A kind of multifunctional high-efficiency gas-making briquette and its preparation method

A multi-functional and efficient technology, applied in the petroleum industry, solid fuel, fuel, etc., can solve the problems that hinder the development and application of coal briquettes, the cost of coal remains high, and the cold and hot strength of briquettes is low, achieving low ash content, High cold strength and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A multifunctional and efficient gas-making briquette consists of the following components in parts by weight:

[0048] 87 parts of pulverized coal

[0049] 11 parts of water

[0050] 2 parts adhesive

[0051] The binder in the above-mentioned, its proportioning by weight is:

[0052] Clay 54 parts

[0053] Calcium hydroxide 16 parts

[0054] 16 parts petroleum coke powder

[0055] 8 parts ammonium bicarbonate

[0056] 6 parts of cement

[0057] Weigh pottery clay, calcium hydroxide, petroleum coke powder, ammonium bicarbonate and cement according to the above proportions, mix and stir evenly, add pulverized coal and water weighed in the above proportions, mix well and extrude, then send them into the drying furnace , and dried at 180-220°C for 2-3 hours to make briquettes. The prepared briquette was burned at 1000° C. for 15 minutes. The technical performance indicators of the prepared briquette in the present embodiment are as follows:

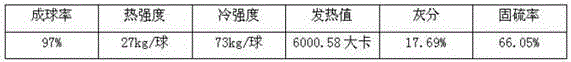

[0058]

Embodiment 2

[0060] A multifunctional and efficient gas-making briquette consists of the following components in parts by weight:

[0061] 84 parts of pulverized coal

[0062] 13 parts of water

[0063] 3 parts adhesive

[0064] The binder in the above-mentioned, its proportioning by weight is:

[0065] Clay 54 parts

[0066] Calcium hydroxide 16 parts

[0067] 16 parts petroleum coke powder

[0068] 8 parts ammonium bicarbonate

[0069] 6 parts of cement

[0070] Weigh pottery clay, calcium hydroxide, petroleum coke powder, ammonium bicarbonate and cement according to the above proportions, mix and stir evenly, add pulverized coal and water weighed in the above proportions, mix well and extrude, then send them into the drying furnace , and dried at 180-220°C for 2-3 hours to make briquettes. The prepared briquette was burnt at 1000°C for 15 minutes, and the prepared briquette technical performance index in the present embodiment is as follows:

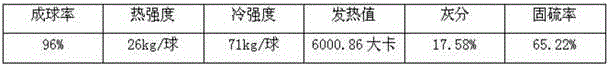

[0071]

Embodiment 3

[0073] A multifunctional and efficient gas-making briquette consists of the following components in parts by weight:

[0074] 85 parts of pulverized coal

[0075] 12 parts of water

[0076] 3 parts adhesive

[0077] The binder in the above-mentioned, its proportioning by weight is:

[0078] Clay 59 parts

[0079] Calcium hydroxide 15 parts

[0080]14 parts petroleum coke powder

[0081] 8 parts ammonium bicarbonate

[0082] 4 parts of cement

[0083] Weigh pottery clay, calcium hydroxide, petroleum coke powder, ammonium bicarbonate and cement according to the above proportions, mix and stir evenly, add pulverized coal and water weighed in the above proportions, mix well and extrude, then send them into the drying furnace After drying at 180-220°C for 2-3 hours, briquettes are made. The prepared briquette was burned at 1000° C. for 15 minutes. The technical performance indicators of the prepared briquette in the present embodiment are as follows:

[0084]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com