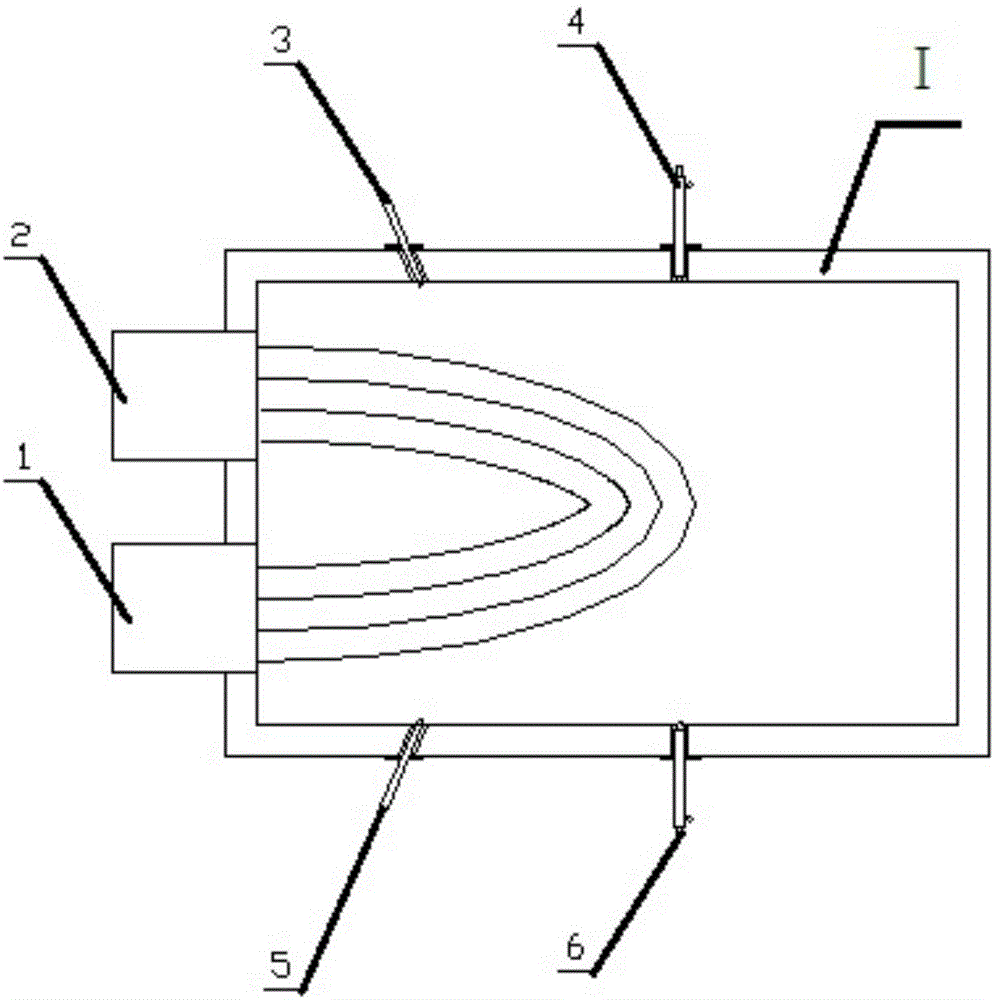

Staged pure oxygen combustion supporting system for horse shoe flame glass melting furnace and method thereof

A technology of combustion-supporting system and glass melting furnace, which is applied in glass melting devices, glass production, glass furnace equipment, etc., can solve the problem that the cost of flue gas treatment of glass melting furnace remains high, affects the product competitiveness of glass manufacturing enterprises, and the structure of combustion-supporting system. Complexity and other problems, to achieve the effect of simple and stable production process, easy popularization and application, and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

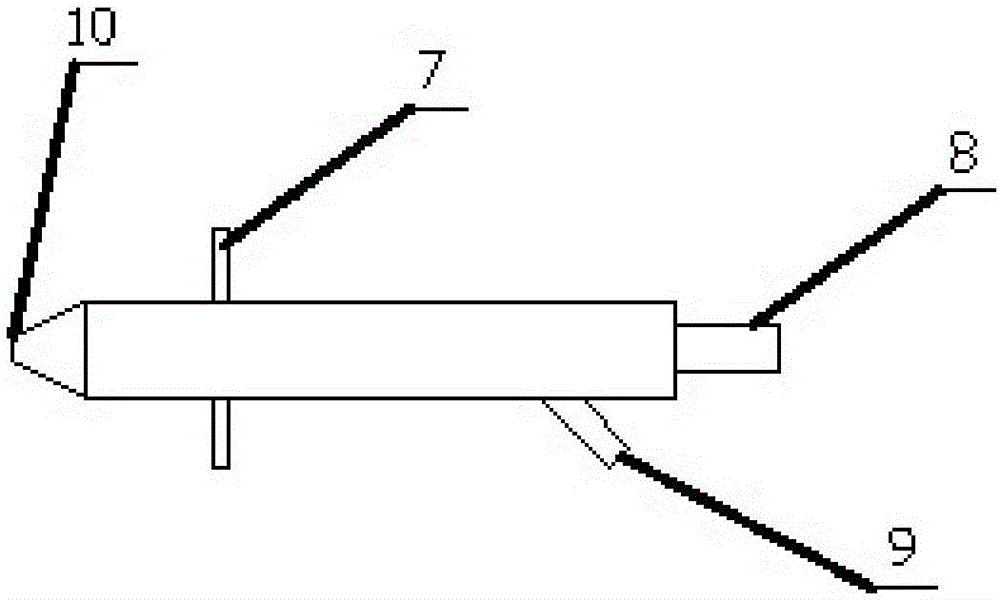

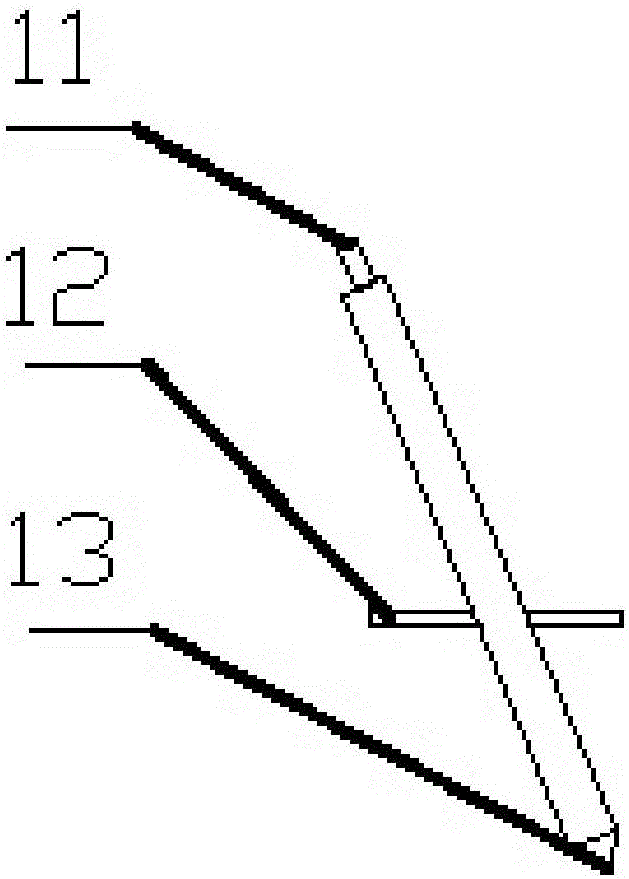

Method used

Image

Examples

Embodiment 1

[0044] Taking an 80-ton glassware horseshoe flame glass melting furnace as an example, using the staged pure oxygen combustion-supporting system and method of the present invention, the oxygen flow rate in the pure oxygen lance and pure oxygen combustion spray gun is 60-80Nm 3 / h, combustion air consumption from 7500Nm 3 / h reduced to 6600Nm 3 / h, reduce 900Nm 3 / h, the reduction ratio is 12%, NO X The emission concentration is 1200-1400mg / Nm 3 , reduced by more than 30%, the total energy consumption reduced by 3%, and the effect of energy saving and emission reduction is obvious.

[0045] In the present invention, by reducing the amount of combustion-supporting air, the combustion reaction is fuel-rich incomplete combustion in the first stage, because the flame temperature is relatively low, and O 2 , N 2 The amount is too small, reducing NO X generation; with the injection of oxygen in the same side of the pure oxygen lance, the second stage is based on O 2 Combustion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com