Waterborne polyurethane and its preparation method and application

A technology of water-based polyurethane and hydrophilic monomers, applied in polyurea/polyurethane coatings, applications, animal husbandry, etc., can solve problems such as easy gel formation, excessive viscosity of prepolymers, and difficulty in dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

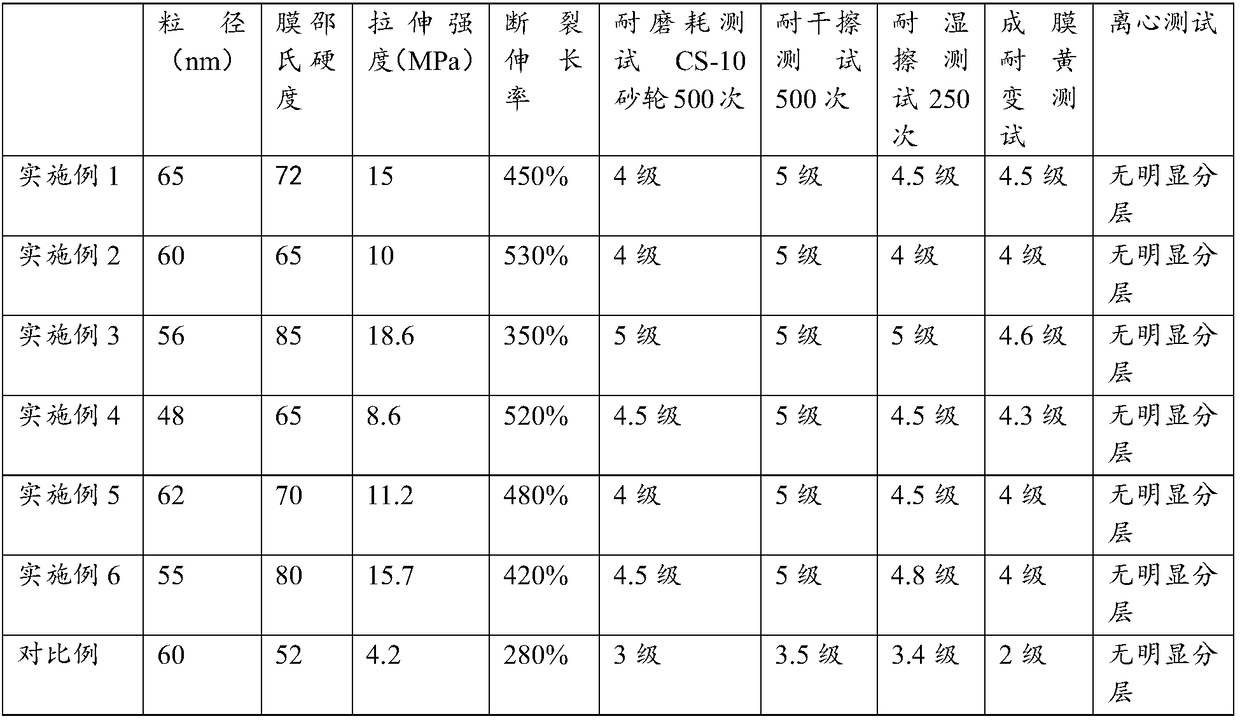

Examples

preparation example Construction

[0015] Some embodiments of the present invention provide a kind of preparation method of waterborne polyurethane, it comprises the following steps:

[0016] S1. Polymerize the HDI trimer or IPDI trimer with polyethylene glycol to obtain a hydroxyl-terminated trifunctional polymer, and then combine the hydroxyl-terminated trifunctional polymer with hexamethylene diisocyanate (HDI ) or isophorone diisocyanate (IPDI) to form an isocyanate-terminated trifunctional polymer and adjust the viscosity with acetone.

[0017] S2. Reacting hexamethylene diisocyanate or isophorone diisocyanate with diol monomers and hydrophilic monomers to obtain a linear waterborne polyurethane prepolymer, and adjusting the viscosity with acetone.

[0018] S3. After carrying out the cross-linking reaction of the isocyanate-terminated trifunctional polymer with adjusted over-viscosity and the linear water-based polyurethane prepolymer with adjusted over-viscosity under the action of a chain extender, aceto...

Embodiment 1

[0059] Add IPDI trimer and polyethylene glycol with a molecular weight of 600 in a molar ratio of 1:3 into a three-necked flask, stir and heat up to 80°C for 3 hours to obtain a hydroxyl-terminated trifunctional polymer, and then add polyethylene glycol Alcohol equimolar amount of HDI, continue to react at 85°C for 3 hours to form isocyanate-terminated trifunctional polymer, cool down to 60°C and add acetone to dilute and continue to cool down to room temperature to obtain Component A. Wherein, acetone is 10% of the total mass of the reactants for forming the isocyanate-terminated trifunctional polymer.

[0060] In a 250m1 four-neck flask equipped with a stirrer, a condensing reflux tube, and a thermocouple, add IPDI, 2000 molecular weight PTMEG and DMPA and react at 90°C for 3 hours to produce a linear water-based polyurethane prepolymer, then cool down to 60°C and add acetone to reduce the temperature. Sticky, Component B is obtained. Wherein, the molar ratio of IPDI and PT...

Embodiment 2

[0063] Add the IPDI trimer and polyethylene glycol with a molecular weight of 1200 in a molar ratio of 1:3 into a three-necked flask, stir and heat up to 76°C for 2.5 hours to obtain a hydroxyl-terminated trifunctional polymer, and then add polyethylene glycol Alcohol equivalent molar amount of HDI was reacted at 90°C for 2.5 hours to form an isocyanate-terminated trifunctional polymer. Cool down to 60°C and add acetone to dilute and continue to cool down to room temperature to obtain Component A. Wherein, acetone accounts for 20% of the total mass of the reactants for forming the isocyanate-terminated trifunctional polymer.

[0064] Add HDI, 2000 molecular weight PCL and DMPA to a 250m1 four-neck flask equipped with a stirrer, condensing reflux tube, and thermocouple, and react at 90°C for 3 hours to produce a linear water-based polyurethane prepolymer, then cool down to 60°C and add acetone to reduce the temperature. Sticky, Component B is obtained. Wherein, the molar ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com