Preparation method of clay-calcium-based sulfur fixing agent and application of agent in fixing cow dung/high-sulfur composite coal

A calcium-based sulfur-fixing agent and technology of sulfur-fixing agent, applied in the desulfurization field, can solve the problems of low investment, poor thermal stability of sulfur-fixed products, low calcium utilization rate, etc., and achieve high sulfur-fixing rate, good practical economy and application The effect of stability and uniform particle distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

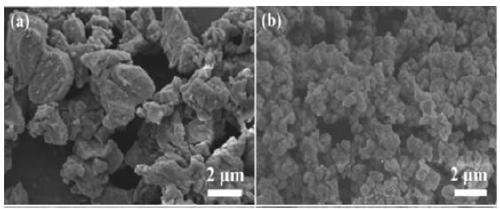

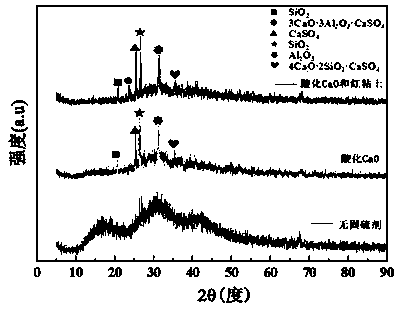

[0025] 1. Preparation of clay-calcium-based sulfur fixative

[0026] At room temperature, dissolve 10.5 g of tartaric acid in 200 mL of water in a beaker, then add 10.0 g of calcium oxide, mix well, heat and stir in a constant temperature water bath at 75°C for 4 h (to ensure complete acidification of the quicklime), and obtain the acidified product ;Dry the acidified product in an oven at 105°C, grind it, then put it into an air atmosphere muffle furnace, raise the temperature to 900°C at a heating rate of 5°C / min, and calcinate for 2 hours to obtain acidified calcium oxide;

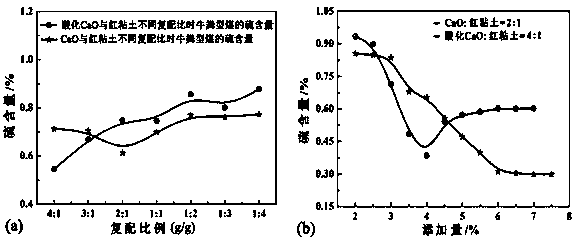

[0027] Acidified calcium oxide and red clay are mechanically mixed at a mass ratio of 3.5:1, and ground evenly to obtain a clay-calcium-based sulfur-fixing agent.

[0028] 2. Preparation of coal briquettes

[0029] Take 6.0 g of dry cow dung, mix well with 18.0 g of high-sulfur foamed coal (passed through a 18-mesh sieve), then add about 2.6 g of binder and 1.4 g of clay-calcium-based sulfur-fixing age...

Embodiment 2

[0031] 1. Preparation of clay-calcium-based sulfur fixative

[0032] Dissolve 12.8 g of tartaric acid in 200 mL of water, then add 14.0 g of calcium oxide, mix well, heat and stir in a constant temperature water bath at 85°C for 4 h (to ensure complete acidification of quicklime), and obtain an acidified product; Dry in an oven at ℃, grind, and then put it into an air-atmosphere muffle furnace, raise the temperature to 950°C at a heating rate of 6°C / min, and calcinate for 2.5 hours to obtain acidified calcium oxide;

[0033] Acidified calcium oxide and red clay are mechanically mixed at a mass ratio of 4:1, and ground evenly to obtain a clay-calcium-based sulfur-fixing agent.

[0034] 2. Preparation of coal briquettes

[0035] Take 6.0 g of dry cow dung, mix it with 18.0 g of high-sulfur foamed coal (passed through a 18-mesh sieve), then add about 2.6 g of binder and 1.6 g of clay-calcium-based sulfur-fixing agent, and add an appropriate amount of water Stir evenly, extrude ...

Embodiment 3

[0037] 1. Preparation of clay-calcium-based sulfur fixative

[0038] Dissolve 11 g of tartaric acid in 200 mL of water, then add 12.0 g of calcium oxide, mix well, heat and stir in a constant temperature water bath at 80°C for 4 h (to ensure complete acidification of quicklime), and obtain an acidified product; Dry in an oven at ℃, grind, and then put it into an air atmosphere muffle furnace, raise the temperature to 950°C at a heating rate of 4.5°C / min, and calcinate for 2 hours to obtain acidified calcium oxide;

[0039] Acidified calcium oxide and red clay are mechanically mixed at a mass ratio of 4.5:1, and ground evenly to obtain a clay-calcium-based sulfur-fixing agent.

[0040] 2. Preparation of coal briquettes

[0041] Take 6.0 g of dry cow dung and mix it with 18.0 g of high-sulfur foamed coal (passed through a 18-mesh sieve), then add about 2.6 g of binder and 1.7 g of clay-calcium-based sulfur-fixing agent, and add an appropriate amount of water Stir evenly, extru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com