Active carbon/nickel cobaltate nano wire composite electrode material and preparation method thereof

A composite electrode and activated carbon technology, applied in the field of materials and electrochemistry, can solve the problems of poor conductivity and achieve the effect of short ion migration path and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

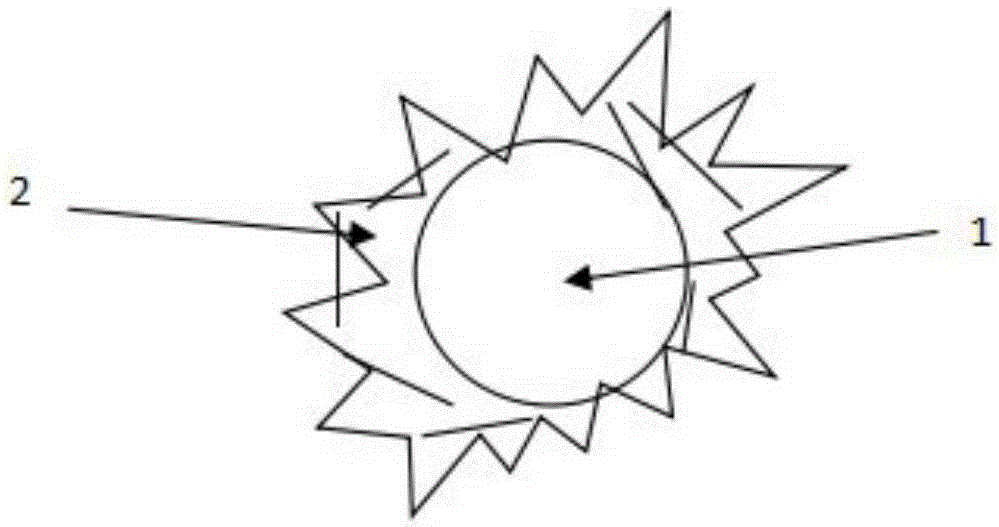

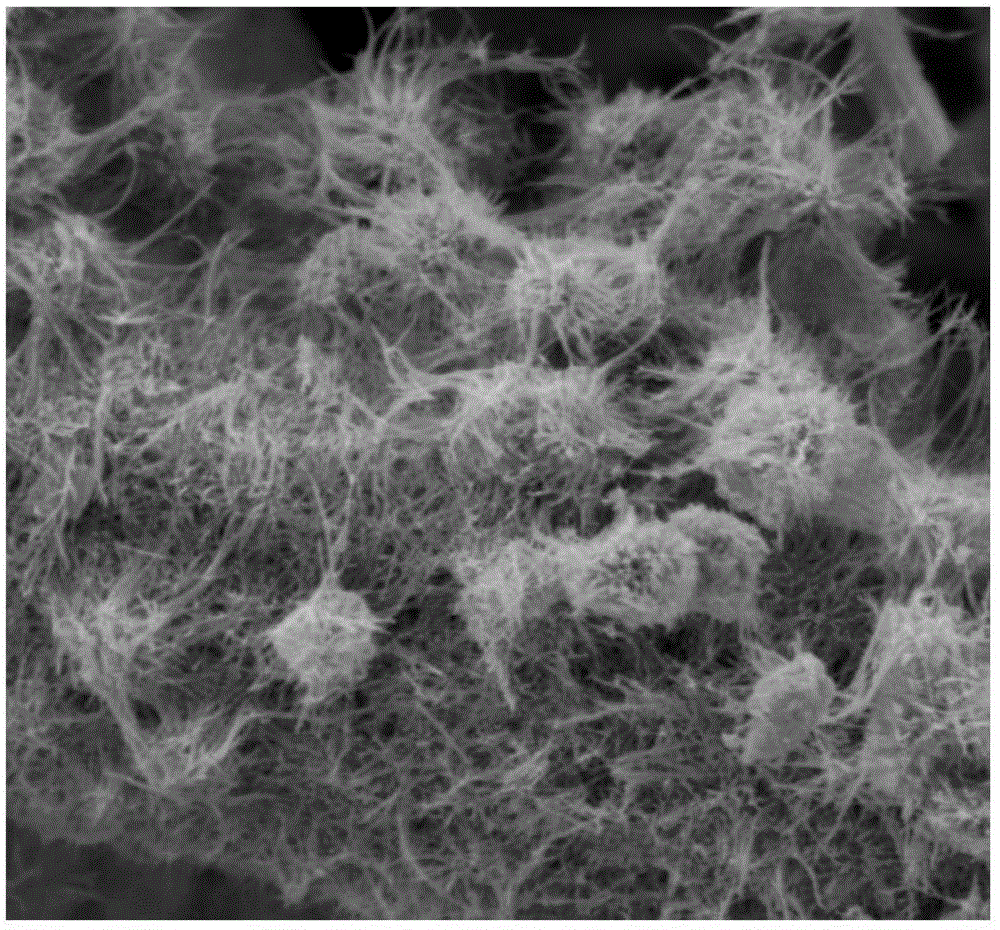

Image

Examples

Embodiment 1

[0028] Step (1), weigh the NiCl of 0.05mol 2 ·6H 2 0 and 0.1mol CoCl 2 ·6H 2 O, NiCl 2 ·6H 2 0 and CoCl 2 ·6H 2 The molar ratio of O is 1:2. NiCl 2 ·6H 2 0 and CoCl 2 ·6H 2 O was dissolved in 1L of deionized water, stirred evenly and prepared to contain Ni 2+ 、Co 2+ mixed metal salt solution, Ni 2+ and Co 2+ The total solubility is 0.15mol / L.

[0029] In step (2), weigh 87g of activated carbon 1, wash it with dilute hydrochloric acid, then wash it with deionized water, add it to the mixed metal salt solution prepared in step (1) after drying, and stir magnetically for 0.1-2 hours.

[0030] In step (3), weigh 0.18 mol of oxalic acid and add it to the mixture in step (2), stir ultrasonically for 2-5 hours, add ammonia water to adjust the pH value, and keep the pH value at 8.2.

[0031] In step (4), the mixed liquid in step (3) is transferred to a hydrothermal reaction kettle, and reacted hydrothermally at a temperature of 100° C. for 12 hours, and then the reacta...

Embodiment 2

[0035] Step (1) weighs the NiCl of 0.05mol 2 ·6H 2 0 and 0.1mol CoCl 2 ·6H 2 O, NiCl 2 ·6H 2 0 and CoCl 2 ·6H 2 The molar ratio of O is 1:2. NiCl 2 ·6H 2 0 and CoCl 2 ·6H 2 O was dissolved in 1L of deionized water, stirred evenly and prepared to contain Ni 2+ 、Co 2+ mixed metal salt solution, Ni 2+ and Co 2+ The total solubility is 0.15mol / L.

[0036] Step (2) Weigh 87g of activated carbon 1, wash it with dilute hydrochloric acid, wash it with deionized water, add it into the mixed metal salt solution prepared in step (1) after drying, and stir magnetically for 0.1-2 hours.

[0037] Step (3) Weigh 0.18 mol of oxalic acid and add it to the mixed liquid in step (2), stir ultrasonically for 2-5 hours, add ammonia water to adjust the pH value, and keep the pH value at 8.0.

[0038] In step (4), the mixed liquid in step (3) is transferred to a hydrothermal reaction kettle, and reacted hydrothermally at a temperature of 100° C. for 12 hours, and then the reactant is ...

Embodiment 3

[0042] Step (1) weighs the NiCl of 0.05mol 2 ·6H 2 0 and 0.1mol CoCl 2 ·6H 2 O, NiCl 2 ·6H 2 0 and CoCl 2 ·6H 2 The molar ratio of O is 1:2. NiCl2 ·6H 2 0 and CoCl 2 ·6H 2 O was dissolved in 1L of deionized water, stirred evenly and prepared to contain Ni 2+ 、Co 2+ mixed metal salt solution, Ni 2+ and Co 2+ The total solubility is 0.15mol / L.

[0043] Step (2) Weigh 87g of activated carbon 1, wash it with dilute hydrochloric acid, wash it with deionized water, add it into the mixed metal salt solution prepared in step (1) after drying, and stir magnetically for 0.1-2 hours.

[0044] Step (3) Weigh 0.18 mol of oxalic acid and add it to the mixed liquid in step (2), stir ultrasonically for 2-5 hours, add ammonia water to adjust the pH value, and keep the pH value at 7.0.

[0045] In step (4), the mixed liquid in step (3) is transferred to a hydrothermal reaction kettle, and reacted hydrothermally at a temperature of 100° C. for 12 hours, and then the reactant is fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com