Production method of low-cost X52 pipeline steel and pipeline steel

A production method and technology for pipeline steel, which are applied to the production method of low-cost X52 pipeline steel and the field of pipeline steel, can solve the problems of increased production cost, high price of alloying element Nb, etc., and achieve the effects of strong adaptability and simple production process control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

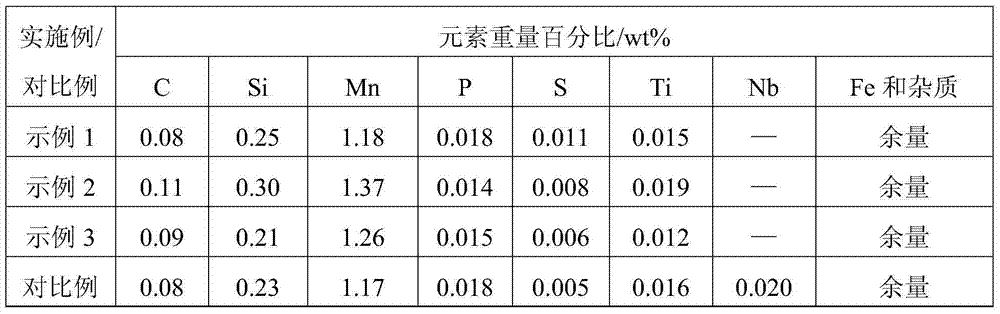

[0040] (1) The molten iron is desulfurized, smelted in a converter, and continuously cast into an X52 pipeline steel continuous casting slab. The weight percentage of its chemical composition is shown in Table 1, and the thickness of the continuous casting slab is 230mm.

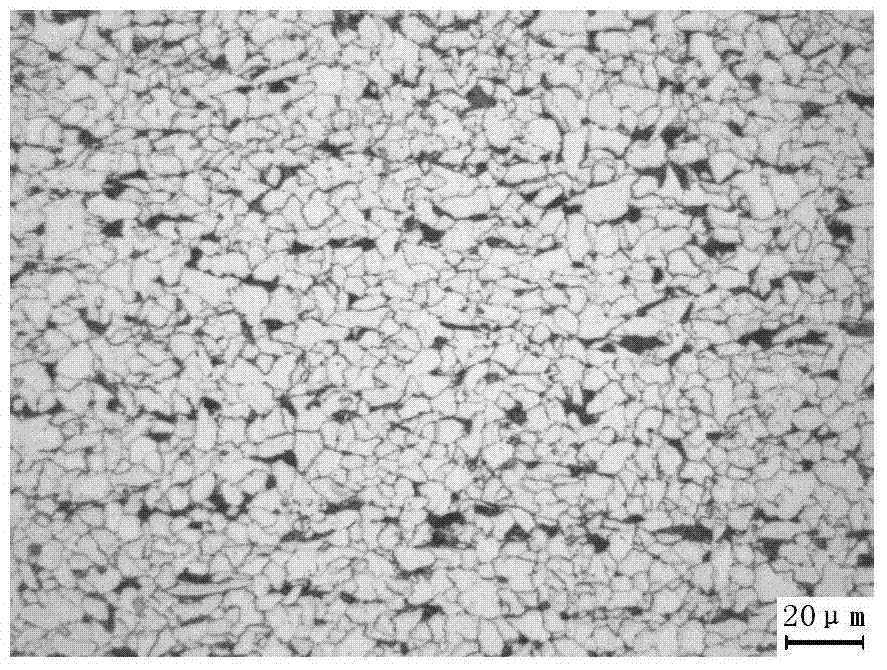

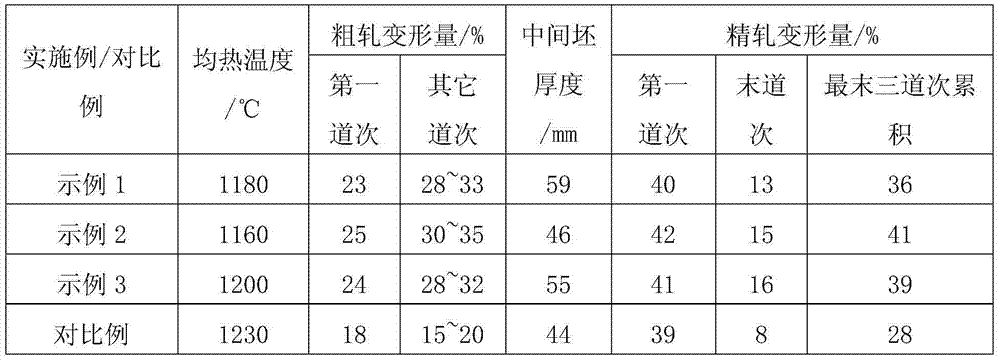

[0041] (2) Heat the continuous casting slab to 1180°C and carry out rough rolling and finish rolling. The deformation of each pass of rough rolling and finish rolling is shown in Table 2. After rough rolling, the thickness of the middle slab is 59 mm, and the finishing mill The final rolling temperature of the last stand is 760°C, and the thickness of the pipeline steel after finishing rolling is 10.0mm.

[0042] (3) The finished rolled pipeline steel is cooled to 580° C. at a cooling rate of 50° C. / s and then coiled to obtain the finished pipeline steel.

[0043] After testing, the mechanical properties of the finished pipeline steel are shown in Table 3.

example 2

[0045] (1) The molten iron is desulfurized, smelted in a converter, and continuously cast into an X52 pipeline steel continuous casting slab. The weight percentage of its chemical composition is shown in Table 1, and the thickness of the continuous casting slab is 200mm.

[0046] (2) The continuous casting slab was heated to 1160°C and then rough rolled and finish rolled. The rough rolling and finish rolling passes and the deformation of each pass are shown in Table 2. The thickness of the intermediate slab after rough rolling is 46mm. The final rolling temperature of the last stand of the finishing mill is 780°C, and the thickness of the pipeline steel after finishing rolling is 5.0mm.

[0047] (3) The finished rolled pipeline steel is cooled to 550°C at a cooling rate of 80°C / s and then coiled to obtain the finished pipeline steel.

[0048] After testing, the mechanical properties of the finished pipeline steel are shown in Table 3.

example 3

[0050] (1) The molten iron is desulfurized, smelted in a converter, and continuously cast into an X52 pipeline steel continuous casting slab. The weight percentage of its chemical composition is shown in Table 1, and the thickness of the continuous casting slab is 200mm.

[0051] (2) Rough rolling and finish rolling were carried out after the continuous casting slab was heated to 1200°C. The rough rolling and finish rolling passes and the deformation of each pass are shown in Table 2. The thickness of the intermediate slab after rough rolling was 55mm. The final rolling temperature of the last stand of the finishing mill is 800°C, and the thickness of the pipeline steel after finishing rolling is 7.0mm.

[0052] (3) The finished rolled pipeline steel is cooled to 600°C at a cooling rate of 65°C / s and then coiled to obtain the finished pipeline steel.

[0053] After testing, the mechanical properties of the finished pipeline steel are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com