Method for fixing sulfur component in high-sulfur coal by using dolomite

A dolomite and sulfur coal-fired technology, applied in the direction of fuel, petroleum industry, fuel additives, etc., can solve the problems of rare reports and low sulfur fixation rate, and achieve the effects of easy availability of raw materials, high sulfur fixation rate, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

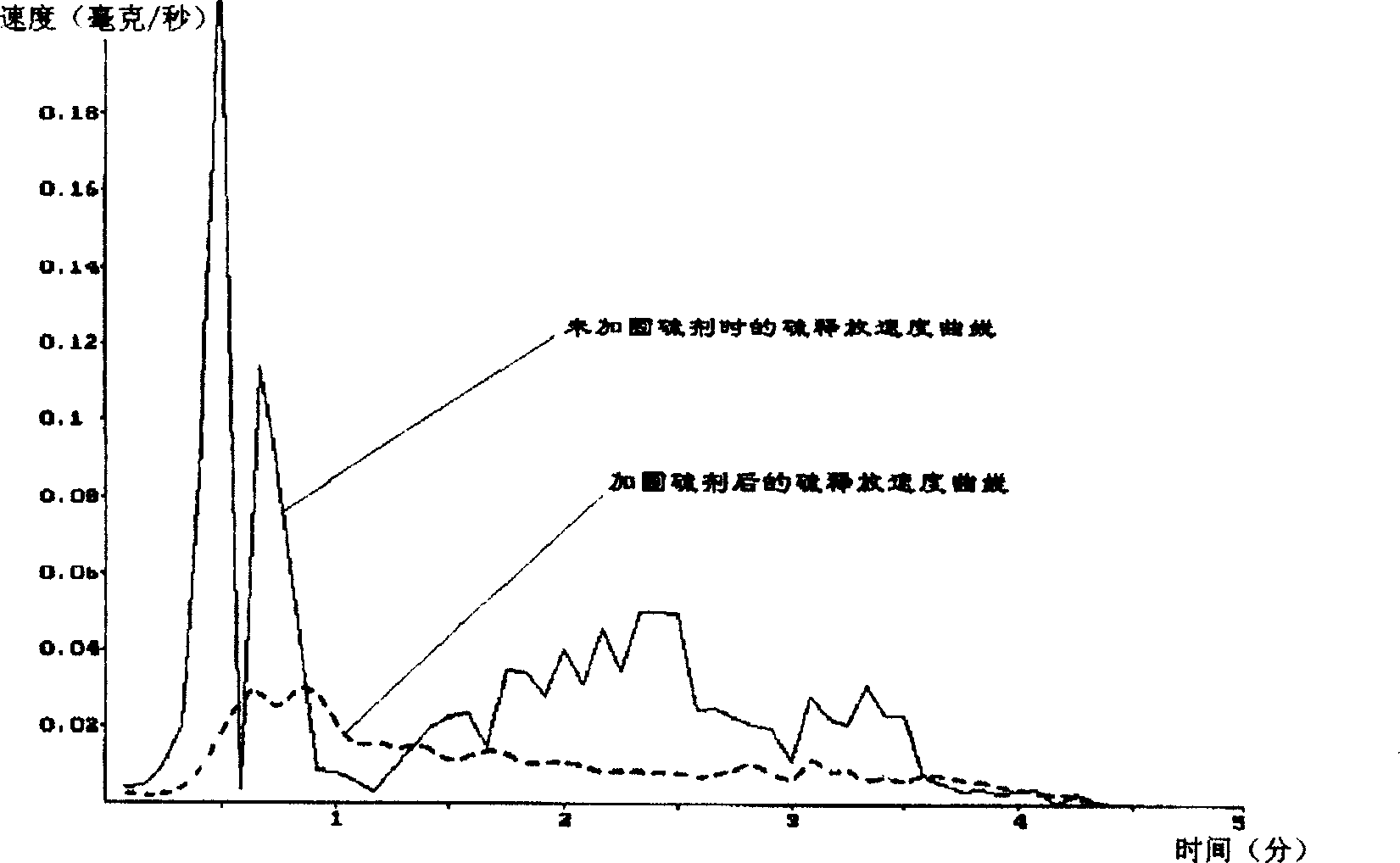

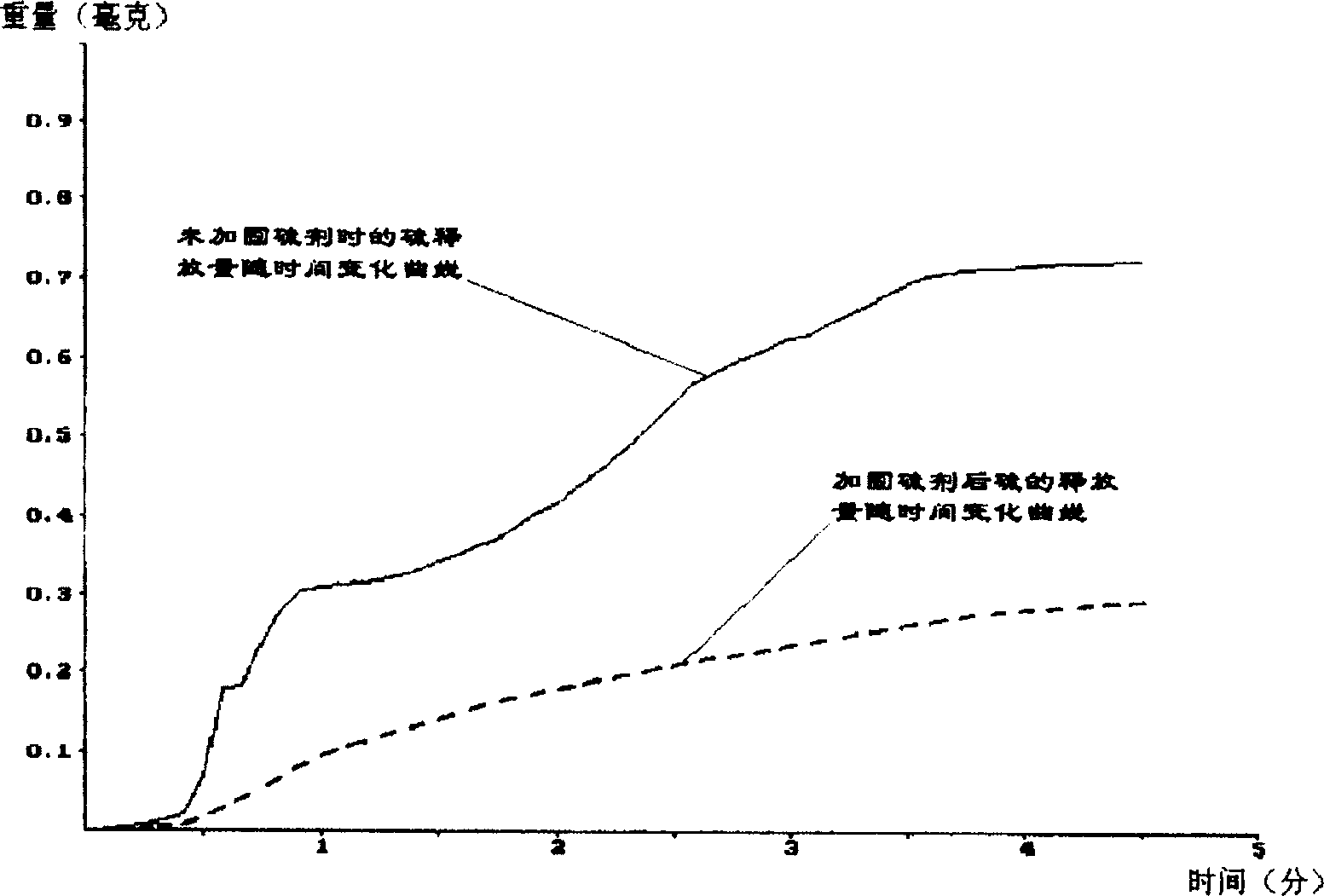

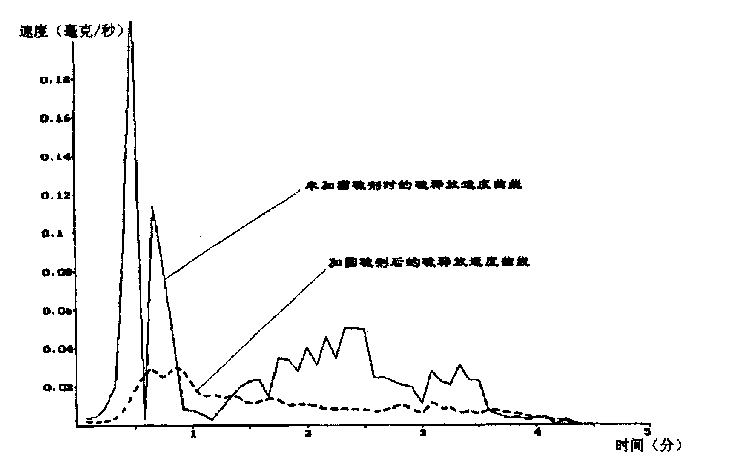

[0013] The first embodiment is carried out under laboratory conditions. The first test step is to take 500 mg of an air-dried coal sample with a particle size of less than 0.2 mm and a sulfur content of 1.72%. According to GB / T 214-1996, the coal sample is analyzed by coulometric titration. Carried out high-temperature combustion to measure sulfur, and the amount of sulfur released after combustion was measured to be 1.72%. During the measurement process, the change data of combustion time and electrolytic power were recorded at the same time, and the electrolytic power was converted into sulfur release by calculation, and the sulfur released The relationship between the velocity and the amount of release over time is drawn as a graph (such as figure 1 and figure 2 solid line in ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com