the non-recrystallization zone is controlled at 830-870 DEG C; and 3) cooling after rolling: after carrying out hot rolling on the steel strip, cooling to 560-640 DEG C at the cooling rate of 15-30 DEG C / s, coiling, and cooling to room temperature. The invention has the advantage of simple component design; the reduction of Mn content in steel is combined with technical control to improve the zonal structure of the hot rolled steel strip and ensure the zonal structure grade to be at most Grade 2.0, thereby enhancing the cold forming property; and no noble alloy elements are added, so the production cost is lower.

Owner:新余钢铁股份有限公司

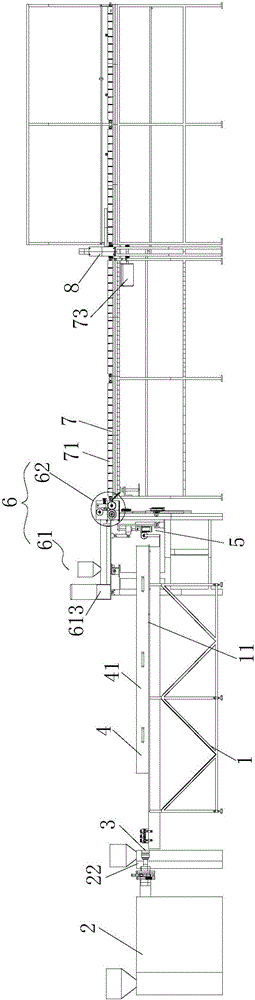

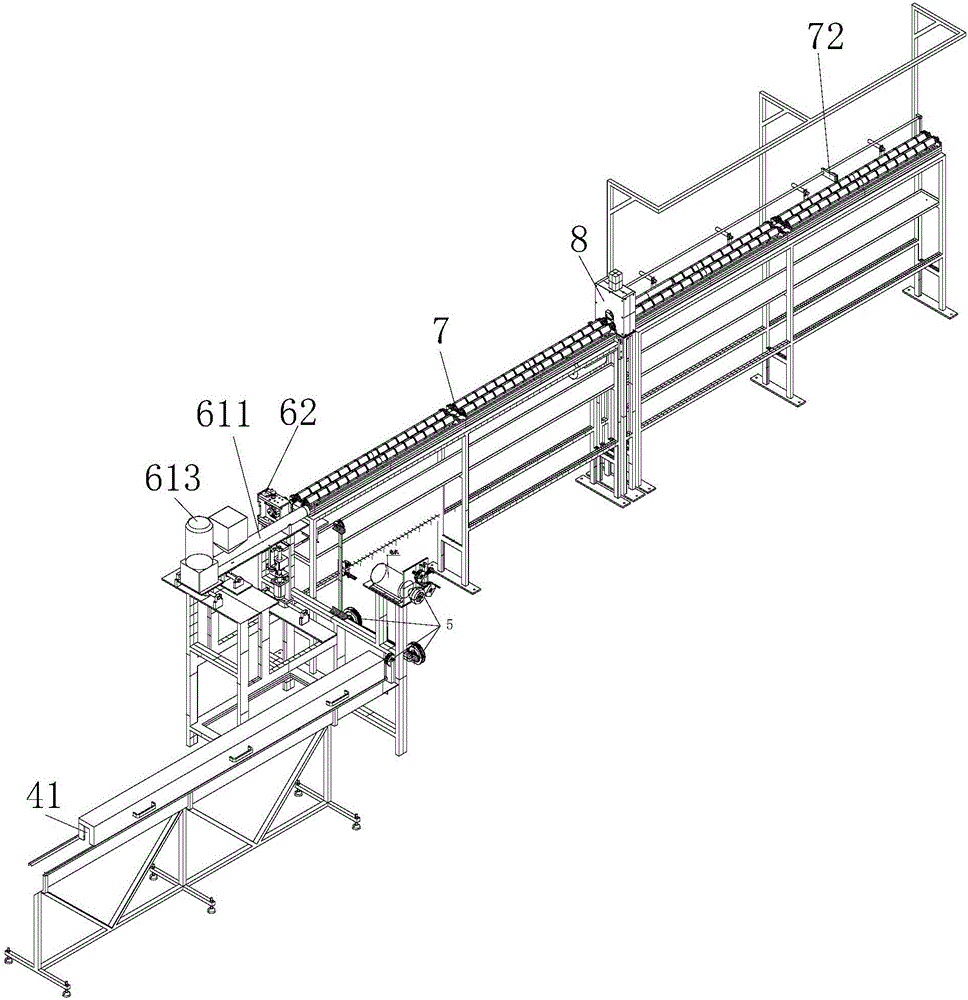

Surface layer co-extrusion winding pipe production equipment

ActiveCN105034338AIncrease productivitySimple production process controlTubular articlesEngineeringCo extrusion

The invention provides surface layer co-extrusion winding pipe production equipment. The surface layer co-extrusion winding pipe production equipment comprises a machine frame and a working platform arranged on the machine frame. The surface layer co-extrusion winding pipe production equipment is characterized by further comprising a main extruder, an auxiliary extruder, a co-extrusion mouth die connected with a discharging outlet of the main extruder and the auxiliary extruder, a cooling device, a traction device, a pipe glue forming device, a guide wheel conveying mechanism and an automatic cutting device, wherein the main extruder and the auxiliary extruder are close to the front end of the machine frame; the cooling device, the traction device, the pipe glue forming device, the guide wheel conveying mechanism and the automatic cutting device are arranged at the rear end of the co-extrusion mouth die and sequentially arranged in the production direction of a winding pipe; the cooling device and the guide wheel conveying mechanism are arranged on the working platform; the traction device, the pipe glue forming device and the automatic cutting device are fixed to the machine frame. The winding pipe production equipment can fully automatically produce plastic winding pipes with the additional properties and is high in production efficiency; the production process is easy to control; produced winding pipe products are stable in quality; after the equipment is used, labor intensity of workers can be greatly relieved, the yield is greatly improved, and the equipment has good market development value.

Owner:PLASTIFLEX SUZHOU

Production method of low-cost X52 pipeline steel and pipeline steel

ActiveCN103572025BReduce manufacturing costSimple production process controlMaterials scienceContinuous casting

The invention provides a production method of a low-cost X52 pipeline steel and a pipeline steel. The production method comprises the following steps: desulphurization, converter smelting and continuous casting are conducted on molten iron to prepare a pipeline steel continuous casting billet; the pipeline steel continuous casting billet is soaked to be at 1160-1200 DEG C, and roughly rolled for 3-7 times by a roughing mill to obtain an intermediate billet; the intermediate billet is finely rolled for 4-7 times by a finishing mill; the finely-rolled pipeline steel is quickly cooled to be at 550-610 DEG C at the cooling speed of 50-100 DEG C / s, and is rolled to obtain a pipeline steel finished product. No Nb is added to the low-cost X52 pipeline steel. Through the adoption of the production method of the low-cost X52 pipeline steel, the production cost of the X52 pipeline steel can be lowered, the production technique control is easy, and the adaptability is high.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD +1

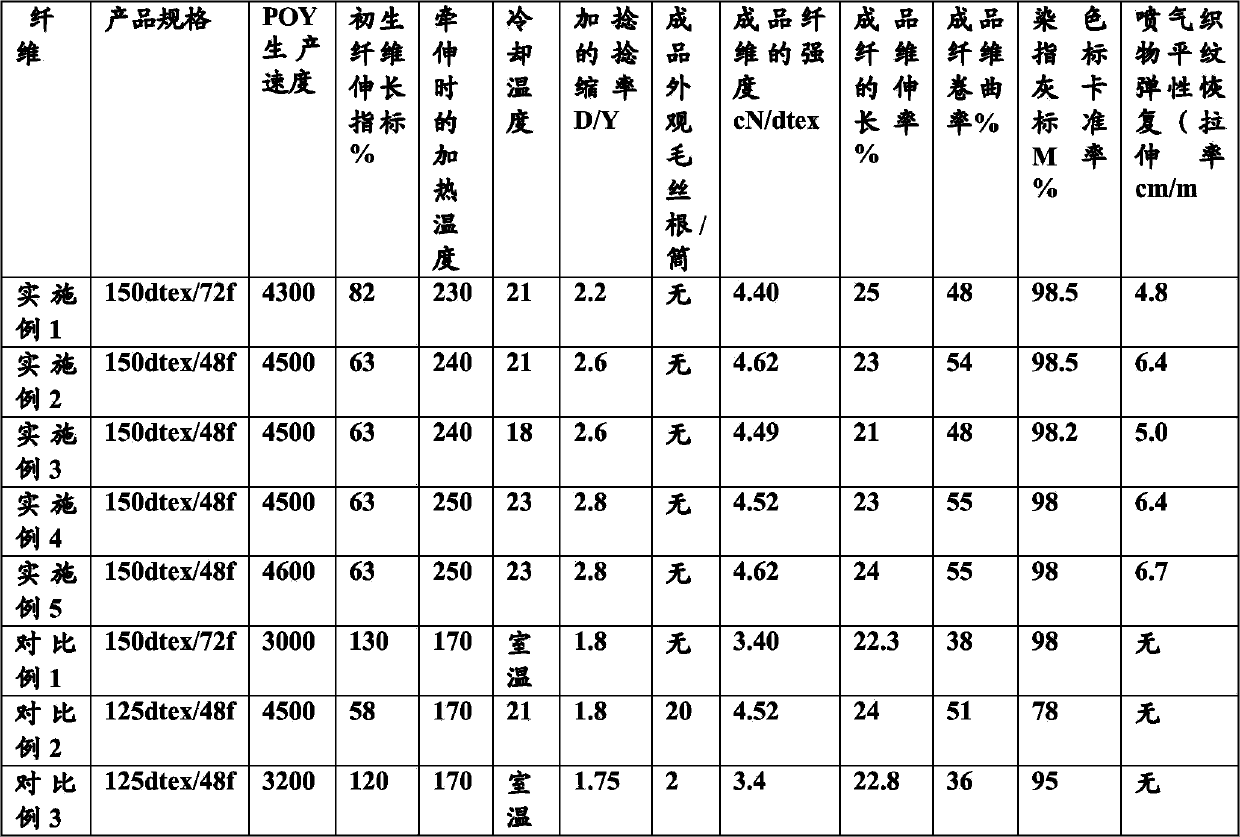

Method for producing high elastic fiber by using PET (polyethylene terephthalate) polyester, and high elastic fiber obtained by same

ActiveCN102776584BIncrease production speedGood orientationMelt spinning methodsMonocomponent polyesters artificial filamentFiberYarn

The invention relates to a method for producing a high elastic fiber by using PET (polyethylene terephthalate) polyester, which comprises the following steps that: (1) a PET polyester melt sequentially enters a spinning box, a metering pump and a spinning assembly to obtain a protofiber, and the protofiber is sequentially cooled, oiled and wound to obtain a POY (Pre Oriented Yarn), wherein the production speed of the POY is controlled between 4300m / min and 4600m / min; and (2) the POY sequentially passes through a first roller, a heating source, a cooling plate, a twisting device and a second roller for drafting and twisting, the tension is stabilized by a molding roller, and the POY is lubricated by an oiling roller and is wound to obtain the high elastic fiber, wherein the heating temperature of the heating source is between 230 DEG C and 250 DEG C, the twist shrinkage rate of twisting is between 2.2 and 2.8, and the cooling temperature of the cooling plate is between 18 DEG C and 23 DEG C. The process provided by the invention has simple control and lower cost.

Owner:SUZHOU LONGJIE SPECIAL FIBER

A kind of preparation method of titanium-aluminum alloy target

ActiveCN111101105BReduce manufacturing costSimple production process controlTransportation and packagingMetal-working apparatusProcessing costHeat treated

The invention discloses a method for preparing a titanium-aluminum alloy target, which comprises a powder mixing step, a filling step, a cold isostatic pressing step, a welding sheath degassing step, a hot isostatic pressing step, a cutting step, and alloying diffusion A heat treatment step and a machining finishing step. The preparation method of the invention has the advantages of simple control, low processing cost and high processing efficiency.

Owner:东莞市欧莱溅射靶材有限公司

F-shaped steel for high magnetic flux density maglev track and production method thereof

The invention discloses F-shaped steel for magnetic levitation rails with high magnetic flux density and a production method thereof. The F-shaped steel contains the following components by weight percent: 0.04-0.07% of C, 0.08-0.20% of Si, 0.5-0.8% of Mn, less than or equal to 0.015% of P, less than or equal to 0.015% of S, 0.015-0.030% of Nb, 0.03-0.05% of Als and the balance of Fe and impurityelements. According to the invention, the F-shaped steel for magnetic levitation rails with high magnetic flux density and excellent mechanical properties is acquired in the manner of designing steelcomponents, controlling quantity and size of impurity grains in the steel-making process and supplementing by high-temperature quick rolling so as to solidly dissolve alloying elements in steel and accelerate quick growth of crystal grains. According to the invention, the magnetic flux density of F-shaped steel is greatly increased and is 15% higher than that of present F-shaped steel.

Owner:武汉钢铁有限公司

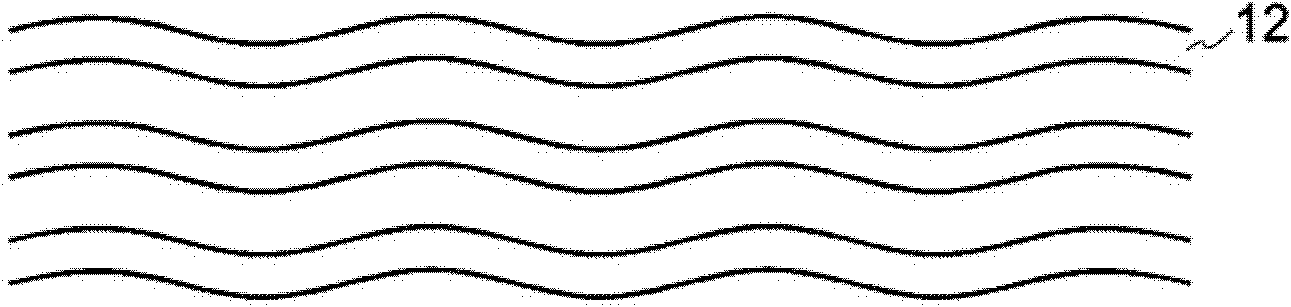

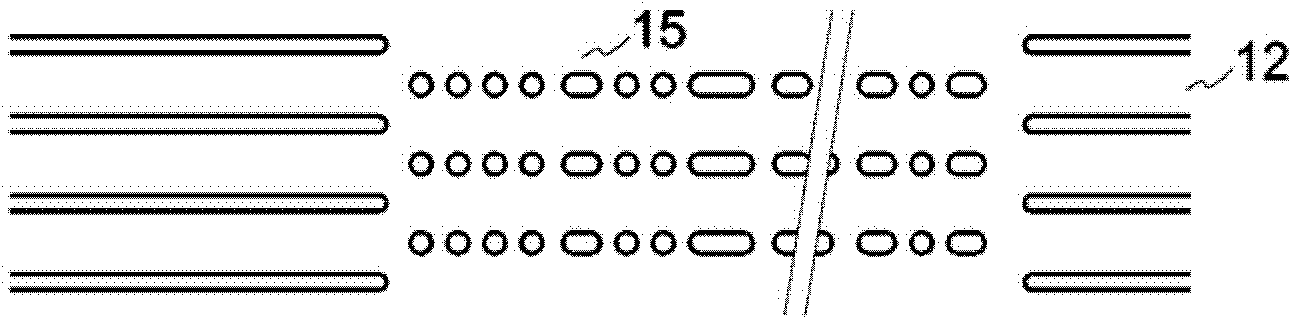

Recordable optical recording carrier and method for manufacturing recordable optical recording carrier compatible with CD-R

InactiveCN102760457AQuality improvementIncreased freedom of choiceInformation arrangementRecord information storageControl dataFull width at half maximum

An optical recording carrier including, in a data recording area, a continuous-grooved main track (12) for recording primary data to be stored, and a subtrack (13) for recording control data including parameter data and address information. The control data includes a clock signal needless to be provided by the main track (12). The subtrack (13) has a narrower full width at half maximum (FWHM) and a shallower depth than the main track (12). The distance (d') between the main track (12) and the subtrack (13) is not more than half of that between two adjacent main tracks (12). The main track (12) and the subtrack (13) form a double-spiral pattern. When recording data, a recording spot tracks mostly along the centerline of the main track (12) and reads the control data in the subtrack (13) simultaneously to control the recording process. A method for manufacturing a recordable optical recording carrier compatible with a conventional CD-R is also provided.

Owner:PRINCO CORP

Vacuum glass sealing structure, semi-finished product and sealing method thereof

The invention provides a vacuum glass sealing structure, a semi-finished product and a sealing method thereof. The sealing method is to coat one side of a metal strip with a glass frit slurry, and then coat the metal strip with the glass frit slurry One side is pasted on the peripheral surface of each layer of glass plates, heated and melted to connect as a whole, and then the metal strips on adjacent glass plates are joined on the outside of the peripheral surfaces and airtightly welded as a whole. The vacuum glass sealing structure is to heat and melt the metal strips on the peripheral surface of each layer of glass plates through glass frit paste, and the metal strips on adjacent glass plates are joined and airtightly welded on the outside of the peripheral surfaces . The invention not only makes full use of the wetting characteristics of glass powder slurry and the bonding ability in molten state, but also makes full use of the easy-welding characteristics of metal materials, so that the flow-through production of vacuum glass by tempered glass and half-tempered glass becomes a reality feasible.

Owner:LUOYANG NORTHGLASS TECH +1

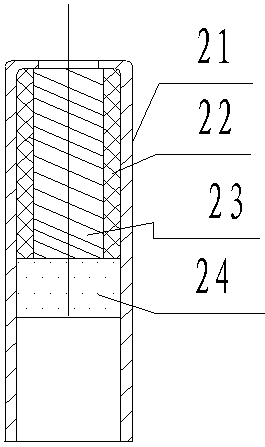

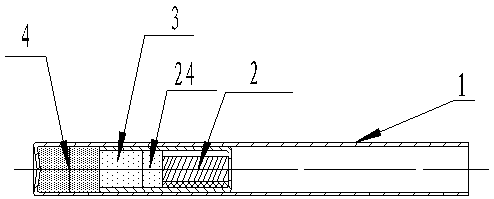

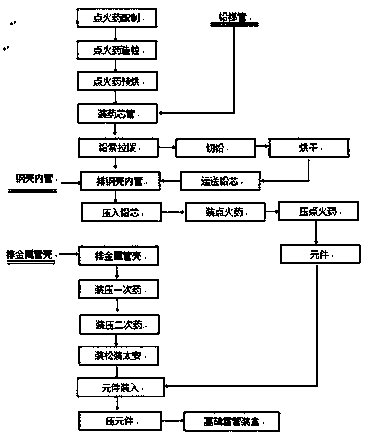

A lead-core type detonating element and a basic detonator composed of the detonating element

ActiveCN108917500BNormal detonationEliminates the phenomenon of incomplete explosionInorganic oxygen-halogen salt explosive compositionsAmmunition fuzesDetonatorThermodynamics

Owner:YAHUA GROUP MIANYANG INDAL

Application of elementary-substance selenium as catalyzer

ActiveCN102862962BBreak through the conditions of high temperature and high pressureHigh puritySulfate/bisulfate preparationSulfur preparation/purificationSulfurSulfite

The invention relates to an application of elementary-substance selenium as a catalyzer, and particularly, the elementary-substance selenium is applied in catalytic reaction of sulfite to prepare elementary-substance sulfur. According to the application of the elementary-substance selenium as the catalyzer, the elementary-substance selenium is applied as the catalyzer to prepare the high-purity elementary-substance sulfur, limits of high-temperature and high-pressure environments required by the elementary-substance sulfur preparation in traditional modes are broken; the catalyzer is stable in structure performance, can be recycled and used repeatedly; and the technology and the equipment are simple, the production cost is low, and the catalyzer is free of environmental pollution.

Owner:CENT SOUTH UNIV

A low-cost long-period fiber grating fabrication method

ActiveCN106353852BAvoiding the Drawbacks of Liquid EtchingReduce manufacturing costCladded optical fibreOptical waveguide light guideFiberCorrosion reaction

The invention discloses a manufacturing method for a low-cost long-period fiber bragg grating. The method is characterized by the following steps: setting a sealed container; dividing the sealed container into upper and lower parts by a cover plate; adding a corrosion solution into the lower part; forming an optical fiber insert hole in a side wall of the upper part; forming a micro-hole on the cover plate; exposing a cladding layer of an area, into which the grating is to be written, on the optical fiber; inserting into the sealed container; fixing one end of the optical fiber on a linear moveable platform; volatilizing the corrosion solution and releasing gas from the micro-hole; performing corrosion reaction between the cladding layer right above the micro-hole on the optical fiber and the gas, thereby forming a deep corrosion groove; periodically moving the horizontal position of the optical fiber by the linear moveable platform; lastly, forming periodically distributed deep corrosion grooves on the surface of the optical fiber, thereby forming the long-period fiber bragg grating. The manufacturing method for the low-cost long-period fiber bragg grating provided by the invention has the advantages of requiring no grating corrosion for mask plate and low manufacturing cost, is suitable for batch manufacturing and is suitable for various optical fibers.

Owner:安徽蓝海之光科技有限公司

Polyurethane high-pressure gas storage tank liner and forming process thereof

ActiveCN114542941AImprove barrier propertiesImprove wear resistancePressure vesselsCoatingsPolymer scienceWear resistance

The invention discloses an inner container of a polyurethane high-pressure gas storage tank, which is integrally formed and is made of a polyurethane material. And preferably, a water-based polyurethane material is adopted. In the invention, the inner container of the polyurethane high-pressure gas storage tank is integrally formed through a rotational molding process. The invention further provides a forming process of the polyurethane high-pressure gas storage tank inner container, a rotational molding method is used, and the cross-linking reaction of polyurethane is completed in the rotational molding process. The inner container of the polyurethane high-pressure gas storage tank can effectively block hydrogen, and has wear resistance, tensile strength, tearing strength and damping effect which are higher than those of nylon and polyethylene materials and high adhesion with metal accessories.

Owner:知春氢能科技(烟台)有限公司

A kind of production method of vanillin-1,2-propanediol acetal

ActiveCN108047188BShort reaction timeRaw materials are easy to getOrganic chemistryPtru catalystDistillation

The invention discloses a production method of vanillin-1,2-propylene glycol acetal. The production method comprises the following steps: firstly, cleaning a reaction still, dehydrating the reaction still and a condensing device thereof so as to enable the water content of the reaction still to be lower than 500 ppm; secondly, adding raw materials vanillin and 1,2-propylene glycol into the reaction still; thirdly, adding an acidic substance as a catalyst into the reaction still and uniformly stirring; fourthly, vacuumizing the reaction still and enabling the reaction still to be in a certain negative pressure state; fifthly, raising the temperature of the reaction still to required temperature and reacting at the required temperature for a certain time; sixthly, carrying out sampling detection on a reaction product, adding a certain amount of alkaline raw materials into the reaction still to neutralize the catalyst after the reaction product is qualified by detecting; seventhly, carrying out reduced pressure distillation on the unreacted 1,2-propylene glycol and finally distilling and collecting to obtain qualified vanillin-1,2-propylene glycol acetal. The reaction time of the production method disclosed by the invention is 3 to 8 hours; compared with the prior production method, the production method disclosed by the invention has the advantages that reaction time is greatly shortened; in addition, the use of an organic solvent benzene is avoided and further environment friendliness is realized.

Owner:CHONGQING THRIVE CHEM

Waterborne polyurethane and its preparation method and application

ActiveCN107857869BIncrease softnessDoes not affect viscosityPolyurea/polyurethane coatingsLeather surface finishingHydrophilic monomerCross-link

The invention relates to the field of macromolecular materials and particularly relates to waterborne polyurethane and a preparation method and application thereof. The preparation method comprises the steps: subjecting an HDI trimer or IPDI trimer to a polymerization reaction with polyethylene glycol, then, subjecting the product to a reaction with hexamethylene diisocyanate or isophorone diisocyanate so as to form an isocyanate terminated tri-functionality polymer, and regulating the viscosity of the isocyanate terminated tri-functionality polymer with acetone; subjecting HDI or IPDI to a reaction with a binary alcoholic monomer and a hydrophilic monomer so as to obtain a linear aqueous polyurethane prepolymer, and regulating the viscosity of the linear aqueous polyurethane prepolymer with acetone; subjecting the isocyanate terminated tri-functionality polymer and the linear aqueous polyurethane prepolymer to a cross-linking reaction under the action of a chain extender, and removingthe acetone, thereby obtaining the waterborne polyurethane. After the waterborne polyurethane prepared by the preparation method forms a film, the softness is relatively good, finished, compliant andsoft surface touch feeling of leather is achieved, and meanwhile, the physical properties are relatively good.

Owner:达威水基聚氨酯(上海)有限公司

Super-thick steel plate with obdurability matching and excellent high-temperature performance and manufacturing method thereof

ActiveCN101613840BExcellent fatigue and creep resistanceExcellent resistance to temper embrittlementFurnace typesMetal rolling arrangementsPressure vesselHeat treating

The invention relates to a super-thick steel plate with obdurability matching and excellent high-temperature performance and a manufacturing method thereof. The method comprises the following steps: adopting a component system of low alloy steel with medium C, high Mn and medium N as a basis; properly improving the acid soluble Als content in the steel and controlling the range of the content; controlling the ratio of Mn equivalent weight to C to between 10 and 20; alloying Cu, Ni, Cr, Mo and V; performing Nb and ultromicro Ti treatment, wherein the ratio of Nb to Ti is more than or equal to 1.50; performing Ca treatment, wherein the ratio of Ca to S is between 1.00 and 3.00; and optimizing the process of controlled rolling and subsequent heat treatment, thus the super-thick steel plate obtains excellent obdurability matching, exhaustion creep resistance, temper embrittlement resistance and welding manufacturability, in particular to excellent exhaustion creep resistance for a weldingjoint, and is particularly suitable to serve as a heat resistant pressure vessel body.

Owner:BAOSHAN IRON & STEEL CO LTD

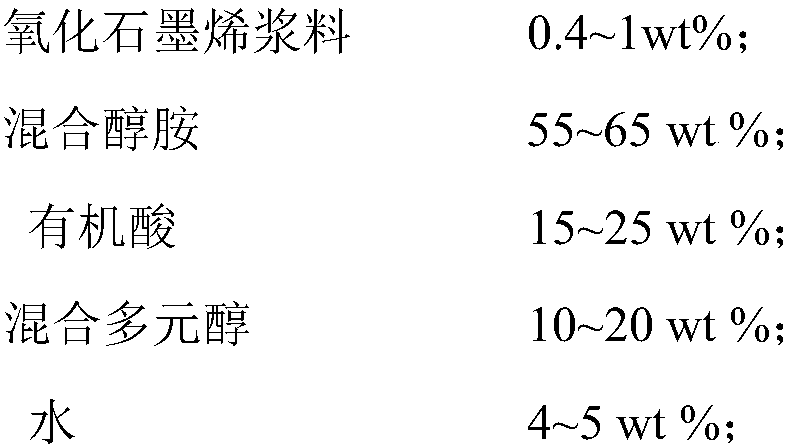

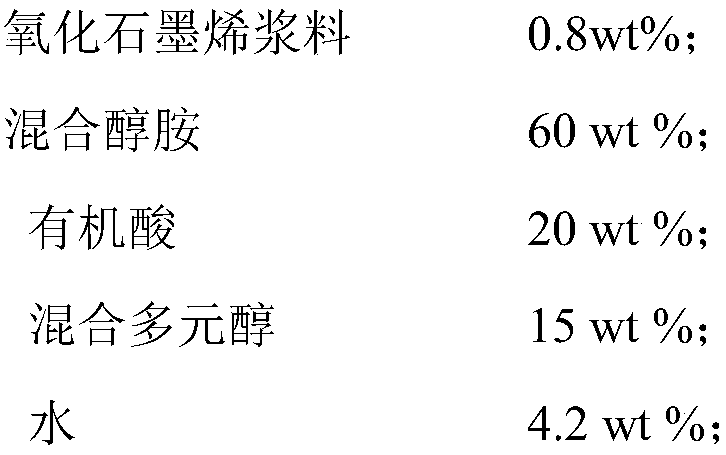

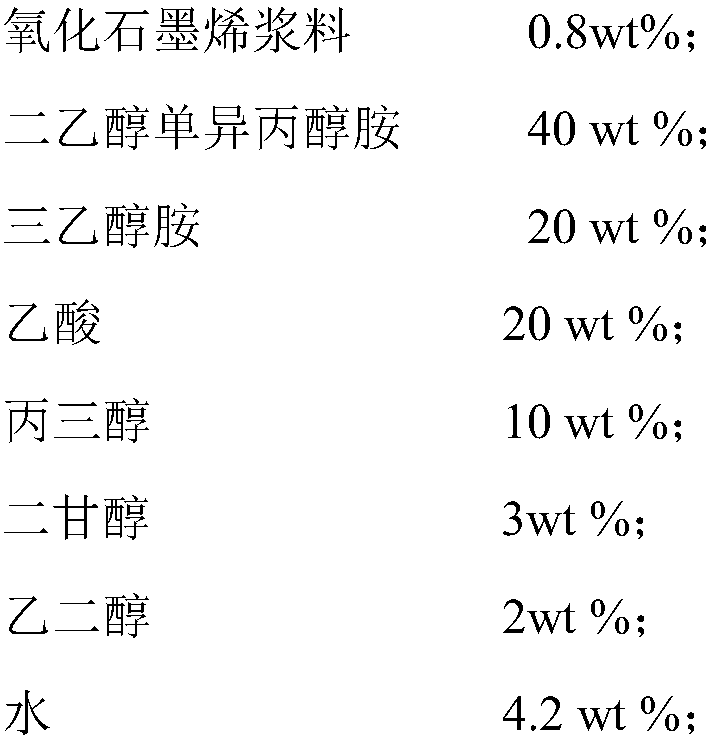

A kind of steel slag activator and its preparation method and application

The invention discloses a steel slag activating agent, and belongs to the technical field of industrial additives. The steel slag activating agent is prepared from graphene oxide paste, mixed alcohol amine, organic acid, mixed polyhydric alcohols and water. The steel slag activating agent is applied to steel slag powder grinding, the activating effect is better, the crystals of a steel slag hydration product are induced to orderly grow, the activating property of the steel slag micropowder is improved, and the problem of activating of steel slag micropowder is solved. The steel slag micropowder can be widely applied to cement and concrete industries, the problem of pollution to environments by steel slag is solved, the demand of cement and concrete enterprises on high-quality raw material is relieved, and the market prospect is better. The activating agent has the advantages that the energy consumption in the production phase is little, and the waste gas, waste liquid and waste slag are not produced; the control of production technology is simple, and the rate of finished products is high; compared with the existing production technology, the energy consumption and environment burden are not increased in the powder grinding phase, and the electric consumption of powder grinding is decreased.

Owner:江苏润天建材(集团)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com