Patents

Literature

59results about How to "Short burn time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

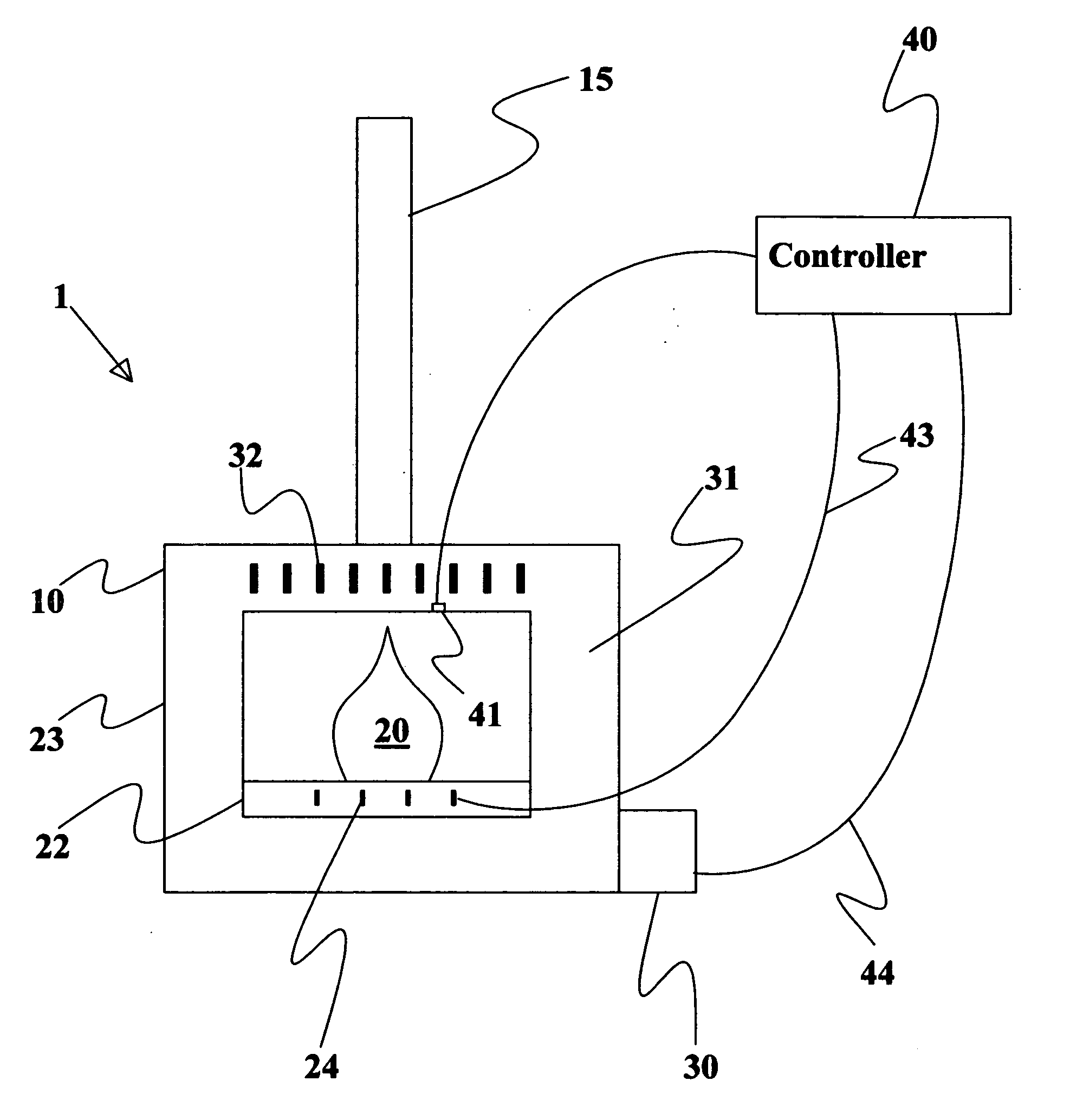

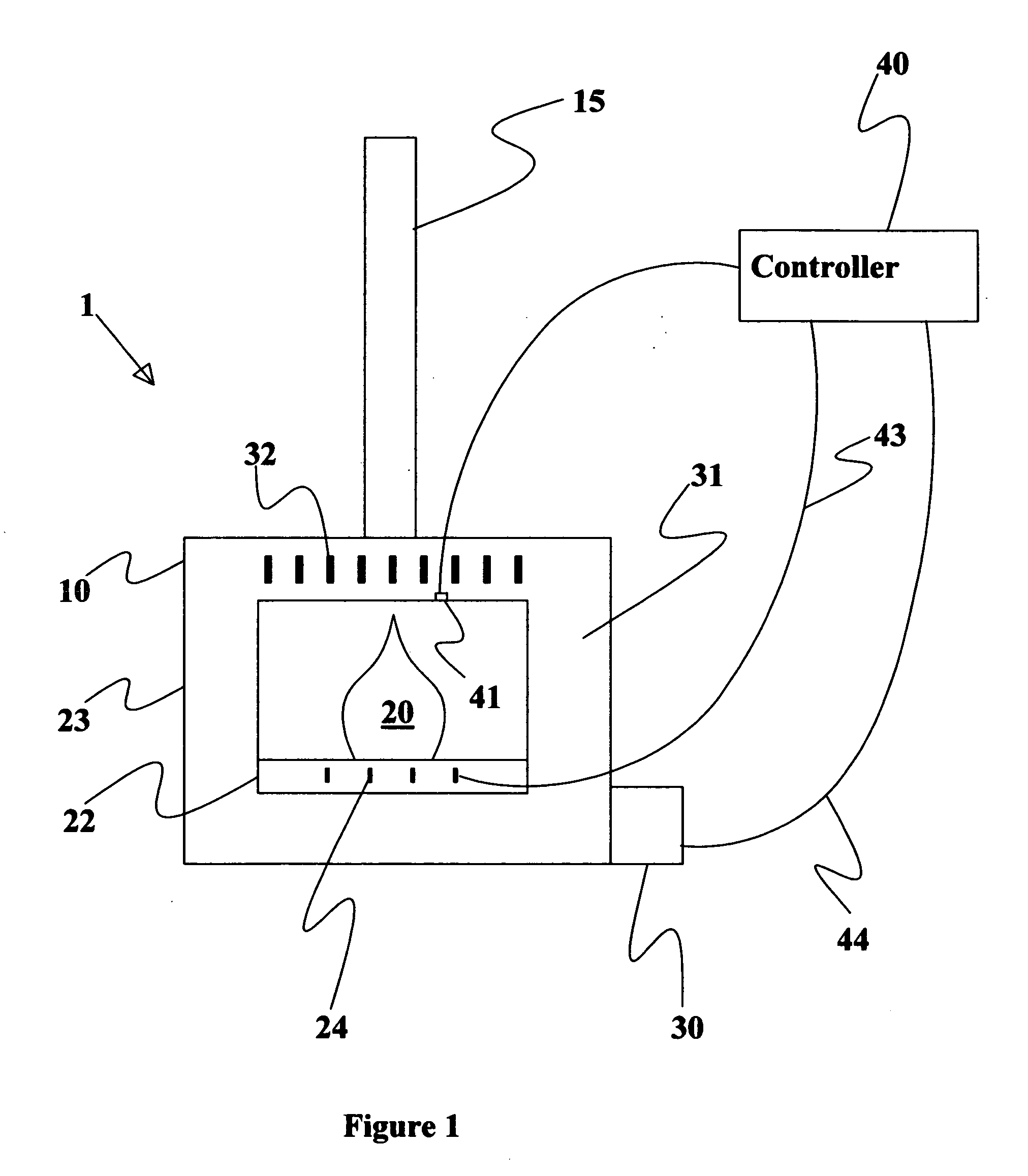

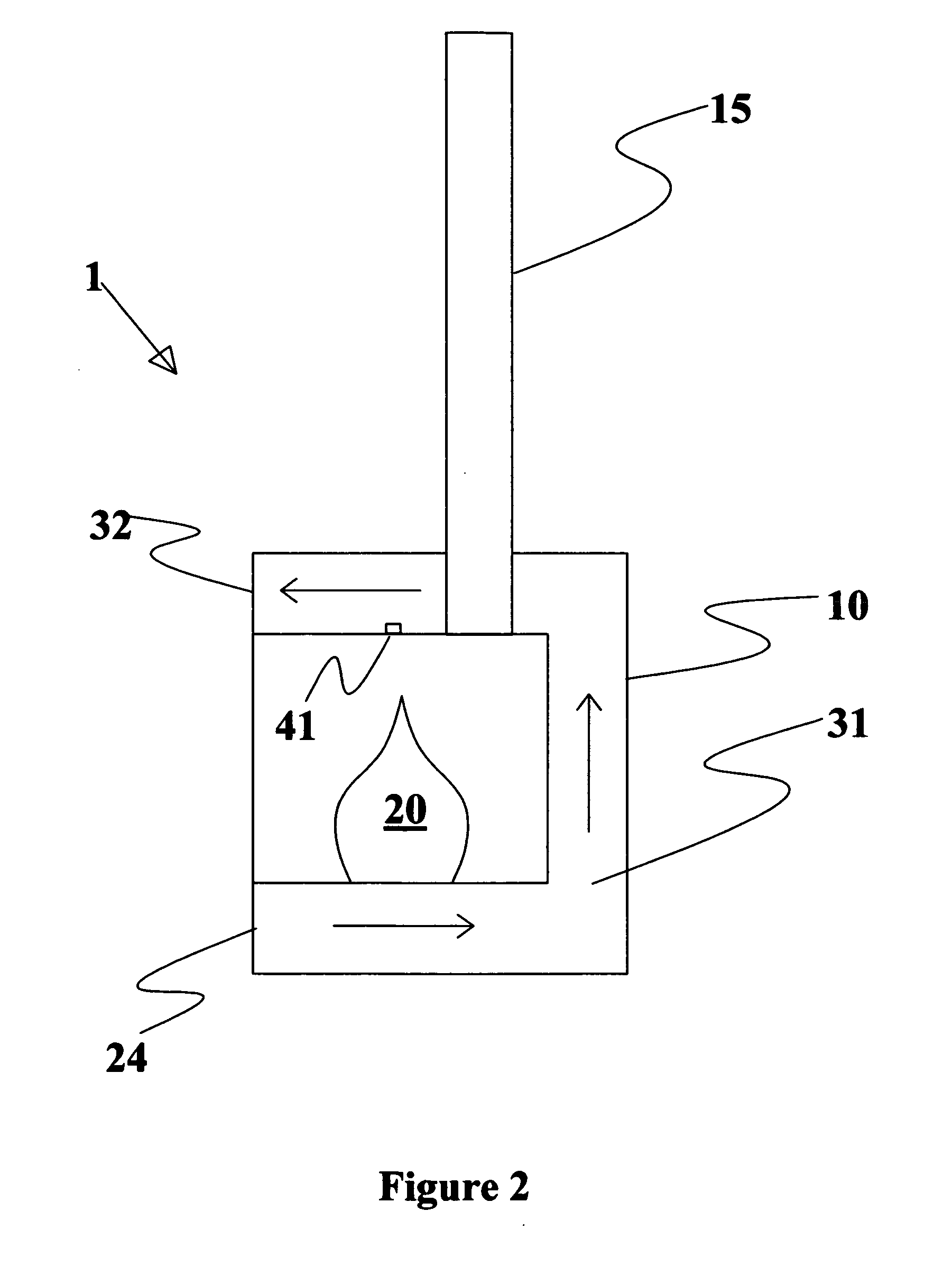

Intelligent and adaptive control system and method for wood burning stove

InactiveUS20070289589A1Maximum burn timeMaximum heating efficiencyDomestic stoves or rangesWater heatersCombustion chamberControl system

A control system and method for a wood stove adjustably operates in accordance with operational characteristics of the wood stove. The system operates air vents to the combustion chamber of the stove to control operating temperatures of the stove. The air vents are adjusted proportionally to changes in temperature of the stove. The temperature of the stove may be controlled to achieve desired operational and burn characteristics. The system further includes a heat exchange fan. The system controls the speed of the heat exchange fan based upon the operational characteristics of the stove.

Owner:MCFARLAND DANIEL T

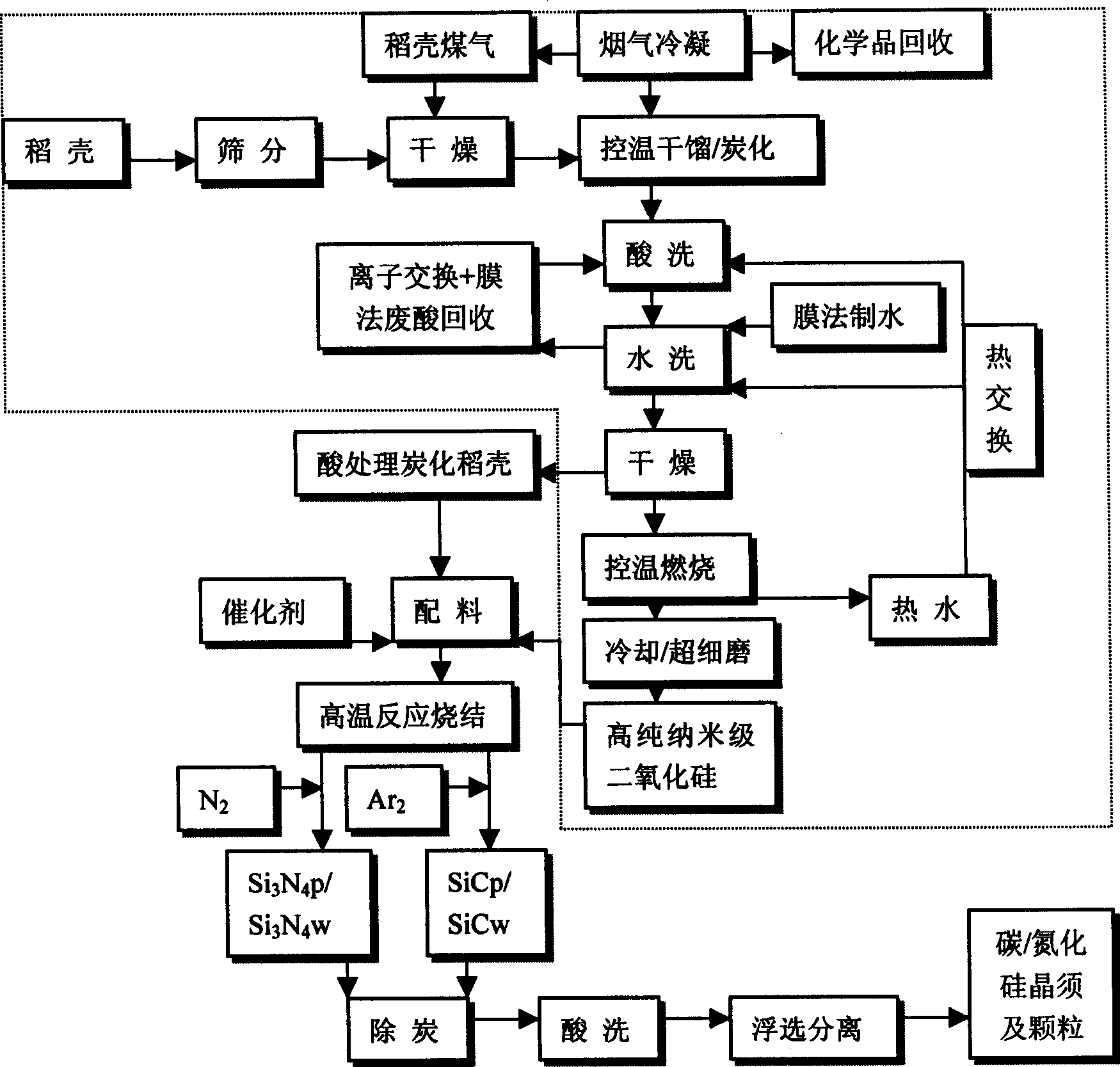

Process and apparatus for preparing high-purity silicon dioxide by utilizing rice hull

The disclosed method to prepare high-pure silicon dioxide with rice hull comprises: sieving the rice hull to remove sand and dust, drying hull and distillating to char the hull at 400-500Deg, and recovering chemical compound and gas; acid washing the hull to remove the alkali metal impurity, and drying the hull to obtain the silicon nitride, silicon carbide and carbon-containing crystal whisker material; controlling temperature 500-600Deg to burn and obtain the amorphous silicon dioxide as material for silicon nitride and silicon carbide; or acid washing to remove the alkali metal impurity, cleaning with pure water directly to obtain hihg-pure ultrathin white carbon black product.

Owner:SECTION OF SCI & TECH DEV

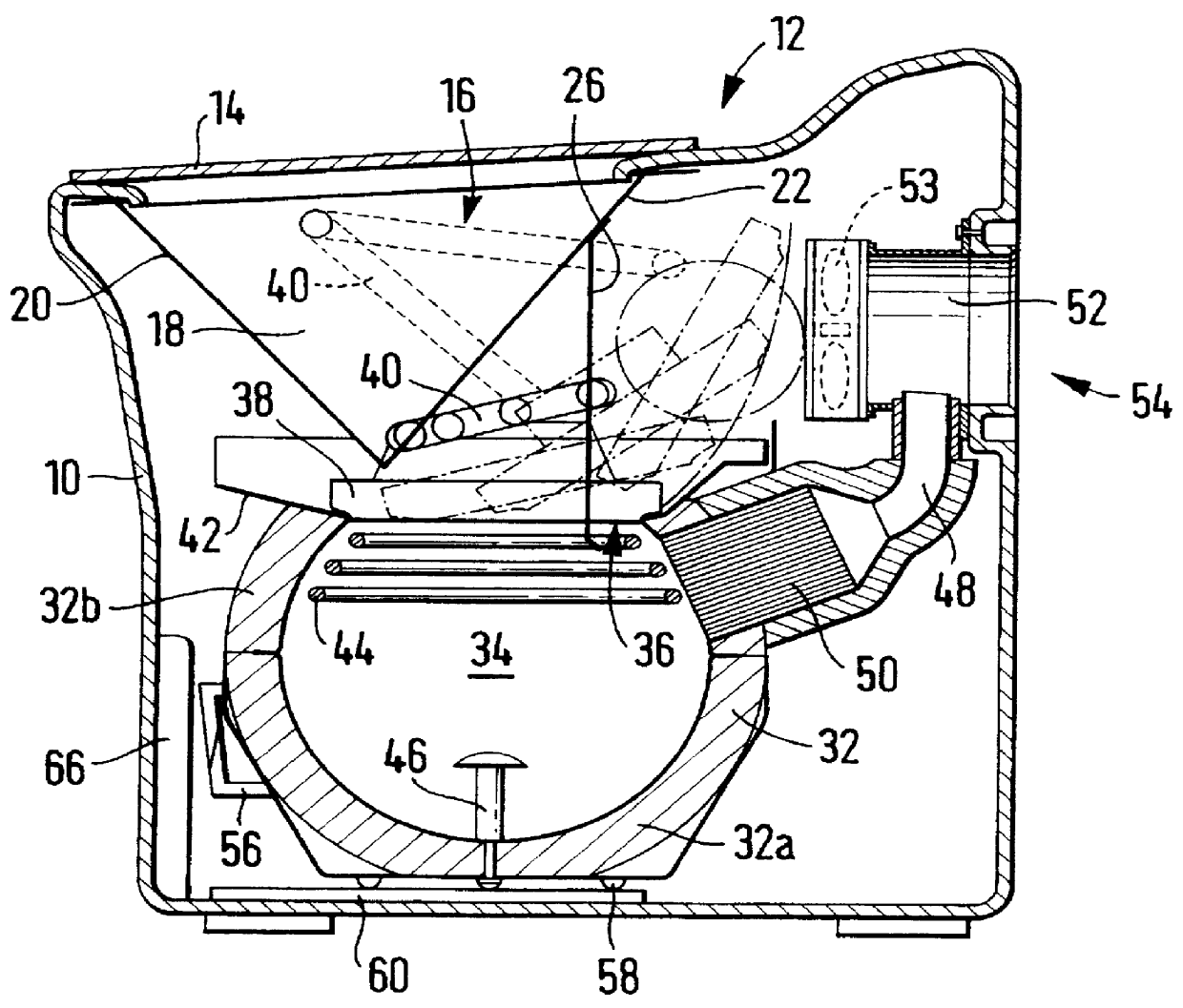

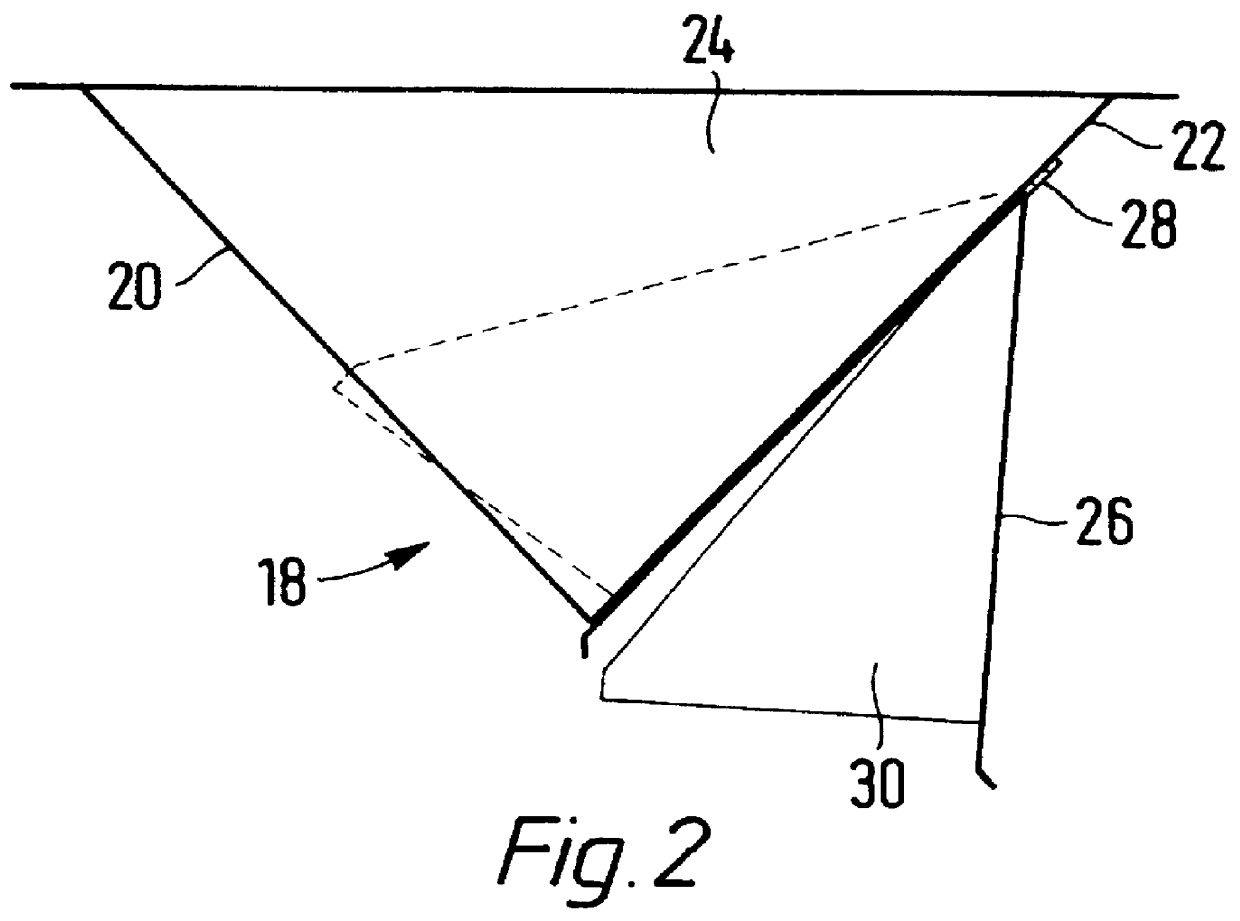

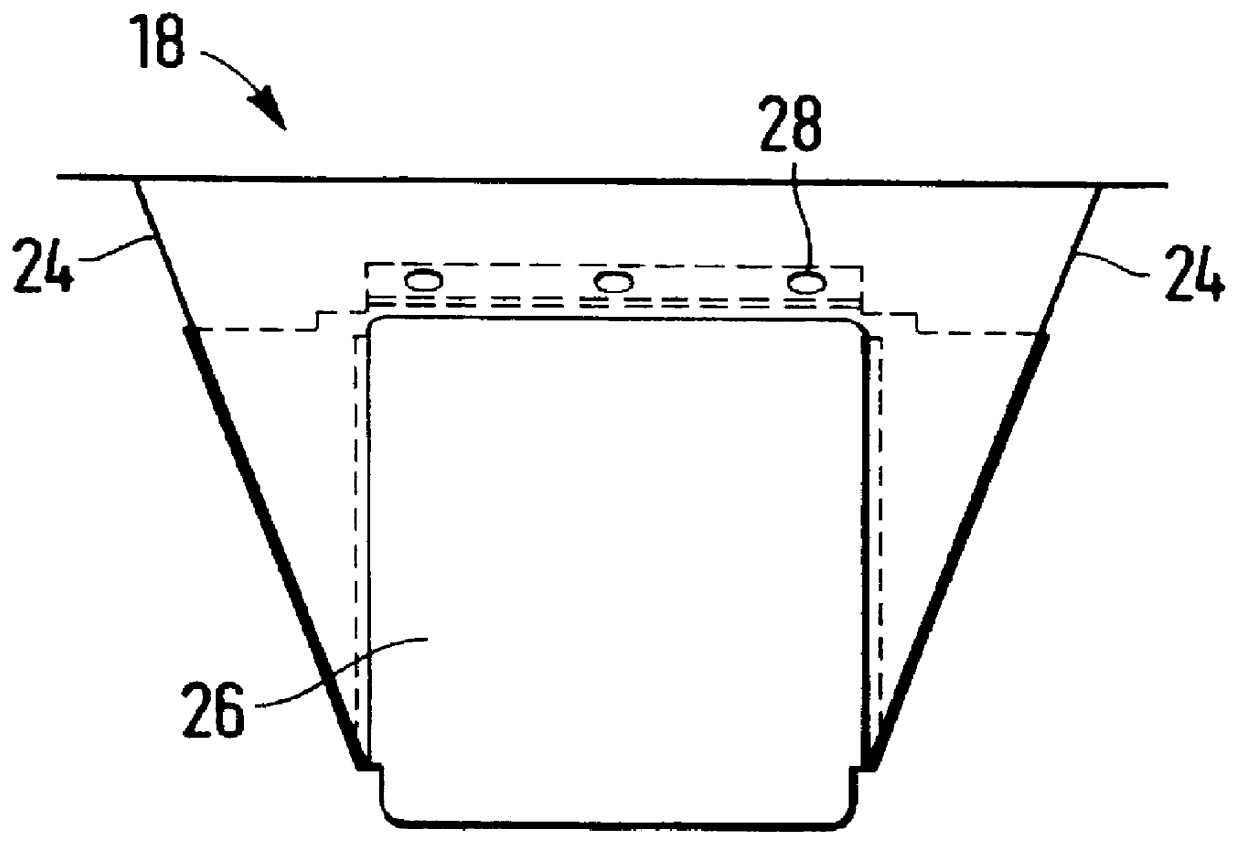

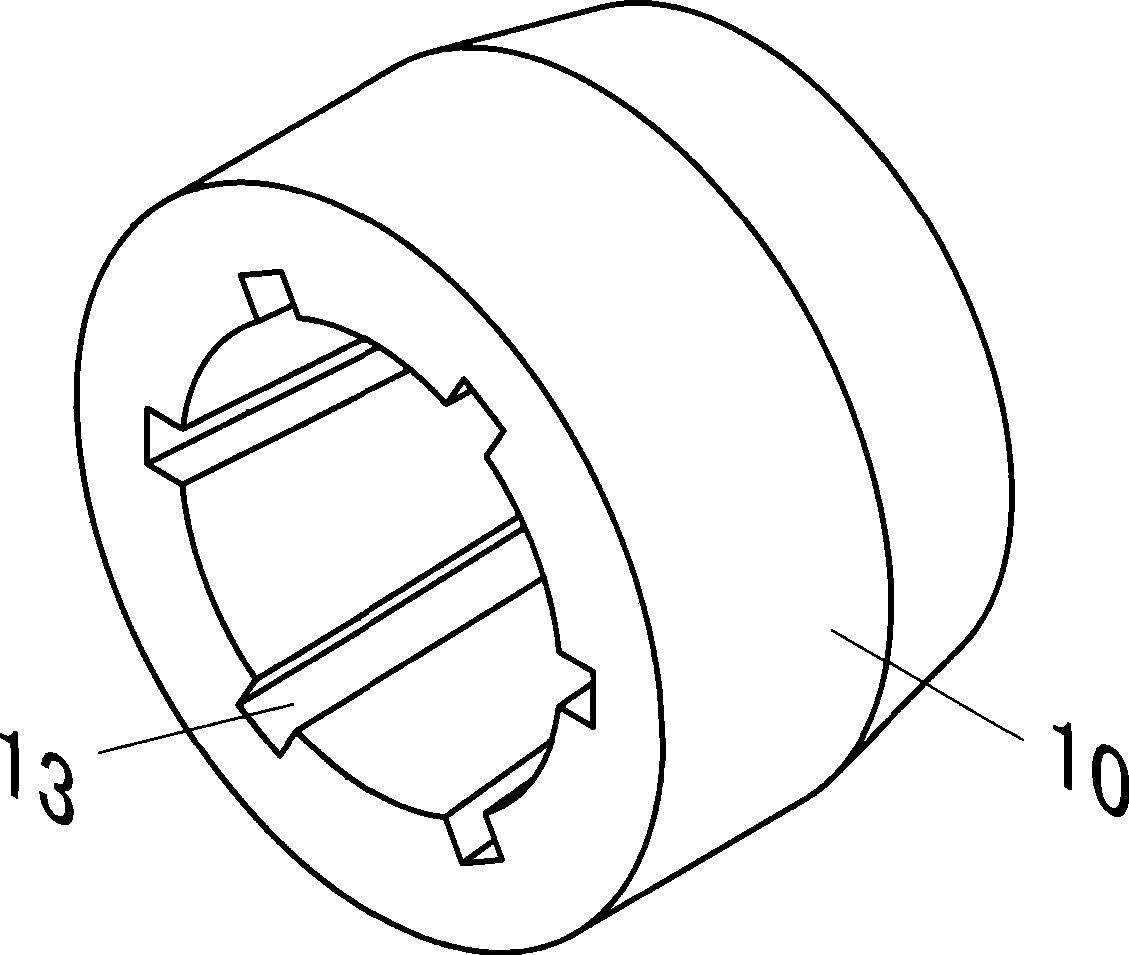

Electric toilet

InactiveUS6052836AAvoid wastingEven heat distributionBathroom accessoriesAgainst vector-borne diseasesEngineeringToilet

PCT No. PCT / SE97 / 01252 Sec. 371 Date Jan. 21, 1999 Sec. 102(e) Date Jan. 21, 1999 PCT Filed Jul. 10, 1997 PCT Pub. No. WO98 / 02079 PCT Pub. Date Jan. 22, 1998An electric toilet comprising a cabinet or housing (10), an opening (16) in the top side of the cabinet, a lid (14) assigned to the opening (14), an upper bowl (18) arranged inside the opening, which bowl is openable downwards, a combustion chamber (32) arranged beneath the upper bowl (18) with a combustion space (34) and provided with an opening (36) directed upwards, assigned to which opening is a lid (38), heating coils (44) arranged in the combustion space (34) and an evacuation device (48, 50, 52) connected to the combustion space (34). The invention is characterized in that at least the combustion space's (34) lower part is formed principally spherically and that the heating coils (44) are arranged in the upper part of the combustion space round its circumference.

Owner:SIRIUS TECH

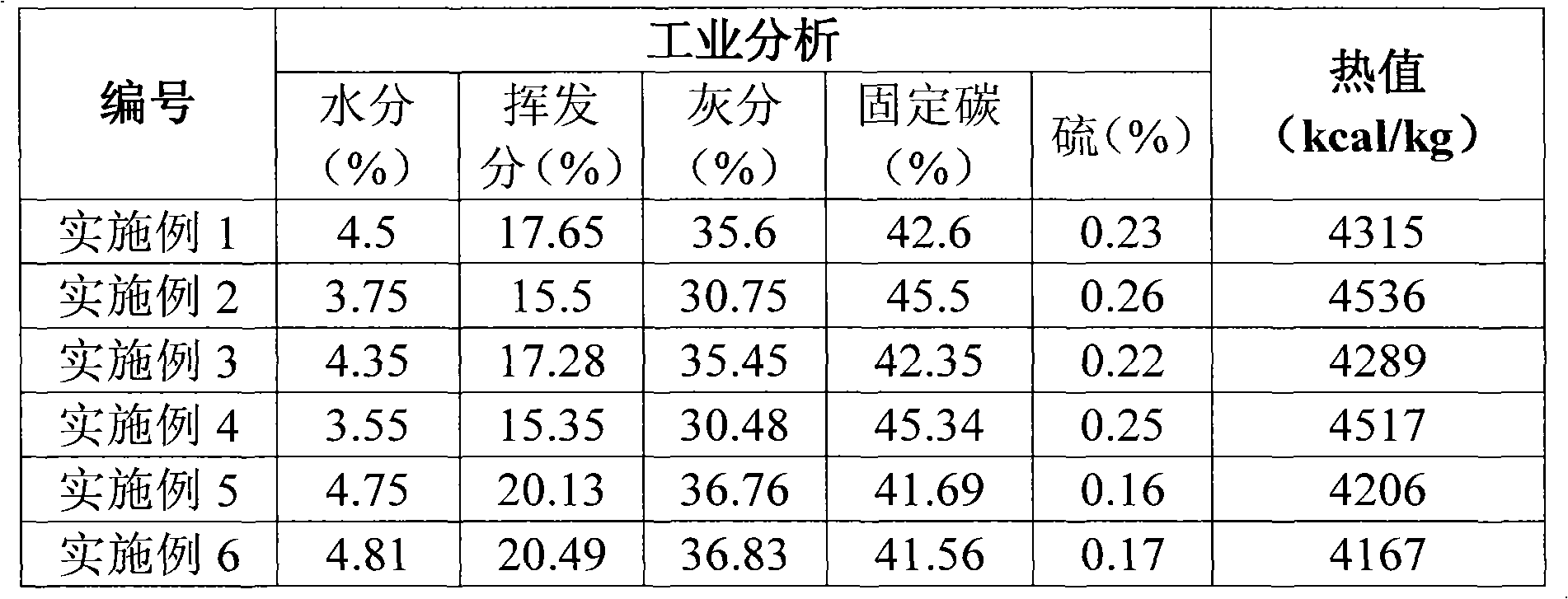

Biomass moulded coal and preparation method thereof

InactiveCN101985575ALow calorific valueLow volatileBiofuelsSolid fuelsFixation agentSodium hydroxide

The invention provides a method for preparing biomass moulded coal by using biomass and inferior smokeless pulverized coal as raw materials. The biomass moulded coal is prepared by uniformly mixing the biomass, the inferior smokeless pulverized coal and additives (a sulfur fixation agent, a biomass binder, an oxidant and a waterproofing agent), and performing low-pressure compression moulding by a wet method, wherein the sulfur fixation agent is calcined lime CaO; the biomass binder is light yellow dope prepared by treating bagasse by using 1 to 2 percent sodium hydroxide solution; the oxidant is potassium permanganate; and the waterproofing agent is tar or a binder. The biomass moulded coal comprises following raw materials in part by mass: 40 to 65 parts of inferior smokeless pulverized coal, 25 to 55 parts of biomass and 5 to 10 parts of additive. The biomass moulded coal has the advantages of low cost, low ignition point, high burn-off rate and integrative desulfurization and water proofing performance, and has great significance of energy conservation and environmental protection.

Owner:SOUTH CHINA UNIV OF TECH

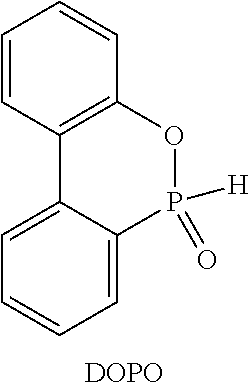

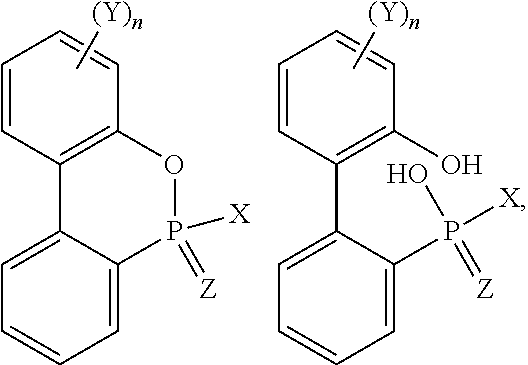

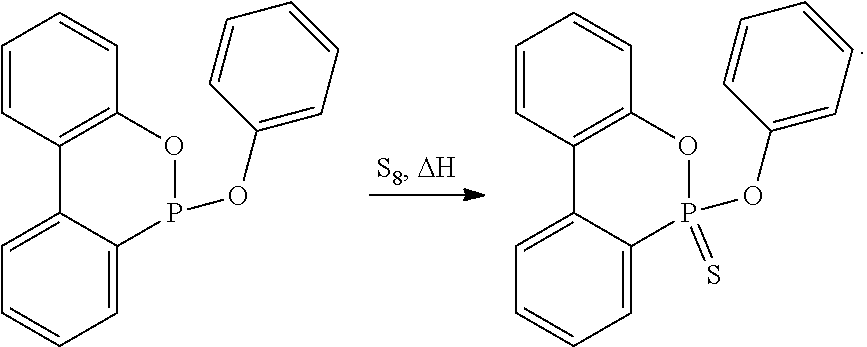

Flameproof expandable polymerizates

The invention relates to flameproof expandable polymers containing at least one blowing agent, wherein at least one phosphorus compound is contained as a flame retardant. Novel 9,10-dihydro-9-oxa-10-phosphaphenanthrene derivatives, namely 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-thione, 9,10-dihydro-10-hydroxy-9-oxa-10-phosphaphenanthrene-10-thione, 9,10-dihydro-10-hydroxy-9-oxa-10-phosphaphenanthrene-10-thione ammonium salt, 9,10-dihydro-10-mercapto-9-oxa-10-phosphaphenanthrene-10-thione, 9,10-dihydro-10-mercapto-9-oxa-10-phosphaphenanthrene-10-thione triethylammonium salt, 9,10-dihydro-10-hydroxy-9-oxa-10-phosphaphenanthrene-10-thione triethylammonium salt, 9,10-ei-hydro-10-hydroxy-9-oxa-10-phosphaphenanthrene-10-thione melaminium salt, 9,10-dihydro-10-hydroxy-9-oxa-10-phosphaphenanthrene-10-thione guanidinium salt, bis(9,10-dihydro-9-oxa-10-oxo-10-phosphaphenanthrene-10-yl)sulfide, 9,10-dihydro-10-(9,10-dihydro-9-oxa-10-phospha-10-thioxophenanthrene-10-ylthio)-9-oxa-10-phosphaphenanthrene-10-one, bis(9,10-dihydro-9-oxa-10-phospha-10-thioxophenanthrene-10-yl)sulfide, bis(9,10-dihydro-9-oxa-10-phospha-10-thioxophenanthrene-10-yl)disulfide, bis(9,10-dihydro-9-oxa-10-phospha-10-thioxophenanthrene-10-yl)tetrasulfide, di(9,10-dihydro-9-oxa-10-phospha-10-thioxophenanthrene-10-yl)ether and / or 9,10-dihydro-10-(9,10-dihydro-9-oxa-10-phospha-10-thioxophenanthrene-10-yloxy)-9-oxa-10-phosphaphenanthrene-10-one, or ring-opened hydrolyzates thereof, are provided as flame retardants.

Owner:SUNPOR KUNST

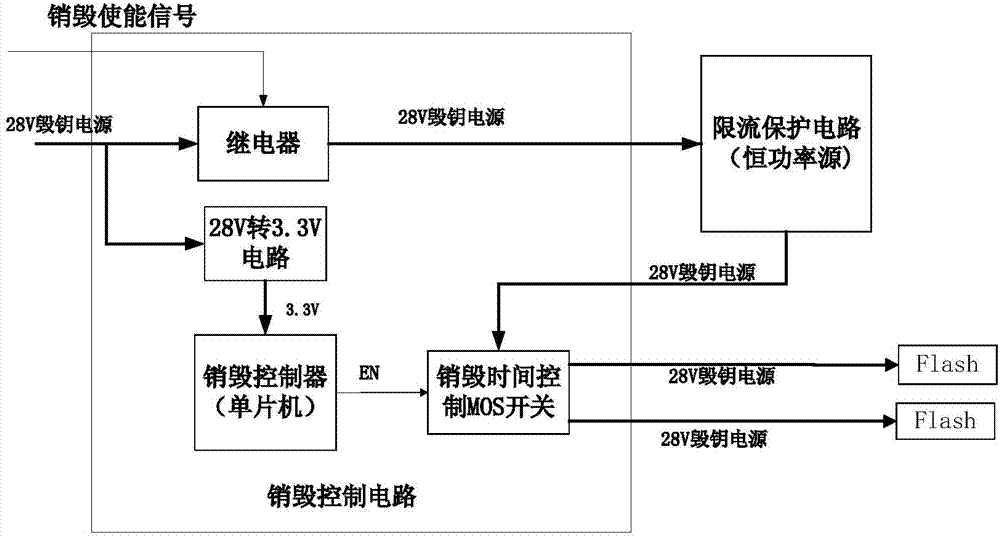

Physical destruction system

The invention relates to a physical destruction system, including a destruction control circuit module and a current limiting protection circuit module. When the physical signal destruction is effective, a 28V high voltage large current destruction power supply is directly loaded to a storage medium NAND FLASH chip power supply base pin of a large capacity data storage module by control, and in the manner of reverse high voltage impact or positive large current heating, a storage wafer element of a NAND FLASH chip internal tube core can be completely destroyed. A current limiting protection circuit is designed in the physical destruction process to ensure the physical destruction process does not affect other circuits and only destroy storage FLASH effect. The physical destruction system can physically damage storage FLASH to achieve store data unrecoverability and ensure the complete elimination of important sensitive data in case of emergency.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

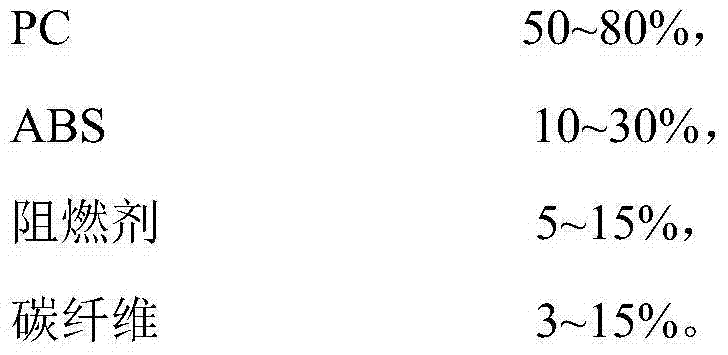

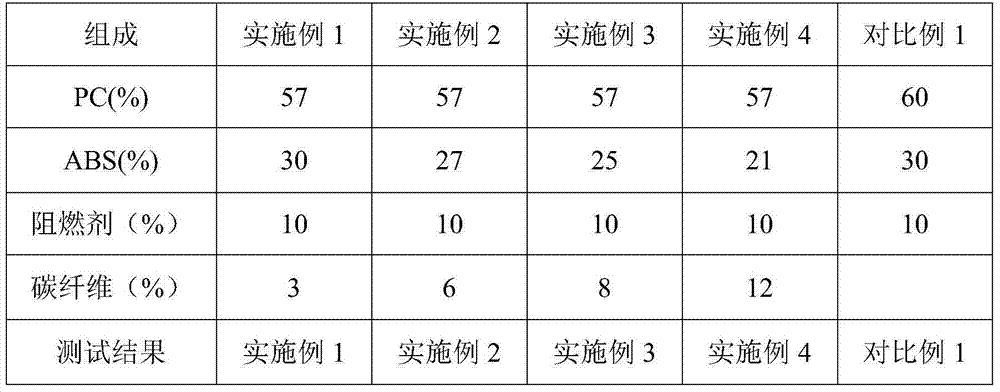

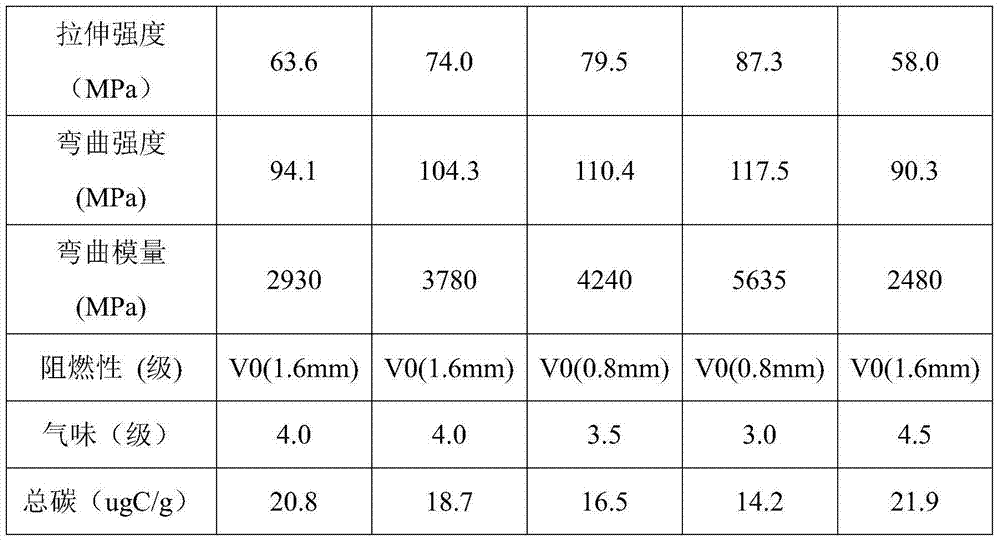

Highly environmental-friendly flame retardant reinforced PC (Polycarbonate)/ABS (Acrylonitrile Butadiene Styrene) blending material and preparation method thereof

The invention discloses a highly environmental-friendly flame retardant reinforced PC / ABS blending material and a preparation method thereof. The flame retardant reinforced PC / ABS blending material comprises the following raw materials in percentage by weight: 50-80% of PC, 10-30% of ABS, 5-15% of flame retardant and 3-15% of carbon fiber. The carbon fiber is subjected to surface activating treatment. The flame retardant reinforced PC / ABS blending material obtained through the technical scheme of the invention has the many advantages, such as high strength, high flame retardance and high environmental-friendly property. By addition of the carbon fiber subjected to surface activation, stretching and bending performance of the blending material can be enhanced, and various organic volatile matter constituents in the PC / ABS can be adsorbed effectively by lots of micropores on the surface of the carbon fiber, so that multiple environmental indexes, such as material odor and TVOC (Total Volatile Organic Compounds), are improved, more importantly, the promotion of environmental performance is not at the cost of sacrificing the flame retardance of material, on the contrary, the flame retardance of the blending material is also promoted, the combustion time of the blending material away from the fire becomes shorter, and the self-extinguish ability of the blending material becomes better.

Owner:SHANGHAI PRET COMPOSITES +2

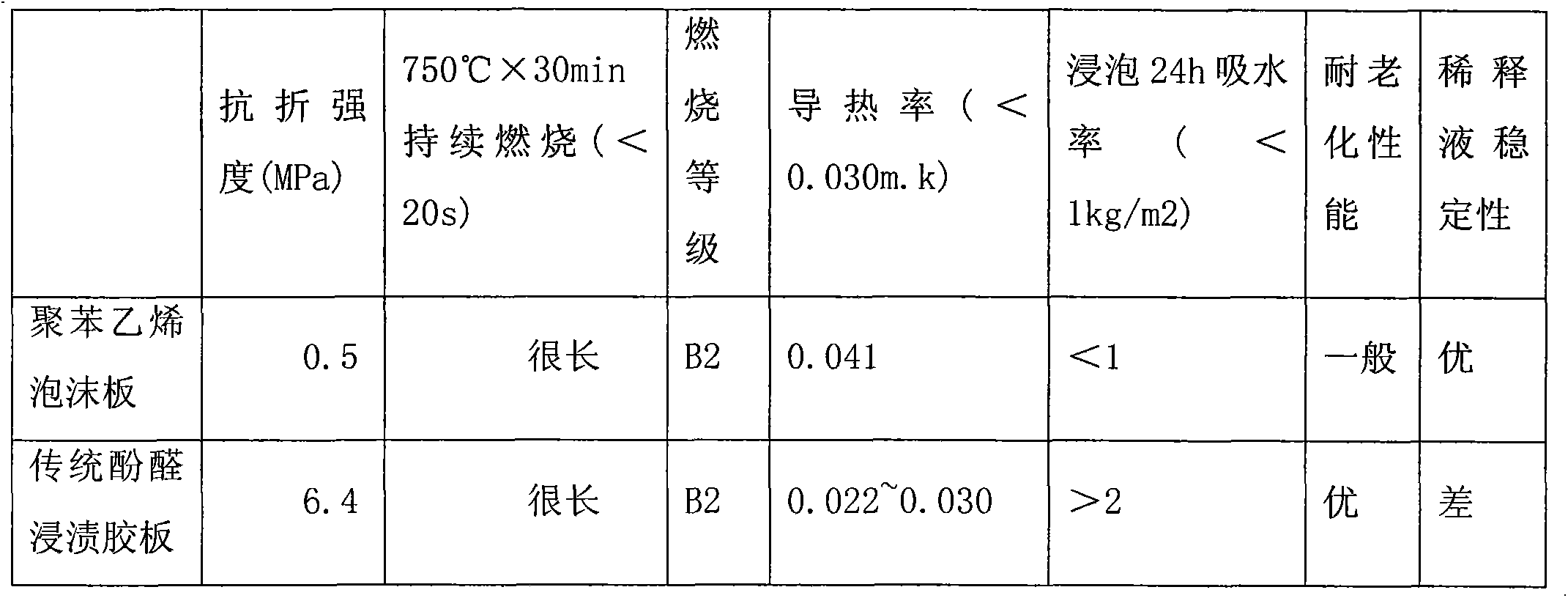

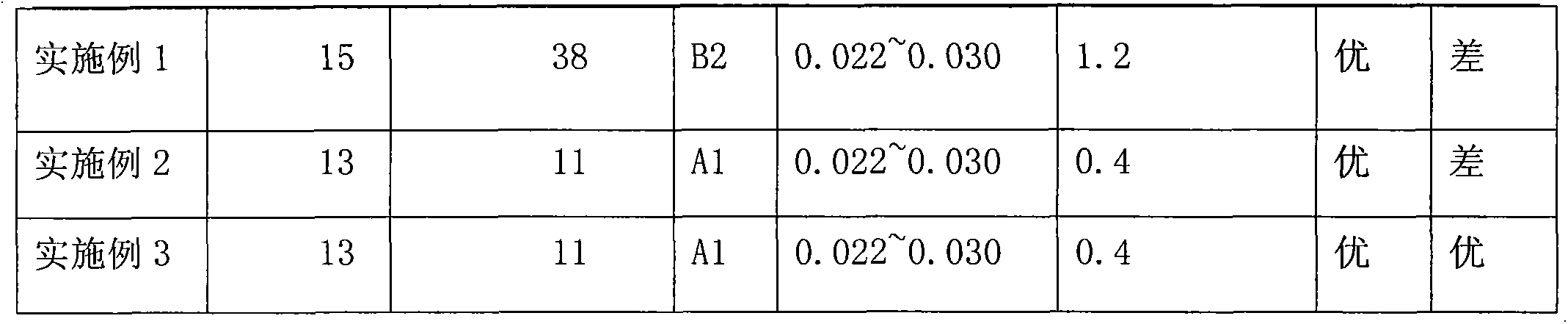

Composite impregnating adhesive for making fireproof heat insulation plate, and its use method

ActiveCN103173169AEmission reductionExcellent burning resistanceAldehyde/ketone condensation polymer adhesivesCarbon fibersAdhesive

A composite impregnating adhesive for making a fireproof heat insulation plate comprises a phenolic resin, a flame inhibitor, a smoke inhibitor, a chelating agent, a charring agent, an inorganic adhesive, a waterproof agent, a catalyst and a stabilizing agent, wherein the phenolic resin is a primary adhesive. The aqueous impregnating adhesive is prepared through adding water and adopting a normal temperature mixing stirring process. Water is added as needed in the use process to dilute and adjust the concentration. The composite impregnating adhesive has the characteristics of no use of organic solvents bringing dangers and pollution, use convenience, simple control of the production process, less discharge of pollutants, and low cost. Compared with coats of other resin based impregnating adhesives, a coat of the composite impregnating adhesive, formed on the surfaces of fibers, has the advantages of protruding high temperature and burning resistances, almost no combustion or smoke at a high temperature, and low heat conductivity; and the fireproof heat insulation plate made through adopting the composite impregnating adhesive has a protruding fireproof heat insulation performance reaching an A1-level fireproof standard. The composite impregnating adhesive can be used for processing basalt fibers, and can also be used for processing various organic and inorganic fibers comprising rock wool, glass fibers, carbon fibers, stainless steel fibers, aramid fibers terylene and the like.

Owner:BEIJING RUNHIGH SCI & TECH

Manufacturing method of red nitride fluorescent powder for LED

InactiveCN102660284AReduced sintered hardnessImprove excitation efficiencyEnergy efficient lightingLuminescent compositionsHardnessNitride

The invention relates to a manufacturing method of red nitride fluorescent powder for LED. The manufacturing method comprises the following steps of weighing raw materials, carrying out ball milling of one or more fluxing agents, sieving, mixing, sintering, crushing, washing, sieving and carrying out packaging. Compared with the existing high-temperature solid-state technology, the manufacturing method has the advantages that only one high-temperature sintering process on the raw materials is carried out and thus sintering hardness of powder is reduced obviously and sintered powder blocks are incompact so that processes and energy consumption are reduced and product quality is improved; and the one or more fluxing agents are subjected to ball milling in advance so that ball milling time of an initial product is greatly reduced and crystal brightness of a final product is improved.

Owner:徐州泰歆塬光电科技有限公司

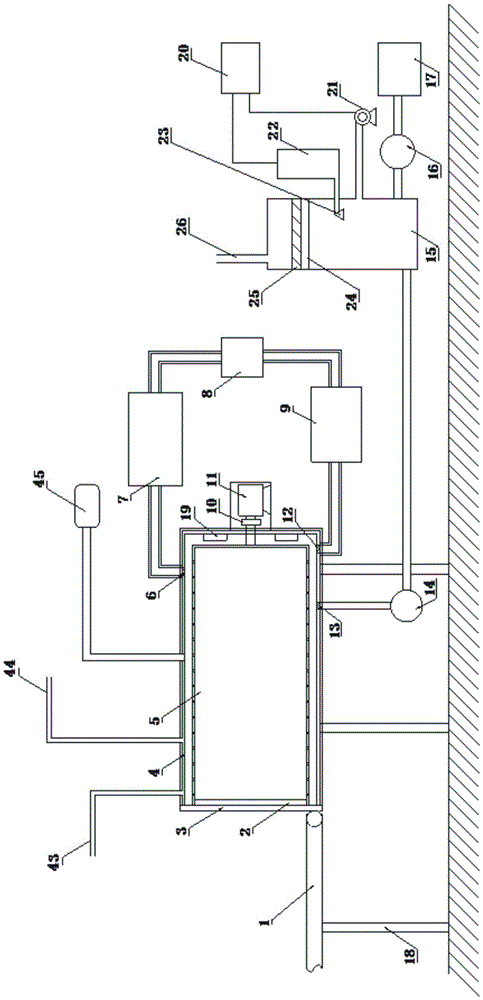

Environment-friendly liquid nitrogen iced corpse processing device and method

PendingCN105598141AWill not polluteDealing with scientific humanitySolid waste disposalInlet valveNitrogen

The invention discloses an environment-friendly liquid nitrogen iced corpse processing device. The device comprises a conveying belt, a processing cabin, a liquid nitrogen storage tank, a liquid nitrogen purification device, a liquid nitrogen recycling tank, a first drawing pump, a high-temperature gasification furnace, a second drawing pump and a cremains storage pot, wherein the conveying belt is arranged at the left side of the processing cabin, an opening is formed in the left side of the processing cabin, an electric lifting sealing door is arranged at the opening, a roller is arranged in the processing cabin, the processing cabin is provided with a driving mechanism for driving the roller to rotate, a liquid inlet valve is arranged at the upper end of the processing cabin and is connected with the outlet end of the liquid nitrogen storage tank, a liquid outlet valve is arranged at the lower end of the processing cabin and is connected with the inlet end of the liquid nitrogen recycling tank, and the outlet end of the liquid nitrogen recycling tank is connected to the liquid nitrogen storage tank via the liquid nitrogen purification device. The invention also provides a processing method based on the environment-friendly liquid nitrogen iced corpse processing device. The corpse processing method is safe and environmentally friendly and is free of pollution.

Owner:云南新财富投资有限公司

Hydrocarbon-free, non-polymeric formulations and articles

InactiveUS20080172930A1Simple processImproving flame-burning characteristicBiofuelsSolid fuelsTG - TriglycerideCandle

Disclosed herein are compositions comprising blends of at least one triglyceride; at least one fatty acid; and at least one fatty acid derivative, whereby said compositions exhibit improved processing and flame / burn characteristics. The compositions may, optionally, further comprise fillers, extenders, modifiers, binders, flame and article colorants, and perfumes and are useful in the manufacture of, for example, fireplace logs, fire starter blocks, candles, and the like.

Owner:PMC BIOGENIX

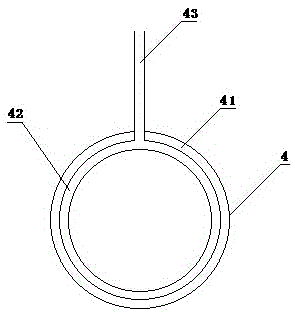

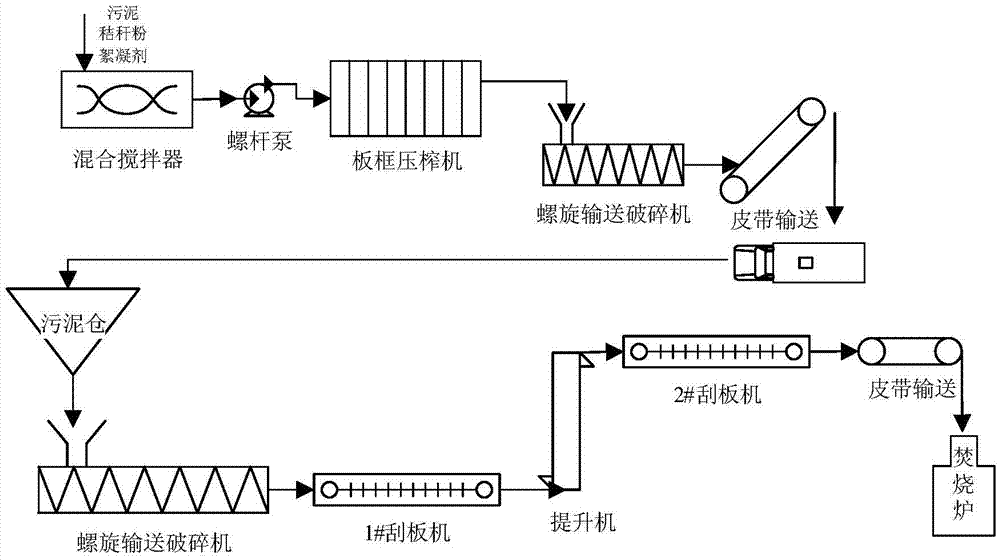

Sludge and straw mixed squeezing treatment method and device

InactiveCN105439409AWell mixedAvoid stickingSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgePulp and paper industry

The invention provides a sludge and straw mixed squeezing treatment method and device. The method comprises the following steps: step S1: pre-treating the sludge so as to remove partial water in the sludge, and allowing the water content of the sludge to be decreased to 75 to 85 percent; step S2: crushing straws to a target granularity, and mixing the crushed straws with the sludge in the step S1; and step S3: squeezing and dehydrating a mixture obtained in the step S2 to obtain a squeezed filter cake. The sludge and straw mixed squeezing treatment method and device have the following advantages: 1, the sludge and the straw powder are ensured to be uniformly mixed; a screw transport mixer is employed in the stirring and mixing process of the sludge and the straw powder, and the rotation speed of the screw transport mixer is 40 to 60 rpm / min, so that the sludge and the straw powder are uniformly mixed, and the sludge and the straw are transported forwards while in stirring and mixing, therefore, not only can the mixing time be controlled, but also the sludge is not thinned due to the excessively stirring, and the adherence of the sludge onto the wall is avoided; and 2, the water content is low after the sludge is squeezed, so that the total heat value is increased.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECH RES INST SHENZHEN CO LTD +2

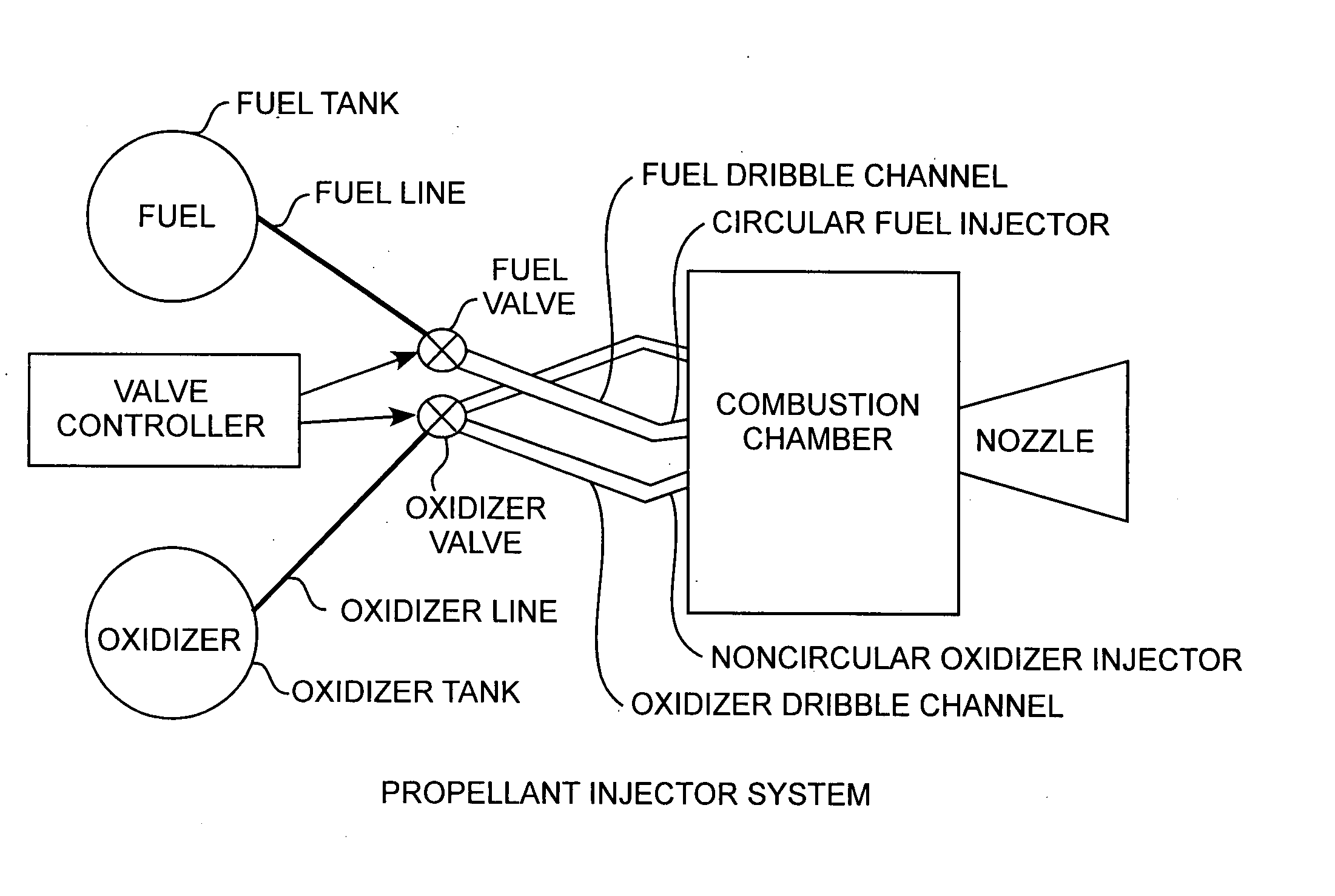

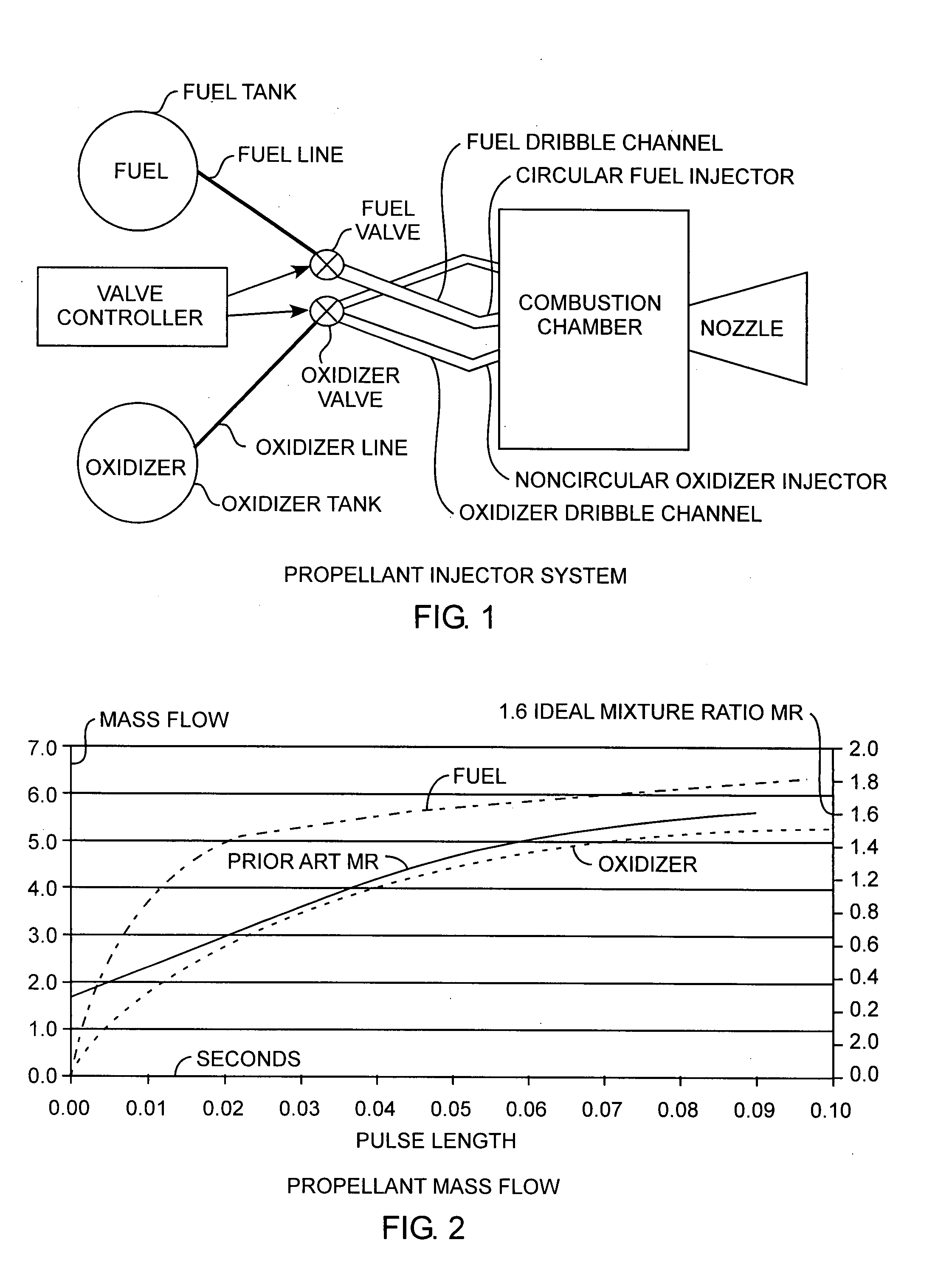

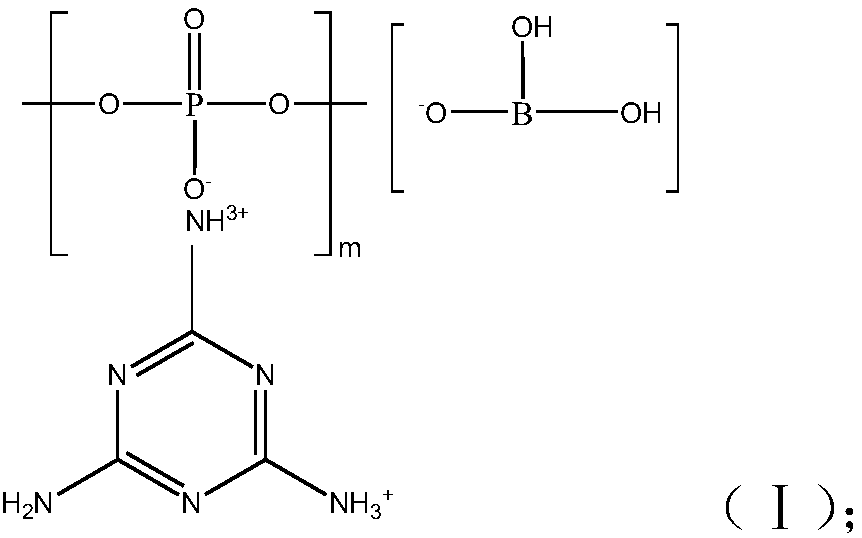

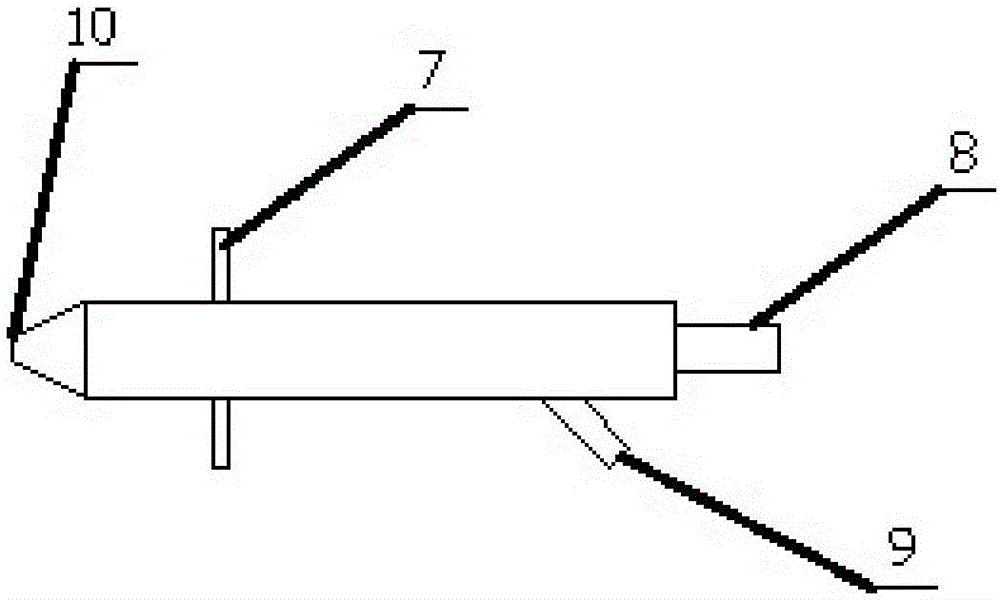

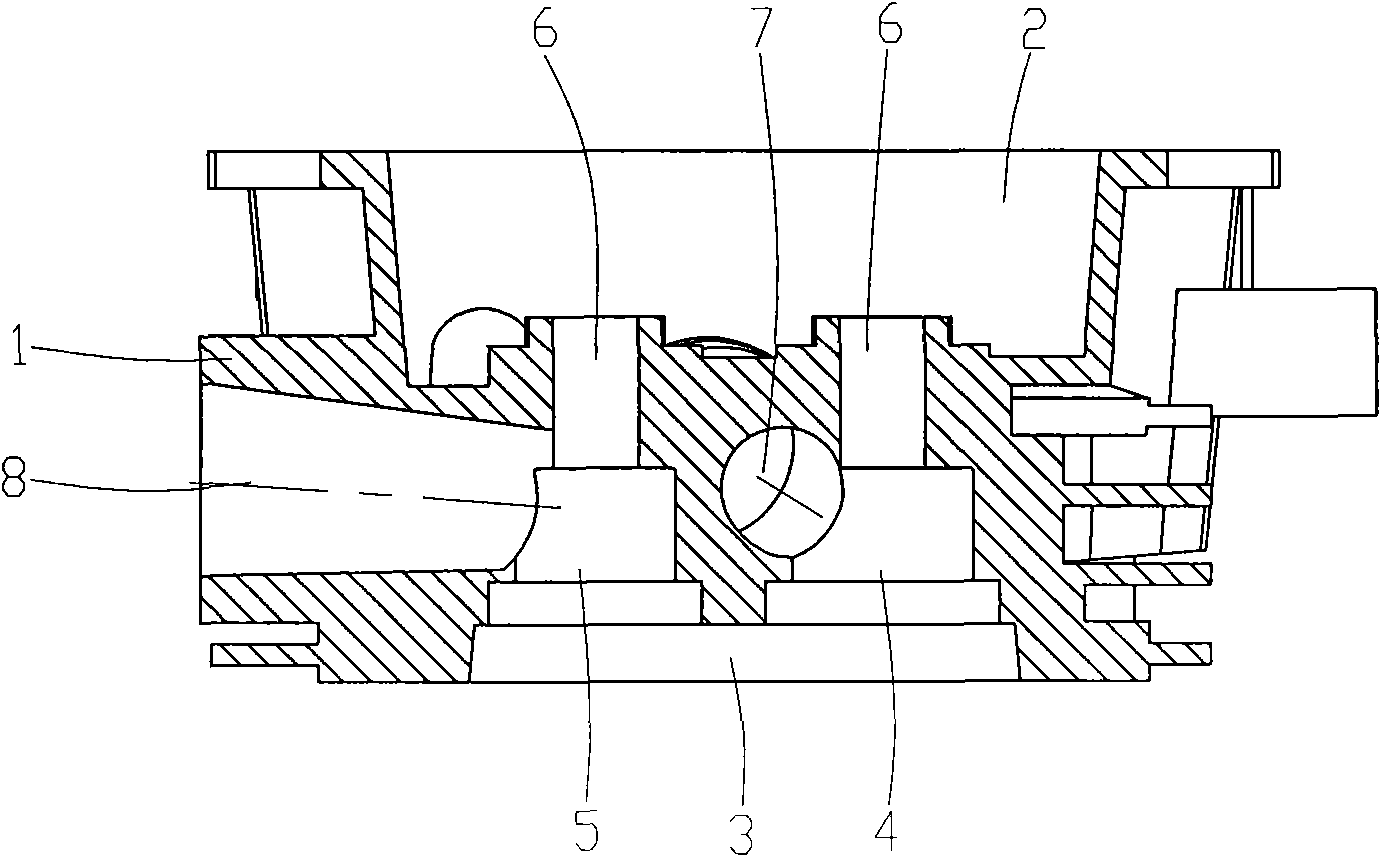

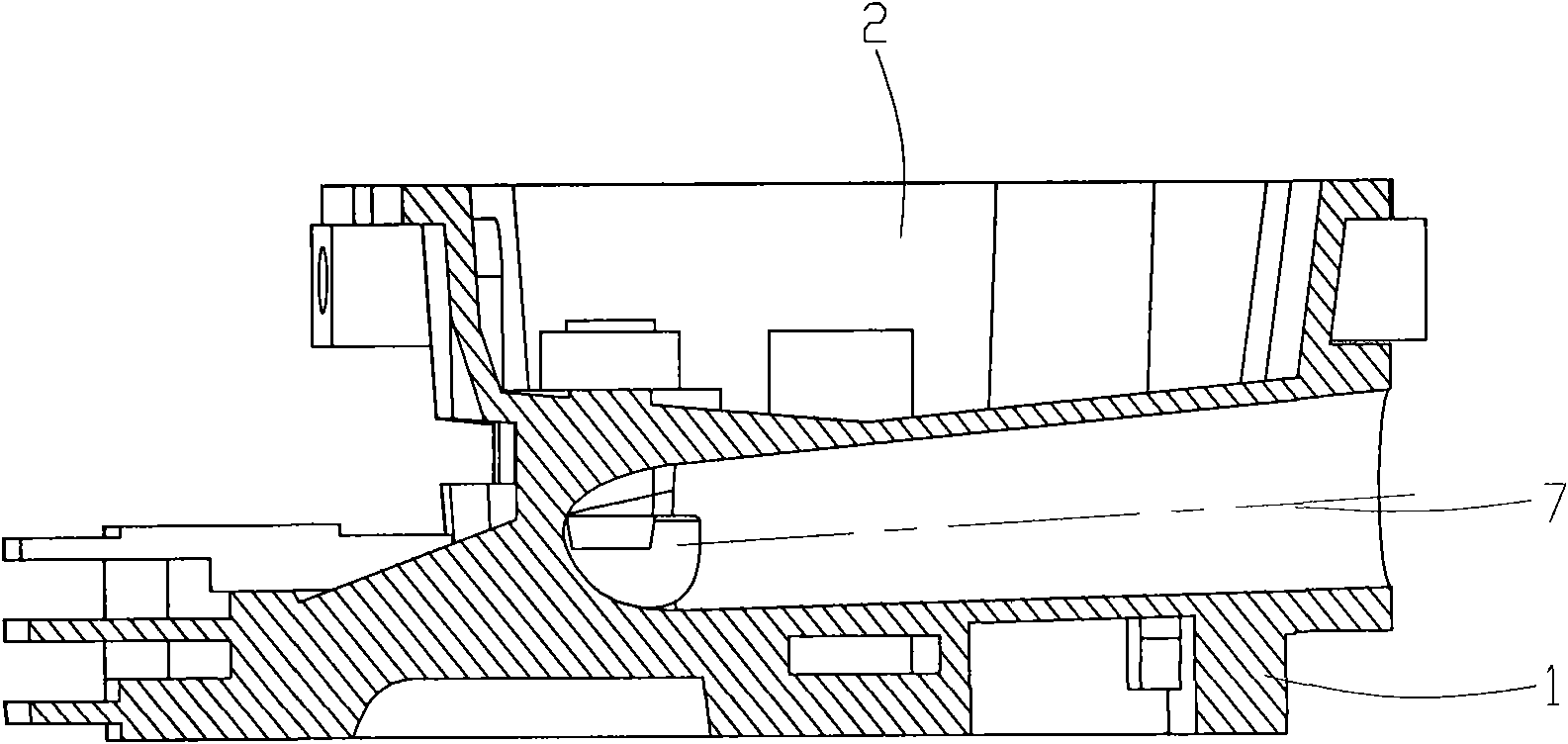

Noncircular transient fluid fuel injector control channels in propellant injector combustion systems

InactiveUS20080236140A1Improve efficiencyShort burn timeGas turbine plantsIntermittent jet plantsCombustion systemCombustion chamber

A fuel injector system for combustion engines and motors, such as pulsed bipropellant thrusters, includes noncircular fuel and oxidizer injectors at the ends of respective dribble channels for controlling the mixture ratio of the propellants passing into a combustion chambers for maintaining a desire or ideal mixture ratio as determined by the cross-sectional area of the injectors well suited for pulse combustion fuel injector systems.

Owner:THE AEROSPACE CORPORATION

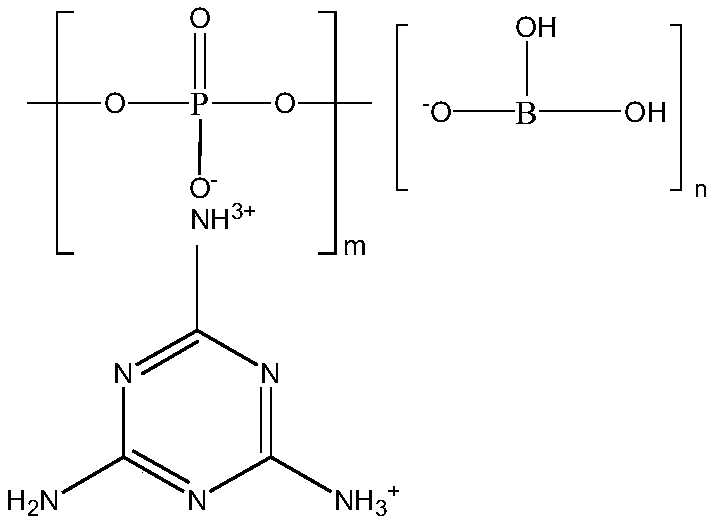

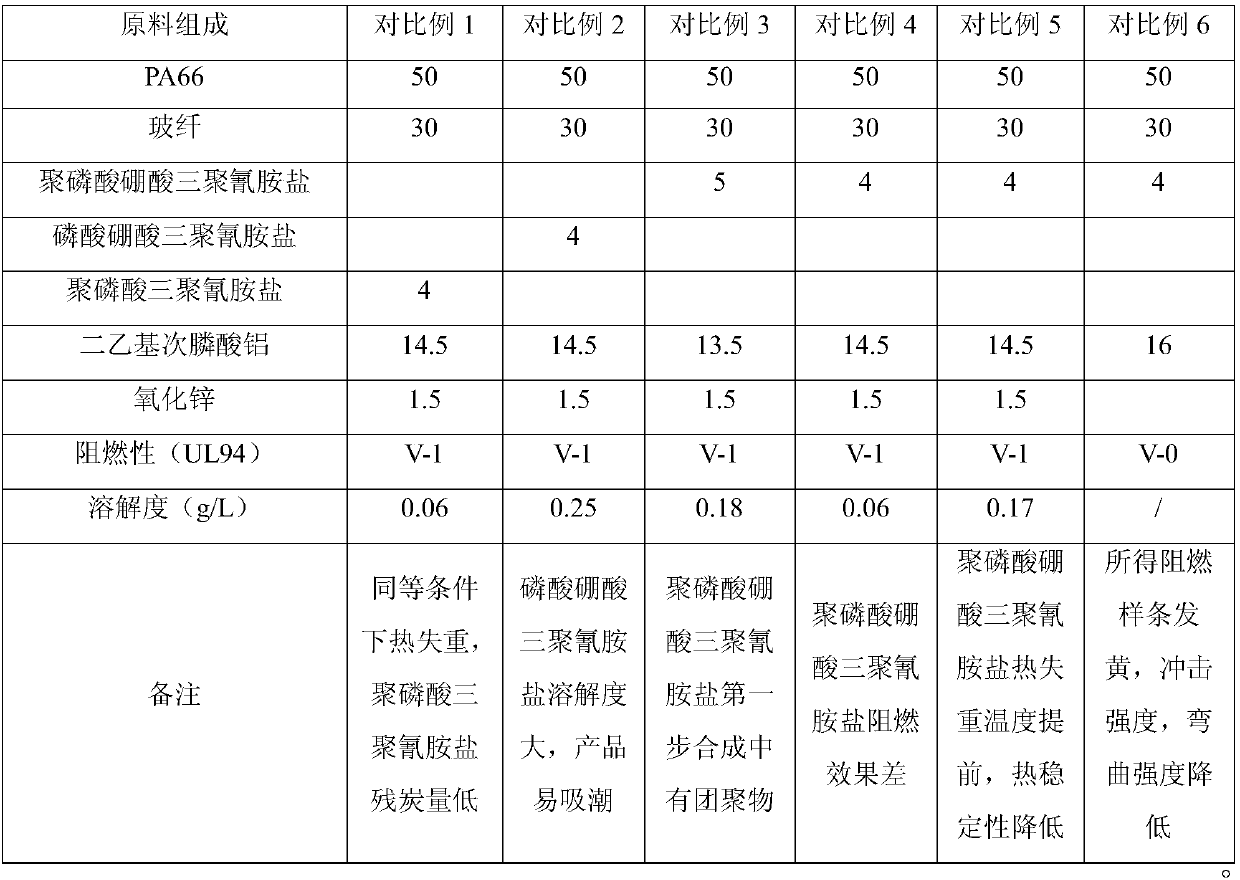

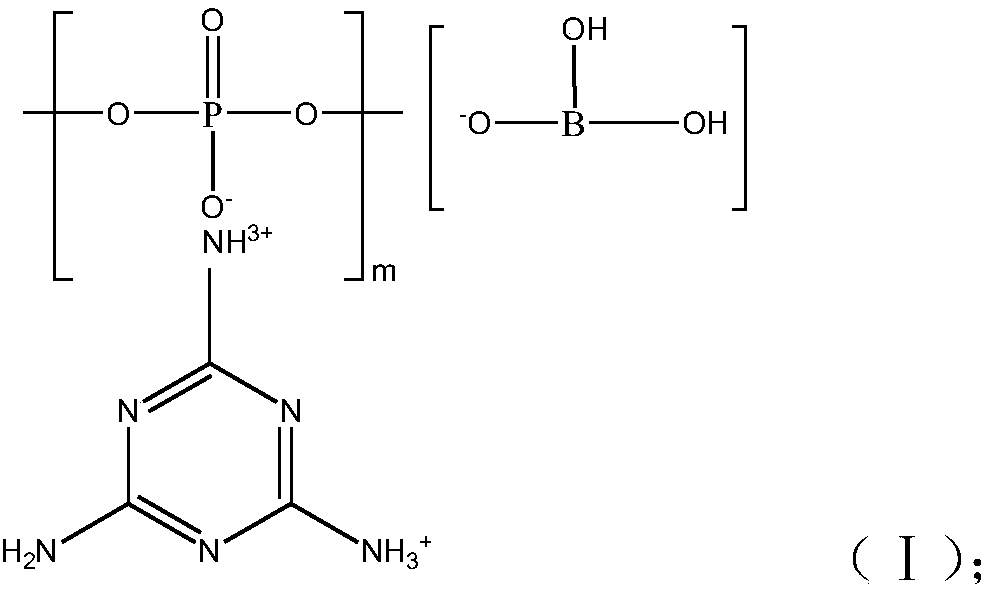

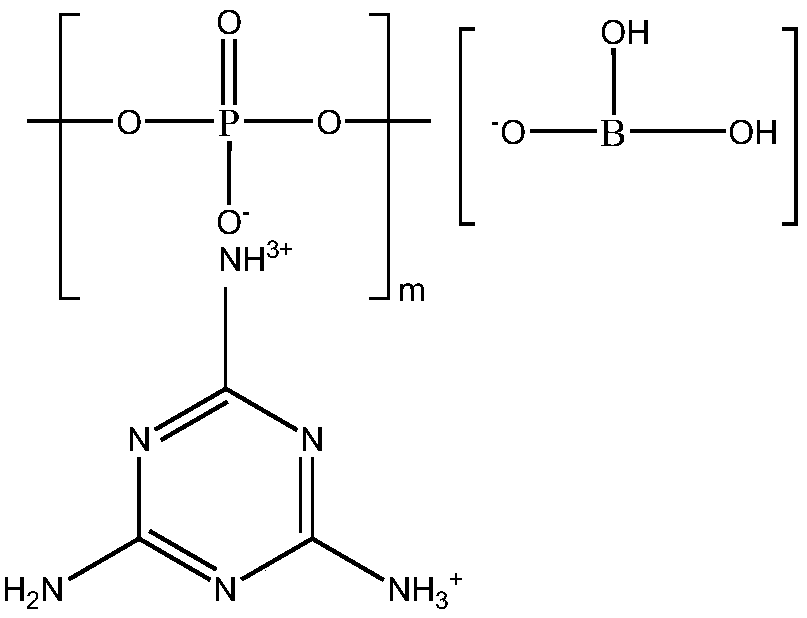

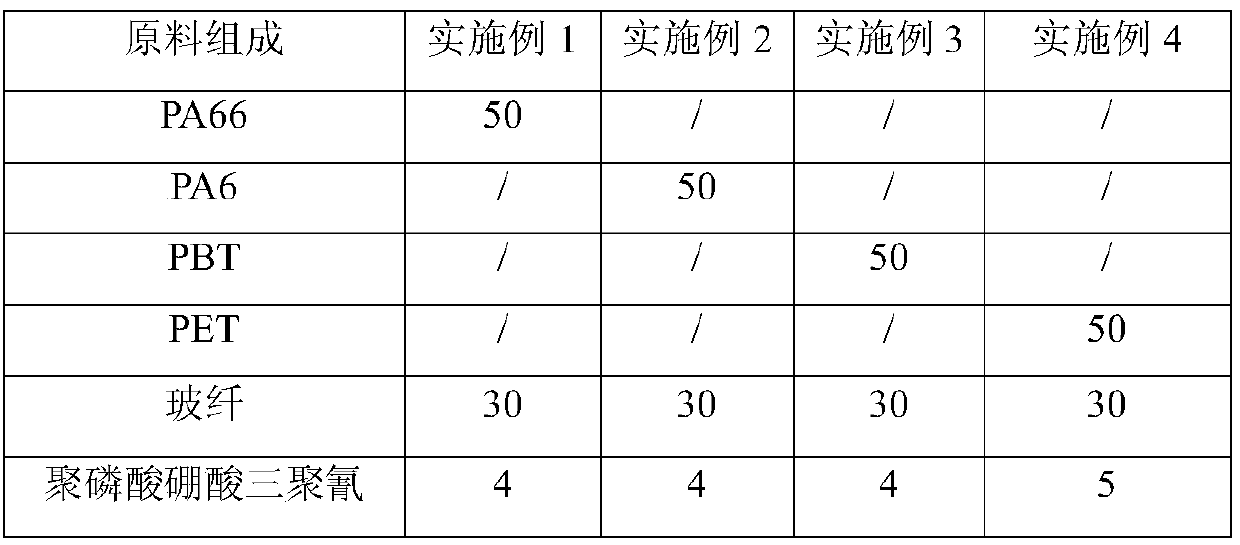

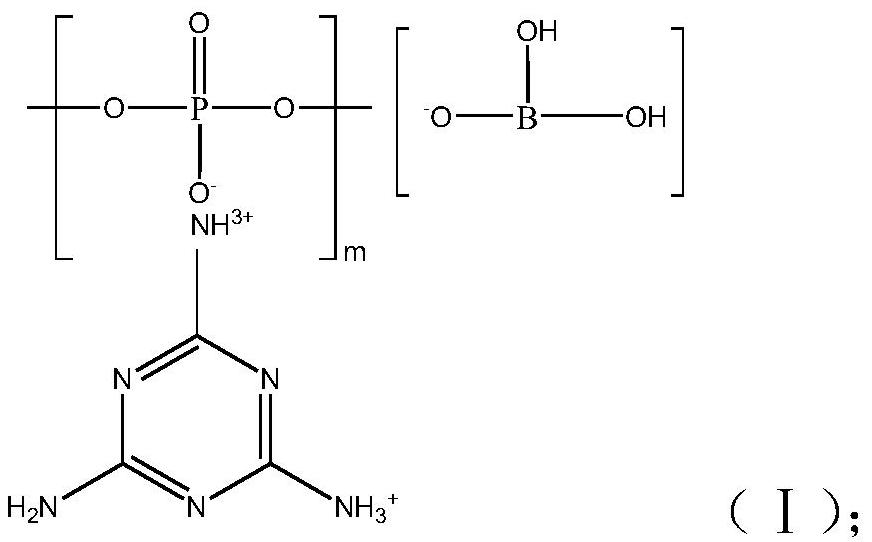

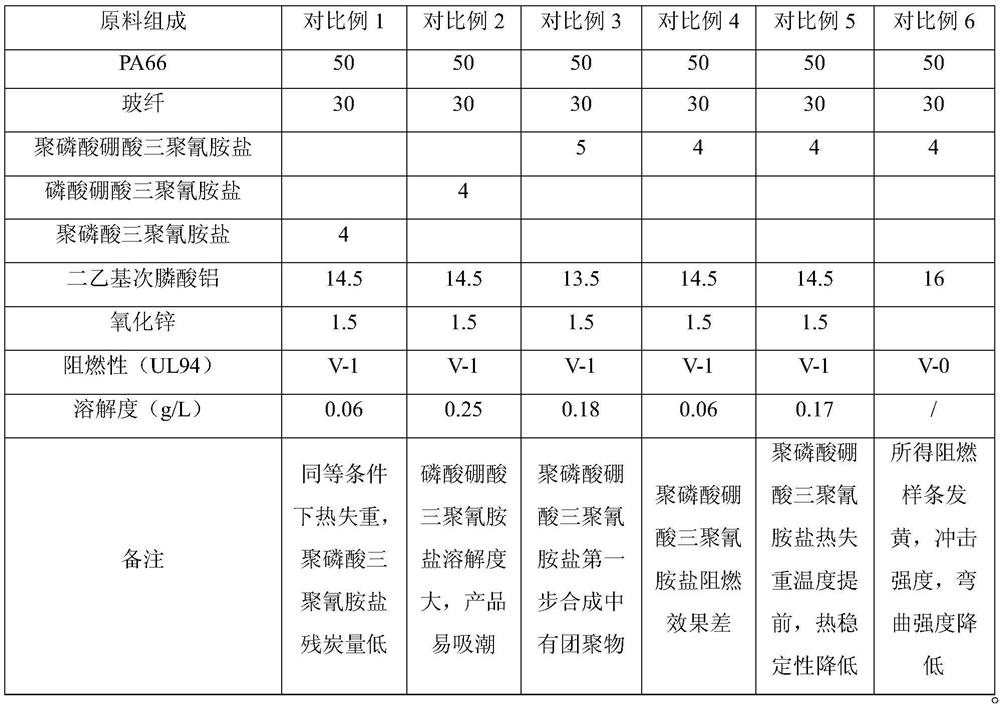

Halogen-free flame-retardant glass fiber reinforced nylon

The invention discloses halogen-free flame-retardant glass fiber reinforced nylon. The halogen-free flame-retardant glass fiber reinforced nylon comprises, by weight, 30-60% of nylon, 20-40% of glassfiber and 10-30% of a halogen-free flame-retardant compound system, wherein the halogen-free flame-retardant compound system comprises, by weight, 60-85% of organic hypophosphite, 13-35% of polyphosphoboric acid melamine salt and 2-8% of a charring agent. The structural formula of the polyphosphoboric acid melamine salt is shown in the formula (I); in the formula, m refers to the molar ratio of two structural units including polyphosphoric acid melamine and boric acid, and m is equal to 3-6. The halogen-free flame-retardant glass fiber reinforced nylon adopts the novel halogen-free flame-retardant compound system, and the halogen-free flame-retardant compound system is low in solubility and high in char yield, so that the prepared halogen-free flame-retardant glass fiber reinforced nylon has an excellent flame-retardant effect and can reach the flame-retardant standard of UL94-V0(1.6mm). The formula is shown in the description.

Owner:江苏利思德新材料股份有限公司

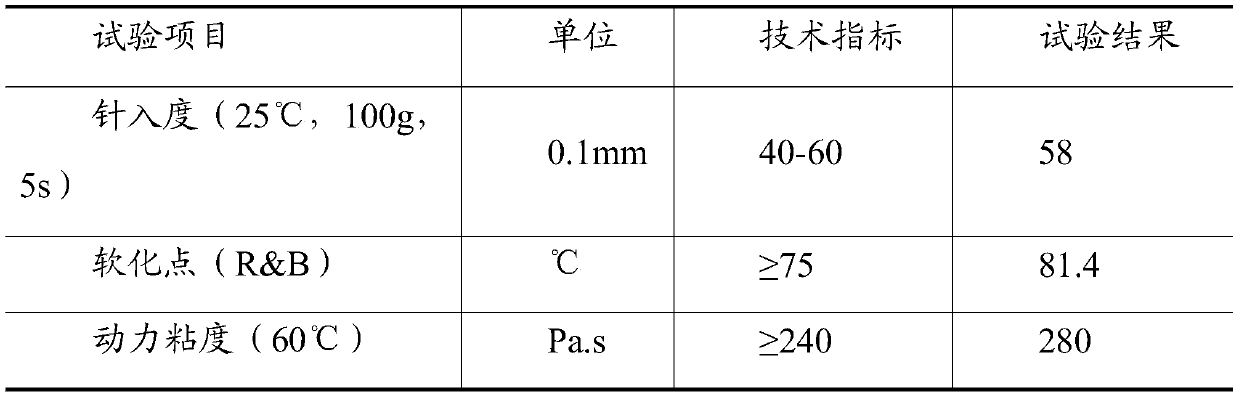

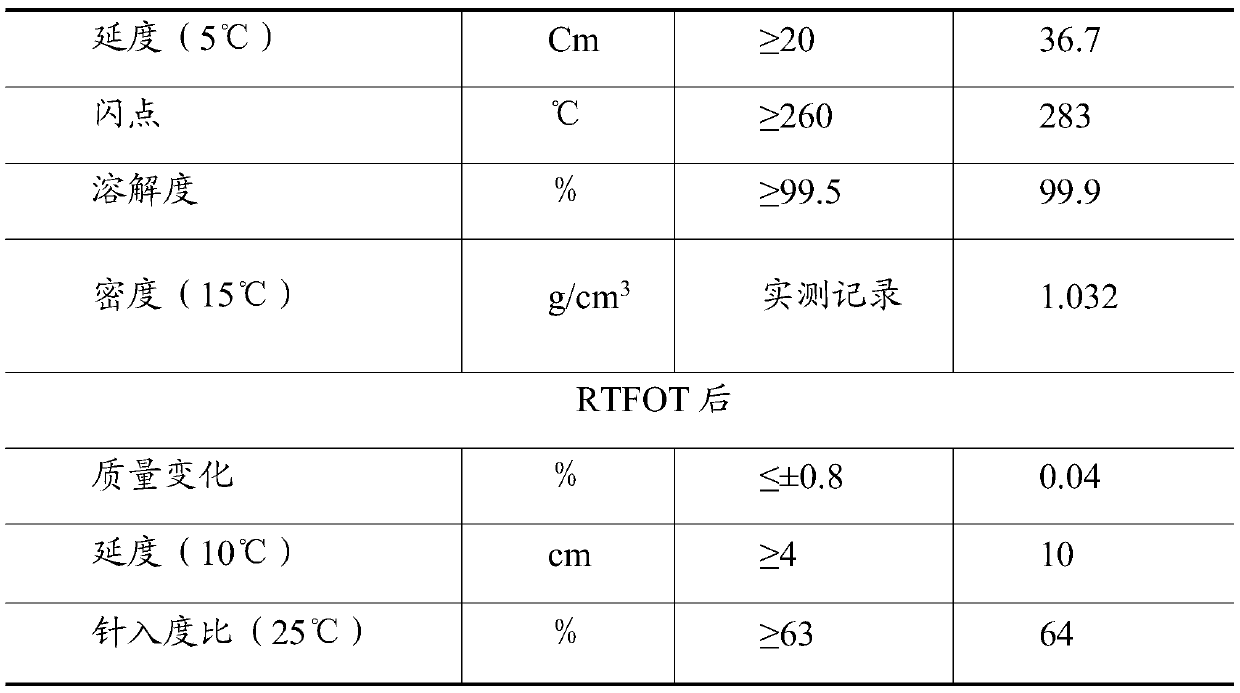

Asphalt flame retardant, preparation method and application

InactiveCN110204784ANon-toxic and harmlessLow smoke productionBuilding insulationsInsulation layerActive oxygen

The invention discloses an asphalt flame retardant, a preparation method and application of the asphalt flame retardant. Flame-retardant asphalt is formed by mixing 75-85% of SBS modified asphalt and15-25% of a flame retardant, the flame-retardant asphalt has good flame-retardant performance, an active oxide formed through heating decomposition of a metal hydroxide is a good fireproof material and covers the surface of the asphalt to form an insulation layer, flowing of combustible volatile substances is stopped, the situation is also slowed down that external oxygen permeates into the asphalt, so that a sufficient oxidation reaction of the burning surface is difficultly conducted, and accordingly the flame retardance and smoke inhibition function is achieved; the highest limit oxygen index reaches 29.2%, the synergistic flame retardance efficiency can reach 1.34, the influence on various technical indexes of the asphalt and an asphalt mixed material is small, no poisonous gas is generated, the asphalt flame retardant is safe and environmentally friendly, the production technology is simple, the quality is table, the cost is low, and the asphalt flame retardant has high economic applicability.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

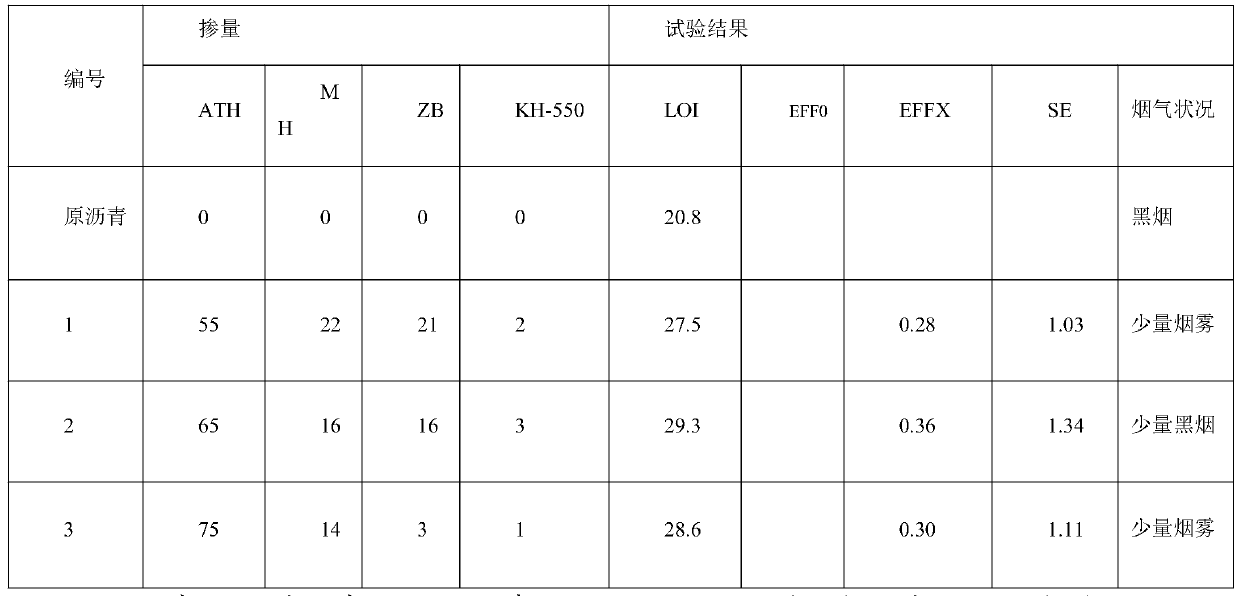

Method for calcining novel dry-method cement clinker by brown coal

The invention discloses a method for calcining novel dry-method cement clinker by brown coal, wherein the method comprises that the brown coal is sent to a decomposing furnace as a calcining fuel after crushed and homogenized. Based on characteristics of short combustion time of the decomposing furnace and long combustion time of a rotary kiln, the method of the invention uses brown coal to replace common novel dry-method soft coal as a fuel of the decomposing furnace, and the rotary kiln still uses soft coal or / and anthracite with characteristics of high heating value and long combustion time, wherein the brown coal has characteristics of low heating value, low price, fast flaming speed and short combustion time, and the soft coal has characteristics of high price and long combustion time. The method enables fuel characteristics to accord with different combustion characteristic requirements of the decomposing furnace and the rotary kiln, is in favor of raising a burn-off rate of coal dust and raising a decomposition speed of calcium carbonate, reducing buildups jam of a preheater system, enables a utilization rate of brown coal for producing novel dry-method cement to reach more than 60%, fully utilizes a local coal resource, raises an energy utilization rate, and further reduce a production cost of cement.

Owner:KUNMING IRON & STEEL HLDG CO LTD

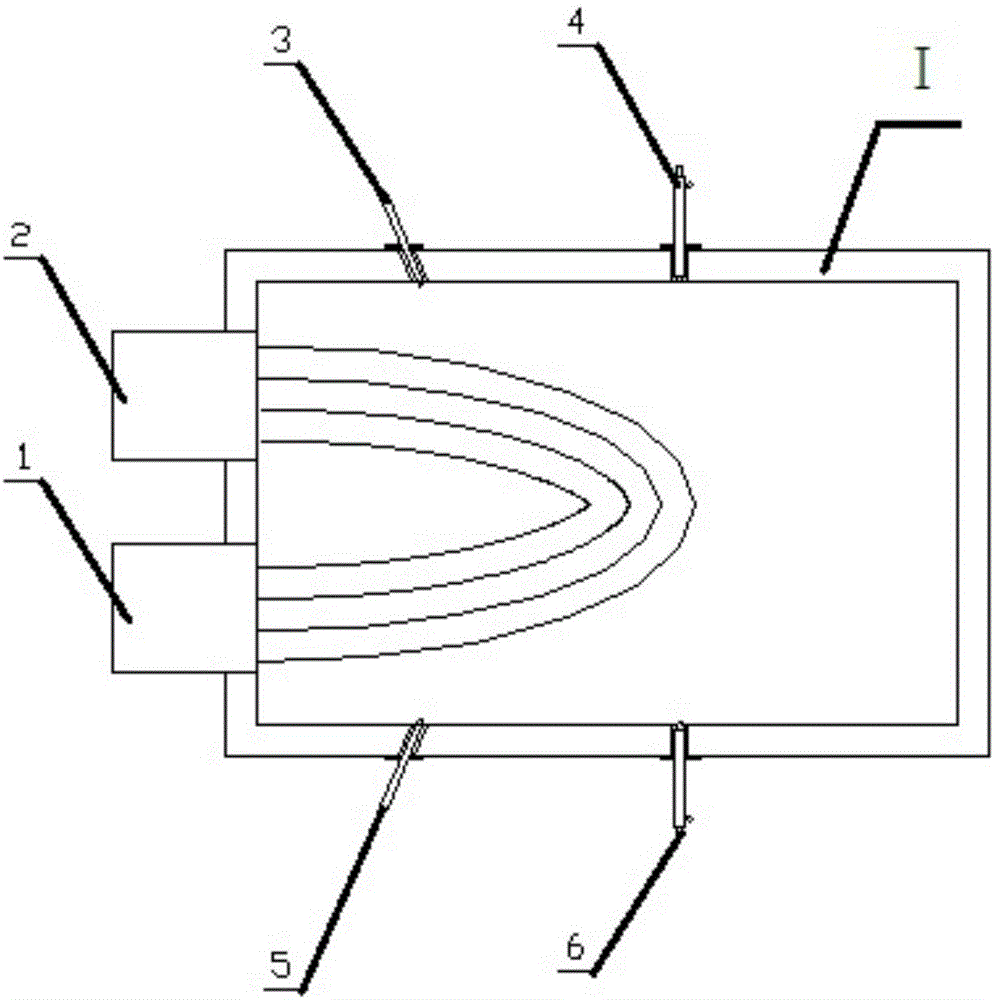

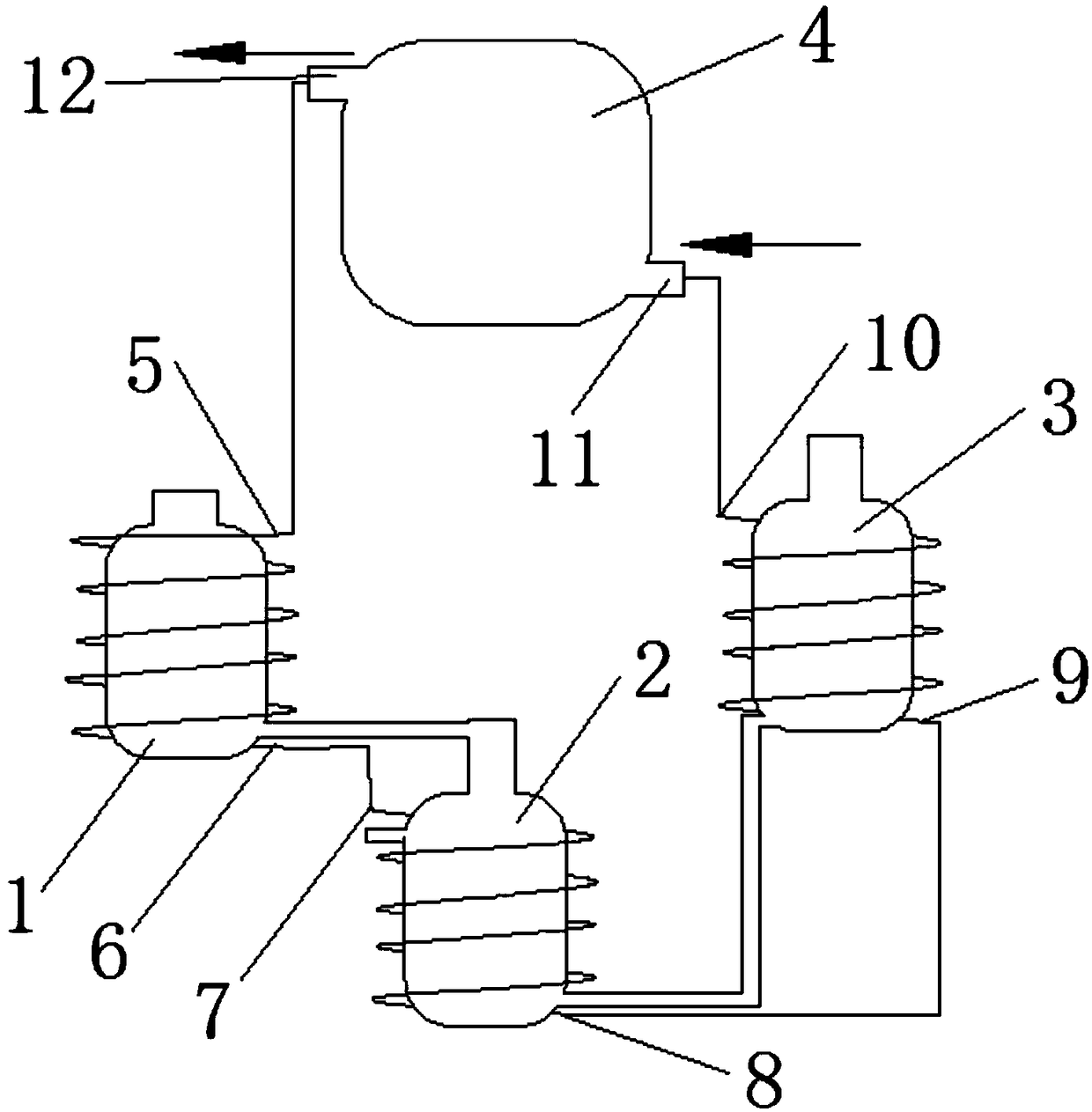

Staged pure oxygen combustion supporting system for horse shoe flame glass melting furnace and method thereof

ActiveCN106316076AUniform lengthIncrease heat loadGlass furnace apparatusGlass melting apparatusCombustionControl system

The invention discloses a staged pure oxygen combustion supporting system for horse shoe flame glass melting furnace and a method thereof. The system comprises two pure oxygen combustion spray guns, two pure oxygen lances and an oxygen pipeline control system, wherein the pure oxygen lances and the pure oxygen combustion spray guns are symmetrically arranged on breast walls of the left side and the right side of the horse shoe flame glass melting furnace in sequence from front to back, and the oxygen pipeline control system is connected with the pure oxygen lances and the pure oxygen combustion spray guns and is used for controlling the switching of the pure oxygen lances and the pure oxygen combustion spray guns, and adjusting the flow of oxygen in the pure oxygen lances and the pure oxygen combustion spray guns and the proportion between fuel and oxygen in the pure oxygen combustion spray guns. For the horse shoe flame glass melting furnace, after adopting the staged pure oxygen combustion supporting system and the method, the NOX emission concentration is reduced by 30-40%, and the total energy consumption is reduced by 2-4%, thus saving energy consumption and reducing pollution to environment.

Owner:QINHUANGDAO GLASS IND RES & DESIGN INST

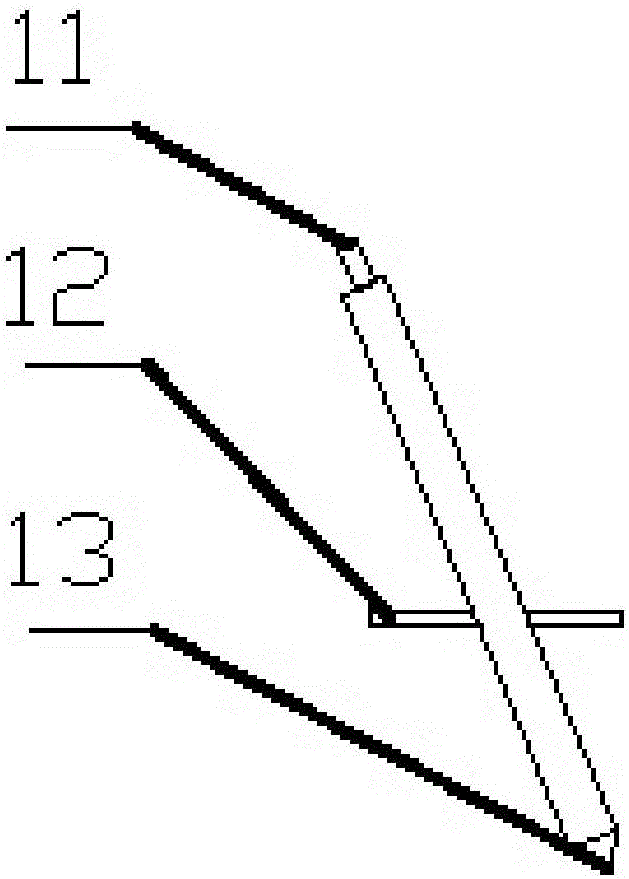

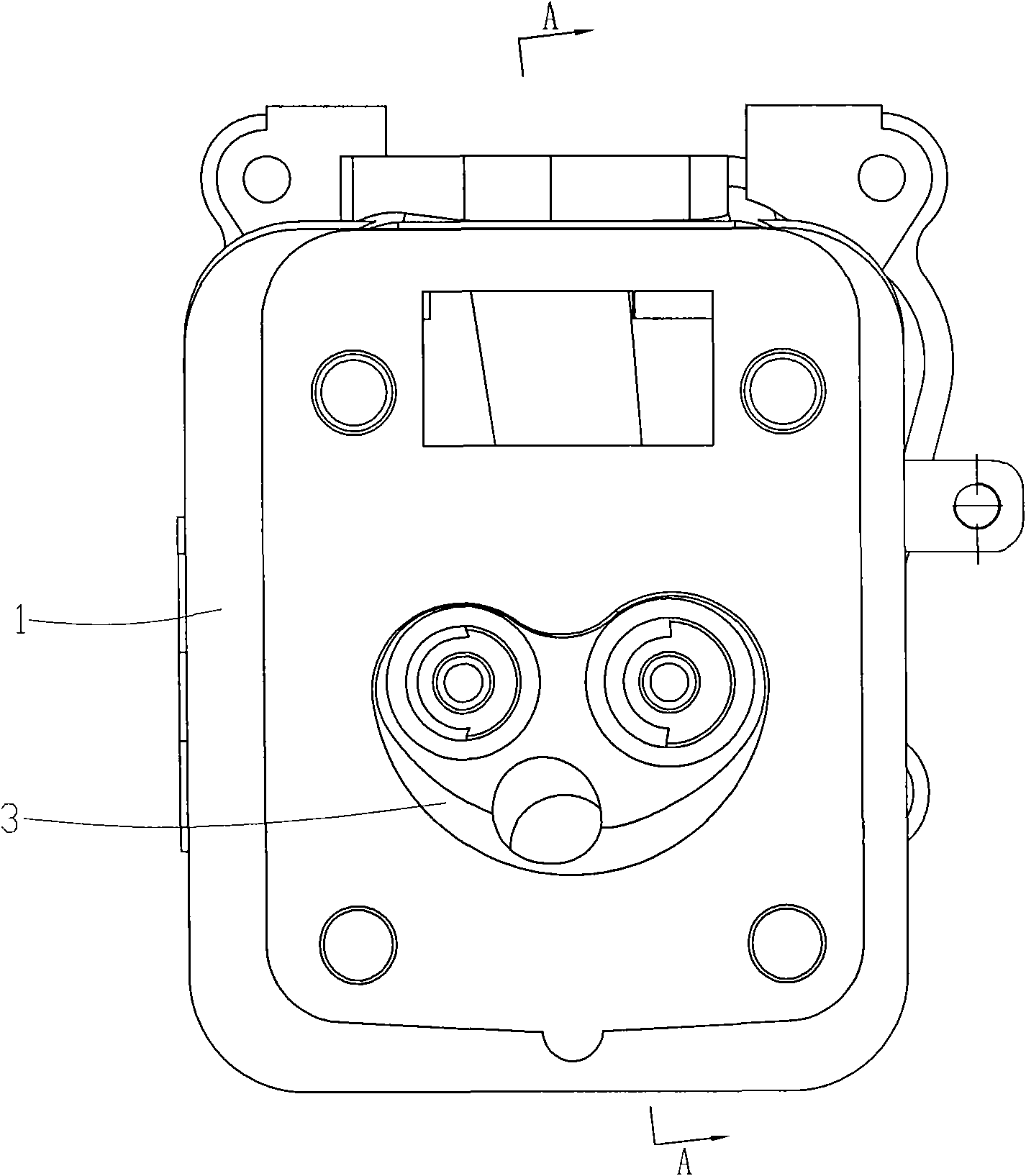

Energy-saving motorcycle engine cylinder head

InactiveCN106870193AIngenious designSimple structureInternal combustion piston enginesCylinder headsAutomotive engineeringPressure rise

The invention discloses an energy-saving motorcycle engine cylinder head. The energy-saving motorcycle engine cylinder head comprises a cylinder head basal body; the bottom middle of the cylinder head basal body is a combustion cavity with a flaring structure; and an intake channel and an exhaust channel communicated with the combustion cavity are respectively formed in the left and right two sides of the top of an inner cavity of the combustion cavity. The energy-saving motorcycle engine cylinder head adopts the combustion cavity designed as the flaring structure and with the bottom as the conical surface design; when the internal volume of the combustion cavity is increased to improve the contribution and the torque of an engine, the surface-to-volume ratio of the combustion cavity is small, the flame propagation distance and the combustion time are short, the pressure rise speed is fast, and the combustion is more thorough; and the energy-saving motorcycle engine cylinder head is simple in structure, can realize the purposes of energy conservation and emission reduction, and can be popularized and applied.

Owner:重庆正柱电子工程有限公司

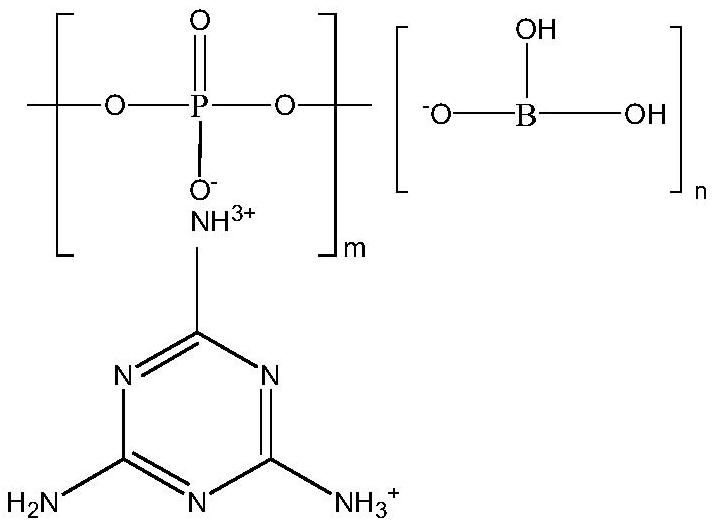

Halogen-free flame retardant melamine poly-phosphate borate as well as preparation method and application thereof

ActiveCN109679138AImprove water absorptionImprove charcoal efficiencyOrganic chemistryPolyesterPhosphate

The invention discloses melamine poly-phosphate borate as well as a preparation method and an application thereof. The structural formula of melamine poly-phosphate borate is shown in the following formula (I) in the description, wherein m is the molar ratio of two structural units of melamine poly-phosphate borate and boric acid and is 3-6. The preparation process comprises the steps as follows:a. dispersing melamine in water, mixing the melamine solution with phosphoric acid, and performing thermal reaction at 70-100 DEG C to obtain an intermediate; b, mixing boric acid with water until boric acid is completely dissolved, then mixing the solution with the intermediate prepared in the step a, and continuously raising the temperature to 80-100 DEG C for thermal reaction to obtain an intermediate product; c, performing thermal treatment on the intermediate product prepared in step b at 300-360 DEG C. Melamine poly-phosphate borate prepared with the process has the advantages of good water absorption resistance and high carbonization efficiency, and can be compounded with organic hypophosphite for flame retardant treatment on engineering plastics such as glass fiber reinforced nylon, polyester and the like.

Owner:JIANGSU LISIDE NEW MATERIAL

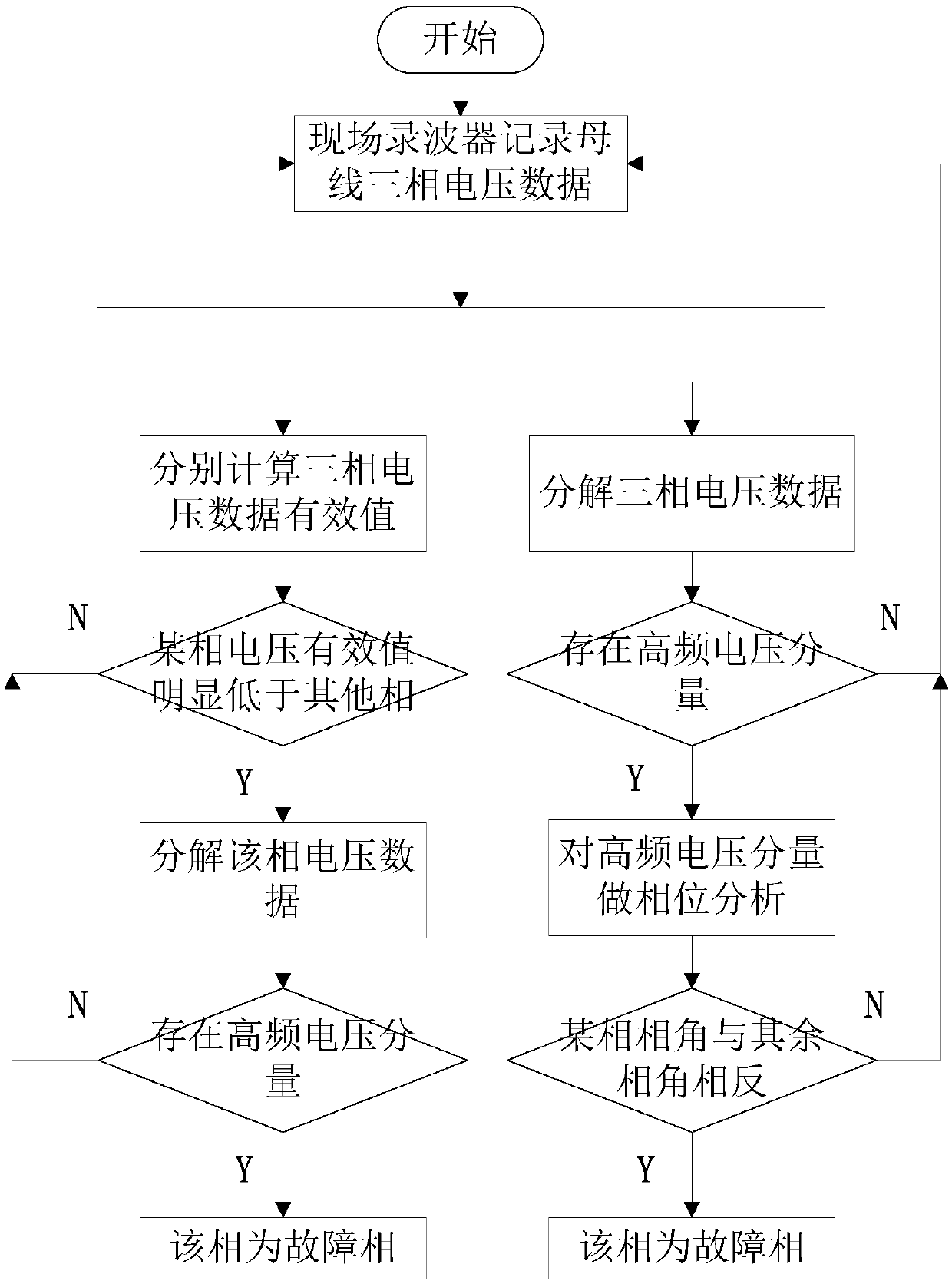

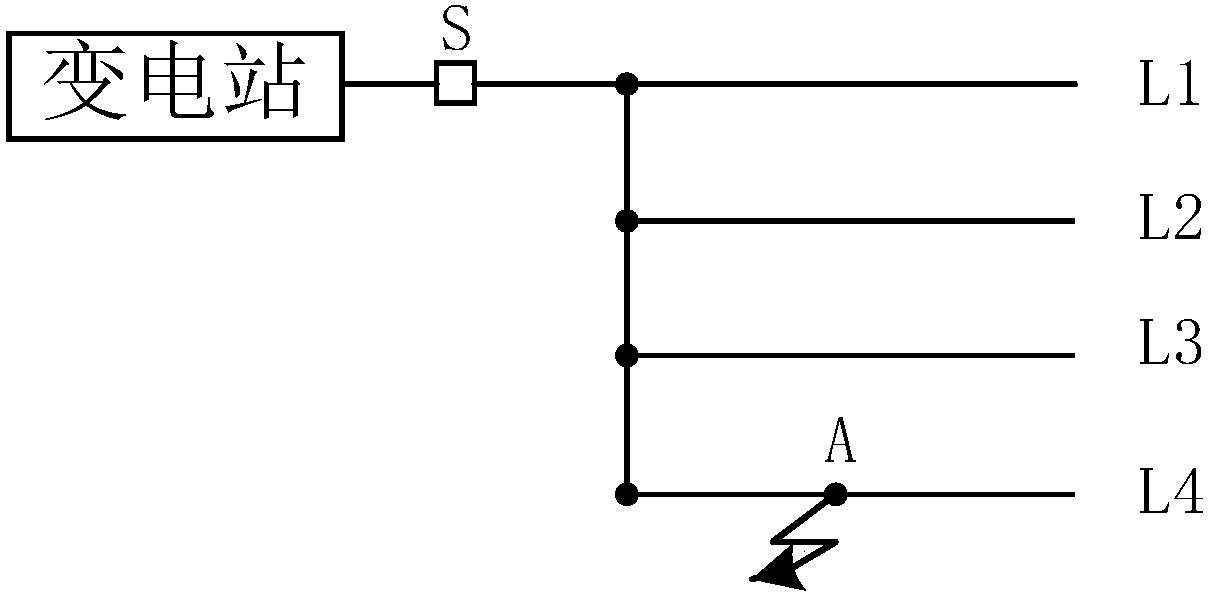

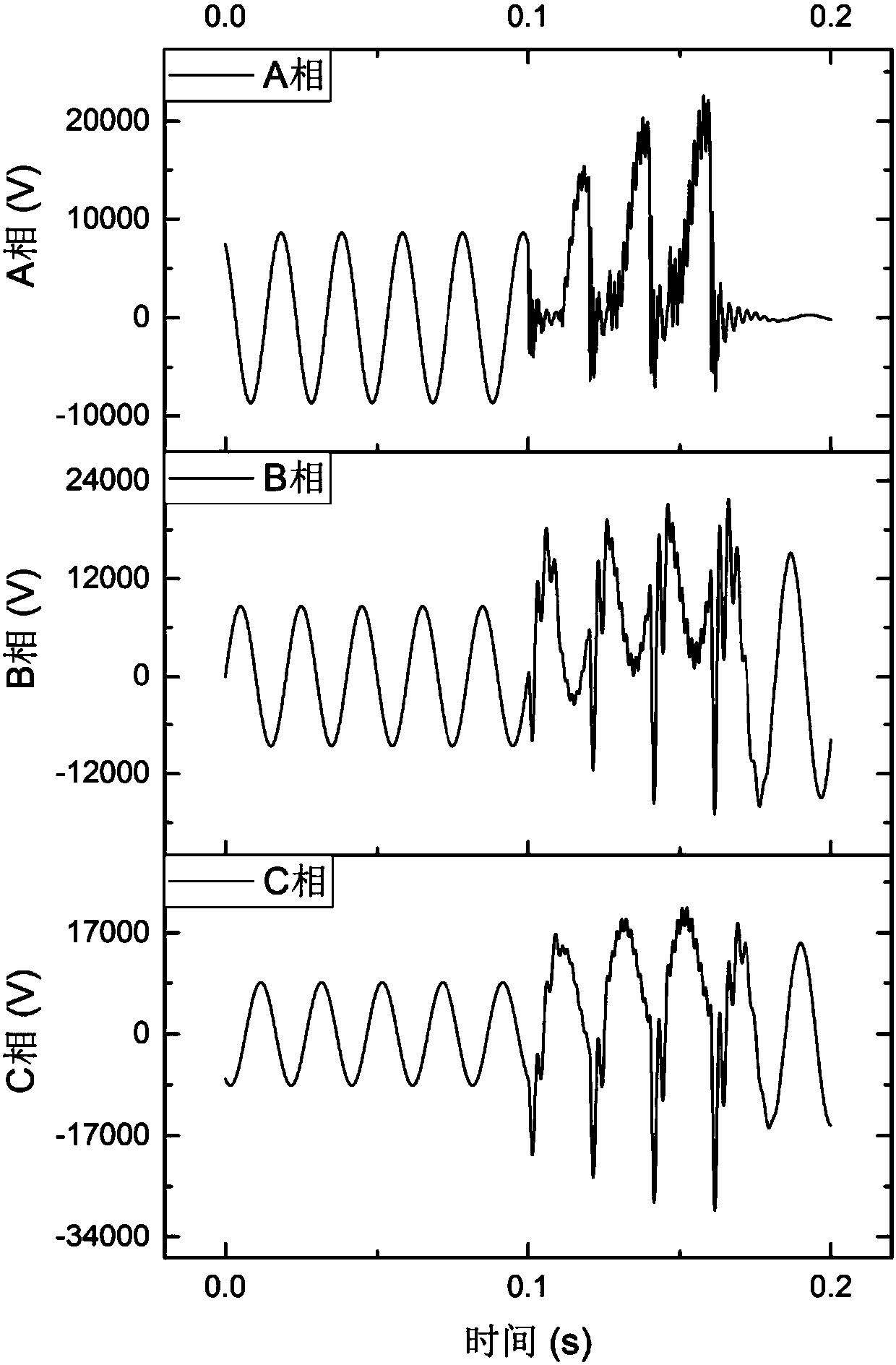

Fault phase determining method of arc extinguishing cabinet based on transient high-frequency component

The invention discloses a fault phase determining method of an arc extinguishing cabinet based on a transient high-frequency component. A traditional fault phase determining method of the arc extinguishing cabinet based on a single criterion, that the effective voltage value of the fault phase approaches 0 after a single-phase arc grounding fault, is low in accuracy causes cases of fault phase determining errors onsite, and threatens the reliability of the power system. According to the fault phase determining method of the invention, the criterion that the high-frequency component phase of the fault phase after arc extinguishing is opposite to the high-frequency component phase of a non-fault phase is used, and the criteria that the effective value of the fault phase is reduced before arcextinguishing and a high frequency component only exists in the fault phase are also used, so that the fault phase can be determined accurately and rapidly.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

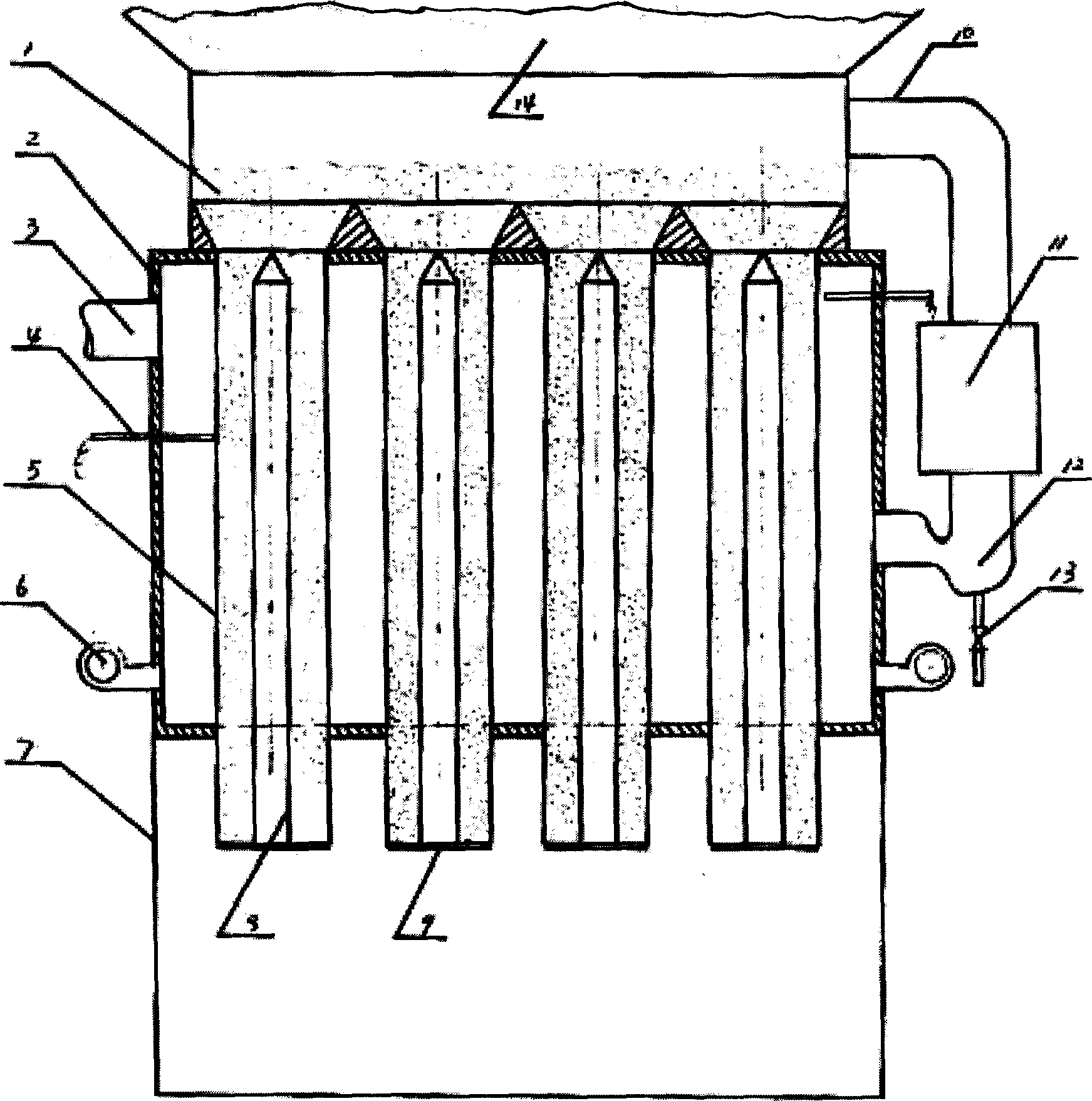

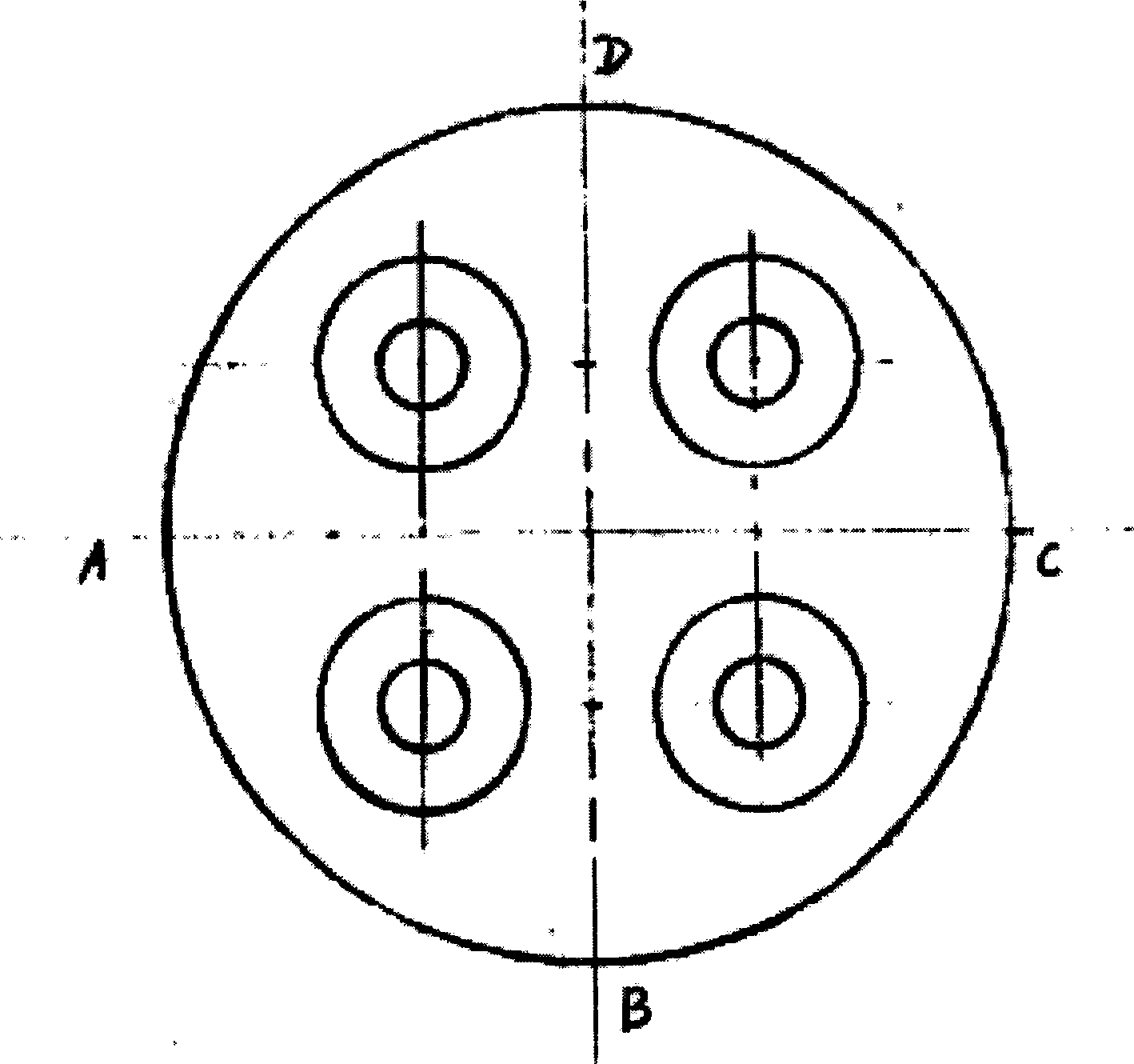

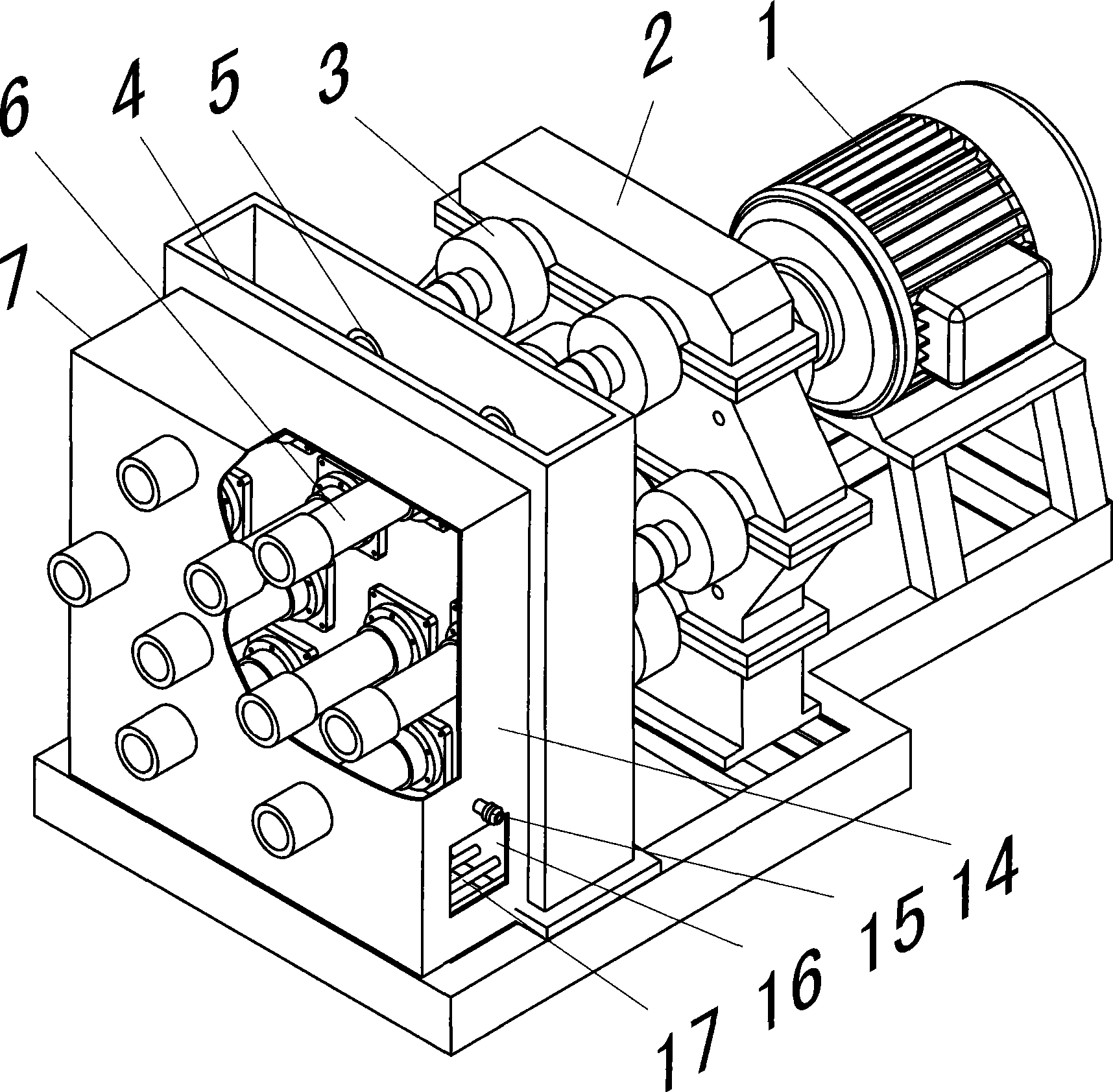

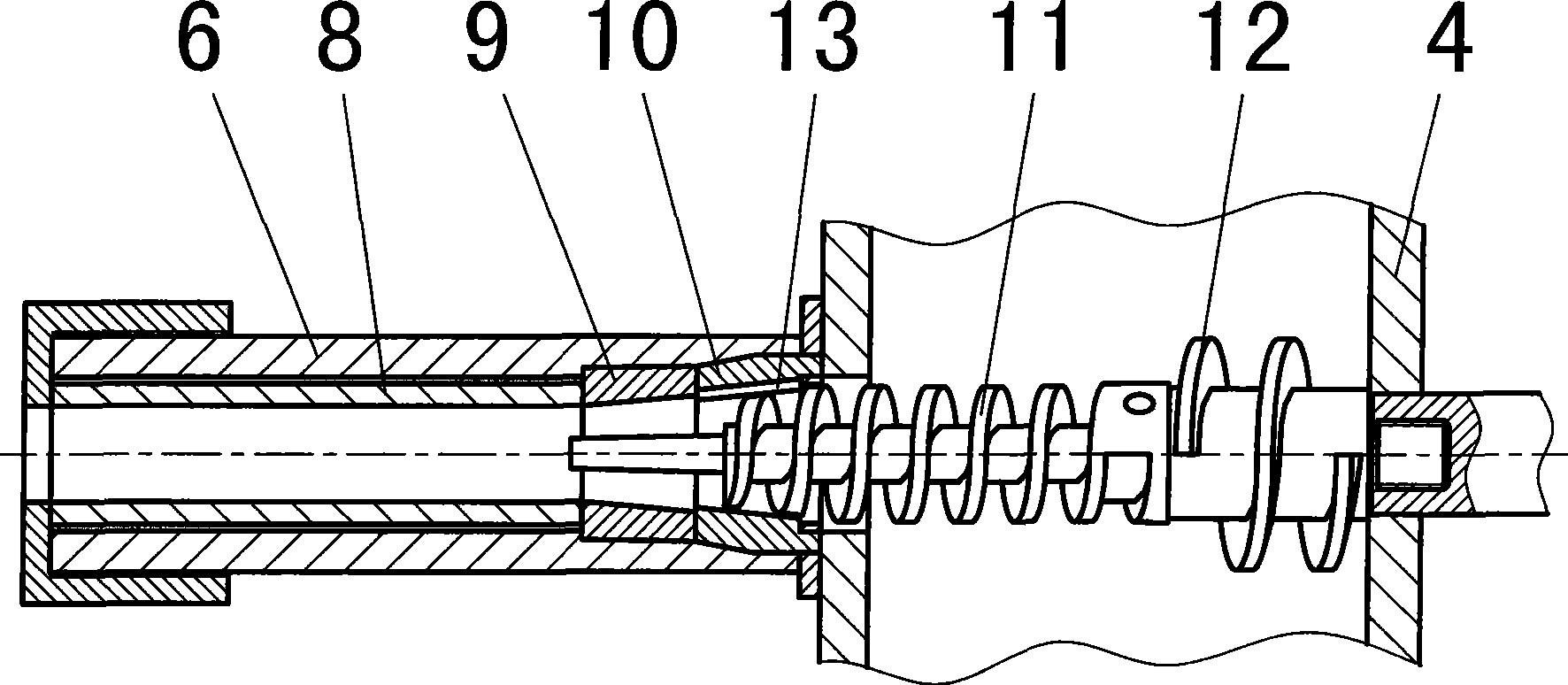

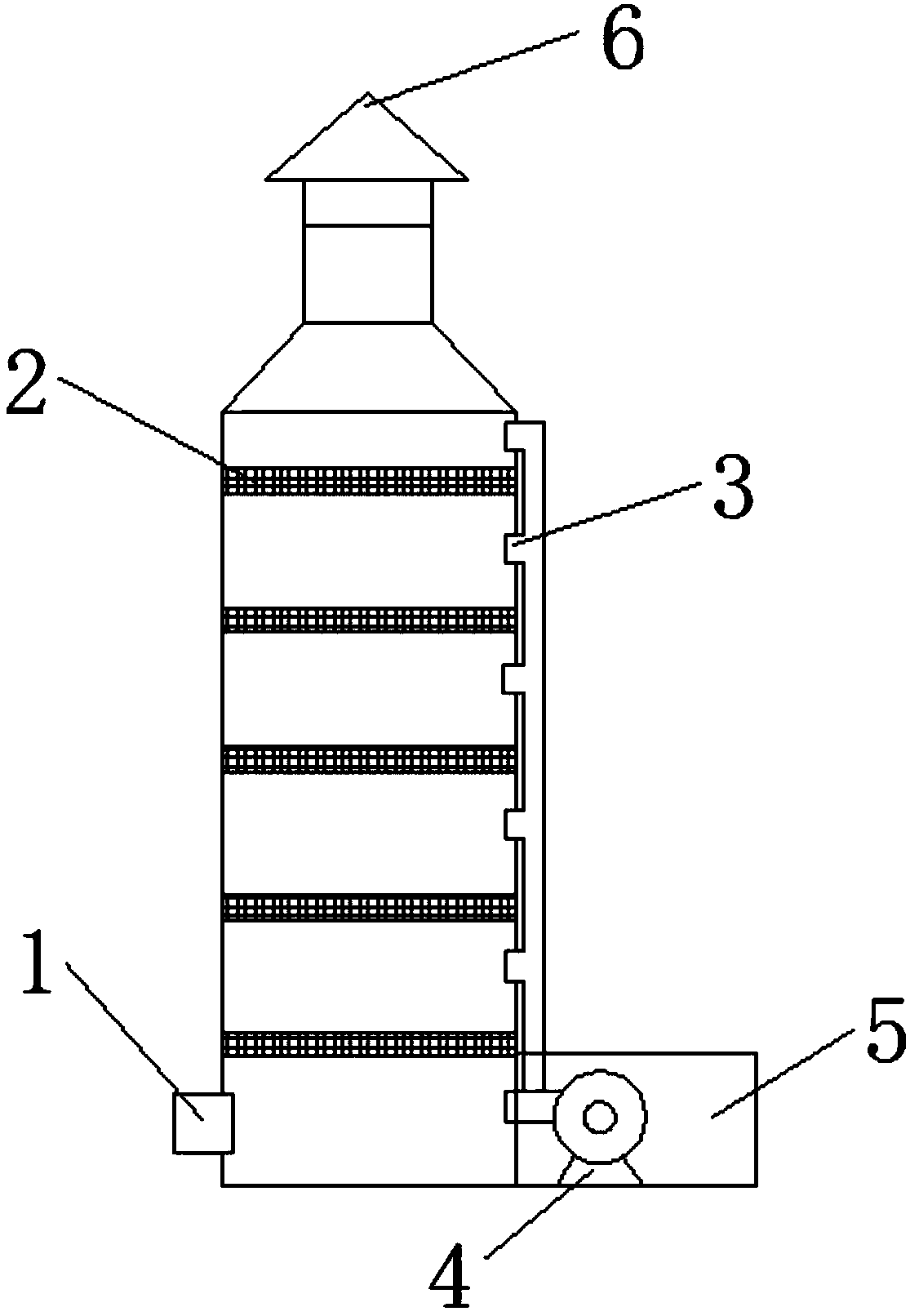

Multi-head rod making method and used energy-saving environmental protection rod making device

InactiveCN101391428ALow efficiencyImprove efficiencyDomestic articlesWood charring/burningReduction driveFlue gas

The invention discloses a multi-head rod making method and an energy saving and environmental protection rod making machine used by the method. The method uses a multi-output shaft reducer, each output shaft of the reducer drives a set of rod pressing device which is located in a charging bucket, a feeder and a spiral presser in the rod pressing device together press the raw material sawdust in the charging bucket to form a sawdust rod from the hole of a long internal sleeve through an exhausting sleeve and a compressing sleeve. The sawdust in the long internal sleeve is simultaneously heated during the course of pressing. The invention can realize an intensive production of machine-made charcoal, the occupied area of the workshop is reduced, the energy consumption is reduced, and the flue gas is recycled beneficially. The pollution of the working environment in the production zone is reduced, the working environment is improved, and the production is increased. The charcoal made out is loose outside but tight inside, the production quality of the charcoal can be improved, the burning of the charcoal in the course of combustion is fast, the combustion time after burned is as long as 4 to 5 hours, the residual ash on the surface is easily shed, the heat value reaches about 8000 kcal, and the equipment is easy to be maintained, so the maintenance cost of the equipment is reduced.

Owner:李观德

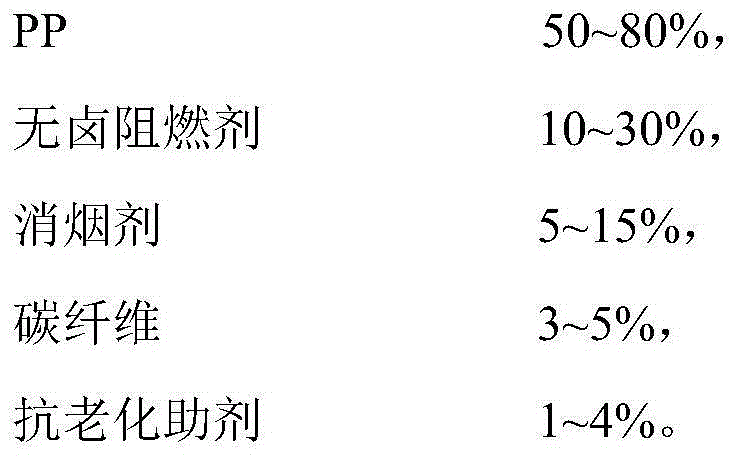

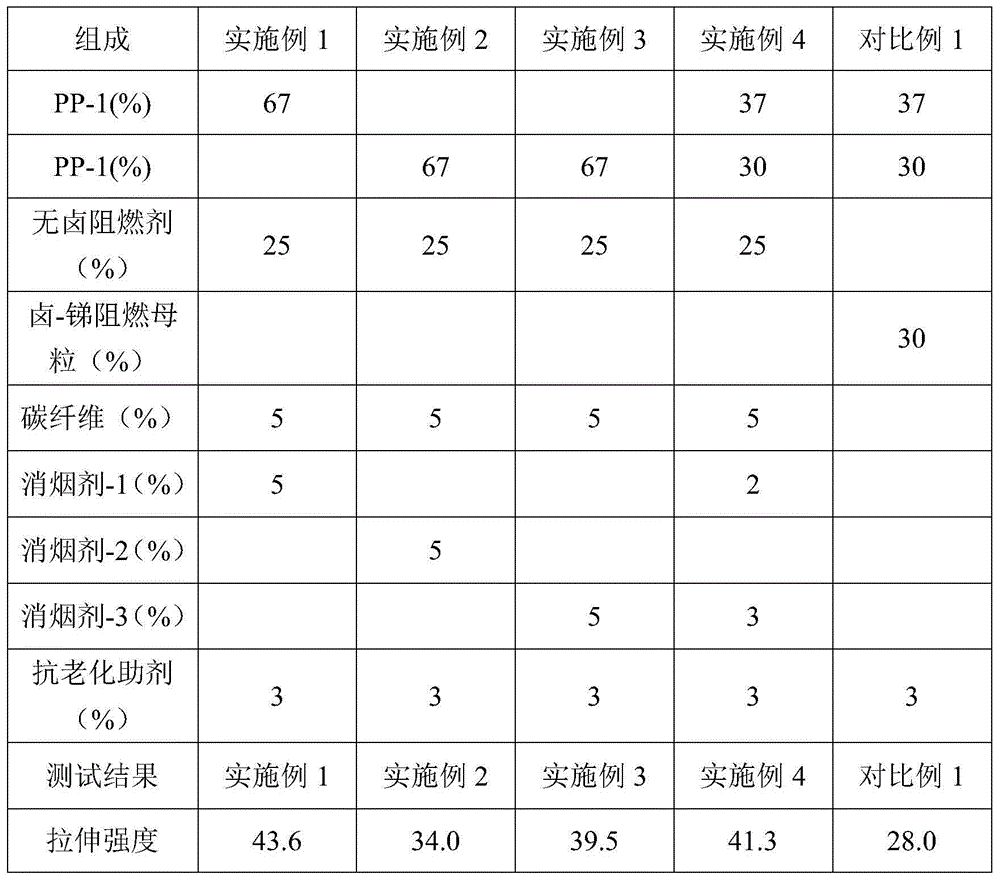

High-weather-resistance low-smokiness and high-rigidity flame-retardant reinforced PP blending material and preparation method thereof

The invention discloses a high-weather-resistance low-smokiness and high-rigidity flame-retardant reinforced PP blending material and a preparation method thereof. The high-weather-resistance low-smokiness and high-rigidity flame-retardant reinforced PP blending material comprises the following formula in percentage by weight: 50%-80% of PP resin, 10%-30% of halogen-free environment friendly fire retardants, 5%-15% of smoke suppressors, 3%-5% of carbon fibers and 1%-4% of anti-aging auxiliary agents, wherein the carbon fibers are subjected to surface activation treatment. By adopting the technical scheme, the flame-retardant reinforced PP blending material disclosed by the invention has high weather resistance and extremely small smoking amount and can be used for enhancing the surface carbonizing effect of the fire retardants through good synergistic effect of the added carbon fibers and the halogen-free environment-friendly fire retardants, keeping the fire retardance of a material and obviously improving the mechanical property of the material, thereby reflecting the application characteristics of outstanding high property and high environmental friendliness.

Owner:ZHEJIANG PRET NEW MATERIALS +2

Incineration method for salt-contained organic mixed waste liquid

InactiveCN106122981AStable combustion cycleEfficient combustion cycleEmission preventionIndirect carbon-dioxide mitigationHigh concentrationTherapeutic effect

The invention discloses an incineration method for salt-contained organic mixed waste liquid. The method includes the steps of separation, incineration, waste heat recovery and tail gas purification. In the incineration step, an air blower and a combustor are started, the temperature of an incinerator reaches 500 DEG C-1200 DEG C, compressed air is led into the waste liquid, the compression air leading-in amount is controlled to range from 0.6 L to 0.7 L, the waste liquid is thrown into the waste liquid combustor after being atomized, the temperature of a high-temperature combustion furnace ranges from 1150 DEG C to 1900 DEG C, and the incineration time ranges from 2 s to 7 s. According to the incineration method for the salt-contained organic mixed waste liquid, the combustion time is short, the combustion efficiency is high, energy conservation and consumption reduction are achieved, and continuous and stable operation can be achieved through the method; high-temperature hot air is led into the incinerator combustor, and therefore an efficient and stable combustion cycle of the high-concentration organic salt-contained waste liquid is ensured; and the high-concentration salt-contained organic waste liquid and high-concentration organic salt-contained waste water or waste oil are combusted through atomization of the compressed air, and a treatment effect is good.

Owner:NANTONG FANGDU ESTATE CO LTD

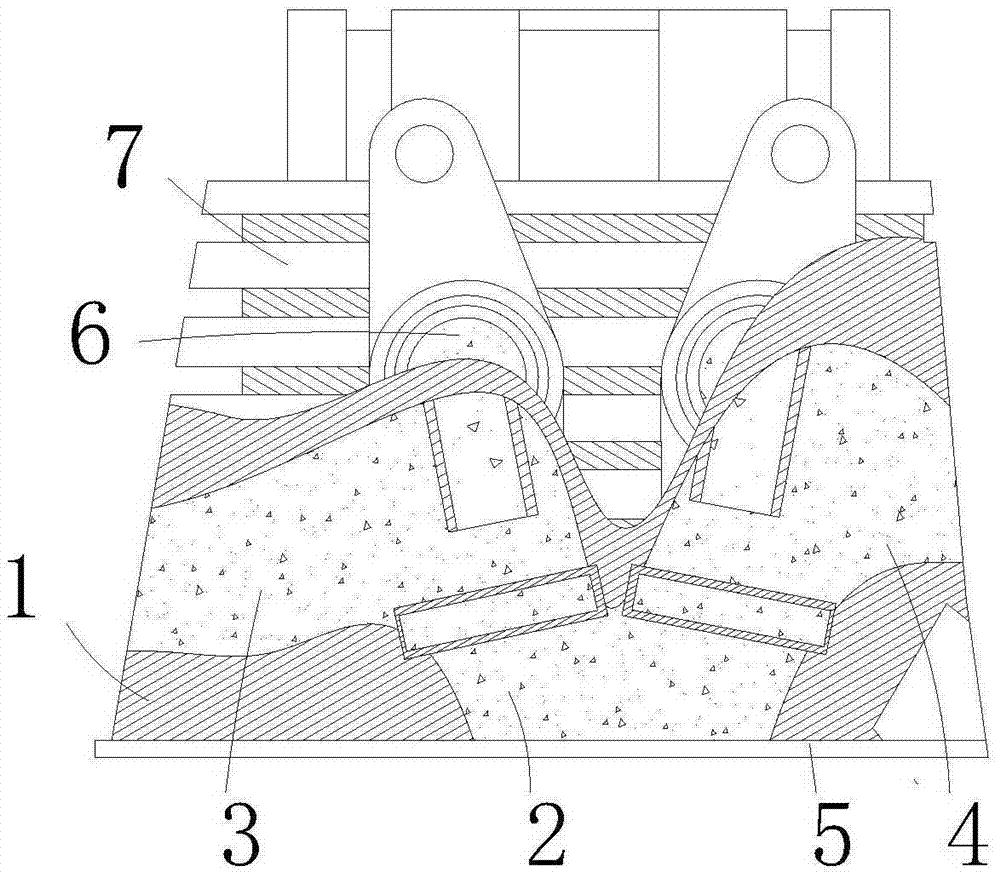

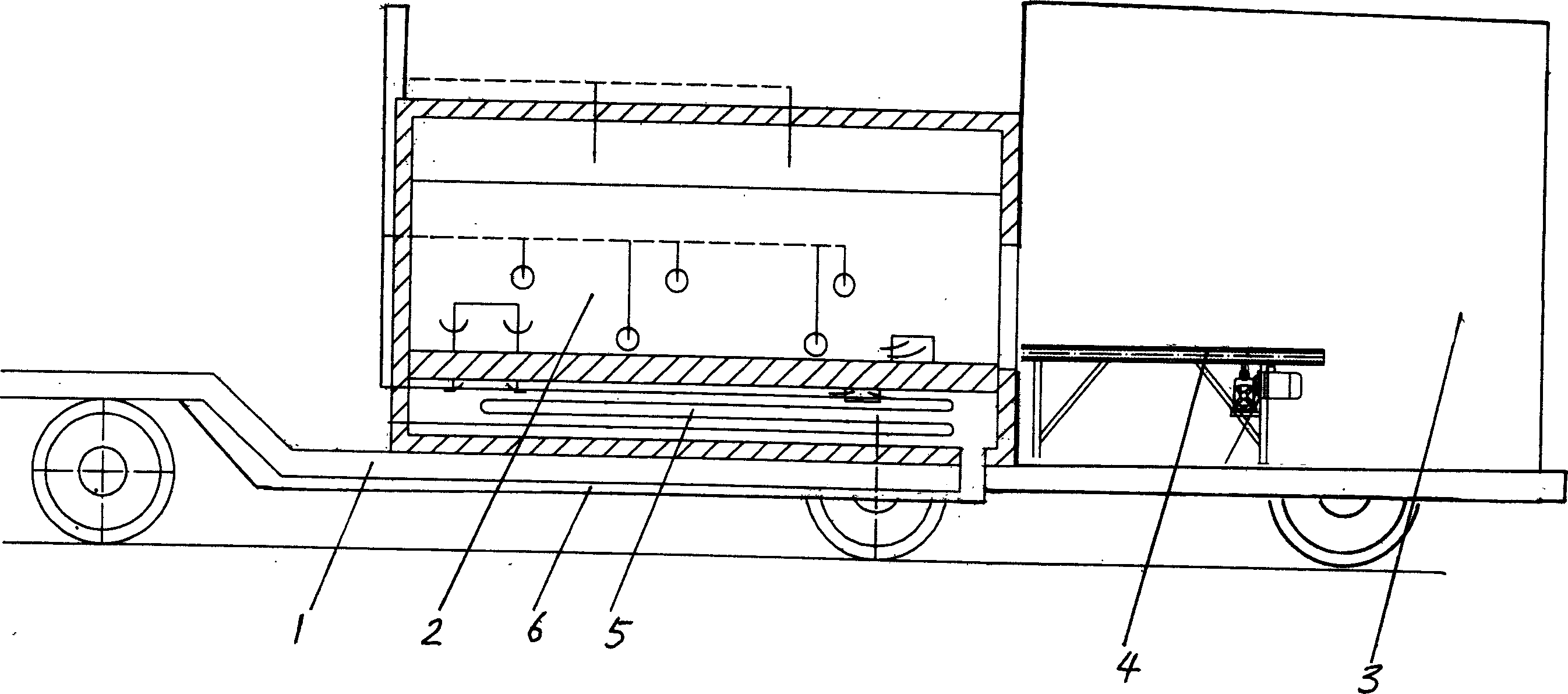

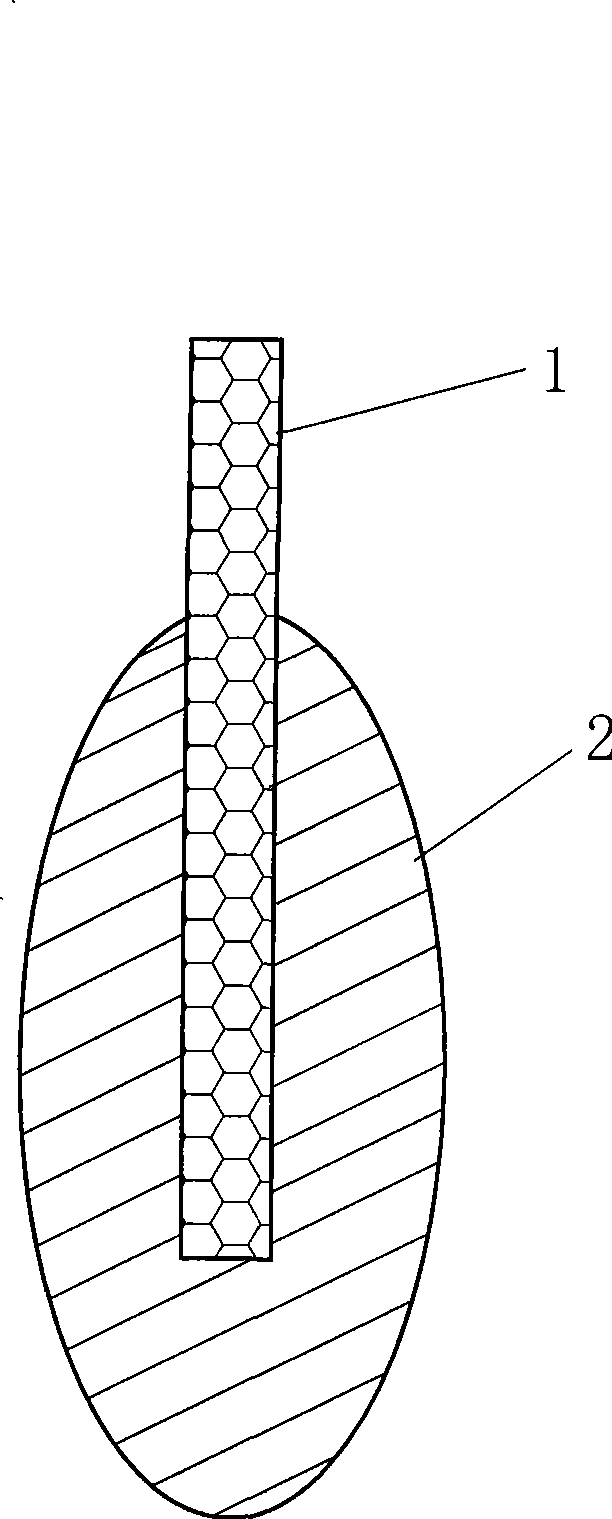

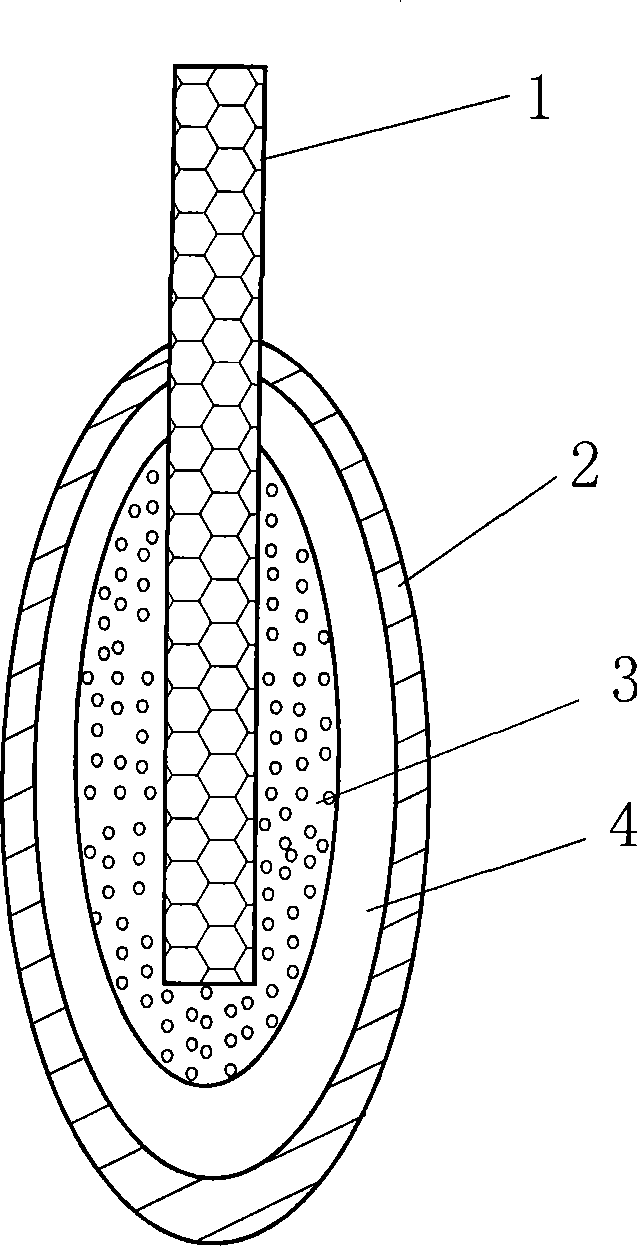

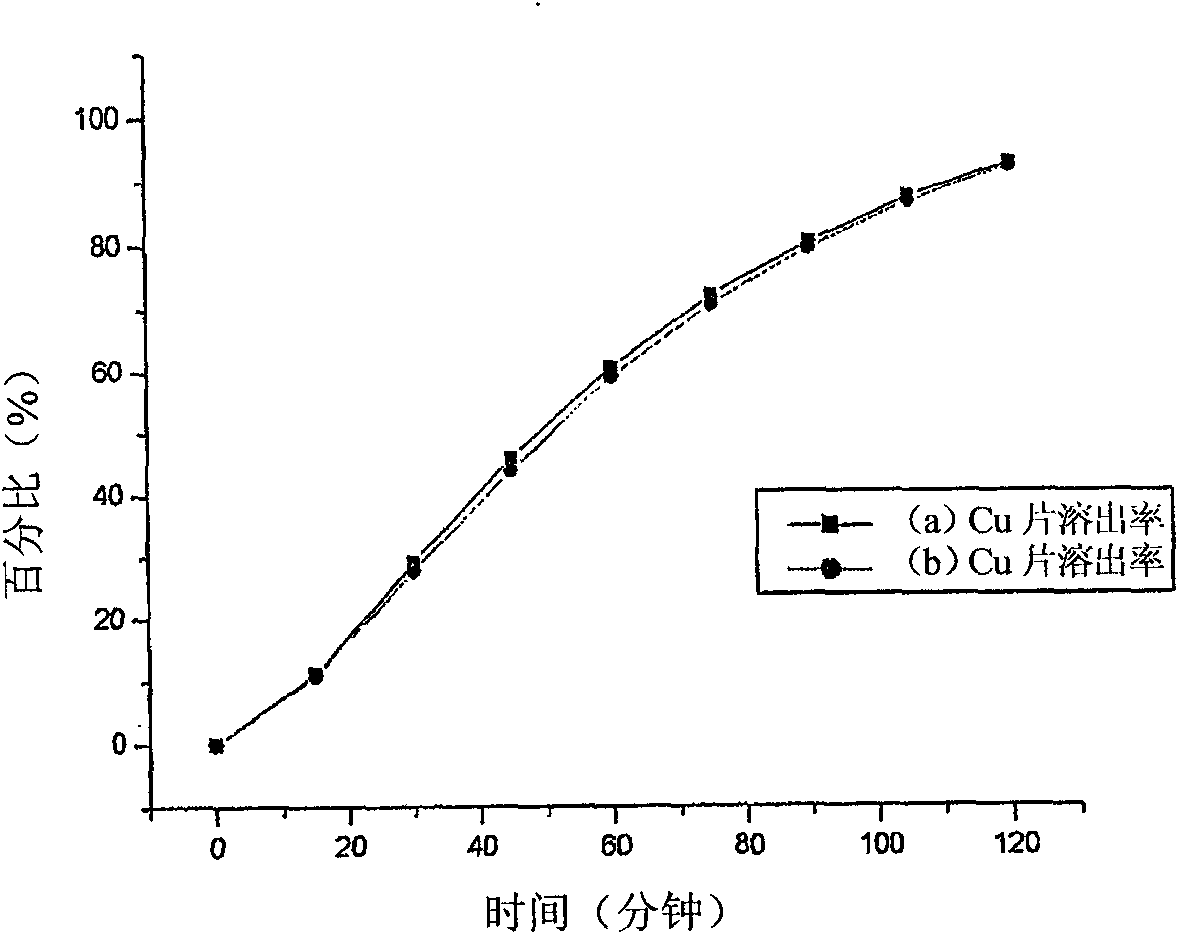

Mobile morgue

InactiveCN101084856ABurn fullyReduce fuel consumptionFuneral devicesCremation furnacesCombustionEngineering

The invention relates to cadaveric cremation and funeral parlour, specifically to a moving funeral parlour, which is provided with trailer, cremation machine and container. Cremation machine with carcase input port rearward is arranged at the forepart of the trailer. Container with arranged at the posterior part of the trailer and is provided with carcase input port at the position corresponding to the input port and a carcase deliver vehicle. The invention has the advantages of complete combustion, high efficiency, no enviromental pollution, low oil consumption, short combustion time, simple operation, good legerity and flexibility, and high maneuverability; and is especially suitable for countryside, troop or underpopulated zone.

Owner:丁云波

Firework bright bead and manufacture technology thereof

The invention provides a firework bright bead and manufacture technology thereof. One end of a lead is adhered with photochromic powder, so the bright bead forms a specific geometrical shape. When manufacturing the bright bead, appropriate drying is carried out after the photochromic powder is adhered each time, until the required shape is formed. The invention overcomes the shortcomings of the prior art in firing effect and safety production, and the bright bead can generate special effects of sibilant rale, rotation or firework spraying.

Owner:邹国文

Method for synthesizing metal products by using metal-bearing article

The invention discloses a method for synthesizing metal products by using a metal-bearing article, which comprises the steps of: dissolving metal which is contained in the metal-bearing article with acid liquid and used for synthesizing metal products; and selecting a precipitation way of adding alkali or a burning way of adding fuel to obtain the metal products. The method does not comprise metal smelting and purifying steps and has the advantage of simple and consistent technical process.

Owner:余炳盛 +1

A halogen-free flame retardant glass fiber reinforced nylon

ActiveCN109627758BHigh flame retardant efficiencyImprove mechanical propertiesGlass fiberPolymer science

The invention discloses halogen-free flame-retardant glass fiber reinforced nylon. The halogen-free flame-retardant glass fiber reinforced nylon comprises, by weight, 30-60% of nylon, 20-40% of glassfiber and 10-30% of a halogen-free flame-retardant compound system, wherein the halogen-free flame-retardant compound system comprises, by weight, 60-85% of organic hypophosphite, 13-35% of polyphosphoboric acid melamine salt and 2-8% of a charring agent. The structural formula of the polyphosphoboric acid melamine salt is shown in the formula (I); in the formula, m refers to the molar ratio of two structural units including polyphosphoric acid melamine and boric acid, and m is equal to 3-6. The halogen-free flame-retardant glass fiber reinforced nylon adopts the novel halogen-free flame-retardant compound system, and the halogen-free flame-retardant compound system is low in solubility and high in char yield, so that the prepared halogen-free flame-retardant glass fiber reinforced nylon has an excellent flame-retardant effect and can reach the flame-retardant standard of UL94-V0(1.6mm). The formula is shown in the description.

Owner:JIANGSU LISIDE NEW MATERIAL

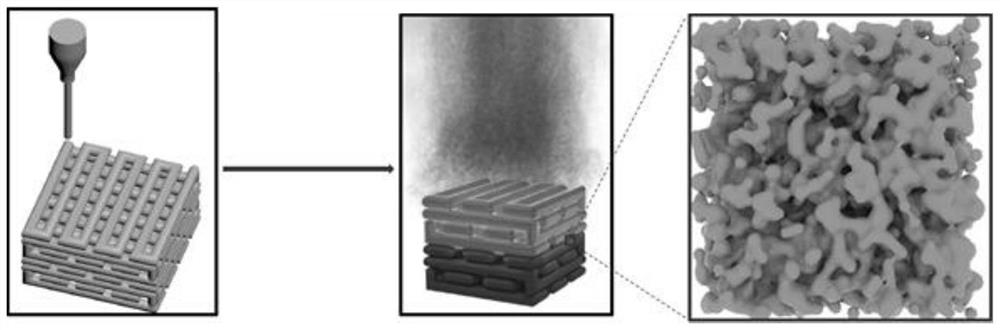

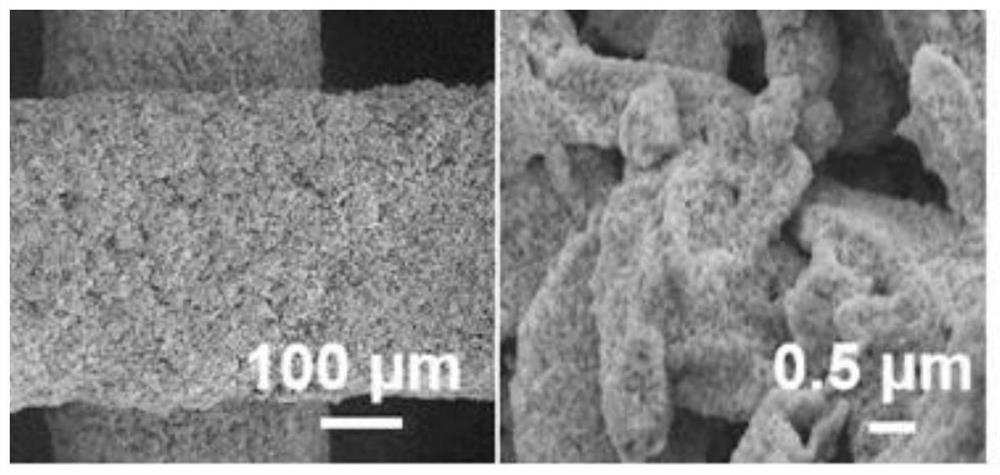

Combustible 3D direct writing ink, and preparation method and application thereof

ActiveCN113426995AImprove adjustabilitySimple structureAdditive manufacturing apparatusIncreasing energy efficiencyPrinting inkMetal powder

The invention provides combustible 3D direct writing ink, and a preparation method and application thereof. Combustible printing ink disclosed by the invention is formed by adopting metal powder as a shape maintaining material, taking an oxide of the corresponding metal powder as an oxidizing agent, adopting a water-soluble polymer as a fuel, adding the materials into water and uniformly mixing the materials; the combustible printing ink can be ignited by means of a hot table, etc.; after 3D direct writing printing is used to ignite an ink printing structure, a graded hole electrochemical electrode is prepared; compared with the prior art, the ink is novel in formula; the ink prepared by adopting the formula is used for 3D printing; the printing process is simple to operate; the production period is short; and the graded hole electrochemical electrode can be prepared on a large scale.

Owner:WESTLAKE UNIV

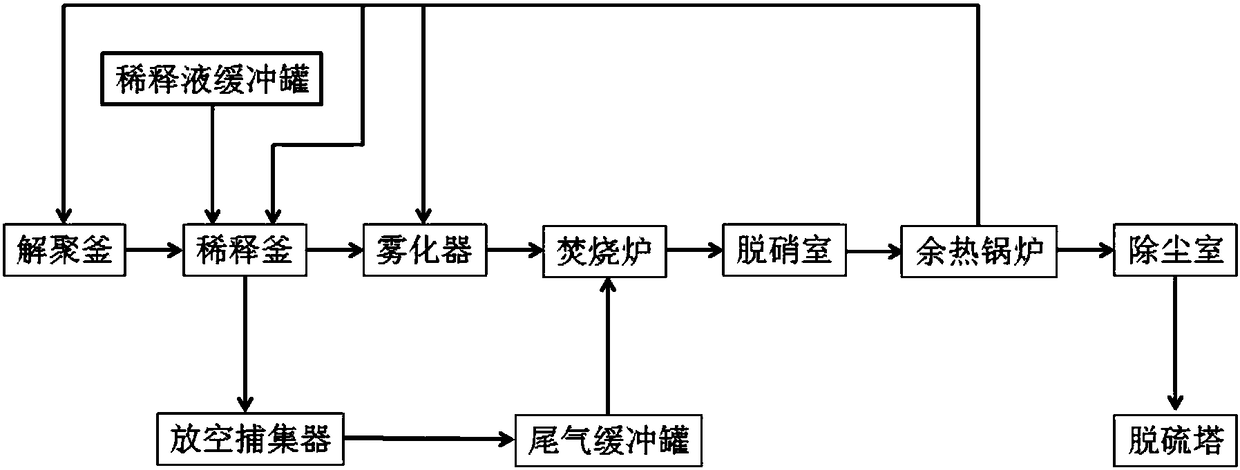

Treatment system and method for acrylic acid and ester waste oil of acrylic acid

PendingCN108413413ALow viscosityImprove combustion effectCombination devicesLiquid fuel feeder/distributionEmission standardWaste oil

The invention discloses a treatment system and method for acrylic acid and ester waste oil of the acrylic acid. The treatment system comprises a depolymerizing kettle, a diluent buffer tank, a diluting kettle, an emptying and trapping machine, a tail gas buffer tank, an atomizer, an incinerator, a denitrating tower, a waste heat boiler, a dust removal chamber and a desulfurization tower. The treatment method is characterized in that organic waste acid is used for diluting the acrylic acid and the ester waste oil of the acrylic acid so as to reduce the viscosity of the acrylic acid and the ester waste oil of the acrylic acid, then the acrylic acid and the ester waste oil of the acrylic acid are thoroughly treated after undergoing atomization, incineration, denitration, waste heat recovery,dust removal and desulfuration and can meet the national emission standards, and meanwhile, steam which is generated through burning heat of the acrylic acid and the ester waste oil of the acrylic acid is returned to a production line for recycling. According to the treatment system and method, the breakthrough design concept of using waste to treat waste is adopted, pretreatment, atomization, incineration, denitration, waste heat recovery, dust removal and desulfuration of the acrylic acid and the ester waste oil of the acrylic acid are integrated, various flue gas emission indexes are far lower than the national environmental protection emission standards, so that remarkable practicability and economic benefits are achieved.

Owner:JIANGSU XINDONGFENG CHEM TECH

Cylinder head of internal combustion engine

InactiveCN101649789AEasy to excludeTimely exclusionCylinder headsCylindersCombustion chamberEngineering

The invention discloses a cylinder head of an internal combustion engine. The body of the cylinder head is provided with a die cavity, a combustion chamber, an inlet valve chamber, an exhaust valve chamber, valve guide pipes, an inlet duct and an exhaust duct, wherein the die cavity is positioned on the top of the body of the cylinder head; the combustion chamber is positioned at the bottom of thebody of the cylinder head; the inlet valve chamber and the exhaust valve chamber arranged in parallel are positioned between the die cavity and the combustion chamber; the inlet duct is communicatedwith the combustion chamber through the inlet valve chamber; the inlet valve chamber is also communicated with the die cavity through one valve guide pipe; the exhaust duct is communicated with the combustion chamber through the exhaust valve chamber; the exhaust valve chamber is also communicated with the die cavity through another valve guide pipe; and an included angle which is between 80 and 85 degrees is formed between the central line of the inlet duct and the central line of the exhaust duct. The cylinder head of the internal combustion engine can ensure the sufficient combustion of a combustible mixed gas to effectively reduce the oil consumption of the entire engine and reduce the exhaust pollution; and simultaneously, the cylinder head of the internal combustion engine can also reduce the thermal load of the engine and improve the dynamic property of the engine, and is suitable for various types of gasoline engines.

Owner:力帆科技(集团)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com