Micro oxygen rich combustion W flame boiler and CO2 emission reduction system

An oxygen-enriched combustion and flame technology, which is applied in the fields of micro-oxygen-enriched combustion W-flame boilers and CO2 emission reduction systems, W-flame boilers and CO2 emission reduction systems, can solve the problems of collection and emission reduction, insufficient research, etc. problems, to achieve the effect of reduced energy consumption and investment, low cost, and zero emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

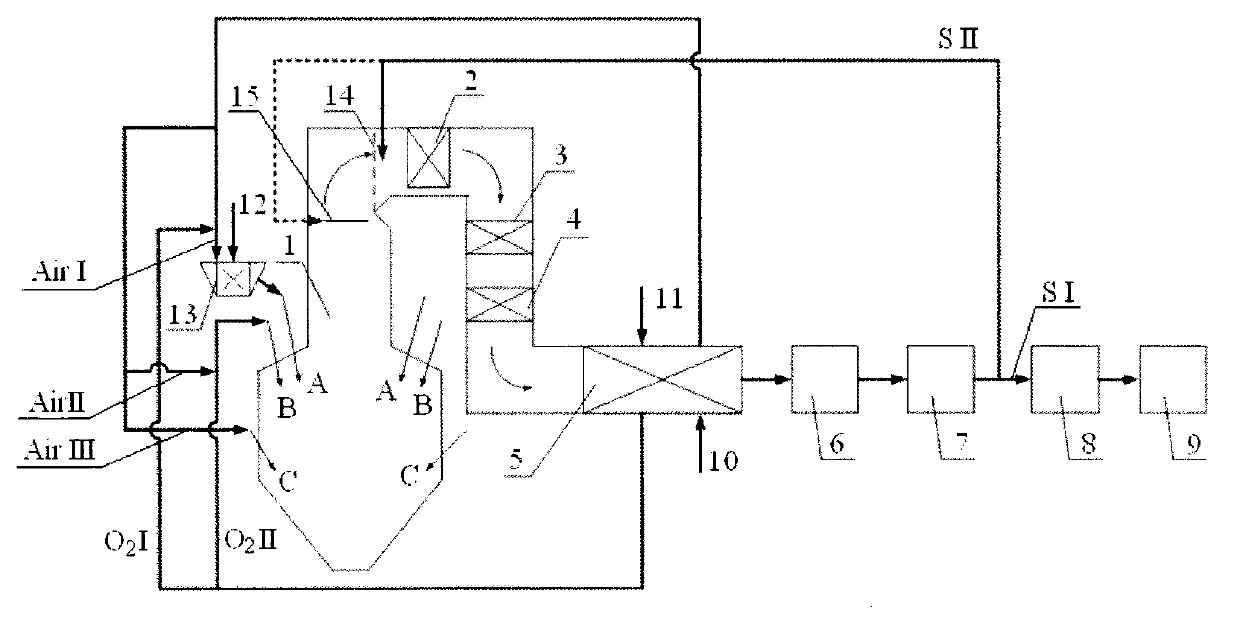

[0034] like figure 1 Shown, for the micro-oxygen-enriched combustion W flame boiler provided by the present invention and CO 2Schematic diagram of the flow of the emission reduction system, anthracite or low volatile coal enters the W flame boiler furnace 1 through the coal mill 13 through the primary air duct A of the furnace arch in the atmosphere of the combustion enhancer 12 and burns fully. The combustion aid is a mixed gas of air and oxygen, and the volume ratio of oxygen to air is 1:6-1:10. The flue gas formed by combustion passes through the main flue through the heat exchange zone and the gas-gas heat exchanger 5 to cool down, and then passes through the dust collector 6 and the water removal device 7 to remove the ash and moisture in the flue gas respectively. The heat exchange zone includes a superheater 2 , a reheater 3 and an economizer 4 which are sequentially connected from the furnace exit chimney 14 . Then the flue gas is divided into two streams, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com