Acetylene sludge desulfurization method and equipment for coal-fired boiler

A coal-fired boiler and calcium carbide slag technology, which is applied in the field of flue gas purification, can solve the problems of large equipment maintenance, large equipment investment, and increased staffing, and achieve the effect of reducing SO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The coal-fired boiler of this embodiment is located in the 1# boiler of Junzheng Thermal Power Plant in Wuhai, Inner Mongolia.

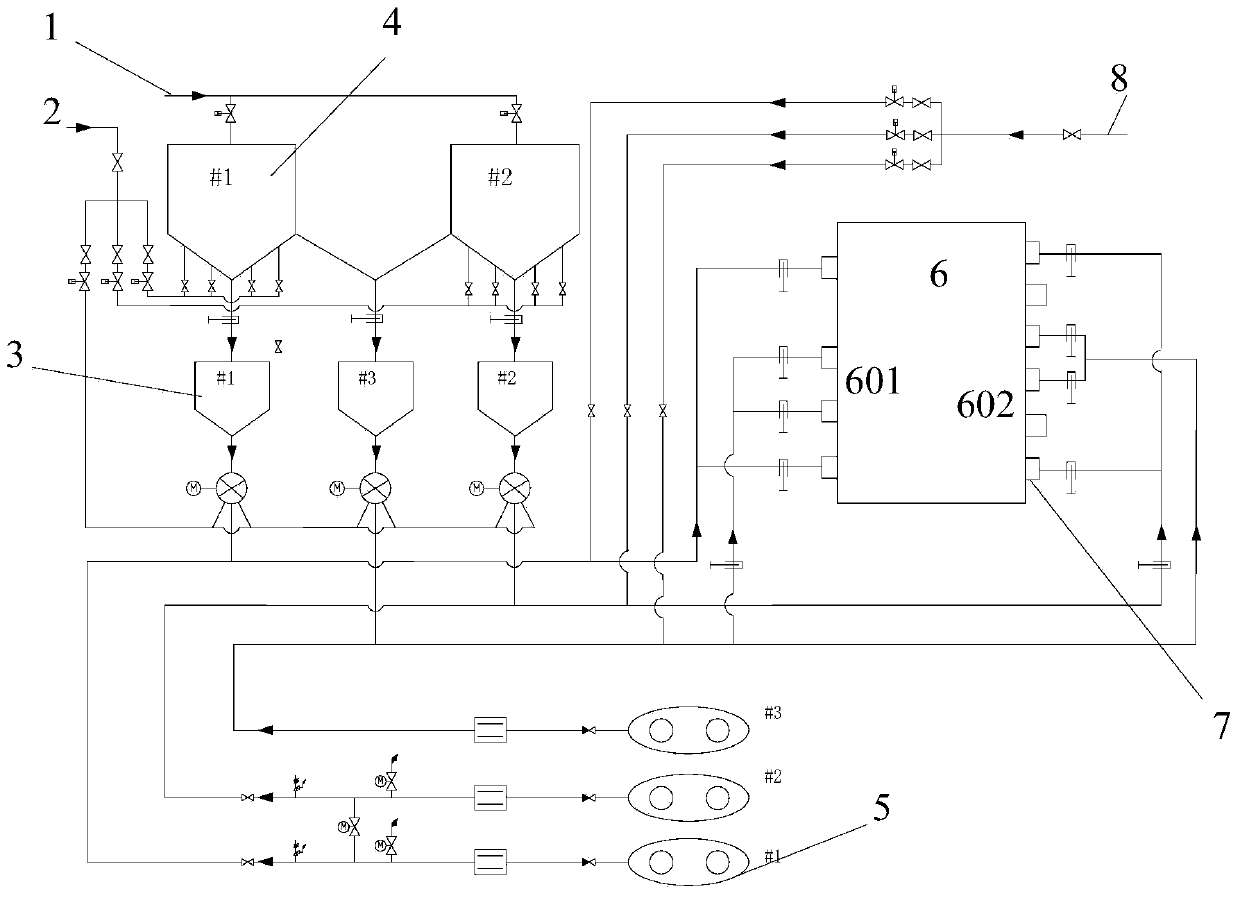

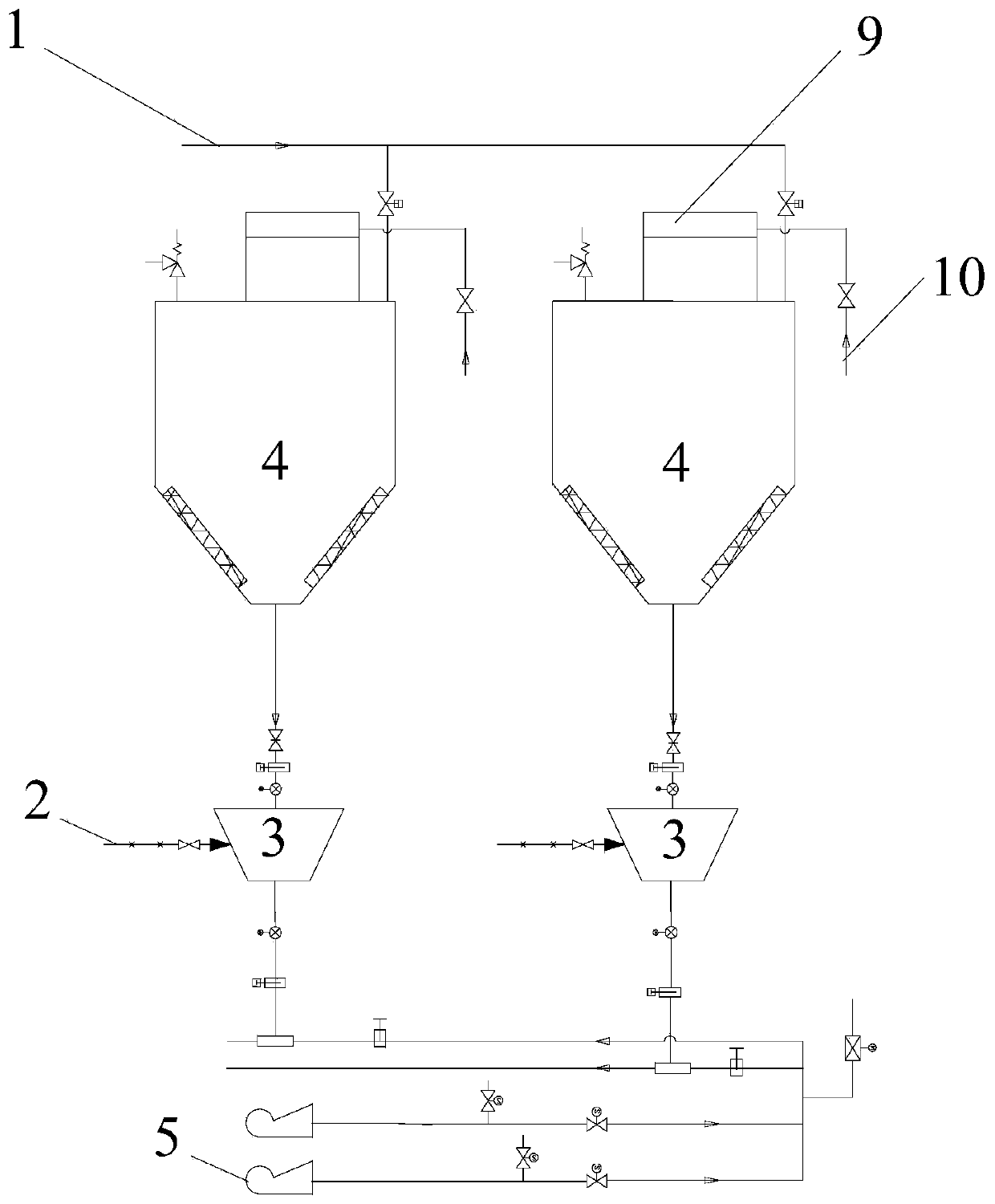

[0045] Desulfurization equipment see figure 1 , including Roots blower 5 for conveying desulfurizer, feeding pipe 7, and feeding system;

[0046]The Roots blower 5 is arranged on the conveying pipeline, and the conveying pipeline adopts a pipe distributor near the furnace to enter two groups of feeding pipes of the front wall and the rear wall, and the feeding pipe 7 is connected with the secondary air pipe of the coal-fired boiler, The material pipe is opened at the elbow where the lower secondary air pipe enters the furnace, and penetrates the calcium carbide slag feed pipe to the end of the lower secondary air port along the direction of the secondary air pipe entering the furnace, and is welded and connected (see Figure 4 , the arrow at the secondary air inlet 13 indicates the air intake direction), and it is connected to the secondary a...

Embodiment 2

[0051] Embodiment 2: the operation of desulfurization

[0052] The main component of carbide slag is Ca(OH) 2 , as the industrial waste slag left over from calcium carbide plus water to generate acetylene gas, the calcium contained in it can be combined with SO in the flue gas in the form of CaO 2 Reaction, reduce SO2 emission to realize desulfurization in circulating fluidized bed boiler furnace. However, the problems of calcium carbide slag transportation blockage, uneven feeding, incomplete reaction, and large fluctuations in desulfurization indicators of circulating fluidized bed boilers have not been resolved. , Insufficient response, large fluctuation of desulfurization index and other problems.

[0053] The desulfurizer uses calcium carbide slag with a moisture content of less than 2% after drying, and chooses the technology of feeding from the secondary air outlet of the boiler. The calcium carbide slag material enters the furnace under the action of the secondary ai...

Embodiment 3

[0060] Embodiment 3: the operation of desulfurization

[0061] Adopt the system of embodiment 1 to carry out in-furnace desulfurization:

[0062] 1) Carbide slag has been dried (particle diameter is about 0.5mm) and the water content is less than 2%, and the carbide slag is blown in at a bed temperature of 850°C;

[0063] 2) Use a Roots blower to blow calcium carbide slag into the furnace of the coal-fired boiler. When it penetrates into the furnace, the amount of fuel when burning is 70t / h. The calcium sulfur ratio is 2. The fuel burned by the coal-fired boiler is 40% of raw coal, 40% of washed medium coal, 20% of coal gangue, and the particle size is 0-9mm. The sulfur content of the fuel is 1.3%.

[0064] The primary air inlet temperature of the coal-fired boiler is 245°C, the secondary air inlet temperature is 245°C, and the temperature before the calcium carbide slag enters the furnace is 20°C to 25°C.

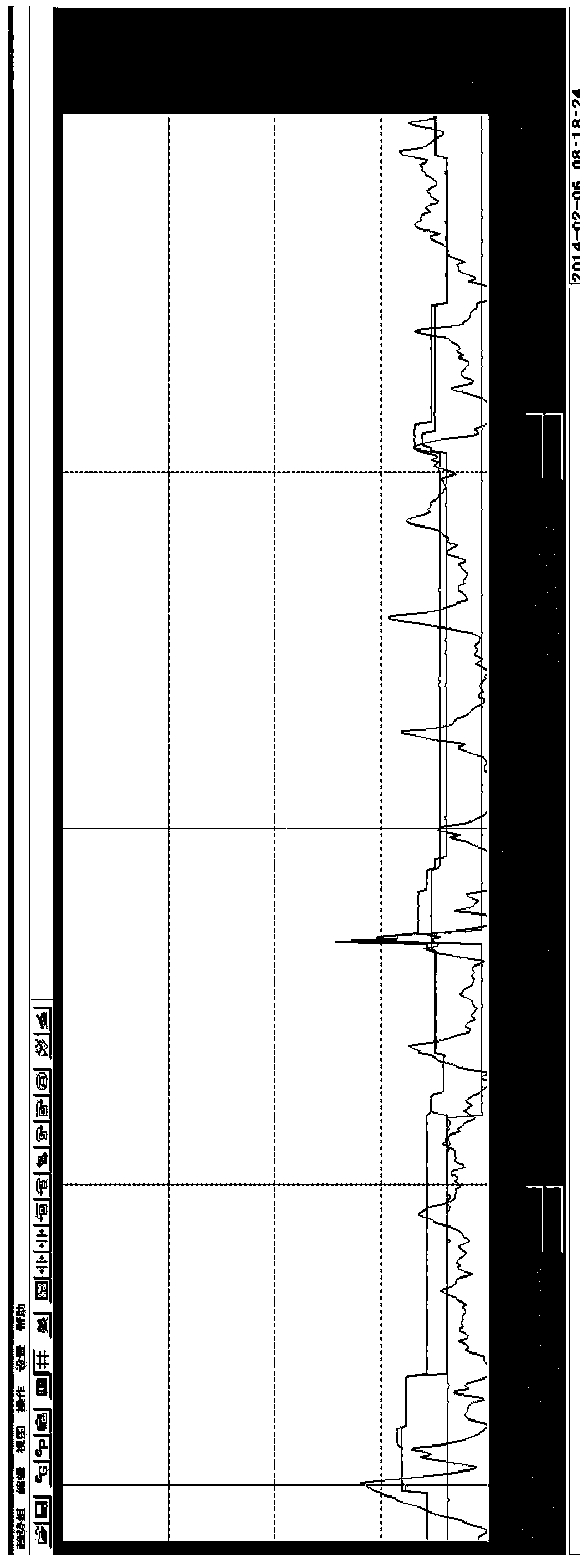

[0065] Two sets of desulfurization systems are running, one set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com