Smelting slagging agent and smelting slagging method adopting AOD (Argon Oxygen Decarburization) double slag process

A double-slag method and slag-removing agent technology, which is applied in the fields of stainless steel smelting slag-removing agent and smelting slag, AOD double-slag method smelting slag agent and AOD double-slag method smelting slag, can solve the problem of high cost, equipment human body and Environmental damage, insufficient slag effect, etc., to achieve the effect of reducing the impact on the body and equipment, lowering the melting point of slag, and reducing the cost of slag process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

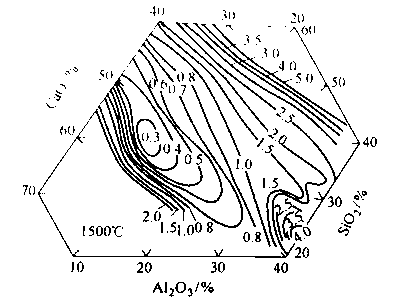

Image

Examples

Embodiment 1

[0027] An AOD double-slag method smelting slag agent, which is composed of high-alumina waste bricks with a thickness of 10 cm and fluorite. The high-alumina waste bricks are composed of the following components by weight percentage (%): Al 2 o 3 68-72, SiO 2 22-28, CaO2-5, Fe 2 o 3 2-5, and the rest are impurities; the slag in the AOD double slag method smelting is composed of the following components according to mass percentage (%): CaO 61-65, SiO 2 31-35, Al 2 o 3 3-5, the rest are impurities; during AOD smelting, 6Kg of high-alumina waste bricks needs to be added for every ton of steel smelted; during the AOD smelting, 6Kg of fluorite needs to be added for every ton of steel smelted; the slag-forming agent is refined in the AOD furnace In the pre-reduction process of the reduction, the pre-reductant ferrosilicon is added to the steel, and the basicity of the slag in the AOD furnace is controlled to 2, the viscosity of the slag is controlled to 0.3, and the stirr...

Embodiment 2

[0029] An AOD double-slag method smelting slag agent, which is composed of high-alumina waste bricks with a thickness of 6 cm and fluorite. The high-alumina waste bricks are composed of the following components by weight percentage (%): Al 2 o 3 68-72, SiO 2 22-28, CaO2-5, Fe 2 o 3 2-5, and the rest are impurities; the slag in the AOD double slag method smelting is composed of the following components according to mass percentage (%): CaO 61-65, SiO 2 31-35, Al 2 o 3 3-5, and the rest are impurities; during AOD smelting, 9Kg of high-alumina waste bricks need to be added for every ton of steel smelted; during the AOD smelting, 9Kg of fluorite should be added for every ton of steel smelted; the slag-forming agent is refined in the AOD furnace During the pre-reduction process of the reduction, the pre-reductant ferrosilicon is added to the steel, and the basicity of the slag in the AOD furnace is controlled to 3, the viscosity of the slag is controlled to 0.35, and the ...

Embodiment 3

[0031] An AOD double-slag method smelting slag agent, which is composed of high-alumina waste bricks with a thickness of 4 cm and fluorite. The high-alumina waste bricks are composed of the following components by weight percentage (%): Al 2 o 3 68-72, SiO 2 22-28, CaO2-5, Fe 2 o 3 2-5, and the rest are impurities; the slag in the AOD double slag method smelting is composed of the following components according to mass percentage (%): CaO 61-65, SiO 2 31-35, Al 2 o 3 3-5, and the rest are impurities; during AOD smelting, 11Kg of high-alumina waste bricks need to be added for every ton of steel smelted; during the AOD smelting, 11Kg of fluorite should be added for every ton of steel smelted; the slag-forming agent is refined in the AOD furnace In the pre-reduction process of the reduction, the pre-reductant ferrosilicon is added to the steel, and the basicity of the slag in the AOD furnace is controlled to 4, the viscosity of the slag is controlled to 0.4, and the sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com