Patents

Literature

37results about How to "Improve sulfur fixation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing molybdenum nickel alloy by directly reducing and smelting molybdenum nickel ore

The invention relates to a method for preparing molybdenum nickel alloy by directly reducing and smelting molybdenum nickel ore. The method comprises the following steps: grinding the molybdenum nickel ore into molybdenum nickel ore powder with the average particle size of less than or equal to 0.18 mm; adding a slag forming agent and a reducing agent with the average particle size of less than or equal to 0.18 mm into the molybdenum nickel ore powder to obtain furnace charge; mixing the furnace charge uniformly and pelletizing to obtain pellet; heating the pellet to 1,600 to 1,800 DEG C; smelting; and collecting liquid alloy, slag, smoke dust and furnace gas respectively, wherein the liquid alloy is crude molybdenum nickel alloy; the direct yield of the molybdenum and the nickel is 96 percent and 94 percent respectively; the molybdenum content of the smoke dust is less than 0.2 percent and the nickel content of the smoke dust is less than 0.2 percent; and the SO2 concentration of thefurnace gas is less than or equal to 400 mg / m<3>. The process method is simple and reasonable, and convenient to operate; the molybdenum nickel ore is not subjected to oxidizing roasting de-sulfuration; and the crude molybdenum nickel alloy is prepared by directly reducing and smelting the molybdenum nickel ore and by using the carbon of the molybdenum nickel ore as a reducing agent, so that indirect smelting is changed into direct smelting. The prepared molybdenum nickel alloy is low in sulfur content and phosphorus content, environment friendly and low in production cost; and the method is suitable for extraction of the molybdenum nickel ore.

Owner:CENT SOUTH UNIV +2

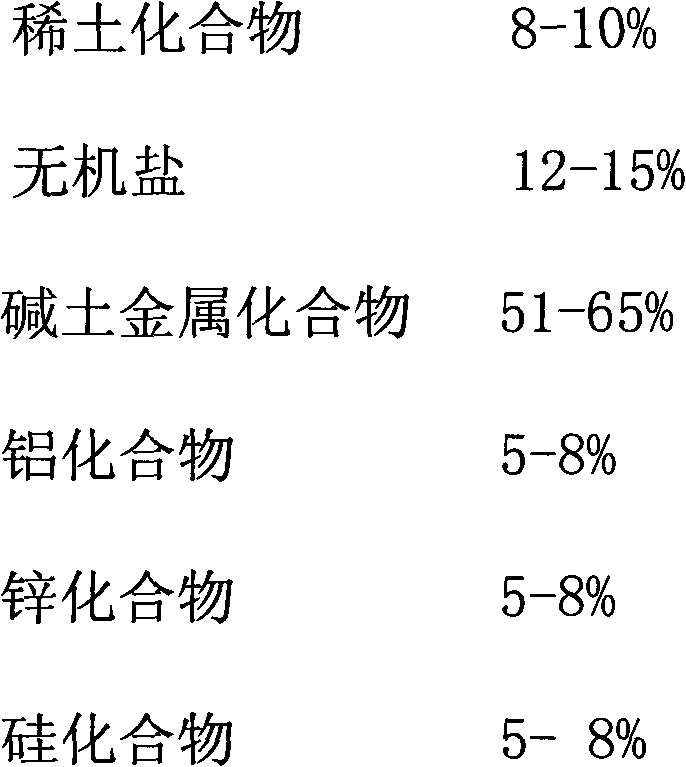

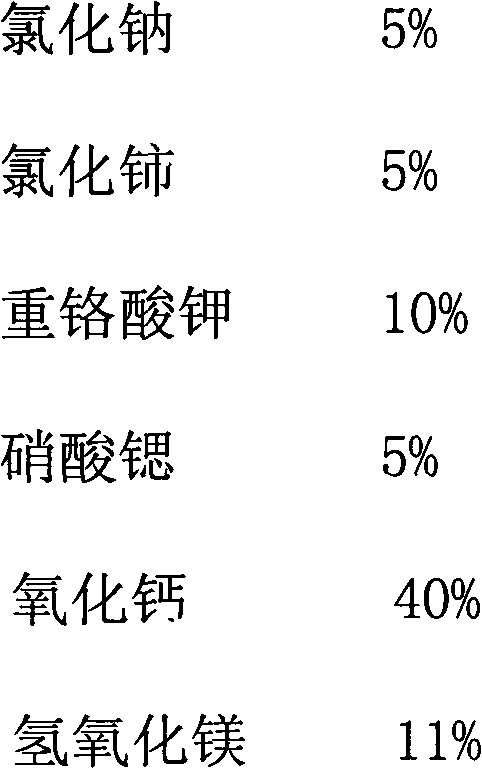

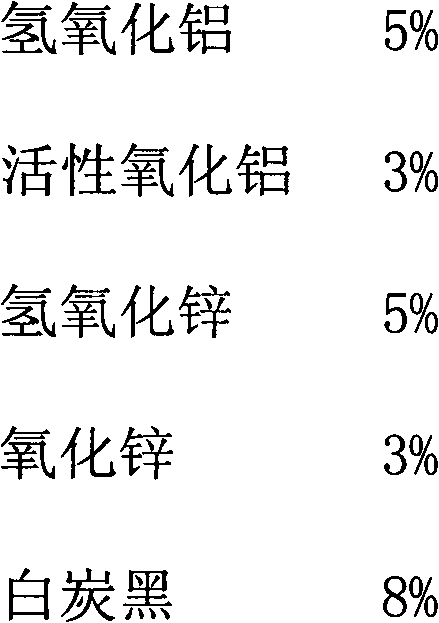

Multifunctional rare earth sulfur-fixing denitration energy-conservation additive

The invention discloses a multifunctional rare earth sulfur-fixing denitration energy-conservation additive, which solves the problems that the conventional sulfur-fixing agent has relatively low sulfur-fixing rate and does not have the function of reducing NOx emission. The additive is characterized by consisting of the following raw materials in percentage by mass: 8 to 10 percent of rare earth compound, 12 to 15 percent of inorganic salt, 51 to 65 percent of alkaline earth metal compound, 5 to 8 percent of aluminum compound, 5 to 8 percent of zinc compound and 5 to 8 percent of silicon compound. The additive is prepared by the following steps of: grinding the raw materials into fine particles with the particle size of 100 to 300 meshes; proportioning the particles according to the mass percentage at normal temperature; uniformly stirring and mixing; preparing powder from the mixture; and compounding. The additive has the advantages of capability of being popularized in a large area, high sulfur-fixing rate and denitration function and is suitable for coal-smoke type heavily-polluted production links.

Owner:阳泉鑫环高新技术有限责任公司

Desulfurization and denitration combustion improver in blast furnace coal injecting as well as preparation method and using method thereof

The invention provides a desulfurization and denitration combustion improver in blast furnace coal injecting as well as a preparation method and a using method thereof. The desulfurization and denitration combustion improver is prepared from the following raw materials in percentage by weight: 18 to 23 percent of manganese dioxide, 5 to 8 percent of ferric oxide, 9 to 13 percent of barium carbonate, 10 to 16 percent of calcium oxide, 5 to 8 percent of sodium carbonate, 10 to 16 percent of rare earth oxide, 2 to 6 percent of titanium dioxide, 3 to 6 percent of potassium nitrate and the balanceof activated carbon; the rare earth oxide is prepared from the following raw materials in percentage by weight: 40 to 55 percent of yttrium oxide, 25 to 35 percent of lanthanum oxide and 20 to 30 percent of indium oxide; the average particle diameter of the rare earth oxide is 10 to 40 mum. The desulfurization and denitration combustion improver provided by the invention has a remarkable combustion-supporting effect on pulverized coal, the combustion efficiency of the pulverized coal can be effectively improved, emission of NOx and SOx can be effectively reduced, and the purposes of energy conservation and emission reduction can be achieved.

Owner:马鞍山科宇环保设备股份有限公司

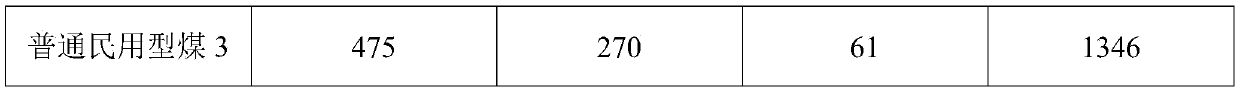

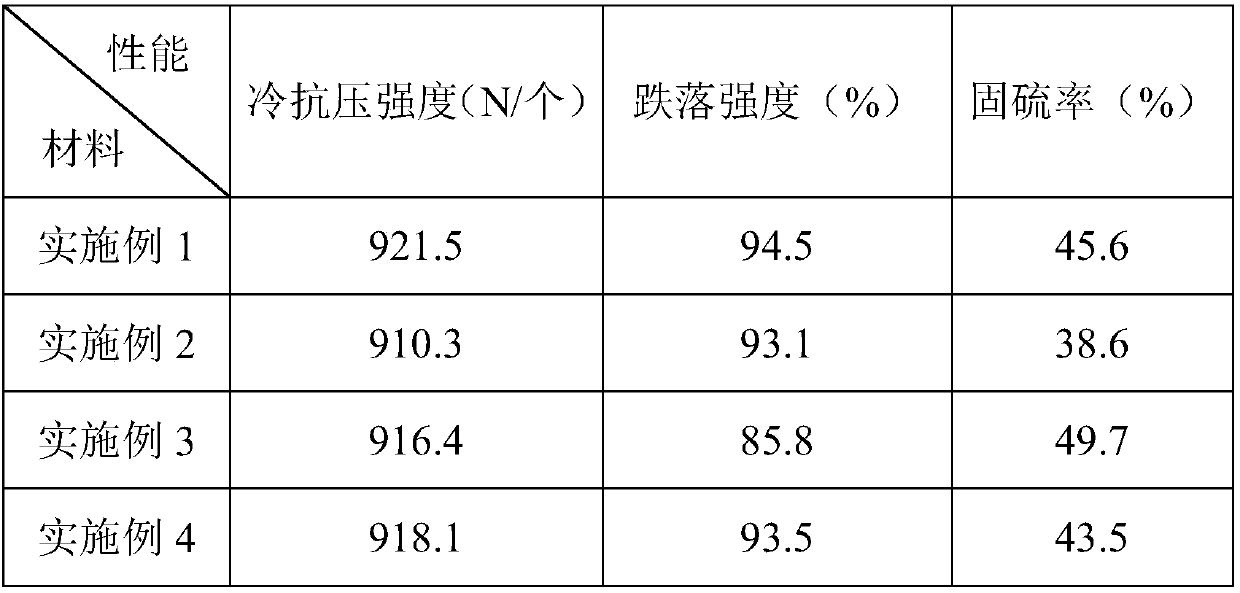

Civil high-strength sulfur-fixing briquette and preparation method thereof

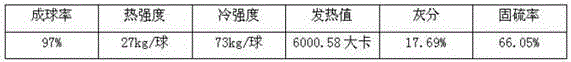

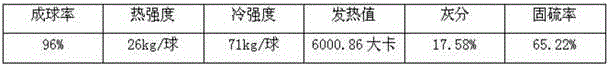

The invention provides a civil high-strength sulfur-fixing briquette and a preparation method thereof. The briquette is prepared by mixing, by weight, 65-70 parts of anthracite powder, 12-15 parts of fat coal powder, 1-2 parts of sodium bentonite, 1-2 parts of calcium oxide, 0.5-1.0 part of corn pregelatinized starch, 0.2-0.5 part of silicon dioxide, 0.2-0.5 part of sodium chloride, 0.1-0.2 part of sodium dodecyl benzene sulfonate and 13-15 parts of water. The preparation method of the briquette comprises the steps of firstly, crushing the anthracite coal and the fat coal powder until the particle size is 3 mm or below; then, adding the crushed anthracite coal powder, the crushed fat coal powder and solid powder of the sodium bentonite, calcium oxide, corn pregelatinized starch, silicon dioxide, sodium chloride and sodium dodecyl benzene sulfonate into a stirrer by proportion for uniform mixing, adding the water by proportion, uniformly mixing the components, and performing standing to obtain a mixed material; finally, pressing the mixed material for shaping, and drying the mixed material to obtain a briquette product. According to the civil briquette prepared by means of the method, the strength of the briquette can be significantly enhanced, the sulfur fixing rate is increased, and the SO2 emission during combustion is reduced.

Owner:SHANXI UNIV

Novel sulphur-fixing agent

The invention discloses a novel sulphur-fixing agent. The novel sulphur-fixing agent is prepared from, by weight, 2-5 parts of kaolin, 3-6 parts of bentonite, 4-8 parts of zeolite, 5-8 parts of kieselguhr, 2-4 parts of perlite, 10-15 parts of cordierite, 1-3 parts of talcum powder, 6-8 parts of calcium oxide, 4-8 parts of ferric oxide, 3-5 parts of zinc oxide, 0.2-0.4 part of calcium peroxide, 6-8 parts of strontium carbonate, 4-7 parts of barium hydroxide, 0.2-0.5 part of potassium sulphate, 0.3-0.7 part of vanadium pentoxide, 6-9 parts of niobium pentoxide, 0.1-0.3 part of aluminum powder, 20-25 parts of ethyl alcohol, 5-9 parts of nanometer titania and 6-8 parts of nano calcium carbonate. The novel sulphur-fixing agent is reasonable in formula, resistant to high temperature and good in high-temperature sulphur-fixing effect, and has good development prospects on the aspect of coal sulphur fixing.

Owner:王璐

Nano sulfur-fixing agent

InactiveCN105950258AImprove high temperature sulfur fixation rateImprove sulfur fixation rateSolid fuelsNiobium pentaoxideBrown iron oxide

The invention discloses a nano sulfur-fixing agent which is prepared from the following components in parts by weight: 4-6 parts of kaolin, 2-5 parts of diatomite, 1-3 parts of diopside, 4-7 parts of cordierite, 1-3 parts of talcum powder, 5-8 parts of calcium oxide, 3-6 parts of iron oxide, 2-5 parts of zinc oxide, 0.3-0.6 part of calcium peroxide, 3-5 parts of strontium carbonate, 2-6 parts of barium hydroxide, 0.3-0.5 part of potassium sulfate, 0.2-0.6 part of vanadium pentoxide, 6-8 parts of niobium pentaoxide, 1-3 parts of sodium ferrate, 0.4-0.8 part of sodium citrate, 20-25 parts of ethanol, 4-7 parts of nano titanium dioxide, 5-8 parts of nano calcium carbonate and 1-3 parts of nano aluminum oxide. The sulfur-fixing agent disclosed by the invention has the advantages of reasonable formula, high temperature resistance and favorable high-temperature sulfur-fixing effect, and thus, has favorable development prospects in the aspect of sulfur fixation of coal.

Owner:王璐

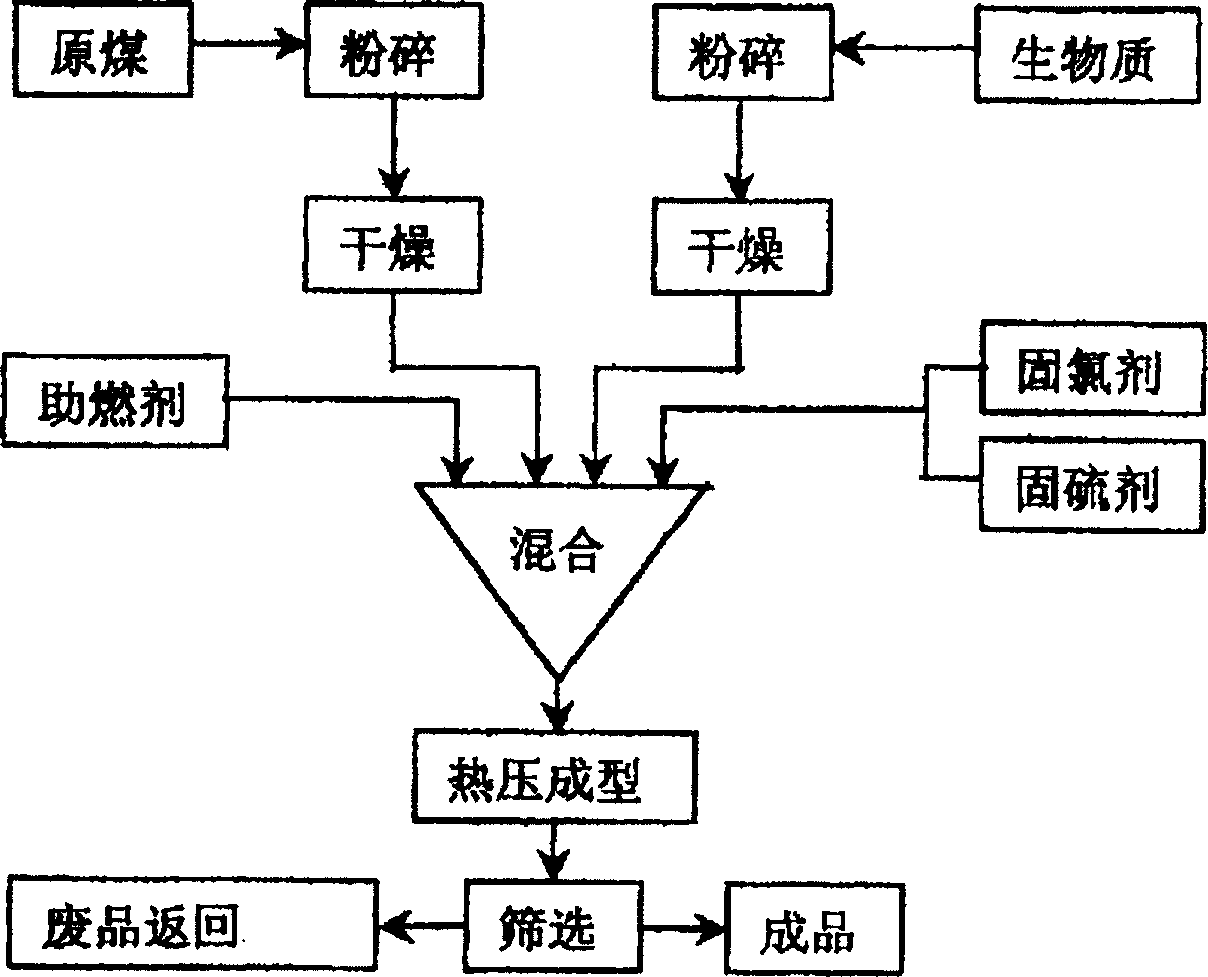

Process for preparing composite biomass briquettes

InactiveCN1236027CHigh compressive strengthSuitable for long distance transportationBiofuelsSolid fuelsForest industryCombustion

A composite biomass briquette is made up of biomass including stalk or straw, wood leftover, city household garbage and raw coal through crushing, mixing with chlorine fixating agent, sulfur fixating agent and combustion promoter, and hot die pressing. Its advnatages are high compression strength, low combustion point, high combustion efficiency and less environmental pollution.

Owner:KUNMING UNIV OF SCI & TECH

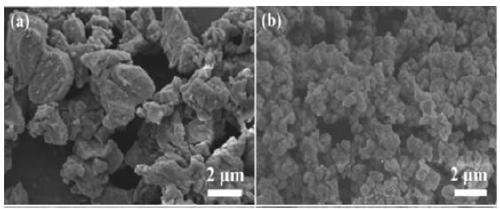

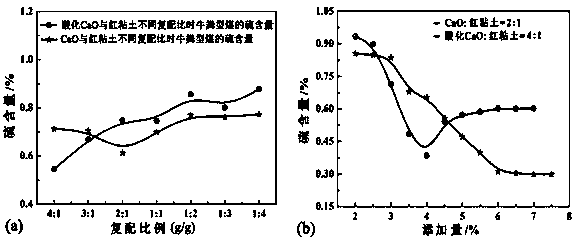

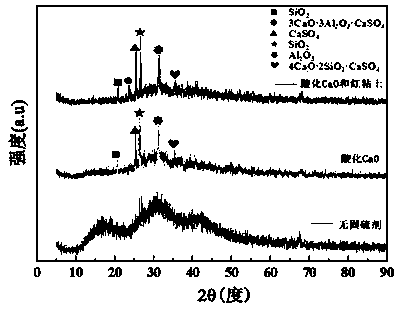

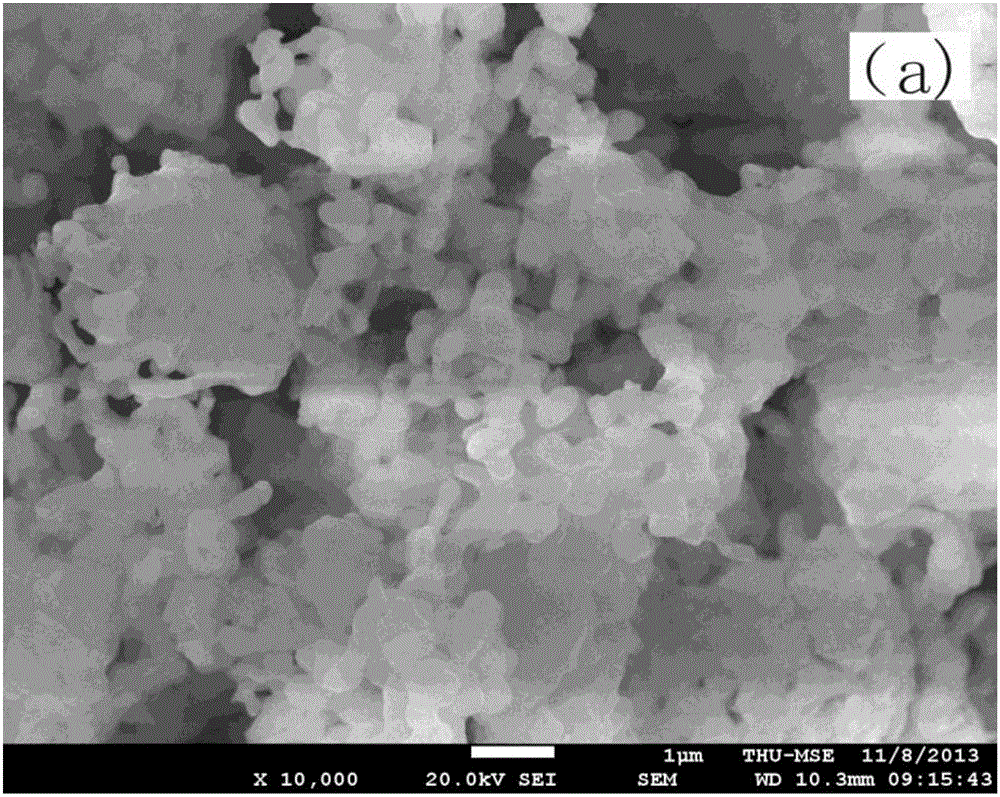

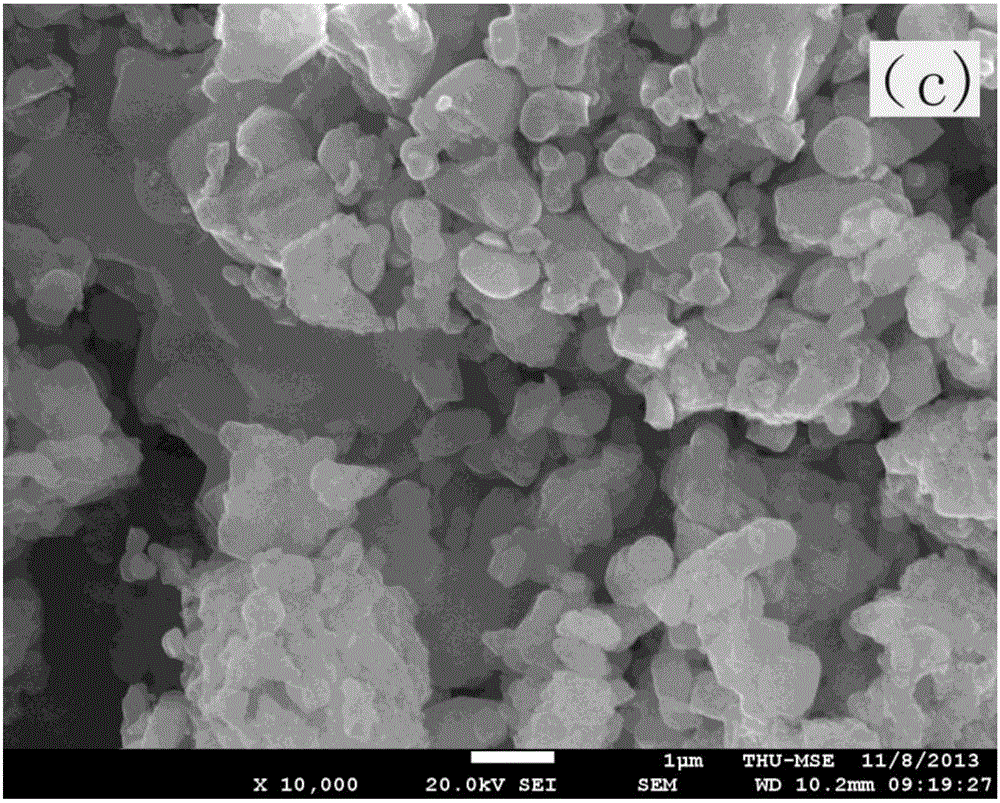

Preparation method of clay-calcium-based sulfur fixing agent and application of agent in fixing cow dung/high-sulfur composite coal

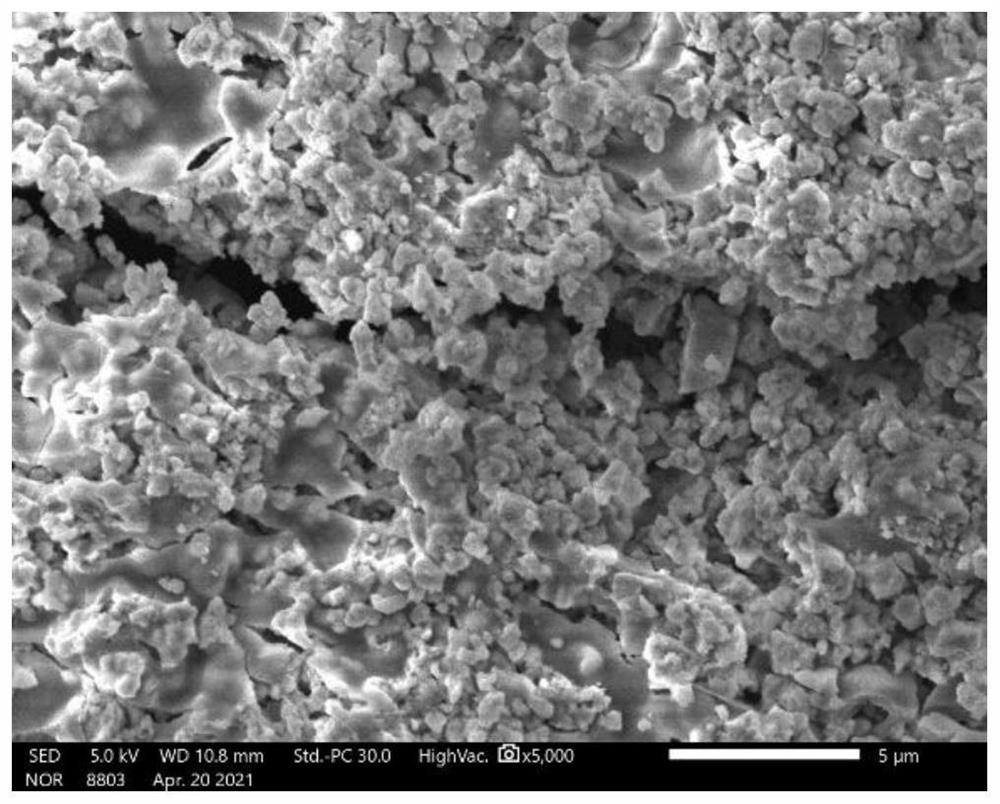

InactiveCN109797022AFluffy structureUniform particle distributionBiofuelsSolid fuelsSulfideMuffle furnace

The invention provides a preparation method of a clay-calcium-based sulfur fixing agent. The preparation method includes acidizing calcium oxide with tartaric acid, drying, grinding, and calcining ina muffle furnace to obtain acidized calcium oxide; and mechanically mixing the acidified calcium oxide and natural clay and grinding evenly to obtain the clay-calcium-based sulfur fixing agent. The sulfur fixing agent has the advantages of fluffy structure, uniform particle distribution, increased specific surface area, high sulfur fixing rate, good thermal stability of sulfur fixing products andthe like, is used for sulfur fixing of cow dung / high-sulfur composite coal, wherein the sulfur content (St, ad) of the briquette is less than 0.50%, and the sulfur fixing rate reaches about 70.0%, andthus sulfide emission during combustion of the cow dung / high-sulfur composite coal is effectively reduced. In addition, the sulfur fixing agent prepared by the method has the advantages of easily-available raw materials, safe use, simple preparation process and better economy and application.

Owner:NORTHWEST NORMAL UNIVERSITY

Combustion-supporting agent for coal

A disclosed combustion-supporting agent for coal is characterized by being composed of the following compositions in parts by weight: 20-30 parts of zirconium slag, 20-30 parts of white mud, 10-20 parts of ferrocene, 5-10 parts of diatomite, 5-10 parts of titanium dioxide, 5-10 parts of active carbon, 1-5 parts of urea, 1-5 parts of manganese oxide, 1-5 parts of carboxymethylcellulose sodium, 1-5 parts of potassium nitrate, 1-2 parts of cerium isooctanoate, and 1-2 parts of sodium chloride. The combustion-supporting agent with the above formula is obtained through a lot of experiments, and through synergic cooperation of the compositions, the obtained combustion-supporting agent has functions of immobilizing sulfur, removing coke, eliminating smoke and the like, is good in effect and is relatively convenient when being used.

Owner:王凯

Briquette binder, preparation method and applications thereof

The invention relates to the technical field of coal processing, and discloses a briquette binder, a preparation method and applications thereof, wherein the briquette binder comprises coking coal pitch, a biomass modification material, an inorganic magnesium-based curing agent and an auxiliary agent according to a weight ratio of (5-20):(8-25):(0.5-5):(0.1-0.3), wherein the auxiliary agent comprises at least one selected from a surfactant, a pore forming agent, a dehydrating agent and a cross-linking agent. According to the present invention, under the synergistic effect of various components, the briquette binder can complete the pulverized coal cementation process, the formed briquette can meet the industrial coal demand, the waste in the industrial and agricultural production process is solved, and the efficient use of resources is improved; and by adding the inorganic magnesium-based curing agent and the auxiliary agent, the strength and the impermeability of the briquette are enhanced, the combustion of the briquette is promoted, and the good sulfur fixation effect is provided.

Owner:BEIJING HUASHI UNITED ENERGY TECH & DEV

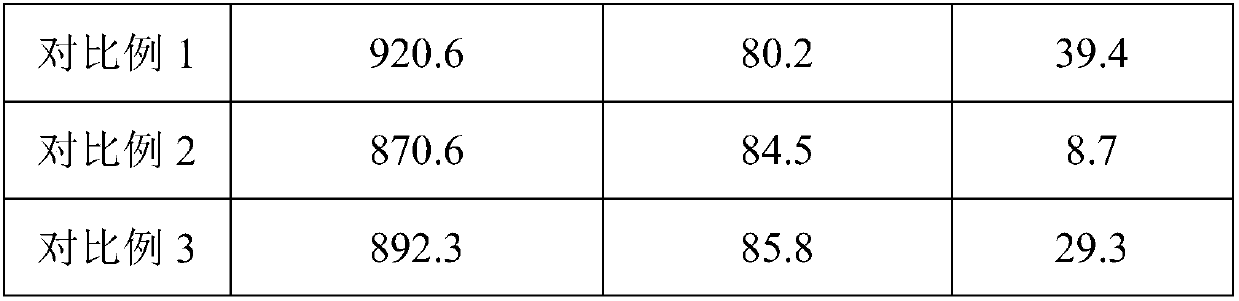

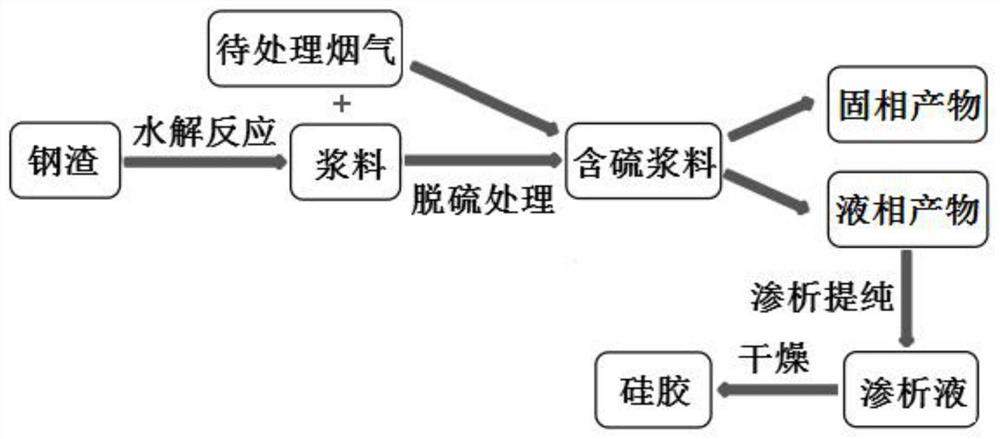

Method for synergistically extracting silica gel by removing SO2 in flue gas through steel slag

PendingCN114229852AIncrease contentEnsure Structural IntegrityMaterial nanotechnologySilicaFluid phaseSlag

The invention belongs to the technical field of industrial waste resourceful treatment, and particularly relates to a method for synergistically extracting silica gel by removing SO2 in flue gas through steel slag. The invention provides a method for synergistically extracting silica gel by using steel slag to remove SO2 in flue gas, which comprises the following steps: mixing steel slag and water, and carrying out hydrolysis reaction to obtain slurry; the slurry is in contact with flue gas to be treated, the flue gas is subjected to desulfurization treatment, sulfur-containing slurry is obtained, and the flue gas comprises SO2 and O2; performing solid-liquid separation on the sulfur-containing slurry to obtain a solid-phase product and a liquid-phase product; and carrying out dialysis purification on the liquid-phase product, and drying the obtained dialysate to obtain the silica gel. According to the method, SO2 in the flue gas is treated by using the steel slag to synergistically extract the silica gel, so that the low-cost and high-efficiency flue gas desulfurization requirements of a thermal power plant are met, a silica gel product with a high additional value can be co-produced, and resource utilization of the steel slag and the sulfur-containing flue gas is synchronously realized.

Owner:SHANXI UNIV

Multifunctional dry powder type coal adhesive, preparation method thereof and briquette coal containing adhesive

The invention relates to a multifunctional dry powder type coal adhesive. The coal adhesive comprises, by weight, 30-80 parts of an adhesive, 5-40 parts of a high-temperature reinforcing agent, 0.5-10parts of a regulator, 1-20 parts of a combustion-supporting ash-removing agent, 1-20 parts of a sulfur-fixing smoke-eliminating agent and 1-10 parts of an accelerant. The invention also relates to apreparation method of the adhesive and briquette coal containing the adhesive. The additives are low in cost and small in addition quantity, and the prepared briquette coal has the advantages of beinghigh in compressive strength, good in water resistance, free of drying, good in combustion-supporting catalysis, high in decoking and ash removal rate and obvious in sulfur fixation effect.

Owner:河北东慈环保科技有限公司

Deep compounding sulphur-fixing agent applicable to low sulfur content barbecue coal

InactiveCN106833804ARealize the purpose of deep sulfur fixationSimple componentsSolid fuelsPotassium carbonateCoal

The invention provides a deep compounding sulphur-fixing agent applicable to low sulfur content barbecue coal, wherein the deep compounding sulphur-fixing agent is prepared from, by weight, 80-90 parts of calcium-based basic aggregate agent, 3-7 parts of salt additive, 3-5 parts of metal oxide additive, and 2-5 parts of reaction catalyst, wherein the calcium-based basic aggregate agent comprises calcium oxide, calcium hydroxide and calcium carbonate; the salt additive comprises potassium carbonate, sodium carbonate and sodium chloride; the metal oxide additive comprises aluminium oxide, iron trioxide and magnesium oxide; the reaction catalyst comprises potassium chlorate and ethylene glycol monoethyl ether. The compound sulphur-fixing agent realizes the in-depth sulphur fixing of the coal when the barbecue coal is prepared by the low sulphur coal type, effectively solves the problem of odor generation easily during the combustion of the barbecue coal; the components are simple and easy to acquire, low in cost, and suitable for industrial production.

Owner:兰州兰煤节净能源有限公司

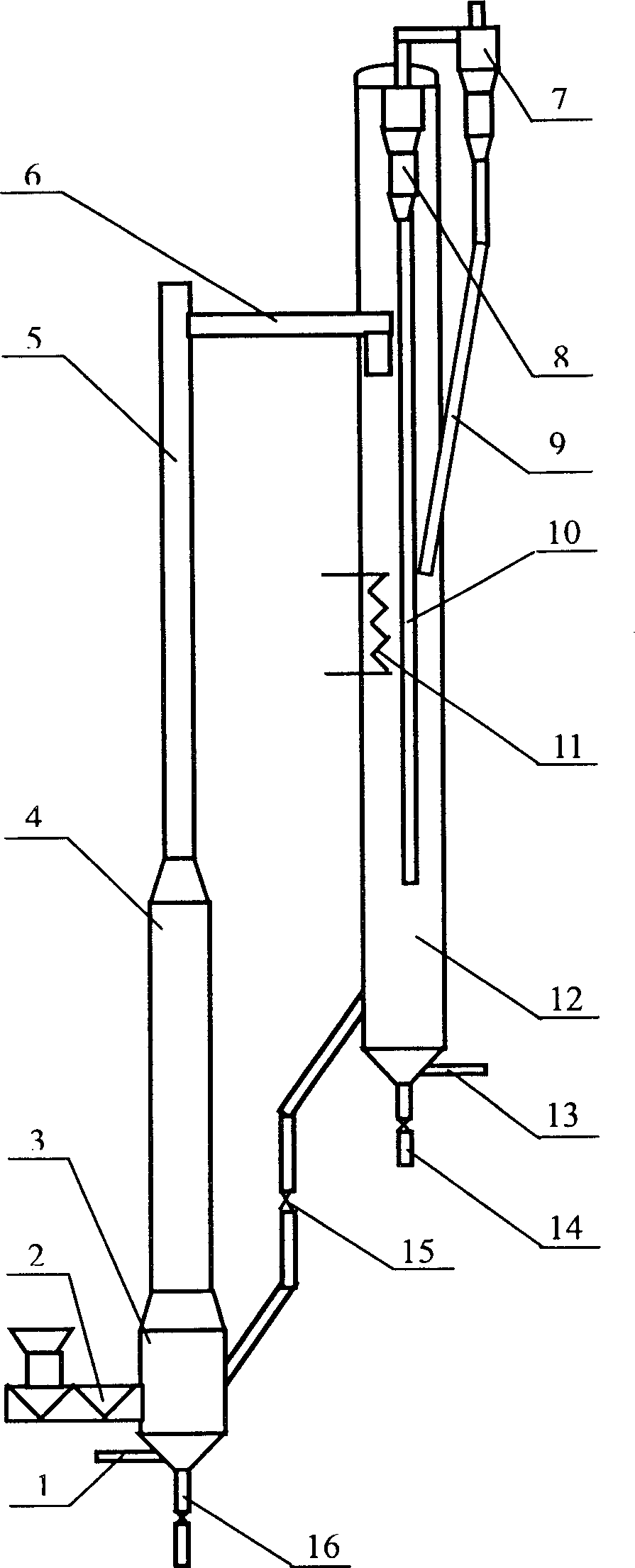

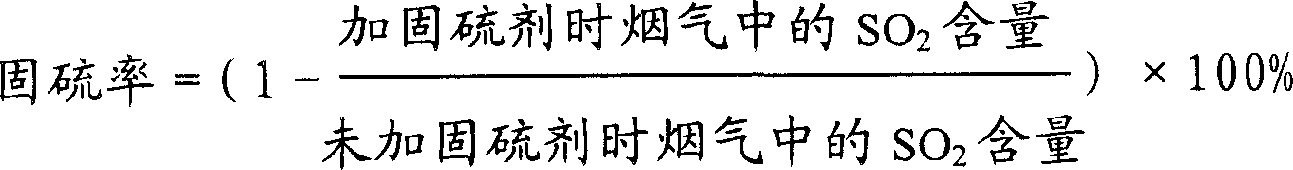

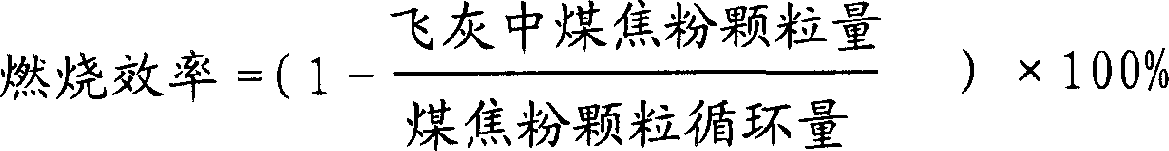

Coal-tar powder combustion method and apparatus

ActiveCN1892106AShort stayReduce backmixingFluidized bed combustionApparatus for fluidised bed combustionGas solidCombustion

The invention provides a coke powder combusting method, comprising: combusting the coke powder in order through low-speed bed and high-speed bed at 0.3-3m / s and 3-25m / s, respectively; separating the combusted coke powder from gas through gas-solid separator and making the solid powder enter in heat-absorbing fluidized bed to reduce the temperature of the solid powder; making the solid powder enter in mixing segment and mix with fresh coke powder, and entering in circulating combustion again; thus, it can completely combust coke powders of different sizes and its combusting efficiency and sulfur-fixing rate are both largely improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

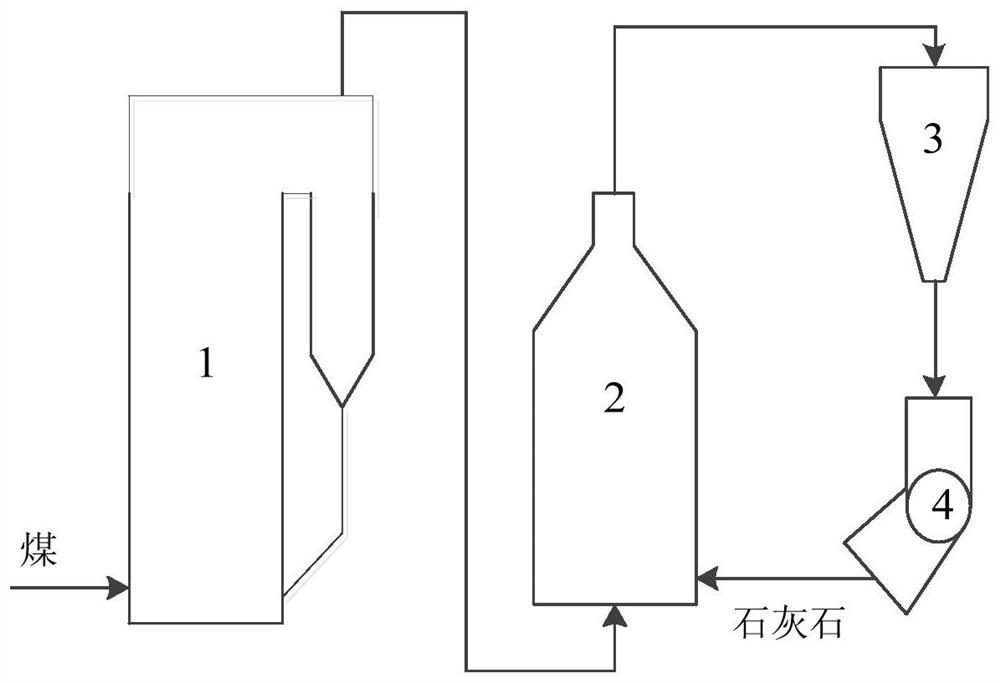

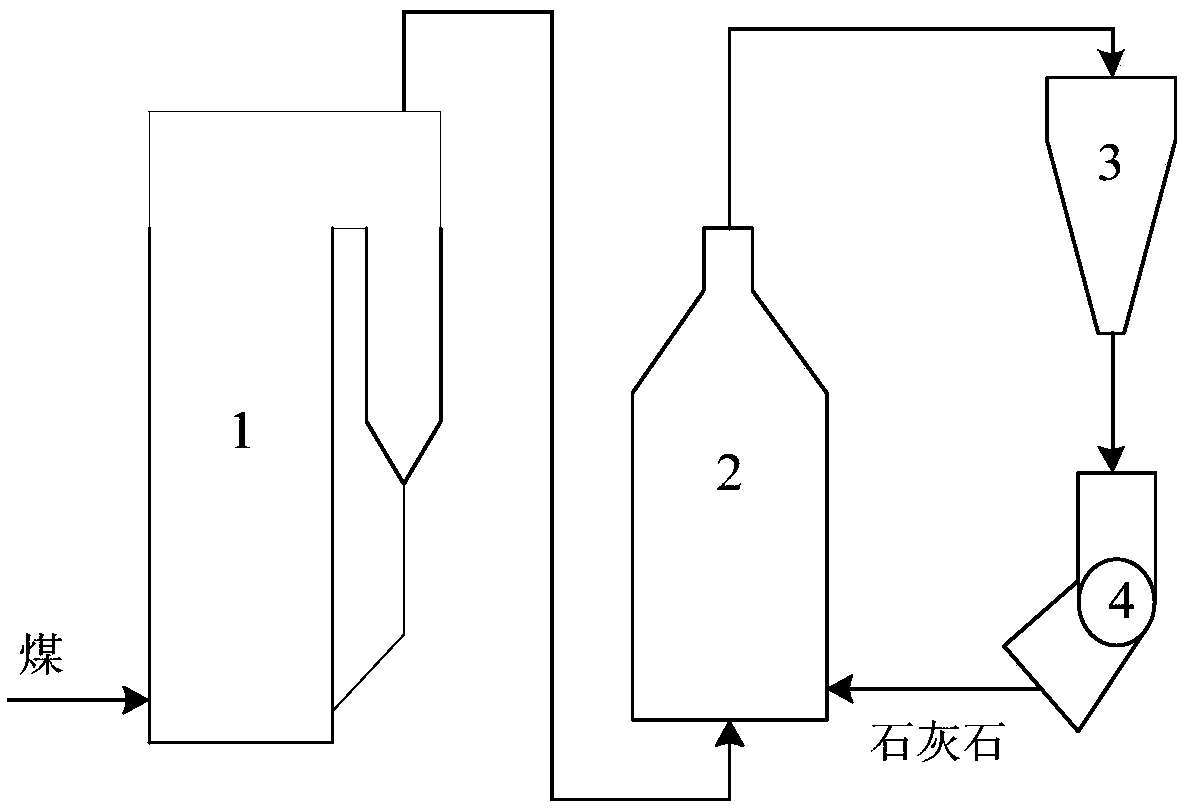

A circulating fluidized bed boiler flue gas desulfurization system and its treatment method

ActiveCN109647148BEliminate the effects ofImprove sulfur fixation rateGas treatmentDispersed particle separationFlue gasFluidized bed

The invention provides a flue gas desulfurization system of a circulating fluidized bed boiler and a treatment method thereof. The system includes a circulating fluidized bed boiler and a desulfurization fluidized bed. The gas inlets provided at the bottom of the fluidized bed are connected, and the desulfurization agent inlet is provided at the bottom of the desulfurized fluidized bed. The system of the present invention installs a desulfurization fluidized bed behind the circulating fluidized bed boiler to move the sulfur fixation reaction to a relatively stable and appropriate temperature area, eliminating the influence of temperature changes and atmosphere in the furnace on the sulfur fixation reaction and its products , and the setting of the separator and the feeder realizes the recycling of the desulfurization agent, and utilizes the cumulative effect in the circulation process to enhance the sulfur fixation reaction, reduce the cost of desulfurization, and improve the utilization rate and desulfurization efficiency of the desulfurization agent.

Owner:YANKUANG GRP CO LTD +1

Circulating fluidized bed boiler flue gas desulfurizing system and treatment method thereof

ActiveCN109647148AEliminate the effects ofImprove sulfur fixation rateGas treatmentDispersed particle separationFlue gasFluidized bed

The invention provides a circulating fluidized bed boiler flue gas desulfurizing system and a treatment method thereof. The system comprises a circulating fluidized bed boiler and a desulfurizing fluidized bed. A flue gas outlet of the circulating fluidized bed boiler is connected with a gas inlet formed in the bottom of the desulfurizing fluidized bed, and the bottom of the desulfurizing fluidized bed is provided with a desulfurizer inlet. The system is provided with the desulfurizing fluidized bed behind the circulating fluidized bed boiler, a sulfur fixation reaction is transferred to the region with the stable and proper temperature, the influences of temperature changes and atmosphere in the hearth on sulfur fixation reactions and products thereof are eliminated, and by arranging a separator and a return feeder, the desulfurizer is recycled; the accumulation effect in the circulating process is used for enhancing the sulfur fixation reaction, the desulfurizing cost is lowered, andthe desulfurizer utilization rate and desulfurizing efficiency are improved.

Owner:YANKUANG GRP CO LTD +1

A kind of briquette composite binder and its preparation method and application

The invention relates to the technical field of coal processing, and discloses a briquette binder, a preparation method and applications thereof, wherein the briquette binder comprises coking coal pitch, a biomass modification material, an inorganic magnesium-based curing agent and an auxiliary agent according to a weight ratio of (5-20):(8-25):(0.5-5):(0.1-0.3), wherein the auxiliary agent comprises at least one selected from a surfactant, a pore forming agent, a dehydrating agent and a cross-linking agent. According to the present invention, under the synergistic effect of various components, the briquette binder can complete the pulverized coal cementation process, the formed briquette can meet the industrial coal demand, the waste in the industrial and agricultural production process is solved, and the efficient use of resources is improved; and by adding the inorganic magnesium-based curing agent and the auxiliary agent, the strength and the impermeability of the briquette are enhanced, the combustion of the briquette is promoted, and the good sulfur fixation effect is provided.

Owner:BEIJING HUASHI UNITED ENERGY TECH & DEV

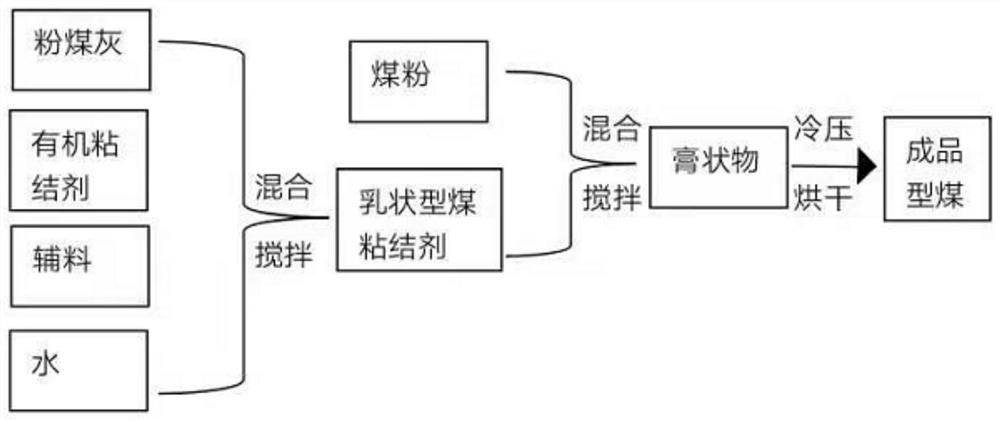

Fly ash-based high-sulfur-fixation coal binder as well as preparation method and application thereof

InactiveCN113214880AHigh market valueRealize economical and efficient comprehensive utilizationSolid fuelsCoal briquetteProcess engineering

The invention discloses a fly ash-based high-sulfur-fixation coal binder and a preparation method and application thereof, the fly ash-based high-sulfur-fixation coal binder is prepared by mixing a binder, an auxiliary material and fly ash according to a certain ratio, the binder plays a role in binding coal powder, and effective components in the auxiliary material and the coal ash play a role in sulfur fixation, the binder and pulverized coal are subjected to extrusion forming and drying to prepare the high-sulfur-fixation coal briquette, the binder has very high pulverized coal bonding capacity, and meanwhile, the prepared coal briquette also has relatively good mechanical strength. The method has the characteristics of wide raw material source and simple process, finds a convenient way for comprehensive utilization of the fly ash, reduces the cost of treating the fly ash as a solid waste traditionally, improves the market value of the fly ash, and has good application value.

Owner:陕西榆能集团能源化工研究院有限公司 +1

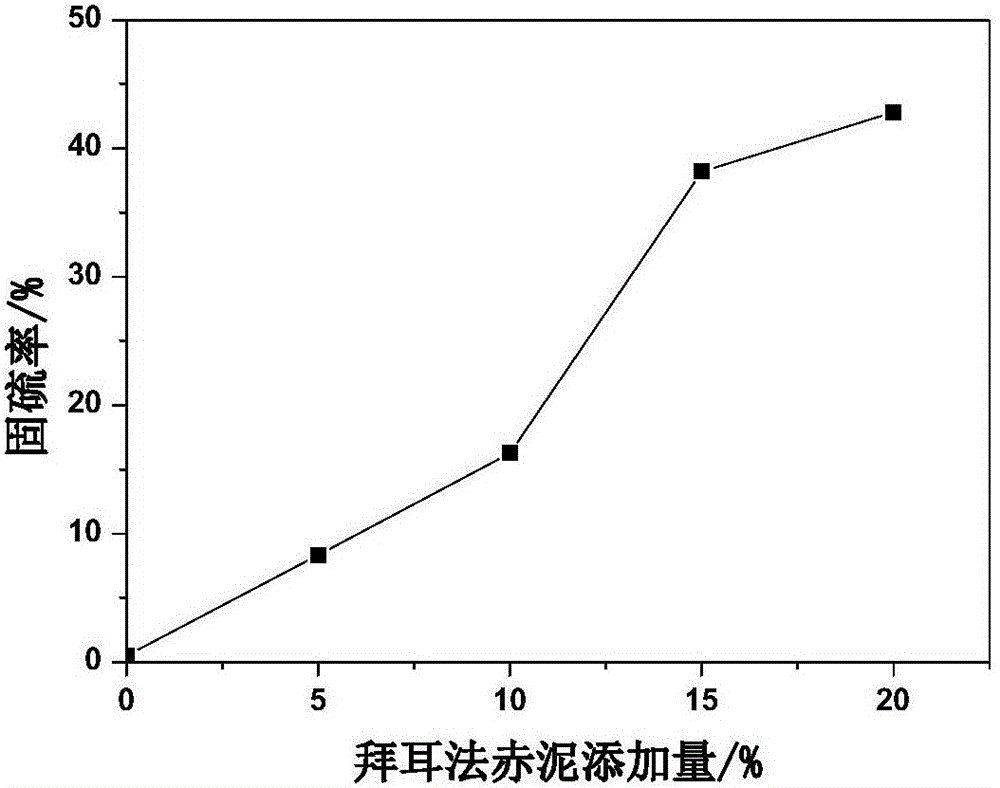

A Coal Combustion Sulphur-fixing Agent Synergized with Red Mud and Mineral Material in Quenched and Tempered Bayer Process

The invention discloses a modified Bayer red mud-mineral material collaborative fuel coal sulphur-fixing agent and a preparation method thereof. The sulphur -fixing agent is composed of modified Bayer red mud, dolomite powder and vermiculite dust, wherein the modified Bayer red mud is obtained by soaking Bayer red mud in a sodium ferrocyanide mother solution or its diluent, and then carrying out drying and crushing. The sulphur fixation rate of the modified Bayer red mud-mineral material collaborative fuel coal sulphur-fixing agent can reach 71%-98%, thus being able to effectively reducing SO2 discharged by fuel coal. At the same time, the invention opens up a new way for utilization of the industrial waste Bayer red mud and vermiculite dust, and provides a cheap and efficient sulphur-fixing agent for fuel coal, thereby realizing efficient use of high pollution waste slag.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Method for preparing coal economizing agents

The invention relates to the field of fuel coal additives, in particular to a method for preparing coal economizing agents. The method has the advantages that multi-walled carbon nano-tubes are used as carriers, Van Der Waals force is available between carbon atoms in the multi-walled carbon nano-tubes and oxygen molecules, the oxygen molecules are restrained on the surfaces of the multi-walled carbon nano-tubes, thermal movement of the oxygen molecules is intensified when the temperatures are increased, accordingly, the oxygen molecules have high kinetic energy, restraint effects of the Van Der Waals force between the oxygen molecules and the multi-walled carbon nano-tubes are broken through by a large portion of the oxygen molecules, the oxygen molecules can be separated from the surfaces of the multi-walled carbon nano-tubes, and oxygen can be released; the coal economizing agents are modified by surfactants and are fabricated by chitosan, the chitosan is adsorptive, connection between the multi-walled carbon nano-tubes and active components-catalysts can be improved by the surfactants, acting force of the multi-walled carbon nano-tubes and the active components can be enhanced,the active components are difficult to dissolve and release, the actual loading of the active components can be increased, accordingly, the efficiency of boilers further can be improved, and coal canbe saved to a great extent.

Owner:内蒙古黑猫煤化工有限公司

Method for improving sulfur fixation rate in coal pyrolysis by using ash heat carrier

PendingCN113621392AImprove removal efficiencyEmission reductionBiofuelsSolid fuelsHeat carrierPulverized fuel ash

The invention discloses a method for improving the sulfur fixation rate in coal pyrolysis by using an ash heat carrier. The method comprises the following specific steps: 1, dissolving a water-soluble calcium salt and / or a water-soluble zinc salt in water to prepare a treatment solution, soaking coal ash after combustion in a power plant in the treatment solution for 20-30 minutes, and drying for later use; 2, mixing a certain amount of raw material coal with the treated coal ash, performing pyrolysis under the condition of air isolation, and inhibiting separation of sulfur-containing compound gas in coal pyrolysis to obtain clean pyrolysis gas; and 3, completely soaking pyrolyzed semi-coke or coke in an acid solution for 1-3 hours, dissolving sulfur in the coal out of the acid solution, and washing to remove coal ash mixed in the coal after soaking so as to remove most sulfur in the coal and obtain clean semi-coke or coke. The method provided by the invention can reduce the emission of sulfur oxides in the pyrolysis gas generated during coal pyrolysis, is simple, has easily controlled process conditions, and has multiple benefits of environmental protection, economy and the like.

Owner:CHINA UNIV OF MINING & TECH +1

Blast furnace injection pulverized coal desulfurization and denitrification combustion aid and its preparation method and use method

ActiveCN108485751BImprove combustion effectGood volatile matter releaseSolid fuelsLanthanumTitanium oxide

The invention provides a desulfurization and denitration combustion improver in blast furnace coal injecting as well as a preparation method and a using method thereof. The desulfurization and denitration combustion improver is prepared from the following raw materials in percentage by weight: 18 to 23 percent of manganese dioxide, 5 to 8 percent of ferric oxide, 9 to 13 percent of barium carbonate, 10 to 16 percent of calcium oxide, 5 to 8 percent of sodium carbonate, 10 to 16 percent of rare earth oxide, 2 to 6 percent of titanium dioxide, 3 to 6 percent of potassium nitrate and the balanceof activated carbon; the rare earth oxide is prepared from the following raw materials in percentage by weight: 40 to 55 percent of yttrium oxide, 25 to 35 percent of lanthanum oxide and 20 to 30 percent of indium oxide; the average particle diameter of the rare earth oxide is 10 to 40 mum. The desulfurization and denitration combustion improver provided by the invention has a remarkable combustion-supporting effect on pulverized coal, the combustion efficiency of the pulverized coal can be effectively improved, emission of NOx and SOx can be effectively reduced, and the purposes of energy conservation and emission reduction can be achieved.

Owner:马鞍山科宇环保设备股份有限公司

Waterproof adhesive and production method thereof

The invention discloses a waterproof adhesive, which is prepared by taking plant pulp as a main material and adding potassium permanganate, sodium hydroxide, sodium dodecyl diphenyl ether disulfonate, boric acid, hydrogen peroxide, light calcium carbonate, white wax and pure water. The waterproof adhesive comprises the following ingredients by weight: 40 percent of the plant pulp, 8 percent of the potassium permanganate, 5 percent of the hydrogen peroxide, 4 percent of sodium hydroxide alkali solution with baume degree of between 16, 10 percent of the boric acid or borax, 5 percent of the sodium dodecyl diphenyl ether disulfonate, 5 percent of OP-10, 4 percent of the light calcium carbonate, 4 percent of the white wax and 15 percent of the pure water. A production method of the waterproof adhesive comprises the steps of preparation of the plant pulp, oxidation, gelatinization, crosslinking, tackification, drying and packaging. Compared with the prior art, the waterproof adhesive has good sulfur fixing effect in briquettes due to an unique formula, and has the sulfur fixing rate high up to 61.5 percent through the test, so the waterproof adhesive does not need to add any inert substance, has good catalytic effect, and can greatly improve reaction activity and combustion performance.

Owner:FENGCHENG YUDA ENERGY SAVING ENVIRONMENTAL COAL

Clean molded coal with steel slag checking tailing additive and preparation method thereof

The invention relates to clean molded coal with a steel slag checking tailing additive and a preparation method thereof, and belongs to the field of clean coal application. The clean molded coal comprises, by mass, 60-85% of coal powder, 5-20% of coke powder, 3-12% of steel slag checking tailings and 5-10% of low-temperature activated steel slag checking tailings. The clean molded coal realizes high efficiency resource comprehensive utilization of steel slag checking tailings, greatly reduces environmental pollution caused by lime production and cement production, and reduces high-quality electric power consumption and land resource destroy. Steel slag checking tailings replace a common molded coal additive so that a clay use amount is reduced and land resource destroy is reduced. Molded coal combustion is clean and a molded coal making cost is low.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

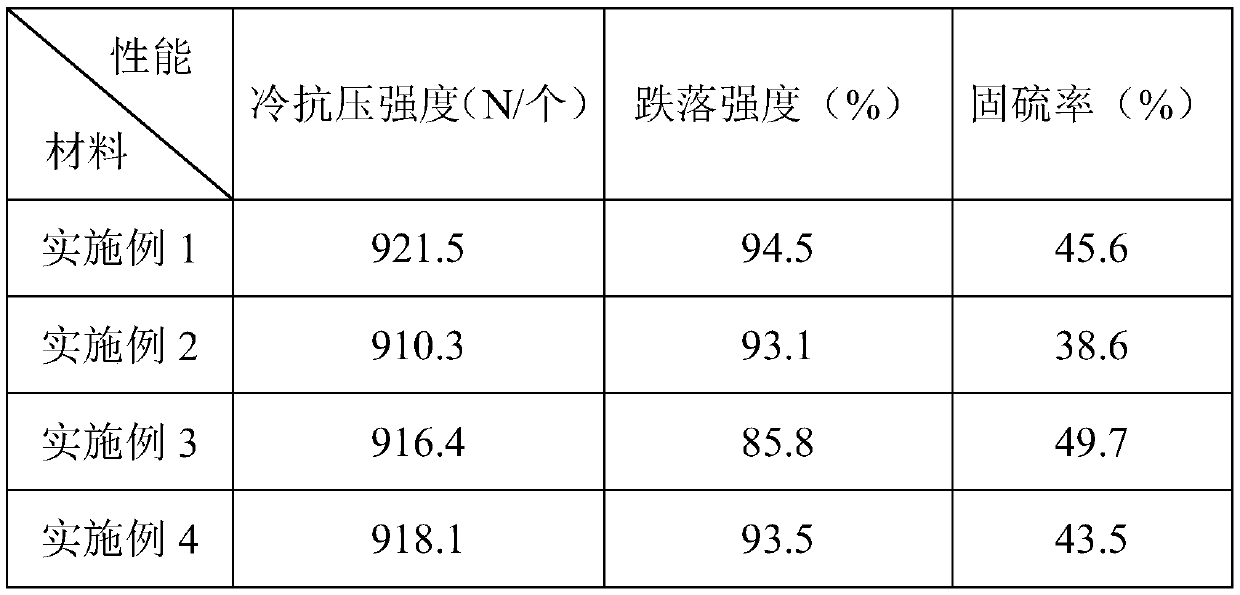

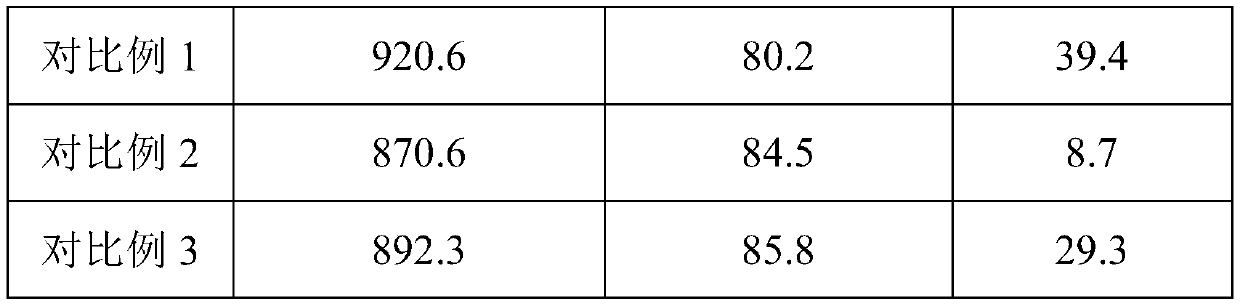

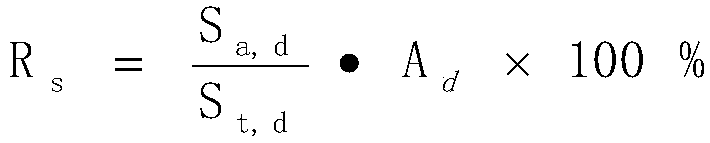

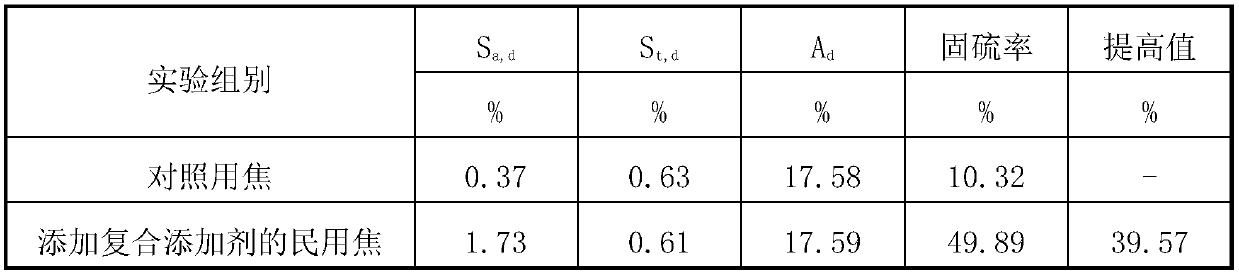

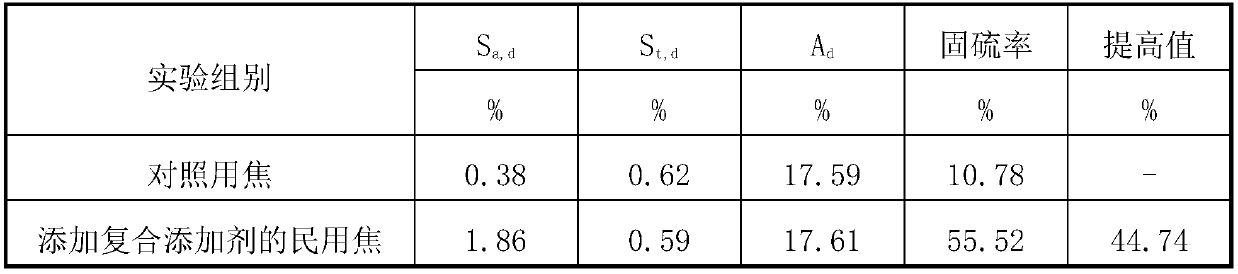

Calcium-based potassium-magnesium-silicon composite additive for improving the high-temperature sulfur fixation effect of civil coke and its preparation method and application

The invention discloses a calcium-based potassium-magnesium-silicon composite additive for improving the high temperature sulfur fixation effect of civil-use coke. The additive comprises, by weight, 60-80 parts of limestone, 10-20 parts of potassium feldspar, 10-20 parts of silicon dioxide and 5-10 parts of magnesium carbonate. The calcium-based potassium-magnesium-silicon composite additive is wide and abundant in raw material source and low in cost and directly added to destructive distillation matching coal, the civil-use coke containing the calcium-based potassium-magnesium-silicon composite additive is produced through high temperature retorting, the high temperature sulfur fixation rate (1250 DEG C) of the civil-use coke can be raised from 10-15% to 50-75%, the sulfur fixation rate is raised by 40-60%, the effect is remarkable, compared with direct combustion of coal, sulfur dioxide pollutant emission can be lowered by 80% or above, and great practical significance is achieved for meeting the requirement of living coal consumption peri-urban villages, improving environment quality of villages and cities and reducing haze weather.

Owner:TAIYUAN UNIV OF TECH +1

A kind of preparation method of coal-saving agent

The invention relates to the field of fuel coal additives, in particular to a method for preparing coal economizing agents. The method has the advantages that multi-walled carbon nano-tubes are used as carriers, Van Der Waals force is available between carbon atoms in the multi-walled carbon nano-tubes and oxygen molecules, the oxygen molecules are restrained on the surfaces of the multi-walled carbon nano-tubes, thermal movement of the oxygen molecules is intensified when the temperatures are increased, accordingly, the oxygen molecules have high kinetic energy, restraint effects of the Van Der Waals force between the oxygen molecules and the multi-walled carbon nano-tubes are broken through by a large portion of the oxygen molecules, the oxygen molecules can be separated from the surfaces of the multi-walled carbon nano-tubes, and oxygen can be released; the coal economizing agents are modified by surfactants and are fabricated by chitosan, the chitosan is adsorptive, connection between the multi-walled carbon nano-tubes and active components-catalysts can be improved by the surfactants, acting force of the multi-walled carbon nano-tubes and the active components can be enhanced,the active components are difficult to dissolve and release, the actual loading of the active components can be increased, accordingly, the efficiency of boilers further can be improved, and coal canbe saved to a great extent.

Owner:内蒙古黑猫煤化工有限公司

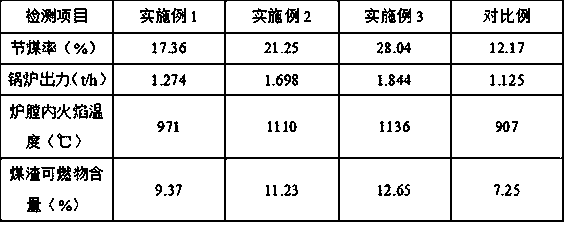

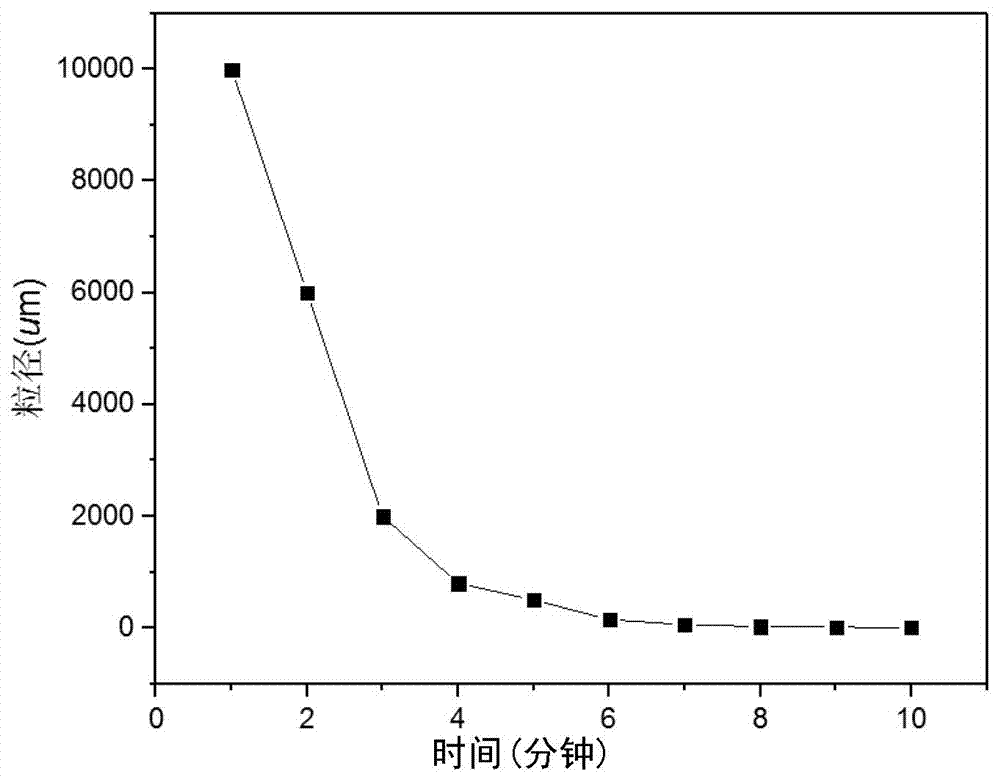

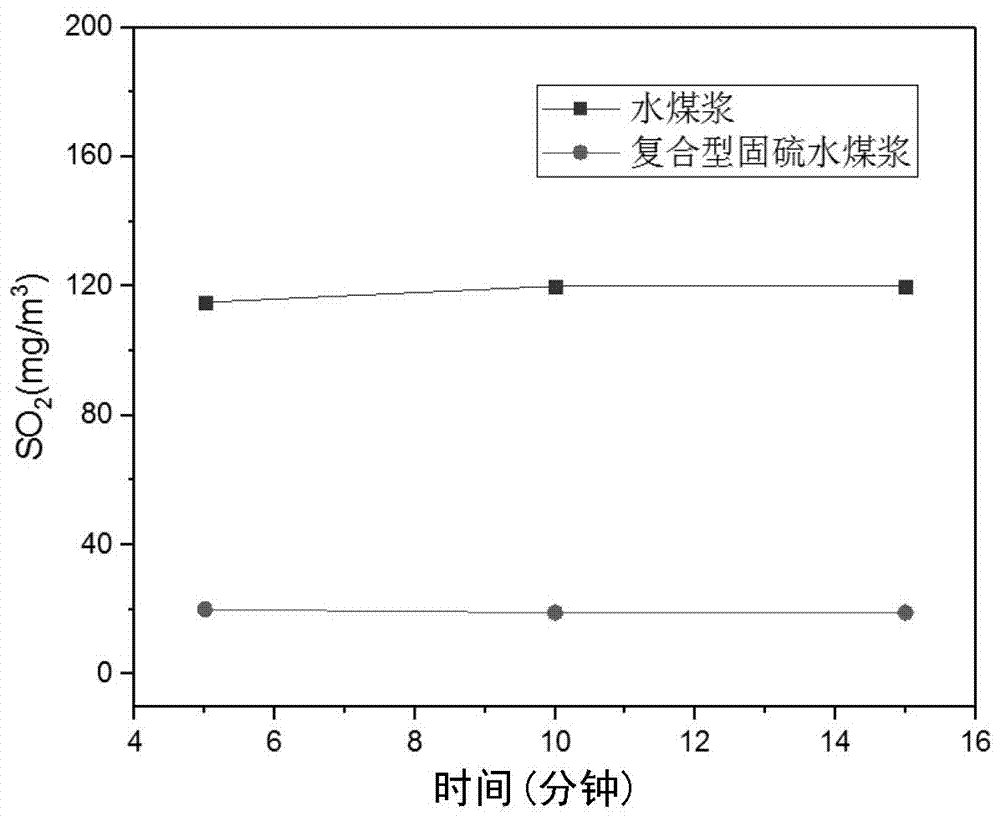

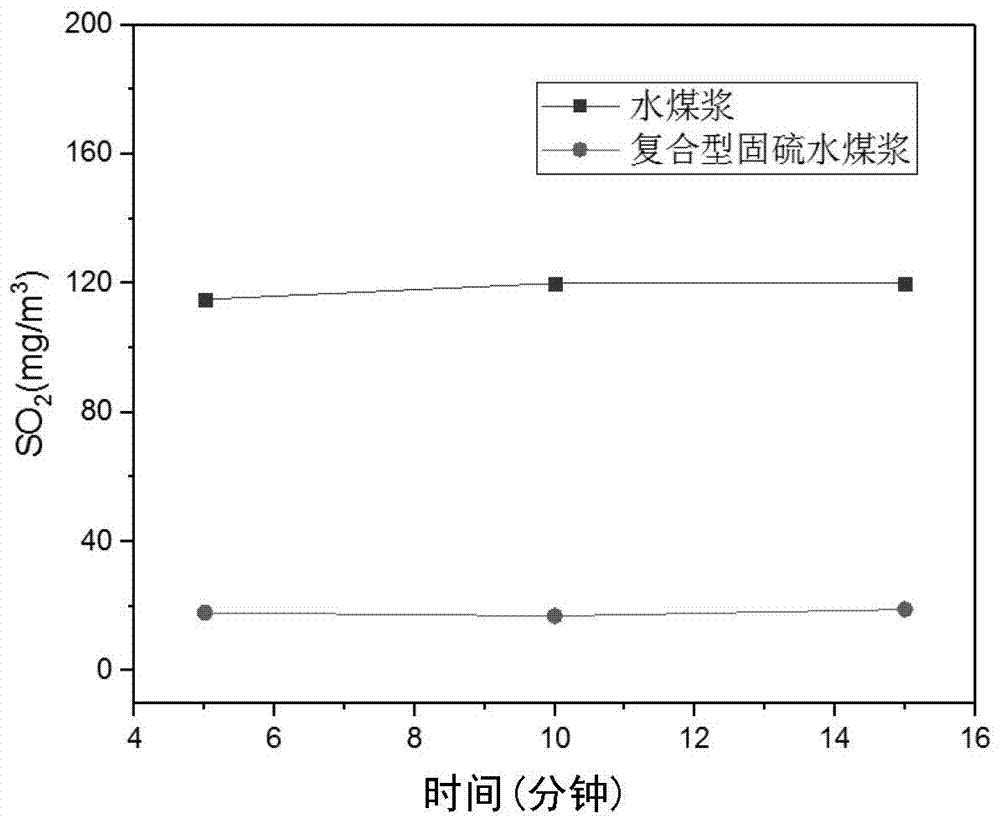

Composite sulfur-fixing agent used for coal combustion as well as composite sulfur-fixing coal water slurry and method for simultaneously performing sintering and fixing sulfur in furnace

ActiveCN107880954ASolve residualImprove sulfur fixation rateLiquid carbonaceous fuelsLump/pulverulent fuel preparationCoal waterSulfur

The invention relates to a composite sulfur-fixing agent used for coal combustion as well as a composite sulfur-fixing coal water slurry and a method for simultaneously performing sintering and fixingsulfur in a furnace. The composite sulfur-fixing agent used for the coal combustion includes calcium carbonate and sodium carbonate, wherein the content of sodium carbonate is 1-2wt% of that of the calcium carbonate. When the above composite sulfur-fixing agent used for the coal combustion provided by the invention is adopted, a higher sulfur fixation rate can be realized.

Owner:MONALISA GRP CO LTD

High-temperature sulphur-fixing agent

InactiveCN105838476AEasy secondary decompositionPhase stableSolid fuelsFuel additivesMicrospherePotassium

The invention discloses a high-temperature sulphur-fixing agent which is prepared from the following components in parts by weight: 4-7 parts of kaolin, 3-6 parts of kieselguhr, 2-4 parts of anorthite, 2-5 parts of talcum powder, 7-9 parts of calcium oxide, 1-3 parts of zinc oxide, 4-8 parts of strontium carbonate, 3-8 parts of barium hydroxide, 0.3-0.5 part of potassium sulphate, 0.2-0.5 part of vanadium pentoxide, 4-9 parts of niobium pentoxide, 0.3-0.6 part of aluminite powder, 0.2-0.5 part of iron powder microballoon sphere, 0.1-0.3 part of calcium titanate, 20-25 parts of ethyl alcohol, 2-4 parts of sodium dodecyl benzene sulfonate, 1-3 parts of nanometer titania and 2-4 parts of nano calcium carbonate. The sulphur-fixing agent disclosed by the invention has a reasonable prescription, is high temperature resistant, good in high-temperature desulfurization effect, and favorable in development prospect of coal sulphur fixing.

Owner:王璐

A kind of multifunctional high-efficiency gas-making briquette and its preparation method

The invention discloses multifunctional high-efficiency gas-making molded coal and a preparation method thereof. The multifunctional high-efficiency gas-making molded coal is composed of powdered coal, an adhesion agent and water, and comprises the component ratios calculated according to the weight parts: 84-87 parts of the powdered coal, 10-13 parts of water, and 2-3 parts of the adhesion agent. The preparation method of the multifunctional high-efficiency gas-making molded coal comprises the following steps: after mixing evenly pottery clay, calcium hydroxide, petroleum coke powder, ammonium bicarbonate and cement to prepare the adhesion agent, stirring evenly the adhesion agent with water and the powdered coal for extrusion molding, then sending into a drying oven, and drying at the temperature of 180-220 DEG C for 2-3 hours to obtain the molded coal. The molded coal has high fixed carbon content, and improves the gas producing amount and the gas producing efficiency; the molded coal has high cold and heat strength, ensures convenient storage and transportation, is not broken into pieces when being put into a furnace, and does not come loose at the high temperature; the molded coal has low ash slag content and good sulfur fixation effect, thereby reducing the pollution of the environment; and the preparation method has the advantages of simple operation and convenient preparation.

Owner:广州中科高成环保科技有限公司

A kind of high-efficiency sulfur-fixing briquette composite binder

The invention provides a high-efficiency sulfur-fixation coal briquette composite adhesive which is compounded from sodium humate, limestone, slaked lime, sodium carbonate, sodium chloride, potassium permanganate and ferrous chloride. In the briquette coal adhesive, various raw materials cooperate with each other and promote each other, and thus, the coal briquette adhesive has the advantages of high bonding property, high sulfur fixation rate and favorable combustion-supporting property. As for any coal type with the sulfur content of lower than 2%, the sulfur fixation rate of 90% can be reached when the addition amount of the composite adhesive is 13-15%; and thus, the composite adhesive has wide adaptability. The strength, heat stability, heating value and other indexes of the coal briquette respectively satisfy the Standard for Coal Briquette for Civilian Use.

Owner:临泽县奋君矿业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com