Patents

Literature

32results about How to "Reduce desulfurization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrodesulfurization Catalyst for Petroleum Hydrocarbons and Process for Hydrodesulfurization Using the Same

InactiveUS20060249429A1Reduce desulfurization activitySufficient desulfurization activityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationPetroleum

The present invention provides a hydrodesulfurization that can attain an extremely high depth of desulfurization to a sulfur content of 10 ppm by mass, exert high denitrogenation activity, and has high nitrogen resisting properties to nitrogen compounds which are substances inhibiting desulfurization reaction. The catalyst is suitable for hydrodesulfurizing petroleum hydrocarbons and characterized in that an inorganic porous support composed of mainly alumina contains, as active metals, at least one metal selected from the metals of Group 8 of the periodic table and at least one metal selected from the metals of Group 6A of the periodic table in a molar ratio defined by [oxide of the Group 8 metal] / [oxide of the Group 6A metal] ranging from 0.105 to 0.265 and the content of the Group 6A metal in terms of oxide is in the range of 20 to 30 percent by mass based on the mass of the catalyst.

Owner:NIPPON OIL CORP

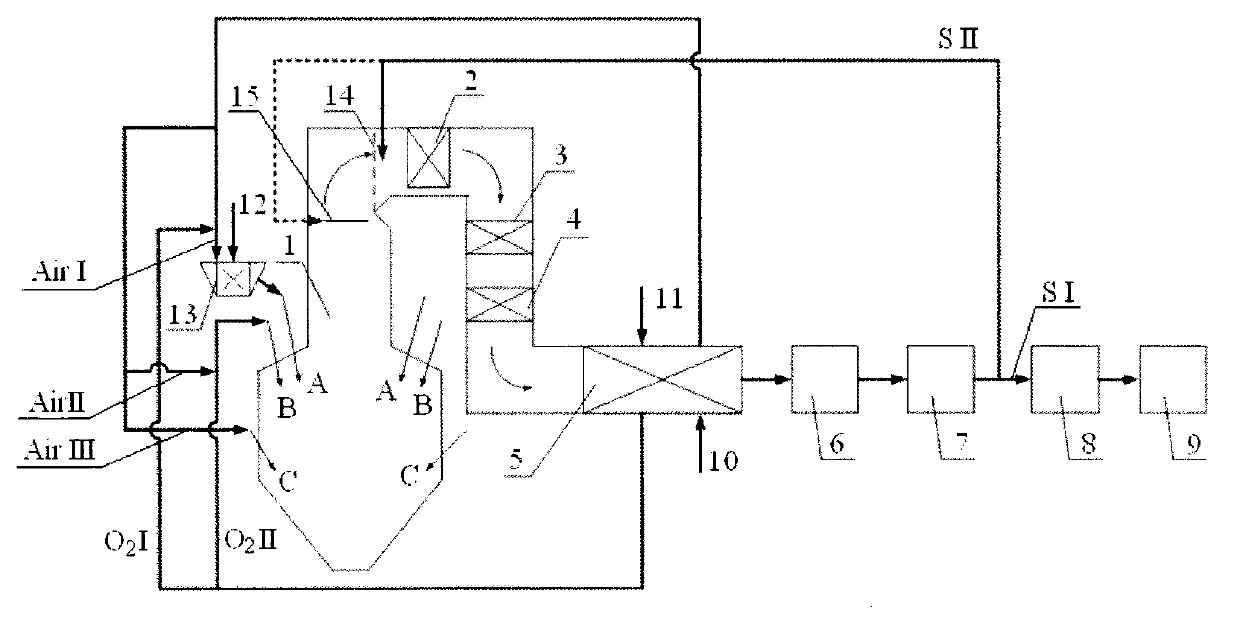

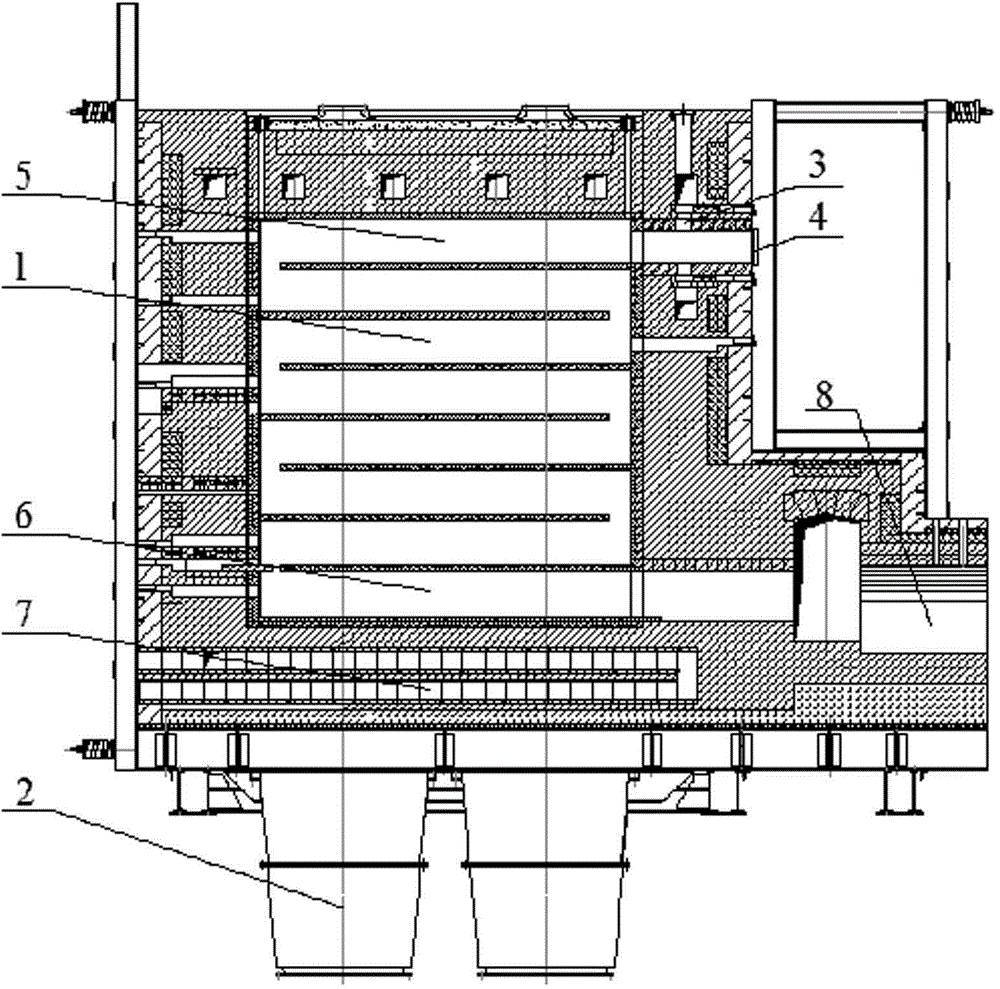

Micro oxygen rich combustion W flame boiler and CO2 emission reduction system

ActiveCN103104910AReduce energy consumptionReduce investmentDirect carbon-dioxide mitigationIndirect carbon-dioxide mitigationBoiler furnaceUnit mass

The invention discloses a micro oxygen rich combustion W flame boiler and a CO2 emission reduction system, which is characterized in that anthracite or low-volatile coal is introduced in the W flame boiler furnace for fully combusting, the formed flue gas is divided into two strands through a heat exchange zone and a gas-gas heat exchanger after cooling, one strand is taken as a recycling flue gas; air and oxygen are simultaneously heated in the gas-gas heat exchanger, the heated air is divided into three strands, oxygen is divided into two strands, a first strand of oxygen and a first strand of air are mixed and introduced in a furnace arch primary air pipeline, a second strand of oxygen and a second strand of air are mixed and introduced in a furnace arch secondary air pipeline, and a third air is introduced in a back and forth wall secondary air pipeline. The invention combines the micro oxygen rich combustion technology and the W flame boiler, the desulphurization, denitration and capture with lower cost can be realized, and zero discharge can be realized. The pure oxygen amount required by fuel combustion with unit mass under a micro oxygen rich combustion mode is obviously reduced by comparing with oxygen rich combustion, and energy consumption and cost of air separation oxygen preparation can be greatly reduced.

Owner:SHANGHAI BOILER WORKS

Meta titanate treatment method

The invention relates to a meta titanate treatment method, comprising the following steps of: pulping metatitanic acid; adding an alkaline compound into the metatitanic acid pulp until the pH value is above 3; filtering and washing; adding dissoluble aluminum salt, dissoluble phosphate, dissoluble potassium-containing compounds and zinc-containing compounds into a filter cake and mixing uniformly; and calcining and crushing to obtain titanium dioxide. Compared with the prior art, the meta titanate treatment method provided by the invention has the advantages that the energy consumption is reduced; the production efficiency is improved; and the mellowness of the titanium dioxide is improved.

Owner:LOMON BILLIONS GRP CO LTD

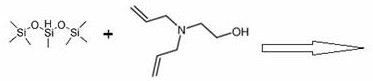

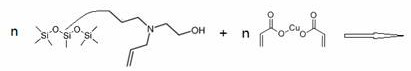

Method for preparing activated rubber crumb by catalysis and activation reaction

InactiveCN101381476AImprove dynamic performanceEasy to usePlastic recyclingPolymer sciencePlasticizer

The invention provides a method for preparing activated rubber powder by catalytic reaction and activating reaction, and relates to a method for comprehensive utilization of waste and scrap rubber. Compared with the production of regenerated rubber, the method reduces processes of desulfurizing, kneading and refining, thereby avoiding secondary pollution to the environment. The prepared activated rubber powder has excellent compatibility with matrix rubber, and improves the physical and mechanical properties of the product. The formulation comprises the following compositions in weight portion: 100 portions of 30 to 40 meshes of waste rubber powder, 8 to 17 portions of plasticizer-dipentene, 5 to 8 portions of dusting agent-pottery clay, 0.2 to 0.5 portion of catalyst-cuprous chloride, 7 to 1.0 portion of promoting agent-polyalkylphenol disulfide, and 1 to 2.5 portions of dispersing agent-ethanol. The method comprises the following steps: placing the 30 to 40 meshes of waste rubber powder into a high-speed stirring reactor, and heating the waste rubber powder to the temperature of between 80 and 100 DEG C; adding the plasticizer, the dusting agent, the catalyst, the promoting agent and the dispersing agent into the reactor sequentially for reacting for 10 to 20 minutes at a temperature of between 80 and 120 DEG C, and cooling and discharging to produce the activated rubber powder. The prepared activated rubber powder can be used in rubber industry and building industry.

Owner:TIANJIN RUBBER IND RES INST

Environment friendly energy-saving super strength combustion supporting efficient synthetic coal

The invention discloses environment-friendly energy-saving extra-strong combustion-supporting high-efficiency synthetic coal, which is characterized by comprising the following steps: adopting plant charcoal power and natural coal powder of powerful renewable resources to prepare into a main material through a scientific formula according to the variety and the quality of coal; adding a mixed material of coal gangue powder and fly ash powder of industrial waste to synthesize a filling auxiliary material, and reconstructing and changing structures, the performance and the characteristics of the coal to make the coal reach the highest efficiency; then adding a strong-oxygen combustion-supporting high-efficiency coal-saving synergistic fire-slowing agent which has quick firing, can prolong the combustion time of the coal, can make low-grade coal completely combusted, improve thermal efficiency, save the coal, has no pollution, and can achieve the aims of eliminating smoke, dedusting, supporting combustion and desulfurizing; and finally adding a certain amount of water , evenly stirring , and performing coal molding and manufacturing by special coal-making machinery . The coal is high-efficiency coal, has the use efficiency three to six times of that of the prior ordinary coal, is a novel energy-saving high-efficiency energy source, has the coal-saving rate reaching 80 percent or so, has extremely high coal-saving rate and convenient use, is safe, reliable and easy to store, and is called 'overground coal mine' and 'green coal'.

Owner:万金林

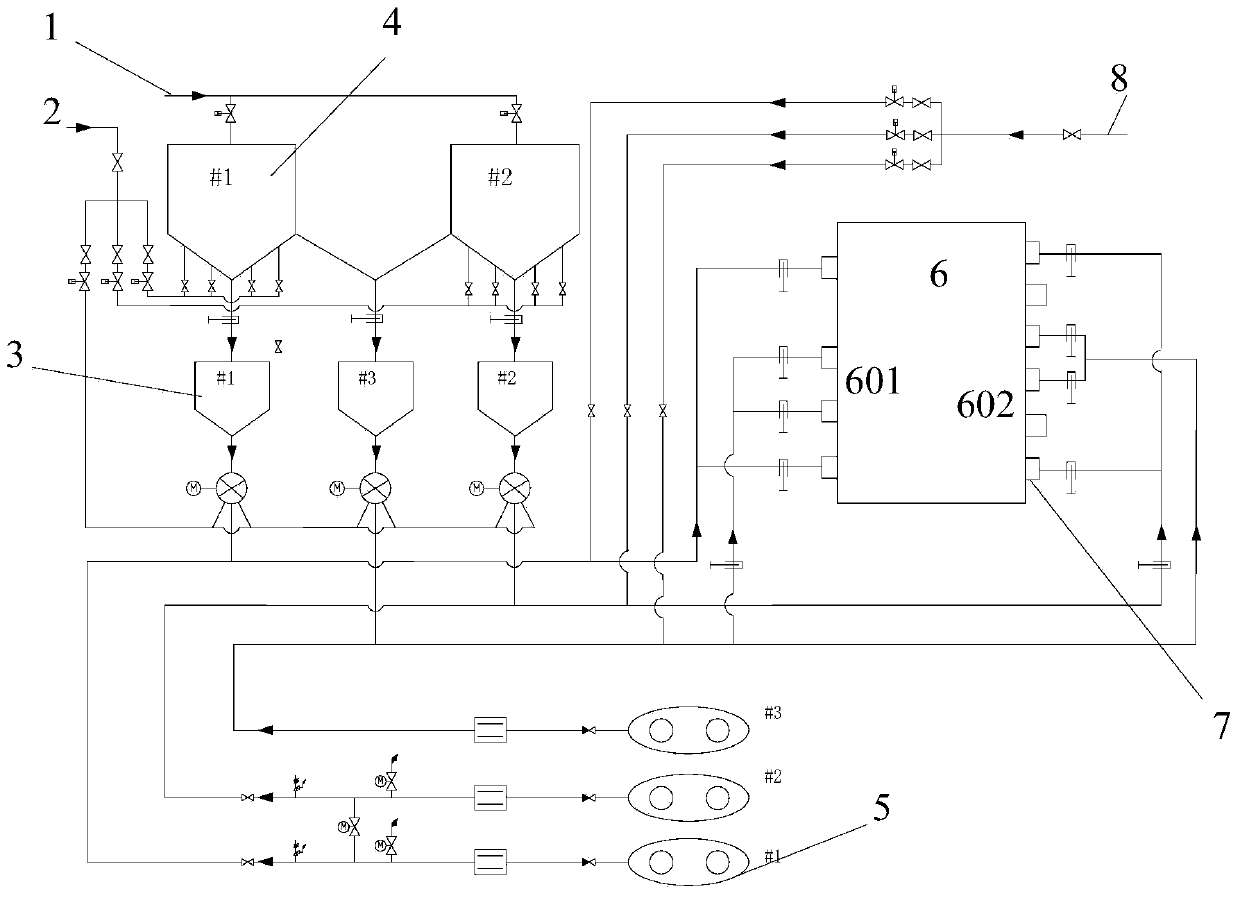

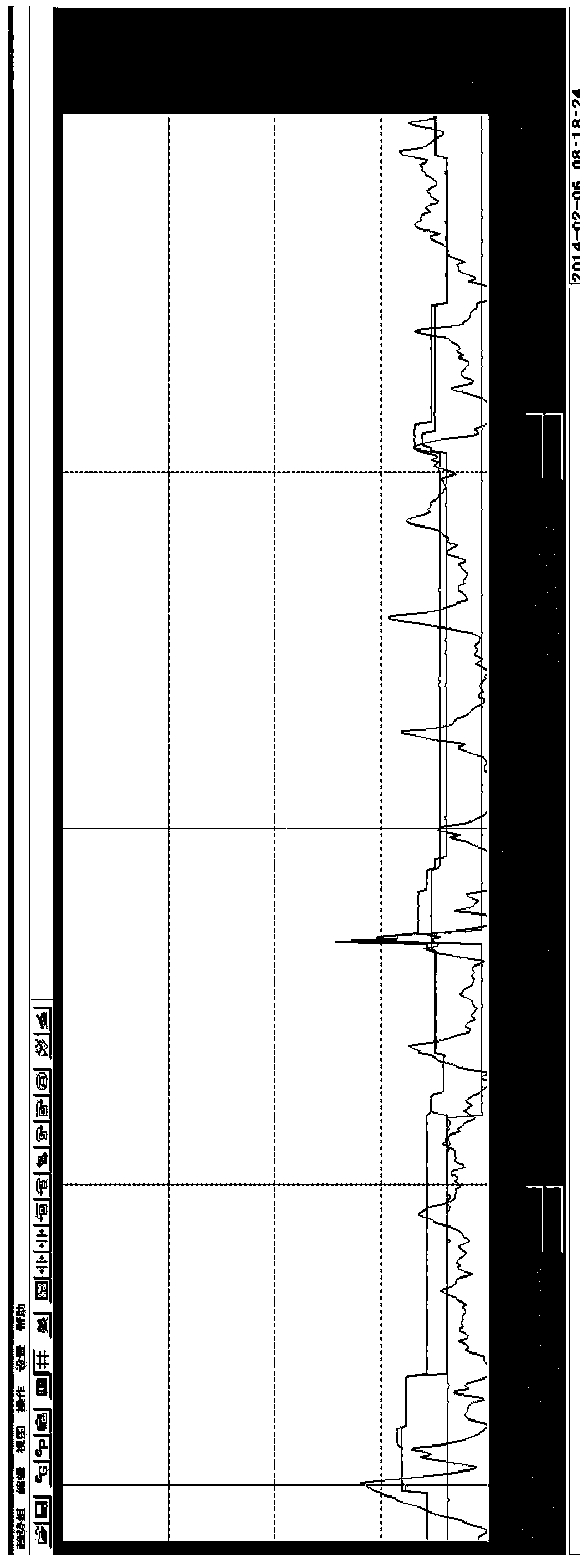

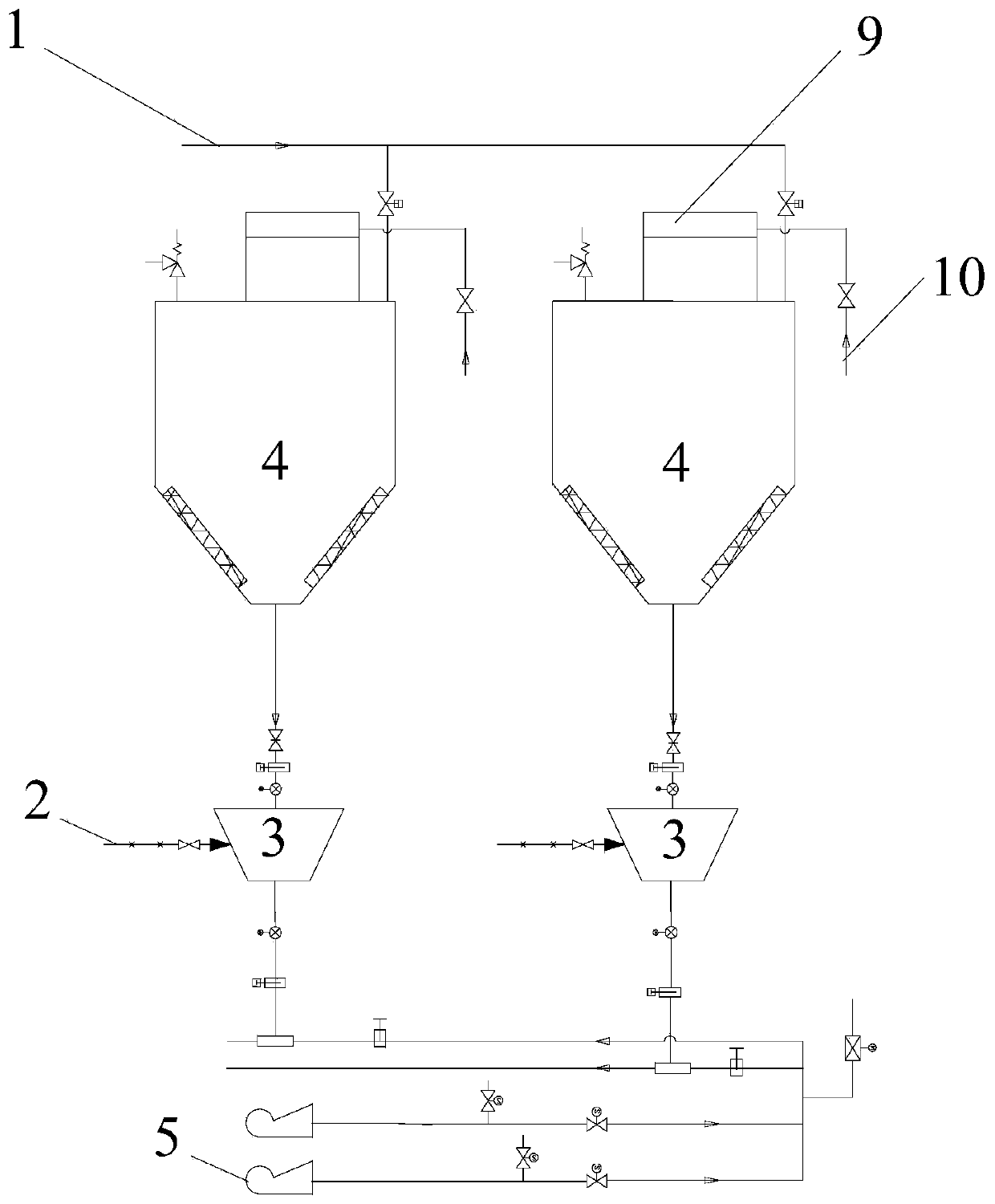

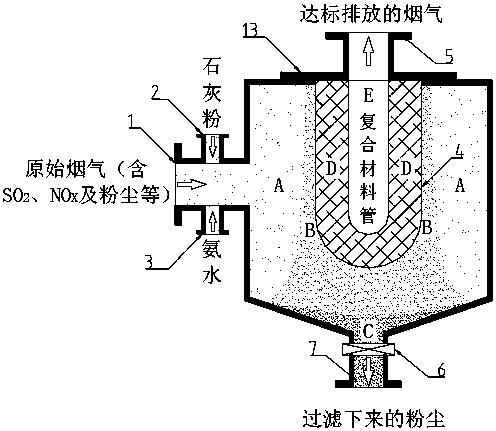

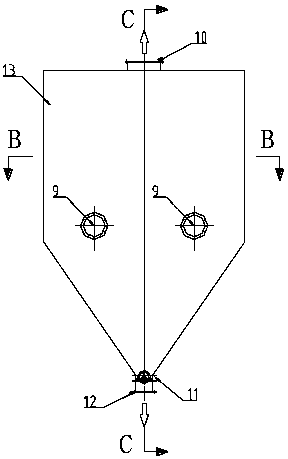

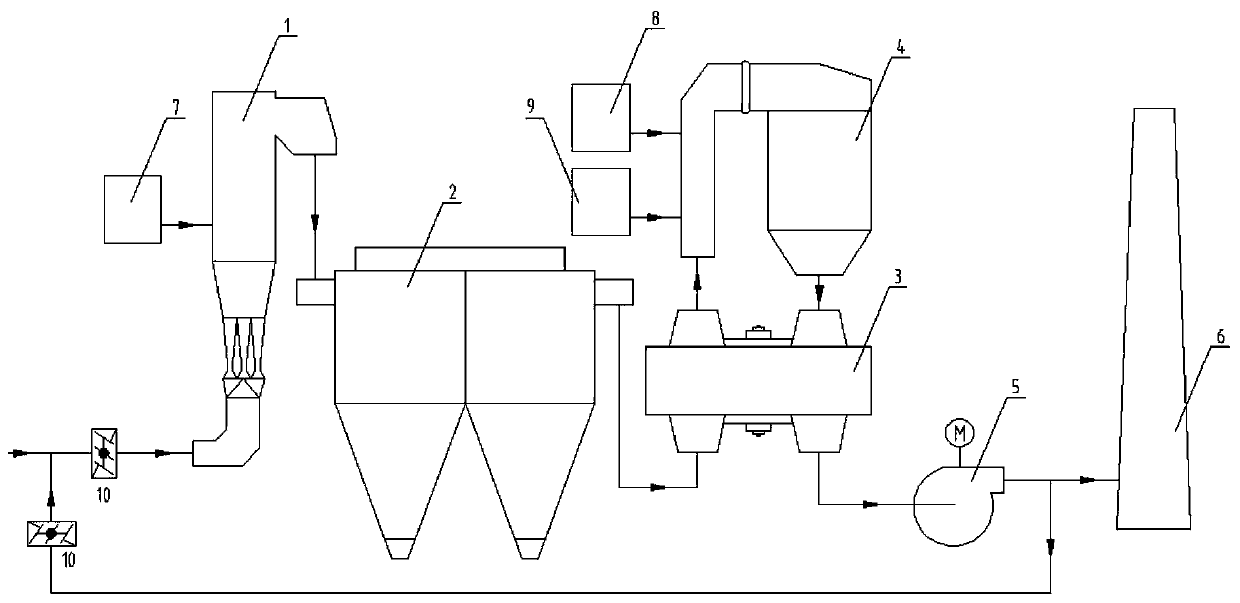

Acetylene sludge desulfurization method and equipment for coal-fired boiler

ActiveCN104190243ASolve shed blockageSolve for uniformityAir supply regulationDispersed particle separationSludgeHearth

The invention belongs to the field of flue gas purification and provides an acetylene sludge desulfurization method for a coal-fired boiler. The method comprises the following steps: (1) drying the acetylene sludge until the moisture content is less than 2 percent; and (2) blowing the acetylene sludge into a hearth of the coal-fired boiler by using a Roots blower, wherein the blowing position is a bend at a secondary air inlet below front and rear walls of the hearth, and four blowing points are distributed on the front wall and another four blowing points are distributed on the rear wall. The main component of the acetylene sludge is Ca(OH)2, calcium element contained in industrial waste residues remained in acetylene gas generated by adding water into calcium carbide can be reacted with SO2 in flue gas in a CaO form, SO2 emission is reduced, and desulfurization in a circulating fluidized bed boiler is realized. However, the acetylene sludge delivery and blockage problem and the problems such as feeding non-uniformity, incomplete reaction and large desulfurization indicator fluctuation in the circulating fluidized bed boiler are not solved. According to the invention, the problems of blockage, feeding non-uniformity, incomplete reaction and large desulfurization indicator fluctuation in the acetylene sludge delivery process are solved.

Owner:内蒙古君正化工有限责任公司

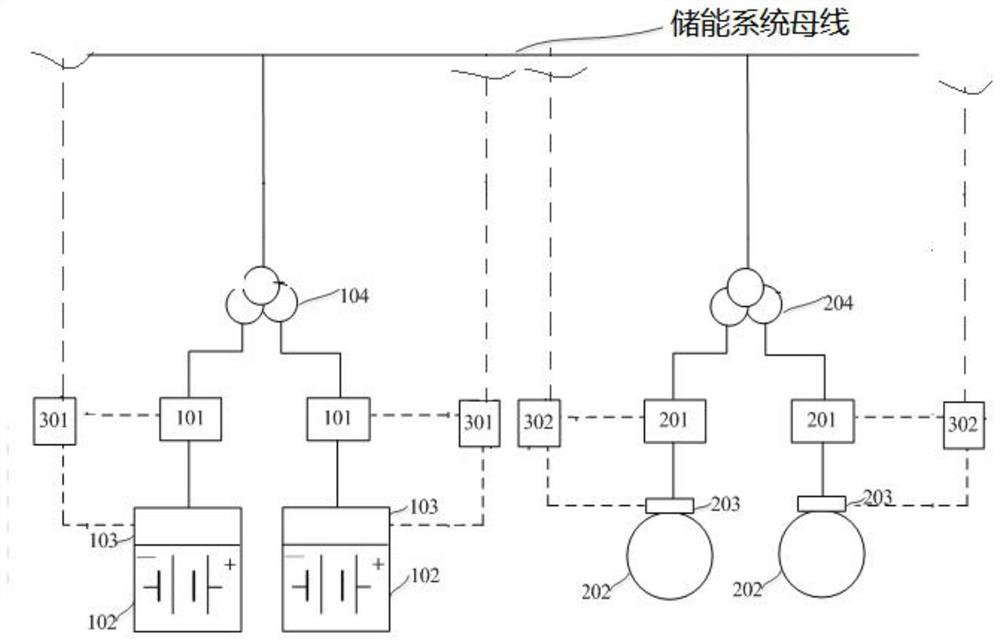

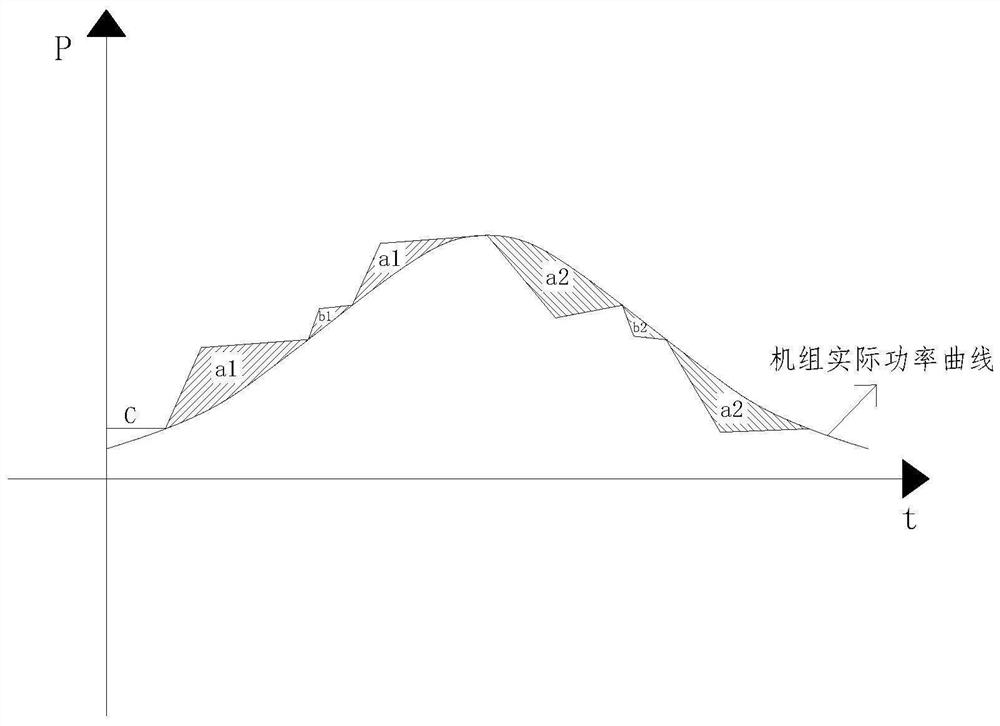

Electrochemical and flywheel hybrid energy storage system

PendingCN112737129AImprove FM capabilityGuaranteed uptimeElectrical storage systemAc network load balancingFlywheel energy storageElectrical battery

An electrochemical and flywheel hybrid energy storage system comprises an electrochemical energy storage device, a battery management system, a flywheel energy storage device, a flywheel control system, an energy storage energy management system, an energy storage auxiliary frequency modulation control device group, a bidirectional converter group and a transformer group. The device of the power plant unit combined with the electrochemical and flywheel hybrid energy storage system comprises the power plant unit and the electrochemical and flywheel hybrid energy storage system. The power plant unit is combined with the electrochemical and flywheel hybrid energy storage system, the electrochemical energy storage device and the flywheel energy storage device are preferentially controlled to perform corresponding actions when a power grid needs to be subjected to load increasing / decreasing frequency modulation, and the system has the advantages of high regulation speed, short response time and high regulation precision; and the electrochemical energy storage device and the flywheel energy storage device can quickly supplement or absorb the part of energy to maintain the stable bus voltage and ensure the safe operation of a high plant transformer.

Owner:若普自动化技术(北京)有限公司

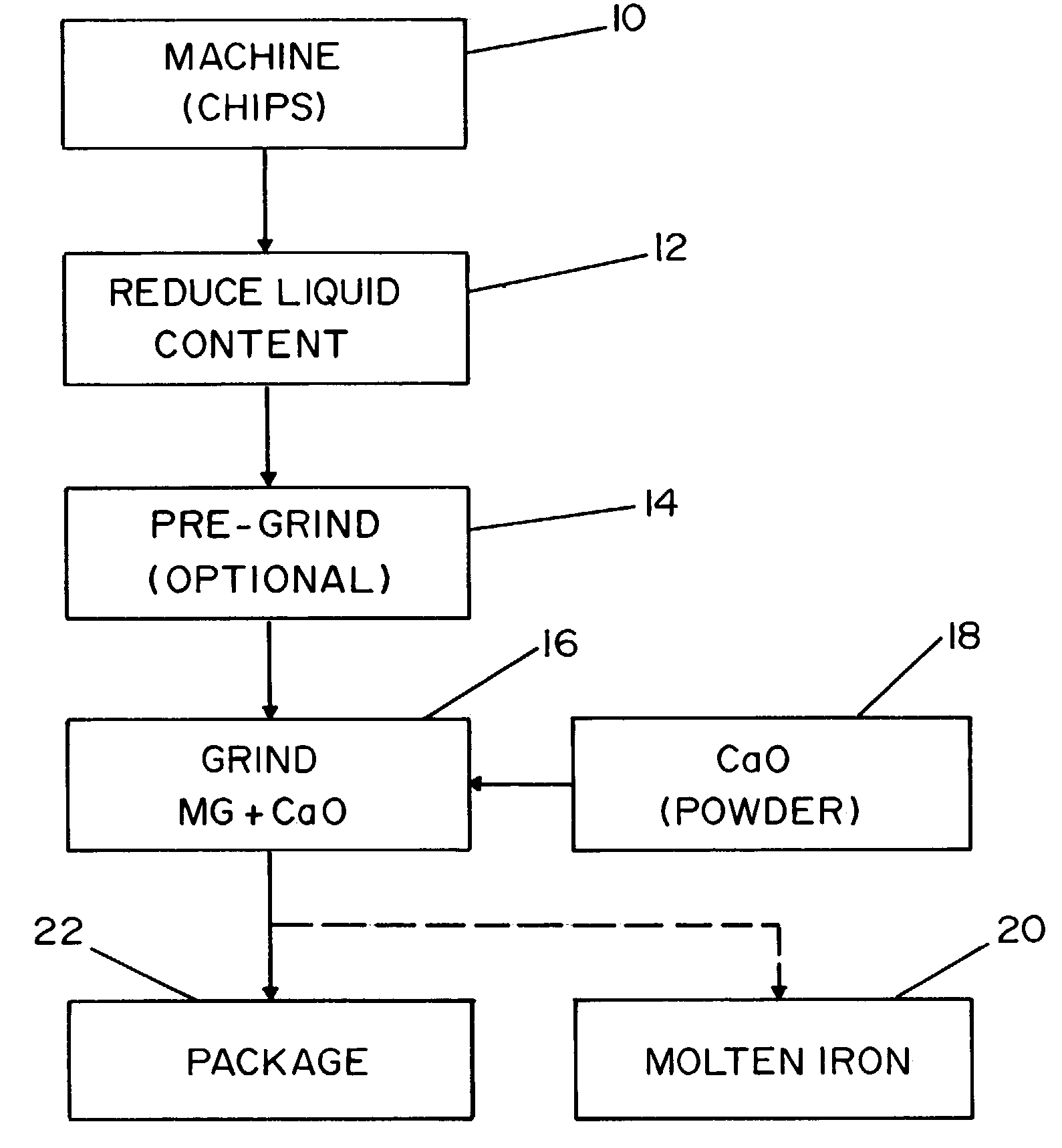

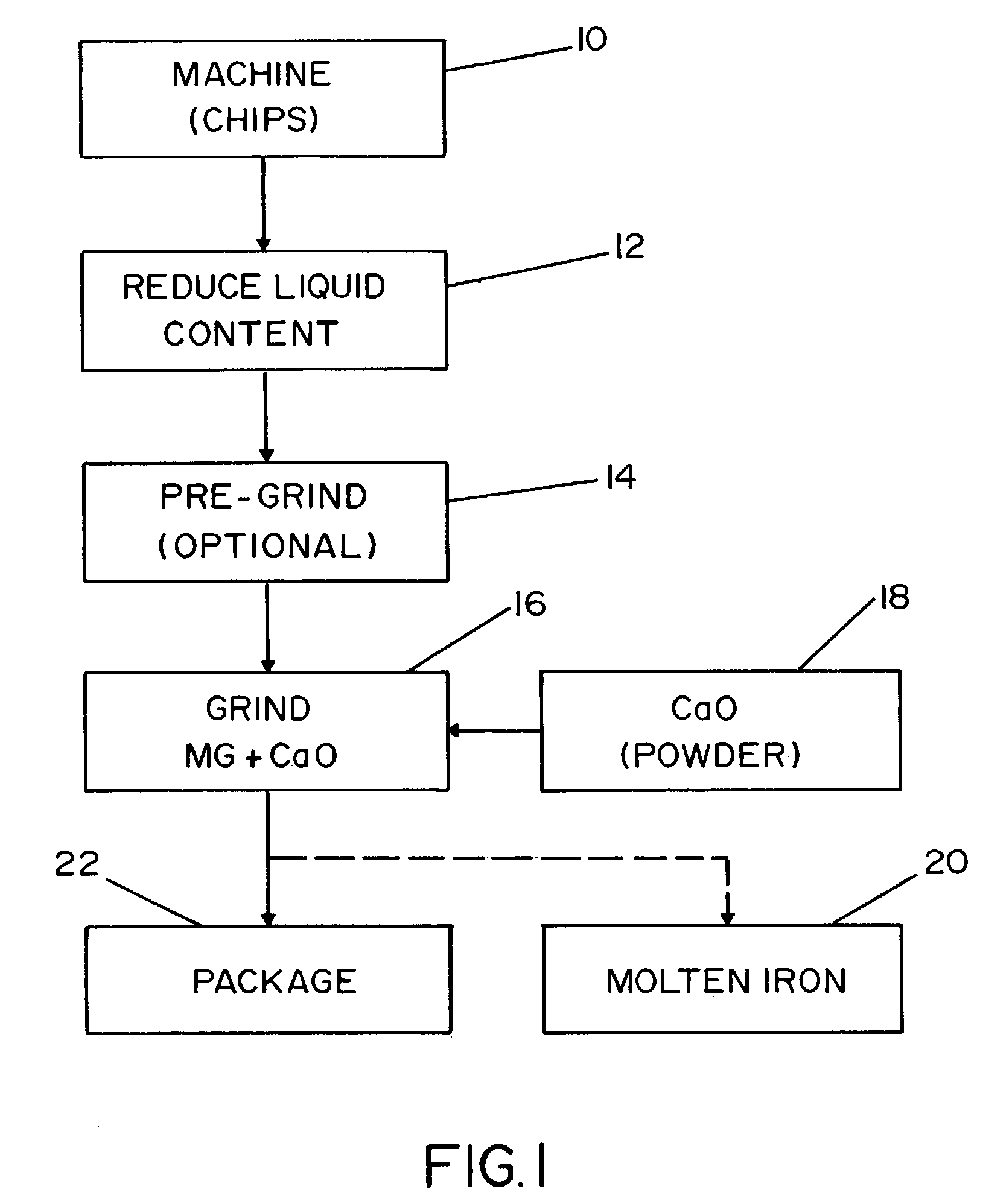

Reclaimed magnesium desulfurization agent

InactiveUS6989040B2Improve desulfurization efficiencyImprove efficiencyBlast furnace componentsBlast furnace detailsSulfurMaterials science

Owner:MAGNESIUM TECHNOLOGIES INC

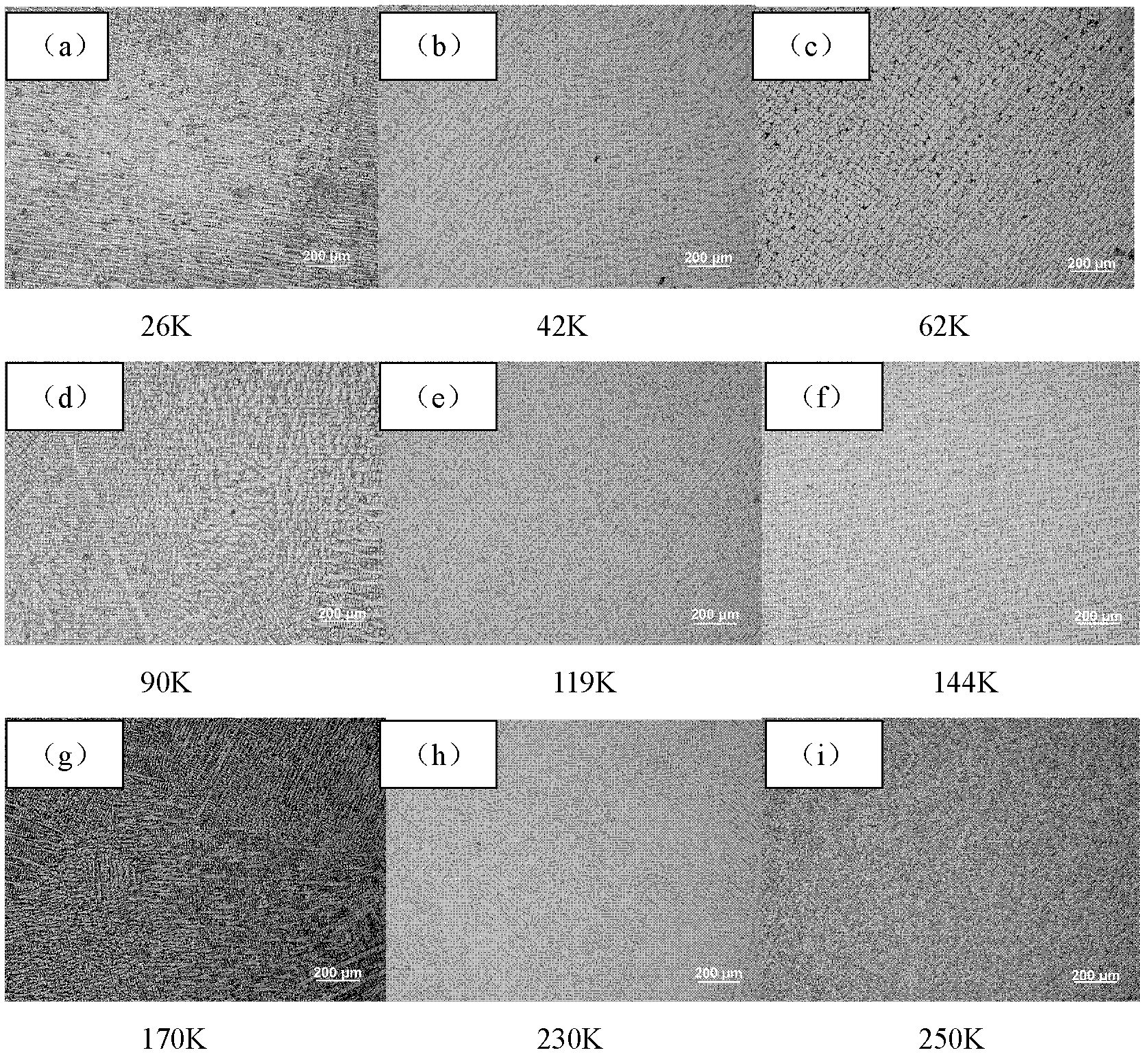

Low-temperature calcining process for pot furnace

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

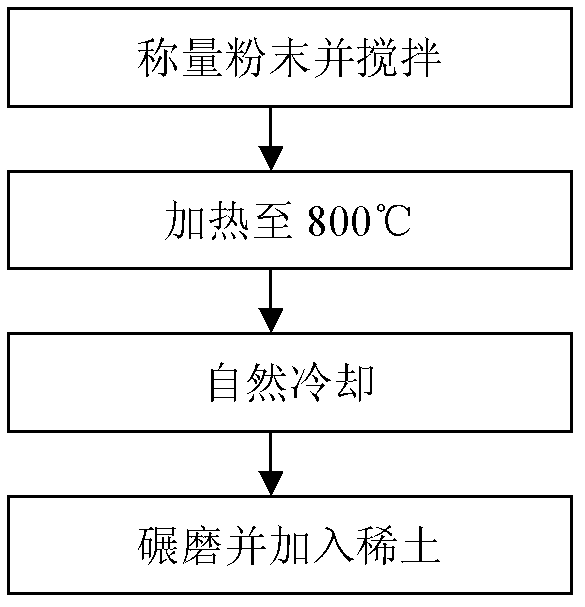

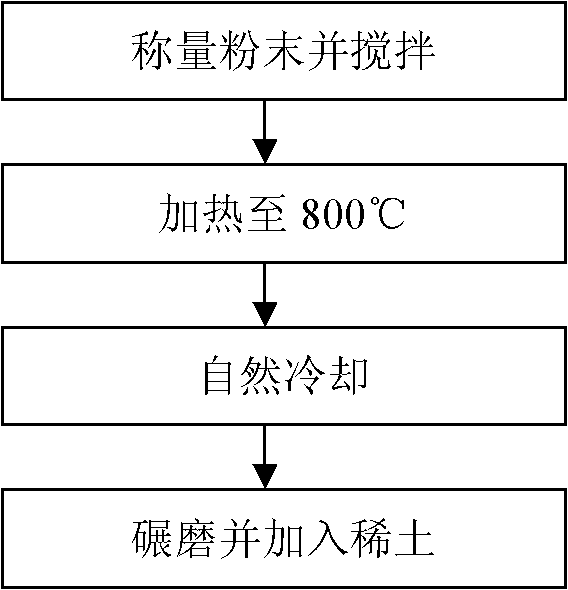

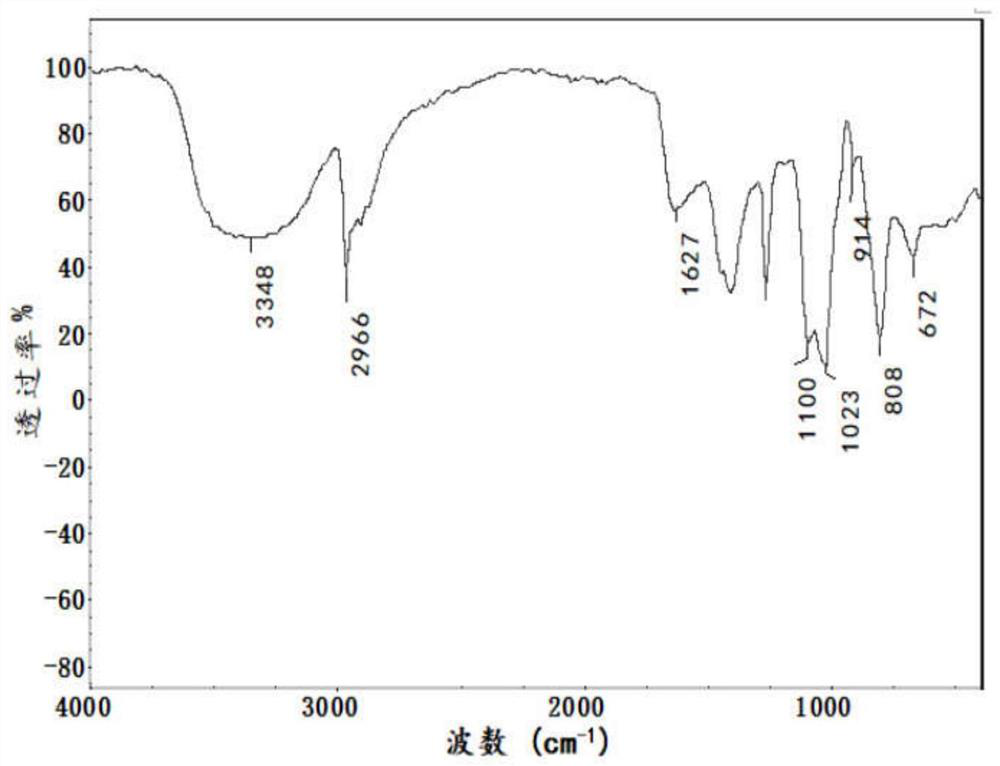

Supercooled IN718 high-temperature alloy purifying agent and preparation method for same

The invention discloses a supercooled IN718 high-temperature alloy purifying agent and a preparation method for the same. The preparation method includes: sufficiently mixing 45-55 parts of CaF2 (calcium fluoride), 8-12 parts of NaCl (sodium chloride), 8-12 parts of KCl (potassium chloride), 18-22 parts of CaO (calcium oxide), 4-6 parts of TiO2 (titanium dioxide), 4-6 parts of MgO (magnesium oxide) and 0.5-1.0 part of AlF3 (aluminum fluoride) to obtain mixed powder; heating the mixed powder to 800 DEG C and then preserving heat for 8 hours; naturally cooling the mixed powder to room temperature after heat preservation; and milling the mixture into powder after crushing the mixture, and adding 0.5-1.0 part of rare earth compound LaCl3 (lanthanum chloride) to obtain the purifying agent. The purifying agent can integrate the functions of overwrite protection, oxidation and volatilization prevention and impurity removal, components of the purifying agent are easy to obtain, the purifying agent is convenient to add, the operating process is simple, and the cost is low.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

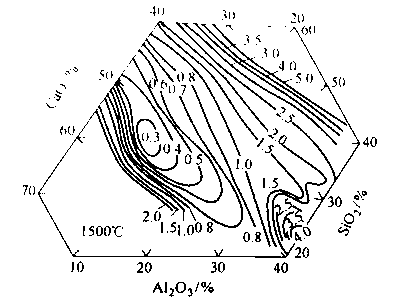

Smelting slagging agent and smelting slagging method adopting AOD (Argon Oxygen Decarburization) double slag process

The invention relates to a stainless-steel smelting slagging agent and a smelting slagging method, in particular to a smelting slagging agent and a smelting slagging method adopting the AOD (Argon Oxygen Decarburization) double slag process, and belongs to the field of stainless-steel smelting. The smelting slagging agent adopting the AOD double slag process comprises a first ingredient and a second ingredient, wherein the first ingredient is waste (high alumina crushed brick) generated after cast steel pouring; the second ingredient is fluorite; high alumina crushed brick comprises the following materials by mass: 68 to 72 percent of Al2O3, 22 to 28 percent of SiO2, 2 to 5 percent of CaO and 2 to 5 percent of Fe2O3; and the mass ratio of the first ingredient to the second ingredient is 0.5 to 1. The smelting slagging agent adopting the AOD double slag process is low in cost, facilitates environmental protection, and is high in comprehensive slagging effect.

Owner:YONGXING SPECIAL STAINLESS STEEL

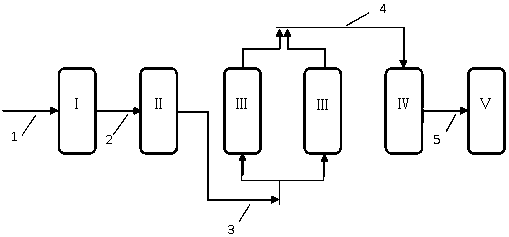

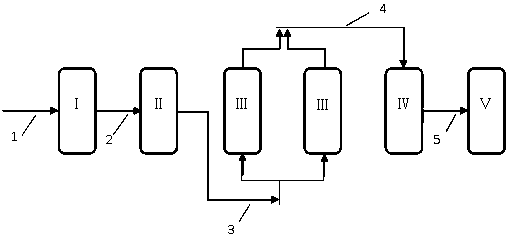

A coal gas purification method

PendingCN108165321ASolve the blockageReduce in quantityGas purification with selectively adsorptive solidsGas contaminants removalPurification methodsSulfide

The invention relates to a coal gas purification method and mainly overcomes a technical problem that cooling pipelines of compressors are liable to be blocked and sulfur dioxide emission is excessivebecause sulfides, tar, benzene and naphthalene are not thoroughly removed in coke oven gas purification in the prior art. The problem is solved well by adopting a technical scheme, wherein the methodincludes a) feeding coal gas from a coking plant into a crude desulfurization unit to form a stream I; b) feeding the stream I into an integrated purification column so that aromatic hydrocarbons andsulfides in the gas are adsorbed and a stream II is formed; and c) feeding the stream II into a compressor, compressing the stream II, and then conveying the stream II to a gas turbine for power generation. The method can be applied in industrial production of power generation with coke oven gas.

Owner:湖北申昙环保新材料有限公司 +1

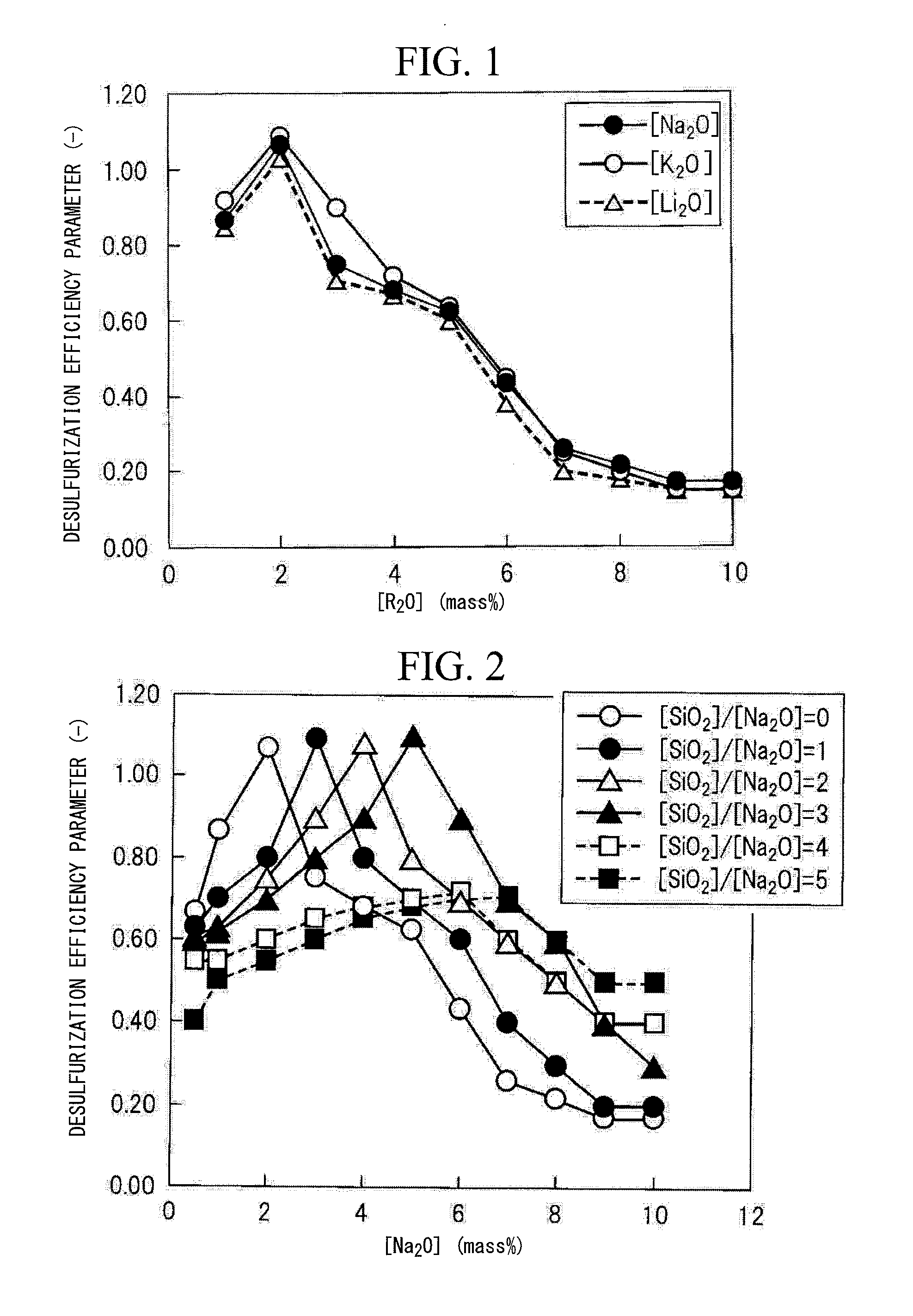

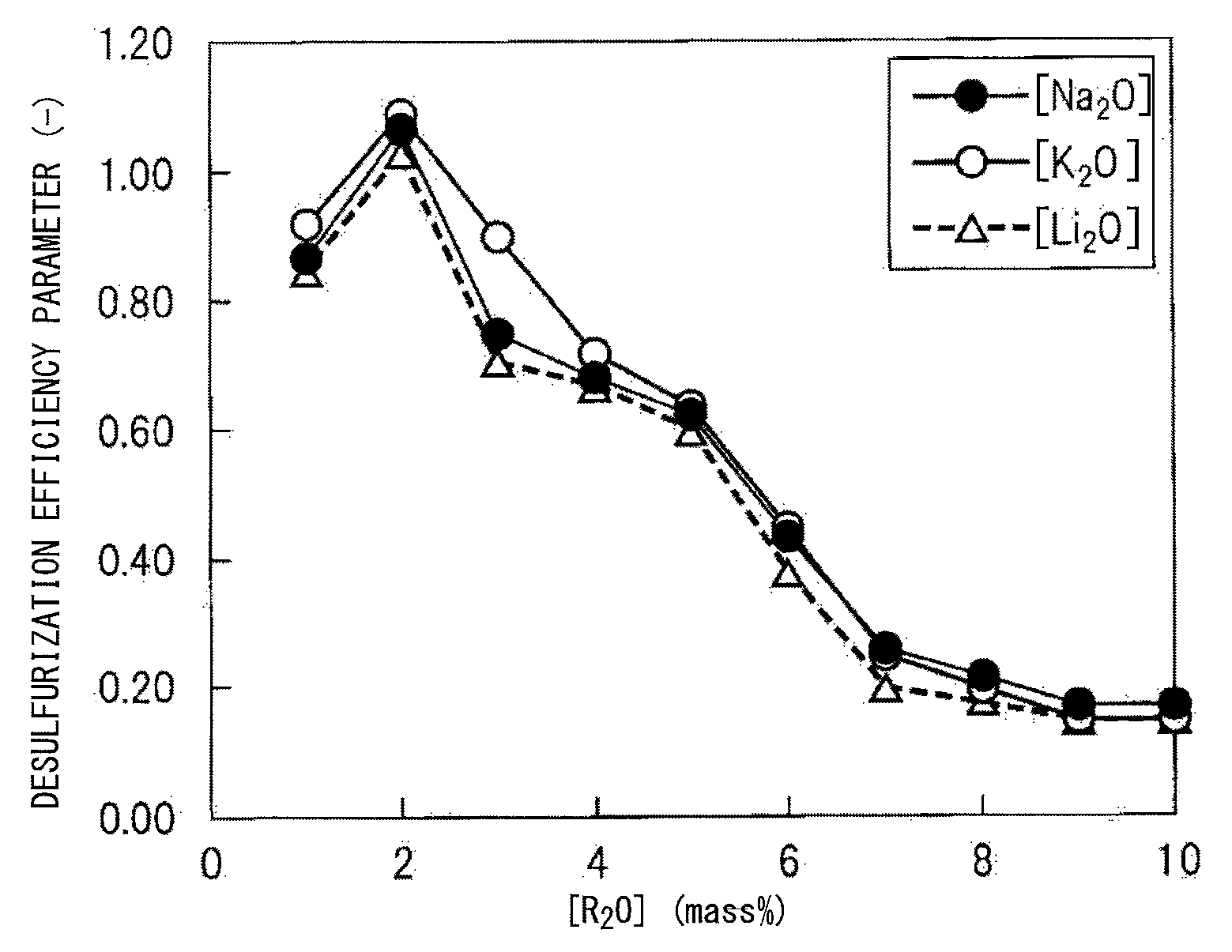

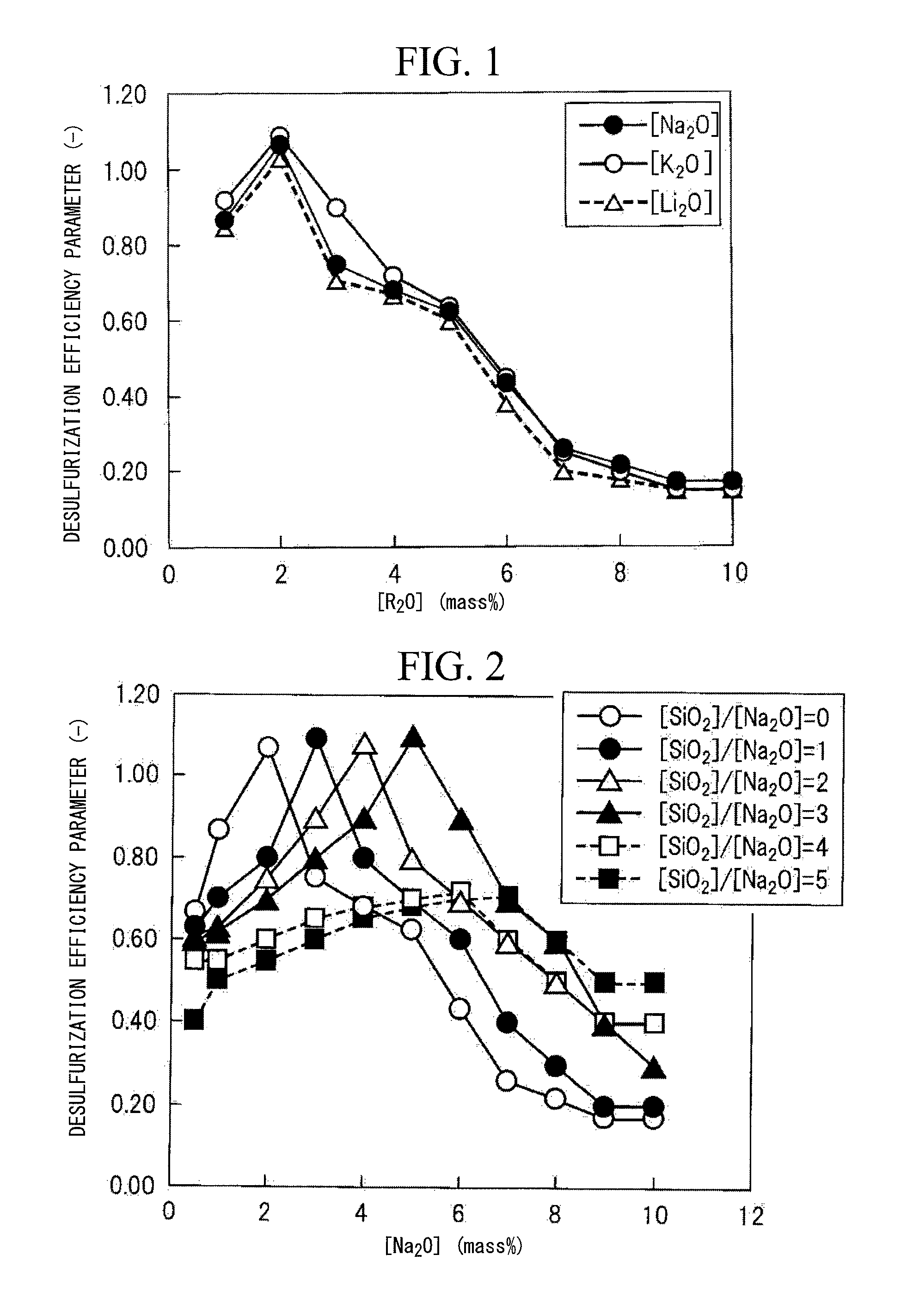

Environmentally friendly flux for molten steel desulfurization

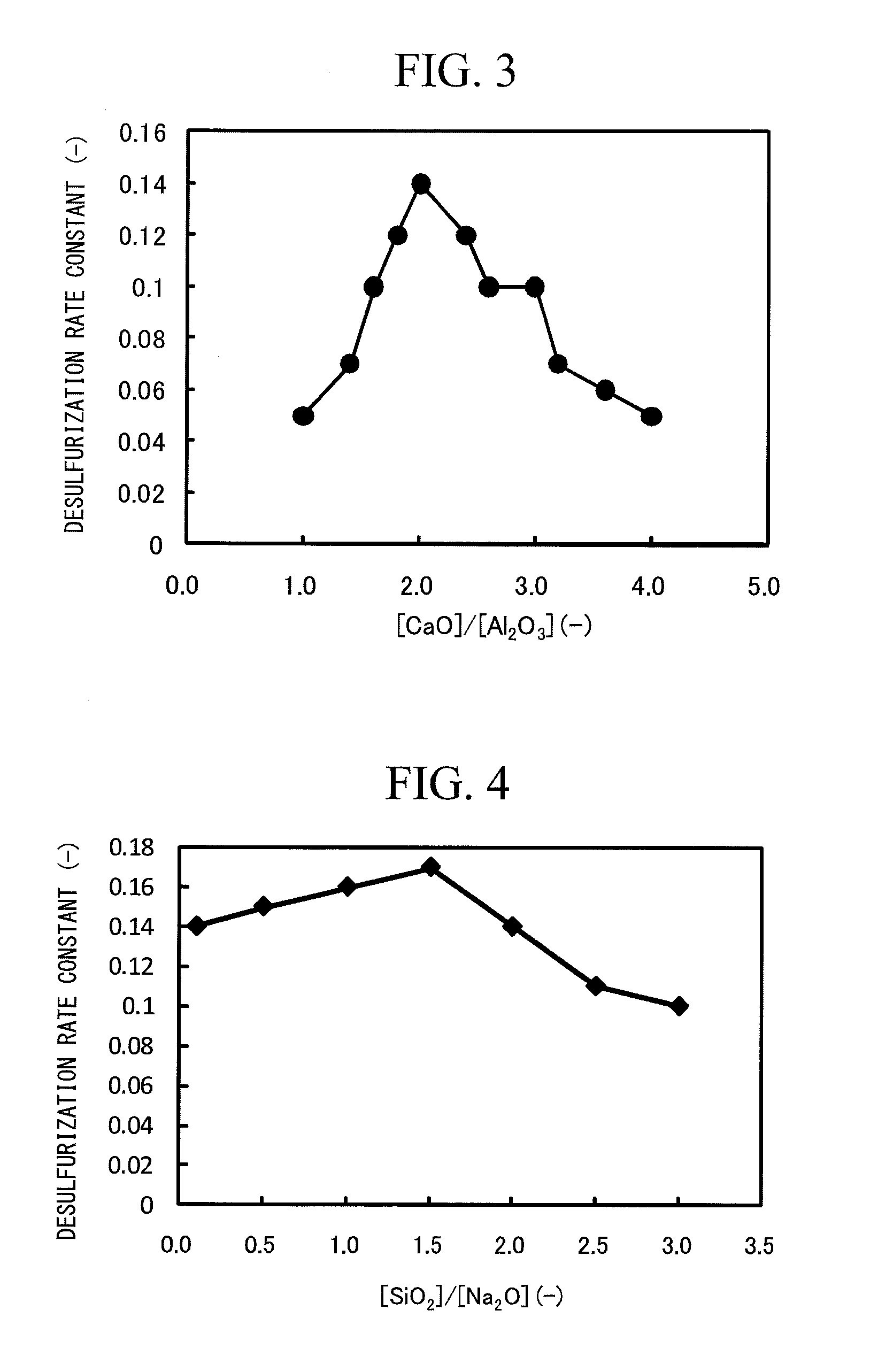

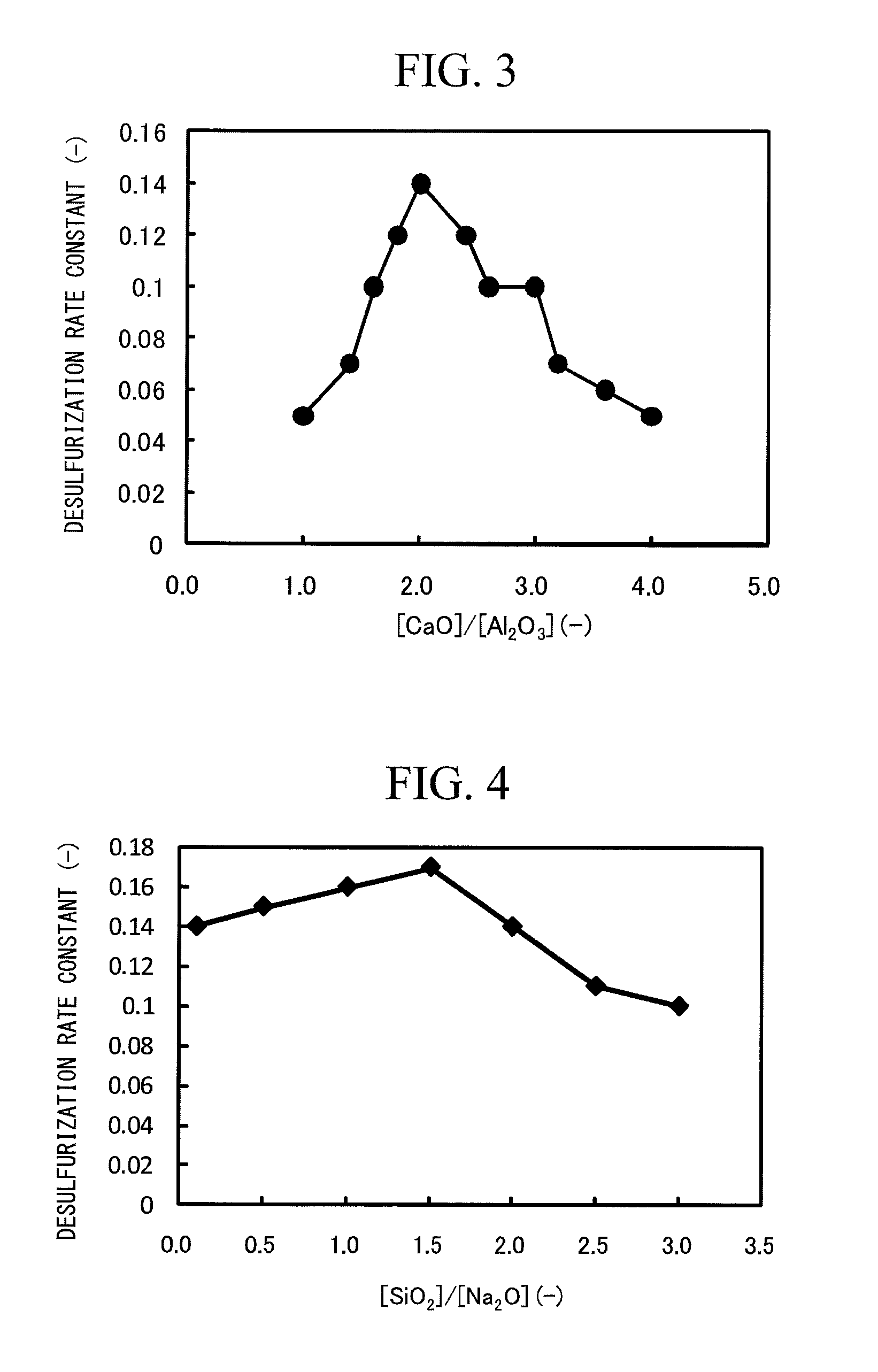

ActiveUS20130333518A1Decrease productivityReduce desulfurizationBlast furnace componentsBlast furnace detailsAlkali metal oxideMolten steel

An environmentally friendly flux for molten steel desulfurization includes CaO and Al2O3 so that [CaO] / [Al2O3] is within a range of 1.6 to 3.0, and includes one or more alkali metal oxides of Na2O, K2O, and Li2O, and SiO2 so that [SiO2] / [R2O] is within a range of 0.1 to 3, [R2O] is within a range of 0.5 mass % to 5 mass %, and [SiO2] is within a range of 0.05 mass % to 15 mass % in a case in which the [CaO], the [Al2O3], the [SiO2], and the [R2O] represent the mass % of CaO, the mass % of Al2O3, the mass % of SiO2, and the total amount of the mass % of Na2O, the mass % of K2O, and the mass % of Li2O respectively.

Owner:NIPPON STEEL CORP

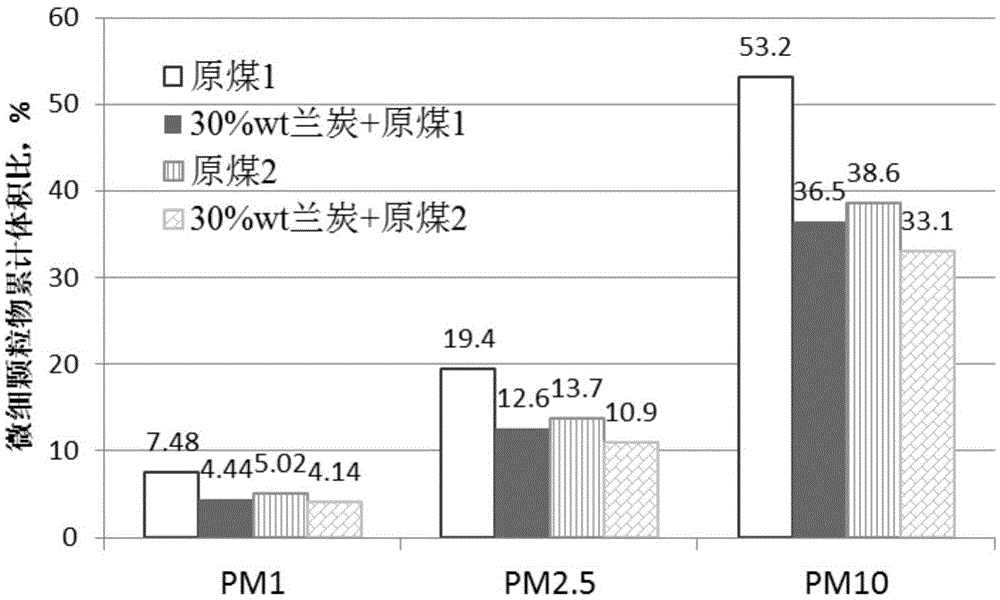

Method for reducing fine particles of coal burning boiler

ActiveCN104807030AReduce contentReduce generationLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationProcess engineeringSoftening

The invention discloses a method for reducing fine particles of a coal burning boiler. The method comprises the following steps of (1) measuring ash softening temperature ST and erosive wear index Ke of semi coke and raw coal, and according to the ash softening temperature ST and the erosive wear index Ke, determining the highest fuel semi coke blending proportion; (2) according to the highest fuel semi coke blending proportion, after uniformly mixing the semi coke and the raw coal, feeding the mixture into a coal pulverizer to uniformly mixing the semi coke and the raw coal to obtain semi coke powder and the raw coal powder which are uniformly mixed; (3) feeding the semi coke powder and the raw coal powder which are uniformly mixed into the hearth of the coal burning boiler by wind to be combusted. The method is simple in process and convenient to operate, and the method can be realized by most of the current thermal power generating units at a coal field through blending.

Owner:XIAN THERMAL POWER RES INST CO LTD

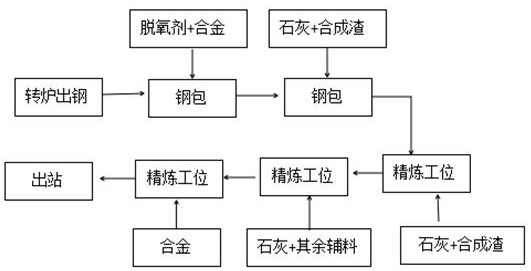

Method for refining and quickly slagging low-carbon low-silicon aluminum-containing killed steel

ActiveCN113832290APrecise control of alkalinityIncrease the allocation ratioManufacturing convertersProcess efficiency improvementMetallic aluminumSlag

The invention discloses a method for refining and rapidly slagging low-carbon low-silicon aluminum-containing killed steel, and belongs to the technical field of alloy steel. The method comprises the following steps: adding the refining synthetic slag accounting for 28-35% of the total amount of a converter and lime slag accounting for 28-35% of the total amount of the converter in the tapping process of the converter; adding the residual refining synthetic slag and lime slag in the refining process; the total amount ratio of the refining synthetic slag to the lime slag is 1: (5-7); the refining synthetic slag is prepared from the following components in percentage by weight: 20-50% of metal aluminum, 35-60% of Al2O3 and 10-20% of CaO, and the granularity of the metal aluminum is less than 5 mm. According to the method, white slag operation is achieved within 15 minutes in the refining process, the generated white slag has sufficient time for desulfuration and inclusion removal in the later stage of refining, and meanwhile cost can be reduced and efficiency can be improved.

Owner:山西新泰钢铁有限公司

Preparation method of small-particle-size machine-made semi-coke barbecue carbon

ActiveCN113265283AHigh strengthEmission reductionSolid fuelsWaste based fuelCelluloseCompression molding

The invention relates to the field of carbon preparation, and discloses a preparation method of small-particle-size machine-made semi-coke barbecue carbon, which comprises the following steps: crushing, mixing, stuffiness gelatinization and molding drying. According to the method, cellulose salt, plant starch and semi-coke are mixed and then gelatinized by water vapor under high pressure, and then compression molding is performed to obtain the barbecue charcoal which has the characteristic of high strength; and according to the invention, a catalytic composite sulfur-fixing agent is also added into the formula, the use of the sulfur-fixing agent can make the coal combust more fully, reduce the emission of sulfur dioxide and desulfurization and reduce the consumption of fire coal at the same time, and is beneficial to reducing the emission of dust and harmful gas, and the barbecue carbon is a healthy, safe and environmentally friendly product. And health and safety of barbecued food are facilitated.

Owner:内蒙古蓝色火宴科技环保股份公司

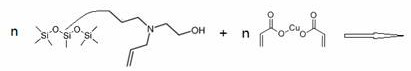

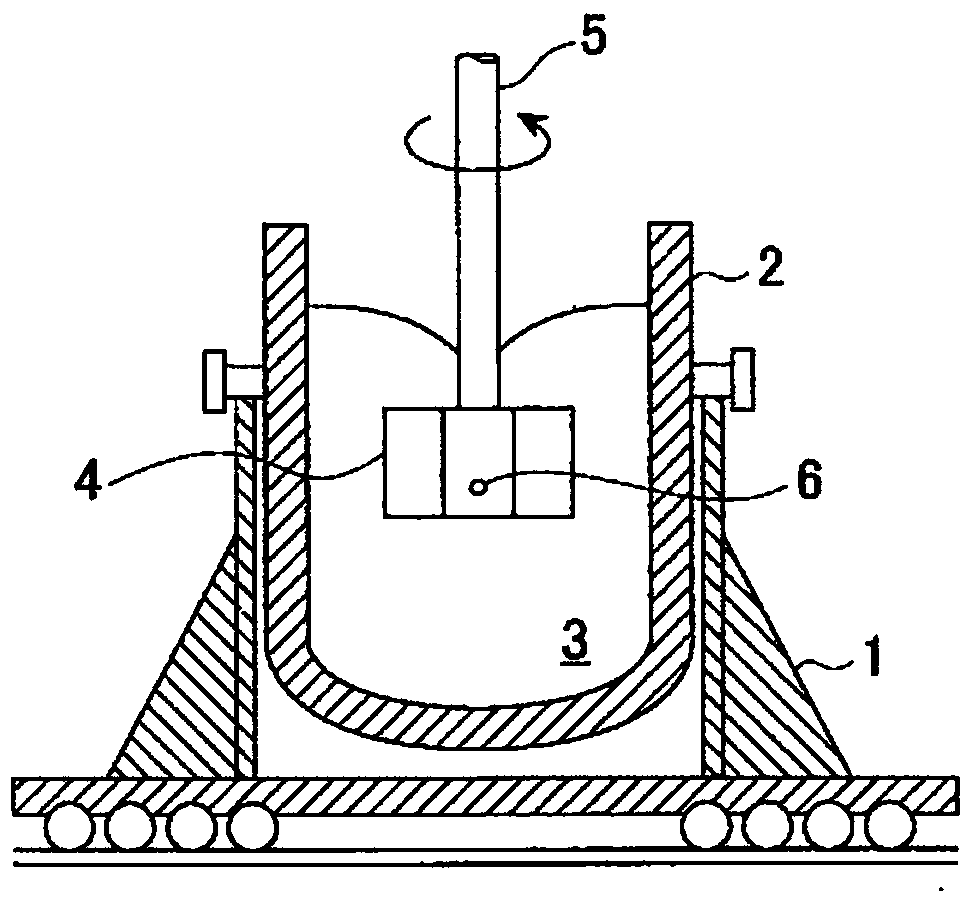

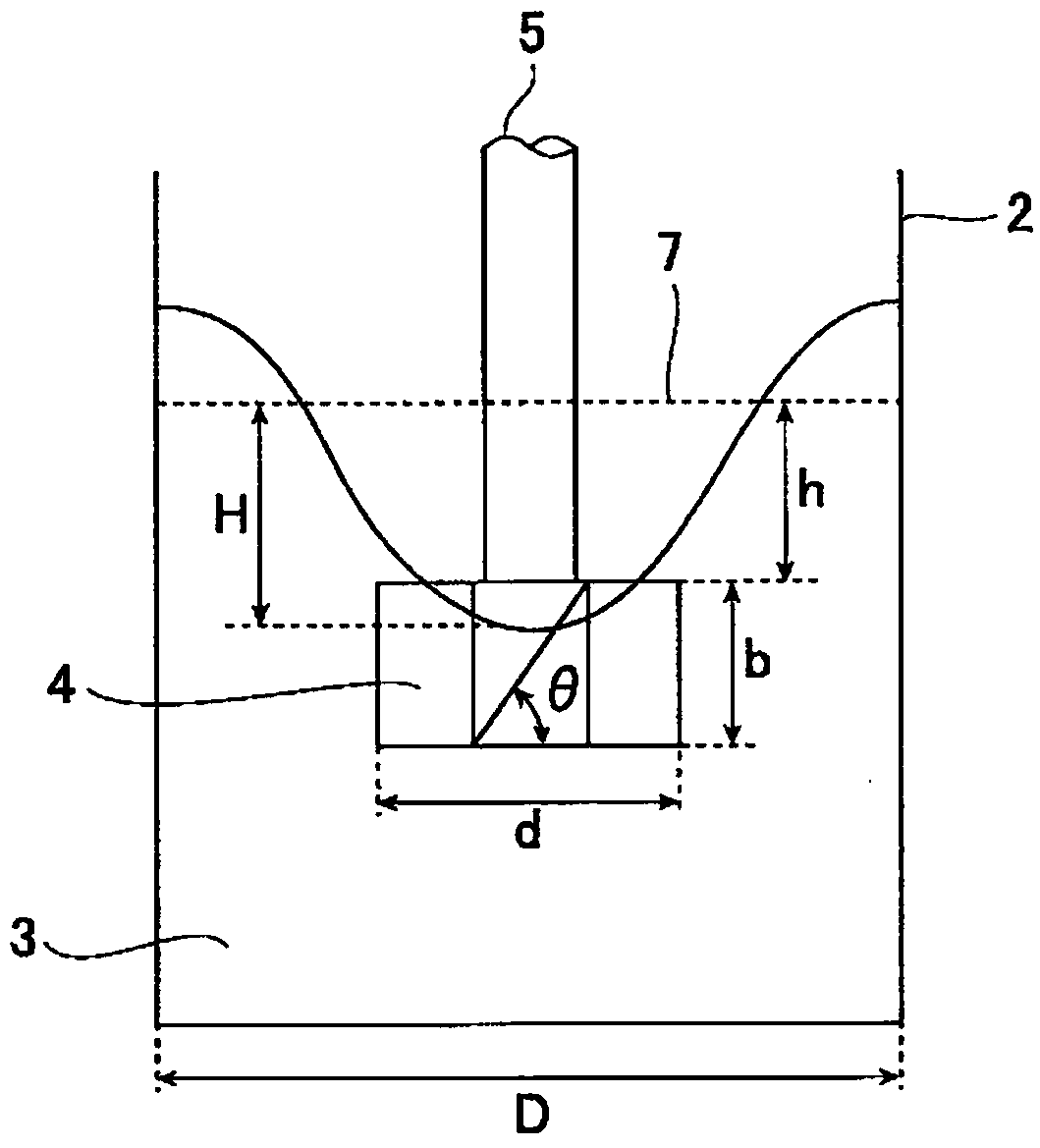

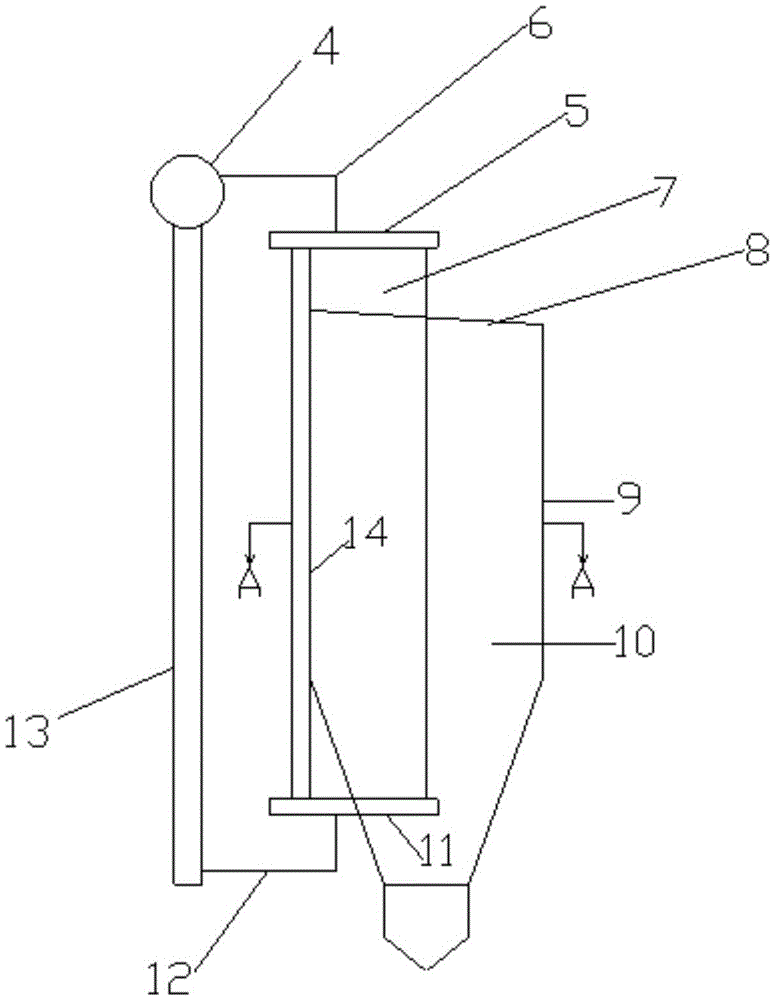

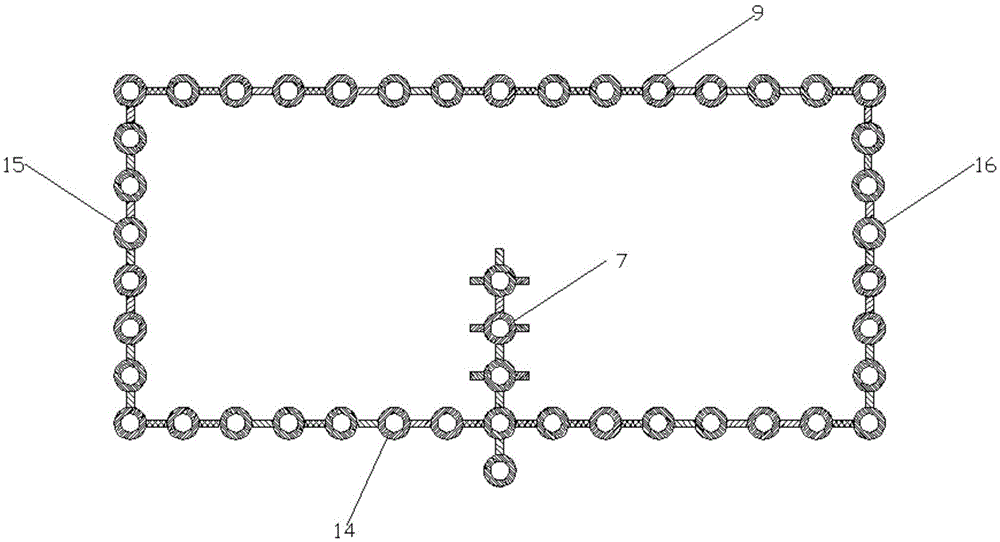

Method for preventing resulfurization of molten iron after desulfurization treatment

InactiveCN105899689BReduce desulfurizationBack sulfur reductionStirring devicesSteel manufacturing process aspectsImpellerSulfur

In processes for manufacturing molten steel from molten pig iron by performing, on desulfurized molten pig iron, a subsequent step of decarburization refining, etc., the present invention prevents resulfurization arising from microscopic desulfurization slag suspended in the molten pig iron or desulfurization slag adhering to the side walls of the processing vessel that is generated during desulfurization of the molten pig iron. This method for preventing resulfurization of molten pig iron after desulfurization: performs desulfurization of molten pig iron inside a processing vessel using a mechanical stirring desulfurization apparatus; then blows inert gas into the molten pig iron from gas-jetting holes (6) set in the impeller (4) of the mechanical stirring desulfurization apparatus and stirs the molten pig iron (3); floats the desulfurization slag suspended in the molten pig iron and / or desulfurization slag adhering to the inner walls of the processing vessel up to the surface of the molten pig iron by said stirring; discharges the floating desulfurization slag from the processing vessel; and subsequently conveys the molten pig iron inside the processing vessel to the next step.

Owner:JFE STEEL CORP

A coal gas purification method

InactiveCN108165323AReduce in quantityReduce manufacturing costGas purification with selectively adsorptive solidsGas contaminants removalTarMolecular sieve

The invention relates to a coal gas purification method to mainly overcome a technical problem that cooling pipelines of compressors are liable to be blocked and sulfur dioxide emission is excessive because sulfides, tar, benzene and naphthalene are not thoroughly removed in coke oven gas purification in the prior art. The problem is solved well by adopting a technical scheme, wherein the method includes a) feeding coke oven gas discharged from a coke oven into a crude debenzolization unit, and performing crude debenzolization to form a stream I, with a molecular sieve adsorbent A being adopted in crude debenzolization; b) feeding the stream I into a crude desulfurization unit, and performing crude desulfurization to form a stream II, with a molecular sieve adsorbent B being adopted in crude desulfurization; c) feeding the stream II into an integrated purification column containing a molecular sieve adsorbent C, and removing residual aromatic hydrocarbons and sulfides in the gas at thesame time to form a stream III; and d) feeding the stream III into a subsequent gas utilization workshop section. The method can be applied in industrial production of power generation with coke ovengas.

Owner:湖北申昙环保新材料有限公司 +1

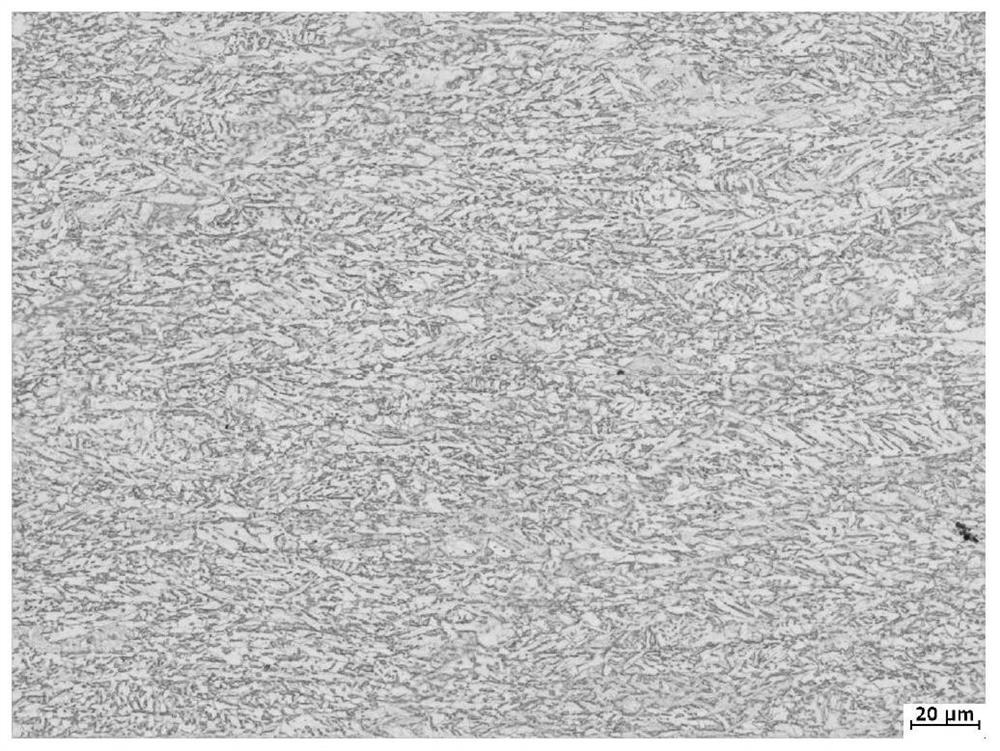

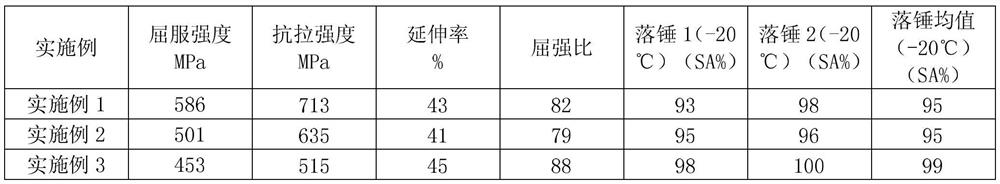

A wide-thick specification pipeline steel with excellent low-temperature toughness and its manufacturing method

ActiveCN113046655BReduce oxygen contentRefined grain sizeManufacturing convertersUltimate tensile strengthToughness

The invention discloses a wide-thick specification pipeline steel with excellent low-temperature toughness and a manufacturing method thereof, and relates to the technical field of iron and steel production. Its chemical composition and mass percentage are as follows: C: 0.030%-0.080%, Si: 0.10%-0.40%, Mn : 1.50%~1.80%, P≤0.015%, S≤0.0030%, Ni≤0.30%, Cr≤0.30%, Cu≤0.30%, Al: 0.005%~0.015%, Nb: 0.030%~0.070%, Mo≤ 0.30%, Ti: 0.006%~0.020%, Mg: 0.0008%~0.0015%, N≤0.0050%, the balance is Fe and unavoidable impurities. The structure type mainly composed of acicular ferritic iron is obtained, and the strength and toughness are well matched, which meets the requirements of the API of pipeline steel and the standard requirements of China Petroleum and Petrochemical.

Owner:NANJING IRON & STEEL CO LTD

Sulfur solidifying catalyst

ActiveCN105251539AActiveDistributeOrganic-compounds/hydrides/coordination-complexes catalystsSolid fuelsPtru catalystGlycerol

The invention provides a sulfur solidifying catalyst. The sulfur solidifying catalyst is prepared by mixing the following raw materials by weight percent: 20%-30% of glycerol, 5%-10% of sodium carbonate, 5%-15% of sodium methylallyl sulfonate, 8%-13% of sodium gluconate, 6%-15% of titanium dioxide, 2%-6% of triethanolamine and 25%-35% of water, wherein the sum of the weight percent of the raw materials is 100%. Titanium dioxide is modified to obtain nano titanium dioxide material. According to the sulfur solidifying catalyst, fire coals can be burned sufficiently, 10% or above dosages of fire coals can be reduced, the emission amount of sulfur dioxide can be reduced, 30% or above desulfurization amount can be achieved, and meanwhile, the emission amount of dust and harmful gas can be reduced.

Owner:张家界鸿燕新材料科技发展有限公司

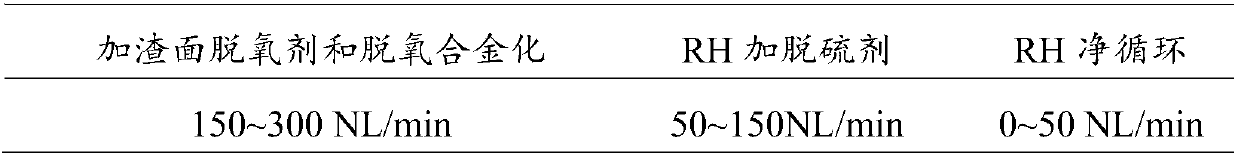

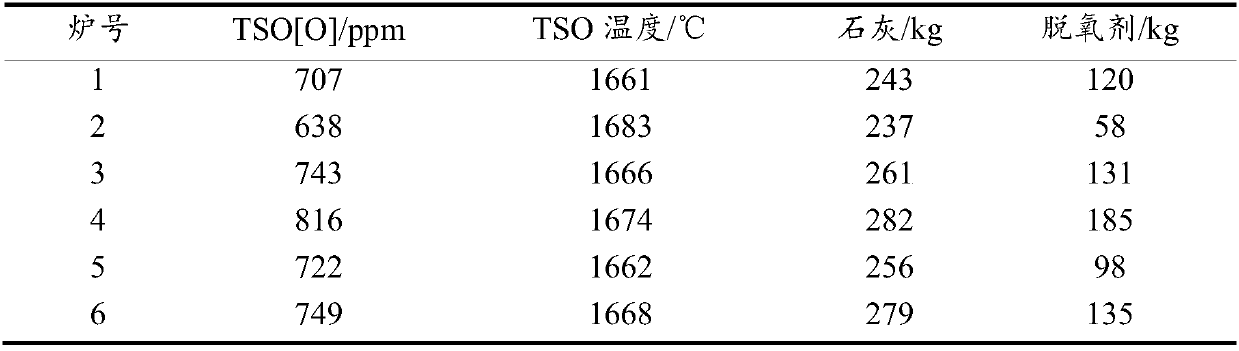

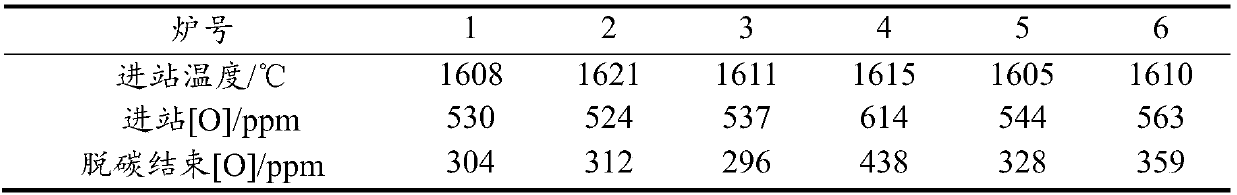

A method for synchronous desulfurization of molten steel and slag in rh vacuum furnace for non-oriented silicon steel

The invention discloses a method for synchronously desulphurizing molten steel and slag of a non-oriented silicon steel RH vacuum oven. The method mainly comprises the following steps: molten steel pretreatment (a KR method), converter smelting and RH vacuum refining, wherein the RH vacuum refining comprises the steps of carrying out vacuumizing and decarbonization on RH entering a station, after the decarbonization of RH is finished, adding a low-carbon steel slag surface deoxidant into the surface of the steel slag, simultaneously carrying out steel ladle bottom blowing to promote the reduction of the low-carbon steel slag surface deoxidant to steel ladle slag, after the low-carbon steel slag surface deoxidant is added, adding metal aluminum, silicon iron and manganese metal into molten steel, carrying out deoxygenation and alloying, carrying out circular processing for 4-7 minutes, adding a desulphurizing agent in different stages, simultaneously adjusting the steel ladle bottom blowing flow to promote slag-metal reaction to realize desulphurization, carrying out desulphurizing molten steel by virtue of the desulphurizing agent and the steel ladle slag so as to improve the desulphurization efficiency, after the desulphurization is finished, carrying out clean circulation for more than 8 minutes, and carrying out vacuum breaking and steel tapping. The sulfur content of an RH end point is less than 30ppm, and the standardized rate is increased from original about 22% to 95% or above.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

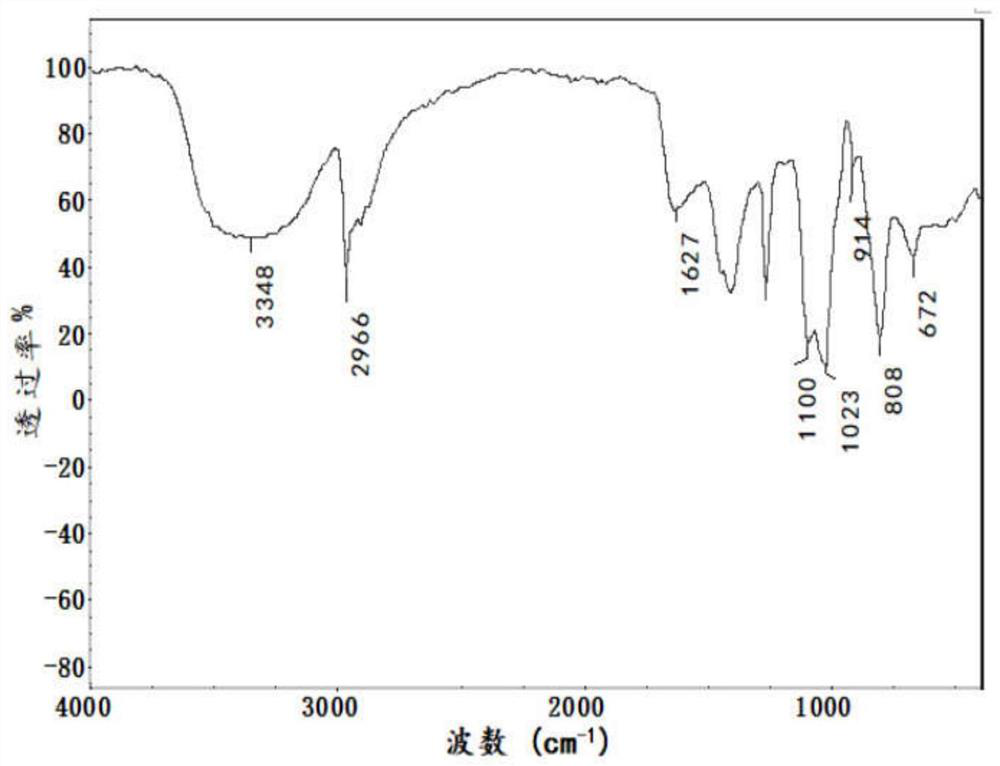

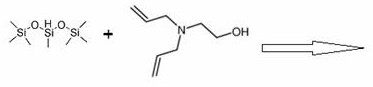

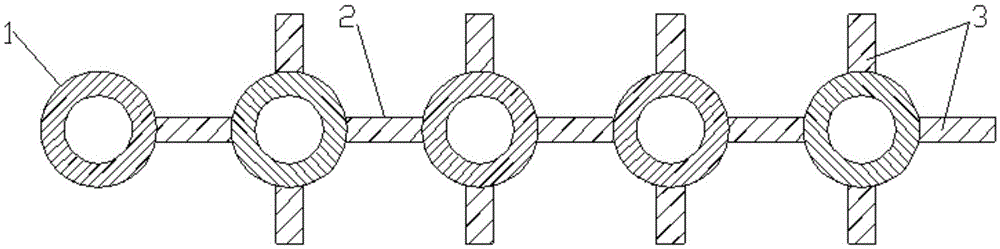

Glass fiber composite tube

InactiveCN108404652AReduce desulfurizationFluoride shorteningGas treatmentDispersed particle separationGlass fiberYarn

The invention relates to the field of industrial flue gas treatment equipment, in particular to a glass fiber composite tube. The glass fiber composite tube is obtained by mixing a glass fiber material, a catalyst and a binder and then pressing, drying and forming, wherein the catalyst accounts for 3-30% of the total mass of all the materials. The glass fiber material is one or more of glass fiberspun yarns, glass fiber rough yarns and a chopped strand mat; the catalyst is a denitration catalyst or a dioxin removing catalyst; and the binder is a high-temperature-resistant inorganic binder. The glass fiber composite tube is used in the field of flue gas treatment, a large number of tiny gaps are formed in the tube wall, gas out of the tube can enter the inside of the tube through the gaps,and meanwhile, dust with the size greater than 2.5-10 mu m is stopped from penetrating the tube wall; the highest tolerable temperature of the glass fiber composite tube is 950 DEG C, the glass fibercomposite tube is suitable for treating high-temperature flue gas in various boilers, kilns, incinerators, ship tail gas and the like, and the problem that an existing cloth bag for cloth bag dust removal only resists 220 DEG C is solved effectively; and the glass fiber composite tube can desorb oxynitride in flue gas and remove dioxin, and meanwhile, desulfuration is assisted.

Owner:TONGXIANG ZHIYUAN ECO FRIENDLY TECH

A kind of preparation method of small particle size mechanism blue charcoal barbecue carbon

ActiveCN113265283BHigh strengthEmission reductionSolid fuelsWaste based fuelWater vaporEnvironmental engineering

The invention relates to the field of carbon preparation. The invention discloses a method for preparing a small particle size machine-made blue charcoal barbecue carbon. The steps include: crushing, mixing, sultry gelatinization and molding drying; the method uses cellulose salt and vegetable starch After being mixed with blue charcoal, the barbecue charcoal obtained by steam gelatinization under high pressure and then pressed into shape has the characteristics of high strength; the present invention also adds a catalytic composite sulfur-fixing agent in the formula, and the use of this kind of sulfur-fixing agent can Make coal burn more fully, reduce sulfur dioxide emission and desulfurization, and reduce coal consumption at the same time, which is conducive to reducing dust and harmful gas emissions. The barbecue carbon of the present invention is a healthy, safe and environmentally friendly product, which is beneficial to the health and safety of barbecued food .

Owner:内蒙古蓝色火宴科技环保股份公司

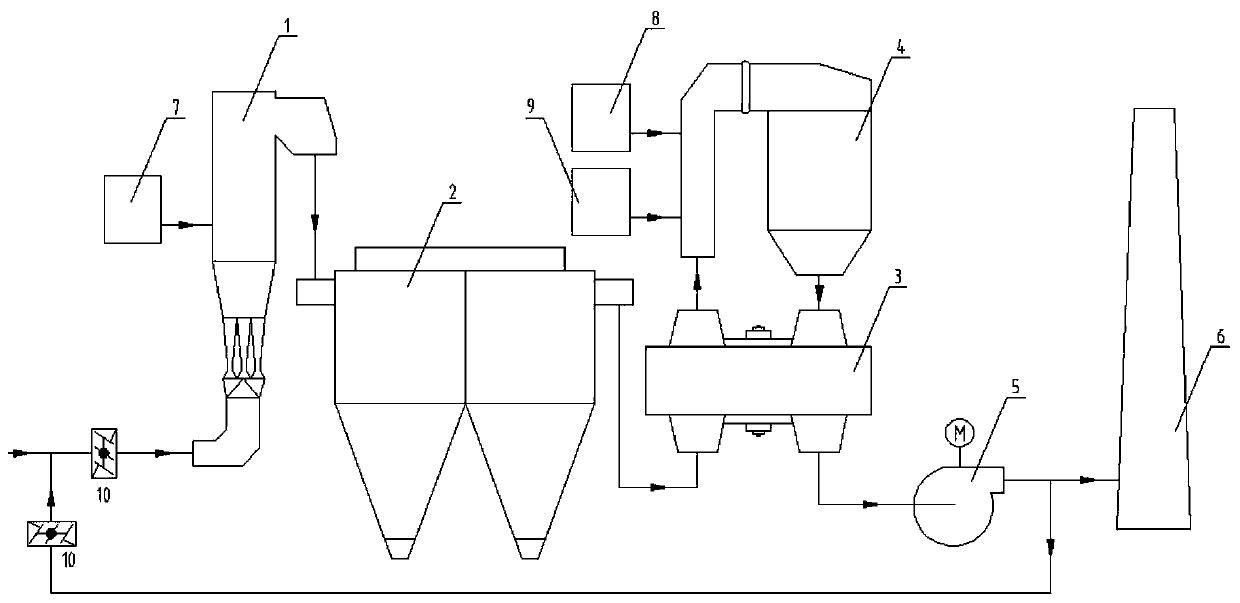

Sintering machine head flue gas desulfurization and denitrification treatment device and treatment method thereof

PendingCN111151108ARunning balance and stabilityReduce desulfurizationDispersed particle filtrationPtru catalystFlue gas

The invention discloses a sintering machine head flue gas desulfurization and denitrification treatment device and a treatment method thereof. The device comprises a dry desulfurization tower, a bag-type dust collector, a GGH flue gas heat exchanger, a low-temperature catalyst SCR reactor, a variable-frequency fan and a chimney which are sequentially communicated. The GGH flue gas heat exchanger is provided with a first input end, a first output end, a second input end and a second output end. The air outlet end of the bag-type dust collector is communicated with the first input end, the firstoutput end is communicated with the air inlet end of the low-temperature catalyst SCR reactor, the air outlet end of the low-temperature catalyst SCR reactor is communicated with the second input end, and the second output end is communicated with the variable-frequency fan. The dry desulfurization technology and the low-temperature SCR catalyst are combined for use, the stability of the system is improved, excessive consumption of a desulfurizing agent is avoided, and consumption of heating fuel is reduced.

Owner:中冶大地工程咨询有限公司 +1

Hearth temperature water-cooling control device for large circulating fluidized bed boiler

InactiveCN105588121AExtended service lifeGuaranteed tightnessFluidized bed combustionApparatus for fluidised bed combustionEngineeringSteam drum

The invention discloses a hearth temperature water-cooling control device for a large circulating fluidized bed boiler. By the adoption of the hearth temperature water-cooling control device for the large circulating fluidized bed boiler, the problem that the hearth temperature of a circulating fluidized bed boiler is slightly higher and difficult to control is solved. The hearth temperature water-cooling control device for the large circulating fluidized bed boiler comprises a hearth, a water-cooling partition wall, a steam pocket, connecting pipes, an upper header and a lower header, wherein the water-cooling partition wall, the steam pocket, the connecting pipes, the upper header and the lower header are located in the hearth. The hearth comprises a hearth roof, a front wall, a rear wall, a left side wall and a right side wall, wherein a rectangular cylinder is formed by the front wall, the rear wall, the left side wall and the right side wall. The water-cooling partition wall comprises a plurality of heat exchange pipes, abrasion-proof fins and flat steel, wherein the heat exchange pipes are arranged on the same plane in parallel, the flat steel is welded between every two adjacent heat exchange pipes, and the heat exchange pipes and the flat steel are arranged linearly; the abrasion-proof fins are welded to the two sides of each heat exchange pipe. The water-cooling partition wall horizontally extends to the middle of the hearth and vertically penetrates through the hearth. The upper end and the lower end of the water-cooling partition wall communicate with the upper header and the lower header correspondingly. The upper header and the lower header communicate with the steam pocket through the connecting pipes, and a circulation loop is formed. One side of the water-cooling partition wall is fixedly connected to the middle of the front wall of the hearth and is perpendicular to the front wall, and the other side of the water-cooling partition wall horizontally extends to the middle of the hearth.

Owner:SHANXI GUOFENG COAL POWER CO LTD +1

Environmentally friendly flux for molten steel desulfurization

ActiveUS9127327B2Decrease productivityReduce desulfurizationBlast furnace componentsBlast furnace detailsAlkali metal oxideMolten steel

An environmentally friendly flux for molten steel desulfurization includes CaO and Al2O3 so that [CaO] / [Al2O3] is within a range of 1.6 to 3.0, and includes one or more alkali metal oxides of Na2O, K2O, and Li2O, and SiO2 so that [SiO2] / [R2O] is within a range of 0.1 to 3, [R2O] is within a range of 0.5 mass % to 5 mass %, and [SiO2] is within a range of 0.05 mass % to 15 mass % in a case in which the [CaO], the [Al2O3], the [SiO2], and the [R2O] represent the mass % of CaO, the mass % of Al2O3, the mass % of SiO2, and the total amount of the mass % of Na2O, the mass % of K2O, and the mass % of Li2O respectively.

Owner:NIPPON STEEL CORP

Method for preparing sulphur capturing catalyst

ActiveCN105289753ABurn fullyReduce dosageOrganic-compounds/hydrides/coordination-complexes catalystsSolid fuelsPtru catalystDisulfur dioxide

The invention provides a method for preparing a sulphur capturing catalyst, which comprises steps: raw materials with percentage by weight comprising glycerol 20%-30%, sodium carbonate 5%-10%, sodium methallyl sulfonate 5%-15%, sodium gluconate 8%-13%, titanium dioxide 6%-15%, triethanolamine 2%-6% and water 25%-35% are weighed; the odium carbonate, the sodium methallyl sulfonate and the sodium gluconate are added into 3 / 4 water, are fully stirred for 50-70 hours through a stirring tank to prepare a mixed liquid A; the titanium dioxide is added into the residual 1 / 4 water to be stirred for 25-35 minutes through the stirring tank, and is fully stirred for 50-70 hours by further adding with the glycerol and the triethanolamine to prepare a dispersion liquid B; and the mixed liquid (b) A ( / b) and the dispersion liquid (b) B ( / b) are mixed to fully stir for 25-35 minutes, thereby preparing the sulphur capturing catalyst. The sulphur capturing catalyst which is made through the method for preparing the sulphur capturing catalyst enables coal to be more fully burnt, can reduce coal usage above 10%, reduces above 30% emission of sulfur dioxide and desulfurization, and reduces emission of dust and harmful gas simultaneously.

Owner:张家界鸿燕新材料科技发展有限公司

A sulfur fixation catalyst

ActiveCN105251539BPromote generationHas a combustion-supporting effectOrganic-compounds/hydrides/coordination-complexes catalystsSolid fuelsSulfurSodium methacrylate

Owner:张家界鸿燕新材料科技发展有限公司

A kind of water-soluble rubber and plastic recycled plastic softener and its preparation method and application

The invention discloses a water soluble rubber and plastic regeneration plasticizing softening agent, and a preparation method and applications thereof in the field of regenerated rubber. The preparation method comprises following steps: (1) emulsifier alkyl sodium sulfonate and water are prepared into a solution A at a certain ratio; (2) rubber auxiliary agent rosin and resin are delivered into a reactor at a certain ratio for mixing, and a mixed solution B is obtained via fusion at 110 to 140 DEG C, the mixed solution B is cooled to 95 DEG C, and the temperature is maintained; (3) the solution A obtained in step (1) is added into the mixed solution B dropwise at a constant speed, and an obtained mixture is stirred at 90 to 95 DEG C until stable emulsion states are reached so as to obtain the water soluble rubber and plastic regeneration plasticizing softening agent. The preparation method is simple; operation is convenient; and industrial application prospect is promising. The water soluble rubber and plastic regeneration plasticizing softening agent is capable of realizing standard production of waste rubber and plastic regeneration plasticizing softening agent products; controllability of secondary pollution in rubber regeneration and plasticizing process is improved; product cost is reduced; and the quality of regenerated rubber is increased.

Owner:安徽丰运高分子材料有限公司

A kind of preparation method of sulfur fixation catalyst

ActiveCN105289753BEmission reductionReduce desulfurizationOrganic-compounds/hydrides/coordination-complexes catalystsSolid fuelsSulfurGlycerol

The invention provides a preparation method of a sulfur-fixing catalyst, comprising: weighing the following raw materials in weight percentages: 20% to 30% of glycerol, 5% to 10% of sodium carbonate, and 5% to 15% of sodium methacrylate , sodium gluconate 8% ~ 13%, titanium dioxide 6% ~ 15%, triethanolamine 2% ~ 6%, water 25% ~ 35%; add sodium carbonate, sodium methacrylate, sodium gluconate to 3 / 4 in the water, fully stirred with a stirring tank for 50-70 hours to obtain a mixed solution A; add titanium dioxide to the remaining 1 / 4 of the water and stir for 25-35 minutes with a stirring tank, then add glycerol and triethanolamine and fully stir for 50 ‑70 hours to prepare dispersion B; mix mixed solution A and dispersion B and fully stir for 25‑35 minutes to obtain a sulfur-fixing catalyst. The sulfur-fixing catalyst prepared by the invention can make coal burn more fully, reduce coal consumption by more than 10 percent, reduce sulfur dioxide discharge and desulfurization by more than 30 percent, and simultaneously reduce dust and harmful gas discharge.

Owner:张家界鸿燕新材料科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com