Coal-tar powder combustion method and apparatus

A combustion method and technology of coal char powder, applied in the field of coal chemical industry, can solve the problems of long effective combustion time, low ignition temperature and ember temperature, long residence time of small particles, etc., and achieve high mass transfer rate and heat input intensity. , the effect of improving combustion efficiency and sulfur fixation rate, and increasing combustion and sulfur fixation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

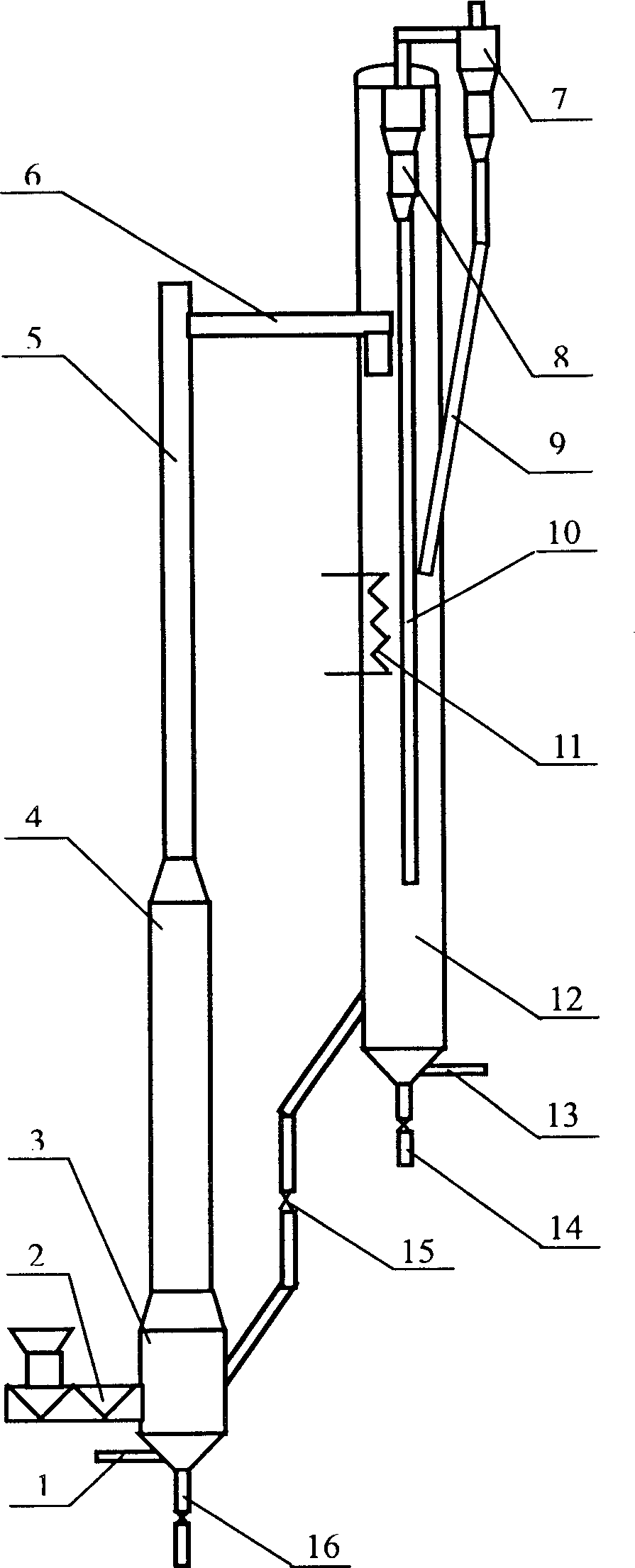

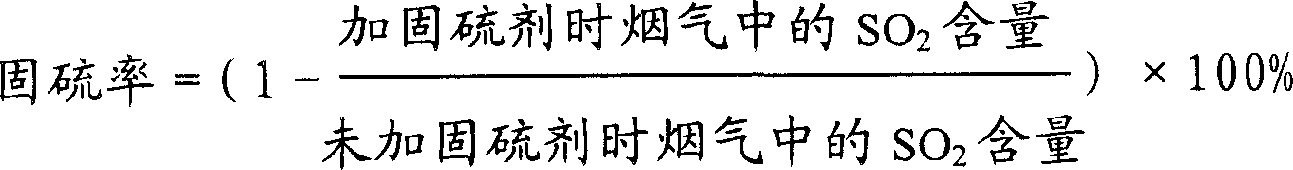

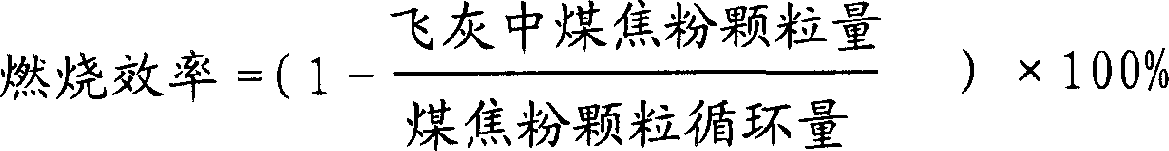

[0031] The thermal state experiment of coal coke powder was completed in a set of steel circulating fluidized bed, the procedure is shown in the attached figure 1 . The experimental process is as follows: first, coal coke powder particles and sulfur-fixing agent are loaded into the screw feeder 2, the heat carrier is loaded into the heat extraction fluidized bed 12, and the mixing section 3 is heated to the ignition temperature (for example, 600° C.) with fuel oil. , start the screw feeder 2 to add fresh particles of coal coke powder into the mixing section 3, after the fresh particles of coal coke powder are burned in the mixing section 3, open the fluidization air duct 1 of the mixing section, take the heat fluidization air duct 13 and lift Air duct 16, add sulfur fixative to the screw feeder at the same time, the coal coke powder combustion particles in the mixing section 3 enter the low-velocity bed 4 under the entrainment of the lifting wind, and the relatively combustibl...

Embodiment 2

[0036] In the experiment, the coal coke powder reserves in the hot fluidized bed, particle density, particle average particle size, operating gas velocity in the mixing section, operating gas velocity in the low-velocity bed and high-speed bed, and the combustion of coal coke powder entering the mixing section from the feed valve The amount of particles, the Ca / S molar ratio, the particle temperature of the heated fluidized bed, and the operating gas velocity are the same as in Example 1. The amount of fresh particles of coal coke powder added to the mixing section by the screw feeder is 15kg / h, and the total circulation of particles is 1163kg. / h, when the circulation ratio is 77.5, the average concentration of coal coke particles in the mixing section is determined to be 191kg / m 3 , low speed bed 123kg / m 3 , high speed bed 20.8kg / m 3 , take heat fluidized bed 600kg / m 3 , the bed temperature in the mixing section is 580°C, the outlet of the high-speed bed is 850°C, the comb...

Embodiment 3

[0038] During the experiment, the coal coke powder reserves in the hot fluidized bed, particle density, average particle size, operating gas velocity in the mixing section, operating gas velocity in the low-velocity bed, operating gas velocity in the high-speed bed, and the gas flow rate from the feed valve into the mixing section were collected. The amount of coal coke powder combustion particles, Ca / S molar ratio, the particle temperature of the heated fluidized bed and the operating gas velocity are the same as in Example 1. When the fresh particle amount of coal coke powder added to the mixing section by the screw feeder is 19kg / h, the coal coke powder The total circulation of coke powder particles is 1167kg / h, and when the circulation ratio is 61.4, the measured average concentration of coke powder particles is 196kg / m in the mixing section 3 , low velocity bed 126kg / m 3 , high-speed bed 21.9kg / m 3 , take heat fluidized bed 600kg / m 3 , the bed temperature is 560°C in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com