Process and apparatus for preparing high-purity silicon dioxide by utilizing rice hull

A technology of high-purity silica and process method, which is applied in the field of devices for extracting high-purity amorphous silica, which can solve the problems of large acid treatment capacity, lack of research, and large pollution, and achieve reduced carbon content and shorter burn-out time Short, pure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

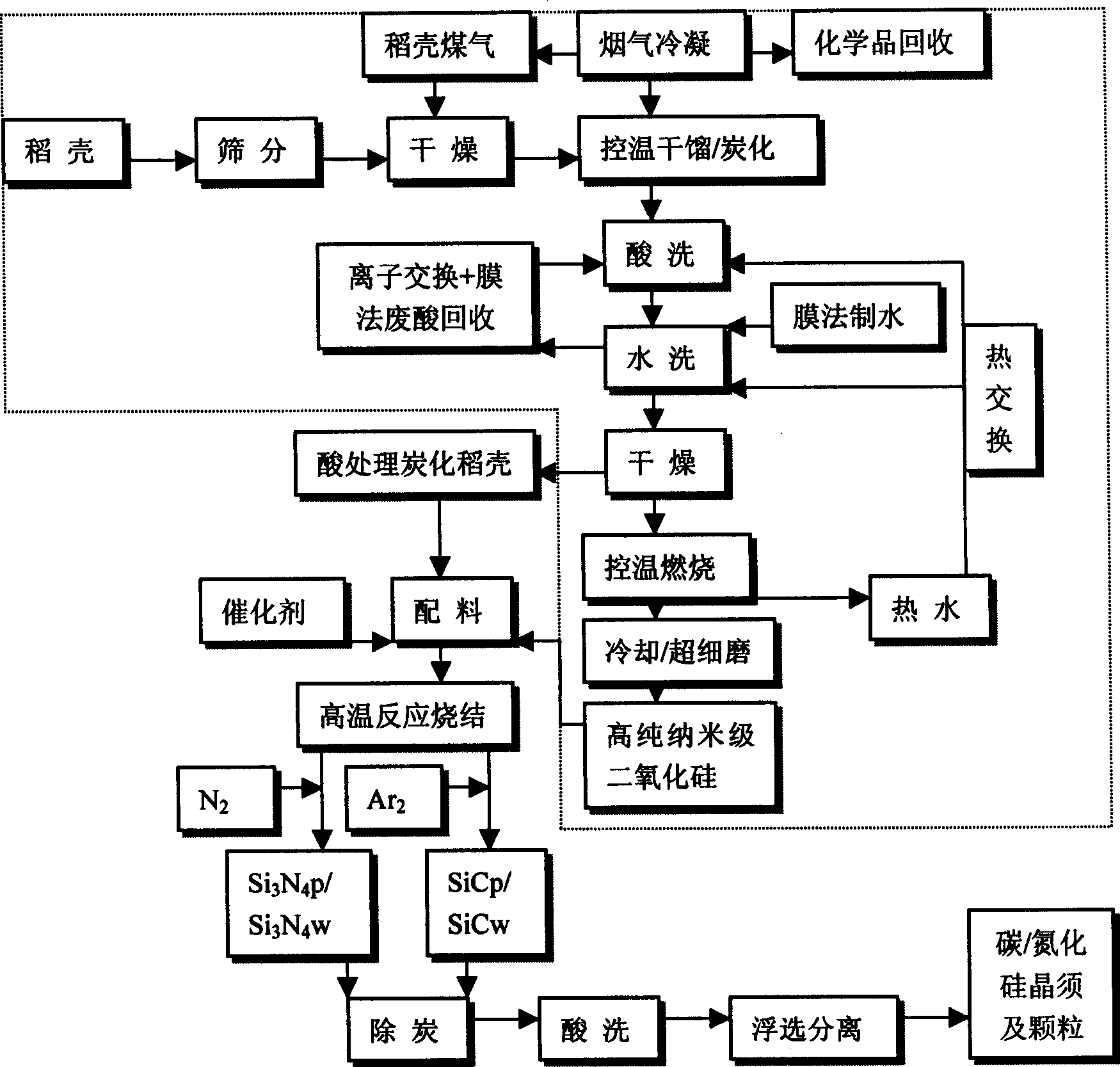

[0041] A process method for producing high-purity silica by using rice husks, the process steps are:

[0042] 1. Sieve the rice husk to remove sand and dust;

[0043] 2. Place the sieved rice husks in a drying oven to dry;

[0044] 3. Send the dried rice husks into a temperature-controlled carbonization device for carbonization by temperature-controlled carbonization to obtain carbonized rice husks, and recover chemicals and rice husk gas. The temperature-controlled carbonized rice husks are placed at a temperature-controlled temperature of 400 ℃, to keep the active state of silica in the rice husk unchanged, and at the same time, the hot water generated by temperature-controlled dry distillation and carbonization is used as heat source for pickling and water washing;

[0045] 4. Put the carbonized rice husk in the pickling device to remove the alkali metal impurity elements in the carbonized rice husk. The acid used for pickling the carbonized rice husk is 5% hydrochloric ac...

Embodiment 2

[0049] A process method for producing high-purity silicon dioxide from rice husks, the process steps are the same as in Example 1, except that the temperature-controlled carbonized rice husks are placed at a temperature of 450°C, and the temperature-controlled temperature of the temperature-controlled combustion is At 550°C, the acid used for pickling carbonized rice husk is 15% citric acid.

Embodiment 3

[0051] A process method for producing high-purity silicon dioxide by using rice husks. The process steps are the same as in Example 1, except that the temperature-controlled carbonized rice husks are placed at a temperature of 490°C, and the temperature of the temperature-controlled combustion is 600°C. ℃, the acid used for pickling carbonized rice husks is 15% acetic acid, and after implementing step 5 of Example 1, carry out temperature-controlled combustion and wash with pure water to obtain a high-purity ultrafine white carbon black product.

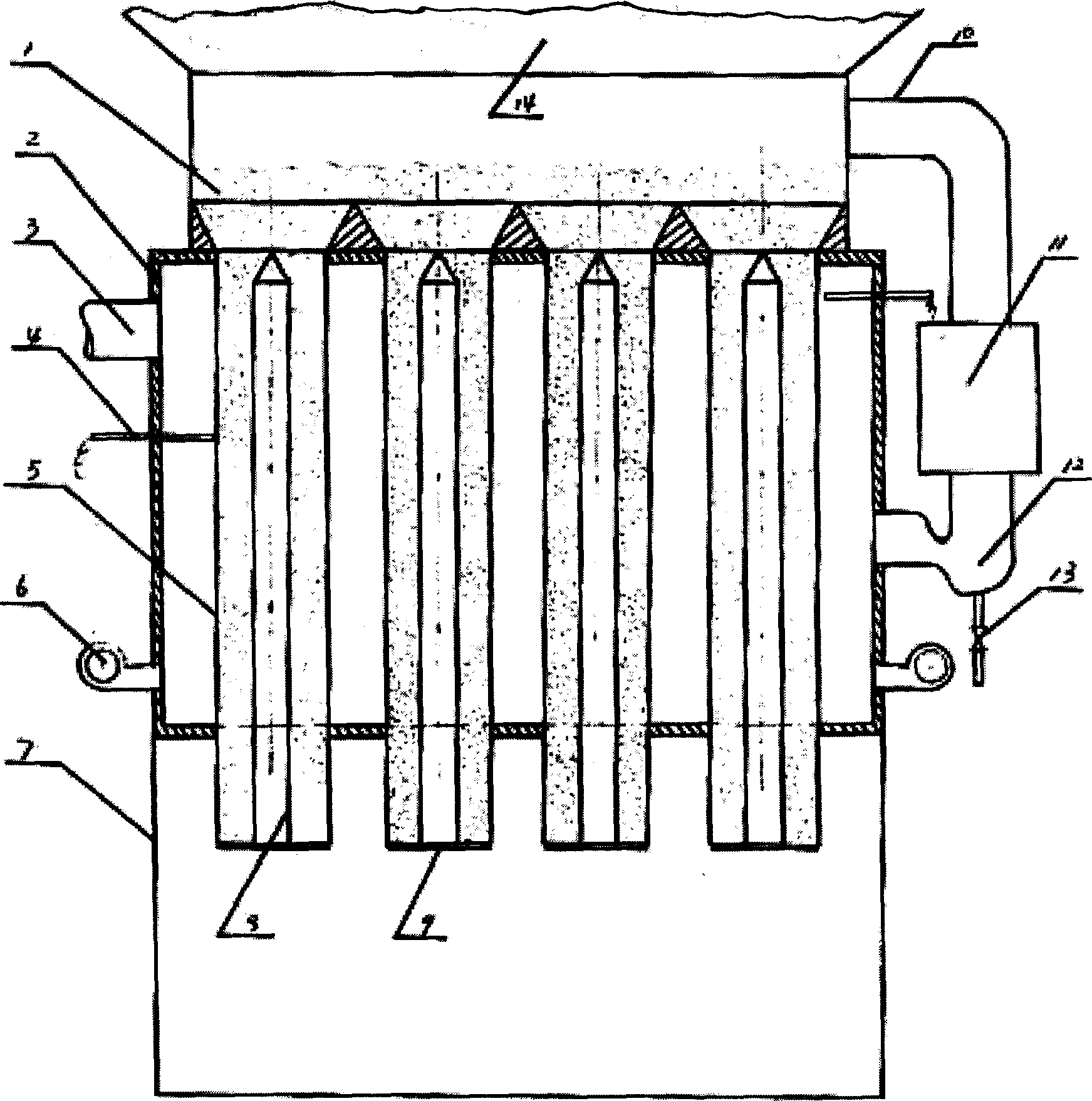

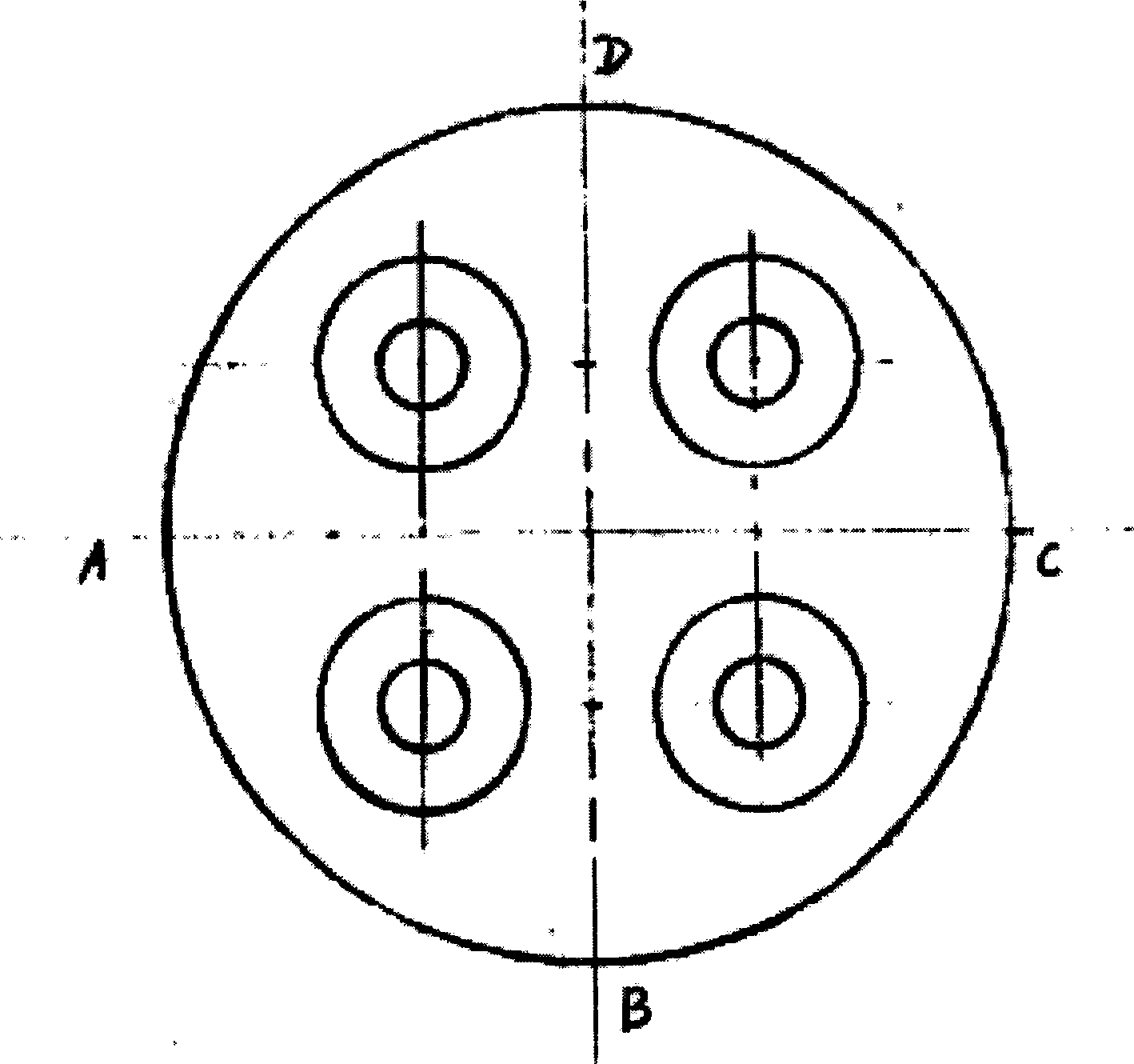

[0052] The device for implementing the process of the present invention includes units such as rice husk screening, drying, temperature-controlled dry distillation carbonization, carbonized rice husk pickling and water washing, temperature-controlled combustion, flue gas condensation, membrane water production, ion exchange + membrane waste acid recovery, etc. The operating device, wherein the temperature-controlled dry distillation c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com