Composite impregnating adhesive for making fireproof heat insulation plate, and its use method

A technology of fireproof insulation board and impregnated glue, which is applied in the direction of adhesive, adhesive type, aldehyde/ketone condensation polymer adhesive, etc., to achieve the effect of outstanding fireproof insulation performance, stable quality, and small water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

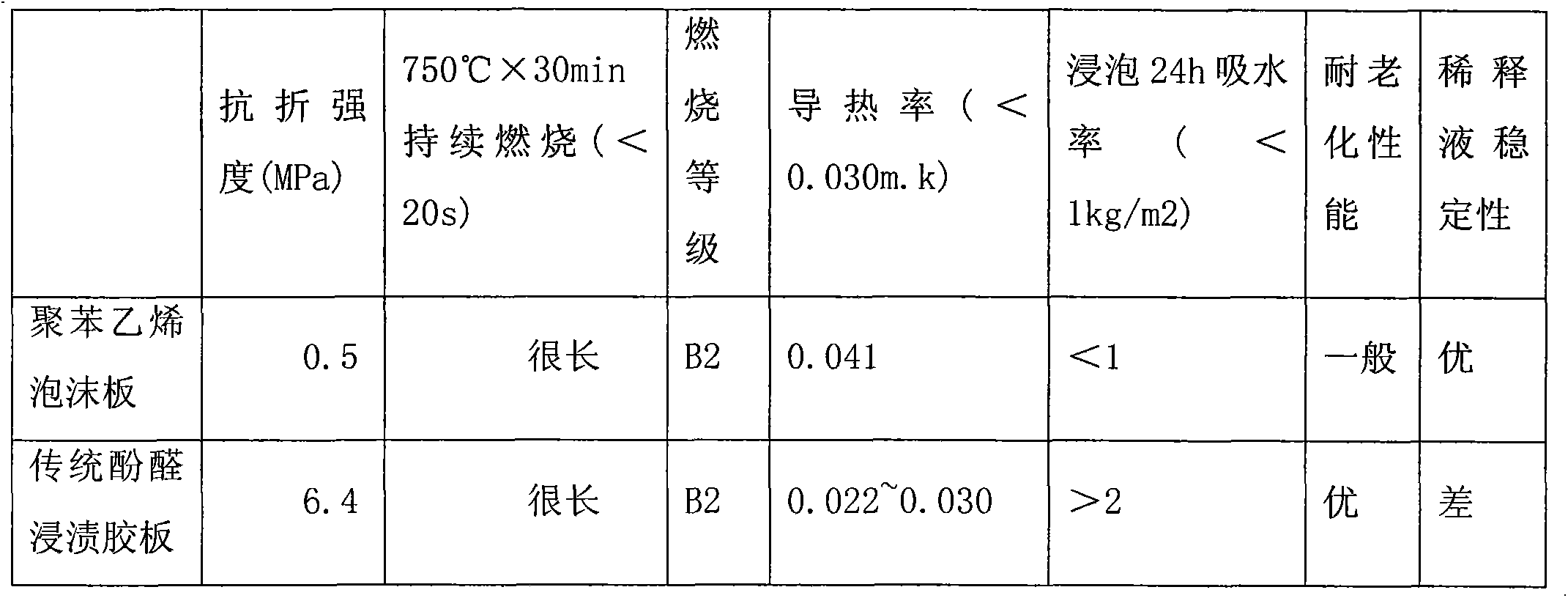

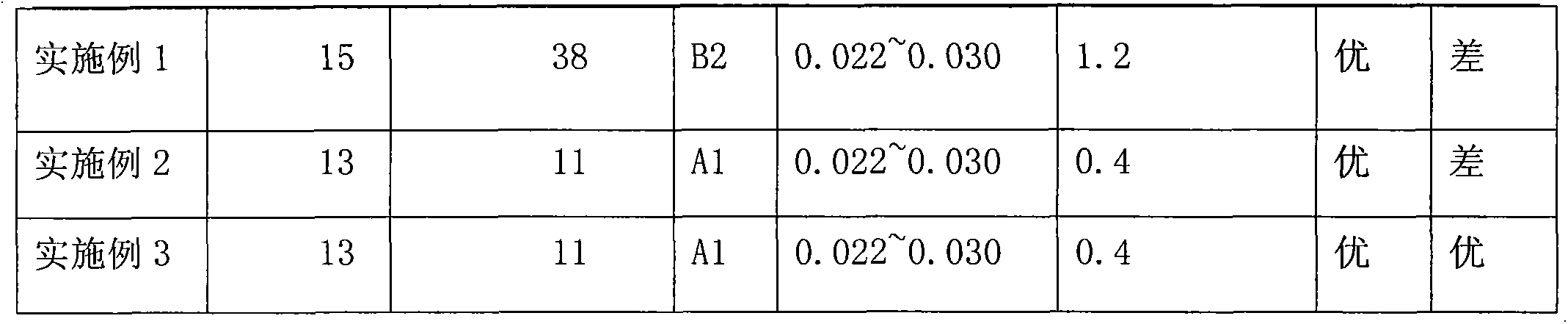

Embodiment 1

[0089] Prepare 100kg of diluent for treating the fireproof insulation board: add 12kg of component A (12% by weight), 84kg of water (84% by weight), and 4kg of component B (4% by weight). Wherein component A includes 70 parts by weight of phenolic resin and 30 parts by weight of water; component B includes 91 parts by weight of water and 9 parts by weight of water repellent.

[0090] The method of use is:

[0091] With glue:

[0092] Add the two-component glue and water into the reaction kettle in proportion, and stir evenly.

[0093] Dipping:

[0094] Pour the evenly stirred dipping glue into the dipping tank, and the fiber needled felt enters the dipping pool driven by the roller to dip into the glue. With the decline of the liquid level in the dipping tank, the newly prepared dipping glue will be continuously replenished to ensure the stable progress of the dipping process.

[0095]Squeeze dry:

[0096] After being dipped in glue, squeeze out the excess glue in the fib...

Embodiment 2

[0105] Prepare 100kg of diluent for treating the fireproof insulation board: add 3kg of component A (3% by weight), 96.5kg of water (96.5% by weight), and 0.5kg of component B (0.5% by weight). Wherein A component comprises the phenolic resin of 70 weight parts, the water of 26 weight parts, the catalyst of 4 weight parts; The B component comprises the water of 50 weight parts, the catalyst of 9 weight parts, the inorganic binder of 9 weight parts, A chelating agent and a carbonizing agent in parts by weight, a flame suppressant in 9 parts by weight, a smoke suppressor in 6 parts by weight, and a waterproofing agent in 9 parts by weight.

[0106] Compared with the examples, this example adds catalysts, inorganic binders, chelating agents, carbonizing agents, smoke suppressants, and flame suppressants to the formula to ensure the high strength, low water absorption, and short afterburning of the fireproof insulation board. On the basis of this, the production and transportation...

Embodiment 3

[0110] Prepare 100kg of diluent for treating the fireproof insulation board: add 3kg of component A (3% by weight), 96.5kg of water (96.5% by weight), and 0.5kg of component B (0.5% by weight). Wherein A component comprises the phenolic resin of 70 weight parts, the water of 20 weight parts, the stabilizer of 5 weight parts, the catalyst of 5 weight parts; B component comprises the water of 50 weight parts, the catalyst of 9 weight parts, the catalyst of 9 weight parts Inorganic binder, 8 parts by weight of chelating agent and charring agent, 9 parts by weight of flame suppressant, 6 parts by weight of smoke suppressant, and 9 parts by weight of waterproofing agent.

[0111] In this example, a stabilizer is added on the basis of Example 2. On the basis of ensuring the high strength, low water absorption, short afterburn, and low cost of the fireproof insulation board, the storage and service life of the impregnated glue are greatly extended by adding the stabilizer .

[0112]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| ablation rate | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com