Patents

Literature

40results about How to "Has a combustion-supporting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing biomass fuel mainly from fresh chicken manure

ActiveCN106244278AWith water absorption and heat releaseReduce moisture contentBiofuelsSolid fuelsMicroorganismMushroom

The invention belongs to the technical field of environmental protection, and particularly relates to a method for preparing a biomass fuel mainly from fresh chicken manure. The method comprises the following steps: 1) pretreating raw materials; 2) fermentation: mixing fresh chicken manure, mushroom sticks and calcined shell powder, inoculating deodorizing composite microbes and nitrogen fixation-desulfurization composite microbes, and carrying out pile fermentation; 3) naturally drying the fermentation material; and 4) adding tea stems, and carrying out extrusion granulation. The fresh chicken manure is used as the main raw material, the waste mushroom sticks, calcined shell powder and tea stems are used as the auxiliary raw materials, the deodorizing composite microbes and nitrogen fixation-desulfurization composite microbes are added, and the flammability and comprehensive combustion characteristics of the reinforcing material of the composite microbes are fully utilized, thereby preparing the biomass granular fuel which has the advantages of low ignition point, high combustion heat value and high combustion rate. The method can greatly consume chicken manure, and solves the problem of environmental pollution caused by chicken manure. The method provides direction for the recycling of the waste mushroom sticks, shells and tea stems.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

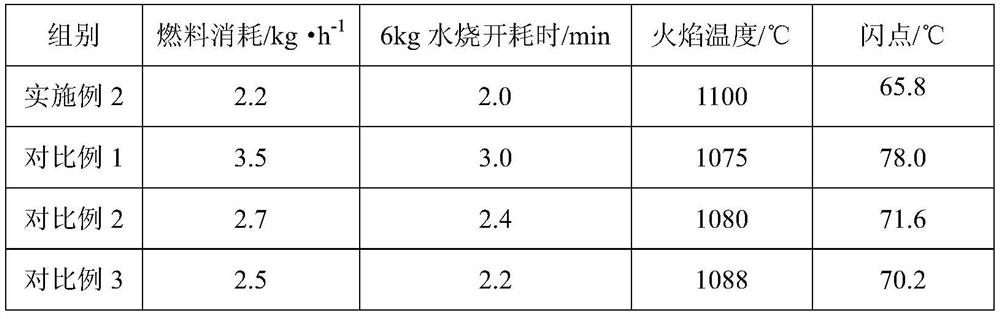

Environmental protection type coal produced from sludge and fatlute and manufacturing method thereof

ActiveCN106367152AEasy to useProcess environmental protectionBiofuelsSolid fuelsEconomic benefitsOil sludge

The invention provides an environmental protection type coal produced from sludge and fatlute and a manufacturing method thereof, and belongs to the field of solid waste integrative utilization. The environmental protection type coal produced from sludge and fatlute makes integrative utilization on the solid waste and can make full use of calorific values of sludge and fatlute. The environmental protection type coal is mainly prepared from, by mass, 60-80 parts of coal powder, 10-40 parts of sludge, 1-20 parts of fatlute, and 0.5-5 parts of briquette cohesive agent. The sludge is prepared through chemical disinfection treatment, the fatlute is prepared by reducing viscosity, and the briquette cohesive agent is prepared after fully stirring the low metamorphic lignitous coal, alkaline waste residues and paper making black liquid. The addition of certain amount of lime into the coal powder is good for desulfuration, and is also good for briquette coal demolding. The environmental protection type coal produced by carrying out mixing extrusion on the materials in certain proportion makes full use of caloric values of the sludge and fatlute, prevents the sludge and fatlute from generating secondary pollution, and has obvious environmental benefits and economic benefits. The environmental protection type coal produced from sludge and fatlute and the manufacturing method thereof can be applicable to the production process of environmental protection type coal.

Owner:SHANDONG UNIV OF SCI & TECH

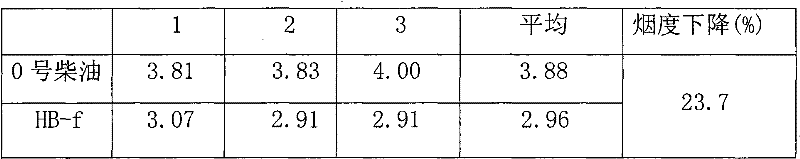

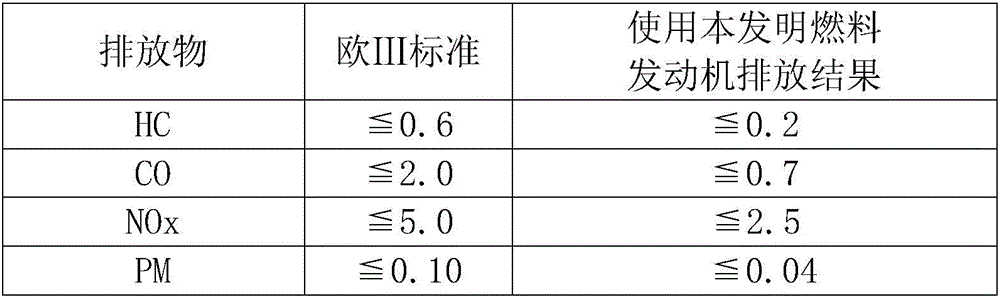

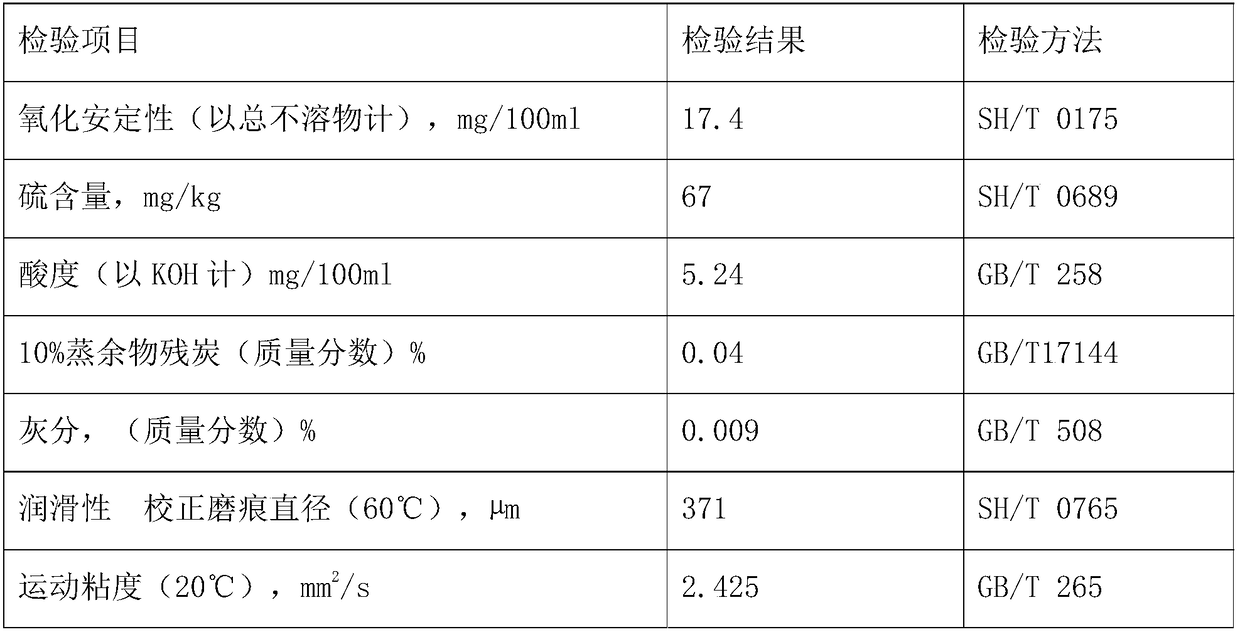

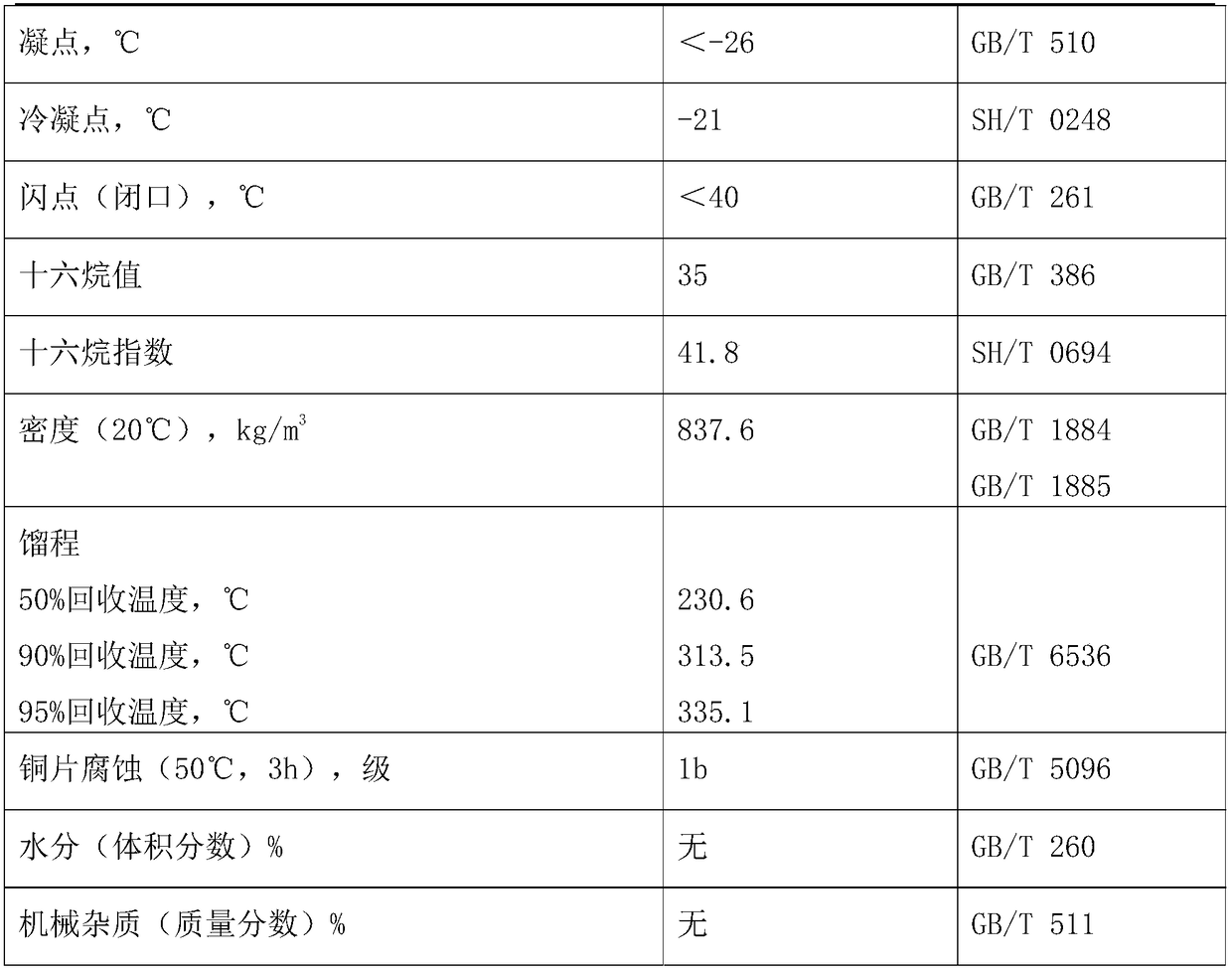

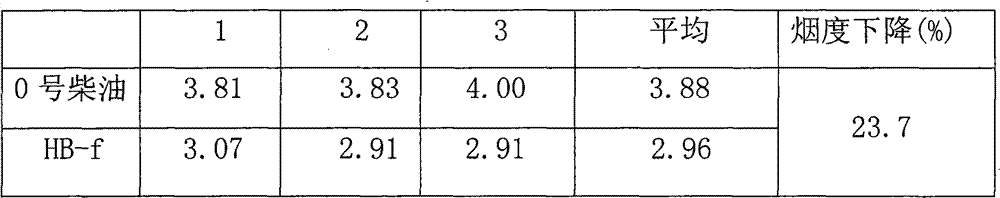

Petrochemical additive and preparation method thereof

The invention relates to a petrochemical additive and a preparation method thereof, belonging to the technical field of the preparation of the chemical additive product. The petrochemical additive consists of naphthenic acid, N,N-dimethylisobutylamine and cyclohexylamine which are the byproducts of the raw material refinery; and the components are fully stirred in a container for 40-60min at the room temperature under the atmospheric pressure to prepare the petrochemical additive and store in a container prepared from the stainless steel material. The petrochemical additive is mixed with water and diesel oil, an air compressor is used to ensure that the pressure is 1atm and the symmetric cross injection method is adopted to fully mix diesel oil, water and the emulsifying additive and produce a microemulsion fuel oil finished product. The raw material components of the petrochemical additive are fewer, the components are available, the preparation method is simple, the used equipment is simple and is easy to prepare, the cetane number of the product is higer than that of common diesel oil, the dynamic property is high, the cost is reduced by 8-9% compared with common diesel oil, the emission rate of harmful gases and black smoke is reduced by 23.7%, the oil-saving rate is 18.9%, and the produced diesel oil has higer social and economic benefits.

Owner:XIANYANG TIANCHENG PETROCHEM ENERGY SAVING TECH

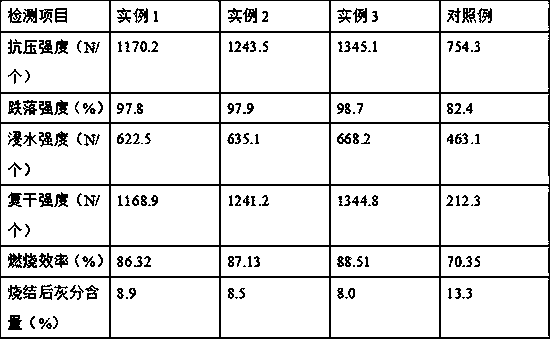

Preparation method for combustible biomass coal briquette binder

InactiveCN108822911AImprove combustion efficiencyHas a combustion-supporting effectSolid fuelsWaste based fuelCoal briquetteCarboxylic acid

The invention relates to a preparation method for a combustible biomass coal briquette binder, and belongs to the technical field of coal briquette preparation. The preparation method comprises the following steps: taking eucalypt wood dust with high volatile contents as raw materials; firstly, carrying out alkali-heat-treatment on the eucalypt wood dust; then, mixing the eucalypt wood dust subjected to the alkali-heat-treatment with organic carboxylic acid, then, carrying out high-temperature and high-pressure reaction, and carrying out hydrogenation reaction to obtain a reactant; then, carrying out rancidification on coconut oil in the environment of high temperature, high moisture and high oxygen; mixing a rancidification product and the reactant to carry out short-term fermentation; carrying out ultraviolet sterilization to obtain the combustible biomass coal briquette binder. The briquette binder prepared by the preparation method has the advantages of good binding effect, high combustion efficiency and wide application prospect.

Owner:FOSHAN LINGCHAO NEW MATERIAL CO LTD

Multifunctional methanol fuel

InactiveCN106433820AHas anti-knock effectBoost octaneLiquid carbonaceous fuelsFuel additivesDetonationPolyvinyl alcohol

The invention belongs to the technical field of fuels and particularly relates to a multifunctional methanol fuel, prepared from, by weight, 60-90 parts of methanol, 20-44 parts of gasoline, 1-7 parts of 3-tert-butyl-4-hydroxyanisole, 0.5-2.3 parts of ethyl levulinate, 0.5-2.3 parts of 4-tert-butyl-2,6-diisopropylphenol, 0.4-2.2 parts of polyvinyl alcohol, 0.2-1.4 parts of dimethyl carbonate, 0.2-1.4 parts of a clearing agent, 0.1-1.3 parts of a corrosion inhibitor, 0.03-0.21 part of dicycloheptadiene, and 0.02-0.2 part of glyceryl monostearate. The multifunctional methanol fuel has the functions, such as clearing, anti-oxidation, combustion supporting, corrosion inhibition and detonation resisting, has good combustion performance, and can combust fully such that energy is saved and emission is reduced.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

Purple ceramic firewood burning method

InactiveCN109837128APreserve the traditional firing effectReduce dosageBiofuelsSolid fuelsFirewoodHeating time

The invention discloses a purple ceramic firewood burning method, and belongs to the technical field of ceramics. The method comprises the following steps: 1) placing a purple ceramic body in a kiln provided with an electric heating device and a firewood burning hall, and heating with the electric heating device at the heating temperature of 800-900 DEG C for 6-8 h; 2) adding firewood for burninginto the burning hall of the kiln after the purple ceramic body is in the vitreous state and turns red, immersing the firewood in diesel oil before burning, carrying out combined burning with the firewood and the electric heating device at the burning temperature of 1150-1200 DEG C for 48-72 h, cooling the burned purple ceramic body to 100 DEG C and below and taking out to prepare the finished product. By the method, use amount of firewood can be effectively reduced, and the environmental pollution is reduced.

Owner:田宝晶

Method for preparing biomass fuel by taking fresh cow dung as main raw material

ActiveCN106244279AWith water absorption and heat releaseReduce moisture contentBiofuelsSolid fuelsResource utilizationMushroom

The invention belongs to the technical field of environmental protection, and particularly relates to a method for preparing a biomass fuel by taking fresh cow dung as a main raw material. The method particularly includes the steps: 1) raw material pretreatment; 2) fermentation: mixing the fresh cow dung, mushroom rods and calcined shell powder, inoculating nitrogen fixation-desulfurization compound microorganisms and performing composting fermentation; 3) naturally airing fermented materials; 4) adding tea stalks and performing extruding granulation. The fresh cow dung serves as the main raw material, the waste mushroom rods, the calcined shell powder and the tea stalks serve as auxiliary raw materials, the nitrogen fixation-desulfurization compound microorganisms are added, and the biomass granule fuel with a low ignition point, a large combustion heat value and a high combustion ratio is prepared by making full use of enhanced material flammability and comprehensive combustion characteristics of the compound microorganisms and the water-absorbing capacity and the heat production capacity of the calcined shell powder. The method can greatly reduce the cow dung, solve the problem of environmental pollution of the cow dung and provide direction for resource utilization of the waste mushroom rods, the shell powder and the tea stalks.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

Straw-wood chip honeycomb fuel and preparation method thereof

Provided are a novel straw-wood chip honeycomb fuel and a preparation method thereof. The preparation method comprises the steps: crushing straw, grass wood chips and the like into a crushed materialwith the particle size of less than or equal to 5 mm, mixing calcium oxide with the crushed material according to a weight ratio of 3:(4-5), adding an appropriate amount of water, and stirring into acohesive state, preparing straw-wood chip honeycomb balls by a coal ball machine, air-drying, baking and charring in a sealed room at the temperature of 300 DEG C or less, spraying a potassium permanganate solution before leaving a factory, and air-drying. The straw-wood chip honeycomb fuel can be fully burned and has no pollution. A principle comprises that quick lime undergoes a reaction with water to produce slaked lime, the slaked lime calcium hydroxide removes grease from the straw and wood chips and undergoes a reaction with carbon dioxide in air to produce calcium carbonate, and the straw-wood chip honeycomb balls are hard and easy to store.

Owner:贾谊峰

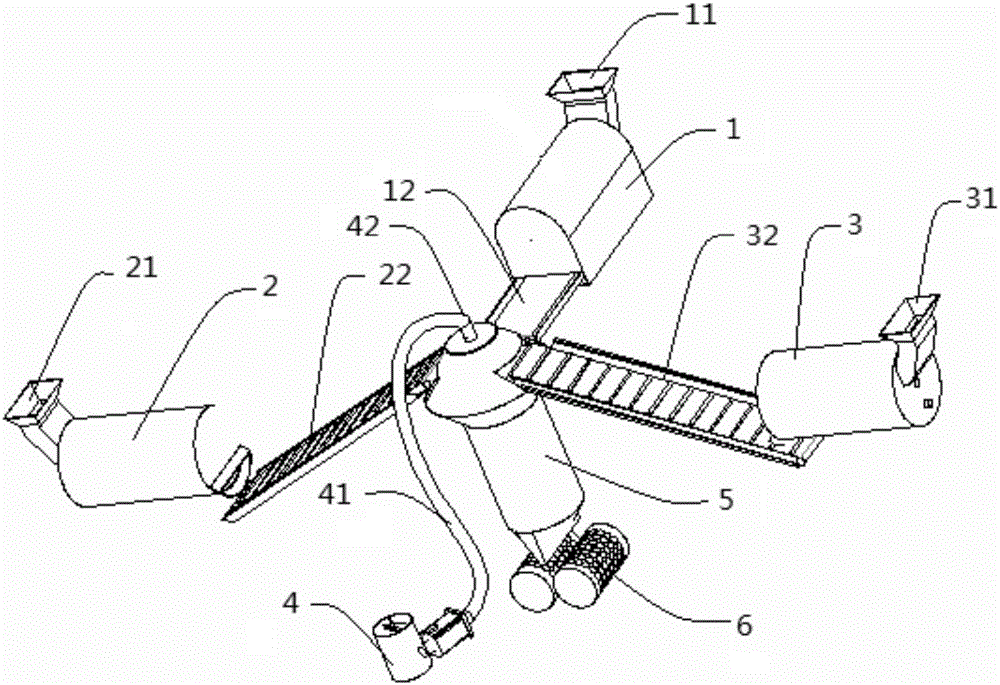

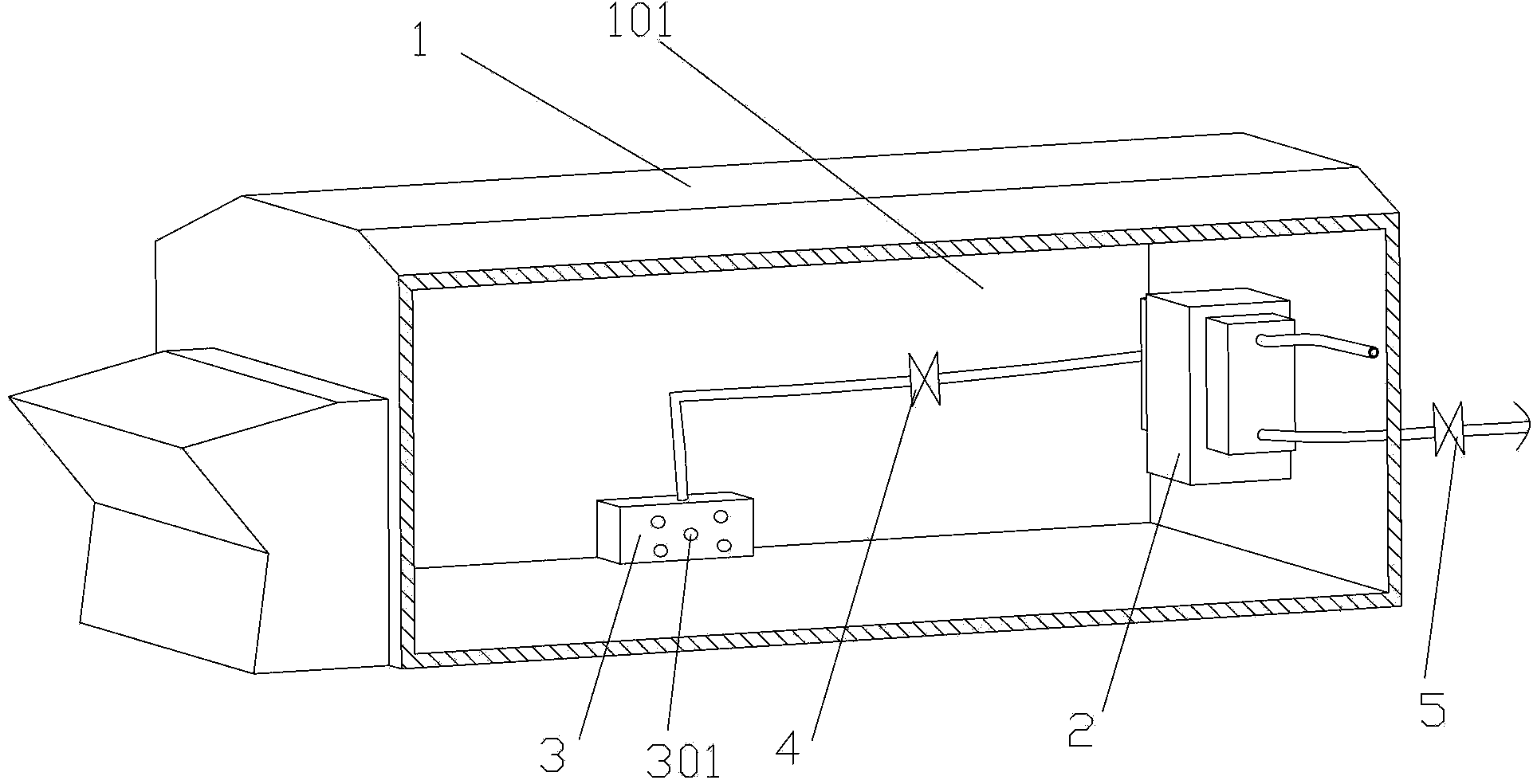

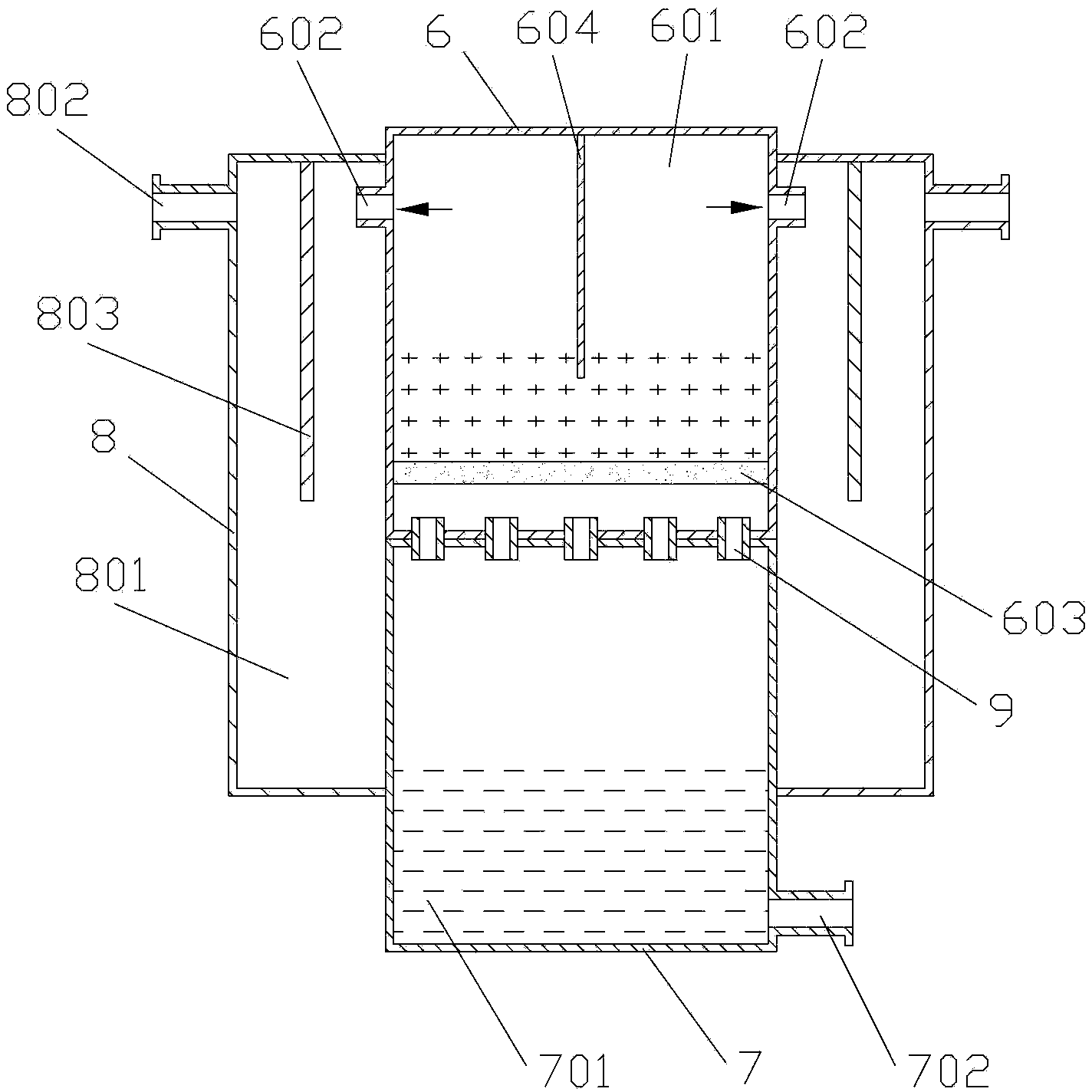

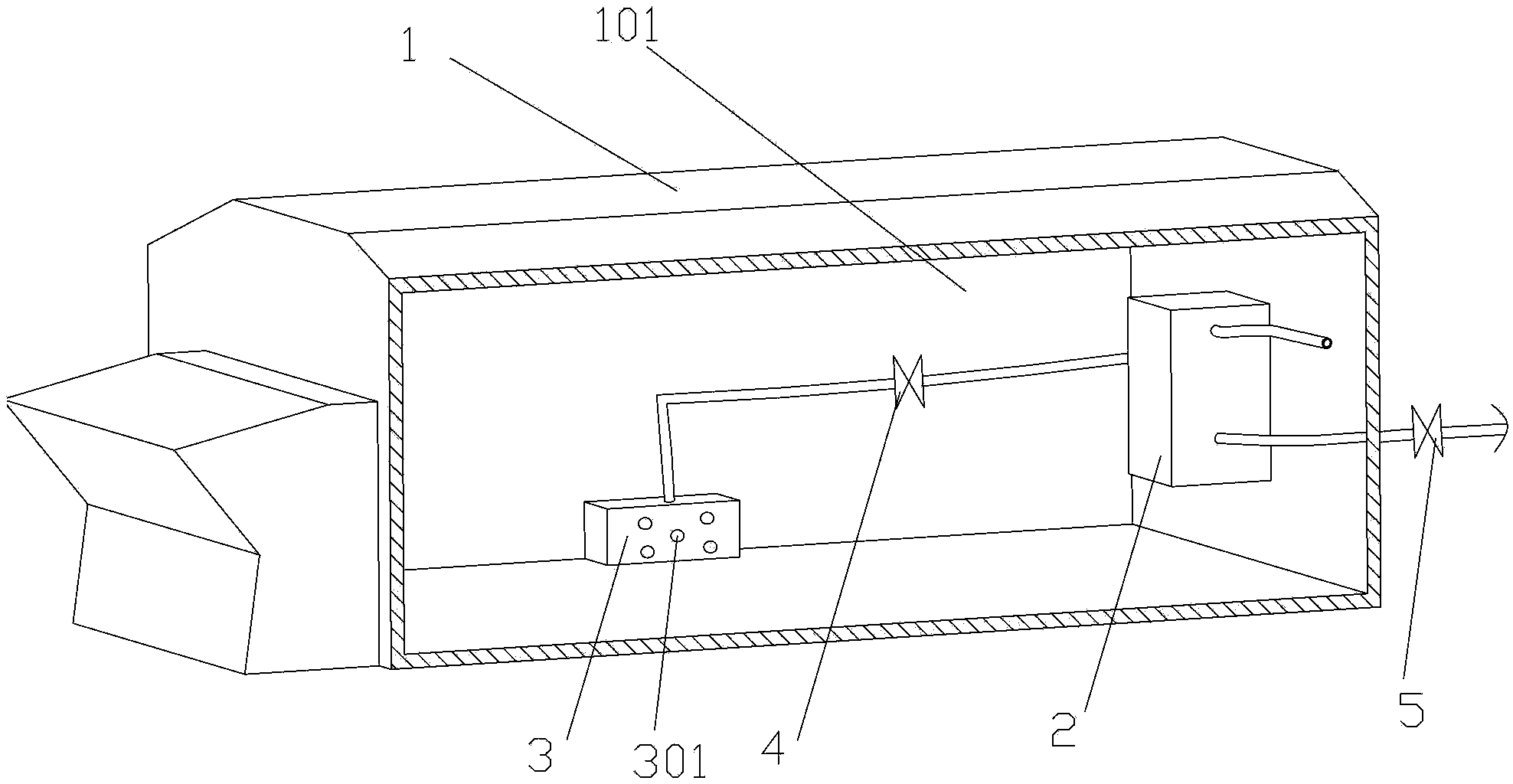

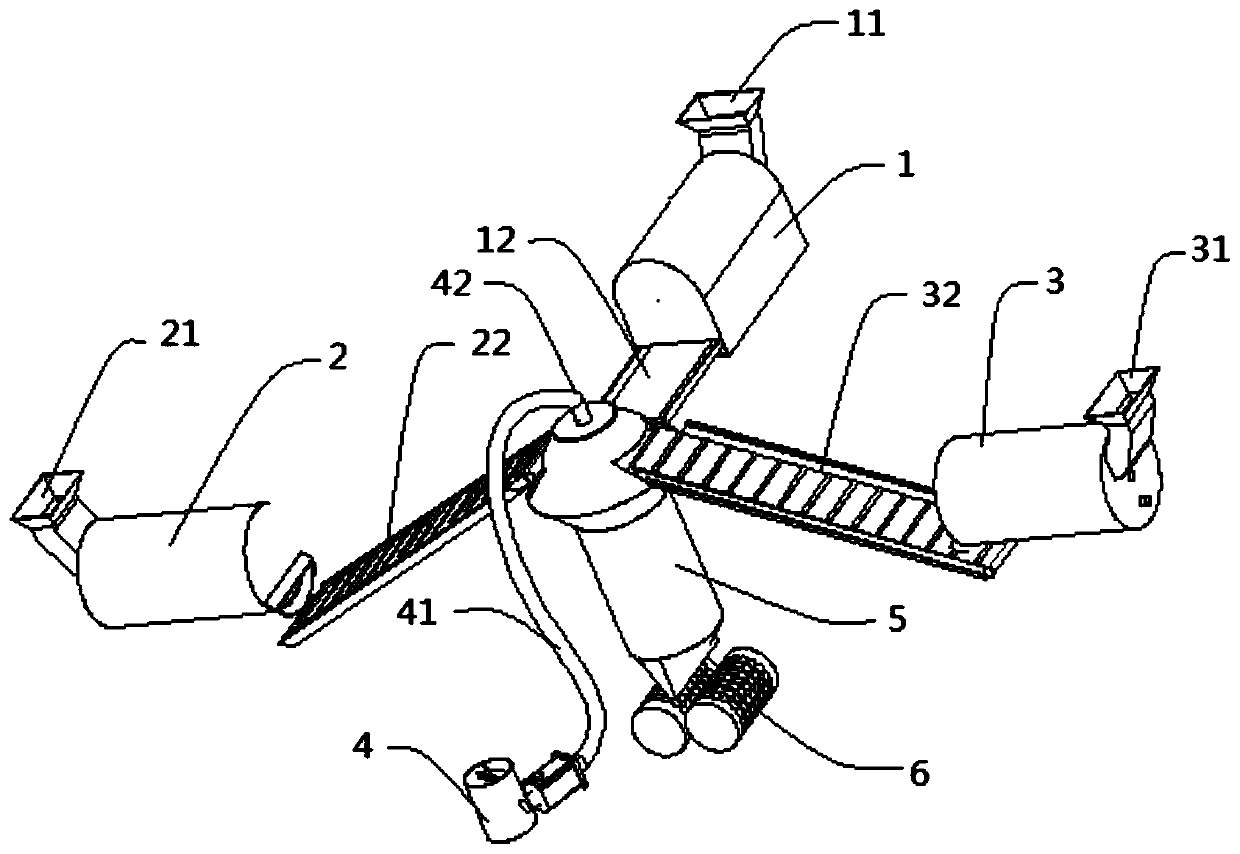

Water fuel oxyhydrogen combustion-supporting boiler

InactiveCN104296157AImprove burnout rateEmission reductionWater heatersSteam boilersWater storageCombustion

The invention discloses a water fuel oxyhydrogen combustion-supporting boiler. The water fuel oxyhydrogen combustion-supporting boiler comprises a boiler body with a hearth, and further comprises a hydrogen and oxygen generating device which is fixed into the hearth and supplies hydrogen and oxygen to the hearth. The hydrogen and oxygen generating device comprises a hydrogen and oxygen generating chamber and a water storage chamber, the hydrogen and oxygen generating chamber is hollow, and a reaction space is formed inside the hydrogen and oxygen generating chamber. The hydrogen and oxygen generating chamber is provided with a first gas outlet communicated with the reaction space. A reaction table for containing a reaction catalyzer is arranged inside the reaction space. The water storage chamber is connected to the lower end of the hydrogen and oxygen generating chamber and provided with a water storage space communicated with the reaction space. The water storage chamber is provided with a water inlet communicated with the water storage space. The water fuel oxyhydrogen combustion-supporting boiler has the advantages that the fuel burn-off rate can be effectively improved, the burning heat efficiency is improved, harmful gas emission is reduced, the environment-friendly and energy-saving effects are remarkable, and the structure is compact.

Owner:杨雪燕 +2

High-efficient enviromental protection additive for fire coal

InactiveCN1315996CHas a defocusing effectHas a combustion-supporting effectSolid fuelsPotassium nitrateCombustion

Owner:梁丽丽

Method for fixing sulfur component in high-sulfur coal by using dolomite

The method for fixing sulfur component in high-sulfur fuel wal by using dolomite includes the following steps: breaking dolomite to obtain broken dolomite whose grain size is below 3 mm, calcining for 3-4 hr. at 900-1000 deg.C pulverizing it to obtain dolomite powder material whose grain size is below 0.2 mm, according to 4-6 % and 2-4% of calcinatino-obtained material weight respectively mixing the pulverized dolomite with Al2O3 and Fe2O3, and adding them into high-sulfur fuel coal according to that its added amount is 5-6 times sulfur content being in fuel coal to make combustion together with fuel coal, so that the sulfur component can be fixed in coal cinder completely.

Owner:SHANXI COKING COAL GROUP +1

Efficient and energy-saving vehicle fuel

InactiveCN106367136AHas a cleansing effectEffective carbon depositionLiquid carbonaceous fuelsFuel additivesDiisononyl adipateHexamethylenetetramine

The invention belongs to the technical field of fuel and particularly relates to an efficient and energy-saving vehicle fuel. The efficient and energy-saving vehicle fuel is prepared from, by weight, 62-86 parts of methanol, 12-24 parts of gasoline, 0.6-1.8 part of hexamethylenetetramine, 0.5-1.7 parts of methyl acrylamide, 0.4-1.6 parts of 2-tertiary butyl hydroquinone, 0.3-0.9 part of ferrocene, 0.1-0.7 part of benzotriazole, 0.01-0.07 part of diisononyl adipate, 0.03-0.15 part of glycerol monostearate and 0.1-1.3 parts of anti-explosion agent. The efficient and energy-saving vehicle fuel has anti-explosion, combustion-supporting, corrosion resistance, oxidation resistance and cleaning effect, is full to burn, high in thermal efficiency and efficient achieves energy saving and emission reduction.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

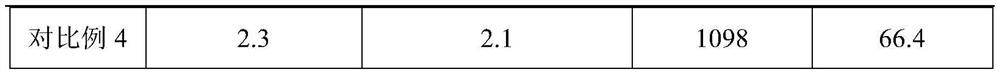

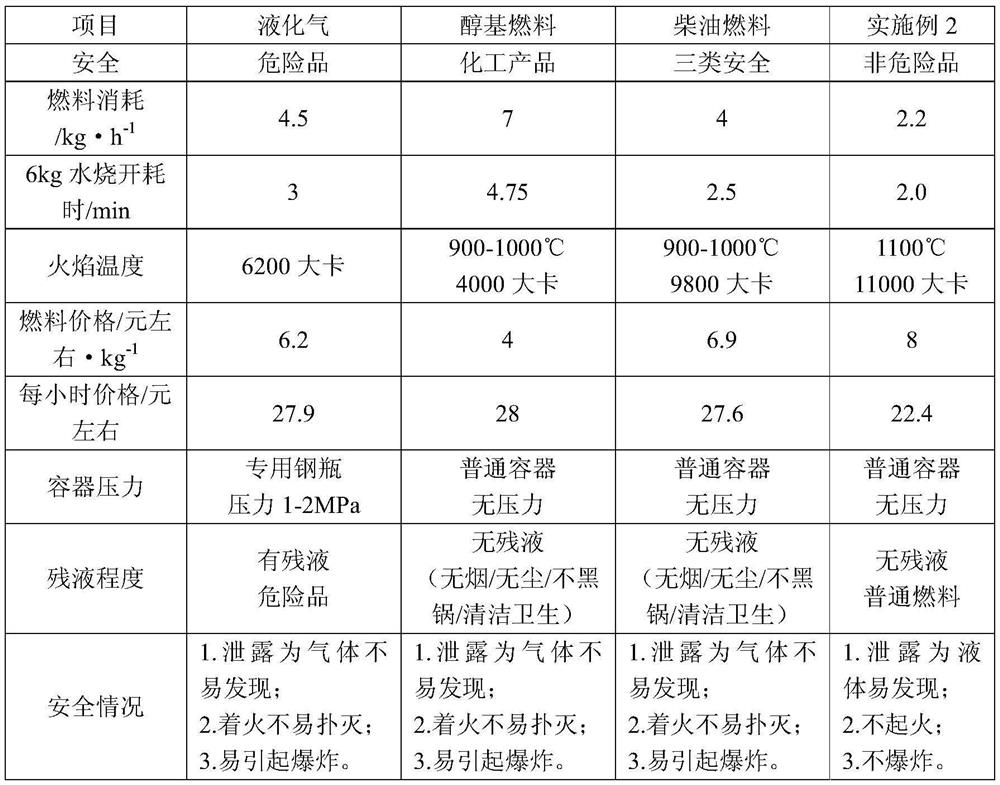

Energy-saving environment-friendly alcohol-free vegetable oil fuel and preparation method thereof

InactiveCN112940807AHigh calorific valueImprove stabilityLiquid carbonaceous fuelsFuel additivesVegetable oilTert butyl

The invention discloses an energy-saving and environment-friendly alcohol-free vegetable oil fuel which comprises the following raw materials: vegetable oil, a POSS-phosphorylated vegetable oil polymer, methyl tertiary butyl ether, isopropanol, ethylene glycol, glycerol, absolute ethyl alcohol, magnesium powder, ferrocene and water. The invention also discloses a preparation method of the energy-saving and environment-friendly alcohol-free vegetable oil fuel, which comprises the following steps: S1, preparing methyl tert-butyl ether, isopropanol, ethylene glycol, glycerol and absolute ethyl alcohol into a mixing agent, and adding the mixing agent and the POSS-phosphorylated vegetable oil polymer into the vegetable oil to prepare a mixed solution; s2, adding water into the mixed solution, carrying out ultrasonic dispersion, and uniformly stirring to obtain a water-in-oil mixed solution; and S3, adding the magnesium powder and the ferrocene into the water-in-oil mixed solution, and uniformly stirring to obtain the magnesium-in-oil composite material. The vegetable oil fuel prepared by the invention is low in flash point, has better properties than liquefied gas, alcohol-based fuel and diesel fuel, and has the advantages of energy conservation, environmental protection, safety, cleanness, high efficiency and good economic benefit.

Owner:NANJING XINGJING CHEM

Vehicle fuel with low tail gas emission

InactiveCN106221823AHas antiknock effectBoost octaneLiquid carbonaceous fuelsFuel additivesCombustionAntioxidant

The invention belongs to the technical field of fuels, and particularly relates to vehicle fuel with low tail gas emission. The vehicle fuel with the low tail gas emission is prepared from, by weight, 62-86 parts of methanol, 12-24 parts of gasoline, 0.6-1.8 parts of sec-butyl methyl ether, 0.5-1.7 parts of isobutyl ether, 0.4-1.6 parts of dimethylformamide, 0.3-0.9 part of 4-hydroxybenzamide, 0.1-0.7 part of methyl heptenone, 0.01-0.07 part of dimethyl carbonate, 0.03-0.15 part of glyceryl triacetate and 0.1-1.3 parts of antioxidant. The vehicle fuel with the low tail gas emission has the effects of resisting explosions, supporting combustion, resisting corrosion and oxidation, achieving cleanliness and the like, tail gas is significantly reduced, and energy conservation and environment protection are achieved.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

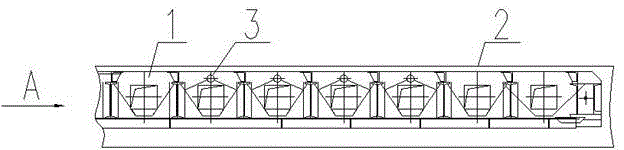

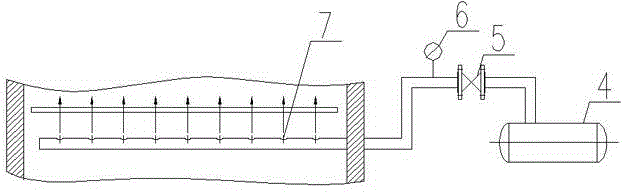

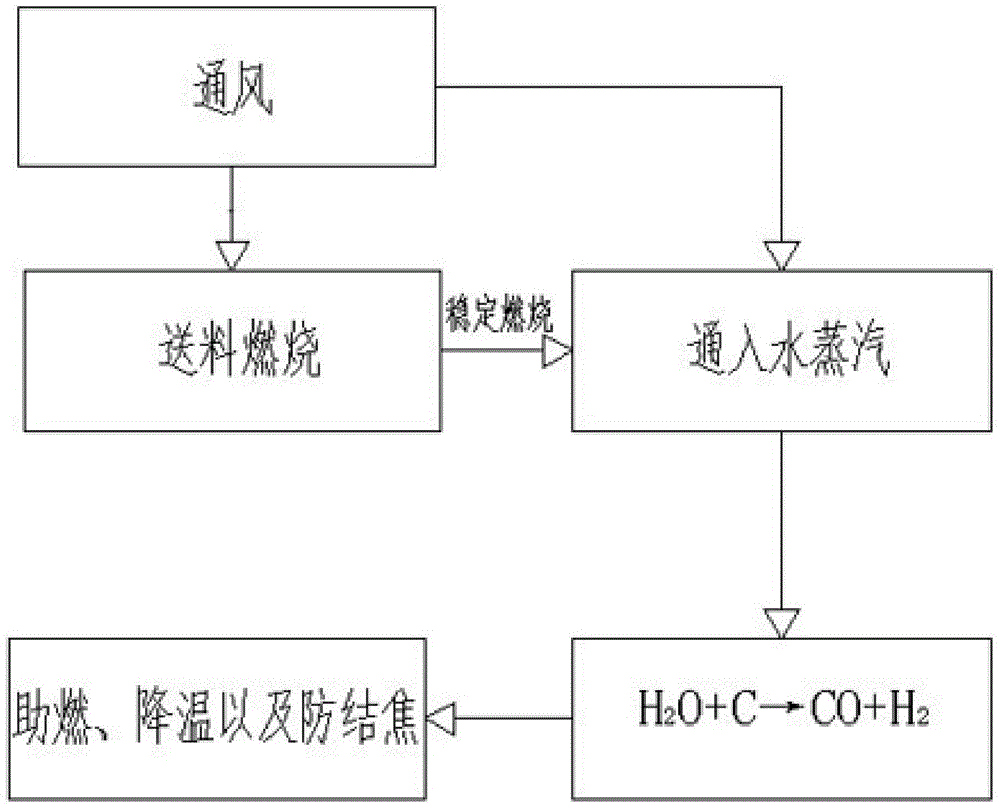

Boiler capable of preventing biomass coking

InactiveCN105003909ALower combustion temperatureReduce the temperatureSolid fuel combustionNon-combustible gases/liquids supplyEngineeringBiomass boiler

The invention discloses a boiler capable of preventing biomass coking. The boiler comprises an air distribution chamber, a chain grate stoker, a steam conveying pipe, a steam manifold, a reducing valve, a pressure gage and steam outlet holes; the air distribution chamber is arranged below the chain grate stoker, and the steam conveying pipe is arranged at the position, above an air distribution bend, of the air distribution chamber, and is fixed to an inclined lateral wallboard of the air distribution chamber through a support; the steam conveying pipe is connected with the steam manifold through the reducing valve; the pressure gage is further installed at the position, in front of the air distribution chamber, of the steam conveying pipe and is located at the front end of the reducing valve; and the steam outlet holes are arranged at the positions, located inside the air distribution chamber, on the steam conveying pipe and face a main burning area of the chain grate stoker, and steam can rapidly reach portions needing to be cooled. The boiler capable of preventing biomass coking includes two steps of feeding burning and steam leading in. According to the method, the air distribution chamber is combined with steam conveying, the structure is compact, using is simple and convenient, biomass burning coking is effectively prevented, the burn-off rate is improved, the cost is reduced, and the method is suitable for industrial production.

Owner:青岛青义锅炉有限公司

Method for preparing biomass fuel with fresh chicken manure as main raw material

ActiveCN106244278BWith water absorption and heat releaseReduce moisture contentBiofuelsSolid fuelsMushroomFermentation

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

Formula of emulsified diesel oil

InactiveCN101328425ASolve the energy problem of shortage of supply and high priceWill not corrodeRefining by water treatmentPhenolStearate

The invention relates to a formula of emulsified diesel oil. The formula consists of diesel oil, water and an addition agent, wherein the compositions in percentage by weight of the formula are: 65 to 95 percent of the diesel oil and 35 to 5 percent of the water, and the addition agent being one thousandth of the total amount of water and diesel oil; moreover, the compositions in percentage by weight of the addition agent are: 35 percent of sorbitol anhydride mono-stearine polyethenoxy ether, 12 percent of sorbitol anhydride mono stearate, 13 percent of polyoxyethylene sorbitol triolein, 6 percent of ethylene-acrylic ester copolymers, 8 percent of alkylene phenol polyvinyl ether, 6 percent of calcium dodecyl benzene sulfonate, 5 percent of benzene-80, 2 percent of alkyl naphthalene, 5 percent of ferrocene, 4 percent of methane nitrate or dinitrotoluene and 4 percent of isopropyl alcohol. The formula has the advantages that: the formula has reasonable proportioning, advanced technological method, low product price and high stability, and capability of being mixed with ordinary diesel oil when used.

Owner:陈金义

Special briquette coal for water treatment of lime and preparation method of special briquette coal

InactiveCN111996052ABurn enoughMore complete combustionWater contaminantsBiofuelsSodium stearateFiltration

The invention discloses special briquette coal for water treatment of lime. The special briquette coal comprises bituminous coal, sawdust powder, rice hull powder, potassium permanganate, potassium perchlorate, shell powder, peanut meal, lignin, sodium stearate, aluminum powder, magnesium powder and a proper amount of water. A method for preparing the special briquette coal used for water treatment of lime comprises the following steps: (1) mixing sodium stearate with water, adding shell powder and lignin, and successively carrying out mixing, standing, suction filtration, washing, drying andgrinding to obtain modified shell powder; and (2) uniformly stirring and mixing bituminous coal, sawdust powder, rice hull powder and peanut meal, adding lignin and water, carrying out uniform mixing,adding the modified shell powder, carrying out uniform mixing, finally adding potassium permanganate, potassium perchlorate, aluminum powder and magnesium powder, carrying out uniform mixing, moldingthe formed mixture in a molding machine, and successively carrying out drying, cooling to room temperature and packaging to obtain the special briquette coal for water treatment of lime. The coal iscombusted more sufficiently and thoroughly, so a combustion heat value can be increased; and bituminous coal, sawdust powder and the like are used as main combustion raw materials, so waste utilization can be achieved, and environmental pollution is reduced.

Owner:NANNING XIAYANG CHEM TECH CO LTD

Inflammable desulfurated straw biomass burning rod and preparation method thereof

The invention discloses an inflammable desulfurated straw biomass burning rod and a preparation method thereof. The burning rod is characterized by being prepared from, by weight, 1-2 parts of urea, 5-10 parts of sludge, 1-2 parts of yeast, 1-2 parts of sphaeropsis clostridia, 5-10 parts of pulverized coal, 2-3 parts of polyvinyl alcohol, 3-6 parts of paraffin, 10-20 parts of yellow mud, 10-20 parts of wheat straw, 1-2 parts of calcium stearate, 5-10 parts of rice straw, 5-10 parts of bamboo wood, 3-5 parts of branches, 4-8 parts of ferric oxide, 0.1-0.4 part of zirconium dioxide and a proper amount of water. The straw and the pulverized coal cooperate to be prepared into the burning rod, full utilization of resources is realized, emission of sulfur dioxide and other poisonous gases is effectively reduced, and the burning rod is beneficial for environmental protection and human health; urea is added in a matched mode, and the combustion supporting effect is achieved.

Owner:太湖县享有新能源有限责任公司

High-efficient enviromental protection additive for fire coal

InactiveCN1657598AHas a defocusing effectHas a combustion-supporting effectSolid fuelsPotassium nitrateCombustion

An environment protection type efficient additive for fire coal contains proportionally potassium chloride, potassium hypermanganate, calcium lime, potassium nitrate and sodium nitrate. It has high effect to increase heat efficiency, decrease the content of C in sinder and the exhaust of toxic harmful gases, and elongate combustion time.

Owner:梁丽丽

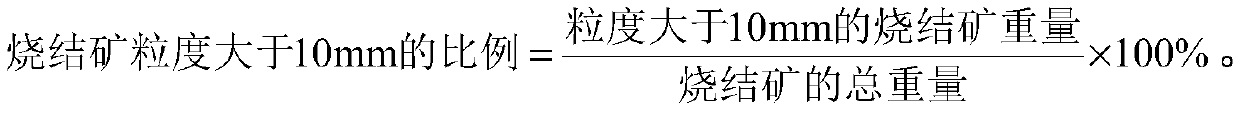

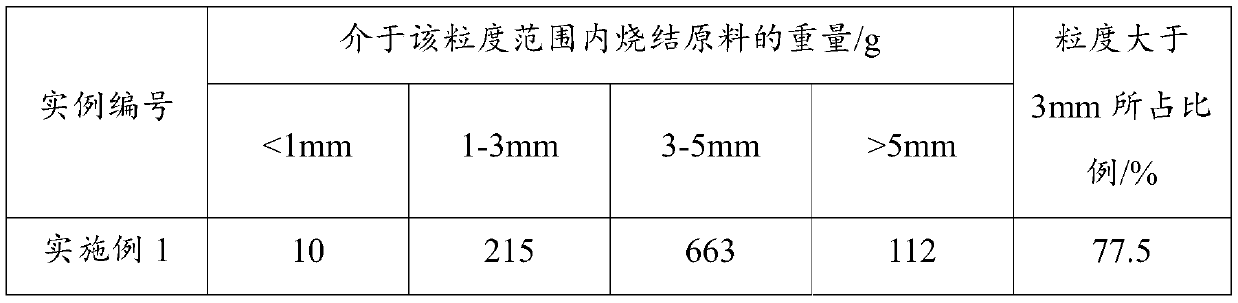

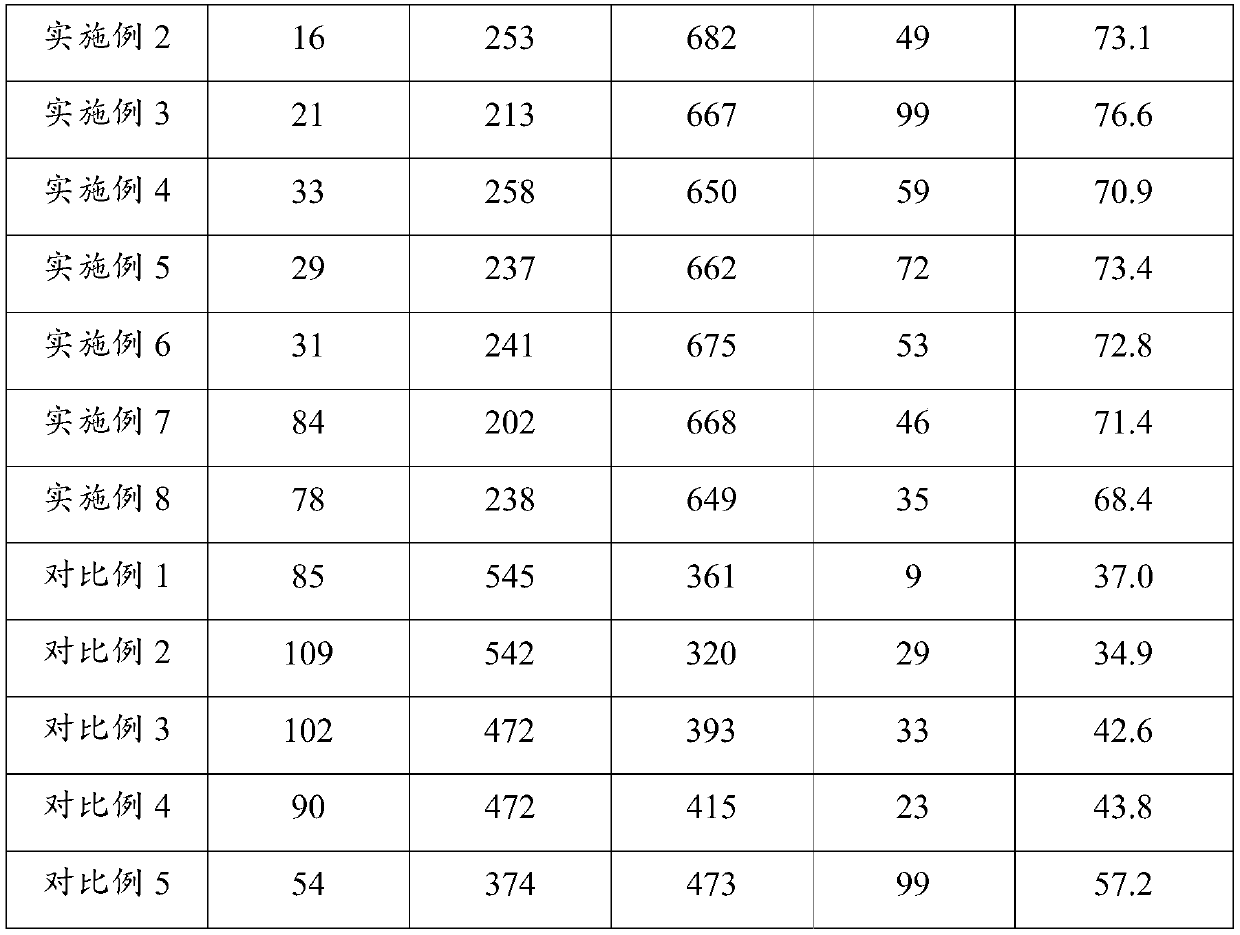

Sintering mixture and mixing method, sintering ore and sintering method

The invention belongs to the technical field of iron ore sintering, and particularly relates to a sintering mixture and a mixing method, sintering ore and a sintering method. The sintering mixture comprises the following components in parts by weight: 90-110 parts of iron ore powder to be sintered, 14-20 parts of returned ore A, 8.5-10.5 parts of returned ore B, 2-4 parts of coke powder, 7-9 partsof quicklime and 6.5-8.5 parts of adhesives, wherein the particle size of the returned ore A is 1-2 mm, and the particle size of the returned ore B is 2.5-5 mm. Through adding the adhesives with an adhesive effect and the returned ore A and the returned ore B with specific particle sizes to the sintered mixture, the particle size and particle structure of the sintering mixture are further improved, so that microparticles with the returned ore as cores are formed, the air permeability of a material layer is greatly improved, the sintering requirement of an ultra-thick material layer of 1000 mmor above is fully met, and the air permeability and the vertical combustion speed of a sintering material layer, and the output and yield of the sintering ore are all improved to various degrees.

Owner:NANKAI UNIV

Method for preparing biomass fuel with fresh pig manure as main raw material

ActiveCN106281562BAppropriate viscosityEliminates the drying stepBiofuelsSolid fuelsMicroorganismDeodorant

The invention belongs to the technical field of environmental protection, and particularly relates to a method for preparing biomass fuel by taking fresh pig manure as a main raw material. The method particularly comprises the following steps that 1, raw materials are pretreated; 2, fermentation is conducted, wherein the fresh pig manure, fungus mushroom rods and / or branch and leaf materials are mixed, and an obtained mixture is inoculated with deodorant compound microorganisms for first-time fermentation and then inoculated with nitrogen fixation-desulfuration compound microorganisms for second-time fermentation; 3, fermented materials are naturally air-dried; 4, tea stalk materials are added, and extruding granulation is conducted. The biomass pellet fuel which is low in ignition point and high in combustion heat value and combustion rate is prepared by taking the fresh pig manure as the main raw material, taking the waste fungus mushroom rods and the tea stalks as auxiliary materials, adding the deodorant compound microorganisms and the desulfuration compound microorganisms, fully utilizing the efficient deodorization property of the compound microorganisms and enhancing the flammability and the comprehensive combustion characteristic of the materials. According to the method, the pig manure can be greatly consumed, the environmental pollution problem of the pig manure is solved, and meanwhile the direction is provided for recycling utilization of the waste fungus mushroom rods and the tea stalks.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

A kind of using sludge and oil sludge to produce environment-friendly briquette and its production method

ActiveCN106367152BEasy to useProcess environmental protectionBiofuelsSolid fuelsBrown coalOil sludge

The invention provides an environmental protection type coal produced from sludge and fatlute and a manufacturing method thereof, and belongs to the field of solid waste integrative utilization. The environmental protection type coal produced from sludge and fatlute makes integrative utilization on the solid waste and can make full use of calorific values of sludge and fatlute. The environmental protection type coal is mainly prepared from, by mass, 60-80 parts of coal powder, 10-40 parts of sludge, 1-20 parts of fatlute, and 0.5-5 parts of briquette cohesive agent. The sludge is prepared through chemical disinfection treatment, the fatlute is prepared by reducing viscosity, and the briquette cohesive agent is prepared after fully stirring the low metamorphic lignitous coal, alkaline waste residues and paper making black liquid. The addition of certain amount of lime into the coal powder is good for desulfuration, and is also good for briquette coal demolding. The environmental protection type coal produced by carrying out mixing extrusion on the materials in certain proportion makes full use of caloric values of the sludge and fatlute, prevents the sludge and fatlute from generating secondary pollution, and has obvious environmental benefits and economic benefits. The environmental protection type coal produced from sludge and fatlute and the manufacturing method thereof can be applicable to the production process of environmental protection type coal.

Owner:SHANDONG UNIV OF SCI & TECH

Moxa-moxibustion stick for improving organism immunity and preparation method of moxa-moxibustion stick

InactiveCN106728575AImprove immunityWith health functionInorganic non-active ingredientsImmunological disordersMedicineRhizome

The invention discloses a moxa-moxibustion stick for improving organism immunity and a preparation method of the moxa-moxibustion stick. The moxa-moxibustion stick comprises, by weight, 90-100 parts of argy wormwood leaves, 40-50 parts of common cruculigo rhizome extracts, 15-19 parts of mongolian milkvetch root extracts, 0.3-0.4 part of eucommia bark extract and 0.2-0.3 part of modified konjaku powder. The prepared moxa-moxibustion stick has the health care function and is difficult to be fractured and extinguished, less in smoke amount and high in safety, and the burning process is more stable.

Owner:河南忠澜艾瓷文化开发有限公司

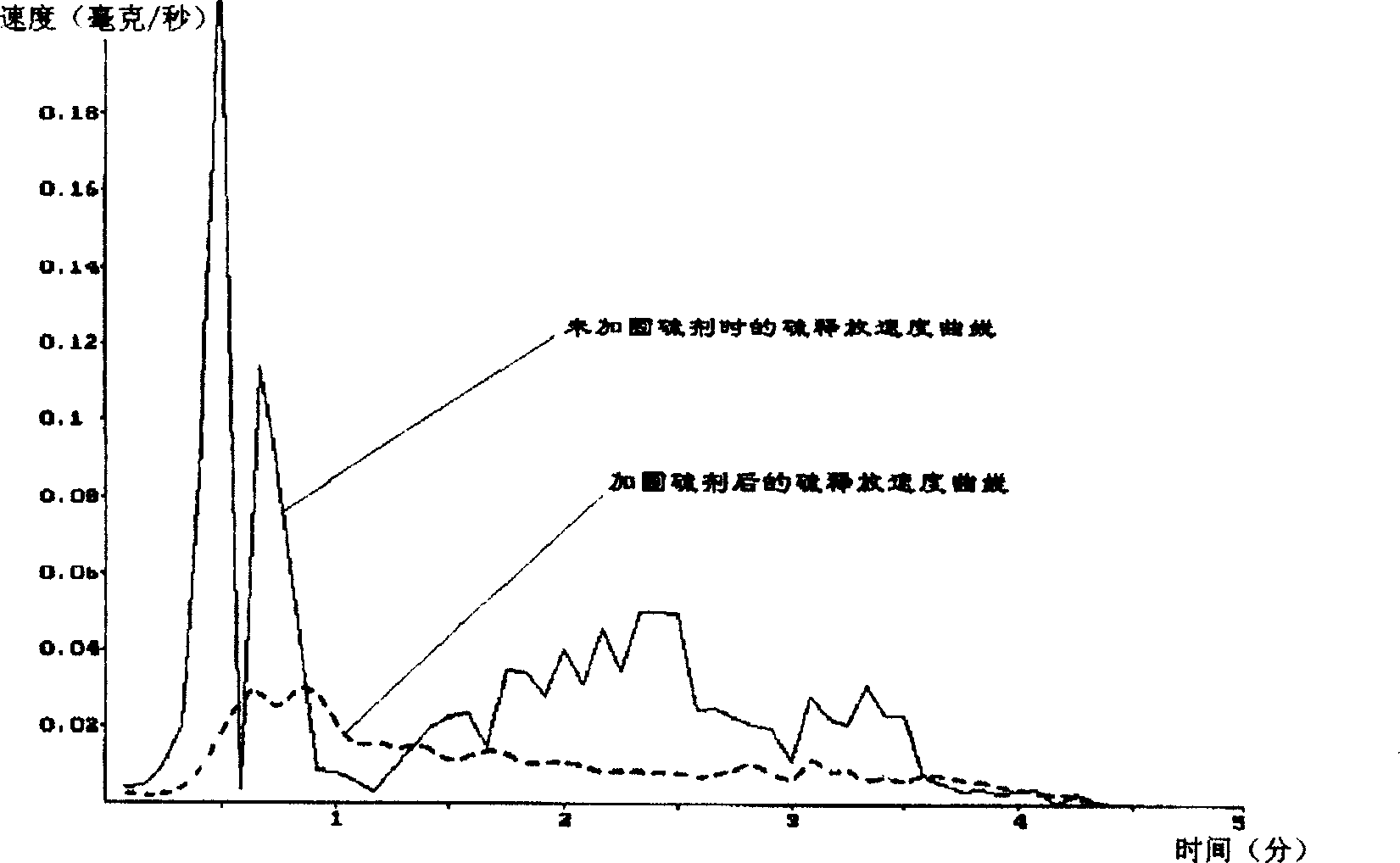

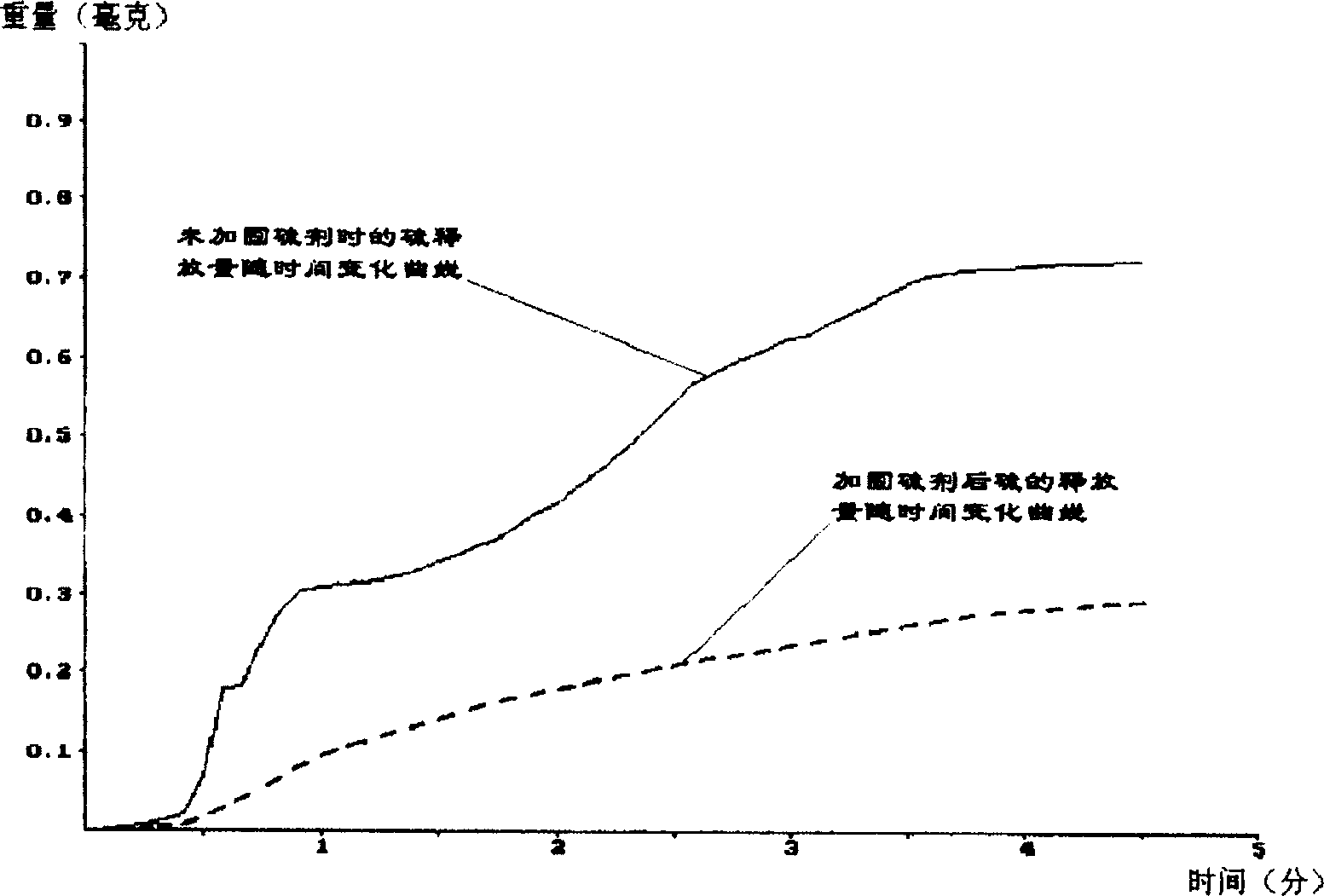

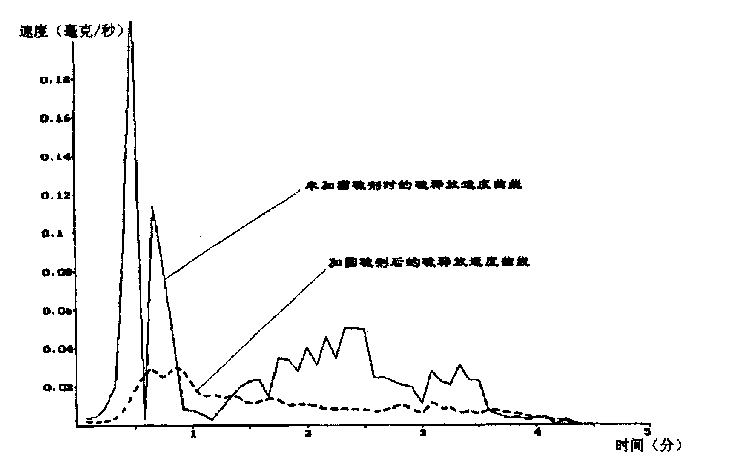

Biomass granular fuel combustion improver

The invention discloses a biomass granular fuel combustion improver. The combustion improver is prepared from the following raw materials in parts by weight: 50-80 parts of rice husks, 30-45 parts ofkaolin, 20-50 parts of diatomite powder, 2-5 parts of ferric oxide, 4-10 parts of quick lime and 10-13 parts of periclase powder. The combustion improver is uniformly mixed inside biomass granular fuel in the process of forming biomass granular fuel, the ash fusion point of biomass granular fuel can be increased in the combusting process due to Al2O3, SiO2, MgO, CaO and Fe2O3 in the combustion improver when the biomass granular fuel containing the combustion improver is combusted, the phenomena of melting and slagging generated on the inner surface of a container in the biomass granular fuel combusting process can be avoided, the influence of the melting and slagging phenomena on combustion of the biomass granular fuel can be further avoided, and a combustion improving effect is achieved for the biomass granular fuel combusting process.

Owner:颍上烨徽生物科技有限公司

Method for treating high-calorific-value oil sludge by using cement clinker device

ActiveCN113045290AReduce processing costsImprove efficiencySludge treatment by de-watering/drying/thickeningSolid fuelsPhysicsExhaust gas

The invention relates to the field of waste treatment, in particular to a method for treating high-calorific-value oil sludge by a cement clinker device, which comprises the following steps of: removing moisture in sludge by using high-temperature tail gas of a cement kiln in a high-speed injection manner, and mixing the sludge with pulverized coal to serve as fuel of the cement kiln; and mixing the incinerated waste residue with auxiliary materials such as clay, and conducting calcining under the action of a plant-based foaming agent to obtain a foamed brick. According to the method, heat of high-temperature tail gas generated by the cement kiln is not wasted, energy can be provided for operation of the cement kiln, the burnt tail gas is completely utilized and made into the foamed brick, and resource utilization of the high-calorific-value sludge is completely achieved. According to the method, special treatment equipment does not need to be designed for treating the high-calorific-value sludge, the treatment process is synergistically completed by depending on the cement kiln, the treatment cost is low, the efficiency is high, the resource utilization rate is high, and the method is a method for circularly and economically treating the high-heat oil-containing sludge.

Owner:浙江红狮环保股份有限公司

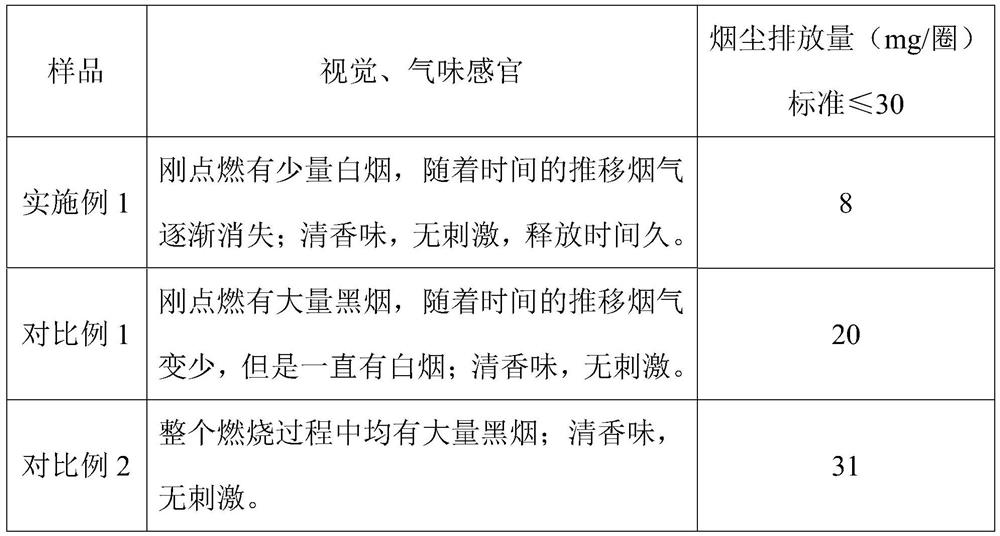

Peony blended incense and preparation method thereof

InactiveCN112807359AImprove immunityImprove antibacterialAntibacterial agentsNervous disorderBiotechnologyChrysanthemum Flower

The invention discloses peony blended incense and a preparation method thereof. The peony blended incense comprises the following raw materials: peony flower pods, cloves, wild chrysanthemum flowers, agilawood, folium artemisiae argyi, safflower carthamus, asarum, dried orange peel, purple perilla and a plant adhesive. The peony blended incense has the following beneficial effects: the peony flower pods are adopted as the main raw material and compounded with the cloves, the wild chrysanthemum flowers, the agilawood, the folium artemisiae argyi, the safflower carthamus, the asarum, the dried orange peel and the purple perilla, so that the peony blended incense has good effects of inhibiting bacteria, purifying air, soothing the nerves, clearing away heart-fire and improving immunity of the organism. The peony flower pods used in the peony blended incense are processed, smoke can be avoided in the incense burning process, the effects of clearing away the heart fire and soothing the nerves can be better achieved, after the peony flower pods cooperate with the raw materials, the fragrance generated by burning is unique and lasting, and the effect that people feel relaxed and happy is achieved. The plant adhesive is added to achieve a combustion-supporting effect, and the aromatic effect of the main incense is increased on the basis of environmental protection.

Owner:北京丹泽生态科技有限公司

Dust-free incense and preparation process thereof

PendingCN112870421ADelayed releaseGood flammabilityBiocidePest repellentsEngineeringBletilla striata

The invention belongs to the technical field of incense, and particularly relates to dust-free incense and a preparation process thereof, and the dust-free incense is prepared from the following components in parts by weight: 10-15 parts of perfume microcapsules, 5-10 parts of charcoal powder, 4-8 parts of bletilla striata powder and 3-5 parts of tea oil. According to the prepared dust-free incense, the plant extract is wrapped in a capsule in a liquid form by adopting a microcapsule technology, release of active ingredients and fragrance can be delayed, and meanwhile, the plant extract contains most volatile oil, is good in flammability and free of dust; in addition, the dust-free incense is made into a hollow type, so that the contact area between the incense and air is further increased, and the incense is combusted more fully and is smokeless and dust-free.

Owner:福建诚盛香业有限公司

Exhaust gas cleaning agent for automotive diesel fuel

InactiveCN108913241AEffective carbon removalReduce carbon contentLiquid carbonaceous fuelsFuel additivesKeroseneEngineering

The invention provides an exhaust gas cleaning agent for automotive diesel fuel. The exhaust gas cleaning agent is prepared from 15-25 parts by weight of methanol, 5-15 parts by weight of ethanol, 5-15 parts by weight of t-butanol, 5-15 parts by weight of a methyl ester, 5-15 parts by weight of an ethyl ester, 5-15 parts by weight of dimethyl carbonate and 40-50 parts by weight of aviation kerosene. Through combination of polyol, esters and aviation kerosene, the exhaust gas cleaning agent can effectively remove carbon from the exhaust gas and reduce the carbon component in the exhaust gas.

Owner:天津恩光科技有限公司

Petrochemical additive and preparation method thereof

The invention relates to a petrochemical additive and a preparation method thereof, belonging to the technical field of the preparation of the chemical additive product. The petrochemical additive consists of naphthenic acid, N,N-dimethylisobutylamine and cyclohexylamine which are the byproducts of the raw material refinery; and the components are fully stirred in a container for 40-60min at the room temperature under the atmospheric pressure to prepare the petrochemical additive and store in a container prepared from the stainless steel material. The petrochemical additive is mixed with water and diesel oil, an air compressor is used to ensure that the pressure is 1atm and the symmetric cross injection method is adopted to fully mix diesel oil, water and the emulsifying additive and produce a microemulsion fuel oil finished product. The raw material components of the petrochemical additive are fewer, the components are available, the preparation method is simple, the used equipment is simple and is easy to prepare, the cetane number of the product is higer than that of common diesel oil, the dynamic property is high, the cost is reduced by 8-9% compared with common diesel oil, the emission rate of harmful gases and black smoke is reduced by 23.7%, the oil-saving rate is 18.9%, and the produced diesel oil has higer social and economic benefits.

Owner:XIANYANG TIANCHENG PETROCHEM ENERGY SAVING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com