Combustible 3D direct writing ink, and preparation method and application thereof

An ink and 3D technology, applied in the field of direct writing ink preparation, can solve the problems such as the template is not easy to be completely removed, remain, and affect the performance of the electrode, and achieve the effects of broad commercial application prospects, low production cost, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

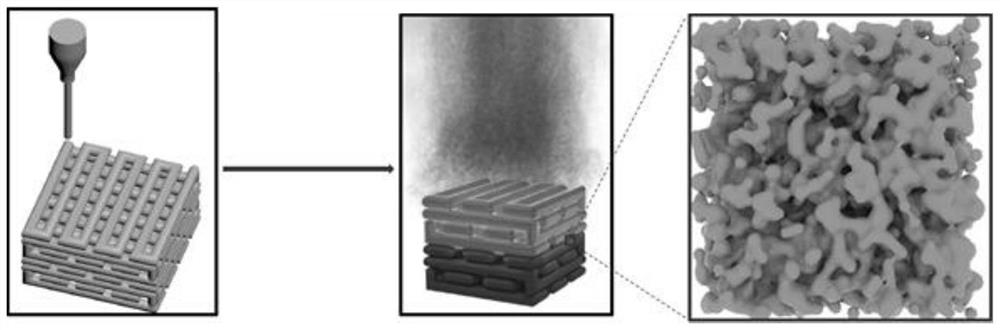

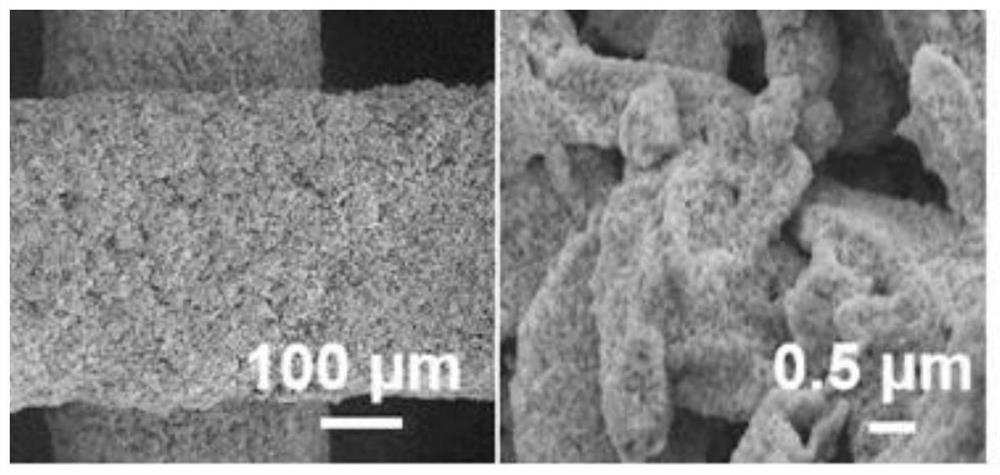

[0028] Select metal nickel powder as filler, select F127 as fuel, Ni(NO 3 ) 2 ·6H 2 O as an oxidizing agent, H 2 Combustion synthesis system with O as solvent, 0.5g F127, 1.45g Ni(NO 3 ) 2 ·6H 2 O. 2g of nickel powder and 0.5g of water are blended by grinding for 20 minutes to prepare a viscous slurry, and then perform 3D ink direct writing. The specific printing parameters are extrusion pressure 50psi, extrusion needle diameter 300um, and wire center distance 400um , the printing speed is 3mm / s. After the printed structure is dried, place the printed structure on a preheated heating stage, use a high-temperature heating stage, set the surface temperature of the heating stage to 300°C for ignition, and construct a metal electrode with a hierarchical hole structure, such as figure 2 shown.

Embodiment 2

[0030] Select metal silver powder as filler, select F127 as fuel, AgNO 3 As an oxidizing agent, H 2 Combustion synthesis system with O as solvent, 0.5g F127, 2g Ni(NO 3 ) 2 ·6H 2 O. 2g silver powder and 0.5g water are blended by grinding for 20 minutes to prepare a viscous slurry, and then perform 3D ink direct writing. The specific printing parameters are extrusion pressure 60psi, extrusion needle diameter 200um, wire center distance 300um, The printing speed is 5mm / s. After the printed structure is dry, the printed structure is placed on the surface of a preheated hot stage (a high-temperature hot stage is used, and the surface temperature of the hot stage is set to 300°C) for ignition to build a metal electrode with a hierarchical pore structure.

Embodiment 3

[0032] Select metal nickel powder as filler, select F127 as fuel, Ni(NO 3 ) 2 ·6H 2 O as an oxidizing agent, H 2 Combustion synthesis system with O as solvent, 0.5g F127, 1.45g Ni(NO 3 ) 2 ·6H 2 O. 2g of nickel powder and 0.5g of water are blended by grinding for 30 minutes to prepare a viscous slurry, and then perform 3D ink direct writing. The specific printing parameters are extrusion pressure 50psi, extrusion needle diameter 300um, wire center distance 400um , the printing speed is 3mm / s. After the printed structure is dried, the printed structure is placed on the surface of a preheated hot stage (a high-temperature hot stage is used, and the surface temperature of the hot stage is set to 250°C) for ignition to build a metal electrode with a hierarchical pore structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com