Patents

Literature

45results about How to "Melt stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-cost non-rare-earth type high-strength magnesium alloy and preparing method thereof

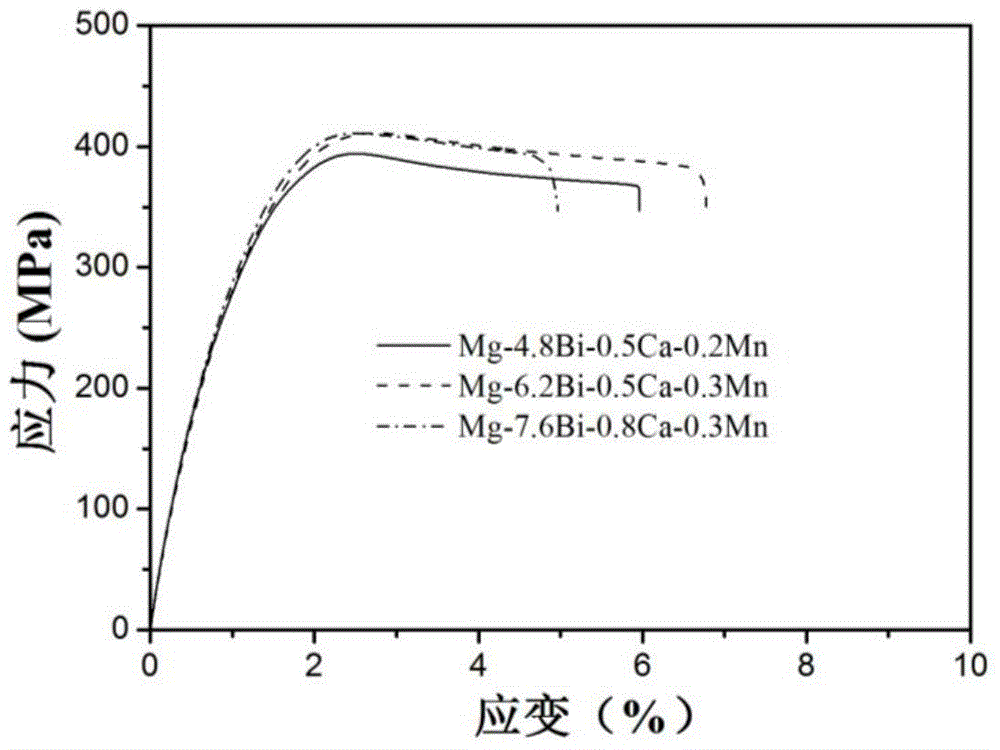

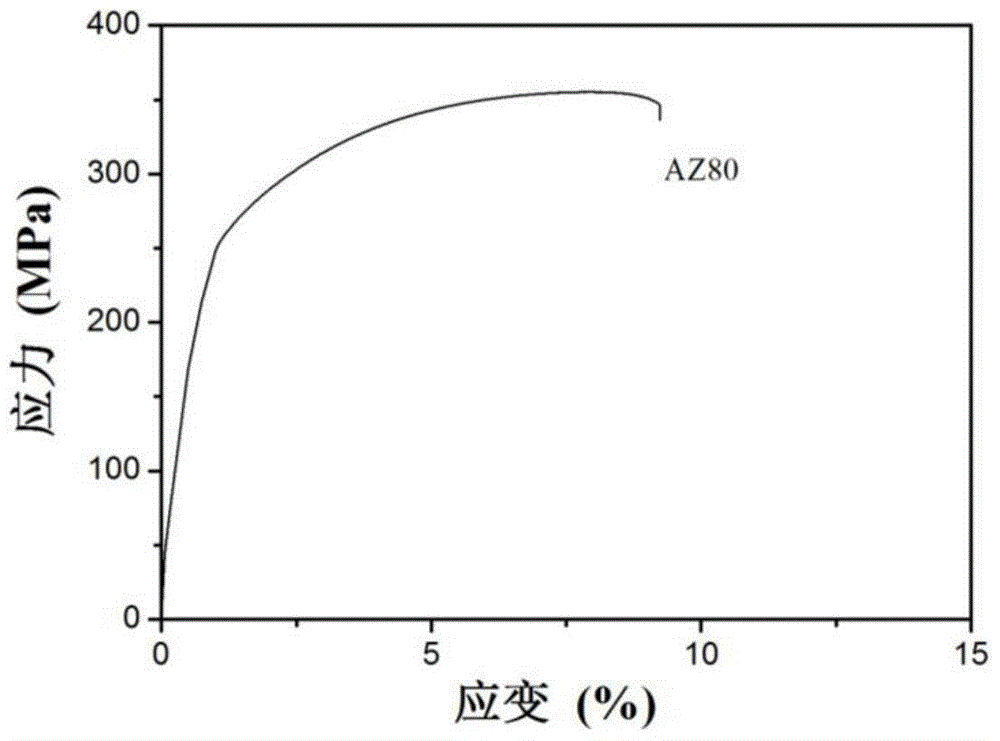

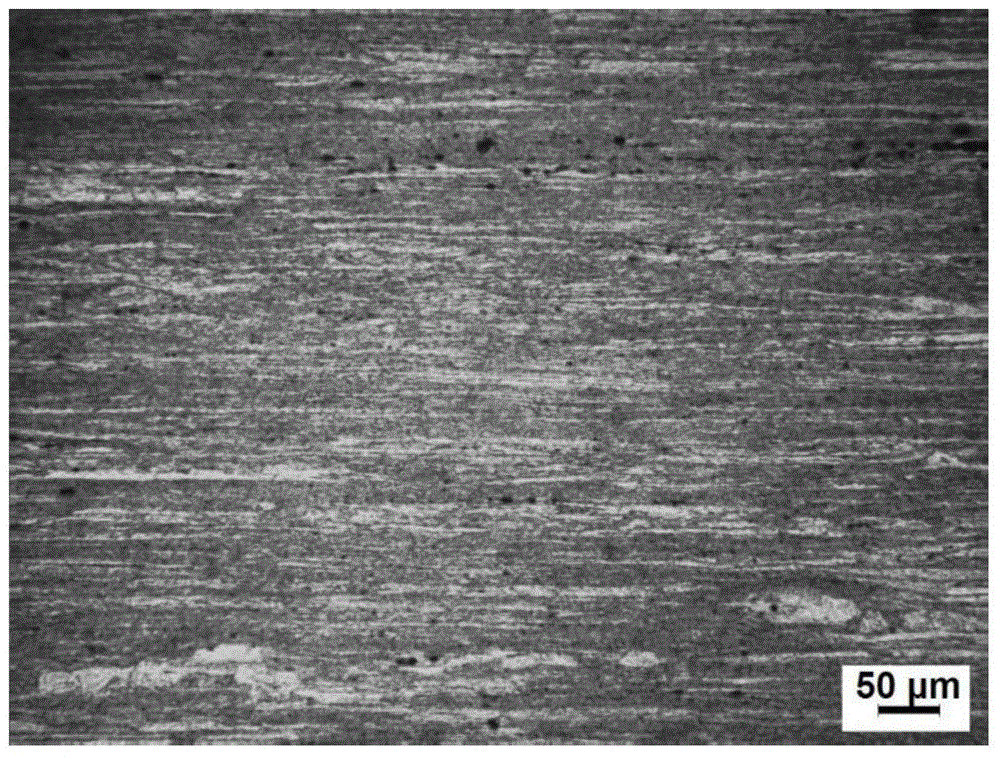

The invention relates to low-cost non-rare-earth type high-strength magnesium alloy and a preparing method thereof. The alloy is Mg-Bi-Ca-Mn magnesium alloy, and is prepared from, by mass, 2-10% of Bi, 0.1-1.5% of Ca, 0.1-1.0% of Mn and the balance magnesium. The novel magnesium alloy is based on a Mg-Bi binary metal series, the element Bi serves as the main alloy element, and the Mg3Bi2 phase with high melting point is contained in the magnesium alloy. Furthermore, the magnesium alloy is evenly dispersed and distributed on a matrix through a simple alloying means, the metamorphism to a second phase by the element Ca and the element Mn and the combination of a plastic deformation processing means so that crystal boundary migration can be effectively pinned in the deformation process to hinder dislocated movement, grains are obviously refined, the strength of the alloy is greatly improved, and thus the ultra-high-strength magnesium alloy is developed in the alloy series.

Owner:HEBEI UNIV OF TECH

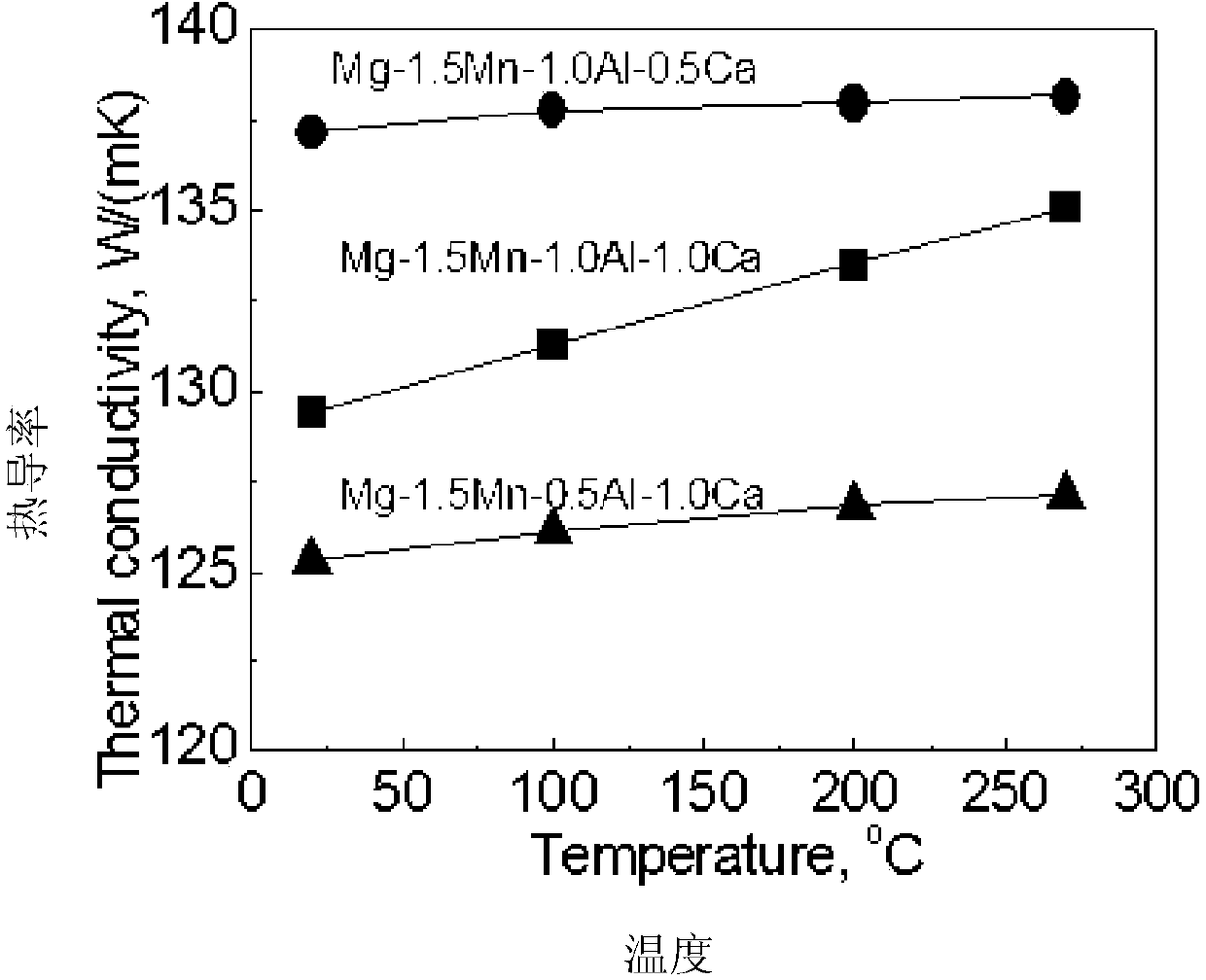

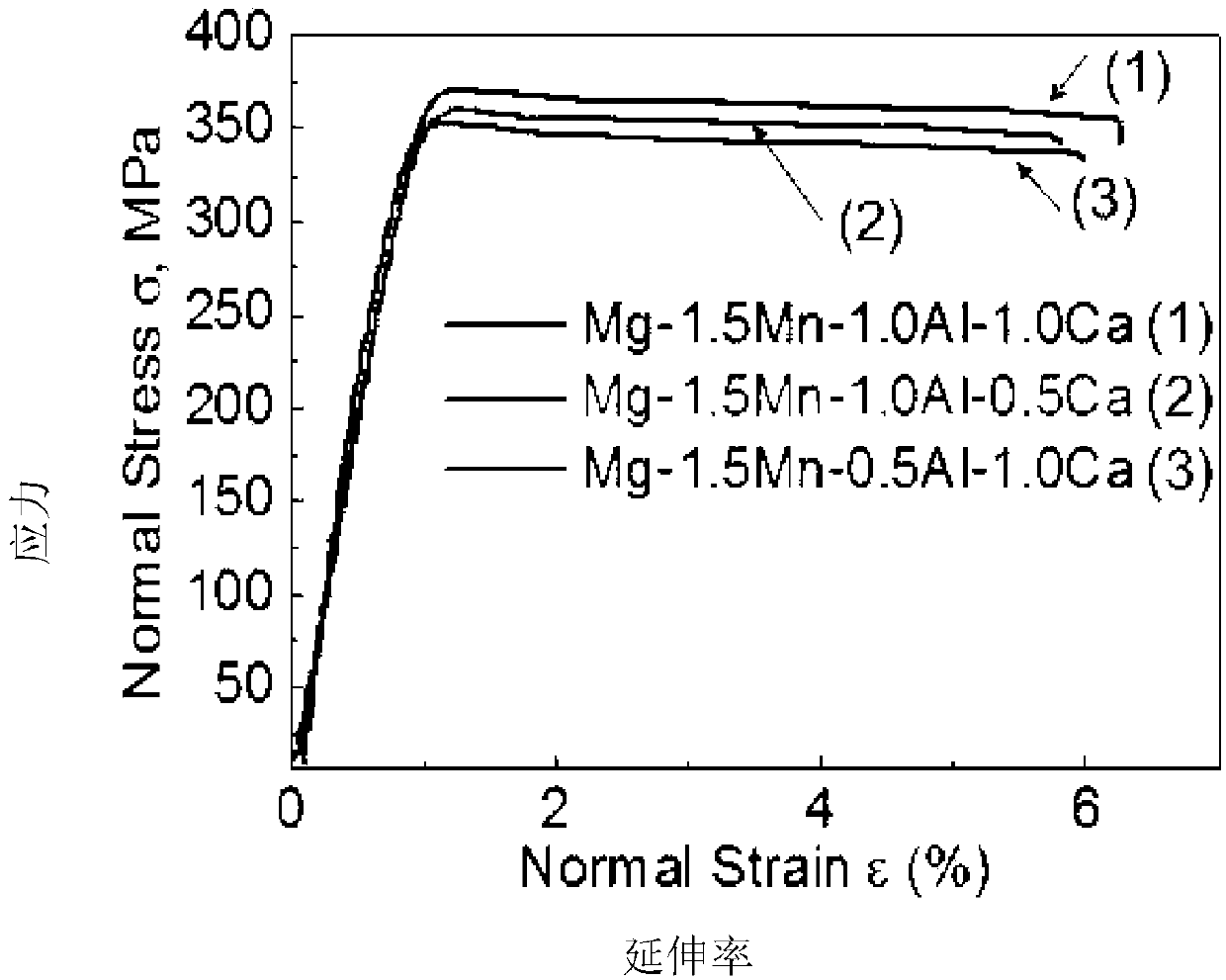

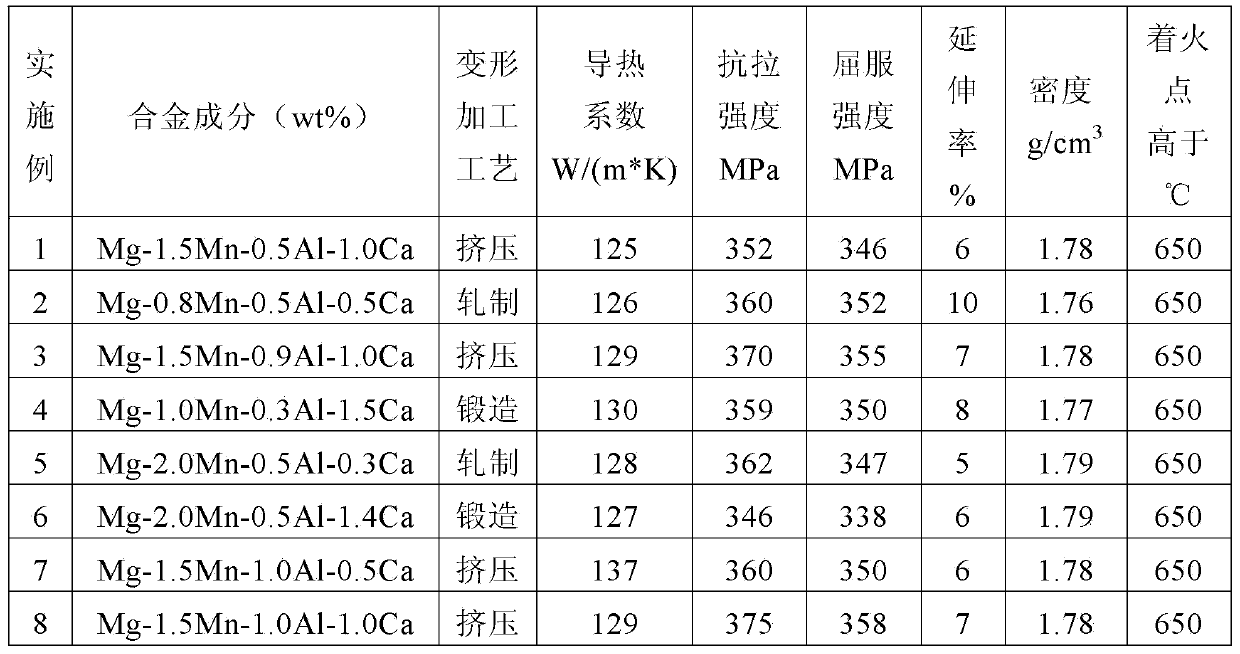

Rare-earth-free low-cost high-strength heat-conducting magnesium alloy and preparation method thereof

The invention relates to a rare-earth-free low-cost high-strength heat-conducting magnesium alloy and a preparation method thereof. The magnesium alloy is composed of the following chemical components in percentage by weight: 0.5-2.0 wt% of Mn, 0.3-1.5 wt% of Ca, 0.3-1.0 wt% of Al, and the balance of Mg and inevitable impurities. The magnesium alloy solves the problem of overhigh cost due to use of multiple rare-earth elements or high-price alloy elements, and the problems of sharp drop of heat conductivity coefficient, overhigh density and the like due to higher alloy element content caused by strength increase in the existing heat-conducting magnesium alloy; and the magnesium alloy has the advantages of higher heat conductivity coefficient, higher strength, higher flame resistance, lower cost and lower density.

Owner:BAOSHAN IRON & STEEL CO LTD

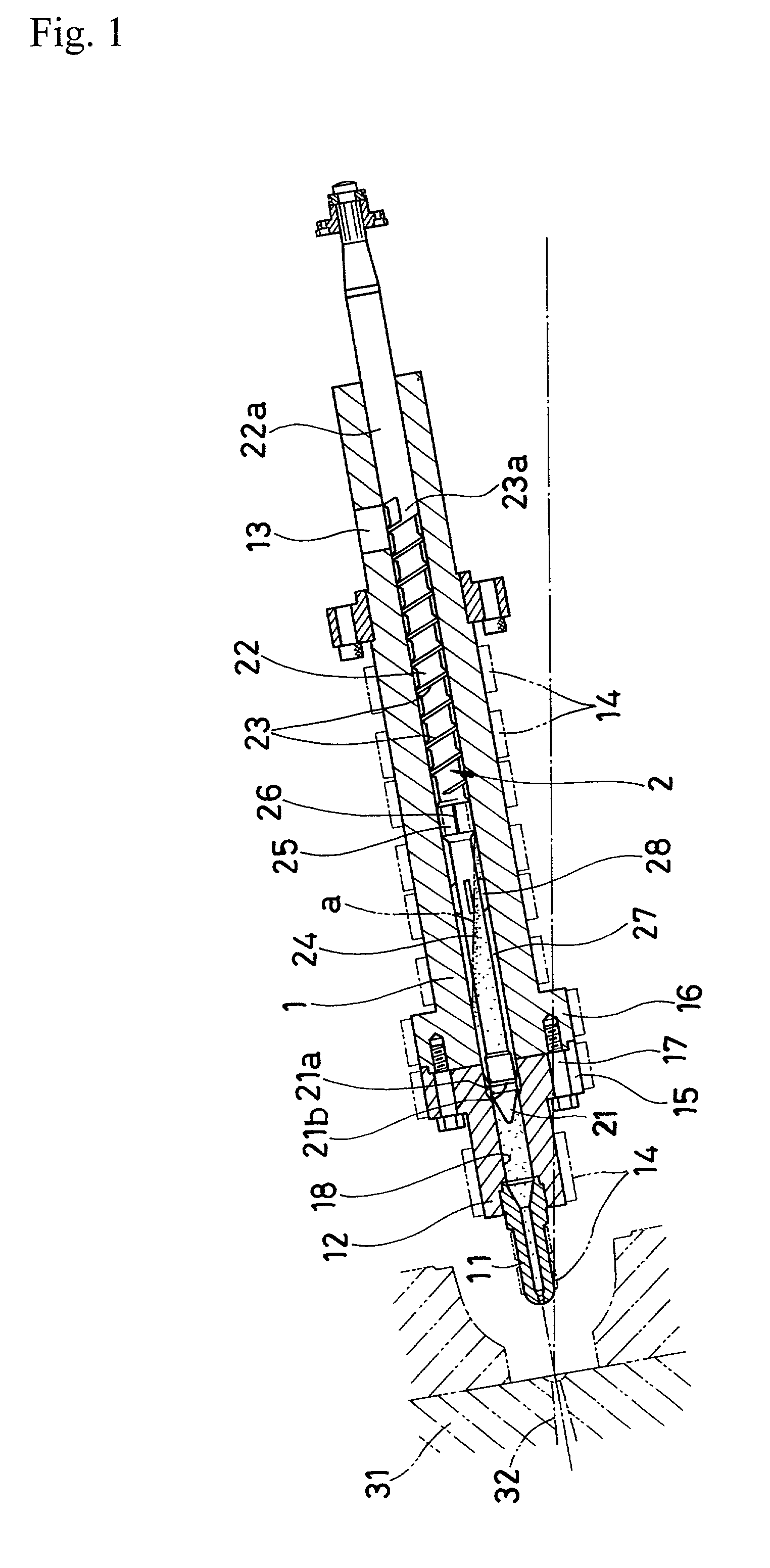

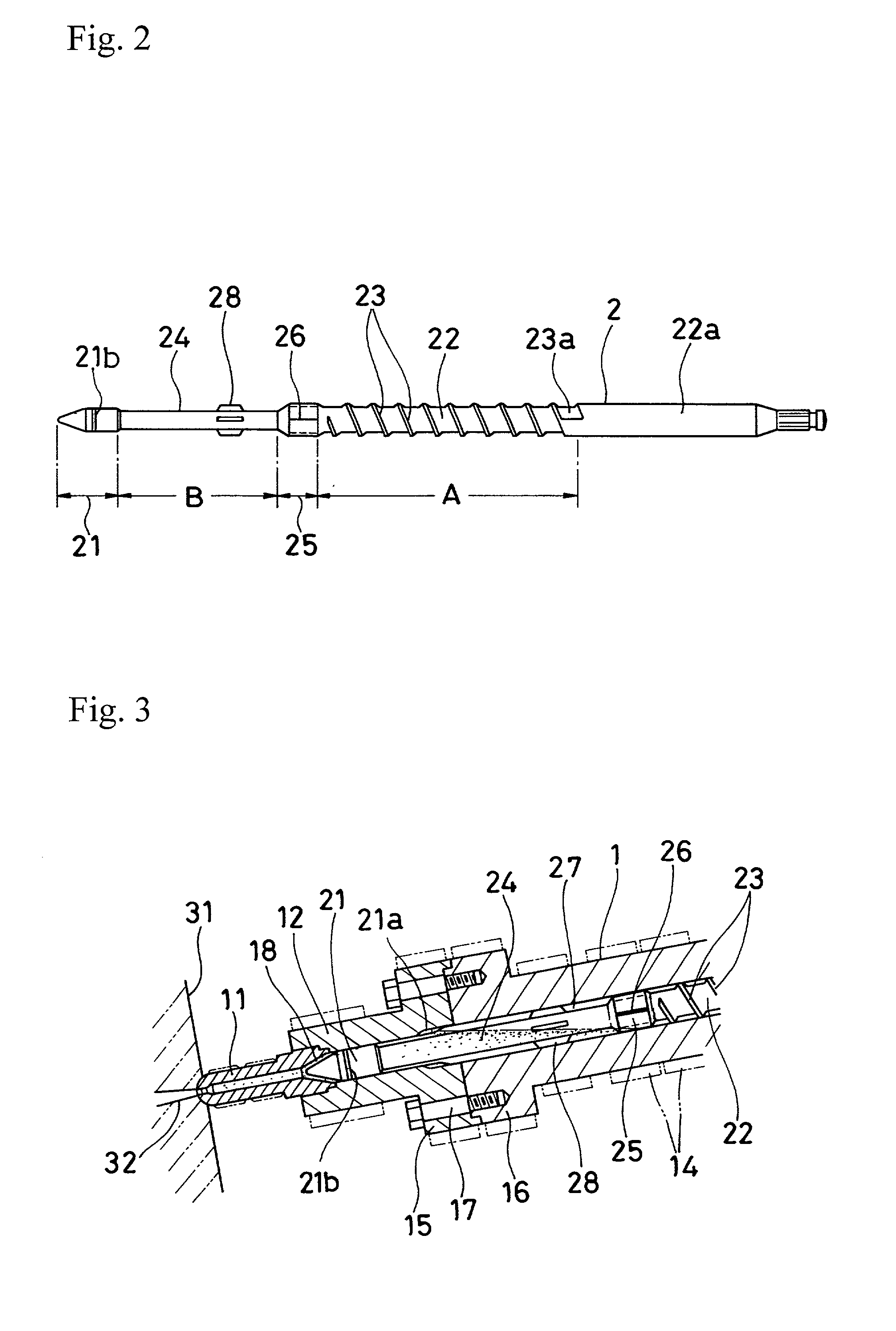

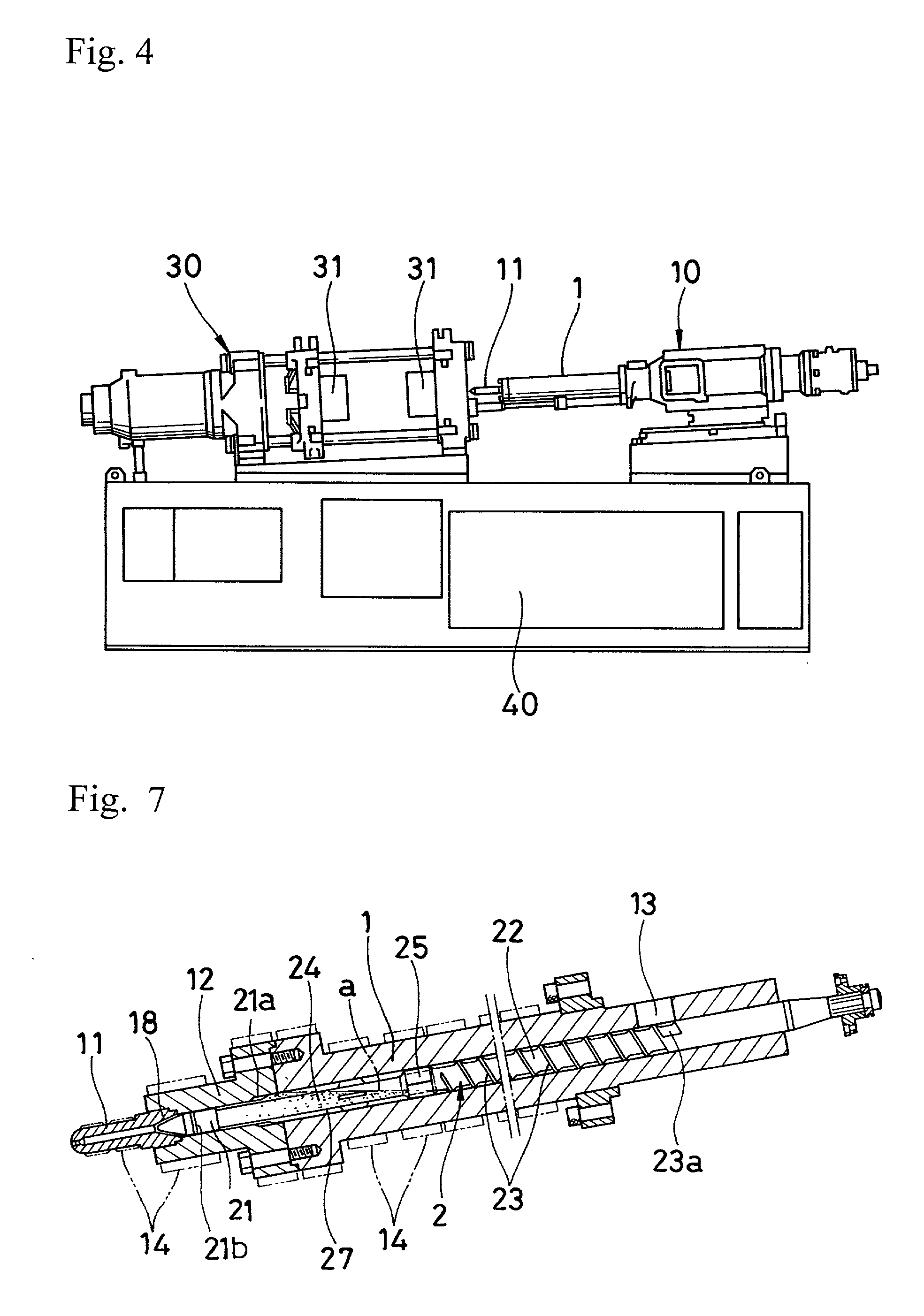

Injection apparatus for melted metals

InactiveUS20010004931A1Stable temperatureAvoid congestionRotary stirring mixersMixing/kneading with horizontally-mounted toolsInjection deviceMolten metal

An injection apparatus for melted metals is provided to be capable of transferring the metals, melting them by the external heat, metering and degassing by employing a reservoir to reserve metals in liquid phase for the injection screw. The injection apparatus comprises a heating cylinder having a fore end portion which communicates with a nozzle member and of which internal diameter is made smaller to serve as a metering chamber, and an injection screw installed within the heating cylinder to be movable and rotational. A tip end of the injection screw is formed in a plunger having a diameter that can insert into the metering chamber with keeping a clearance for sliding. A reservoir, for reserving melted metals in liquid phase, consisting of an axis is provided between the plunger and a feeding portion containing screw flight around the axis. A projected portion for limiting the feeding of granular metals flowing to the reservoir and for preventing the metals in liquid phase from flowing backward during injection is provided on a boundary between the feeding portion and the reservoir.

Owner:NISSEI PLASTIC IND CO LTD

Alloyed powder for directly printing metal parts in 3D (three-dimensional) manner and preparation method of alloyed powder

ActiveCN104668553ANo lossPrevent solidificationTransportation and packagingMetal-working apparatusStructural deformationMicrosphere

The invention provides alloyed powder for directly printing metal parts in a 3D (three-dimensional) manner. The alloyed powder is characterized in that nanometer aluminum is adhered to the surface of oxide of iron through a layer of thin tin powder to form iron-base alloy microspheres, the grain size of the microspheres is 2-10 micrometers, the sphericity is greater than 95%, and the alloyed powder comprises the following materials in part by weight: 60-70 parts of iron oxide, 30-40 parts of nanometer aluminum and 0.1-0.5 part of tin powder. The alloyed powder can be directly used for printing the metal parts in the 3D manner. When the alloyed powder is used for directly printing the metal parts in the 3D manner, the iron oxide is gradually reduced through aluminum, structure deformation caused by direct fusion molding of metal, cooling crystallization is uniform, the strength of a molded piece is improved by formed aluminum oxide, the porosity of products is reduced, and the compactness is high. The alloyed powder can be used for directly printing the high-precision metal parts which have complication shapes.

Owner:康硕(河南)智能制造有限公司

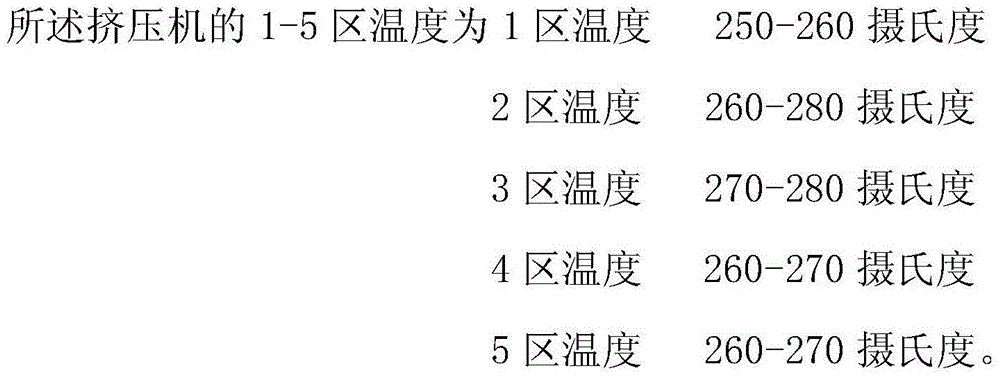

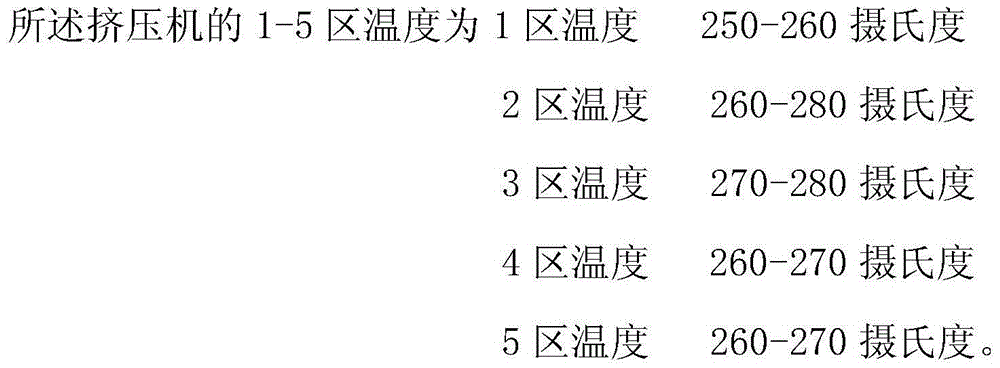

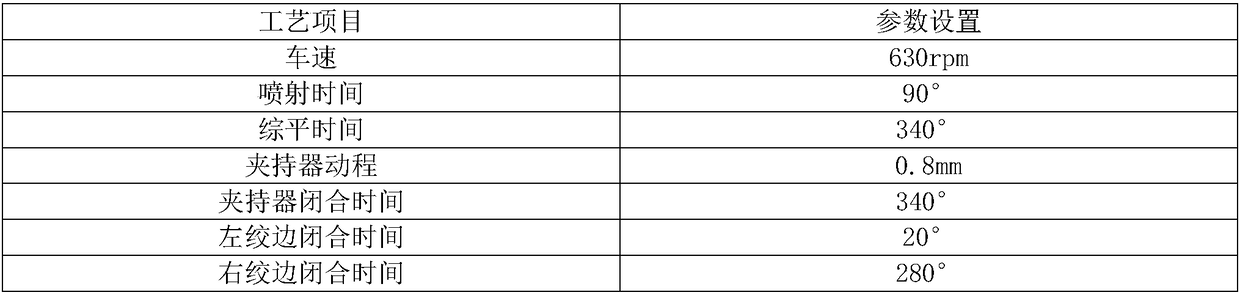

Production process for black nylon stretch yarns

InactiveCN104451916AWell mixedDarkness deepFilament forming substance formingMelt spinning methodsYarnPulp and paper industry

The invention relates to a production process for black nylon stretch yarns. The production process comprises the steps of proportional mixing of nylon chips and black master batches in a master batch mixer, melting in a screw extruder, metering with a metering pump, spinning with a spinning component, cross air blowing cooling, bundling and oiling, packaging, balancing, and texturing, wherein 4 to 10 weight percent of black master batches are added; the temperature of the extruder is 250 to 280 DEG C; the temperature of a spinning box body is 250 to 270 DEG C. The production process has the beneficial effects that differences between the relative viscosity, melting point and the like of the black master batches and those of the spinning chips are little, so that a melt is substantially stable, the black master batches can be uniformly mixed with the melt, the problems of floating yarns, yarn waste, looping yarns and the like during spinning are reduced, and produced black nylon stretch yarn products are deep black; the spinning process is greatly different from the conventional process, and the temperature of each area of the extruder is set to be 250 to 280 DEG C, so that carbon black in the black master batches can be uniformly dispersed in the melt, the melt is endowed with higher flowability, and the produced black yarns are uniform in color.

Owner:烟台华润锦纶有限公司

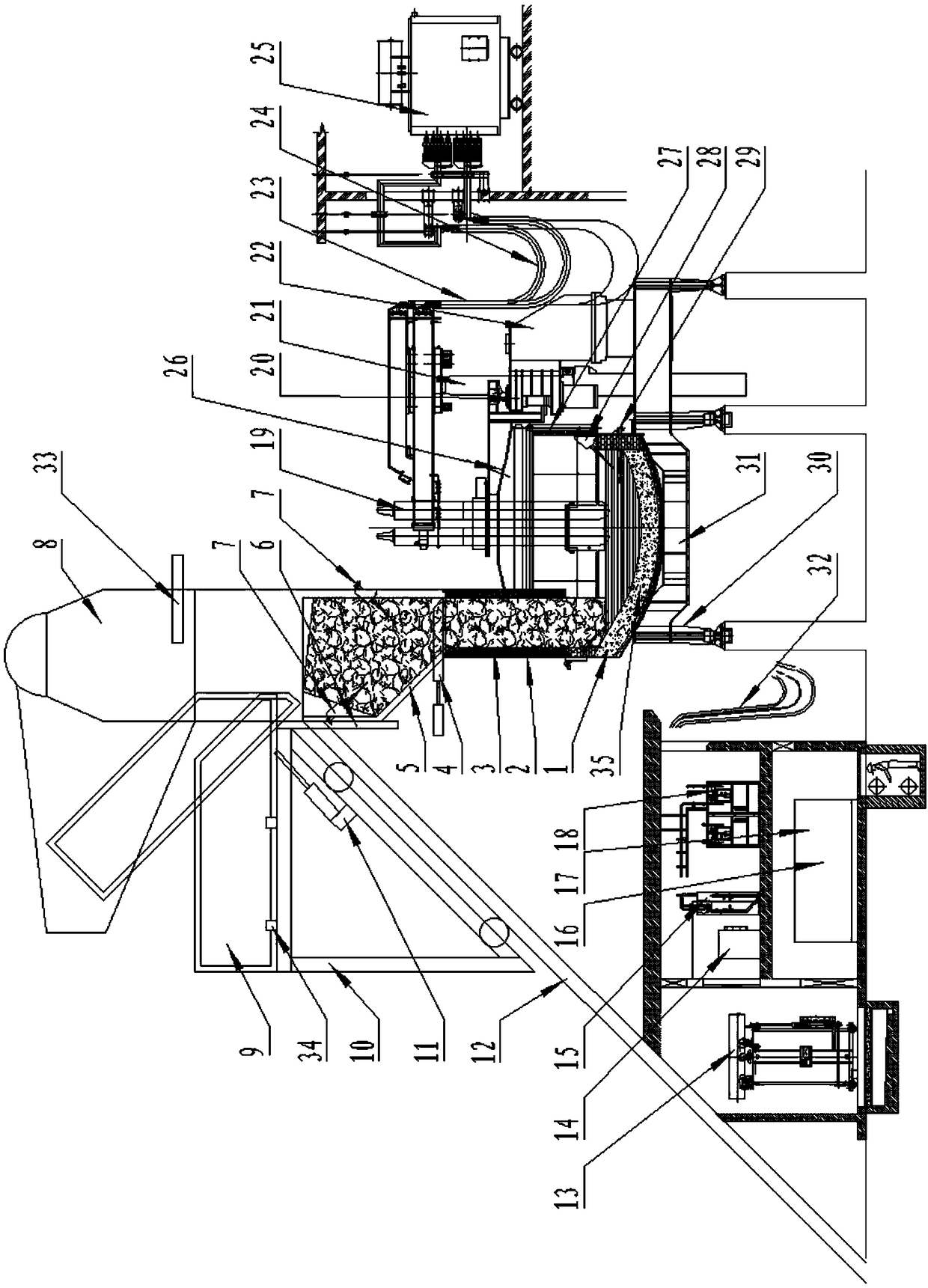

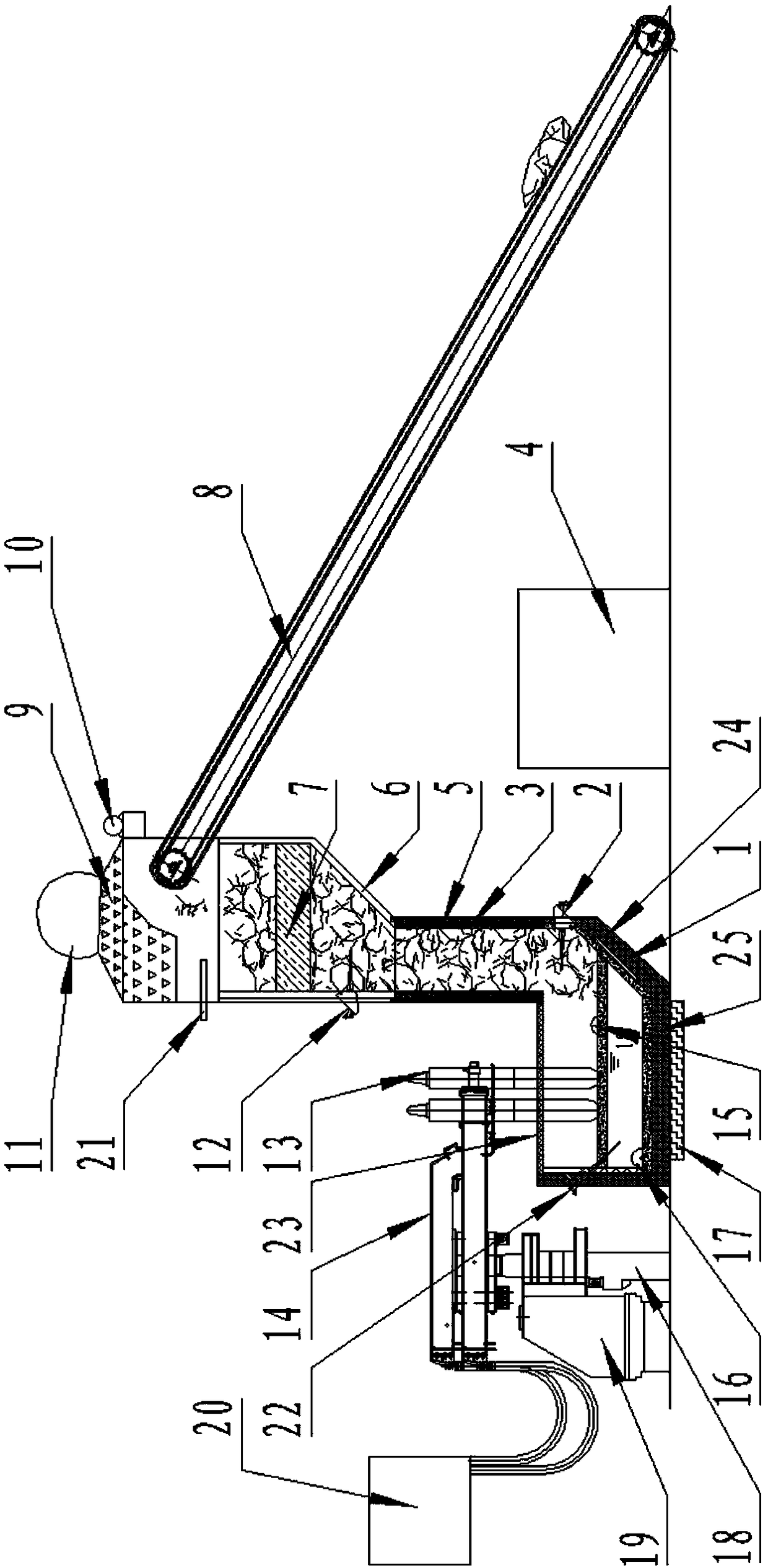

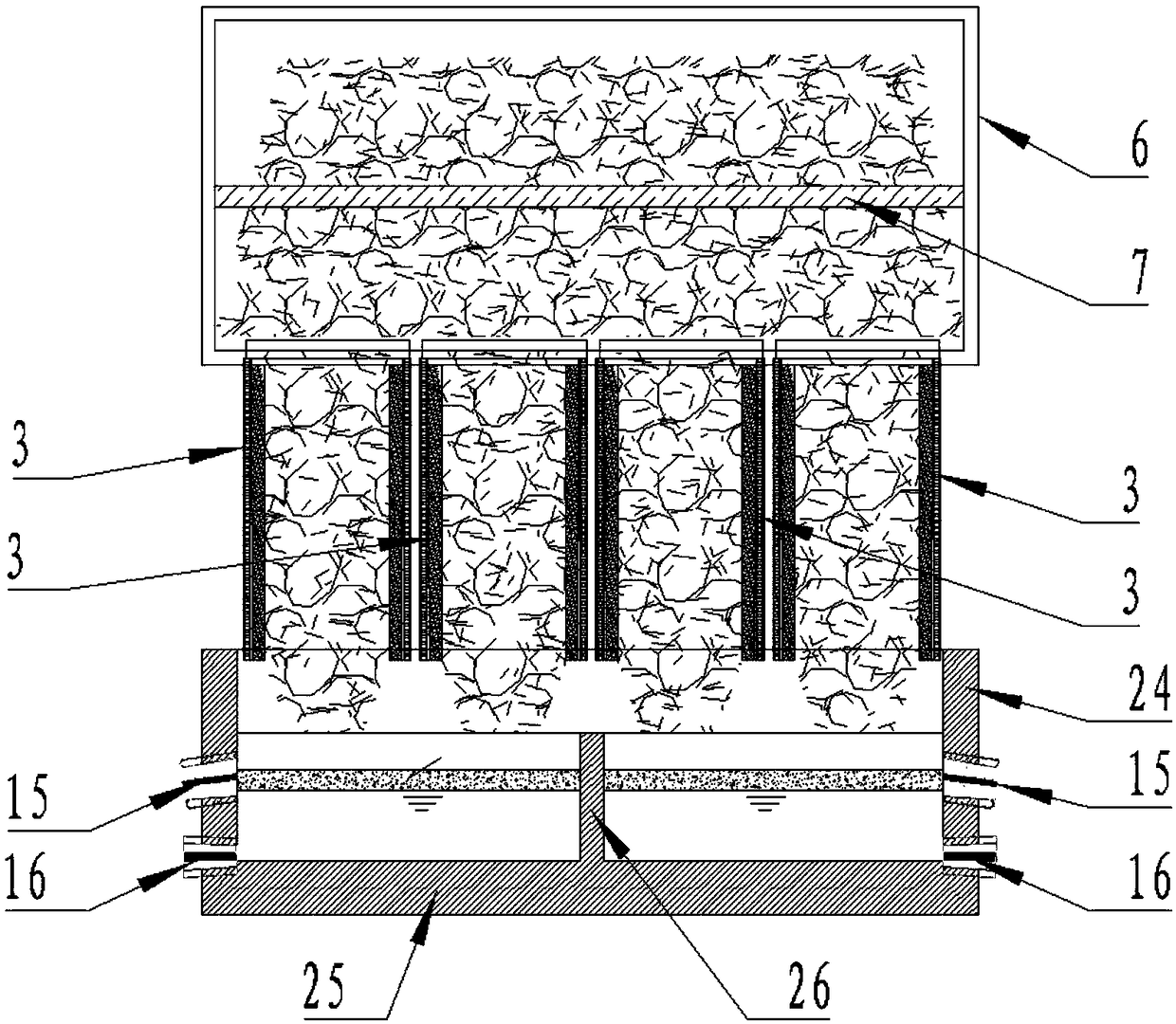

Steelmaking equipment and smelting method for steelmaking by steel scrap

ActiveCN108624740AMelt stableReduce shockElectric furnaceProcess efficiency improvementScrapElectromagnetic induction

The invention discloses steelmaking equipment and a smelting method for steelmaking by steel scrap. The steelmaking equipment for steelmaking by steel scrap comprises an induction warming shaft (2), an electric arc furnace (1) and a steel scrap preheating chamber (5), wherein open cylindrical structures are arranged at the upper and lower ends of the induction warming shaft (2), and the inductionwarming shaft (2) can carry out electromagnetic induction heating on furnace charge in the induction warming shaft (2); the lower part of the induction warming shaft (2) is hermetically connected to the electric arc furnace (1); and the outlet of the steel scrap preheating chamber (5) is correspondingly connected to the inlet of the induction warming shaft (2). The steelmaking equipment and a smelting method for steelmaking by steel scrap disclosed by the invention combine efficient steel scrap preheating, induction warming, electric arc smelting, primary energy source smelting and secondary combustion and change the single energy supply mode of a conventional electric arc furnace which is only supplied by an electrode, so that the problem that conventional steel scrap steelmaking processand device are low in heat efficiency, high in steel consumption, great in soot amount and large in impact to a power grid.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

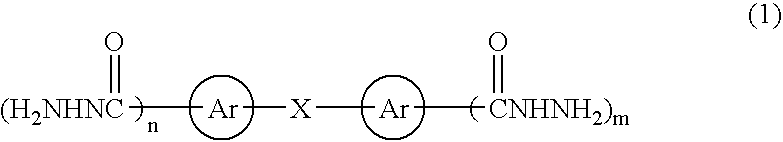

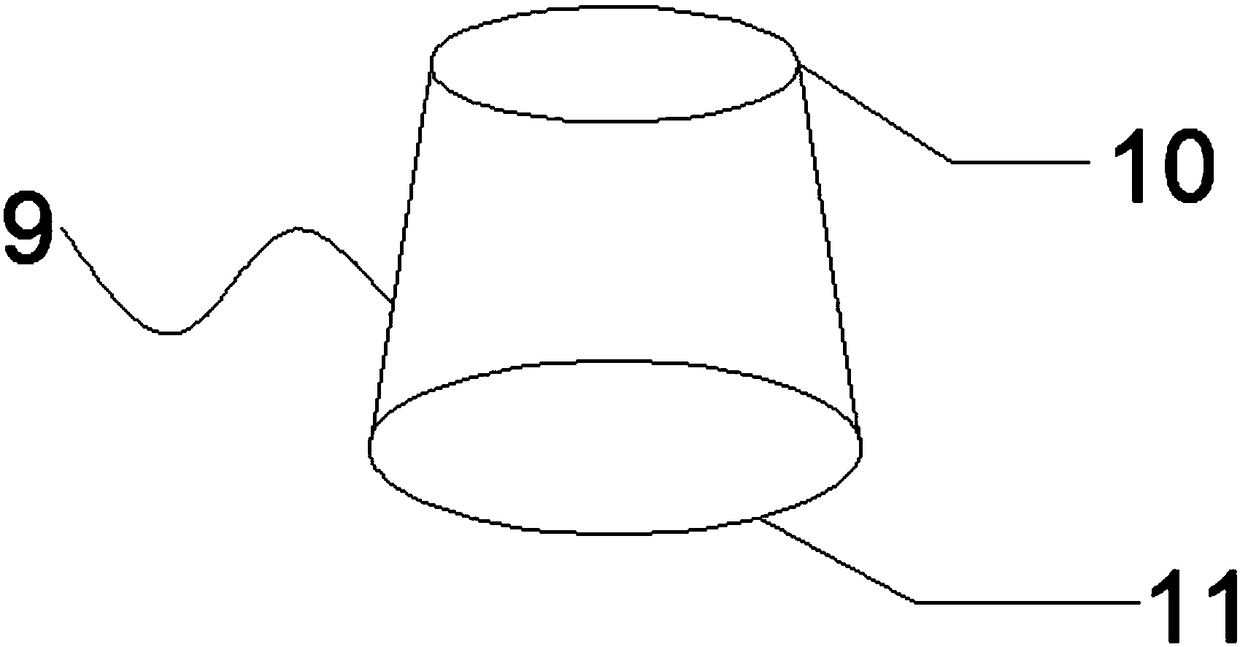

Polyacetal resin composition

InactiveUS20070123617A1Improve environmentUpgrading of quality and moldabilitySpecial tyresChemistryAntistatic agent

A polyacetal resin composition comprises a polyacetal resin, and a polycyclic aromatic carboxylic acid hydrazide or a polycyclic aromatic carboxylic acid hydrazide having a substituent. The proportion of the polycyclic aromatic carboxylic acid hydrazide may be about 0.001 to 20 parts by weight relative to 100 parts by weight of the polyacetal resin. The polyacetal resin composition may further comprise at least one member selected from an antioxidant, a heat stabilizer, a processing stabilizer, a weather (light)-resistant stabilizer, an impact resistance improver, a slip-improving agent, a coloring agent, and a filler. With the use of such a resin composition, stability of a polyacetal resin is improved, and formaldehyde emission is inhibited.

Owner:POLYPLASTICS CO LTD

Anti-wrinkle soft uniform fabric and production process thereof

ActiveCN108950811AImprove uniformityImprove stabilityArtificial thread manufacturing machinesGrip property fibresFiberPolyester resin

The invention relates to a production process of anti-wrinkle soft uniform fabric. Firstly, polyester resin and an auxiliary agent thereof are fused, then extruded and pelletized into polyester chips;secondly, the polyester chips are subjected to a spinning process to form fine-denier polyester staple fibers; thirdly, with blended yarn of conventional polyester staple fibers and carded cotton aswarp yarn and blended yarn of fine-denier polyester staple fibers and combed cotton as weft yarn, the fabric is prepared through a siro spinning and weaving process. The production process has the advantages that according to the anti-wrinkle soft uniform fabric, the fitting surface is soft, comfortable and capable of absorbing moisture and discharging sweat, and the problem of poor comfort of traditional uniform fabric is well solved; the front surface of the fabric is clean, flat, full in granular weave, bright, smooth and soft in luster and smooth and cool in hand feel and has good anti-wrinkle performance, so that daily use and finishing of uniforms are more convenient and simpler; the fabric surface has clear weaves, good stiffness, little hairiness and high strength.

Owner:ZHEJIANG LANTIANHAI FAB TECHNOLAGY CO LTD

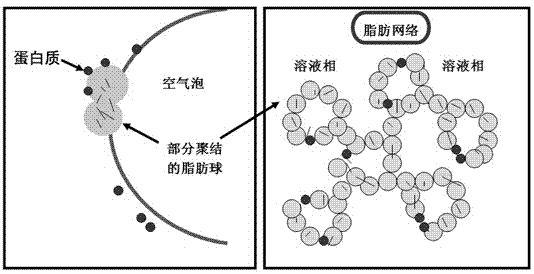

High-expansion-ratio ice cream without food additive and preparation method thereof

The invention discloses a high-expansion-ratio ice cream without food additive and a preparation method thereof. The ice cream is prepared by mixing an emulsified liquid phase A and a solution phase B based on the weight ratio of 1 to (1-3); the emulsified liquid phase A is prepared from the following components in percentage by weight: 20 to 40% of fat, 0.40 to 1.40% of whey protein powder, and the balance of water; the solution phase B is prepared from the following components in percentage by weight: 14 to 21% of skim milk powder, 3 to 5% of soyabean protein powder, 20 to 32% of white granulated sugar, and the balance of water. The ice cream paste is prepared by the combination of double-phase method and high-pressure homogenizing, so that the potential risk caused by properly added additives can be avoided; the ice cream is natural and green; the production cost is greatly saved; in addition, the quality defect of the general preparation method without food additives for processing the ice cream can be obviously reduced; the ice cream is high in expansion ratio, good in taste, high in shape forming capability, and reasonable in nutrition arrangement; the contents of the components are similar to those of the components of the general ice cream paste; other natural materials such as fruits can be mixed as required.

Owner:HARBIN INST OF TECH

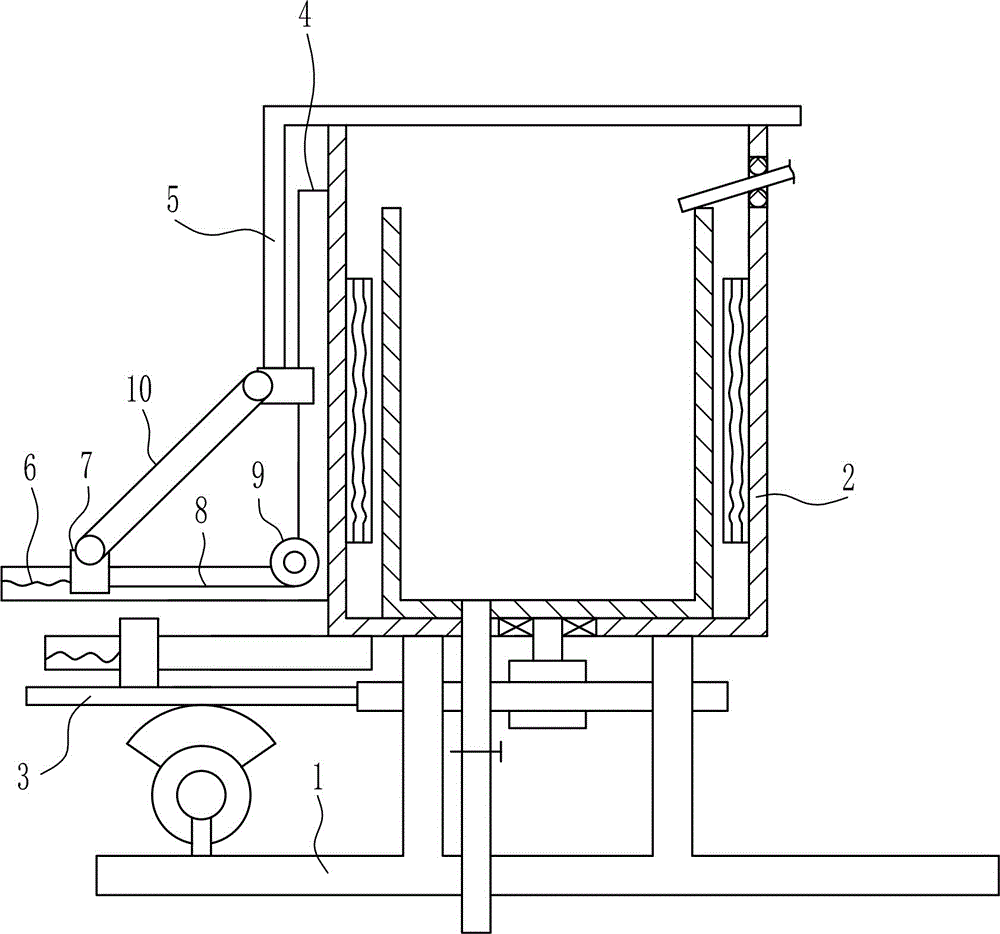

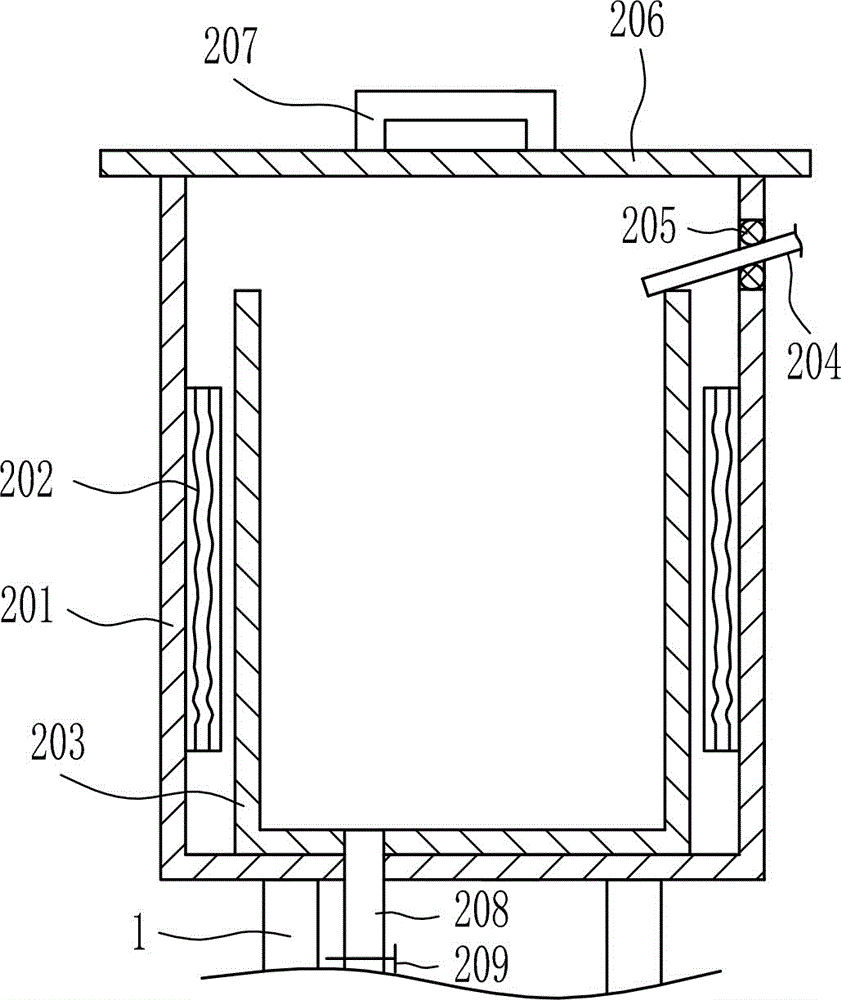

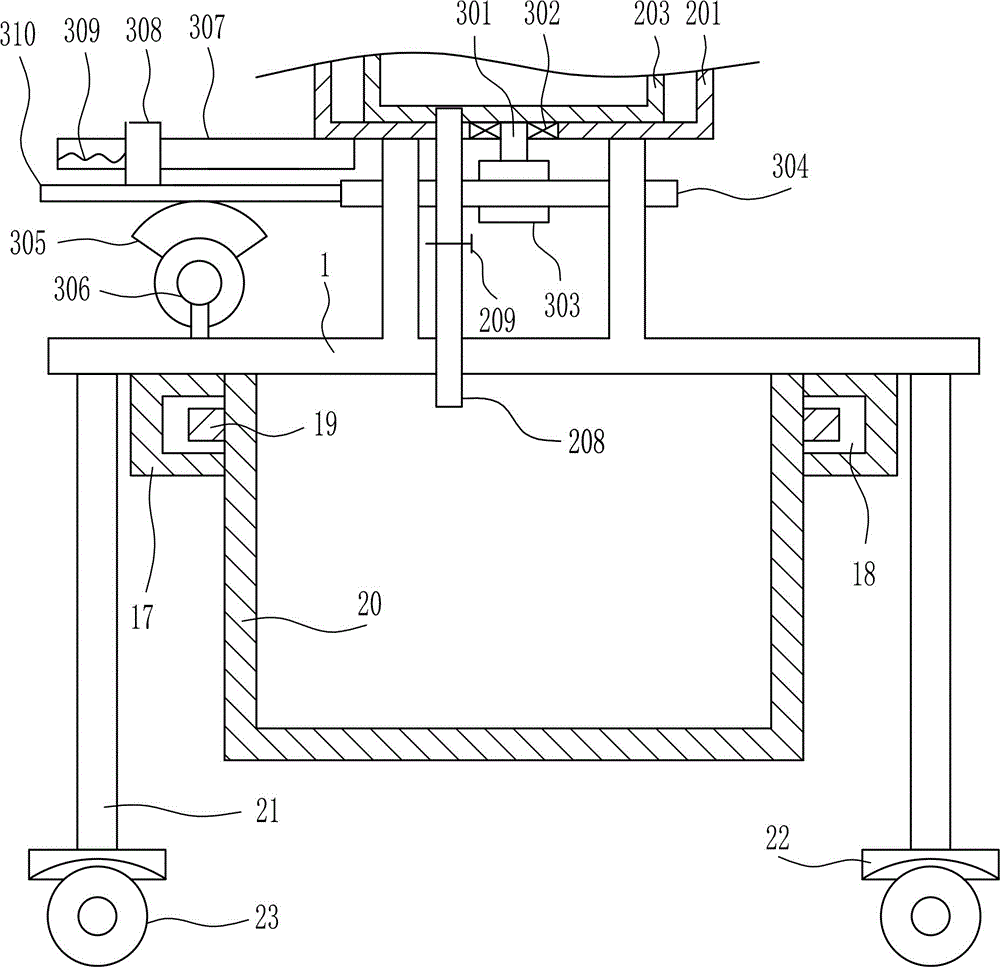

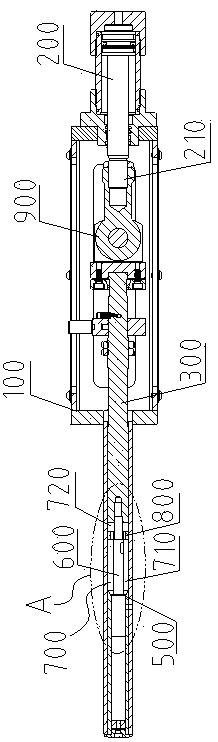

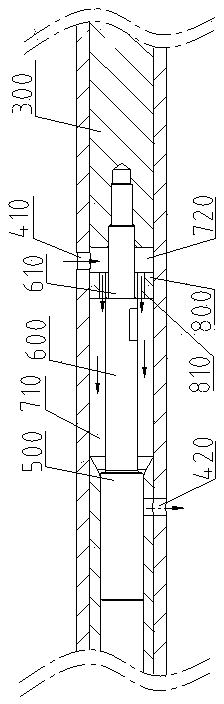

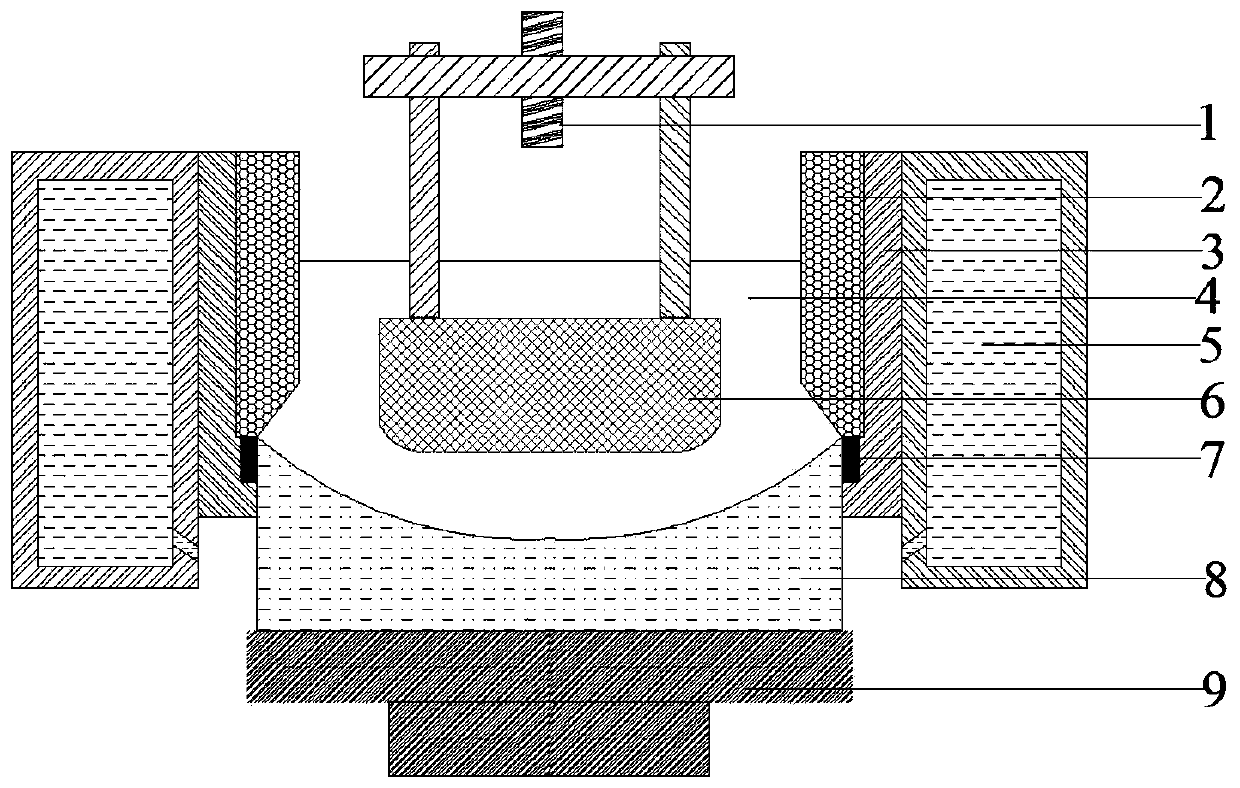

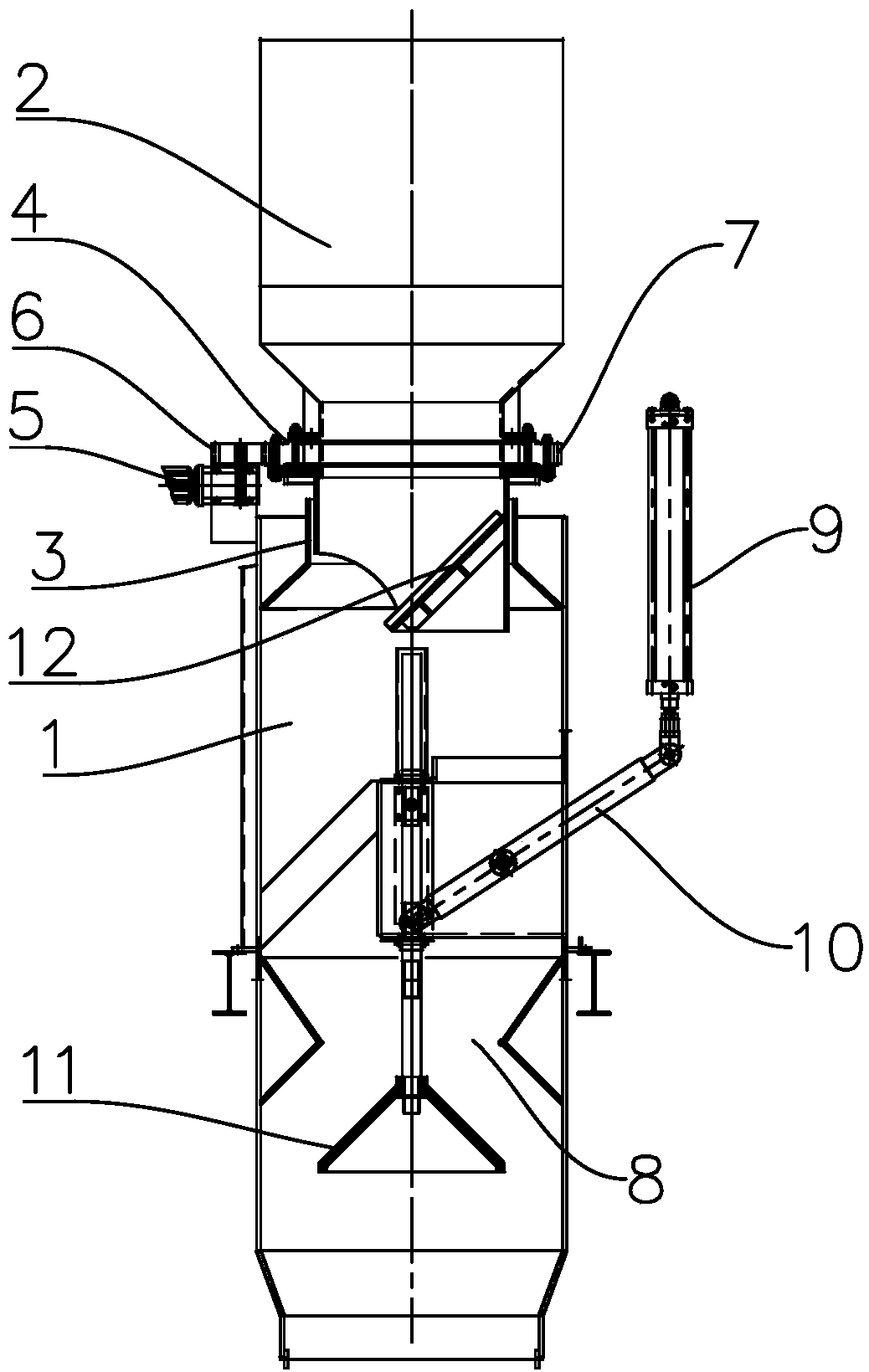

Melting equipment for petroleum asphalt

ActiveCN107523322AMelt evenly and fullyMelt stableWorking-up pitch/asphalt/bitumen by meltingAsphaltPetroleum

The invention relates to melting equipment, in particular to melting equipment for petroleum asphalt. The invention aims at providing the melting equipment for the petroleum asphalt, which can replace manual stirring, enables the petroleum asphalt to be uniformly and sufficiently melt and avoids the conditions that wastes are caused and splashed liquid threatens the safety of workers due to the fact that the petroleum asphalt is not uniformly melt and further is boiled for splashing. For solving the technical problem, the invention provides the melting equipment for the petroleum asphalt. The melting equipment comprises a base plate and the like, wherein a melting device is connected to the top end of the base plate; a driving mechanism is connected to the bottom of the melting device. The invention provides the melting equipment for the petroleum asphalt; the melting device is arranged for quickly melting the petroleum asphalt and preventing the petroleum asphalt from splashing out of the melting device; the driving mechanism is arranged for uniformly and sufficiently heating the petroleum asphalt in a rotating tank and stably melting the petroleum asphalt.

Owner:天津领先正华能源科技发展有限公司

High tensile cold-rolled steel sheet excellent in ductility and in strain aging hardening properties, and method for producing the same

InactiveUS20030047258A1High strengthPromote formationFurnace typesHeat treatment furnacesSheet steelHigh intensity

The present invention provides a high tensile cold-rolled steel sheet having superior ductility, strain age-hardening characteristics, and crash resistance properties, and also provides a manufacturing method therefor. As a particular means, a thin cold-rolled steel sheet containing 0.05% to 0.30% of C, 0.4% to 2.0% of Si, 0.7% to 3.0% of Mn, 0.08% or less of P, 0.02% or less of Al, and 0.0050% to 0.0250% of N on a mass % basis is manufactured in which N / Al is 0.3 or more. This thin cold-rolled steel sheet is heated to a temperature between (an Ac1 transformation point) and (an Ac3 transformation point+50° C.), is cooled at a cooling rate of 5 to 150° C. / second in the range of at least 600 to 500° C., and is held in the temperature range of 350 to 500° C. This steel sheet has superior ductility, strain age-hardening characteristics having a DELTATS of 50 MPa or more, and crash resistance properties.

Owner:JFE STEEL CORP

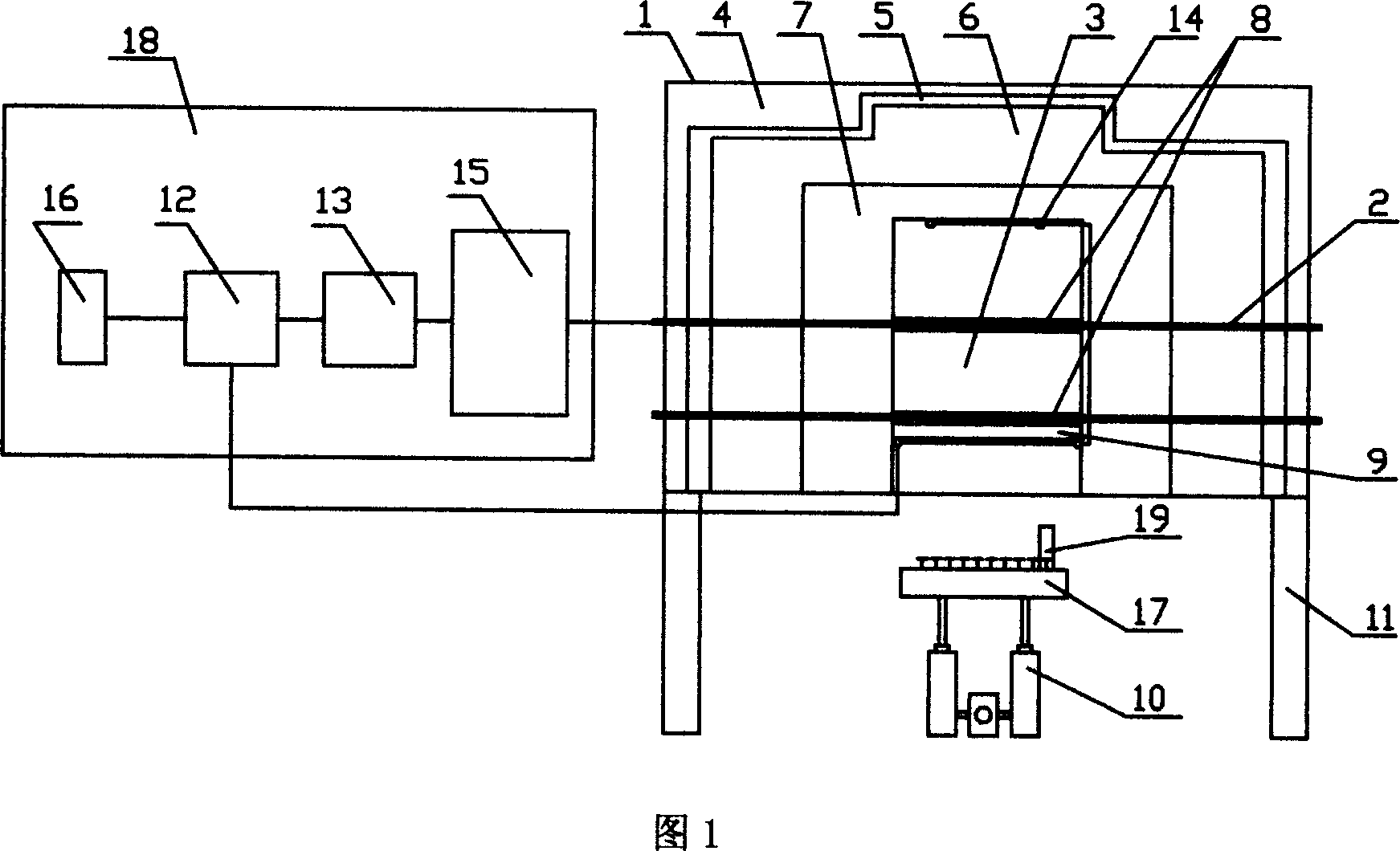

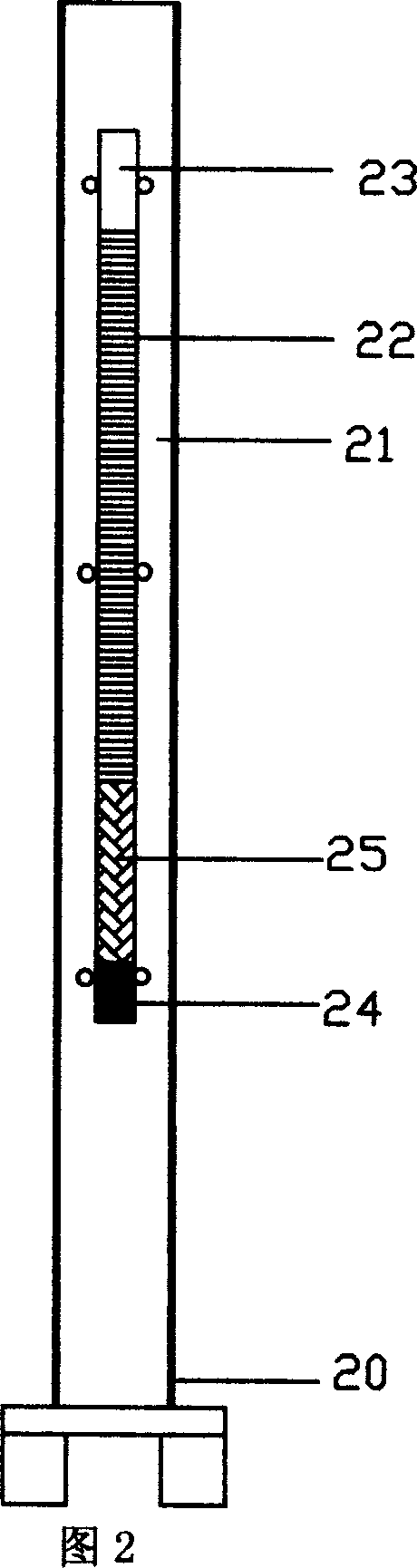

Growth system of crystal by resistance heating vertical multi-crucible descent method

The invention relates the crystal growth device with vertical crucible descent method. The device comprises crystal furnace, crucible, crucible table and controlling temperature unit. Crystal furnace comprises outer shell, insulating cotton, insulating brick, flame retardant coating, root brick, I-shaped brick and bracing frame. Flame retardant coating is near high-temperature region of furnace, and root brick is at the bottom of the furnace. The device can grow many crystals at the same time.

Owner:JIAXING UNIV +1

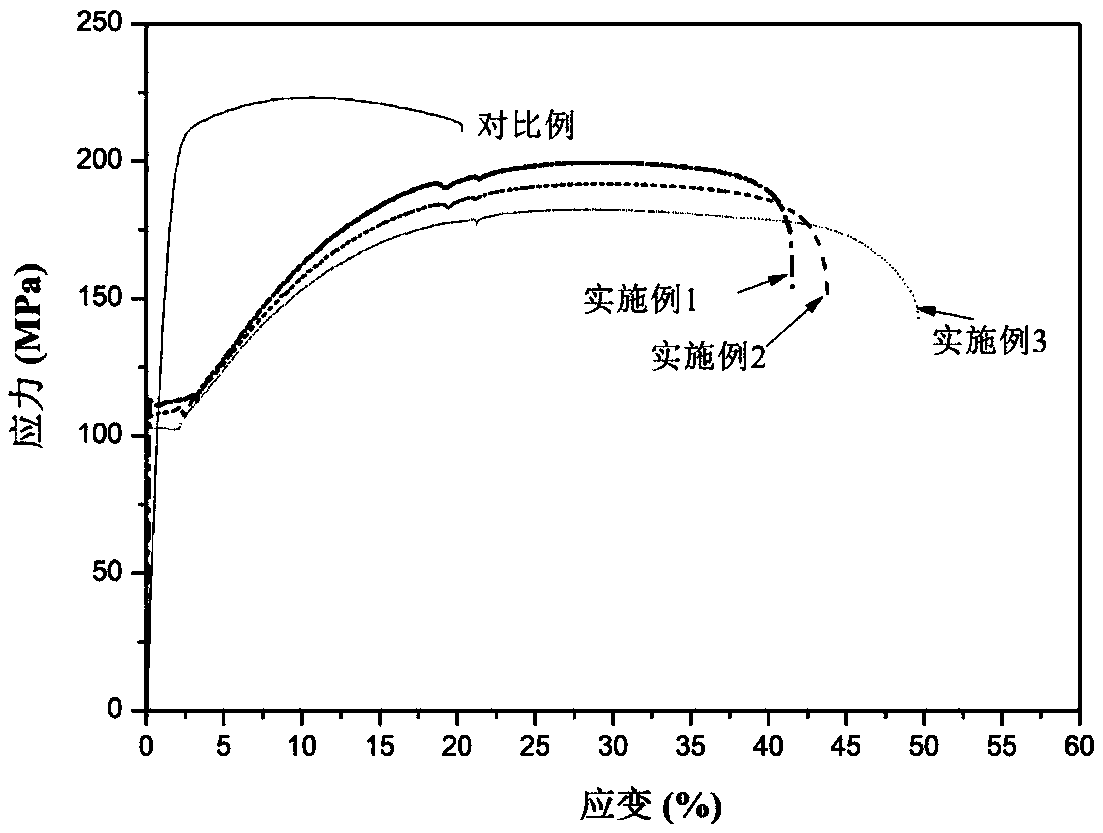

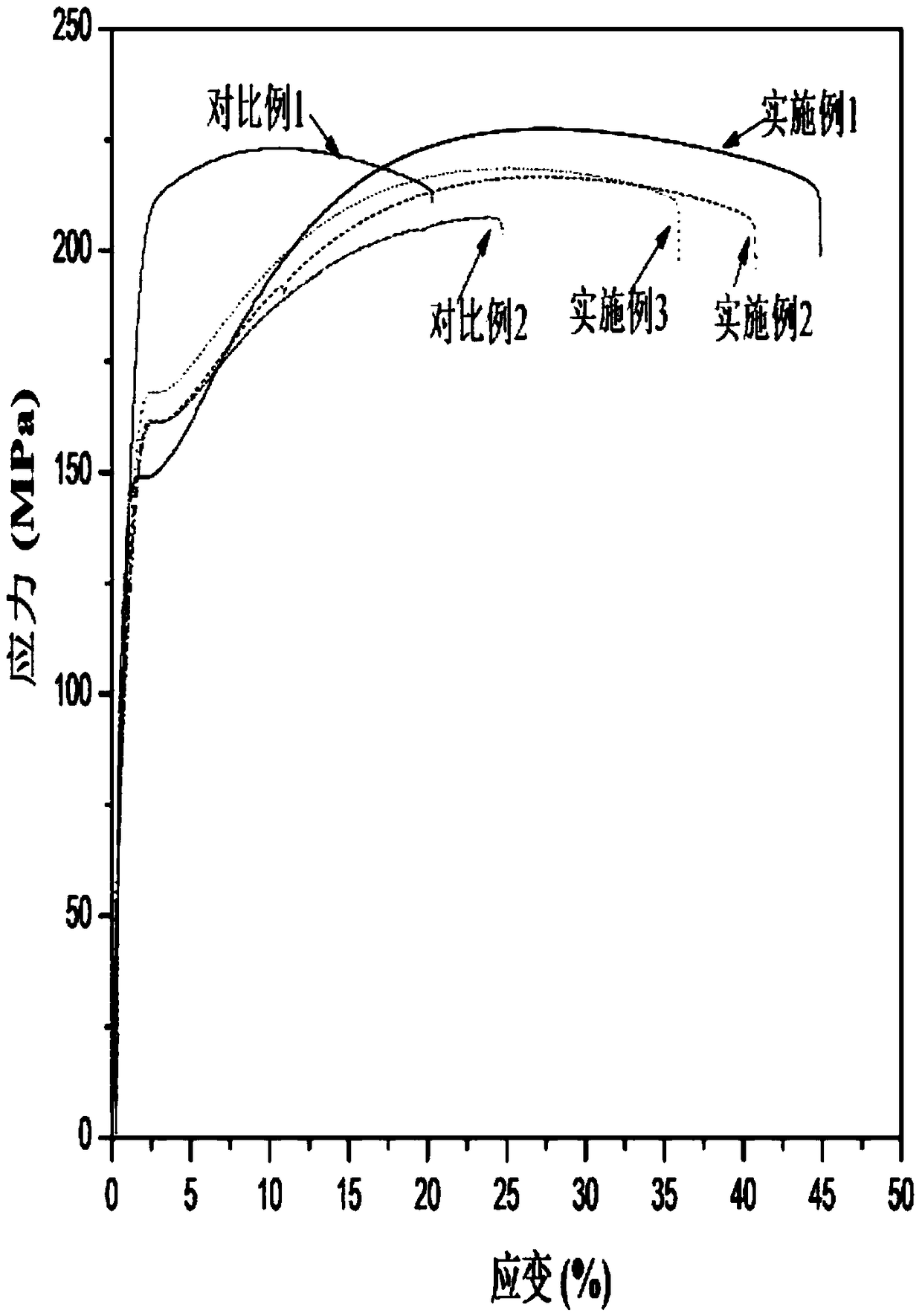

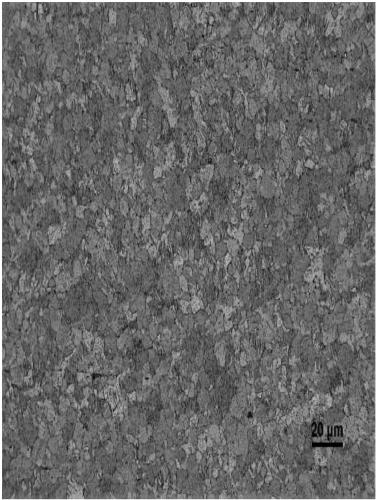

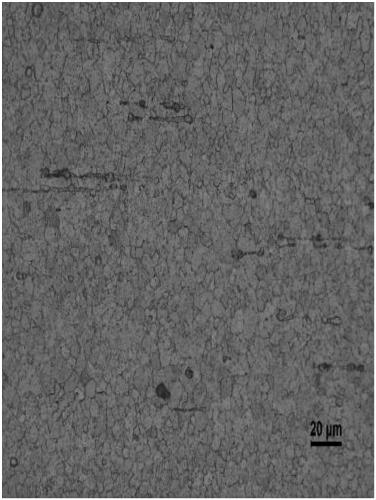

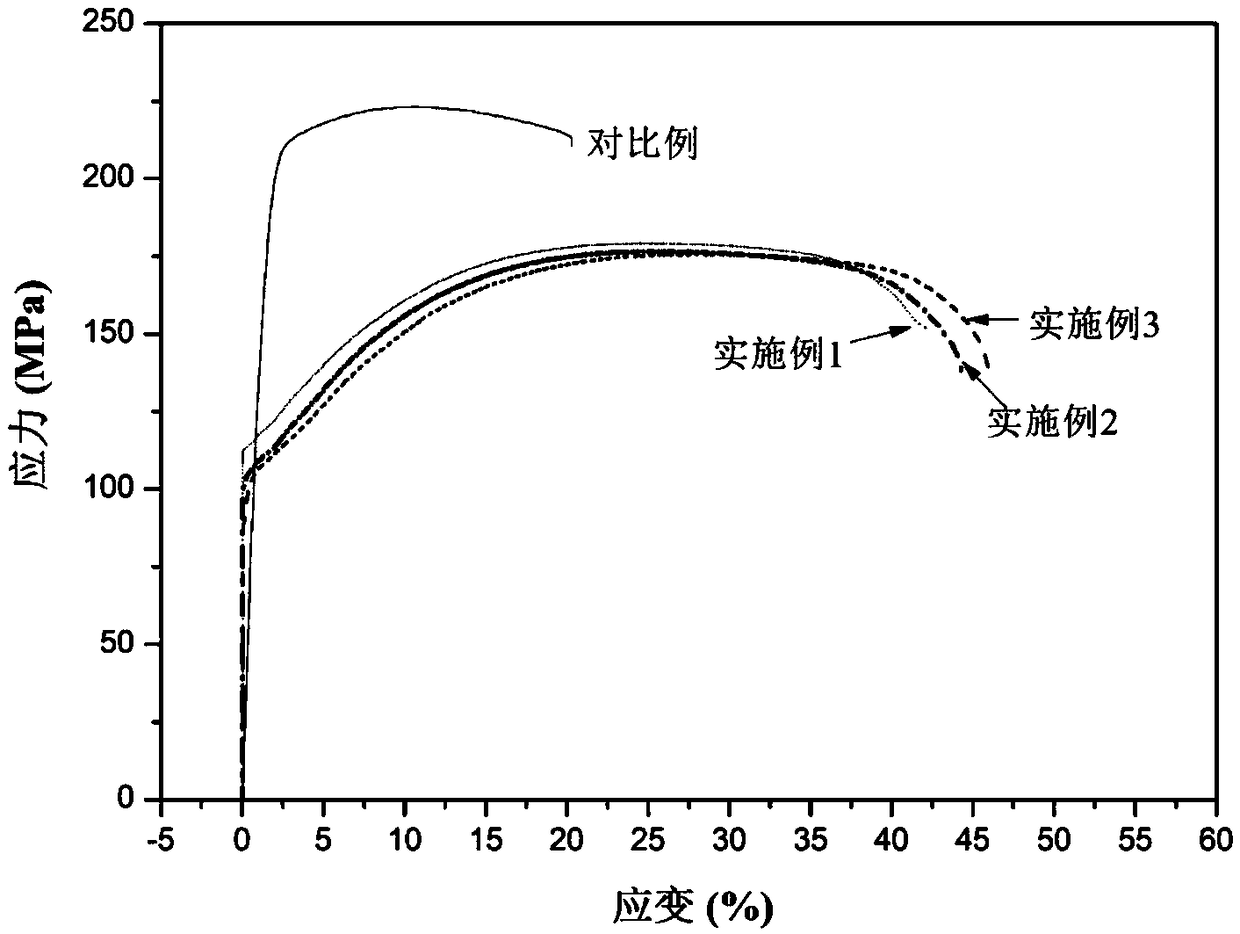

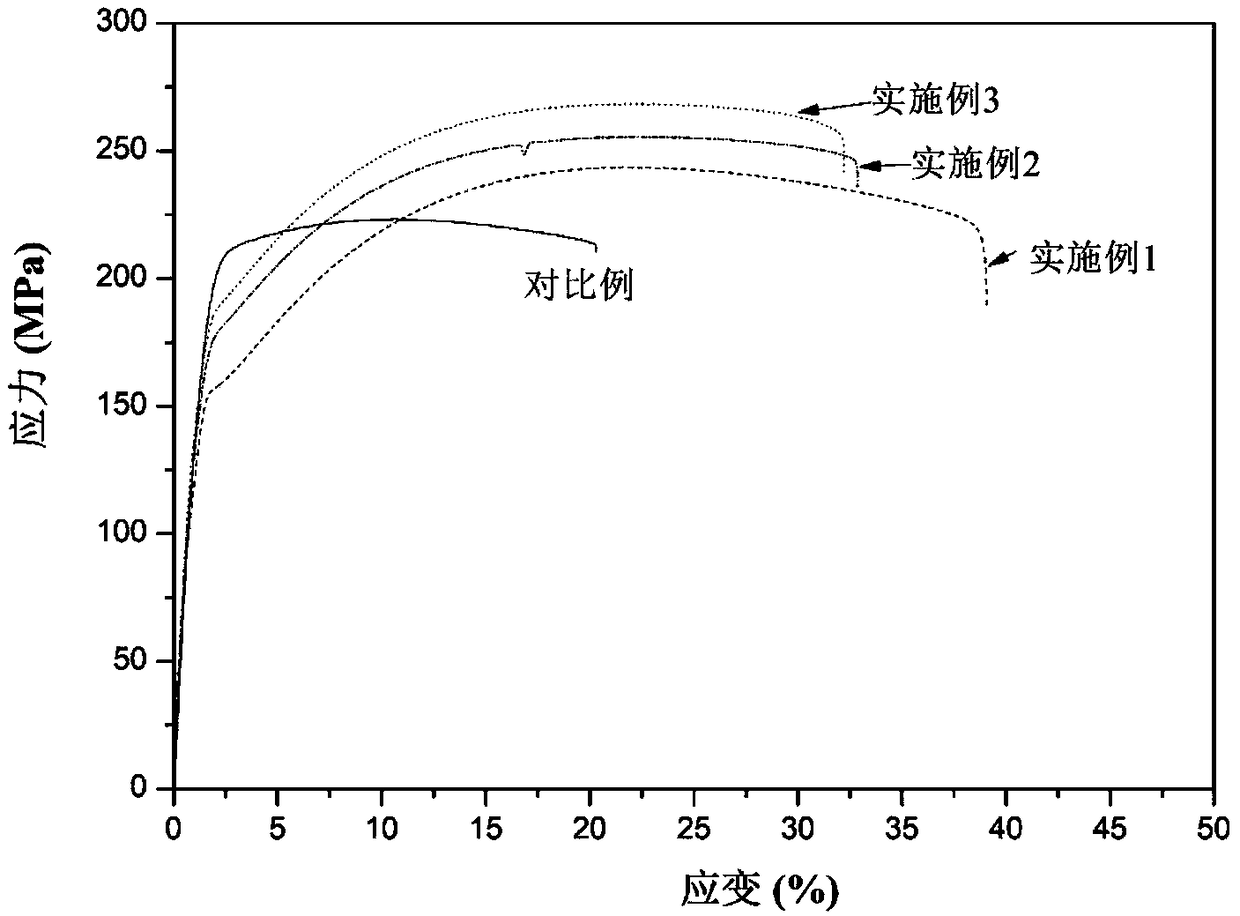

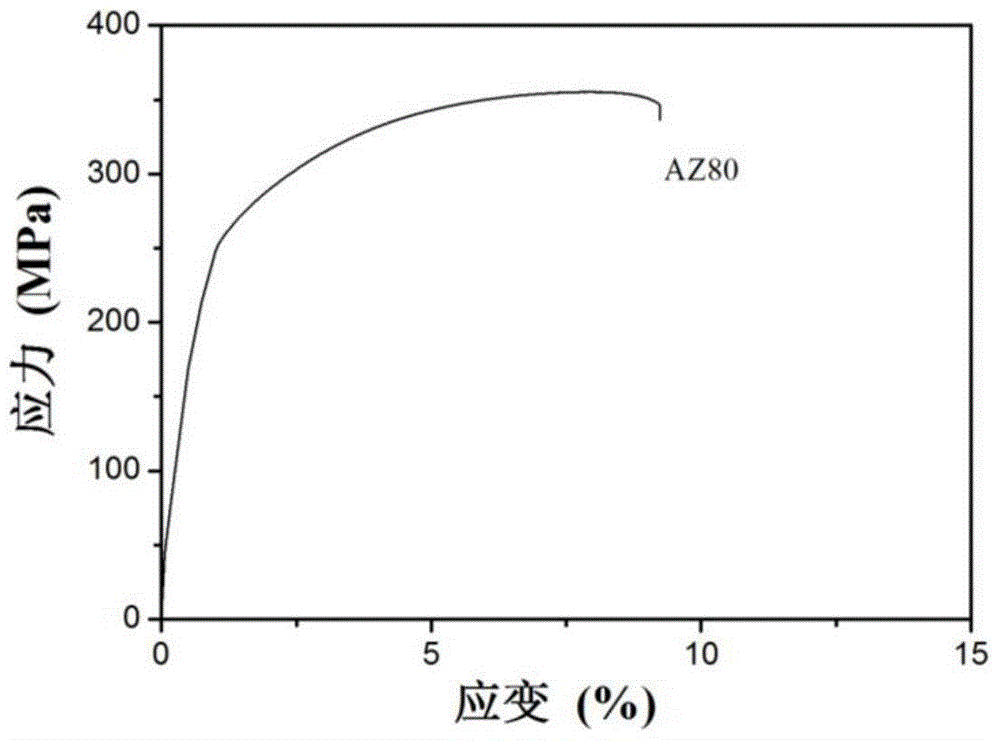

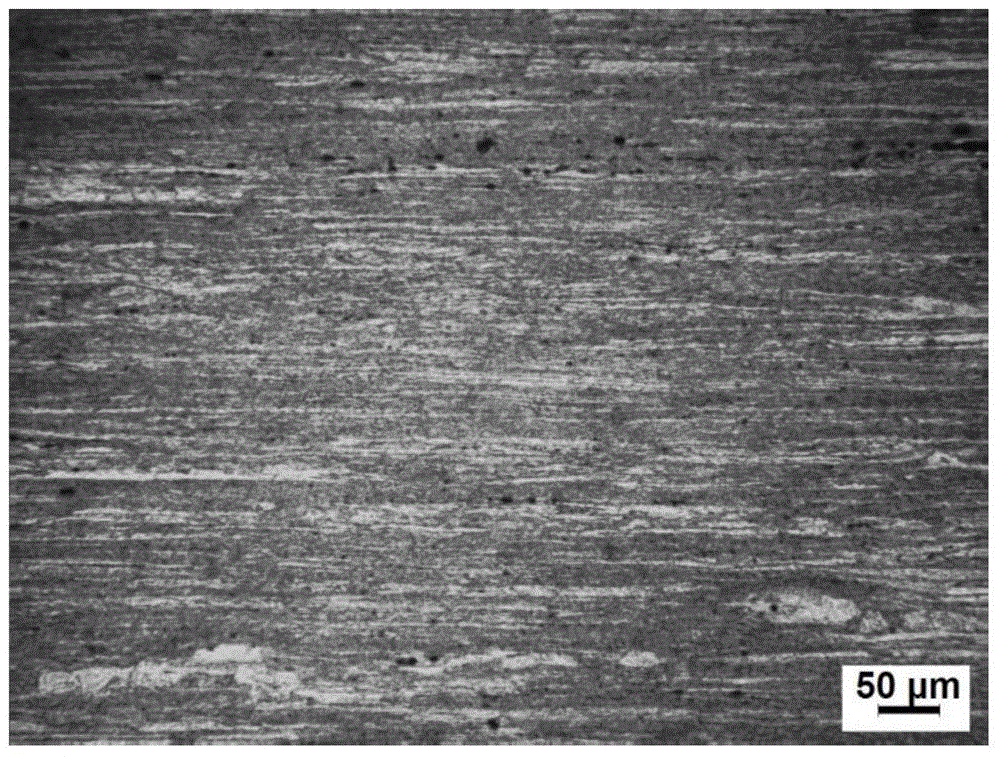

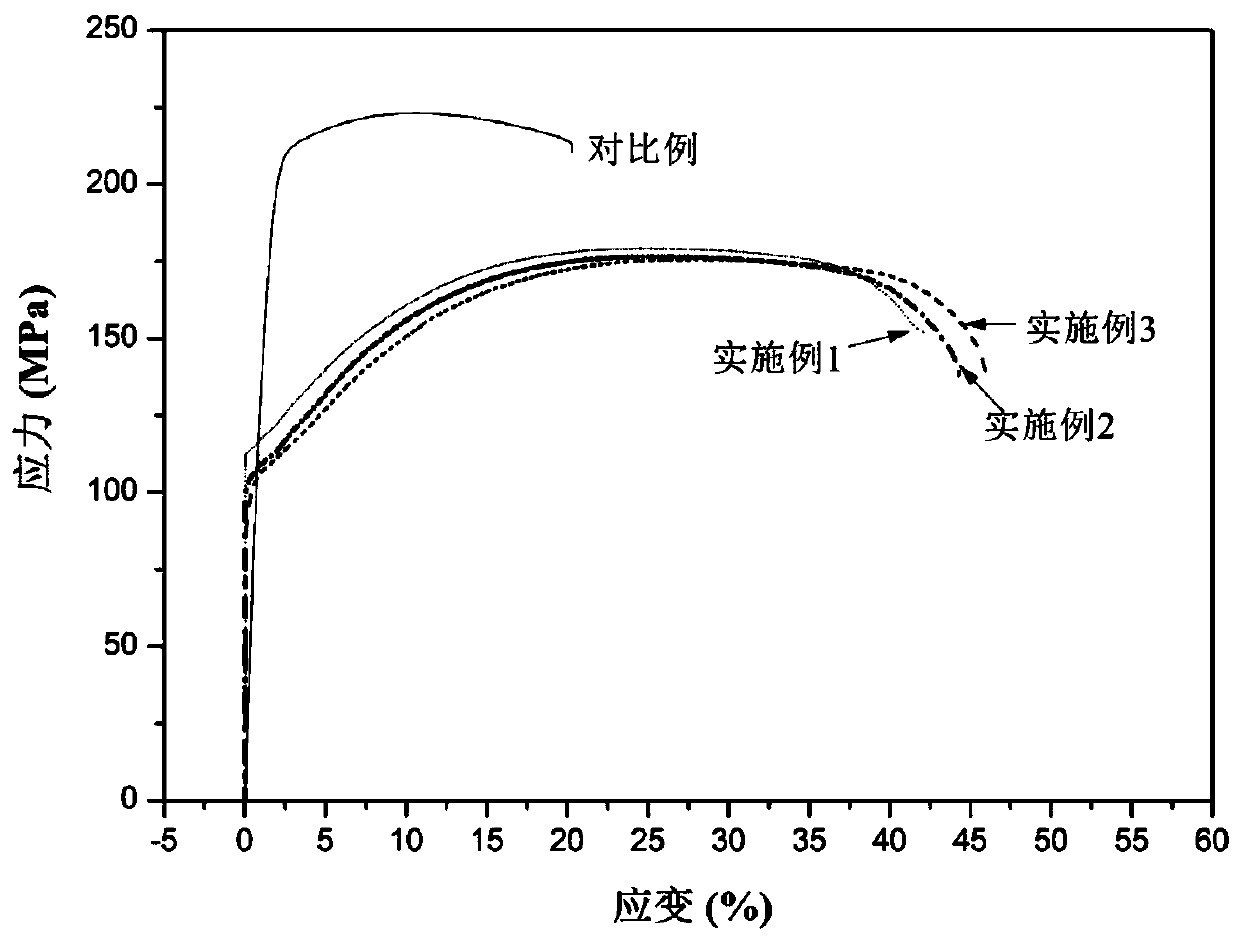

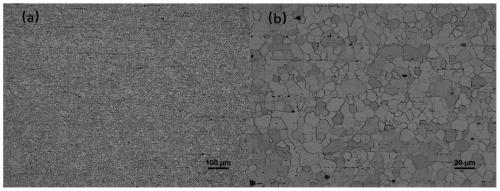

High-plasticity magnesium alloy and preparation method thereof

ActiveCN109402429AImprove flame retardant performanceGood plasticity at room temperatureChemical compositionRoom temperature

The invention relates to high-plasticity magnesium alloy and a preparation method thereof. The alloy is Mg-Bi-Nd-Mn magnesium alloy, and comprises the following chemical components in percentages by mass: 2-8 wt% of Bi, 1.5-4 wt% of Nd, 0.05-0.15 wt% of Mn, and the balance of Mg and inevitable impurities, and moreover, the mass ratio of Bi to Nd equals to 1.3-2: 1. The process is simple, the plasticity of deformed magnesium alloy at the room temperature is excellent, the ductility at the room temperature reaches 43% or above, and meanwhile, the flame retardant property is good.

Owner:HEBEI UNIV OF TECH

Ice cream containing unsaturated fatty acid and beta-carotene, and making method thereof

The invention relates to an ice cream containing unsaturated fatty acid and beta-carotene, belonging to the field of nutritional health-card food, and aiming at solving the health problems caused by eating a great deal of saturated fatty acid and overcoming the quality detects of the ice cream which is made by taking unsaturated fatty acid oil as a raw material. A making method of the ice cream comprises the following steps of: making emulsified liquid A by solid fat, isolated soy protein powder, spent meal, starch sodium octenylsuccinate and deionized water; mixing the beta-carotene and fluid oil and dissolving; making emulsified liquid B by the mixture, spent meal, a sweetening agent and deionized water; respectively sterilizing, homogenizing and ageing the two phases; before congelation, premixing the emulsified liquid A in advance, and then mixing the emulsified liquid B with the premixed emulsified liquid A to obtain ice cream slurry, wherein the quantity of the emulsified liquid B is equal to that of the emulsified liquid A; and finally, carrying out extrusion congelation operation at low temperature. The ice cream prepared by the invention is good in mouthfeel and shape forming ability, and overcomes the quality defects of the ice cream which is made by taking unsaturated fatty acid oil as raw material; and the ideal texture properties and nutrition-allocated proportion can be obtained.

Owner:HARBIN INST OF TECH

Steel-making equipment for steel scrap steelmaking and smelting method

ActiveCN108624739AMelt stableReduce shockProcess efficiency improvementElectric furnaceSteelmakingElectric arc furnace

The invention discloses steel-making equipment for steel scrap steelmaking and a smelting method. The steel-making equipment for the steel scrap steelmaking comprises a non-contact melting device (3),an electric arc furnace (1) and a steel scrap preheating chamber (6), wherein the non-contact melting device (3) can carry out non-contact heating on a furnace burden in the non-contact melting device (3); the lower end of the non-contact melting device (3) is correspondingly connected with the feeding port of the electric arc furnace (1); and an electromagnet (7) capable of attracting the furnace burden is arranged in the steel scrap preheating chamber (6). The steel-making equipment for the steel scrap steelmaking and the smelting method are in a fully-closed state, steel remaining and slagremaining operation are adopted, through energy supplying mode of combining the non-contact melting, electric arc heating, oxygen blowing and carbon spraying, oxygen and fuel gas combustion co-melting, the problems that a traditional steel scrap steelmaking technology and device are low in heat efficiency, a steel material consumption is high, the smoke amount is large, and the impact on a powergrid is large are solved.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

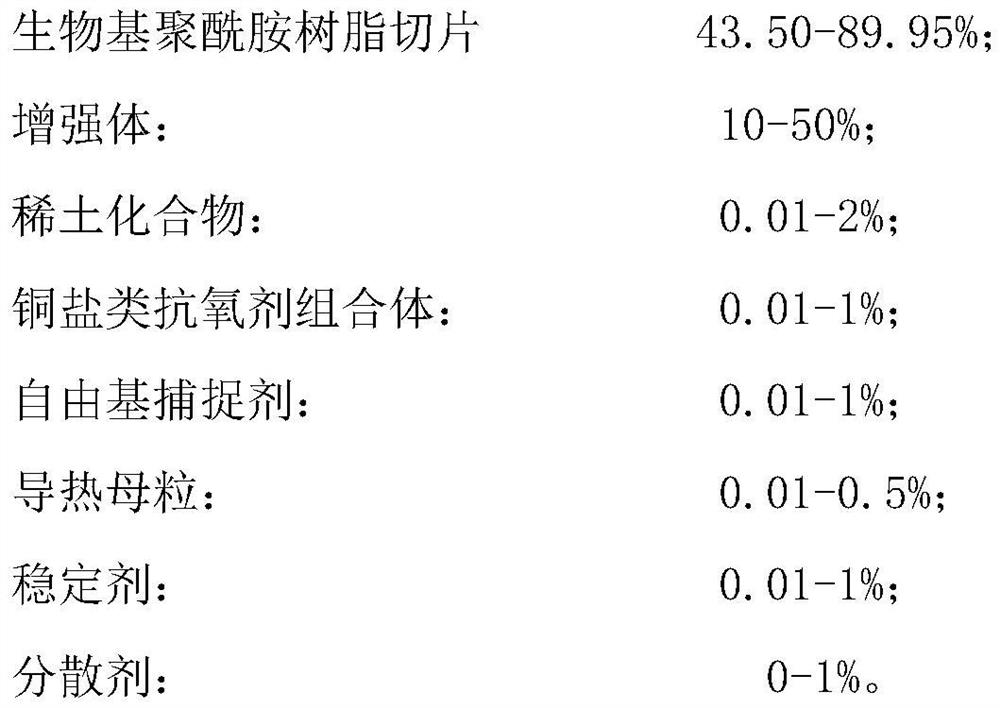

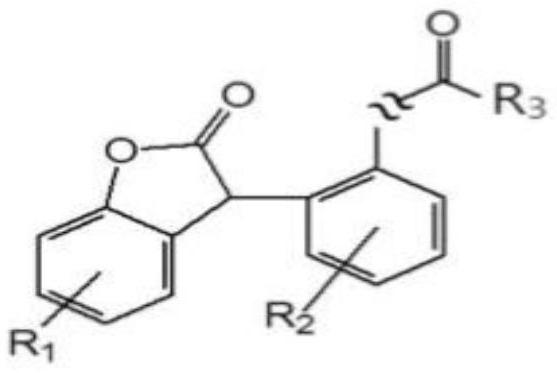

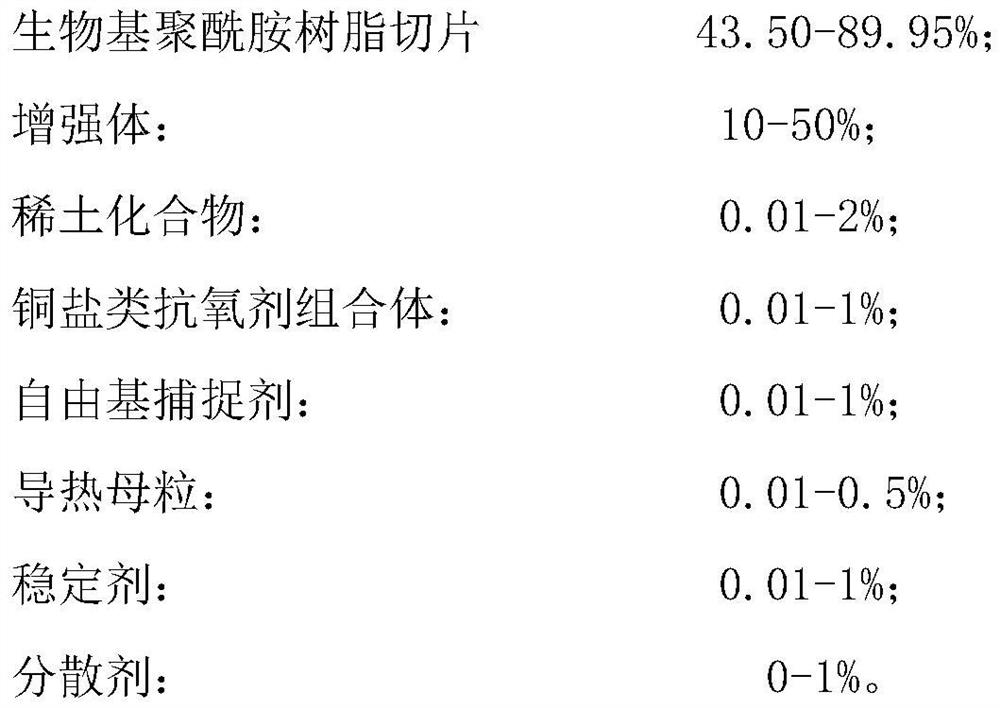

High-strength and high-heat-resistance bio-based polyamide composition and preparation method thereof

The invention discloses a high-strength and high-heat-resistance bio-based polyamide composition and a preparation method thereof. The high-strength and high-heat-resistance bio-based polyamide composition is prepared from the following raw materials in parts by weight: 43.50-89.95% of bio-based polyamide resin slices; 10-50% of a reinforcing body; 0.01-2% of a rare earth compound; 0.01 to 1% of a copper salt antioxidant combination; 0.01-1% of a free radical capturing agent; 0.01 to 0.5% of heat conduction master batch; 0.01-1% of a stabilizing agent; and 0-1% of a dispersant. The preparation method has the advantages that the bio-based polyamide resin slices are prepared from pentamethylene diamine and adipic acid through a step-by-step polycondensation process or prepared from pentamethylene diamine, adipic acid and terephthalic acid through a step-by-step polycondensation process, the pentamethylene diamine is prepared through starch fermentation, and the prepared polyamide resin belongs to environment-friendly engineering plastic; and in order to fill the technical blank in the field of high heat resistance of the bio-based polyamide material, components such as a rare earth compound, a copper salt antioxidant combination, a free radical scavenger and heat-conducting master batch are introduced into the formula design, so that the bio-based polyamide material is endowed with excellent long-period thermo-oxidative aging resistance.

Owner:SHANGHAI PRET COMPOSITES +3

Improved die casting forming method

The invention provides an improved die casting forming method. The improved die casting forming method comprises the following steps that S1, smelting is conducted, wherein an aluminum alloy materialis put into a heating furnace to be continuously heated to obtain molten liquid, then compressed argon or compressed nitrogen serves as a carrier, strengthening particles are evenly added into the molten liquid, slag is removed, and standing is conducted to obtain a first melt; S2, stirring is conducted, wherein the first melt is stirred electromagnetically to obtain a cast ingot; S3, smelting isconducted again, wherein the cast ingot is cut into blanks and re-heated to obtain a second melt; S4, mold treatment is conducted, wherein a mold is preheated and subjected to heat preservation for 1h; S5, die casting is conducted, wherein the second melt is transferred into a holding furnace of a low-pressure casting machine for heat preservation, then the second melt is die-cast into a mold cavity under the low-pressure condition, and a die casting is obtained; and S6, heat treatment is conducted, wherein the obtained die casting is subjected to a heat treatment process including solution treatment and incomplete artificial aging. An aluminum alloy product obtained through the method is compact in structure, good in comprehensive mechanical property and physicochemical property, high inmaterial utilization rate and low in cost.

Owner:GUANGDONG HONGTEO ACCURATE TECH (TAISHAN) CO LTD

Low-cost and high-room-temperature plastic deformation magnesium alloy and preparation method thereof

The invention discloses a low-cost and high-room-temperature plastic deformation magnesium alloy. The low-cost and high-room-temperature plastic deformation magnesium alloy is prepared from the following raw materials: Bi, Ca, Y and Mg. The invention further provides a preparation method of the low-cost and high-room-temperature plastic deformation magnesium alloy; the preparation method comprisesthe following steps: carrying out pre-heating treatment on pure Bi, an Mg-Ca intermediate alloy and an Mg-Y intermediate alloy to obtain a pre-formed material; under protection gas, adding an Mg ingot into a smelting furnace and smelting; adding the pre-formed material; after raising the temperature, smelting and stirring, carrying out refining and degassing treatment; after adjusting the temperature of the smelting furnace and carrying out heat-insulation treatment, removing surface dross and pouring and molding to prepare a casting-state magnesium alloy; after carrying out solid solution and quenching treatment on the casting-state magnesium alloy, cutting a casting ingot into a blank; then extruding and deforming to prepare the low-cost and high-room-temperature plastic deformation magnesium alloy. According to the magnesium ally provided by the invention, the room-temperature plasticity becomes high and the room-temperature elongation percentage is increased; a preparation technology is simple and low in cost and mass production is easy to realize.

Owner:合肥诺瓦新材料科技有限公司

Room-temperature high-plasticity magnesium alloy and preparation method thereof

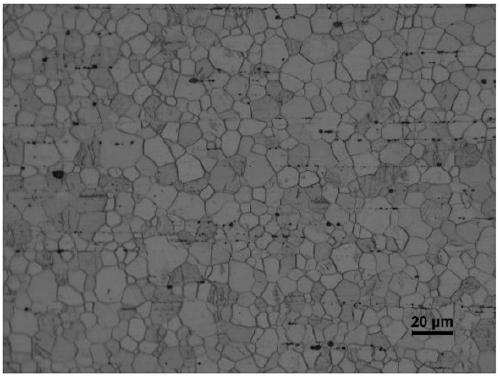

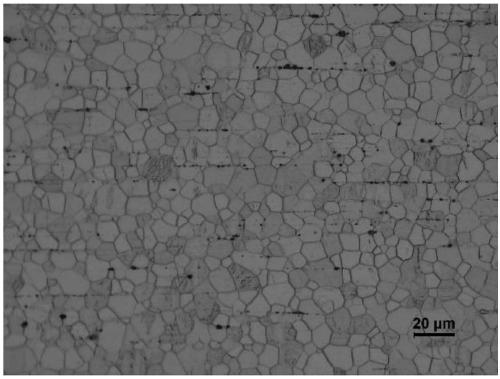

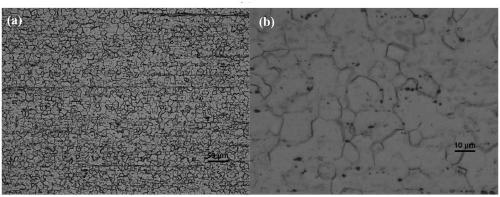

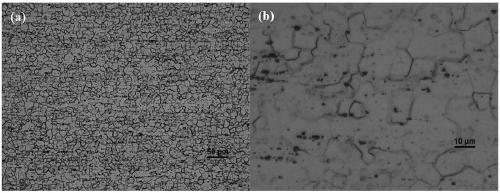

ActiveCN109371301AUniform and fine fully recrystallized structureAvoid overgrowingRoom temperatureMetallic materials

The invention discloses a magnesium alloy with excellent room-temperature plasticity, and a preparation method thereof, and belongs to the technical field of (metal materials) magnesium alloy. The magnesium alloy is prepared from the following components in percentage by weight: 2-7wt% of Bi, 1.5-4wt% of Y, 0.05-0.15wt% of Mn and the balance of Mg, wherein a Bi / Y ratio is 1.3-2, and Y is more thanor equal to 1.5%. The preparation method for the magnesium alloy mainly comprises the following preparation steps of: smelting, thermal treating and deformation processing. At the room temperature, the alloy has ductility which can be 41% or more, shows excellent room-temperature plasticity, and is a potential magnesium alloy material which can be used for further room-temperature plasticity processing or super-plasticity forming technology processing. Besides, in a casting process and a thermal treatment process, the alloy shows excellent flame resistance.

Owner:BEIJING ZHONGKE PUJIN SPECIAL MATERIAL TECHDEV CO LTD

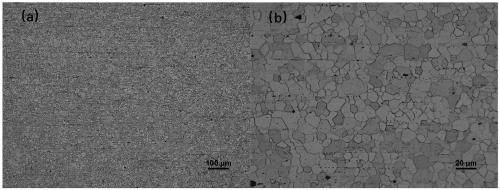

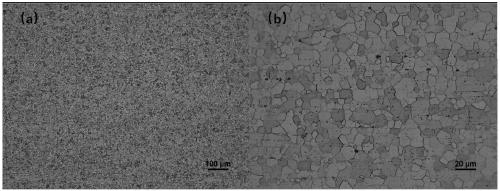

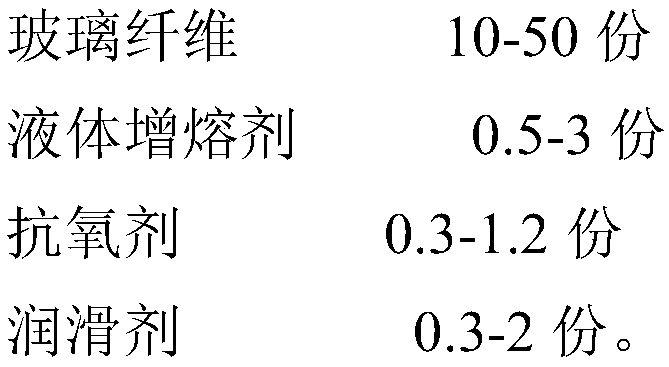

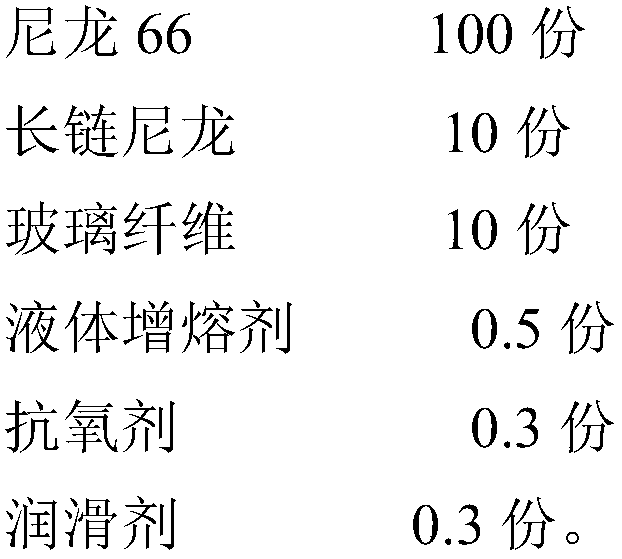

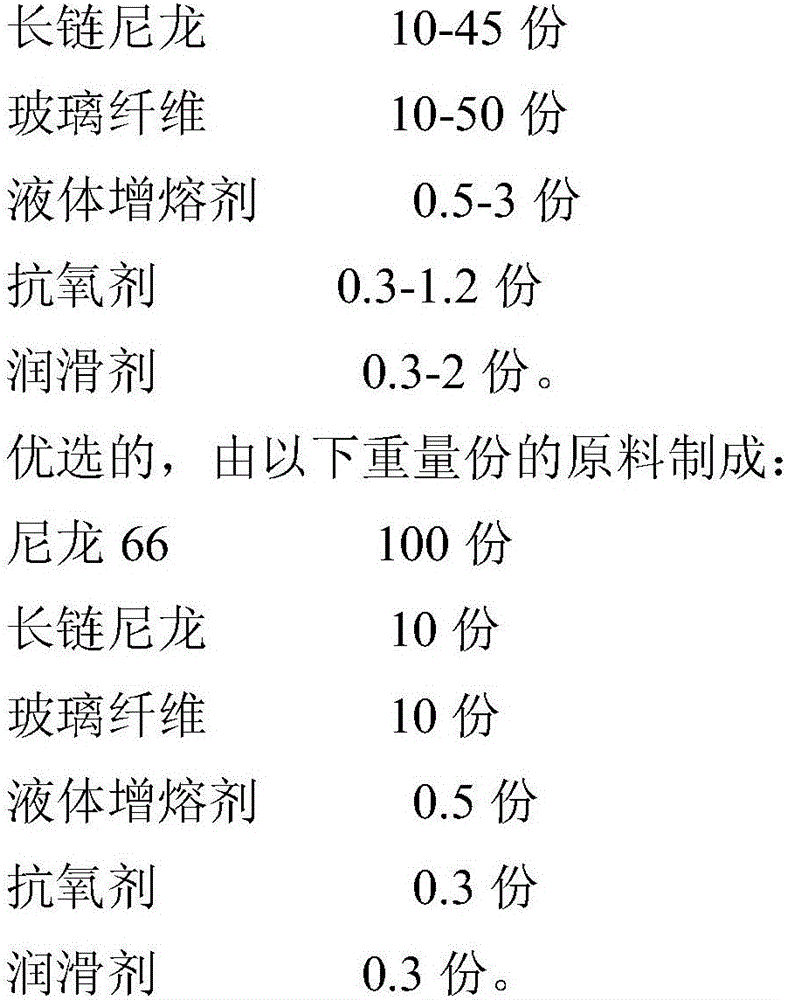

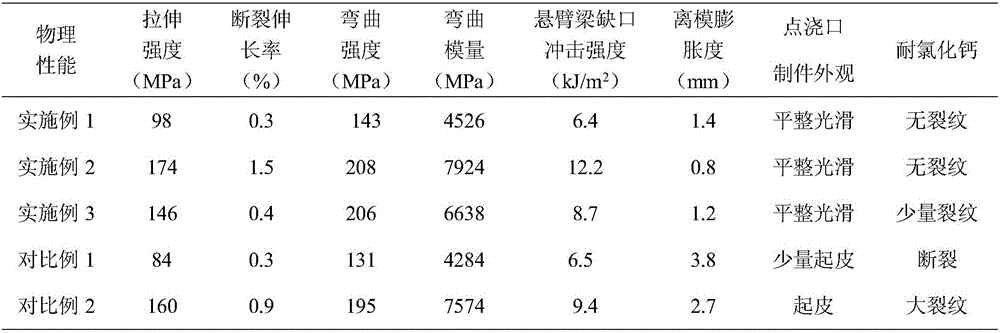

A polyamide material with stable melt and chloride solution resistance and preparation method thereof

The invention relates to a polyamide material with stable melt and anti-chloride solution feature and a preparation method thereof. The polyamide material consists of the following components in parts by weight: 100 parts of nylon 66, 10-45 parts of long-chain nylon, 10-50 parts of glass fiber, 0.5-3 parts of liquid melting enhancer, 0.3-1.2 parts of antioxidant and 0.3-2 parts of lubricant. The preparation method comprises the following steps: uniformly premixing the nylon 66, long-chain nylon and liquid melting enhancer; adding the antioxidant and lubricant and mixing again, and adding the mixture through a main feed port of a twin-screw extruder; adding the glass fiber through a glass fiber port, wherein the rotation speed is controlled at 800-1200r / min and the temperature is controlled at 250-285 DEG C; and performing extrusion granulation to obtain the polyamide material. The material has excellent mechanical property, melt stability, chloride ion corrosion resistance and static pressure resistance and is particularly suitable for water supply components with relatively high requirement on chemical corrosion resistance such as high-pressure water guns, high-pressure water pipes, shower heads and spray heads.

Owner:上海日之升科技有限公司

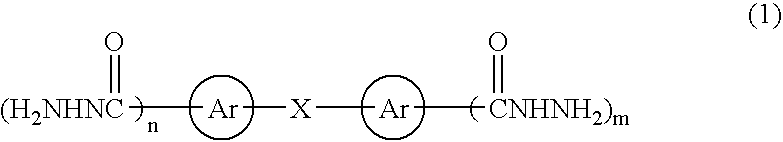

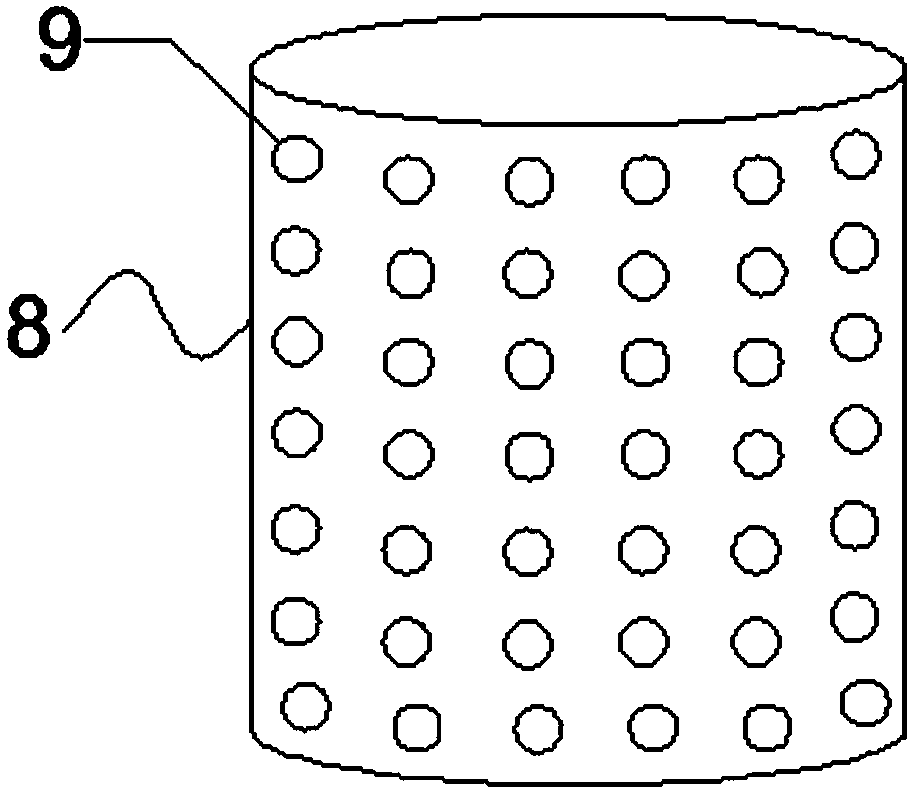

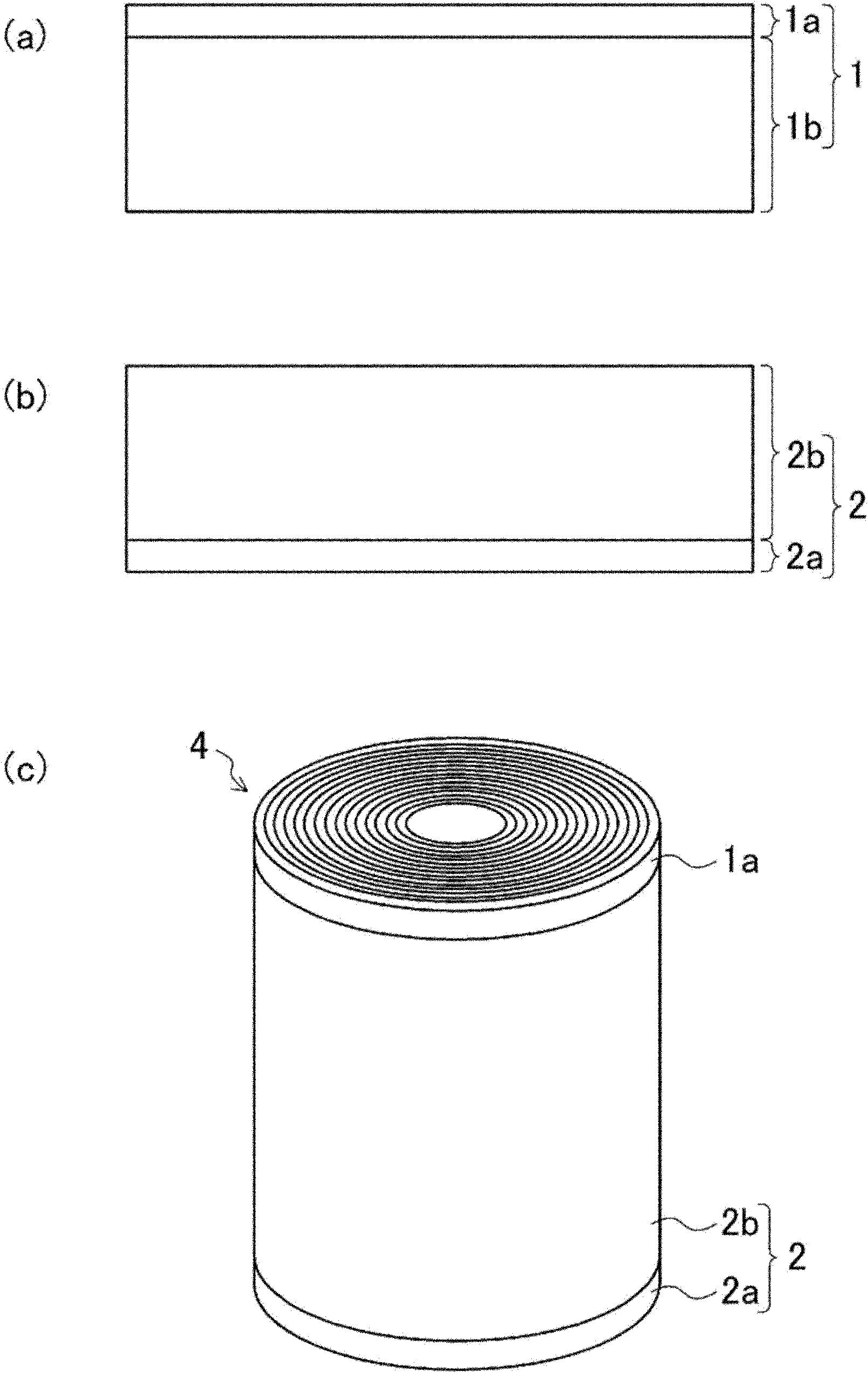

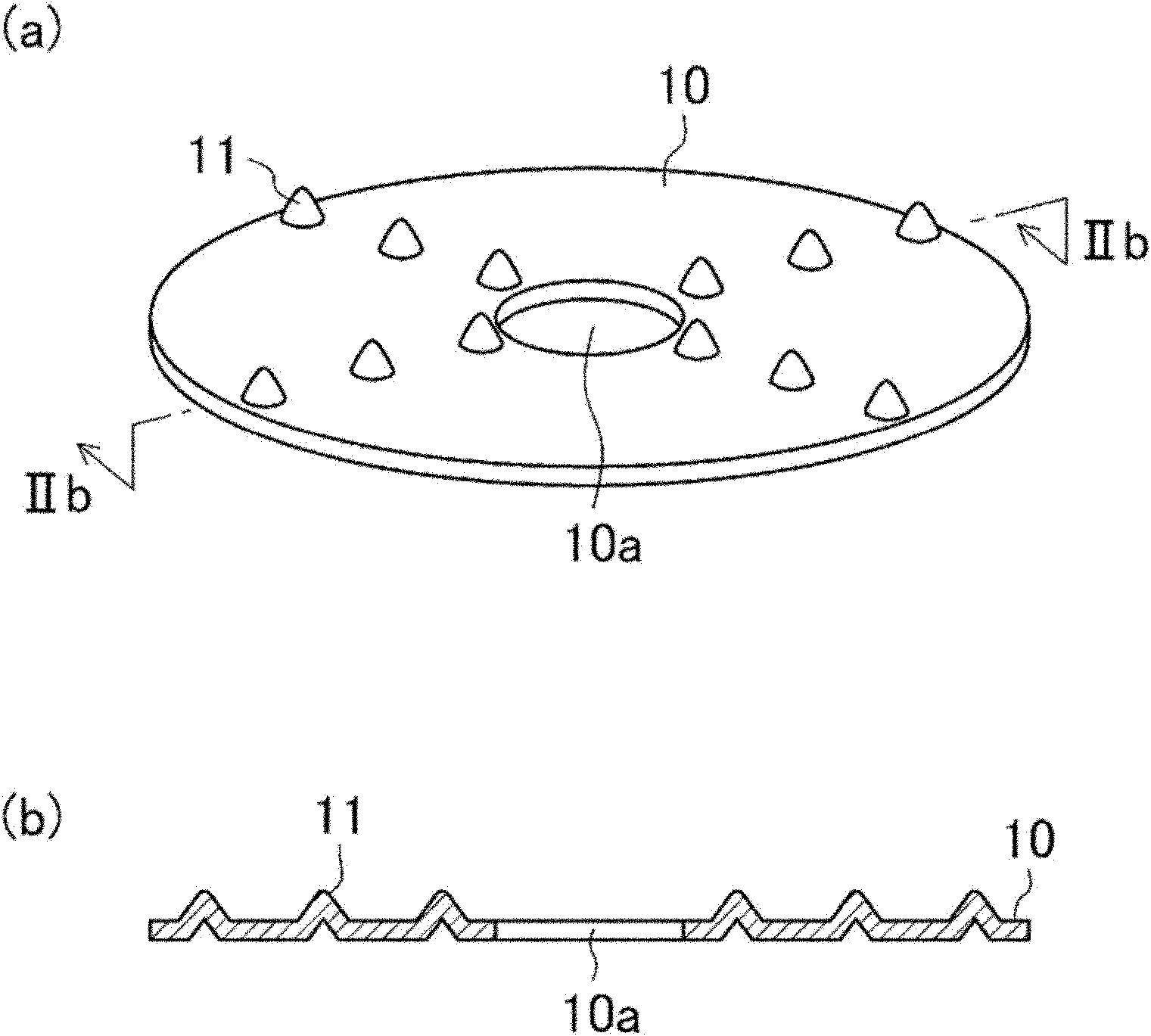

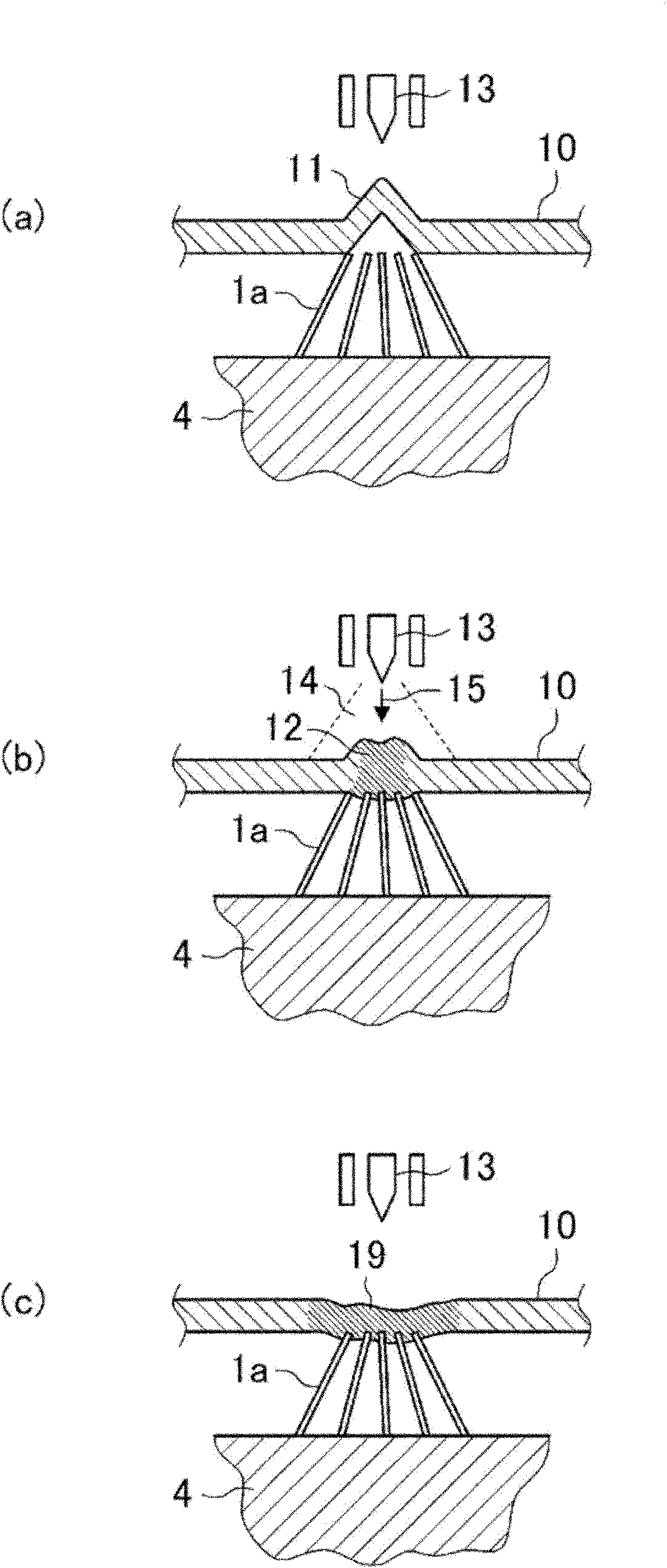

Method for manufacturing secondary battery and secondary battery

InactiveCN102124592ANo heat damageMelt stableFinal product manufactureLi-accumulatorsEngineeringElectrical and Electronics engineering

The present invention provides a method for manufacturing a secondary battery, which comprises: a step of preparing an electrode group (4) in which a positive electrode plate (1) and a negative electrode plate (2) are arranged opposite to each other via a porous insulating layer in such a manner that an end portion (1a, 2a) of at least one of the positive electrode plate (1) and the negative electrode plate (2) projects beyond the porous insulating layer; a step of preparing a collector plate (10), a major surface of which is provided with a plurality of projections (11) each having an apex; a step of bringing the end portion (1a, 2a) of the electrode plate projecting beyond the porous insulating layer into contact with the other major surface of the collector plate (10); and a step wherein a projection (11) is melted by an arc discharge toward the apex of the projection (11) and the end portion (1a, 2a) of the electrode plate and the collector plate (10) are welded to each other by a molten member (12) that is the molten projection (11).

Owner:PANASONIC CORP

Low-cost high-room temperature plastic deformation magnesium alloy and preparation method thereof

The invention discloses a low-cost high-room temperature plastic deformation magnesium alloy and a preparation method thereof. The low-cost high-room temperature plastic deformation magnesium alloy isan Mg-Bi-Sn-Zr-Ca-Y alloy, and comprises the following chemical components by mass percent: 2 wt% to 5.0 wt% of Bi, 2 wt% to 5.0 wt% of Sn, 0.5 wt% to 1.2 wt% of Zr, 0.1 wt% to 0.8 wt% of Ca and 0.01wt% to 0.08 wt% of Y, and the balance being Mg and unavoidable impurities; and besides, the mass ratio of Bi to Ca is (6 to 7) to 1. According to the low-cost high-room temperature plastic deformation magnesium alloy and the preparation method thereof, the high-room temperature plastic deformation magnesium alloy can be obtained through an extremely simple processing means, the room-temperature extension rate reaches 35% or above, raw materials are cheap, processing cost is low, and mass production is each to achieve.

Owner:北京中安璟润新材料技术有限公司

Novel filter screen cleaning structure

ActiveCN104128034AEasy to cleanNo backflowMoving filtering element filtersInternal pressureEngineering

The invention discloses a novel filter screen cleaning structure which is suitable for a disk type filter and comprises an outer shell; one side of the outer shell is provided with a power mechanism, and the interior of the outer shell is provided with a backwash piston connected with the power mechanism; the outer shell is also provided with a melt inlet and a melt outlet, the interior of the outer shell is provided with a discharging piston for opening or closing the melt outlet, the discharging piston is connected with the backwash piston through a connecting shaft, and a melt cavity accommodating a melt is formed between the discharging piston and the backwash piston; the interior of the outer shell is also provided with a backwash feeding valve matched with the action of the backwash piston to control opening and closing of the melt inlet. The internal pressure fluctuation of the melt cavity is small, the melt temperature is easy to control, the cleaning effect is good, an actual production plan is not affected, and the quality of products can be ensured.

Owner:GUANGDONG SHICHENG PLASTIC MACHINERY

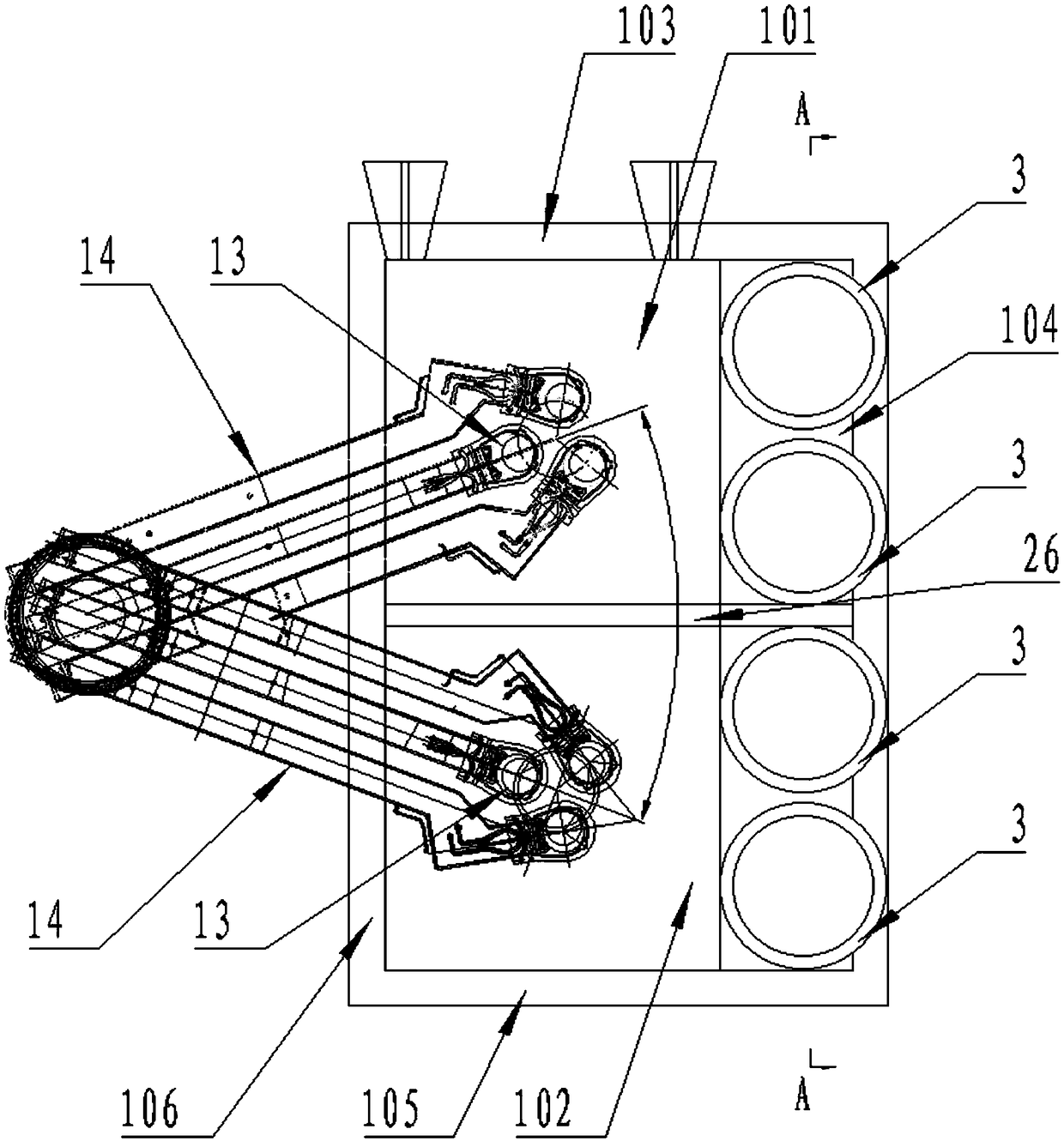

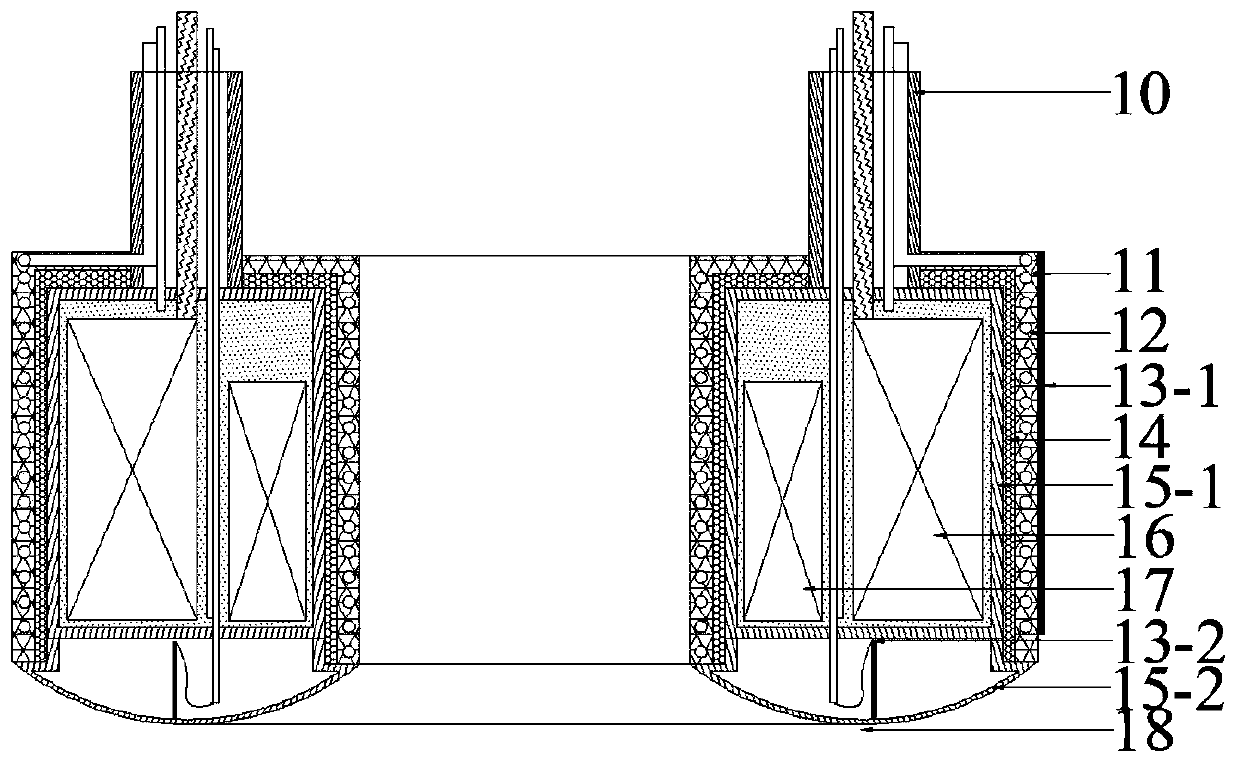

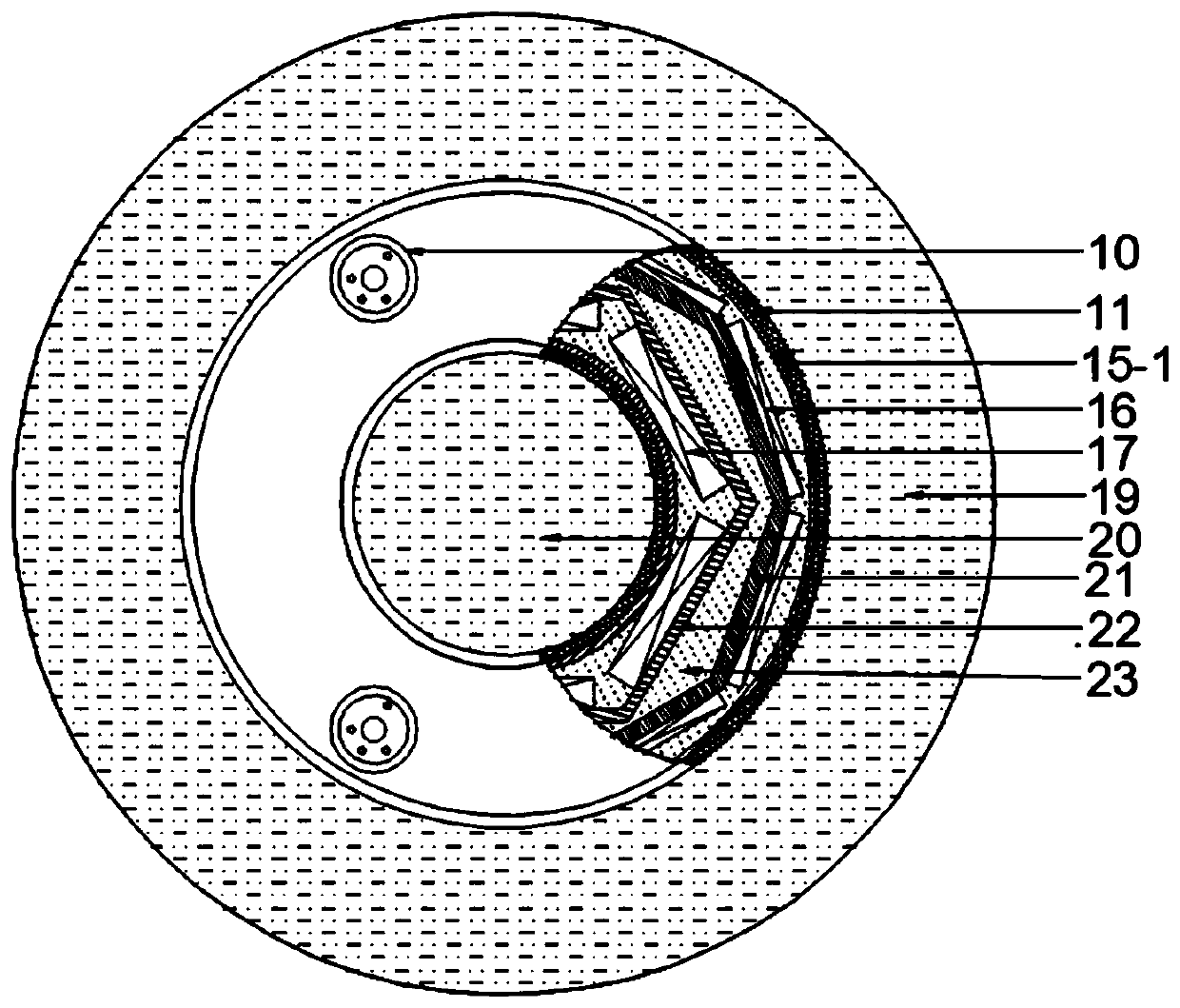

Melt treatment device and method for preparing oversized aluminum alloy ingot

The invention discloses a melt treatment device and method for preparing an oversized aluminum alloy ingot. The device mainly comprises an annular electromagnetic melt treater, a hot top, a crystallizer, a crystallizer water tank, a graphite ring, a dummy ingot and a lifting mechanism, wherein the annular electromagnetic melt treater is arranged in the crystallizer and concentric with the crystallizer, a circuit port and a connecting mechanism are arranged at the top of the annular electromagnetic melt treater, and the annular electromagnetic melt treater is connected with the lifting structure, capable of moving up and down in a height direction of the crystallizer through the lifting mechanism and is positioned at a corresponding position in the crystallizer; a lower end of the hot top is hermetically connected with the crystallizer through the graphite ring; the crystallizer water tank is arranged on the periphery of the crystallizer. When the device is used for melt treatment, theannular electromagnetic melt treater is applied to the alloy melt in a semi-continuous casting process, so that a temperature field and a component field of the super-large-volume alloy melt are effectively and uniformly controlled, melt flow is effectively controlled, and the high-quality oversized aluminum alloy cast ingot with uniform and fine structure and uniform components is prepared.

Owner:有研金属复材技术有限公司

Polyamide material with stable melt and anti-chloride solution feature and preparation method thereof

The invention relates to a polyamide material with stable melt and anti-chloride solution feature and a preparation method thereof. The polyamide material consists of the following components in parts by weight: 100 parts of nylon 66, 10-45 parts of long-chain nylon, 10-50 parts of glass fiber, 0.5-3 parts of liquid melting enhancer, 0.3-1.2 parts of antioxidant and 0.3-2 parts of lubricant. The preparation method comprises the following steps: uniformly premixing the nylon 66, long-chain nylon and liquid melting enhancer; adding the antioxidant and lubricant and mixing again, and adding the mixture through a main feed port of a twin-screw extruder; adding the glass fiber through a glass fiber port, wherein the rotation speed is controlled at 800-1200r / min and the temperature is controlled at 250-285 DEG C; and performing extrusion granulation to obtain the polyamide material. The material has excellent mechanical property, melt stability, chloride ion corrosion resistance and static pressure resistance and is particularly suitable for water supply components with relatively high requirement on chemical corrosion resistance such as high-pressure water guns, high-pressure water pipes, shower heads and spray heads.

Owner:上海日之升科技有限公司

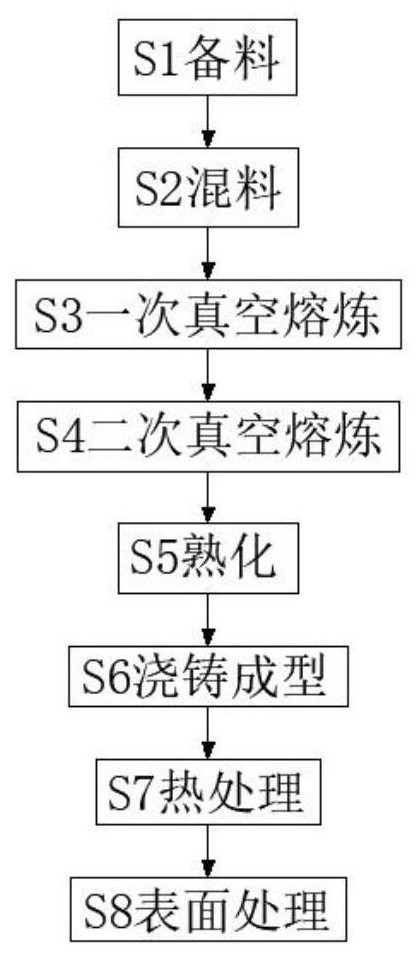

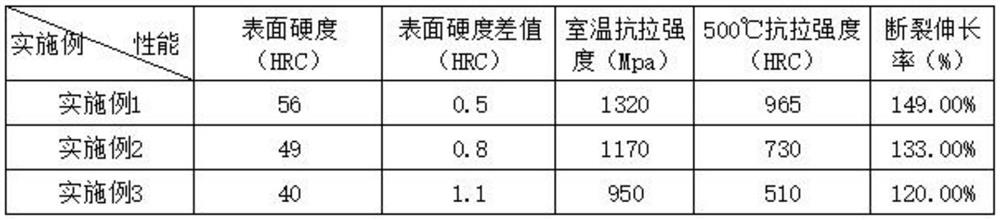

Nickel-based alloy production and processing technology

InactiveCN113981255AImprove wear and corrosion resistanceImprove plasticityOxidation resistantPetrochemical

The invention discloses a nickel-based alloy production and processing technology which comprises the steps of material preparation, material mixing, primary vacuum melting, secondary vacuum melting, curing, casting molding, heat treatment and surface treatment, and finally the finished nickel-based alloy is obtained. In the aspect of raw materials, the nickel-based alloy disclosed by the invention is prepared by weighing and using the following raw materials in percentage: 28.22 percent to 25.57 percent of Cr, 17.51 percent to 15.36 percent of Mo, 15.74 percent to 13.61 percent of Cu, 10.82 percent to 9.21 percent of Fe, 9.88 percent to 7.25 percent of Al, 6.56 percent to 4.76 percent of Si, 5.86 percent to 3.58 percent of Ni, 3.47 percent to 1.85 percent of W, 3.24 percent to 2.45 percent of Nb, 0.83 percent to 0.68 percent of Ti and 0.35 percent to 0.22 percent of In. W and In are added, W is matched with Cr and Ni, so that the wear resistance and corrosion resistance of the alloy can be improved, In is high in plasticity and good in ductility, and the alloy can have high oxidation resistance, corrosion resistance and welding performance in the field of petrochemical engineering; and meanwhile, in the process, through two times of vacuum melting, the mixed raw materials are fully melted and mixed at different vacuum degrees and gradually heated, so that the stability of the meltability of the solution is ensured, the mixing uniformity is improved, and the local accumulation caused by non-uniform mixing of the raw materials and the reduction of the quality of the nickel-based alloy are reduced.

Owner:江苏新马新材料开发有限公司

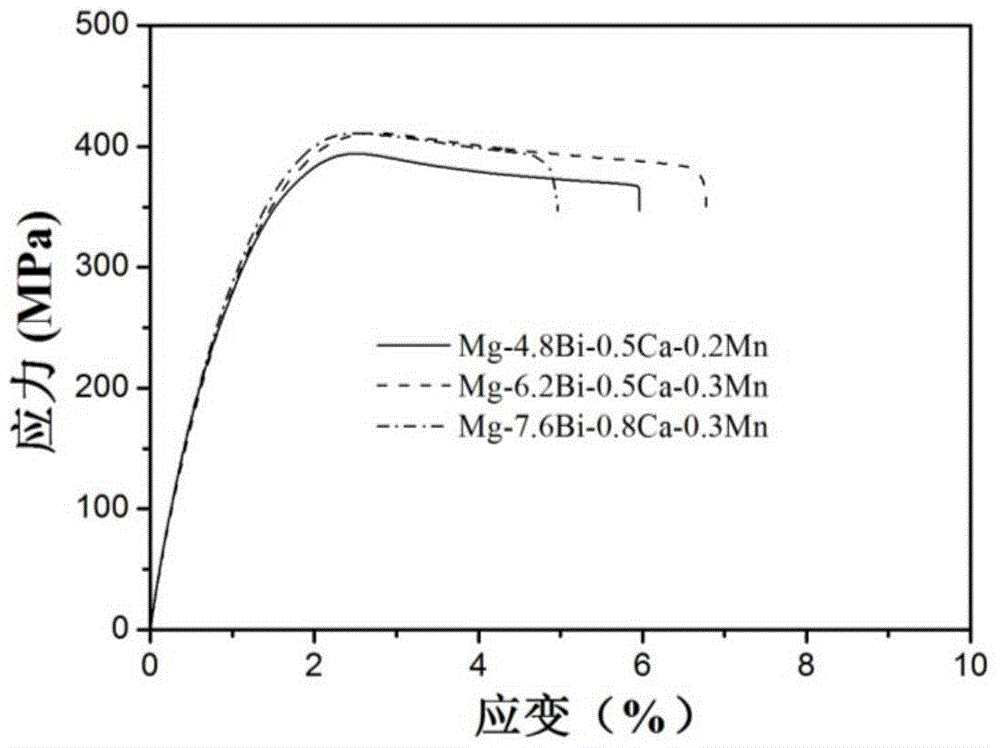

A low-cost non-rare earth type high-strength magnesium alloy and its preparation method

The invention relates to low-cost non-rare-earth type high-strength magnesium alloy and a preparing method thereof. The alloy is Mg-Bi-Ca-Mn magnesium alloy, and is prepared from, by mass, 2-10% of Bi, 0.1-1.5% of Ca, 0.1-1.0% of Mn and the balance magnesium. The novel magnesium alloy is based on a Mg-Bi binary metal series, the element Bi serves as the main alloy element, and the Mg3Bi2 phase with high melting point is contained in the magnesium alloy. Furthermore, the magnesium alloy is evenly dispersed and distributed on a matrix through a simple alloying means, the metamorphism to a second phase by the element Ca and the element Mn and the combination of a plastic deformation processing means so that crystal boundary migration can be effectively pinned in the deformation process to hinder dislocated movement, grains are obviously refined, the strength of the alloy is greatly improved, and thus the ultra-high-strength magnesium alloy is developed in the alloy series.

Owner:HEBEI UNIV OF TECH

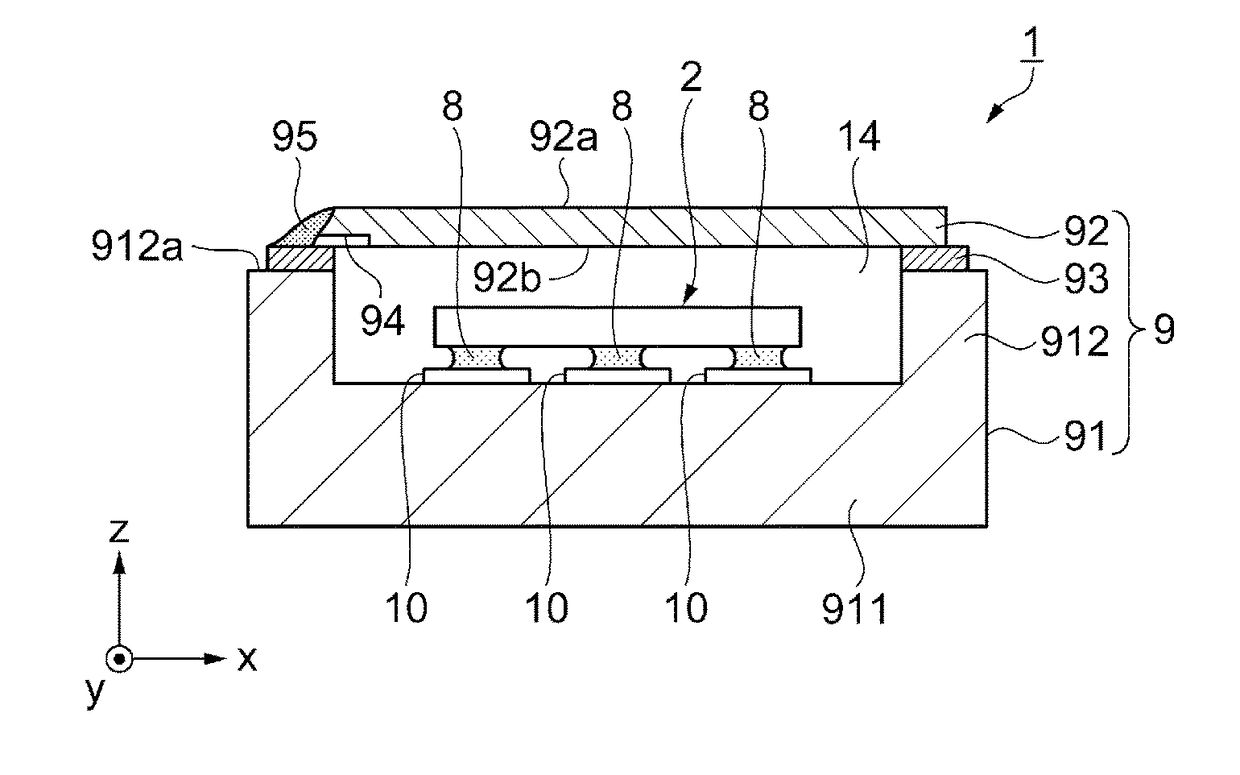

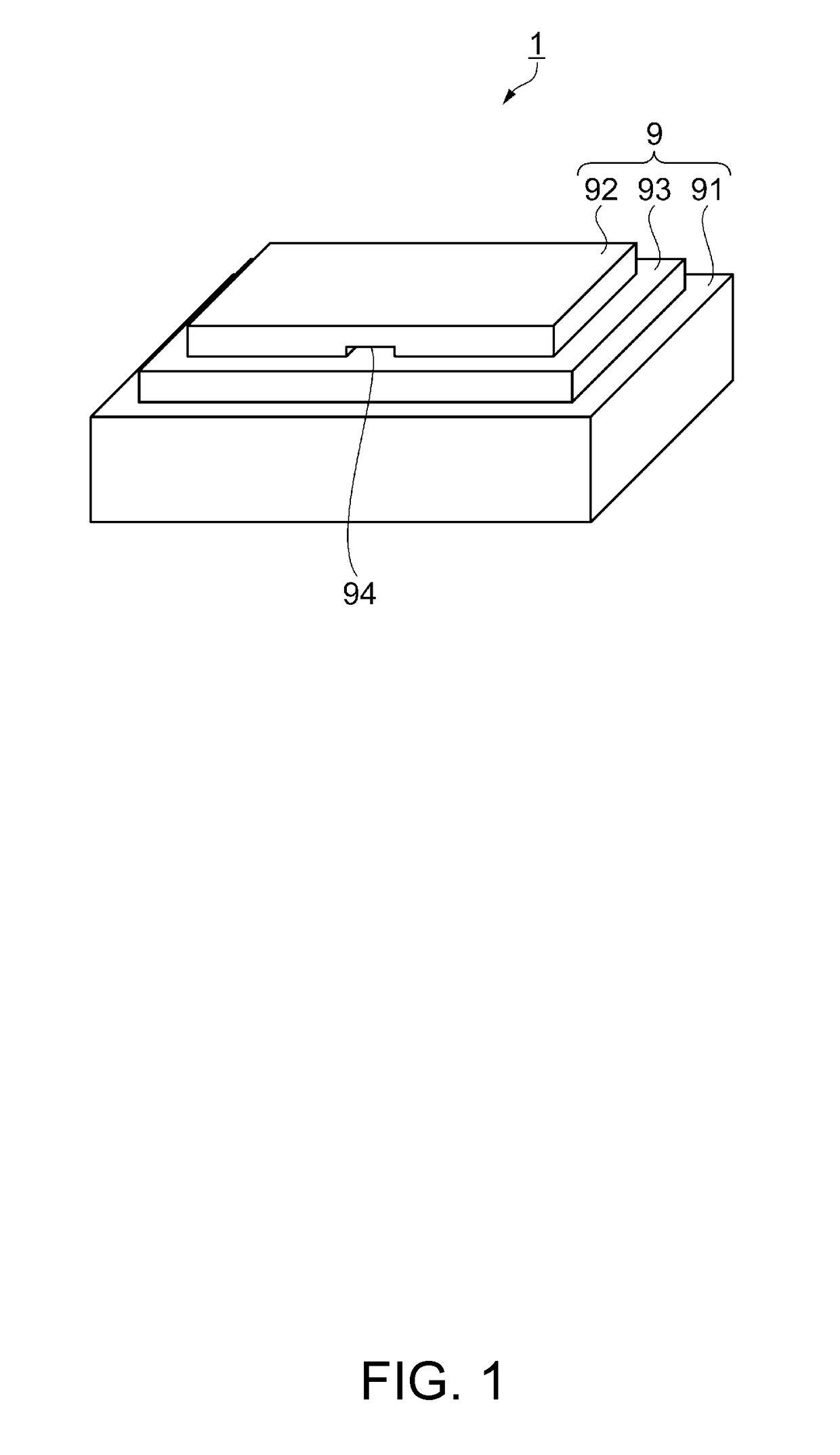

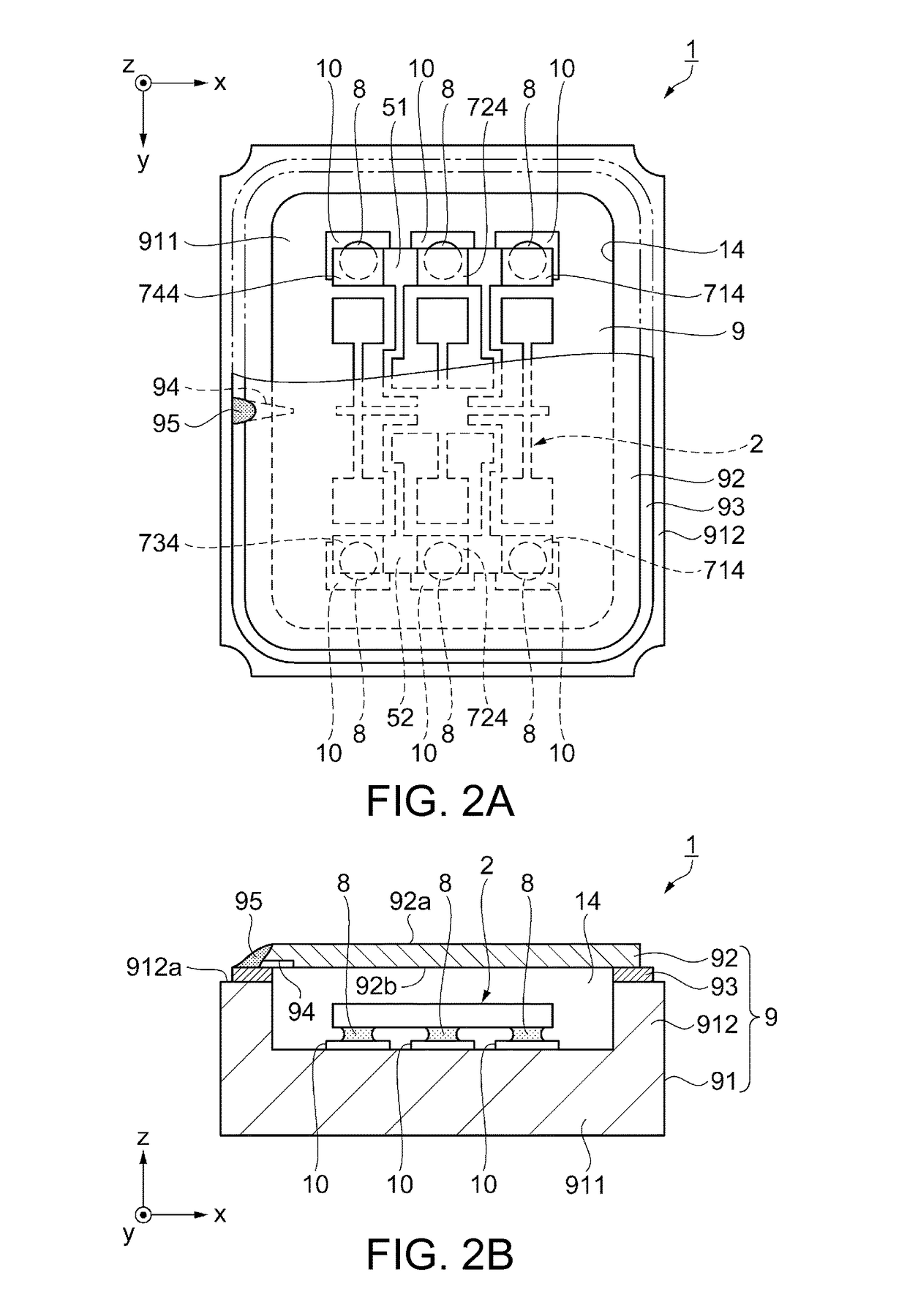

Manufacturing method of electronic device, electronic device, electronic apparatus, moving object, and lid body

ActiveUS9644962B2Reduce the amount requiredSuppress characteristic degradationSemiconductor/solid-state device detailsSolid-state devicesElectronic componentElectric equipment

A manufacturing method of an electronic device, that accommodates a gyro element as an electronic component in an inner space formed by a base and a lid as a lid body, includes: preparing the lid in which a groove is provided on a surface which is welded with the base, and an opening area of the groove on the inner space side which is smaller than an opening area on the outer periphery side of the lid; welding, first, the base and the lid at a portion excluding an unwelded portion that includes at least apart of the groove, of a planned welding portion of the base and the lid; and welding, second, the base and the lid at the unwelded portion such that the groove is closed.

Owner:COLUMBIA PEAK VENTURES LLC

Rotating distributing hopper

PendingCN109626027AImprove uniformityIncrease productionLoading/unloadingBio-packagingSlewing bearingEngineering

The invention provides a rotating distributing hopper. The rotating distributing hopper comprises a distributing bin; an inlet is formed above the distributing bin; a hopper is arranged at the inlet;a slewing bearing is arranged above the distributing bin and located at the inlet; the fixing part of the slewing bearing is fixedly arranged on the distributing bin; the hopper is fixedly arranged atthe rotating part of the slewing bearing; and the rotating part of the slewing bearing can be driven by a driving device to rotate. The rotationally-arranged hopper is arranged, so that the distribution uniformity is improved, stable melt is provided for a cupola furnace, and the yield can be increased remarkably; and meanwhile, the use amount of coke (fuel) is greatly reduced, so that the cost is reduced.

Owner:南通天福机械有限公司

A kind of room temperature high ductility magnesium alloy and preparation method thereof

ActiveCN109371301BImprove mechanical propertiesImprove plastic deformation abilityMetallic materialsThermal treatment

The invention discloses a magnesium alloy with excellent room-temperature plasticity, and a preparation method thereof, and belongs to the technical field of (metal materials) magnesium alloy. The magnesium alloy is prepared from the following components in percentage by weight: 2-7wt% of Bi, 1.5-4wt% of Y, 0.05-0.15wt% of Mn and the balance of Mg, wherein a Bi / Y ratio is 1.3-2, and Y is more thanor equal to 1.5%. The preparation method for the magnesium alloy mainly comprises the following preparation steps of: smelting, thermal treating and deformation processing. At the room temperature, the alloy has ductility which can be 41% or more, shows excellent room-temperature plasticity, and is a potential magnesium alloy material which can be used for further room-temperature plasticity processing or super-plasticity forming technology processing. Besides, in a casting process and a thermal treatment process, the alloy shows excellent flame resistance.

Owner:BEIJING ZHONGKE PUJIN SPECIAL MATERIAL TECHDEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com