A kind of briquette composite binder and its preparation method and application

A technology of binder and briquette, which is applied in the field of briquette binder and its preparation, can solve the problems of weak briquette strength, poor coke quality, and poor sulfur-fixing effect of briquette binder, and achieves high combustion value. , Improve the molding energy and achieve the effect of full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

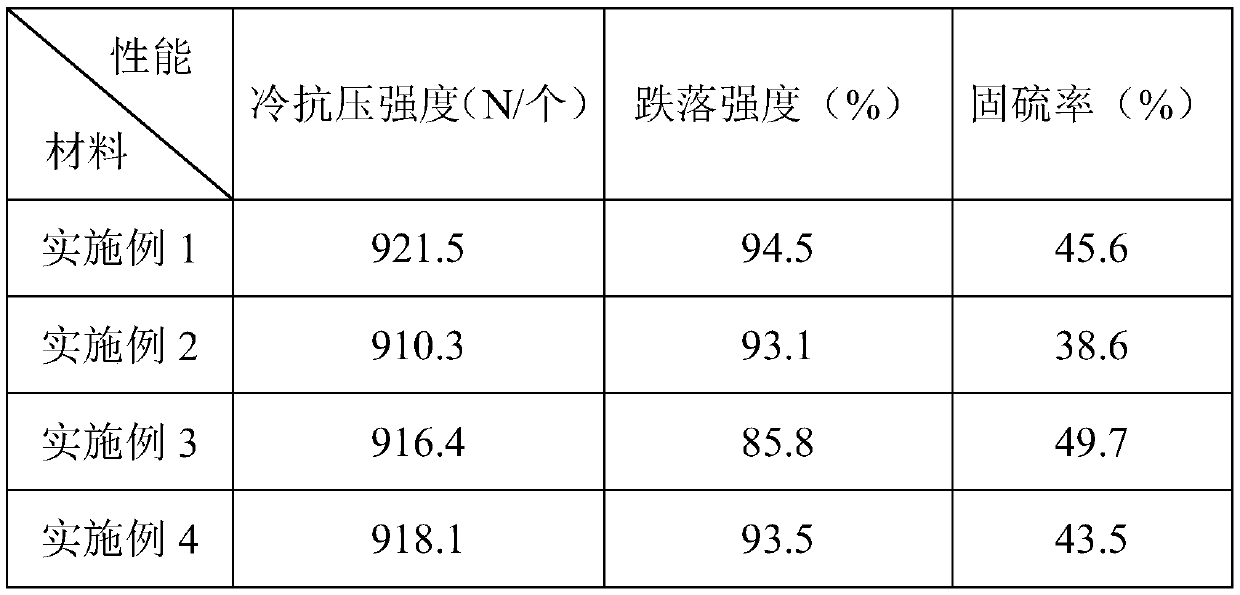

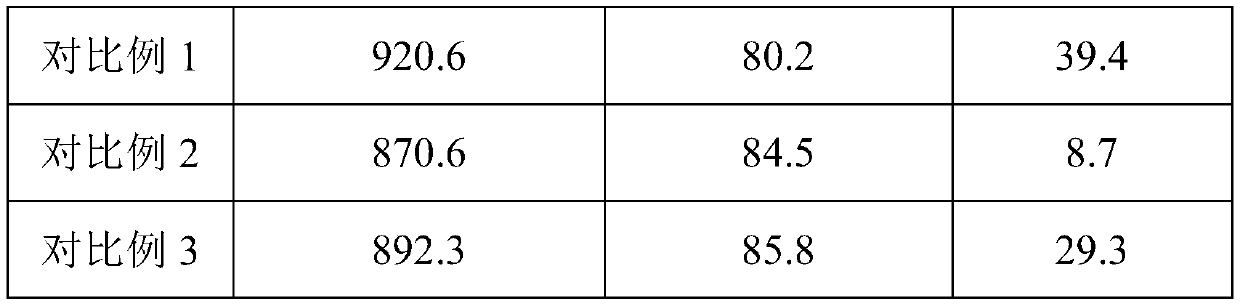

Examples

Embodiment 1

[0037] Present embodiment provides a kind of briquette binder, comprises the component of following weight ratio:

[0038] Coke pitch: biomass modified material: inorganic magnesium-based curing agent: auxiliary agent is 12.5:16.5:2.75:0.2;

[0039]As an embodiment of the present invention, in this embodiment, the coke pitch is the pitch produced in the suspended bed process; the biomass modified material is rice straw modified by sodium hydroxide; the inorganic magnesium-based solidification The agent is MgO; the auxiliary agent is a surfactant with a content of 45wt% and a pore-forming agent with a content of 55wt%, wherein the surfactant is potassium stearate, and the pore-forming agent is ammonium chloride. As a changeable embodiment of the present invention, the surfactant can be one or more of sodium stearate, sodium stearate, calcium stearate; the pore-forming agent can be ammonium chloride, ammonium carbonate, carbonic acid One or more in ammonium hydrogen; The auxili...

Embodiment 2

[0047] Present embodiment provides a kind of briquette binder, comprises the component of following weight ratio:

[0048] Coke pitch: biomass modified material: inorganic magnesium-based curing agent: auxiliary agent is 5:25:0.5:0.3;

[0049] As an embodiment of the present invention, in this embodiment, the coke pitch is the pitch produced in the suspended bed process; the biomass modified material is corn straw modified by sodium hydroxide; the inorganic magnesium-based Curing agent is MgCl 2 ; The auxiliary agent is a surfactant with a content of 30wt% and a pore-forming agent with a content of 70wt%, wherein the surfactant is sodium stearate, and the pore-forming agent is ammonium carbonate.

[0050] The preparation method of described briquette composite binder comprises the following steps:

[0051] S1. Add corn stalk particles with a crushed particle size of 3.5 cm to 3% sodium hydroxide lye, and carry out hydrolysis reaction on the corn stalk particles at 85 ° C. Th...

Embodiment 3

[0057] Present embodiment provides a kind of briquette binder, comprises the component of following weight ratio:

[0058] Coke pitch: biomass modified material: inorganic magnesium-based curing agent: auxiliary agent is 20:8:5:0.1;

[0059] As an embodiment of the present invention, in this embodiment, the coke pitch is the pitch produced in the suspended bed process; the biomass modified material is rice straw and corn stalk modified by sodium hydroxide; the inorganic Magnesium based hardeners are MgO and MgCl 2 ; The auxiliary agent is a surfactant with a content of 60wt% and a pore-forming agent with a content of 40wt%, wherein the surfactant is calcium stearate, and the pore-forming agent is ammonium bicarbonate.

[0060] The preparation method of described briquette composite binder comprises the following steps:

[0061] S1. Add corn stalks and rice straw granules with a crushed particle size of 5 cm to 1% sodium hydroxide lye, and perform the first hydrolysis reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com