Patents

Literature

127results about How to "No heat damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

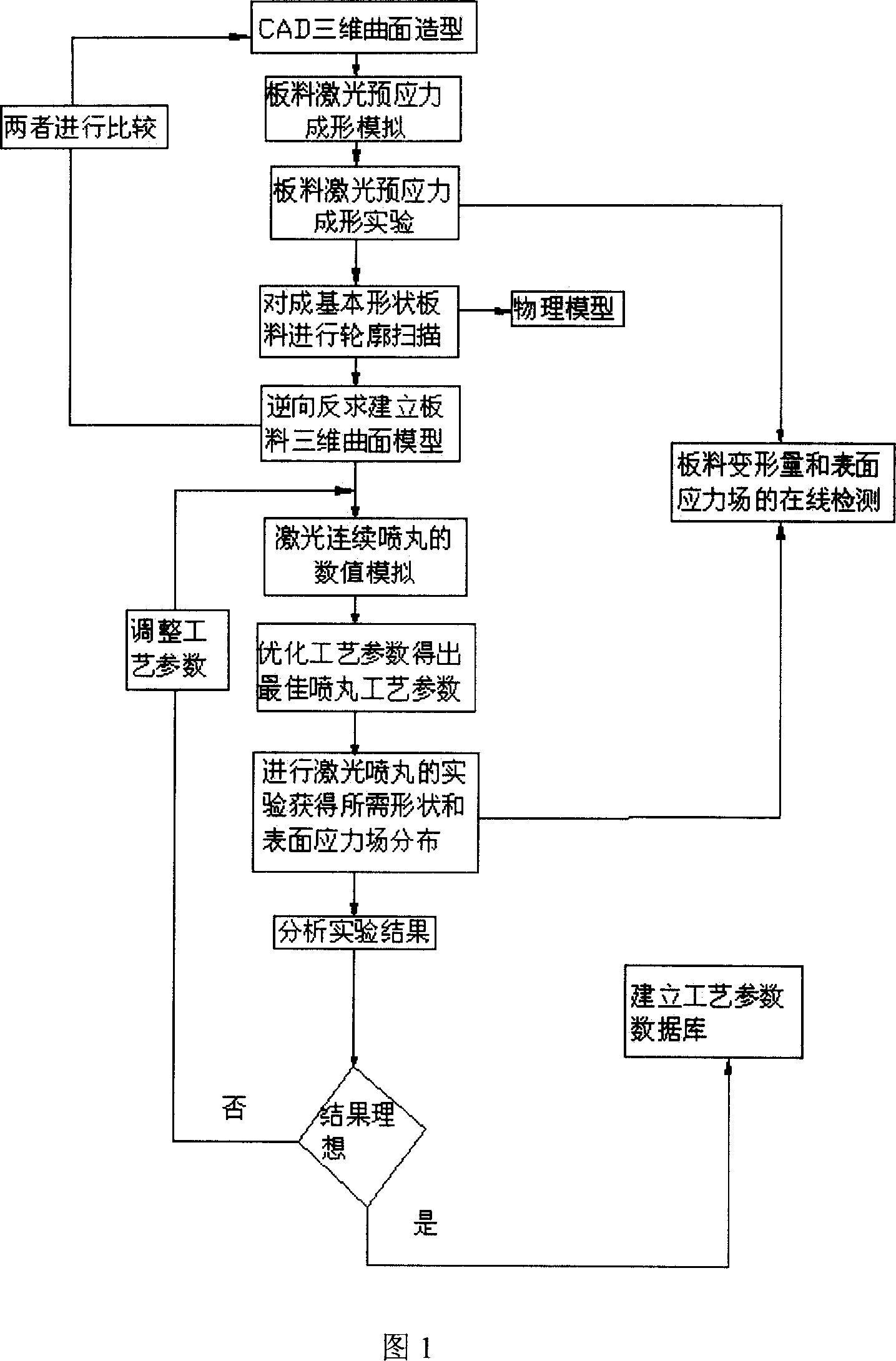

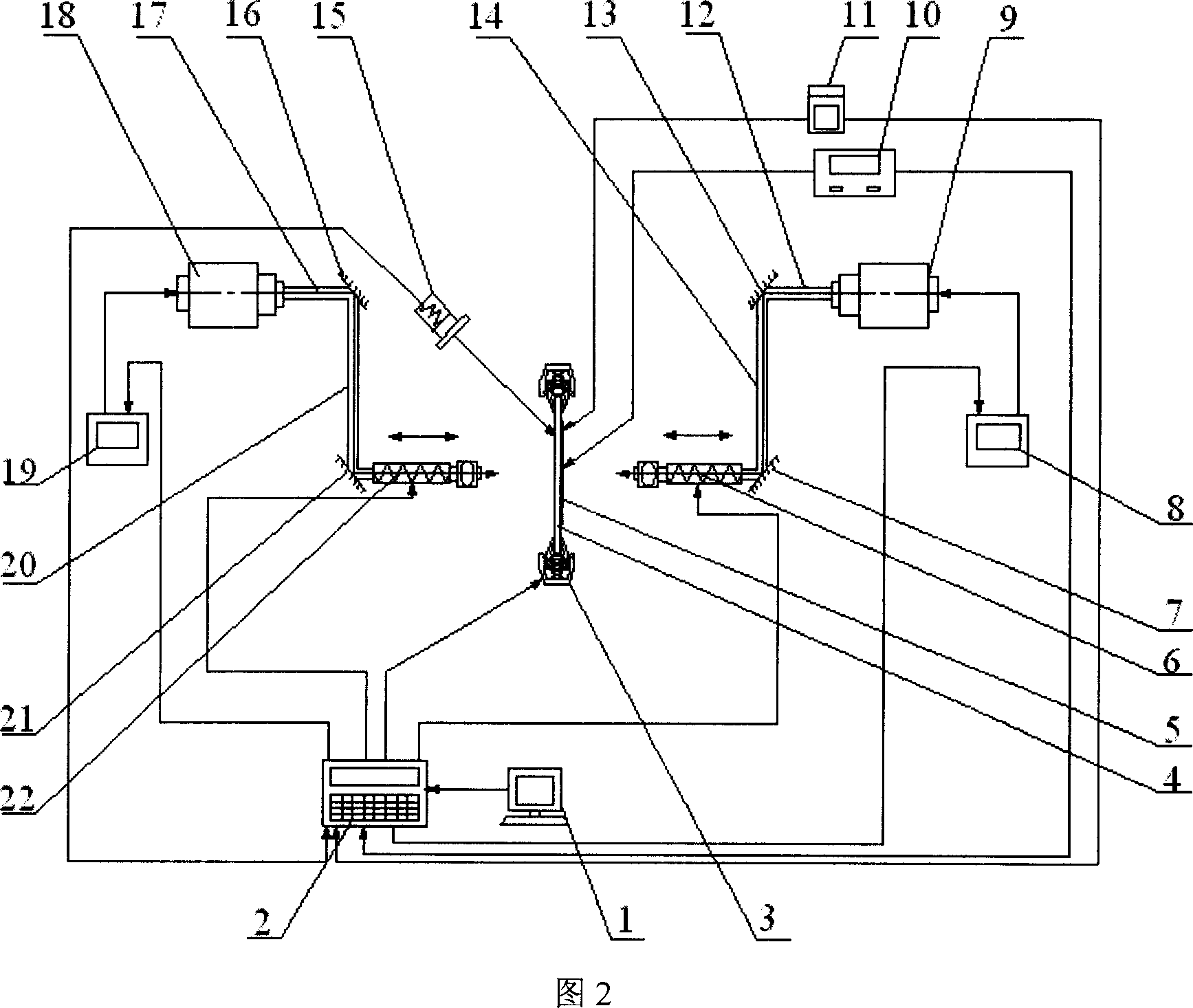

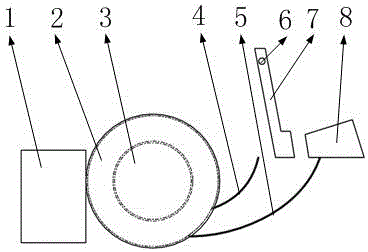

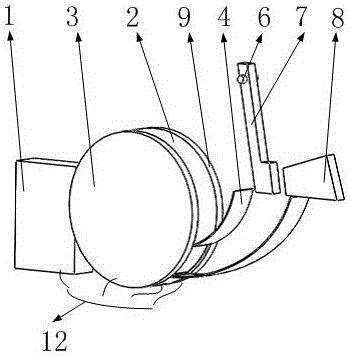

Method and apparatus of forming cut deal laser prestress composite shot blasting

InactiveCN101011777AImprove surface qualityImprove fatigue resistanceNumerical controlLaser beam welding apparatusSurface stressLaser light

A cut deal laser inherent stress composite peen forming features in the clipper using robot, using carbon dioxide to realize the basic formation, profile measuring feedback system controlling the deformation quantity, left stress meter measuring the surface stress of the board, optical scanning the pre formation, realizing board through model analog software, getting optimized process parameter instructing laser consecutive peen formation, using neodymium glass laser providing short pulse strong laser light, laser impact wave as the force source of precise forming, using the profile feedback device and on line measuring board surface stress left stress to control the deformation quantity to realize precision forming with complex shapes.

Owner:JIANGSU UNIV

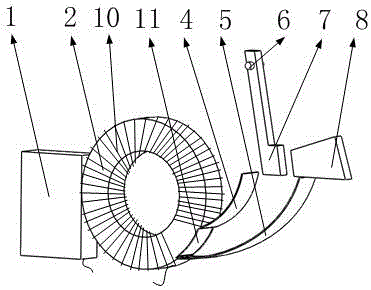

Rotary arc extinguishing mechanism of power circuit breaker

ActiveCN106531585AReduce volumeNo heat damageElectric switchesCircuit-breaking switch detailsCapacitanceElectric arc

The invention belongs to the technical field of power circuit breakers, and particularly relates to a rotary arc extinguishing mechanism of a power circuit breaker. The rotary arc extinguishing mechanism includes a capacitor, electromagnetic rings, thermoelectric units, a first conductive piece, a second conductive piece, a swing rod, a fixed end and a solenoid coil, the conductive pieces and an outer shell form an arc channel, when the swing rod and the fixed end generate an electric arc, since heat of the electric arc itself is high, the electric arc is driven by itself to enter an electromagnetic ring inlet, high heat generated by the electric arc heats a thermoswitch, so that the capacitor and the solenoid coil are energized, the capacitor drives the solenoid coil to generate a toroidal magnetic field, and the electric arc is attracted into the electromagnetic rings; heat of the electric arc is absorbed by thermoelectric units at two sides, and is conducted to the capacitor, and the capacitor is charged and prepares to drive the solenoid coil for the next time. The arc extinguishing mechanism provided by the invention can perform arc extinguishing on the electric arc with huge energy, when the energy of the electric arc is huge, an angle of rotation of the electric arc along the electromagnetic rings increases, at the same time, thermal damage is not caused to equipment under a guiding function of the magnetic field, and thus the rotary arc extinguishing mechanism of the power circuit breaker has a relatively good using effect.

Owner:无锡圣普电力科技有限公司

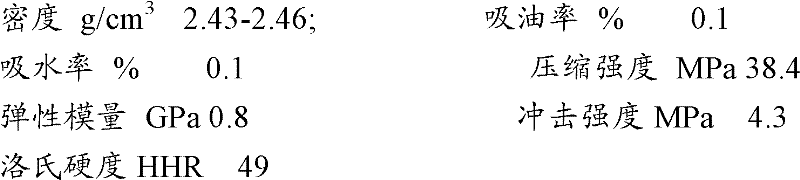

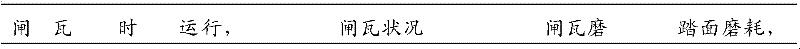

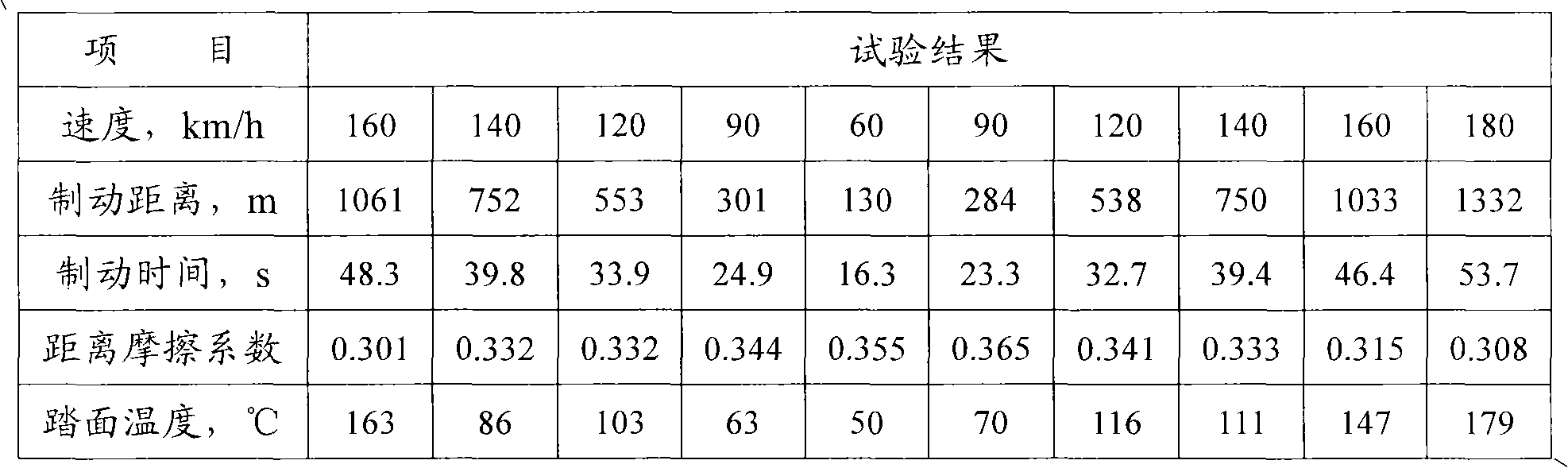

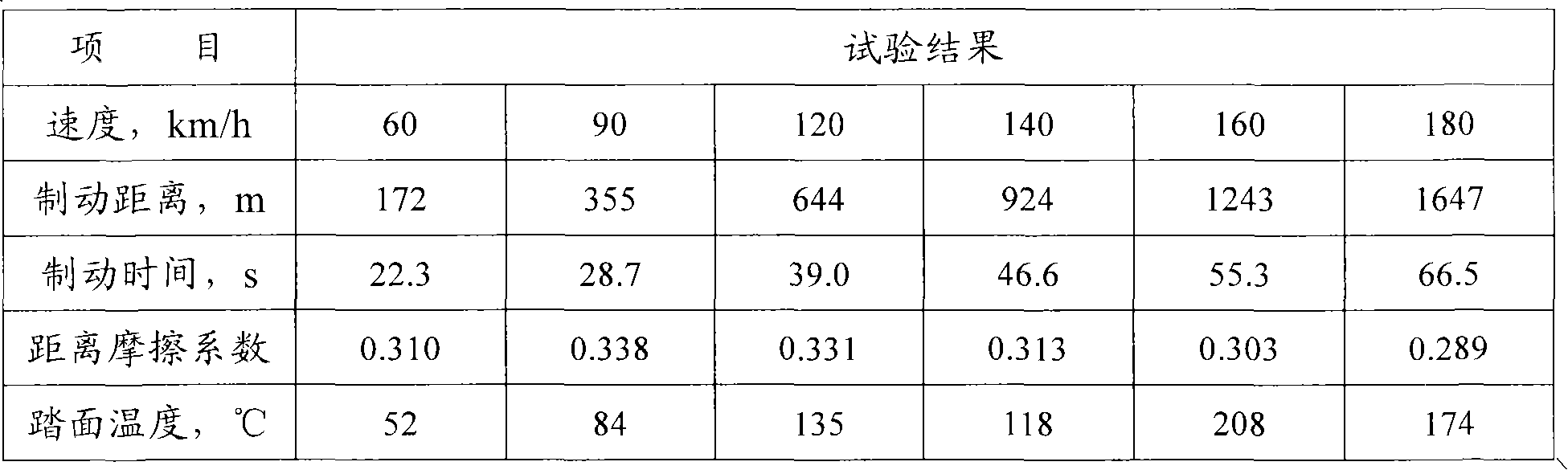

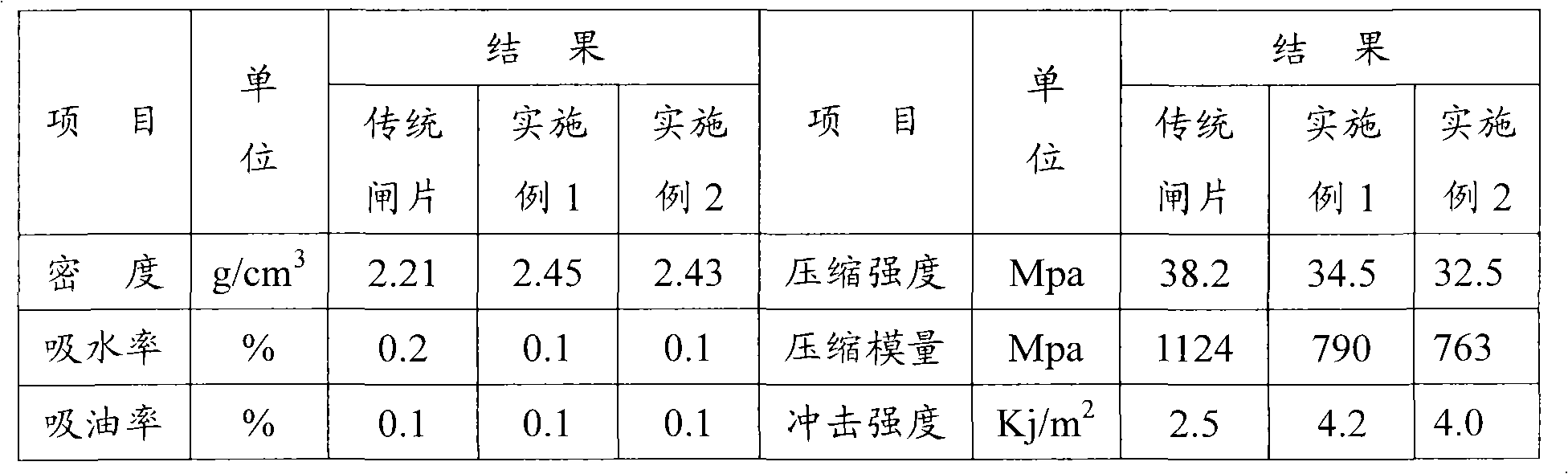

Synthetic brake shoe and preparation method thereof

The invention provides a synthetic brake shoe which comprises the following raw materials in parts by weight: 3-5 parts of phenol formaldehyde resin, 1.5-3.5 parts of nitrile-butadiene rubber, 1.5-3.5 parts of graphite, 3.5-5.5 parts of reduced iron powder, 4.5-6.5 parts of steel fiber, 1.5-3.5 parts of wollastonite, 2.5-4.5 parts of meerschaum, 3.5-5.5 parts of potash feldspar, 0.05-0.20 part ofaluminum oxide, 0.15-0.40 part of sulfur and 0.05-0.20 part of accelerator. The invention selects preferable raw materials and formula to develop the synthetic brake shoe which has the advantages of long service life, low abrasion mating plate and high friction factor. The car loading examination proves that the synthetic brake shoe satisfies the design requirements, does not generate harmful damascene, and does not generate thermal damage on the wheels; the service life is apparently longer than the currently universal synthetic brake shoe with high friction factor, reaching 0.2-0.24 millionkilometers per year; and the application and maintenance cost is lowered, the operation time for replacing the brake shoe is shortened, and the conveying efficiency is enhanced.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

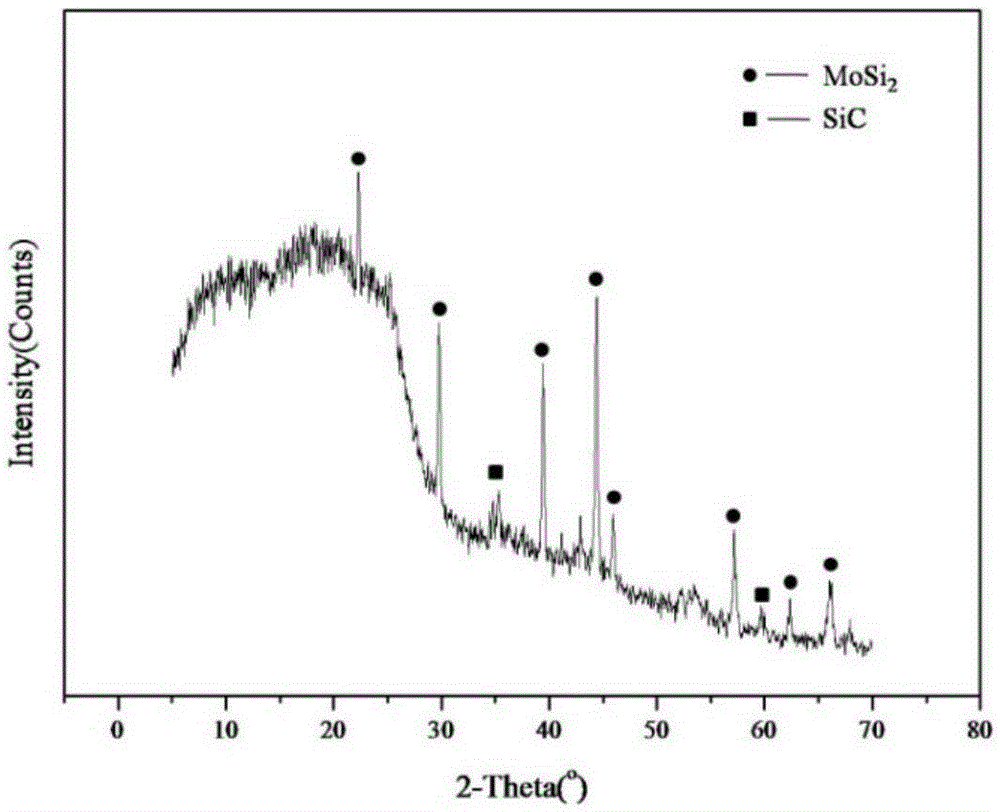

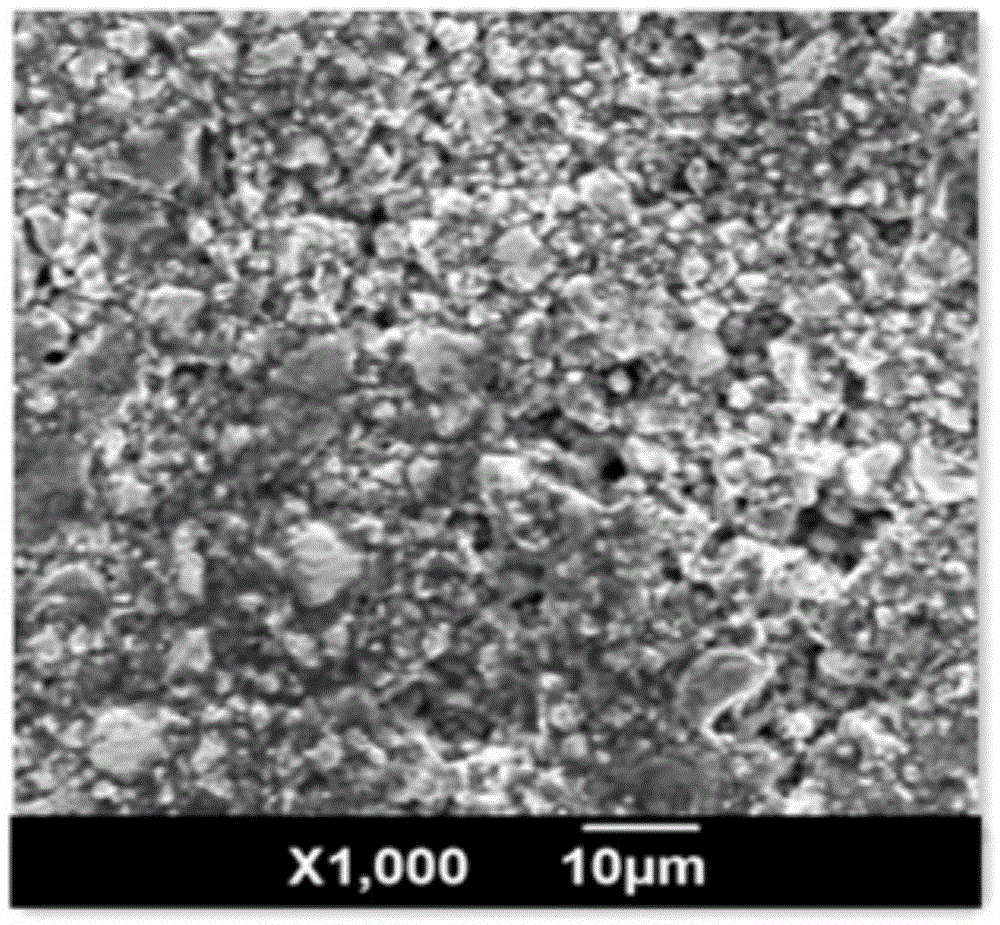

Preparation method of C/C-SiC-MoSi2 ceramic-based composite material

A preparation method of a C / C-SiC-MoSi2 ceramic-based composite material includes the following steps: 1) dispersing silicon carbide powder and molybdenum disilicide powder in isopropyl alcohol, and performing ultrasound vibration and stirring to obtain a suspension liquid A and a suspension liquid B: 2) increasing the density of a low-density carbon fiber stereo fabric in a manner of hydrothermal permeation of glucose, and placing the fabric in a suction filtration device having a glass sand core; 3) pouring the suspension liquid A and the suspension liquid B successively into a suction filtration flat-bottom funnel to enable the suspension liquids to pass the C / C composite material completely; 4) performing a homogeneous phase hydrothermal reaction until the density is 1.2-1.5 g / cm<3>; and 5) performing thermal treatment to obtain the C / C-SiC-MoSi2 ceramic-based composite material. The composite material is moderated in density, is compact in structure, and is excellent in interface binding between a C / C interface and a SiC interface, the SiC interface and a MoSi2 interface and the C / C interface and the MoSi2 interface. The raw materials are easy to obtain. The preparation method is simple in operation, is low in cost, is environment-friendly and is pollution-free.

Owner:浙江领崎科技有限责任公司

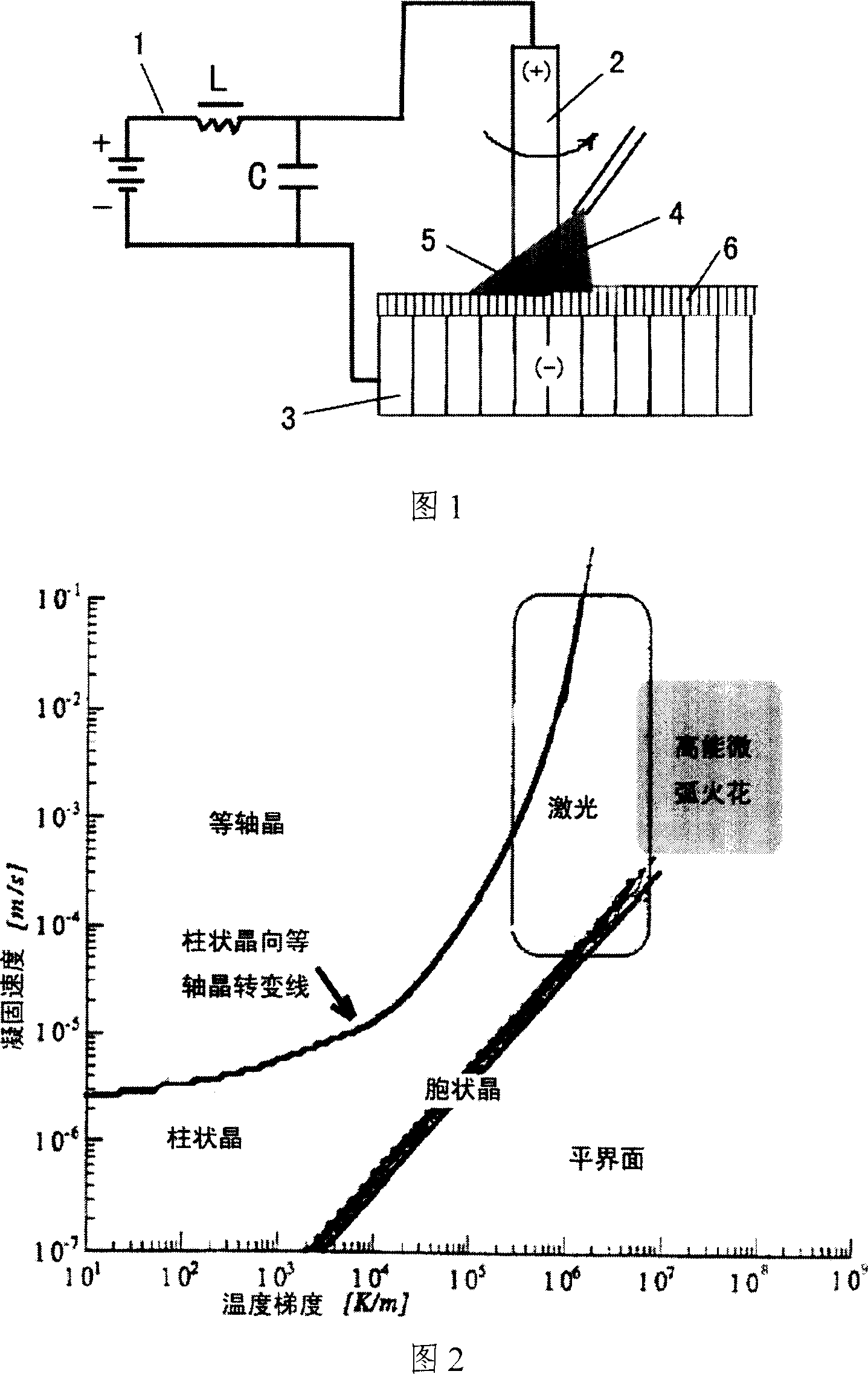

Directional freezing styloid or single-crystal nickel-base high-temperature alloy repairing or coating method

InactiveCN101126143ALittle thermal impactDoes not cause recrystallizationMolten spray coatingArc welding apparatusHeat-affected zoneSingle crystal superalloy

The invention belongs to a preparation technique of the metal surface settled layer, in particular to a method for preparing the directional solidification column crystal or single crystal settled layer which grows on the extension of the surface of the directional solidification column crystal or single crystal high temperature alloy. The proposal of the invention solves the problem of repairing and coating of the directional solidification column crystal or single crystal high temperature alloy; and to gain a compact and flawless directional solidification column crystal or single crystal settled layer which is matched with the directional solidification column crystal or single crystal. The invention discloses an extension high power differential arc spark metal deposition technique. The invention has the advantages of wide process window achieved by the extension high power differential arc spark metal deposition technique, no heat damage to the ferronickel high temperature alloy, narrow heat influence area or no heat influence area, being capable of effectively avoiding the phenomenon of heat flaw of the ferronickel high temperature, no complicated devices such as vacuum room needed and no preheating needed.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

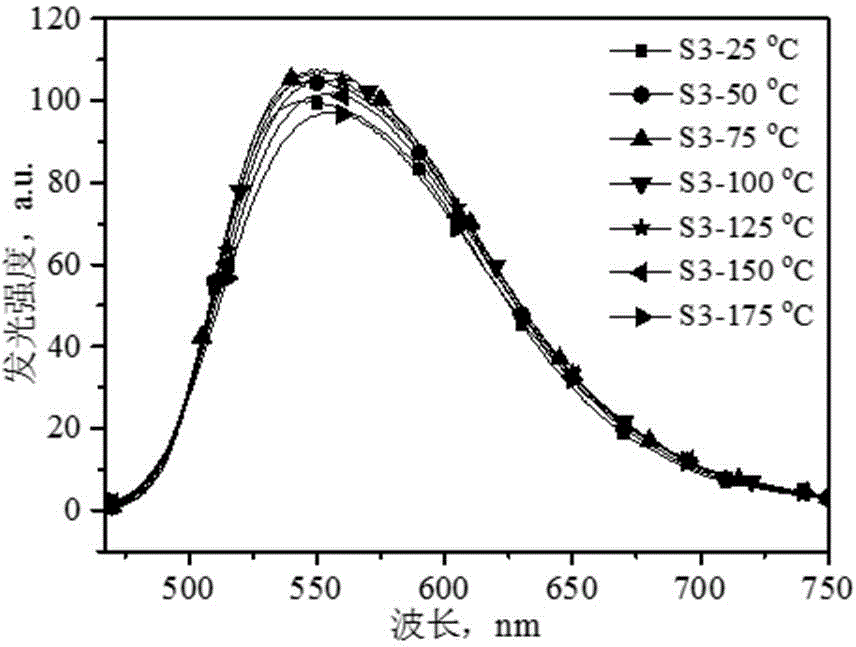

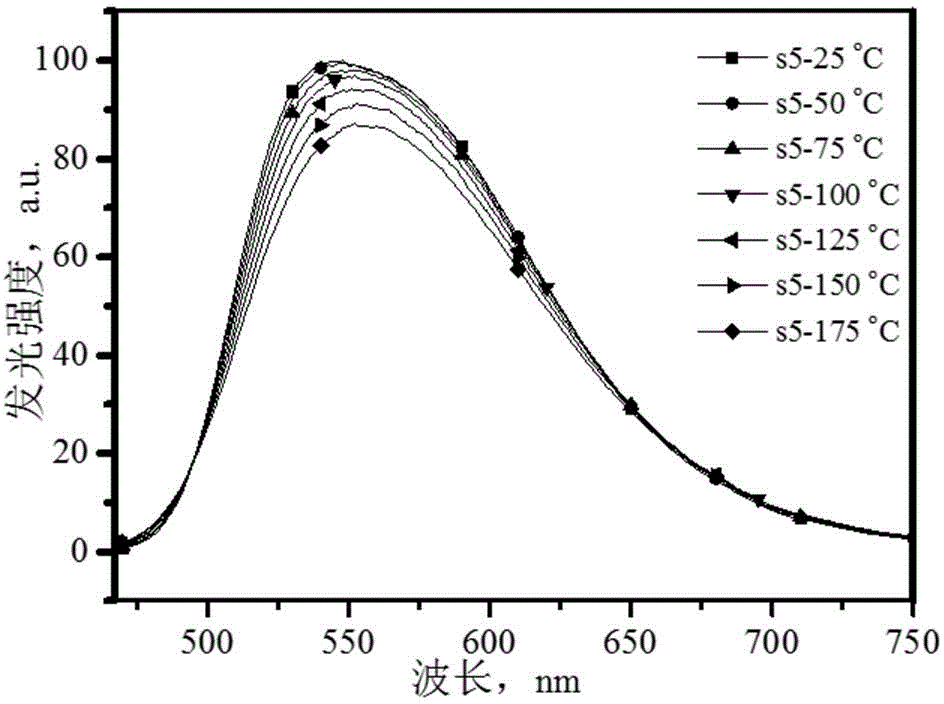

Rare earth luminescent material preparation method containing crystal defect repair technology and product thereof

ActiveCN104818023ADecreased luminosityDecreased Internal Quantum EfficiencyLuminescent compositionsDefect repairRare earth

The invention provides a rare earth luminescent material preparation method containing crystal defect repair technology and a product thereof to overcome disadvantages in synthesis of garnet activated rare earth aluminate fluorescent materials in the prior art. The preparation method comprises the following four steps: preparation of clinker; preparation of clinker blended with a raw material; preparation of a fluorescent powder material having undergone secondary annealing; and preparation of the finished fluorescent material. The finished fluorescent material prepared by using the method has external quantum efficiency of 0.706 to 0.745 and internal quantum efficiency of 0.953 to 0.992 in a temperature range of room temperature to 150 DEG C. The invention has the following beneficial technical effects: the raw material is used to replace an activator during secondary reduction; and in virtue of cooperative action of surface modification and secondary reduction thermodynamics, crystal defects are eliminated, and internal quantum efficiency and photo-thermal stability of the Ce<3+> activated garnet structure rare earth aluminate luminescent material are improved.

Owner:HEFEI UNIV OF TECH

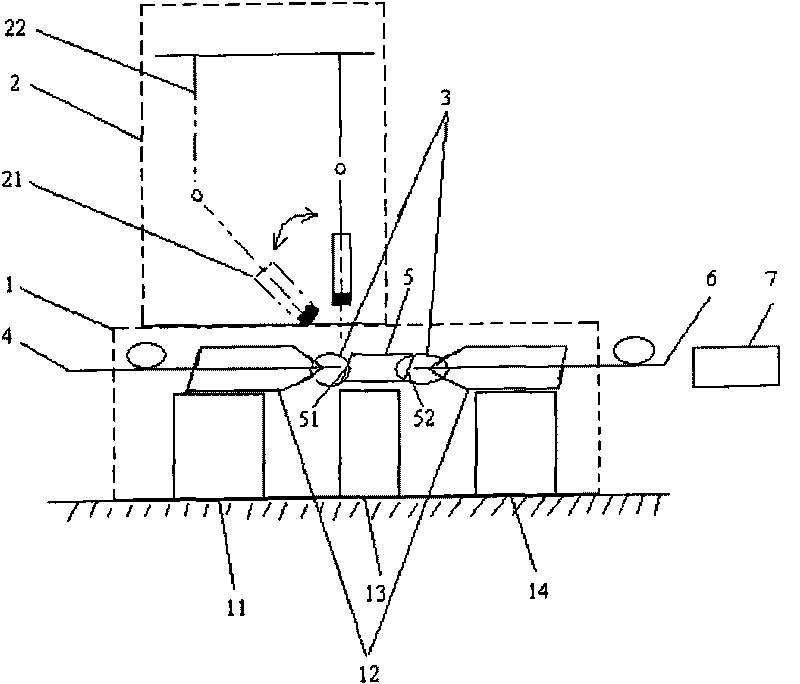

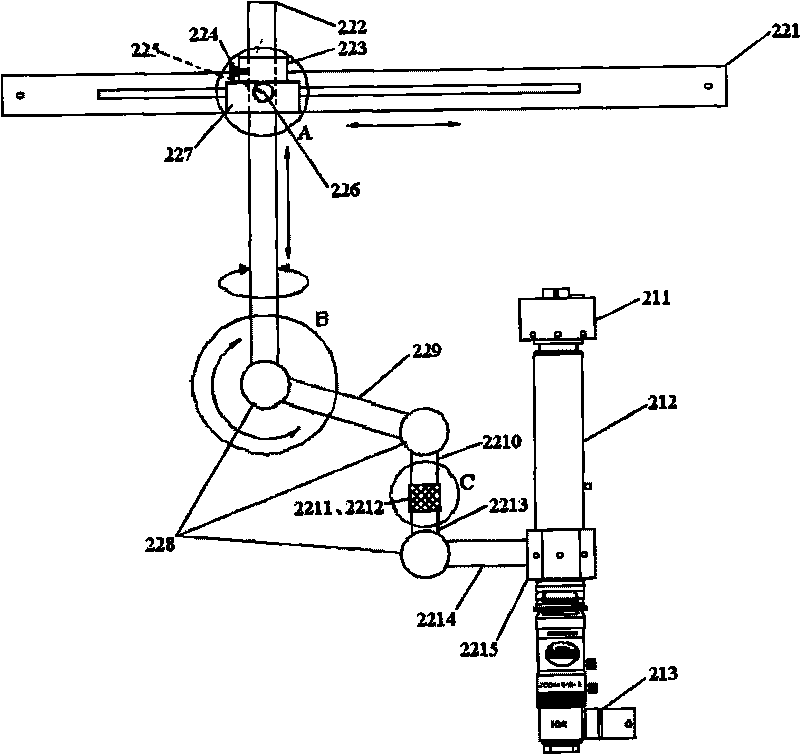

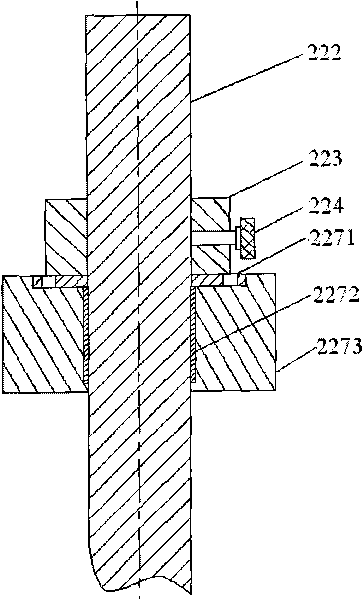

Single-lens multi-angle high-magnification photonic chip coupling and packaging device

The invention discloses a single-lens multi-angle high-magnification photonic chip coupling and packaging device which comprises a coupling adjusting device, a machine vision device and an optical-chip curing device, wherein the machine vision device comprises a lens camera assembly and a multi-angle fixing gyroscope, the lens camera assembly is arranged on the multi-angle fixing gyroscope and comprises a high-magnification lens with optical magnification of 3.5-22.5X and a high-sensitivity CMOS camera, and the high-magnification lens is arranged on the CMOS camera. By the total magnification of 175-1125X of imaging of a CMOS chip in a display, the single-lens multi-angle high-magnification photonic chip coupling and packaging device can realize 180-degree rotation under the self-designed fixing gyroscope and observation of submicron and nanometer wave guide light paths at any angle of nearly 90 degrees from vertical overlooking to horizontal side-looking, wherein an image can not shake.

Owner:SOUTHEAST UNIV

Wearing resistant material, composite brake pad for braking and method for preparing same

The invention provides a wearing material, a composite brake pad for braking and a method for preparing the same, wherein the wearing material comprises the following components: acrylonitrile butadiene rubber, phenolic resin, graphite, iron powder, precipitated barium sulfate, potassium feldspar powder, steel fiber, needle-like wollastonite and other auxiliary materials; the composite brake pad made of the wearing materials can meet the service requirements of a speed increased passenger car, and the use of the loaded speed increased passenger car in the whole road shows that the braking effect is good, no thermal damage and abnormal abrasion is caused on a braking disk, slag and blocks do not fall off from the car, and the service life is long.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +1

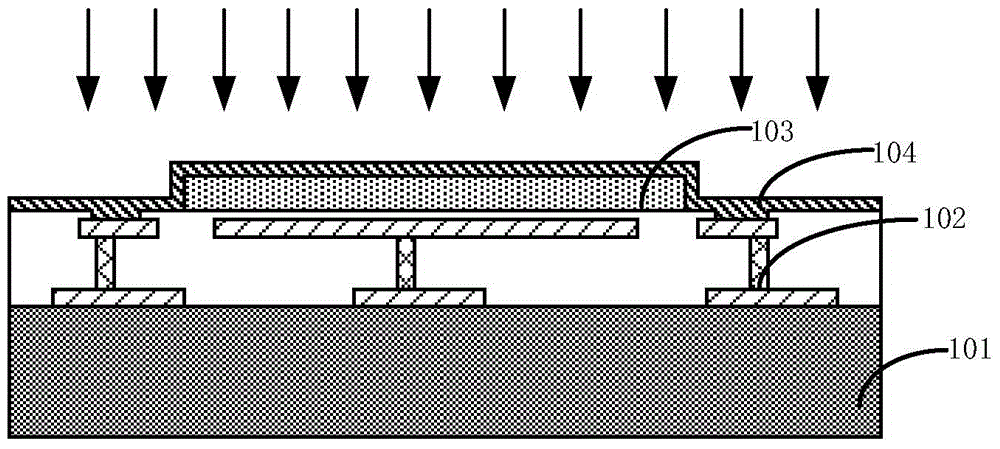

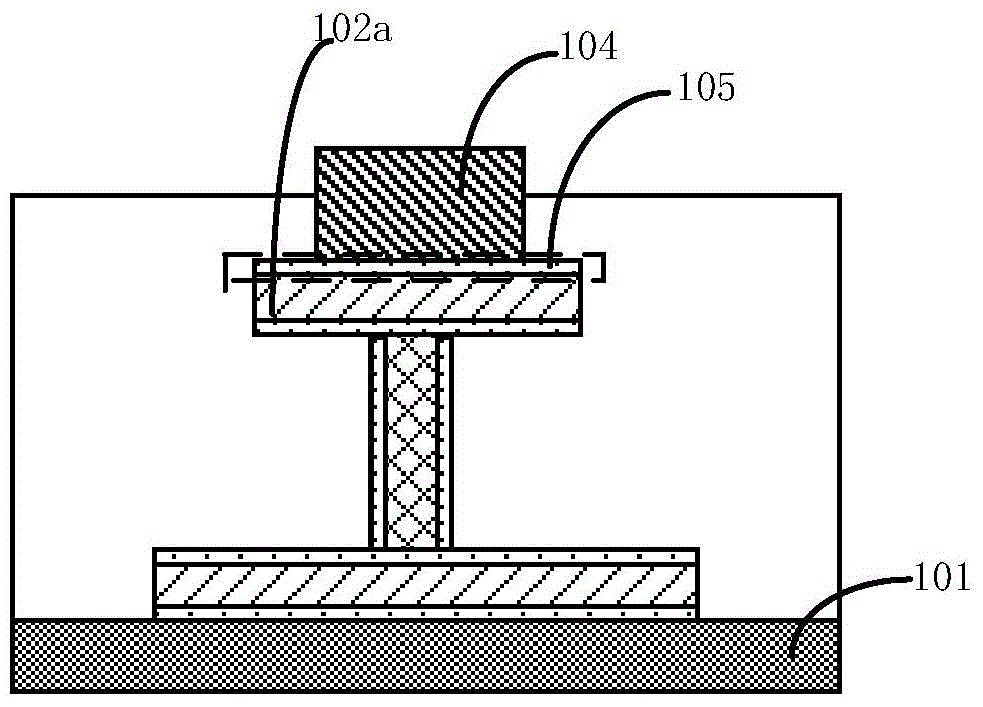

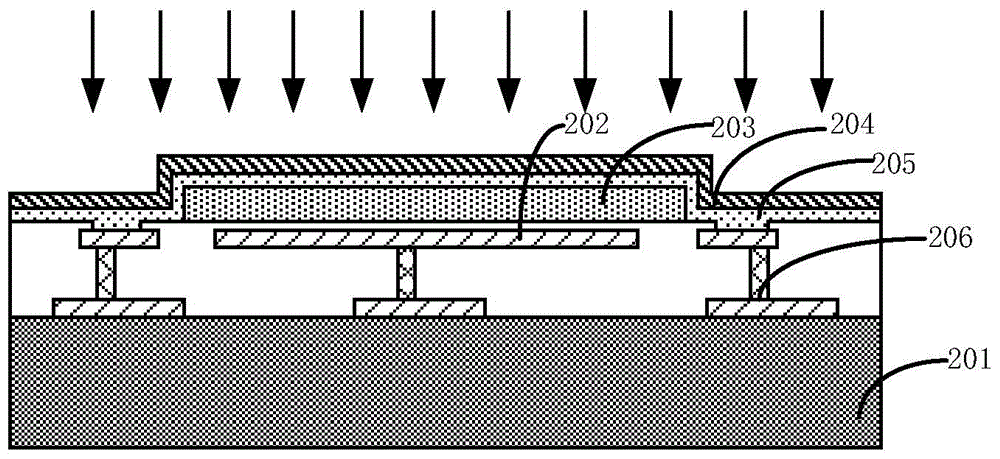

MEMS pressure sensor and preparation method thereof

ActiveCN105092112ANo heat damageEasy to adjustTelevision system detailsImpedence networksInsulation layerThermal insulation

The invention relates to an MEMS pressure sensor and a preparation method thereof. The preparation method comprises the steps of providing a substrate on which an interlayer dielectric layer and a bottom electrode in the interlayer dielectric layer are formed; forming a patterned sacrificial material layer above the bottom electrode; forming a thermal insulation layer above the sacrificial material layer and the interlayer dielectric layer for covering the sacrificial material layer and the interlayer dielectric layer; forming a pressure sensing film on the thermal insulation layer as a top electrode; and performing a laser annealing step for improving the stress performance of the pressure sensing film. The MEMS pressure sensor and the preparation method are advantageous in that (1) no thermal damage to the sacrificial material layer (amorphous carbon) is realized; (2) no thermal damage to a metal layer (Al) in the interconnecting structure of the top electrode is realized; (3) a good adjusting effect for the stress of the insulation layer poly-SiGe is obtained; and (4) breakage or failure of the interconnecting structure of the top electrode is prevented, thereby improving the performance and yield rate of the device.

Owner:SEMICON MFG INT (SHANGHAI) CORP

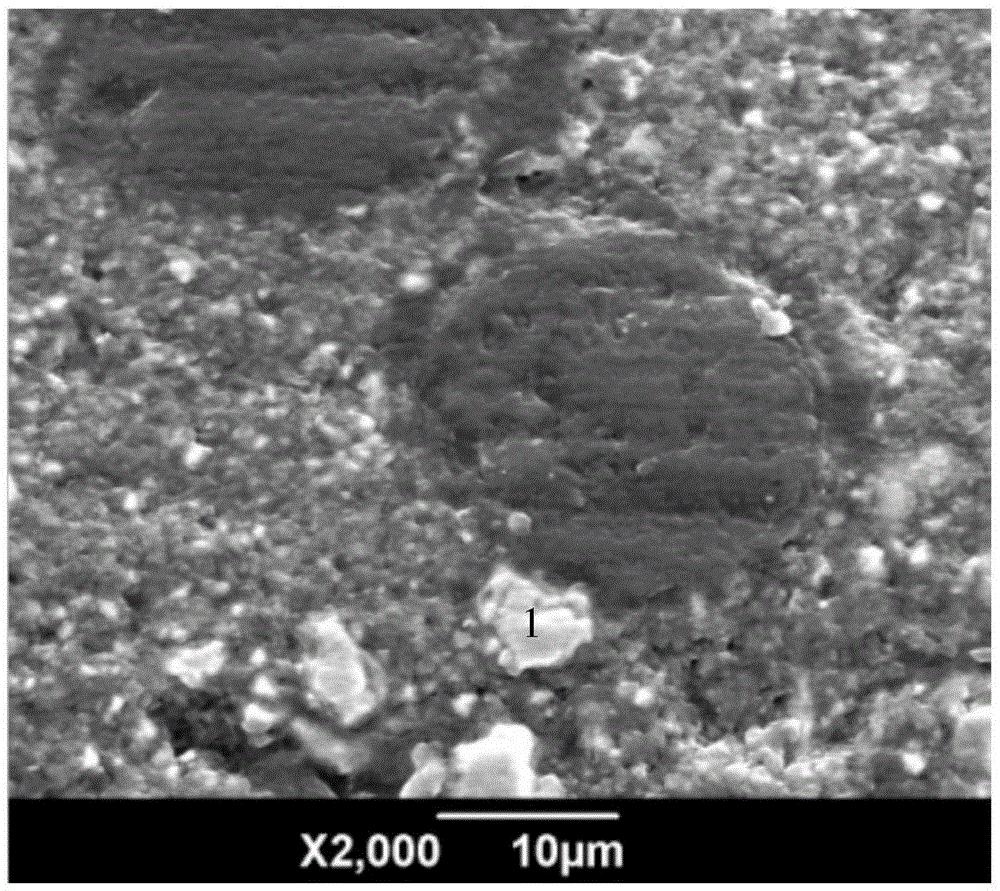

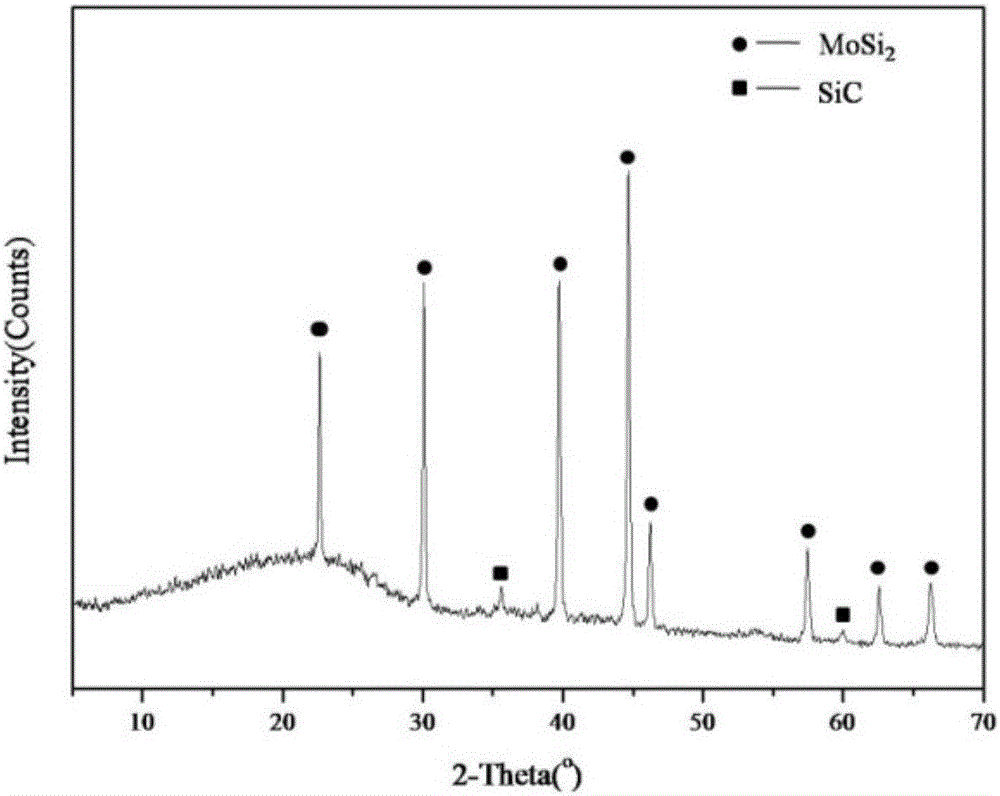

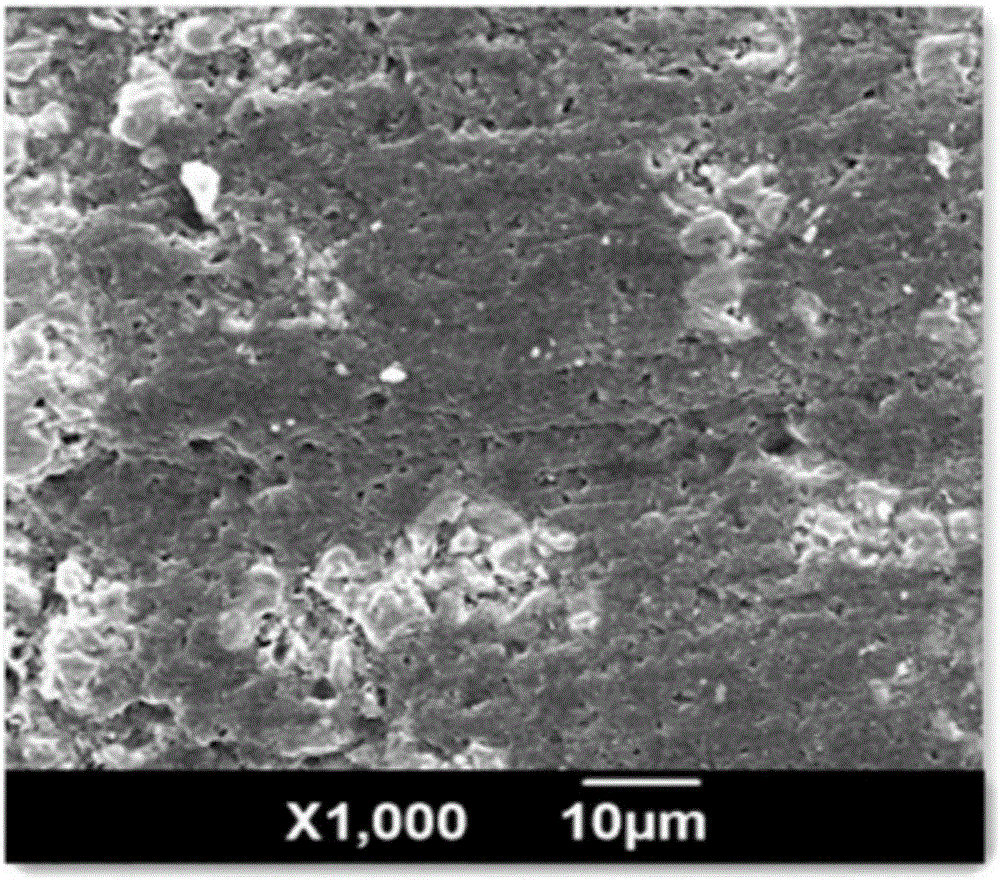

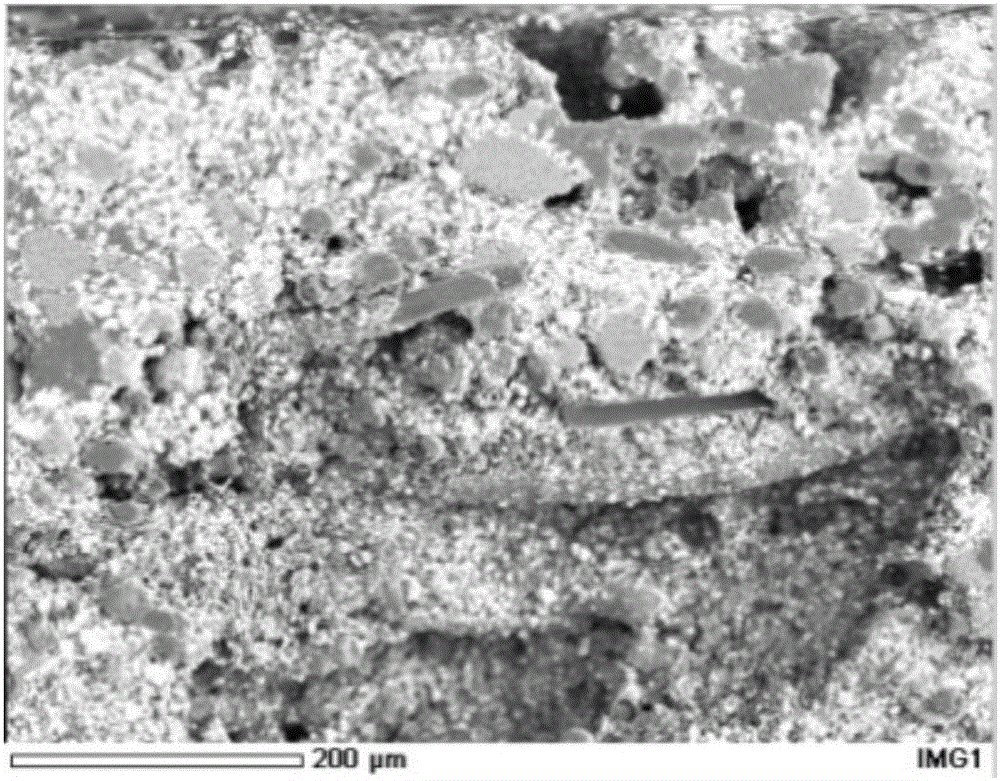

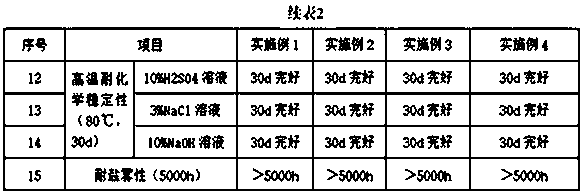

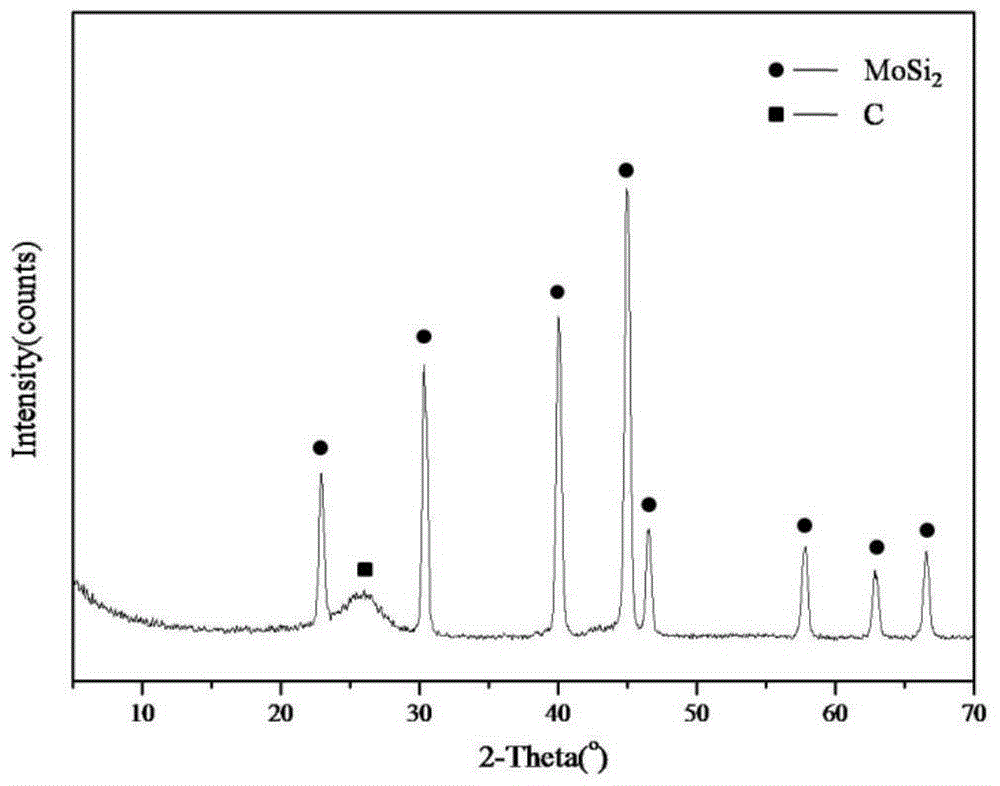

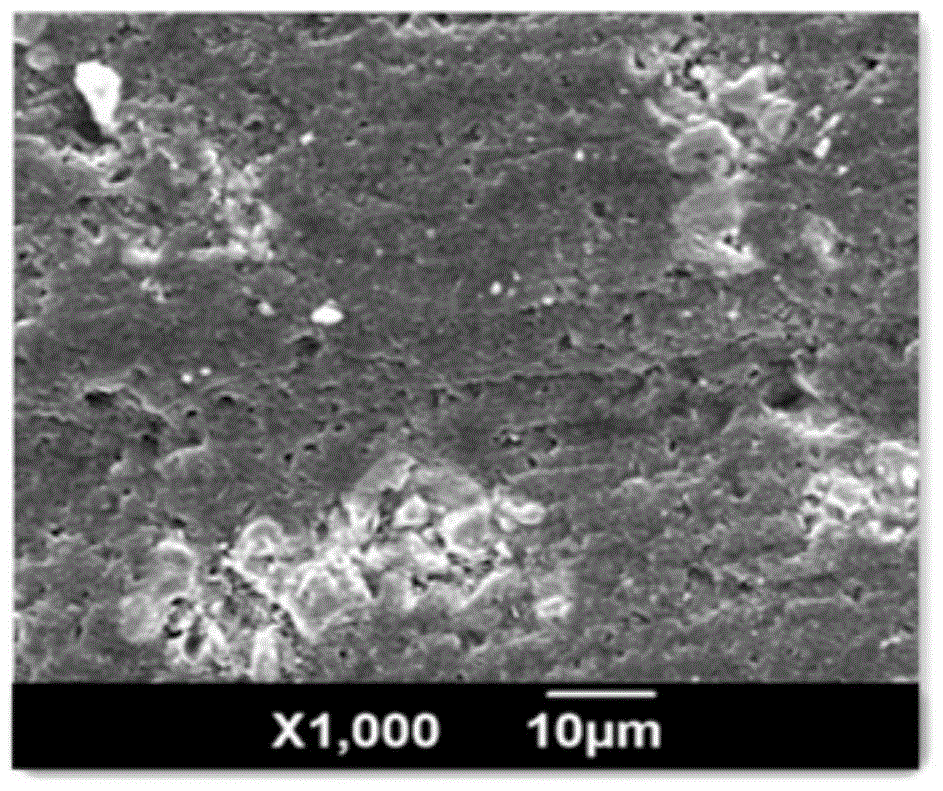

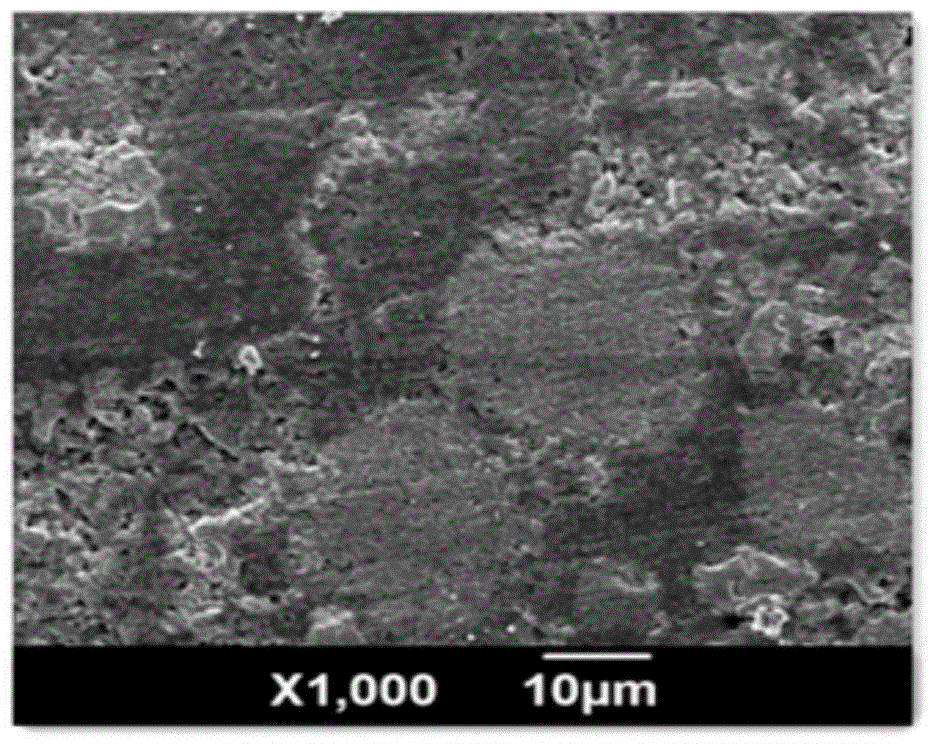

Preparation method for lamellar C/C-SiC-MoSi2 ceramic matrix composite

The invention provides a preparation method for a lamellar C / C-SiC-MoSi2 ceramic matrix composite. The method comprises the steps that silicon carbide powder and molybdenum disilicide powder are dispersed in isopropyl alcohol and then stirred evenly after iodine is added, and first suspension liquid and second suspension liquid is obtained; the density of a carbon-fiber three-dimensional fabric is increased by adopting the mode of hydrothermal glucose permeation, the carbon-fiber three-dimensional fabric is clamped in a specially-made hydrothermal kettle with a positive electrode and a negative electrode, then the specially-made hydrothermal kettle is placed in a drying oven for heat preservation, and then hydrothermal electrophoretic deposition is performed; homogeneous-phase hydrothermal treatment is repeatedly performed in an aqueous glucose solution until the density reaches 1.3-1.5 g / cm<3>, and then heat treatment is performed after the fabric is dried. According to the preparation method for the lamellar C / C-SiC-MoSi2 ceramic matrix composite, the prepared composite is moderate in density and compact in structure, and binding between a C / C interface and a SiC interface, binding between the SiC interface and a MoSi2 interface and binding between the C / C interface and the MoSi2 interface are good; the composite with the high strength and the good high-temperature oxidation resistance can be obtained at low temperature, and the preparation method has the advantages that the raw materials are easy to obtain, the preparation technology is simple, operation is easy and convenient, and the cost is low.

Owner:广西自贸区见炬科技有限公司 +1

Solvent-free oil pipeline anti-corrosion and anti-drag special coating and preparation method thereof

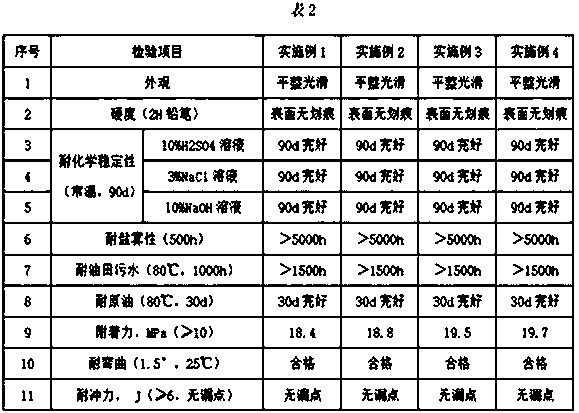

ActiveCN111205746AImprove thixotropyEvenly dispersedAnti-corrosive paintsEpoxy resin coatingsFatty amineSolvent free

The invention discloses a solvent-free oil pipeline anti-corrosion and anti-drag special coating and a preparation method thereof, belongs to the field of anti-corrosion coatings, and solves the problems that an existing solvent-free anti-corrosion coating is high in construction difficulty, a coating is prone to scale formation and the like. The coating is prepared from two components, wherein the component I is prepared from bisphenol A epoxy resin, polyethersulfone modified epoxy resin, aromatic hydrocarbon resin, glass fiber powder, polytetrafluoroethylene wax powder, potassium hexatitanate whiskers, silica powder, a dispersing agent, a leveling agent, an epoxy active diluent, polyethylene wax powder, talcum powder, phthalocyanine blue, lemon yellow and an antifoaming agent, and the component II consists of a cashew nut shell oil modified phenolic aldehyde amine curing agent and a resin type modified fatty amine curing agent. The preparation method comprises the following steps: mixing the component I and the component II according to a mass ratio of (4-12): 1, and uniformly stirring. The coating has the advantages of favorable long-acting property, favorable flexibility, favorable temperature resistance, favorable chemical resistance, favorable drag reduction effect, environment friendliness and easiness in construction. The preparation method is simple, and the productionefficiency can be obviously improved.

Owner:西北永新涂料有限公司

Wear-resistant coating and preparation method thereof, cutter ring of shield hobbing cutter, shield hobbing cutter and shield tunneling machine

ActiveCN110468406ARelieve heat stressInhibition of germinationMetallic material coating processesTunnelsHobbingAlcohol

The invention provides a wear-resistant coating and a preparation method thereof, a cutter ring of a shield hobbing cutter, the shield hobbing cutter and a shield tunneling machine. The wear-resistantcoating comprises at least two brazing filler metal coatings basically identical in structure. Each brazing filler metal coating comprises, by mass part, 3-10 parts of diamond micro-powder, 2-6 partsof an alcohol solvent, 1-5 parts of sodium fluoride and 81-93 pars of nickel-based brazing filler metal. According to the wear-resistant coating, a gradient transition coating is formed by the multi-pass basically identical thin coatings, the thermal stress problem generated when a thick coating is prepared through a surfacing welding method is relieved, and initiation and extension of cracks areinhibited to a certain degree; and meanwhile, the uniform distribution degree of the hard phase diamond micro-powder can be improved, and the advantages of being small in thermal injury, uniform in hard phase distribution and not likely to fall off are achieved. According to the shield hobbing cutter, the surface of the cutter ring is coated with the wear-resistant coating, the wear resisting performance of the cutter ring is effectively improved, and the service life of the cutter ring is prolonged.

Owner:CHINA INNOVATION ACADEMY OF INTELLIGENT EQUIP CO LTD +1

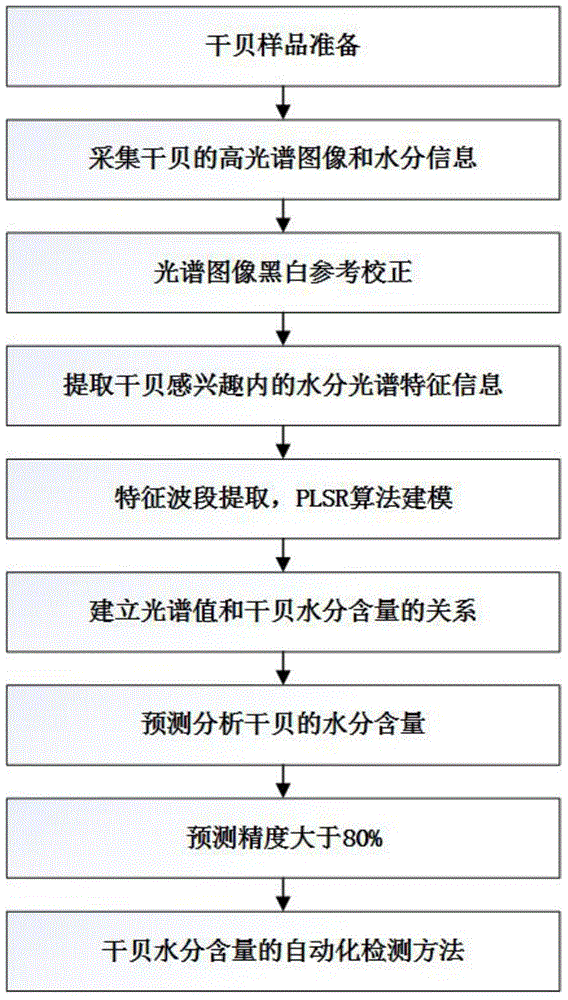

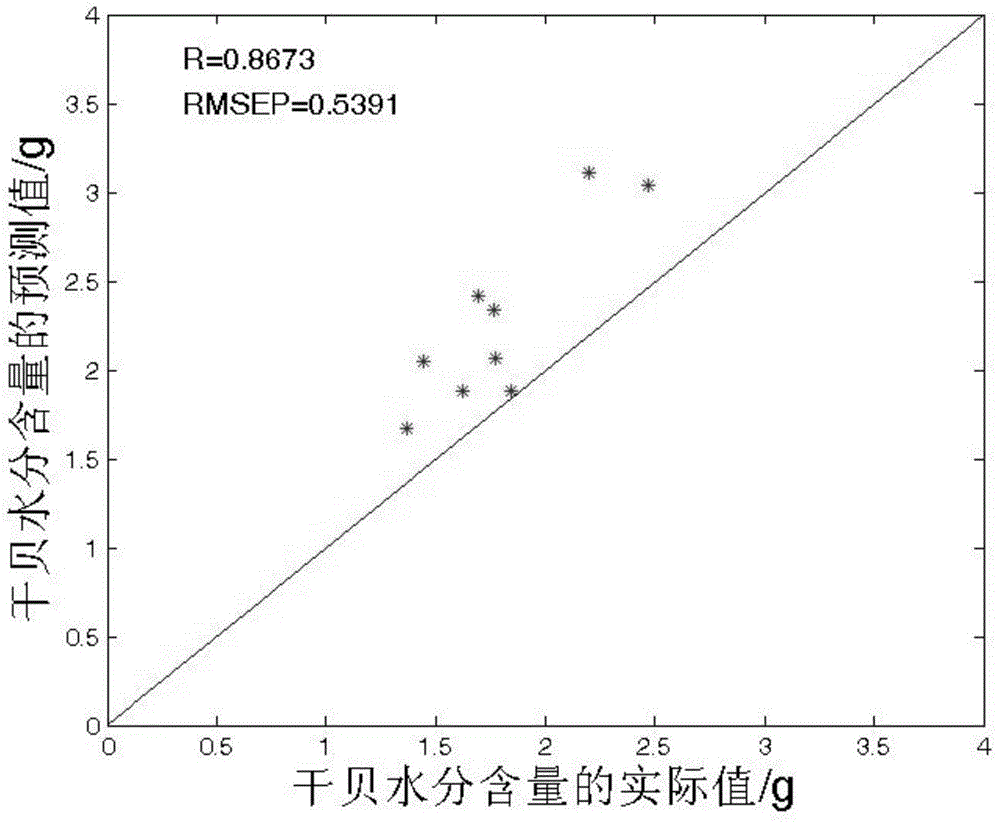

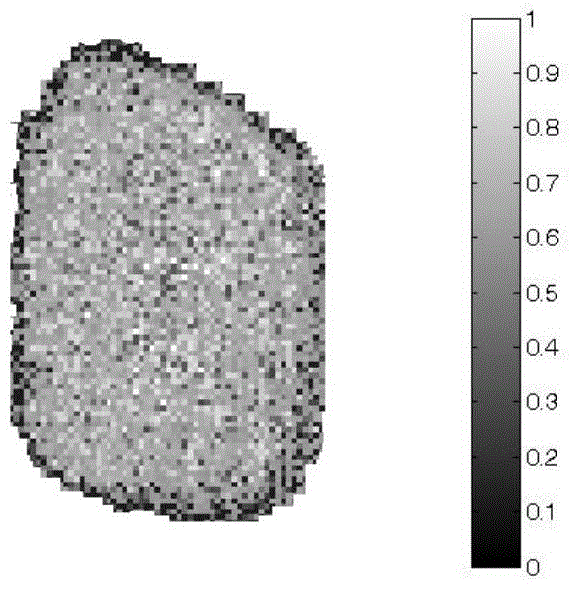

Hyperspectral detection method of dried scallop moisture content

InactiveCN104949927ARapid detection of moisture contentImprove detection accuracyColor/spectral properties measurementsAssembly lineLength wave

The invention discloses a hyperspectral detection method of dried scallop moisture content. The method comprises the following steps: acquiring a spectral image of a dried scallop sample and correcting; designating a region of interest (ROI) of the dried scallop sample by a threshold value method; extracting average spectrum data of all pixel points in the ROT; representing the extracted average spectrum data with a three-dimensional data block; carrying out characteristic bands selection by SPA; modeling by substituting spectrum data corresponding to characteristic wavelength extracted by SPA into partial least squares regression algorithm; and calculating to obtain moisture content of dried scallops corresponding to each pixel point in the spectral image of dried scallops. By the method, heat damage to dried scallops caused by an oven-drying method in detecting moisture can be effectively avoided. The detection process operation is simple, detection precision is high, and detection time is short. The method can be adopted to continuously detect moisture content of multiple dried scallops, is beneficial to assembly line process in production practice of dried scallops and has a good prospect in production application of dried scallops.

Owner:ZHEJIANG UNIV

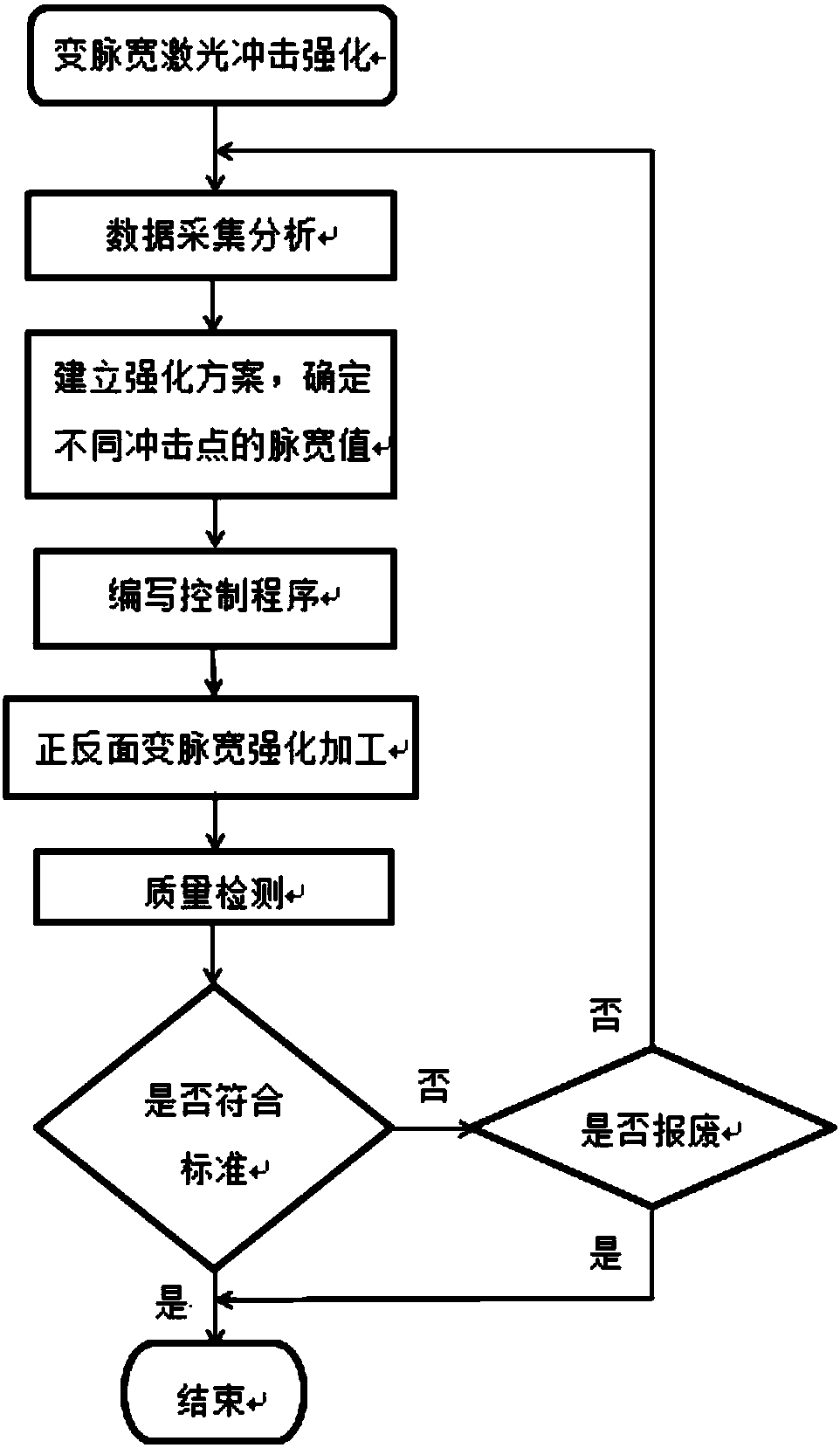

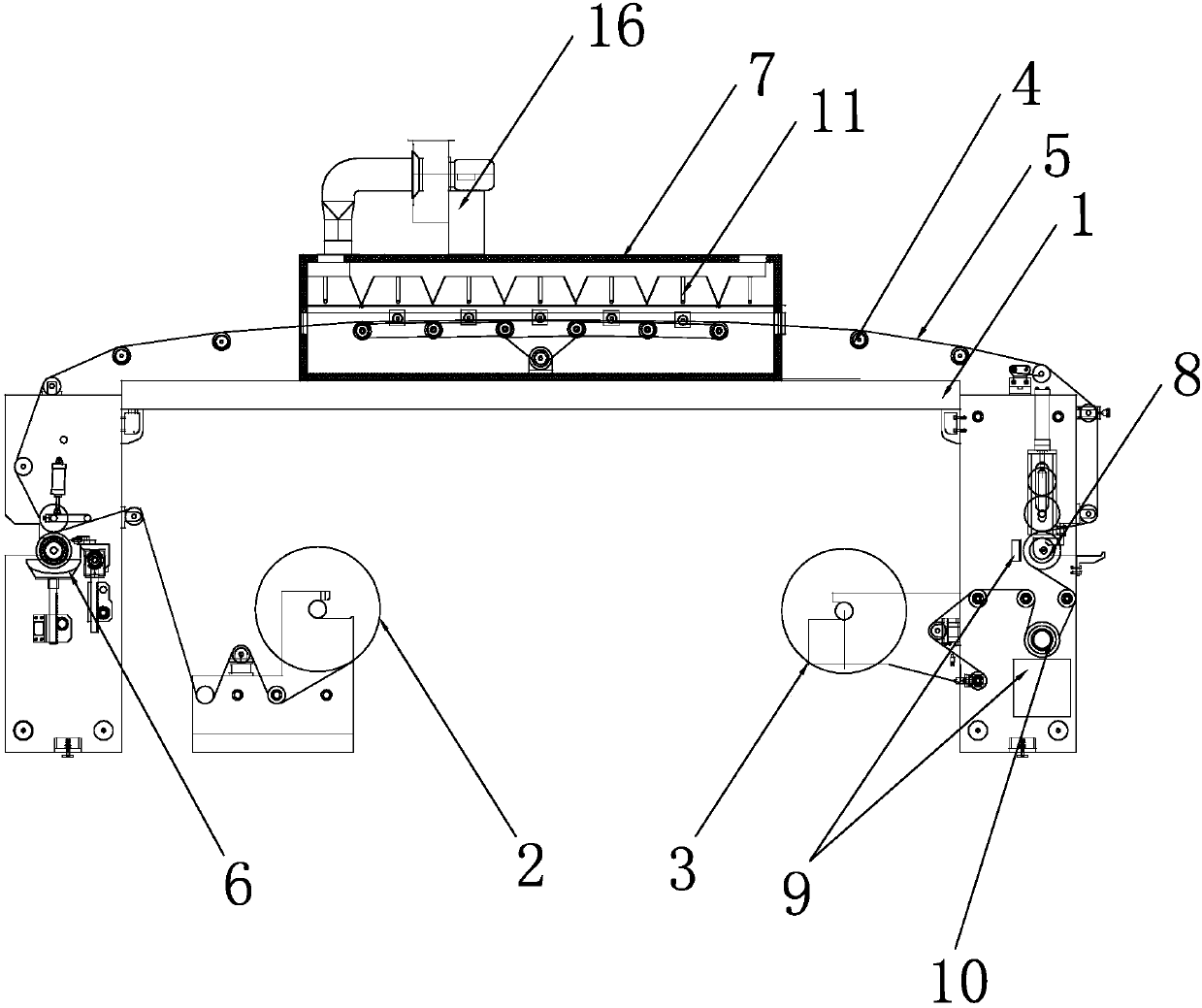

Blade laser shock peening shape-control method with pulse widths variable in real time online

The invention discloses a blade laser shock peening shape-control method with the pulse widths variable in real time online. The method comprises the steps that acquisition and analysis are performed;a peening scheme is built so as to determine the pulse width values of different shock points; a control program is written; laser variable-pulse-width peening machining is performed; and a peening effect is detected. According to the technical scheme provided by the invention, compared with the prior art, in terms of complex curved surfaces and structures with non-uniform wall thicknesses of blades, the pulse widths can be changed in real time online as the blade structures change, it can be guaranteed that the optimal peening effect of different areas is achieved, and the situation that thepulse widths are overlarge, and consequentially, thermal damage and deformation out-of-tolerance of the blades are caused can also be avoided.

Owner:GUANGDONG UNIV OF TECH

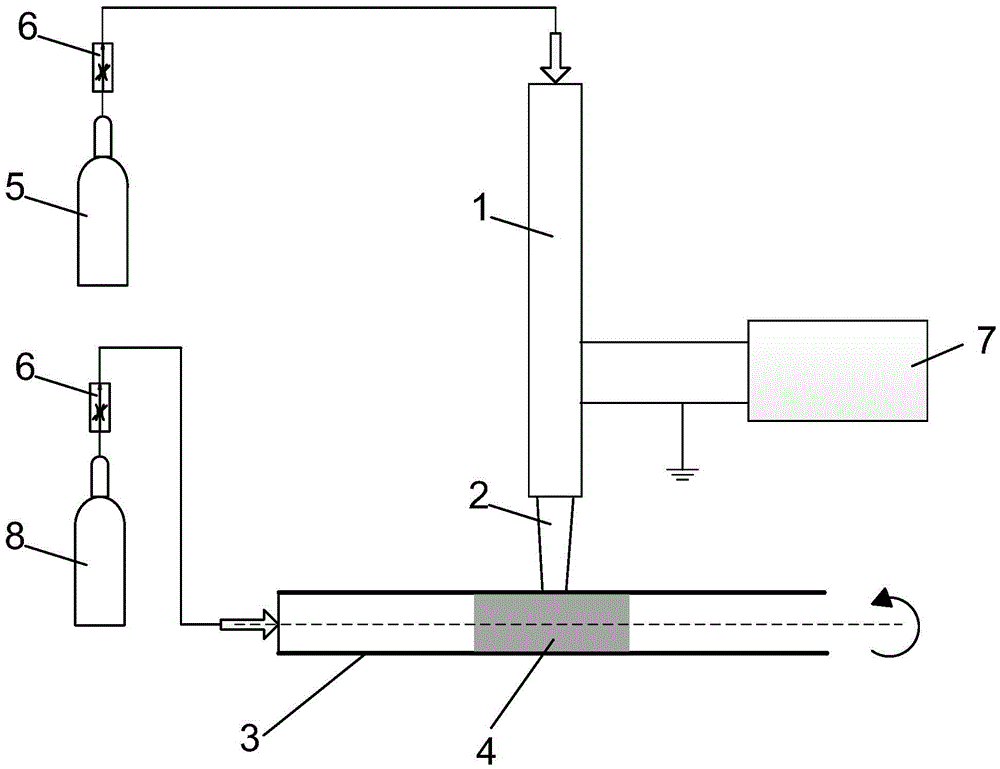

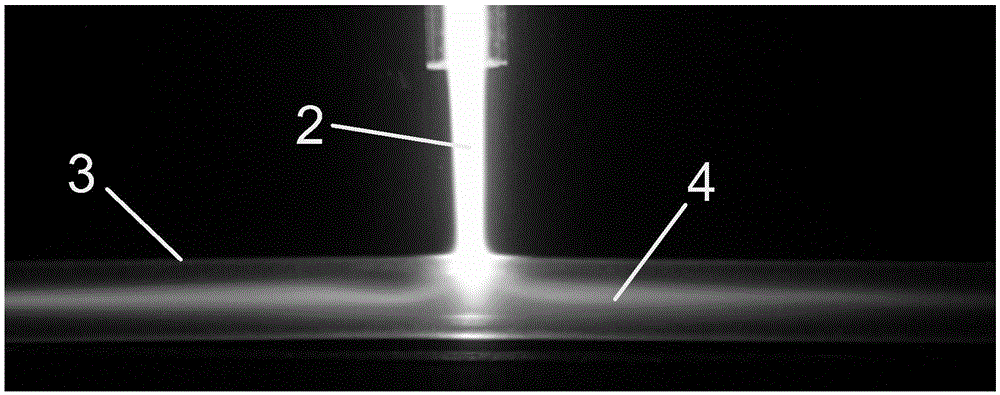

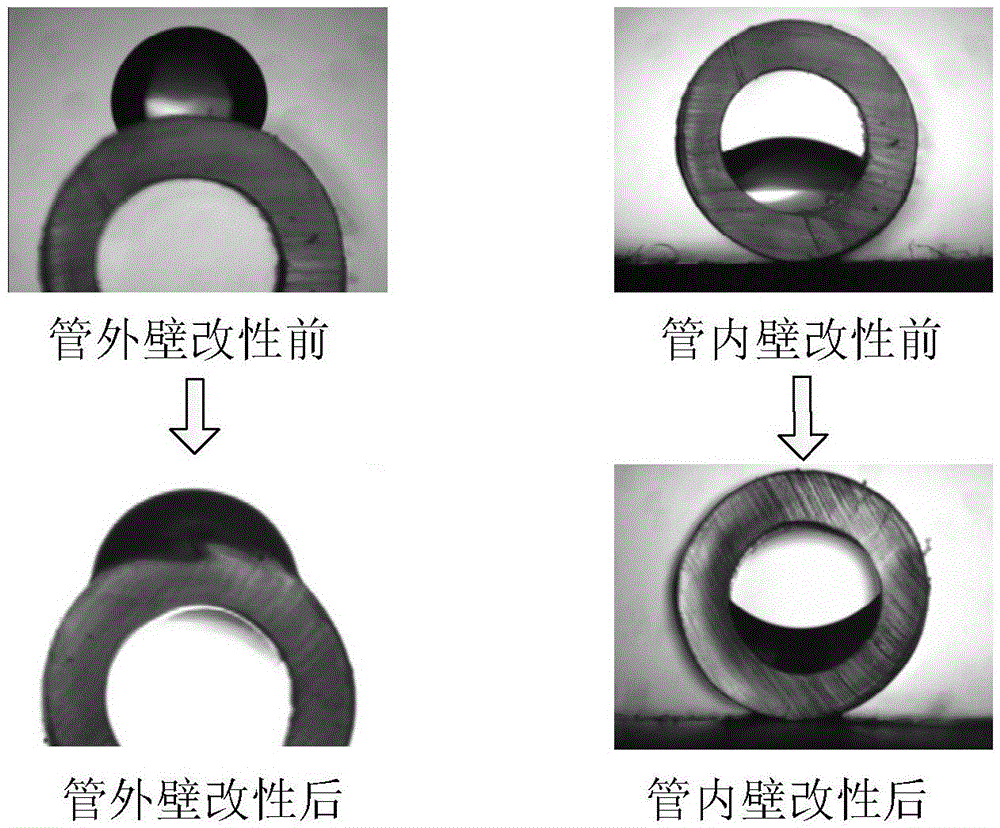

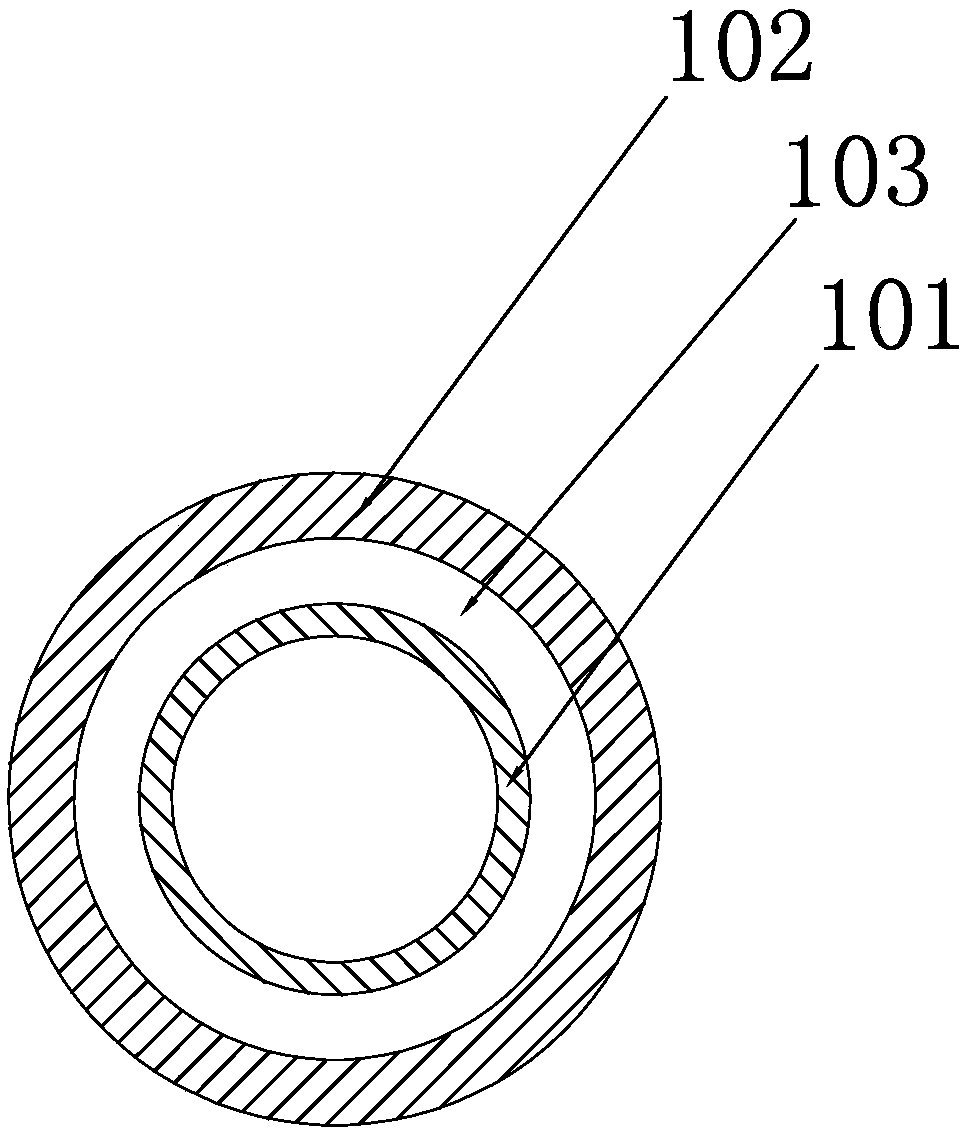

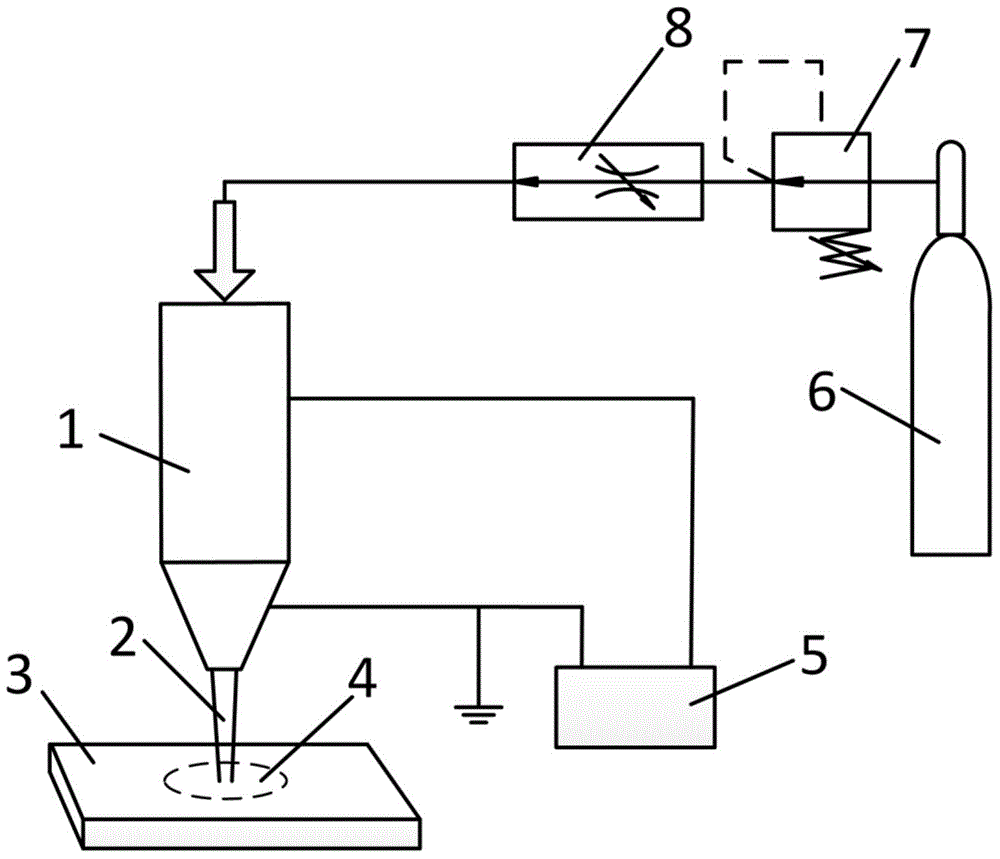

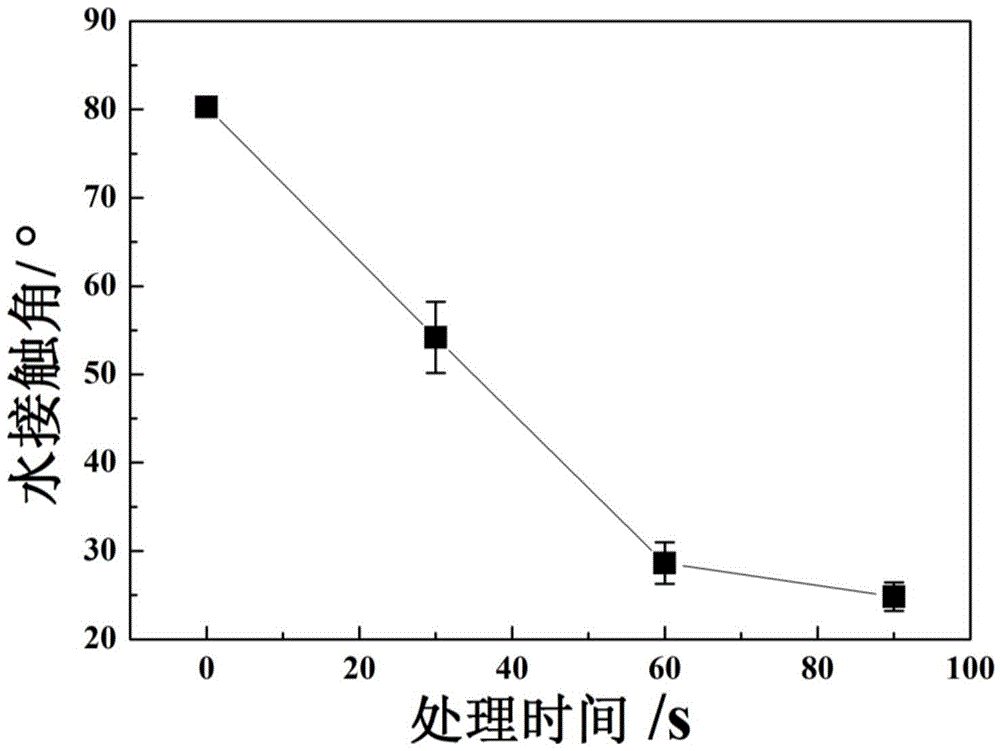

Method for performing surface modification on inner wall and outer wall of tube by adopting atmospheric-pressure plasma

The invention provides a method for performing surface modification on the inner wall and the outer wall of a tube by adopting atmospheric-pressure plasma and belongs to the technical field of surface treatment of plasma materials. The method comprises the steps that produced plasma jet is applied to the surface of a to-be-processed tubular material, working gas is introduced into the to-be-processed tubular material, and plasma is formed in the to-be-processed tubular material; the plasma jet performs surface modification on the outer wall of the to-be-processed tubular material; meanwhile, an electric field for ionizing the working gas in the to-be-processed tubular material is provided, so that the plasma is generated in the tube and realizes surface modification on the inner wall of the to-be-processed tubular material; when the to-be-processed tubular material performs rotating and feeding motion in the axial direction, surface modification on the inner wall and the outer wall of the tubular material with any length can be realized. According to the method, complicated vacuum equipment is not needed, simultaneous modification of the inner wall and the outer wall of the tube with any length is realized by controlling motion of the processed tube, the cost is low, the operation is simple and flexible, environmental pollution is avoided, and the method for surface modification is environment-friendly.

Owner:DALIAN UNIV OF TECH

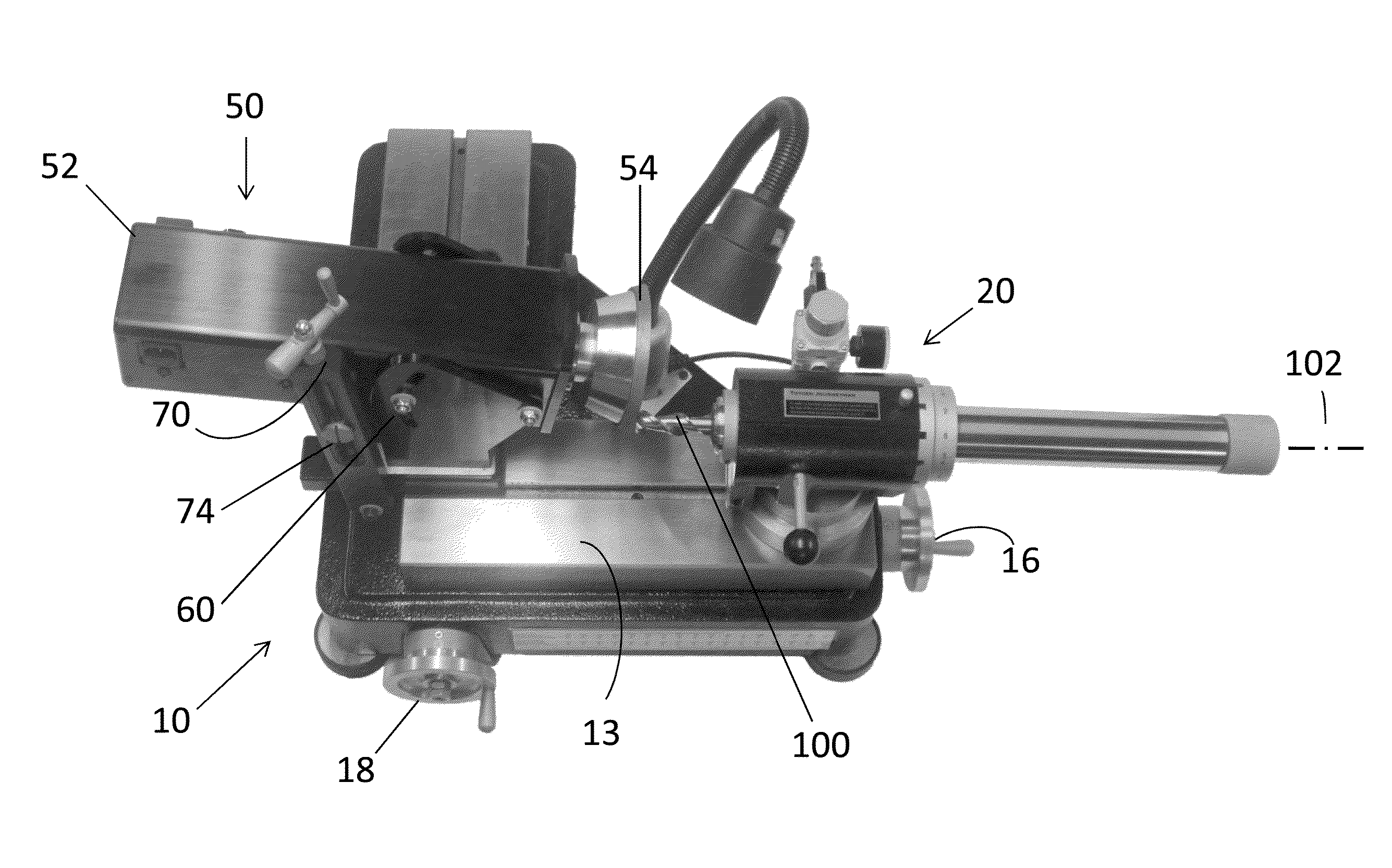

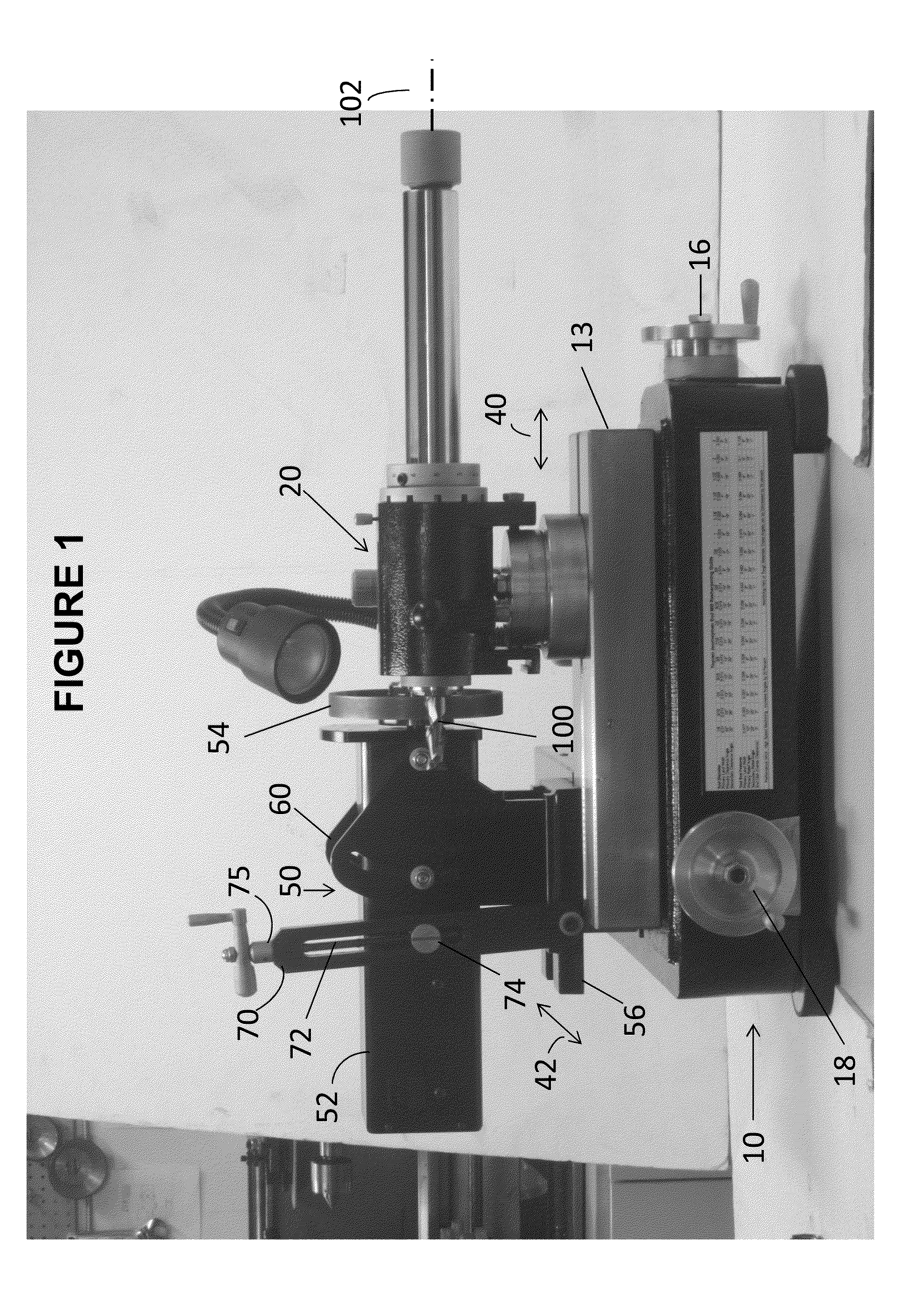

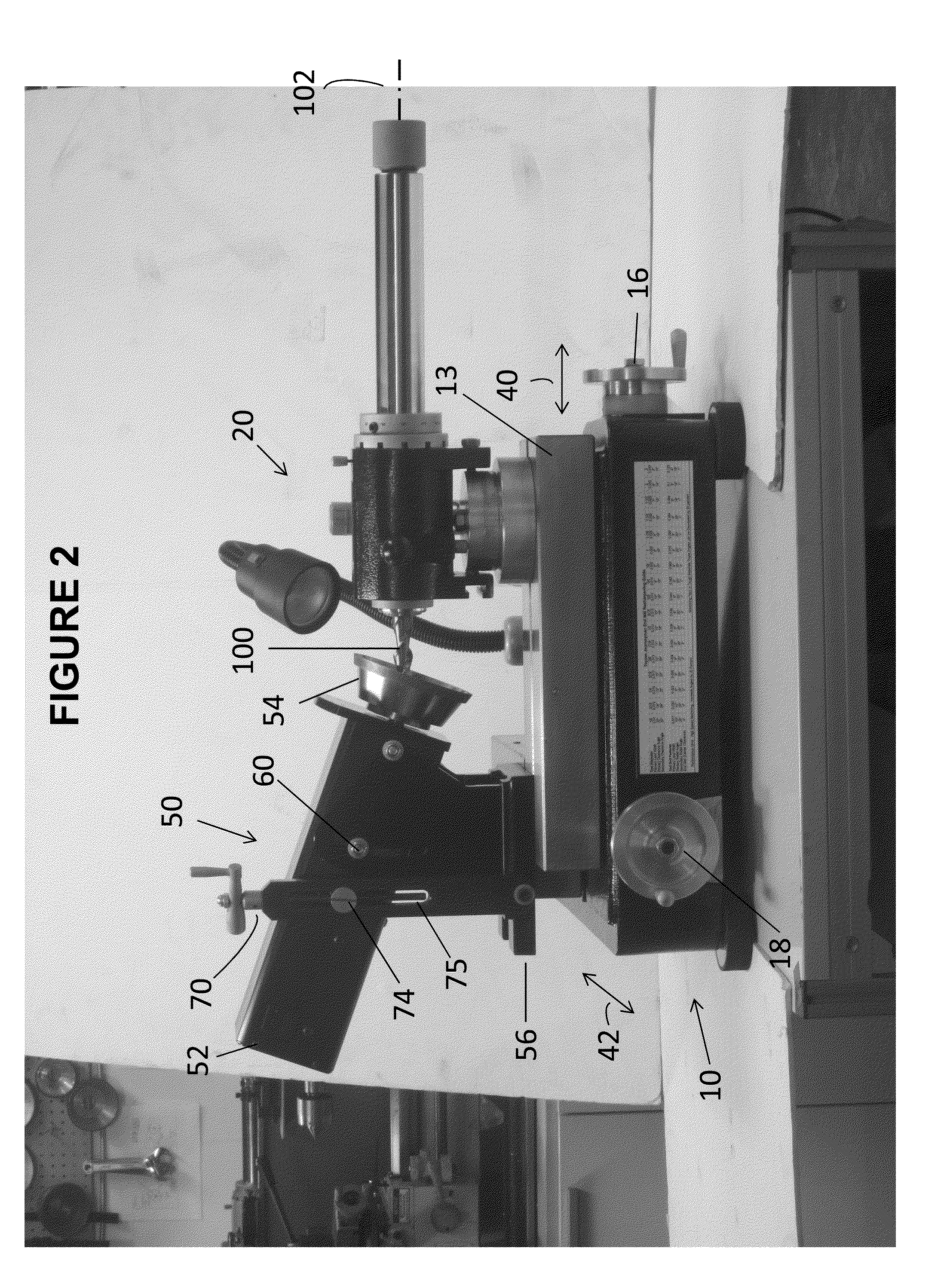

Tool grinder

ActiveUS20160074983A1Easily reproduce tool geometryNo heat damageEdge grinding machinesGrinding carriagesMilling cutterMulti axis

The end mill grinding device of the present invention includes a tool spindle assembly and a motor tower which enables multi-axis positioning of a sharpening wheel in relation to an end mill cutting tool being sharpened, for sharpening the end mill tool. The present invention combines linear sharpening and radial tool end grinding capability in the same device.

Owner:TOYCEN JEFF

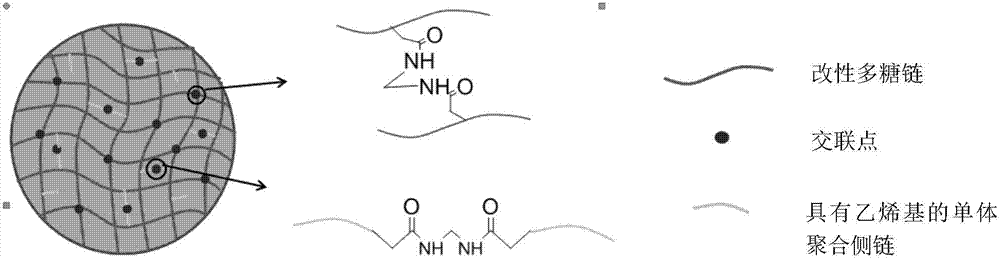

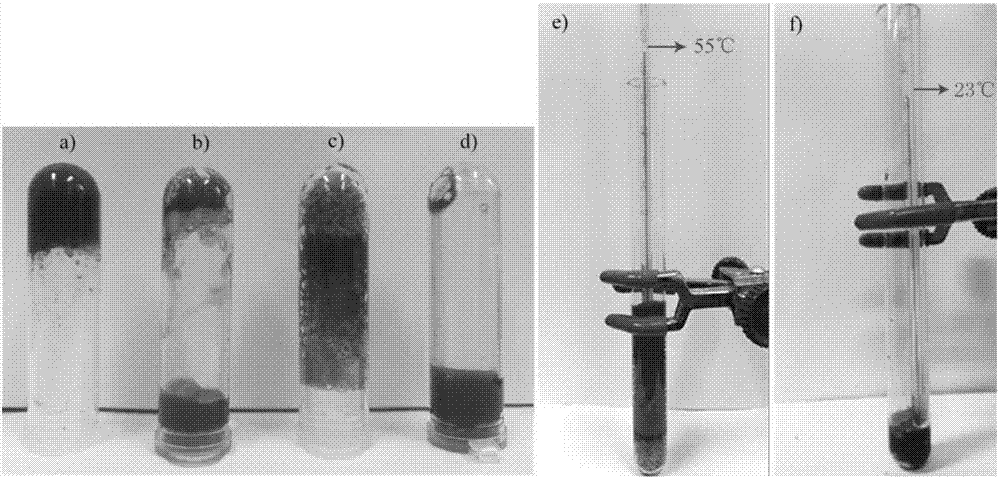

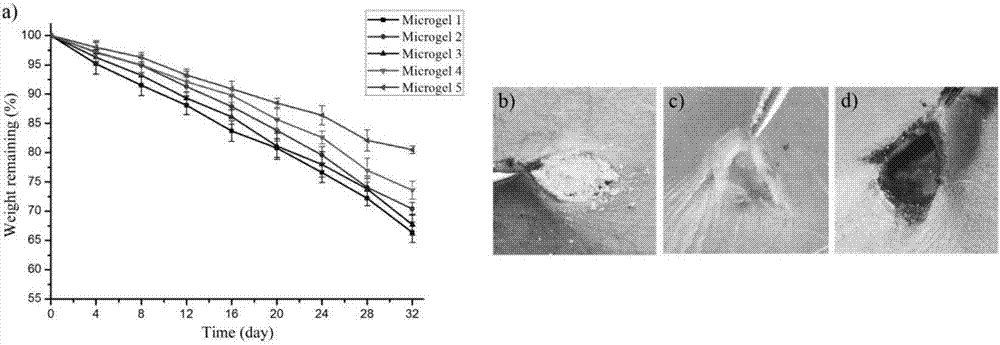

Nanogel hemostatic material modified with modified glucan as well as preparation and application of nanogel hemostatic material

ActiveCN106902383ALarge specific surface areaQuick responseSurgical adhesivesPharmaceutical delivery mechanismLiver hemorrhageArterial hemorrhage

The invention provides a nanogel hemostatic material modified with modified glucan as well as preparation and an application of the nanogel hemostatic material. The nanogel hemostatic material is formed by polymerizing modified glucose and monomers containing vinyl, wherein the modified glucose is glucose modified with glycidyl methacrylate. The nanogel hemostatic material has excellent water absorption and good biocompatibility, the size is increased after the nanogel hemostatic material absorbs water to expand, a polymer hydrogel layer is formed and can block a wound to stop bleeding, modified glucan nonogel has an excellent hemostatic effect on traumatic hemorrhage such as venous hemorrhage, arterial hemorrhage, body surface hemorrhage as well as internal organ hemorrhage such as liver hemorrhage, is a good and novel hemostatic and has good application prospects in clinical trauma. The invention further provides a preparation method of the modified polysaccharide modified nanogel hemostatic material. The raw materials are cheap and easy to obtain, the reaction condition is mild, the reaction operation is simple, and post-treatment is convenient.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

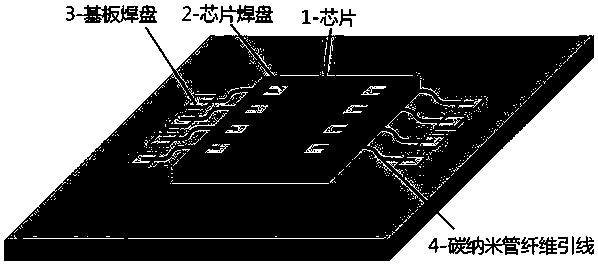

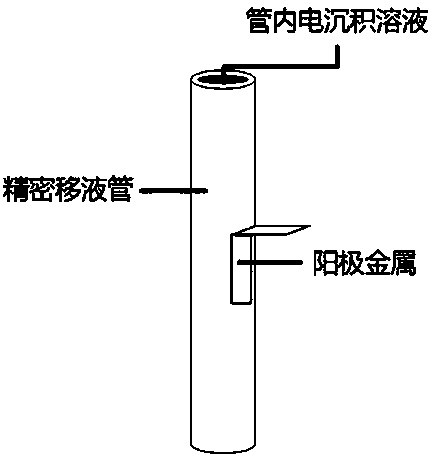

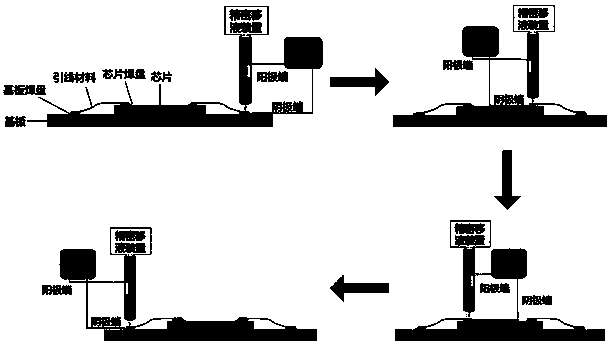

Lead bonding method based on rapid local electrodeposition

ActiveCN108054108AImprove conductivityBroaden your optionsSolid-state devicesSemiconductor/solid-state device manufacturingMicro nanoMetal coating

The invention relates to a wire bonding method based on rapid local electrodeposition, and belongs to the technical field of lead connection. The method comprises the following steps of selecting a novel lead material to be bonded and modifying the novel lead material; placing the lead material on the surface of a bonding pad through a micro-nano operation platform, ensuring that the lead is in good contact with the surface of the bonding pad; and selecting the caliber of a local electrodeposition precise pipette and the type of an anode metal in the pipette to ensure good contact between an electroplating cathode end probe and the bonding pad; forming a metal coating which completely coats the lead material on the surface of the bonding pad through a local electrodeposition method; and cleaning the entire device after the bonding of the electrodeposition leads on the surface of the bonding pad. Compared with a traditional lead bonding process, the method disclosed by the invention hasthe advantage that reliable lead bonding of the novel lead material can be realized, heating connection is not needed in the whole bonding process, and the whole bonding process is free of thermal damage and mechanical damage. The method is simple in technological process and high in bonding speed, and is suitable for various bonding pad materials and wide in connection layer metal variety selection range.

Owner:HARBIN INST OF TECH

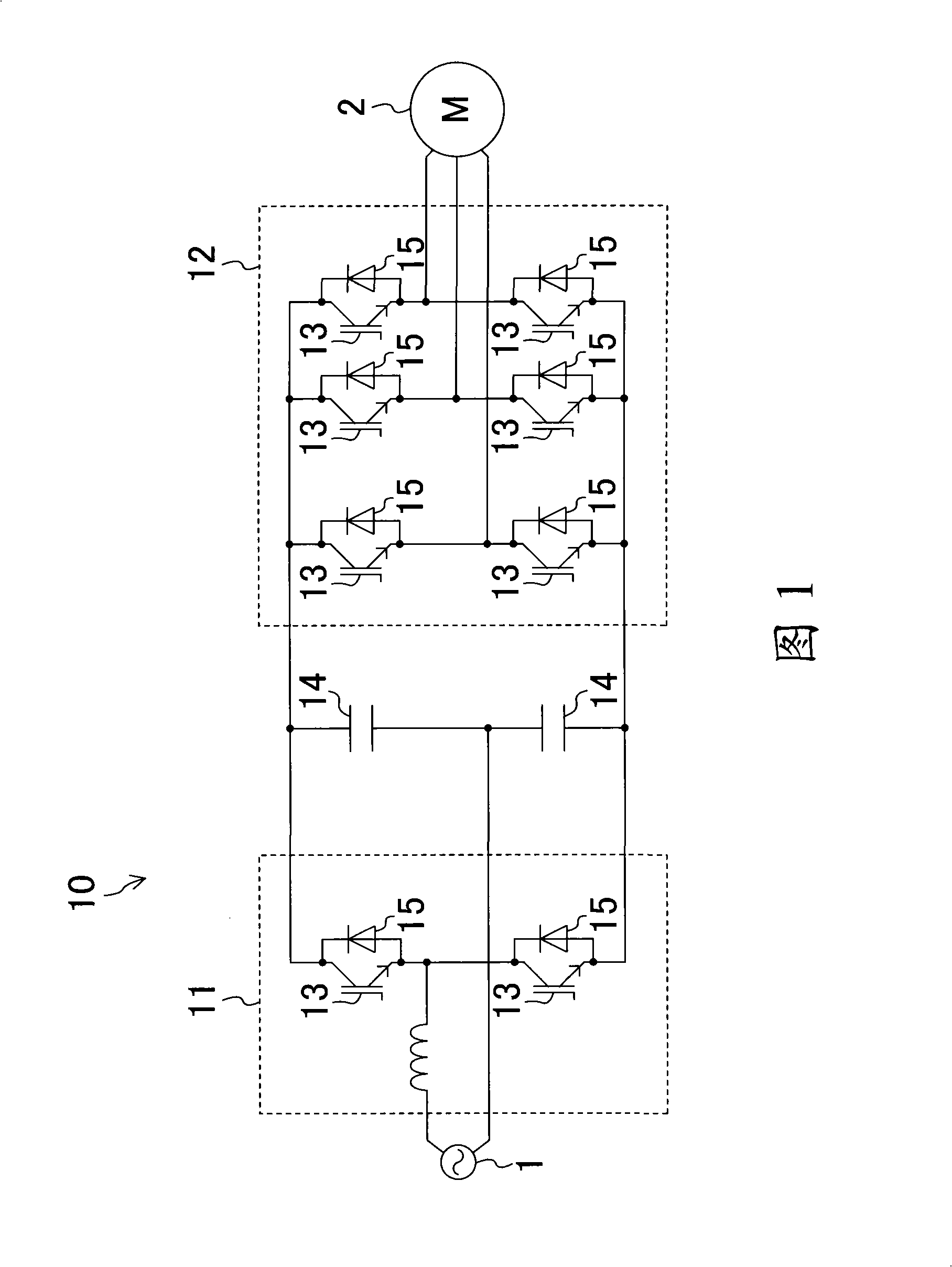

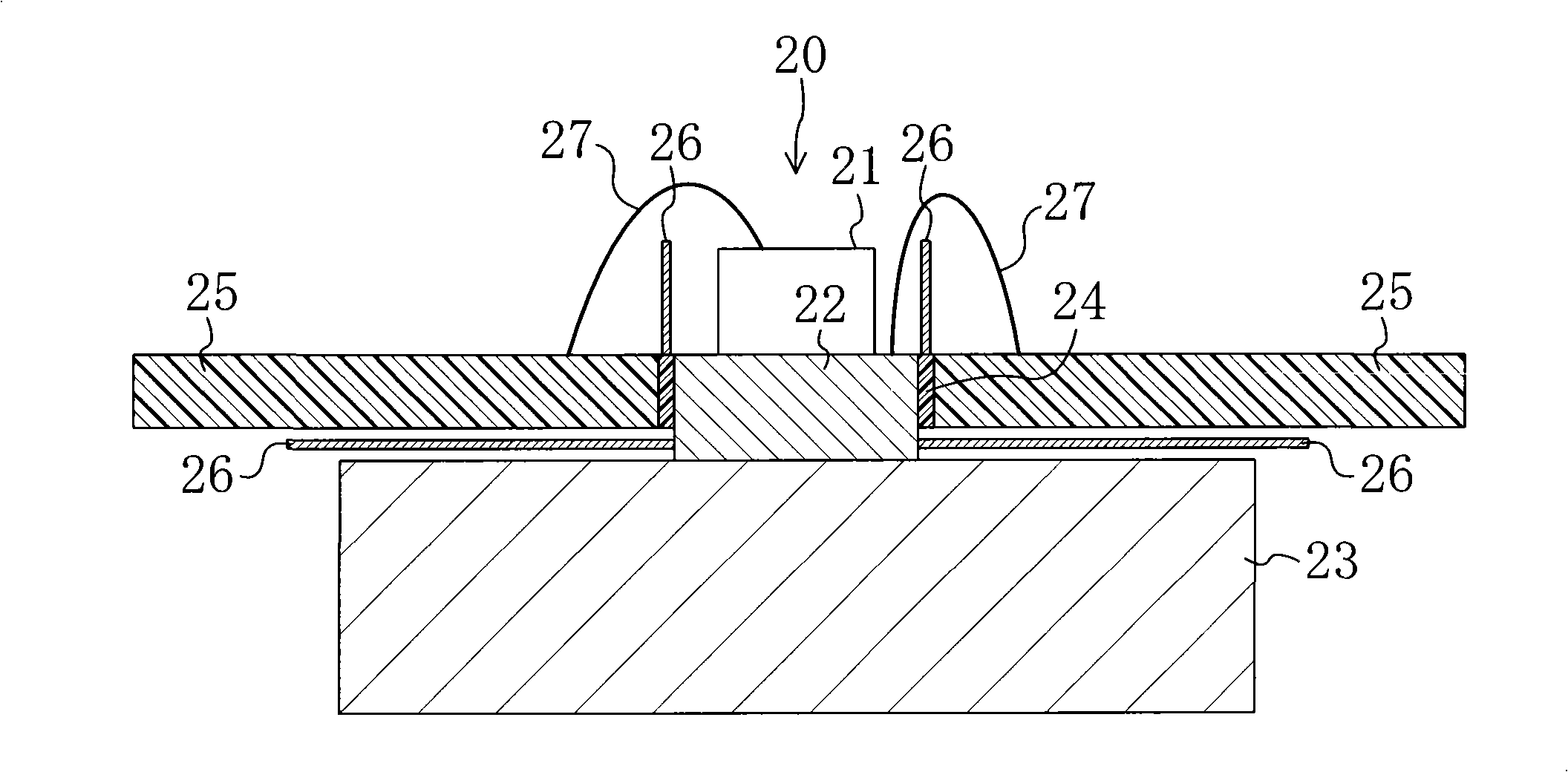

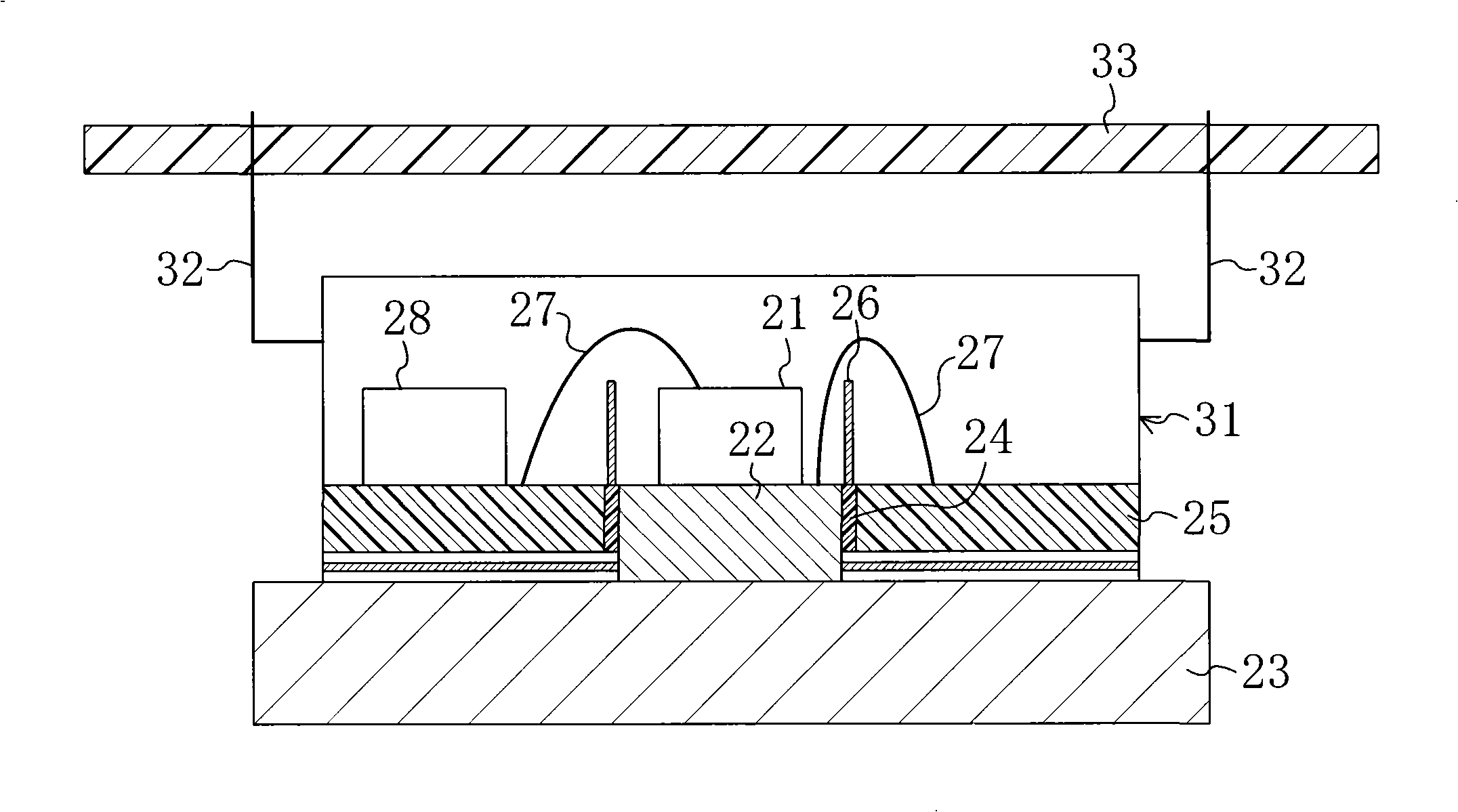

Electric power converter

InactiveCN101496169AAvoid heat damageSimple supporting structureSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringWide band

In the case where a chip is made of wide band gap semiconductor, a power conversion apparatus is obtained in which a component having a low heat resistant temperature is prevented from receiving thermal damage by heat generated at the chip. In a configuration including: a chip portion (20) including a chip (21) made of wide band gap semiconductor and a member (22, 23) having a heat resistant temperature equal to or higher than that of the chip (21); and a peripheral component (25) arranged in the vicinity of the chip portion (20) and having a heat resistant temperature lower than that of the chip (21). The chip (21) and the peripheral component (25) are thermally insulated from each other so that the temperature of the peripheral component (25) does not exceed the heat resistant temperature of the peripheral component (25).

Owner:DAIKIN IND LTD

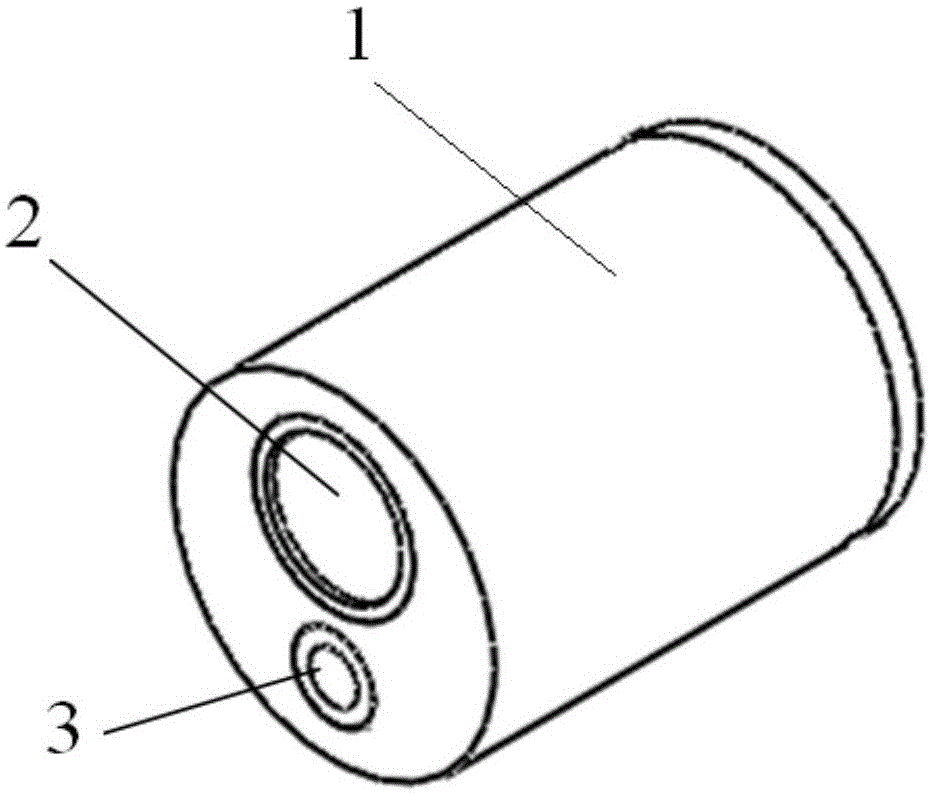

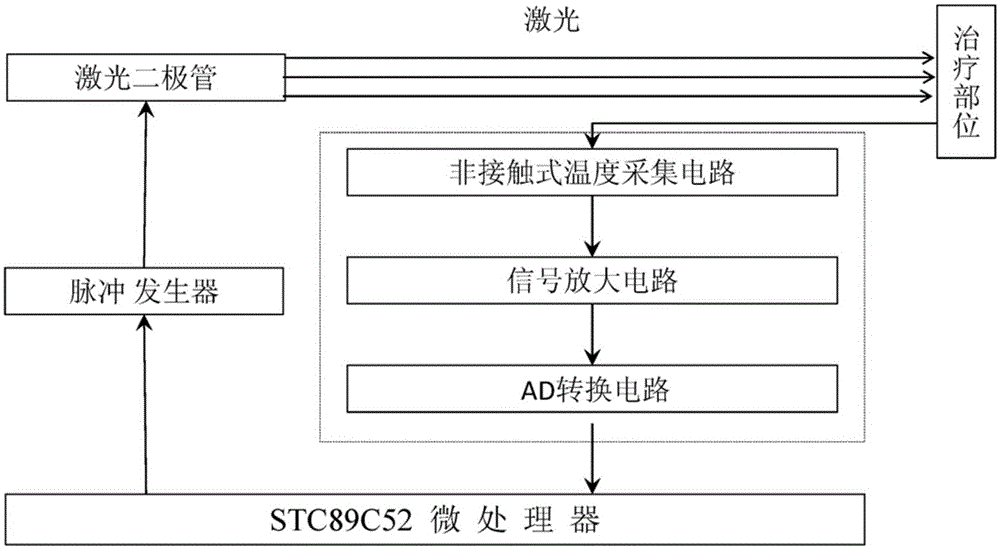

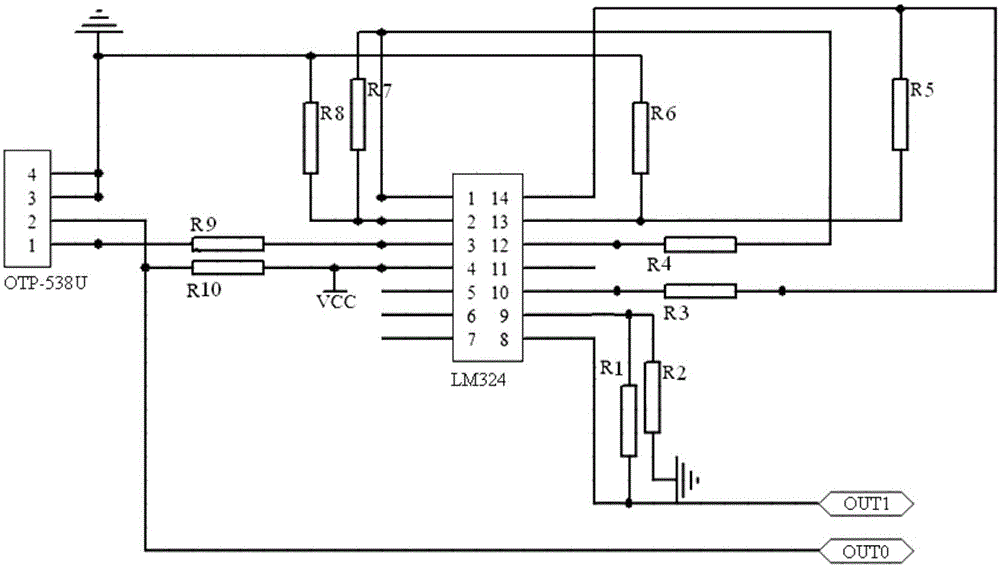

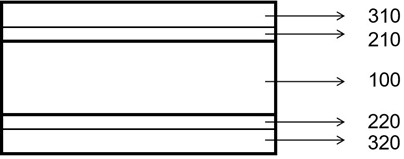

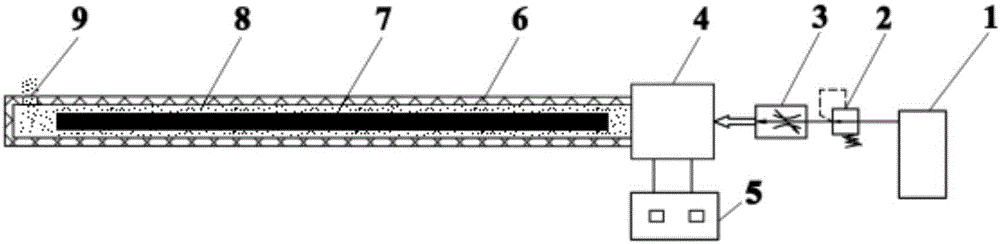

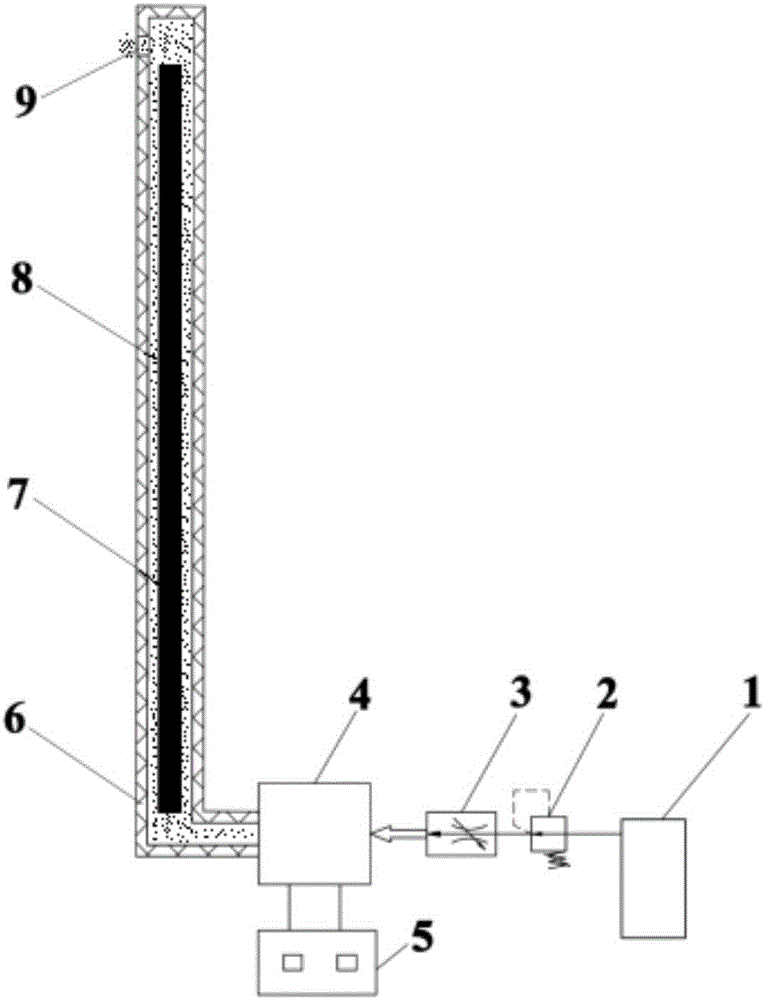

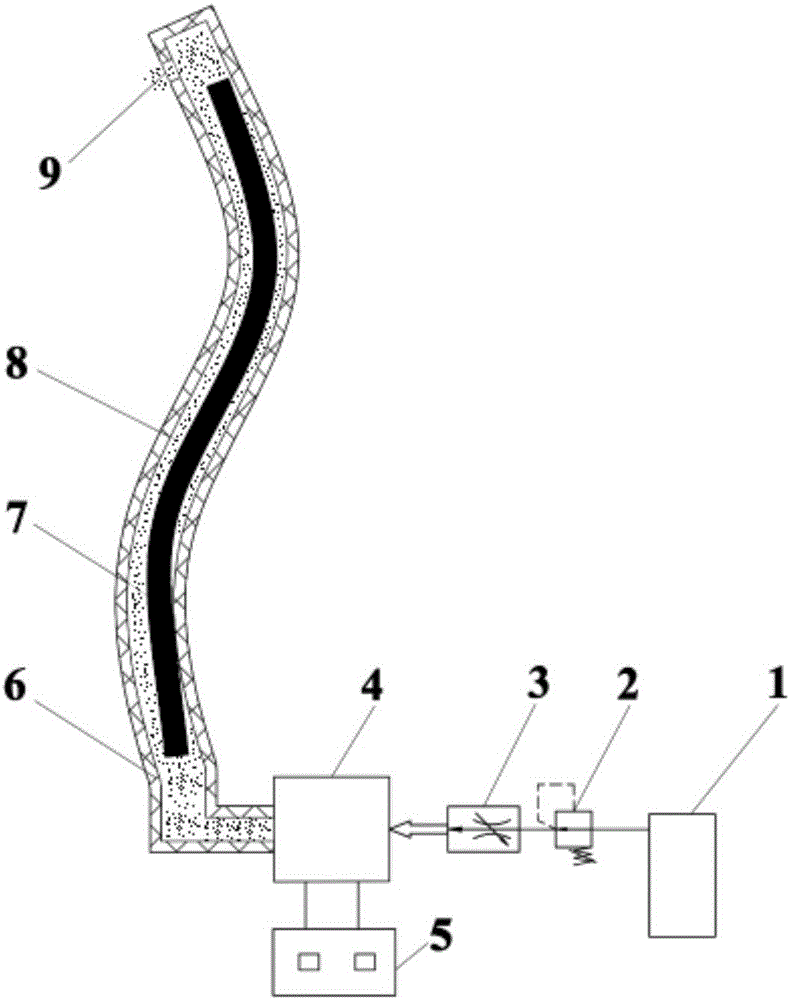

Real-time energy-feedback laser physiotherapy device

ActiveCN105031829AGuaranteed effectEnsure safetyDiagnostic recording/measuringSensorsEnergy feedbackFeedback regulation

The invention provides a real-time energy-feedback laser physiotherapy device, including a housing, a microprocessor, a laser therapy assembly and a temperature detection assembly. According to the invention, the temperature detection assembly detects the temperature within a laser radiation area in a non-contact manner. The microprocessor is utilized for adjusting the volume of the laser output energy. Through the energy-feedback adjustment , radioactive therapy on deep portions of the spinal cord of a user is conducted with no heat damage. The device herein overcomes the failure of prior products in adjusting laser irradiation energy in real time due to incapability of monitoring variations of the temperature of a radiated part of the body, and thus guarantees the effectiveness and safety of the therapy.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

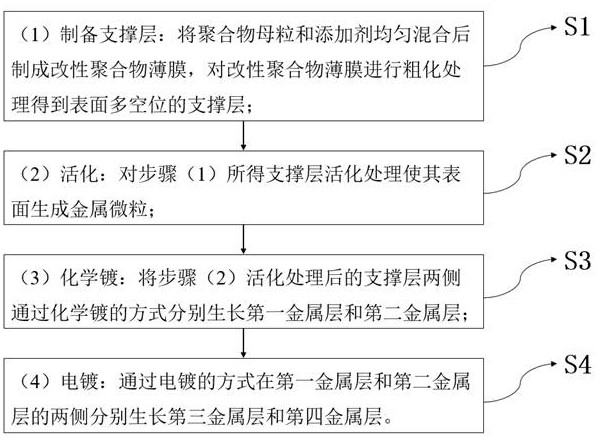

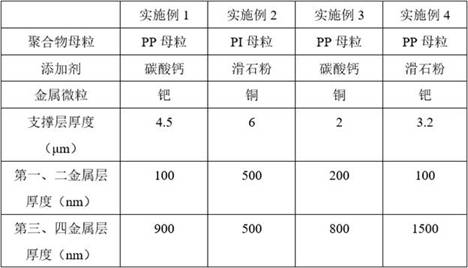

Preparation method of negative electrode composite current collector and product prepared by preparation method

PendingCN114678534ATightly boundUniform and dense distributionElectrode carriers/collectorsSecondary cellsChemical platingElectrical battery

The invention discloses a preparation method of a negative electrode composite current collector and a product prepared by the preparation method, and belongs to the technical field of lithium ion batteries. According to the method, polymer master batches and an additive are uniformly mixed to prepare a modified polymer film, the modified polymer film is subjected to roughening treatment to obtain a supporting layer with multiple vacancies on the surface, and metal particles are generated on the surface of the supporting layer through activating treatment; respectively growing a first metal layer and a second metal layer with a certain thickness on the two sides of the activated supporting layer in a chemical plating mode, and finally respectively depositing a third metal layer and a fourth metal layer on the two sides of the first metal layer and the second metal layer in an electroplating mode. The negative electrode composite current collector prepared by the method has the advantages of no surface defect, small internal stress of the plating layer, small resistivity of the plating layer, low production cost and easy realization of large-scale mass production.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Barometric pressure flexible cold plasma jet endoscope sterilizing device and method

ActiveCN106693009AHigh chemical activityEfficient sterilizationLavatory sanitoryDisinfectionPlasma jetEngineering

The invention relates to the field of sterilization in the medical industry, and particularly relates to a barometric pressure flexible cold plasma jet endoscope sterilizing device and a barometric pressure flexible cold plasma jet endoscope sterilizing method. An endoscope is immersed in a conduit type sterilizing region full of a barometric pressure flexible cold plasma jet, the microorganism on the surface of the endoscope is killed by the barometric pressure flexible cold plasma jet, the conduit type sterilizing region is non-closed and is independent from a plasma electrode discharge region, and the plasma electrode discharge region is used for producing the flexible cold plasma jet. The soft or hard endoscopes in different sizes are sterilized by changing the shape and the size of a conduit without changing the structure of an electrode. The sterilizing method does not need complicated vacuum equipment, the cost is low, the efficiency is high, no chemical reagent is needed, the environmental pollution is avoided, and the method is a low-cost high-efficiency green endoscope sterilizing method.

Owner:大连顺达微创科技有限公司

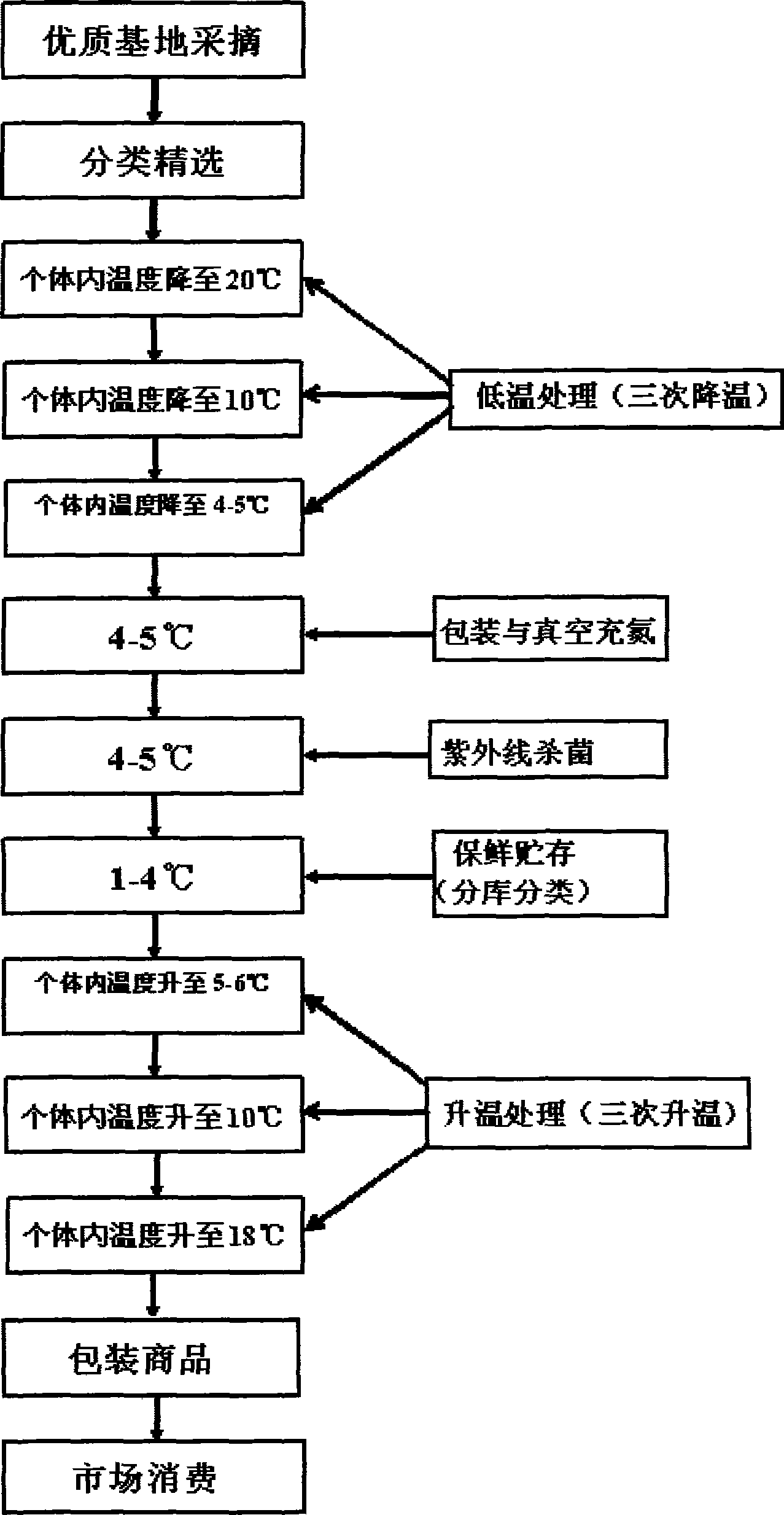

Method for refreshing fruits or vegetables

InactiveCN101543239AFull heat and cold exchangeNo heat damageFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by freezing/coolingFrostAnaerobic bacteria

The invention relates to a method for refreshing fruits or vegetables, which comprises the following steps: screening, cleaning and air drying fruits or vegetables to be refreshed; reducing temperature of the air-dried fruits or vegetables for three times, and performing refreshing packaging and processing on the air-dried fruits or vegetables; sealing a shelly or baggy die filled with the fruits or the vegetables, pumping air in the shelly or baggy die, and filling the shelly or baggy die with nitrogen or inert gas; performing ultraviolet sterilization on the fruits or the vegetables filled in the shelly or baggy die which is filled with the nitrogen or the inert gas; storing the processed fruits or vegetables in a freshness storeroom at a room temperature of between 1 and 4 DEG C for long-term storage; and raising the temperature for three times when the fruits or vegetables stored in the freshness storeroom are delivered out of the storeroom, delivering the fruits or vegetables out of the storeroom and marketing. The method can protect refreshed objects from frost damage or heat damage, can inhibit internal respiration of the refreshed objects, keep the internal moisture, and kill anaerobic bacteria in the fruits or vegetables at the same time.

Owner:北京万农先锋生物技术有限公司

Preparation method of sheet-shaped C/C-MoSi2 composite

The invention provides a preparation method of a sheet-shaped C / C-MoSi2 composite. The method includes the steps of conducting ultrasonic oscillation and stirring to obtain suspension liquid after molybdenum disilicide powder is dispersed in isopropanol, increasing the density of carbon fiber three-dimensional fabric through a hydrothermal glucose osmosis, placing the carbon fiber three-dimensional fabric in a glass sand core pumping filtration device, pouring the suspension liquid in a pumping filtration flat-bottom funnel so that all the suspension liquid can completely penetrate through a C / C composite, placing a sample in a glucose solution to be subjected to a homogeneous phase hydrothermal reaction so that the density of the composite can be further increased, taking out the sample after the reaction to be dried, and finally conducting thermal treatment. The prepared C / C-MoSi2 composite is moderate in density and compact in structure, and the interfaces of C / C and MoSi2 are well bonded. The C / C-MoSi2 composite good in performance can be obtained at a low temperature; experiment raw materials are easy to obtain, the preparation process is simple, operation is easy and convenient, cost is low, and the preparation method is friendly to the environment and free of pollution.

Owner:博兴瑞峰新材料有限公司

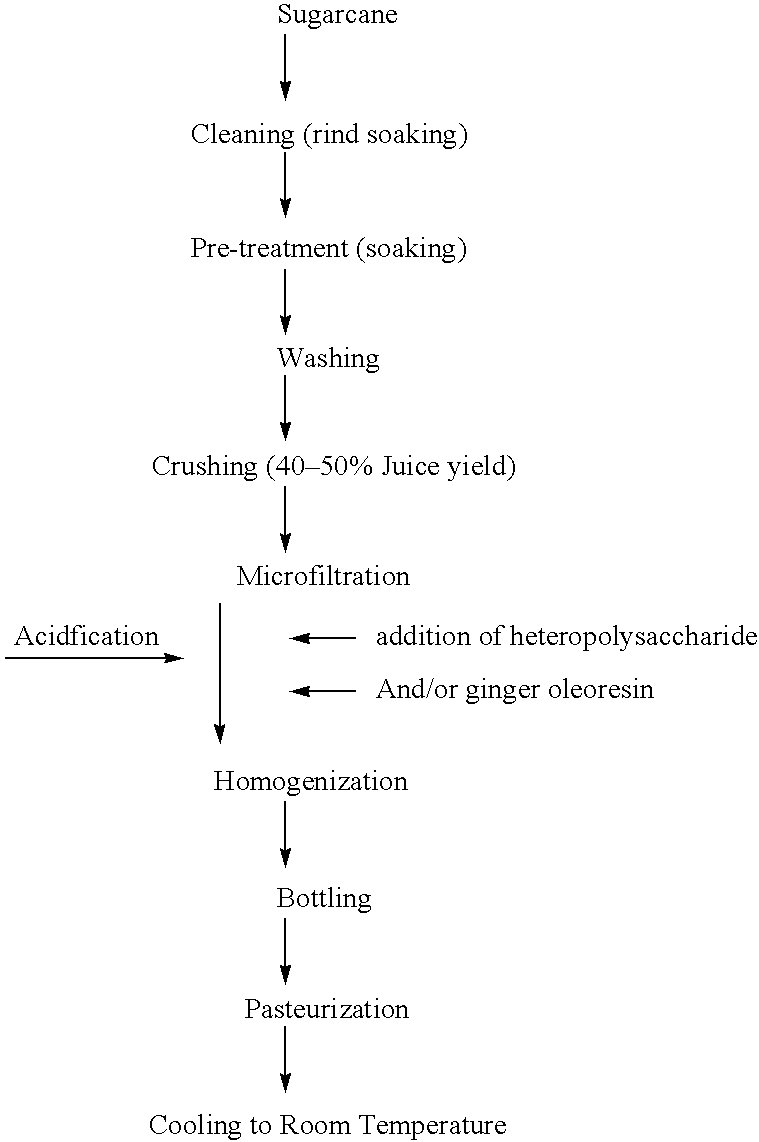

Process for preparing ready-to-drink shelf stable sugarcane juice beverage

The present invention relates to an improved process for the preparation of ready-to-drink, shelf stable sugarcane juice beverage using a membrane-processing unit and subsequent pasterurization.

Owner:COUNCIL OF SCI & IND RES

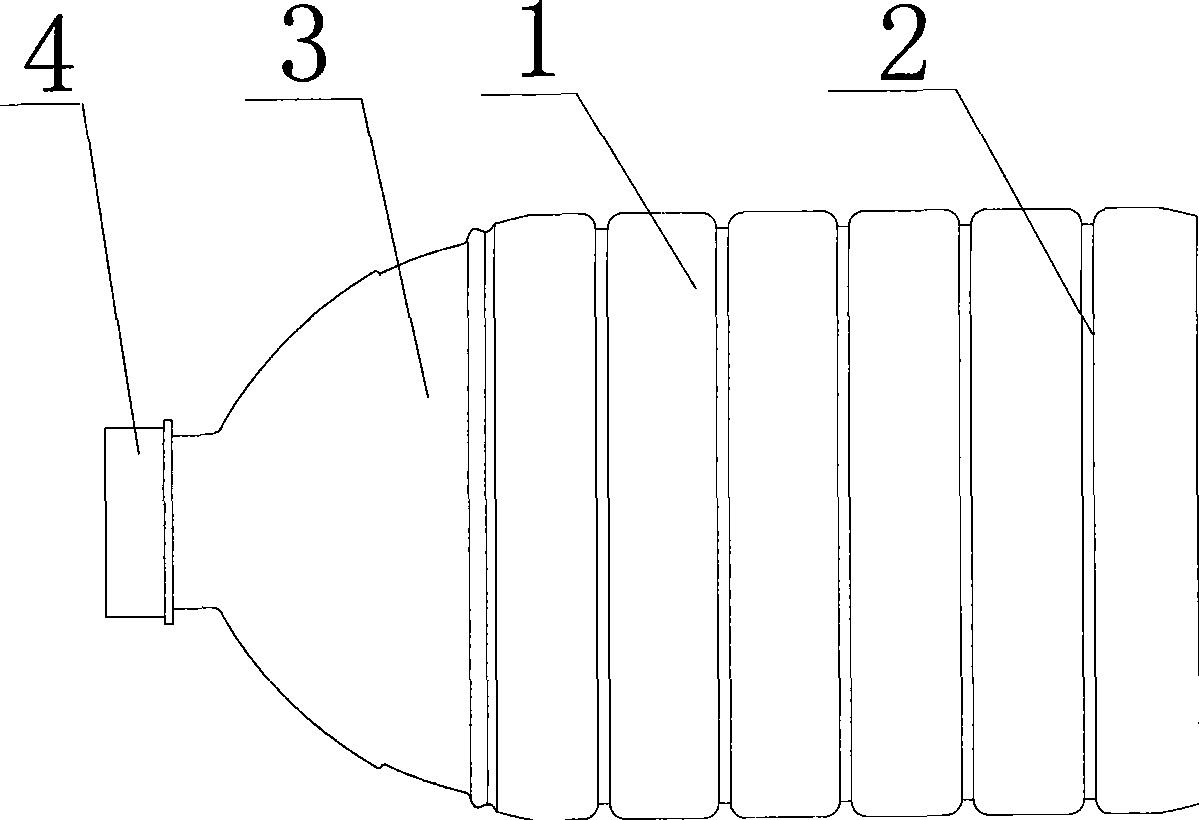

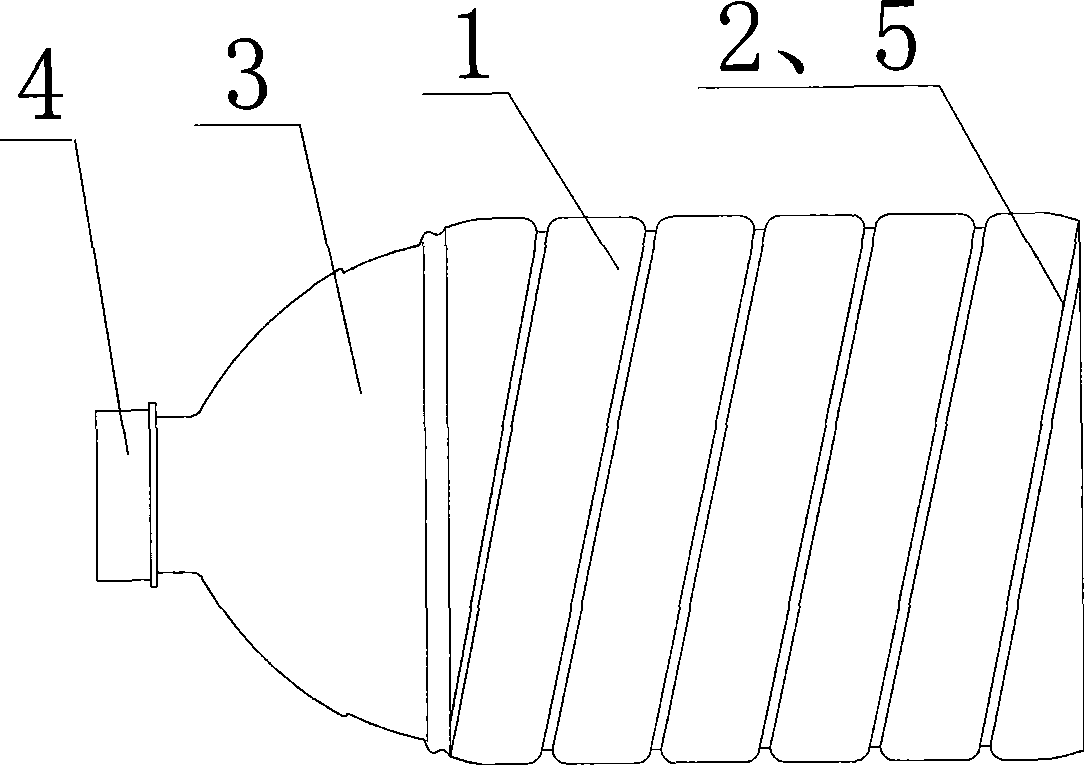

Flexible transparent film having novel electrode structure and preparation method flexible transparent film

InactiveCN105810306AImprove yieldSimple structureConductive layers on insulating-supportsCable/conductor manufactureLaser fiberEngineering

The present invention discloses a flexible transparent film having a novel electrode structure and a preparation method of the flexible transparent film. The flexible transparent film comprises a film body. A surface of the film body is provided with a groove etched by using a picosecond laser. The groove is filled with conductive ink. After being solidified, the conductive ink forms an electrode. During preparation, a film body is placed on a two-dimensionally movable platform first; then, a groove is etched on the film body by using an ultraviolet fiber laser; and then, conductive ink is input into the groove, so that after being solidified, the conductive ink forms an electrode. The flexible transparent film of the present invention is high in product yield; the shape, the width, and the depth of the electrode can be conveniently adjusted to meet use requirements of different film products; and the flexible transparent film is widely applicable. The process of the preparation method of the flexible transparent film is simplified; the preparation costs and the preparation time of the product are greatly reduced; the control during preparation is easy; and parameters of the products are easy to adjust, ensuring that the products can meet different use requirements.

Owner:WUHU ANRUI LASER TECH CO LTD

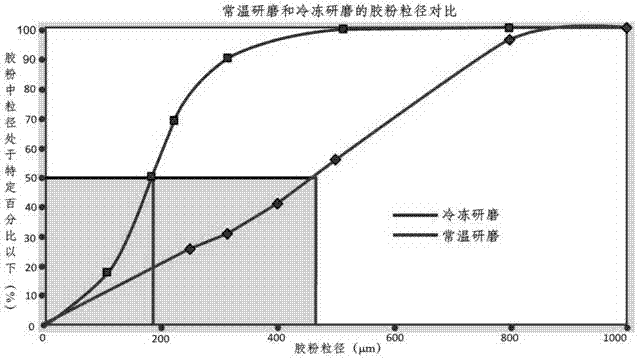

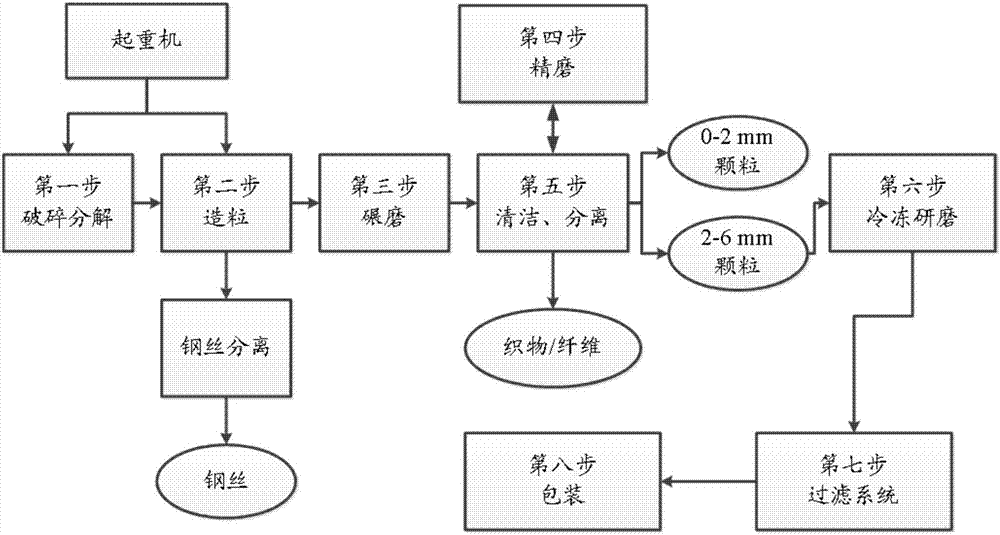

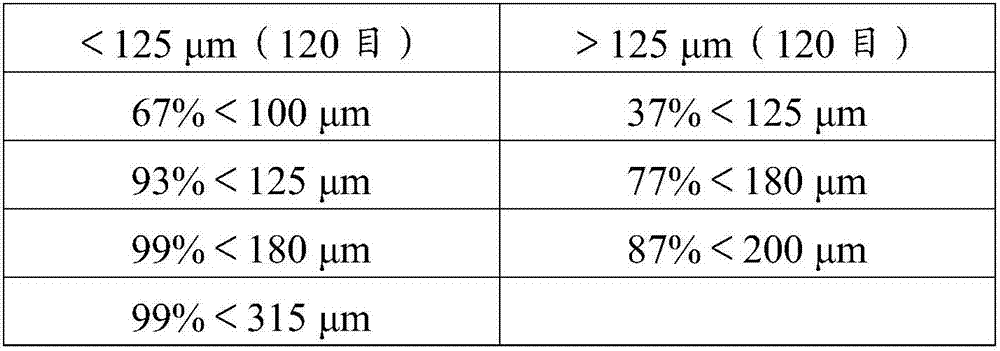

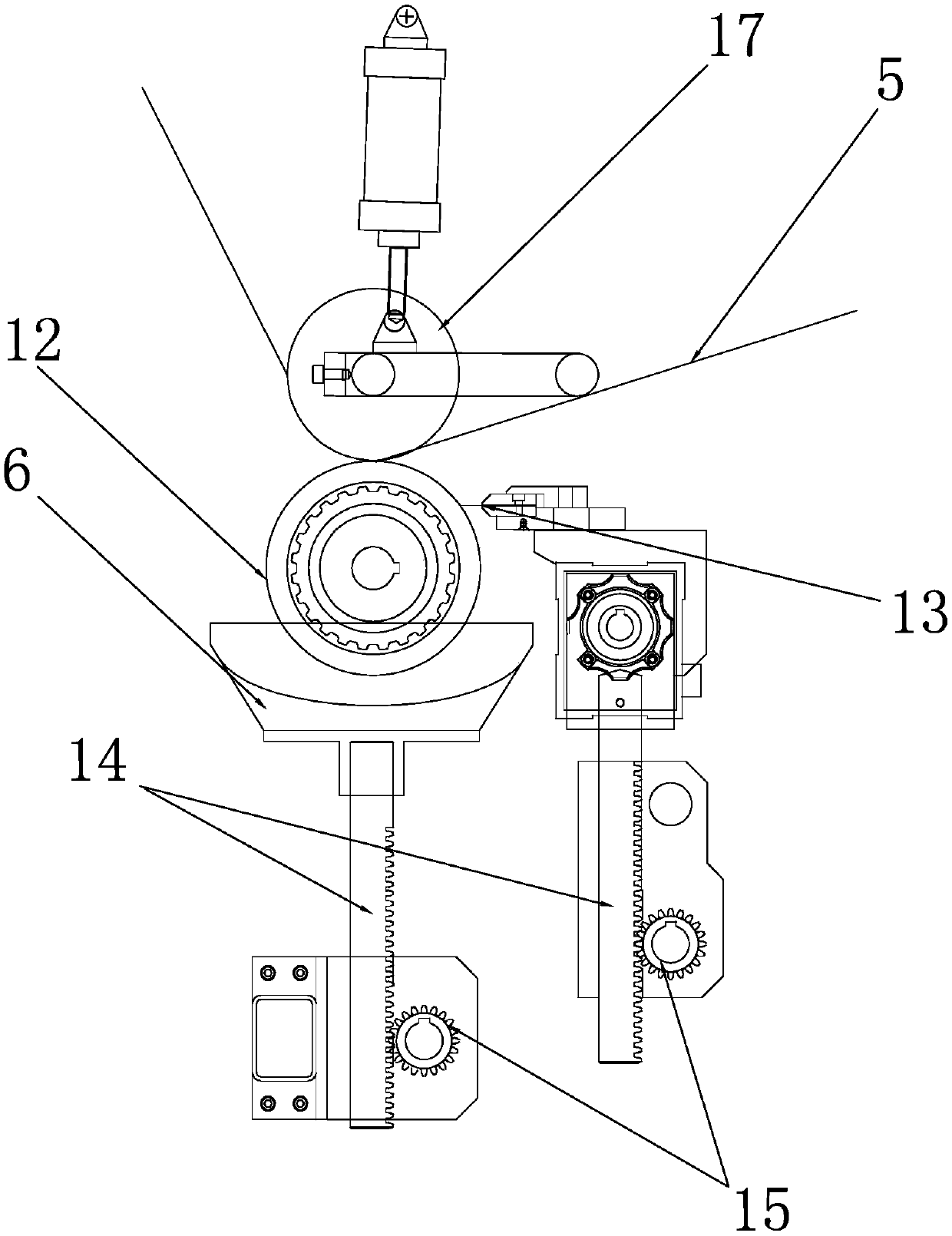

Preparation method for high fine rubber powder and production line thereof

ActiveCN107053538AReduce energy consumptionStable physical and chemical propertiesPlastic recyclingMechanical material recoveryRubbingWaste rubber

The invention provides a preparation method for a high fine rubber powder and a production line thereof. The preparation method for the high fine rubber powder prepared by using waste rubber comprises of smashing and resolving the waste rubber; and rolling the waste rubber after being smashed and resolved so as to obtain coarse rubber powder; milling and then accurate grinding the coarse rubber powder, so as to obtain fine rubber powder; refrigeration rubbing the fine rubber powder, so as to obtain high fine rubber powder. Wherein, milling and accurate grinding are conducted at room temperature and refrigeration rubbing is conducted at the brittle temperature of rubber. The preparation method for high fine rubber powder and production line thereof provides a production line for preparing high fine rubber powder by using waste rubber. The production line comprises smashing system, granulation system, milling and accurate grinding system and refrigeration rubbing system. Wherein, the milling and accurate grinding are conducted at room temperature and the refrigeration rubbing is conducted at the brittle temperature of rubber.

Owner:CHINA GEZHOUBA GRP LVYUAN TECH CO LTD

Silver-aluminum paste easy to sinter for solar cell

InactiveCN105810288AAchieve complete melting and sinteringPrecise heatingNon-conductive material with dispersed conductive materialSemiconductor devicesSilver pasteMetallurgy

The invention discloses a conductive silver paste, which comprises the following components in weight percentage: 60-70% of silver powder, 1-2% of graphite powder, 2-5% of ceramic micropowder, 11-17% of glass powder, and 9% of organic binder ‑18%, auxiliary agent 1‑2%, total 100%; the silver powder is 61‑90nm silver powder; the graphite powder is 200‑400 mesh graphite powder; the glass powder contains the following components: SiO 2 3‑17%, TiO 2 1‑2%, Bi 2 o 3 35‑55%, Al 2 o 3 4-8%, SrCl 2 1‑7%, B 2 o 3 15‑38%, SnO 2 2-5%, CaO 0.1-2%, 100% in total.

Owner:江阴市天邦涂料股份有限公司

Energy-saving consumption-reducing UV mould press

PendingCN108032612AReasonable layoutReduce churnRotary pressesPrinting press partsInfraredHeat losses

The invention discloses an energy-saving consumption-reducing UV mould press. The energy-saving consumption-reducing UV mould press comprises a workbench as well as an unrolling unit and a rolling unit, which are arranged on the workbench, wherein a raw film is transmitted between the unrolling unit and the rolling unit through a transmission roller; the workbench is sequentially equipped with a coating slot, a drying tunnel, a nickel plate roller, an UV LED lamp and a cooling roller in a transmission direction of the raw film; the nickel plate roller, the cooling roller and the transmission roller synchronously transmit; and UV paint used for coating the raw film is contained in the coating slot. The mould press is reasonable in layout; the raw film is coated through the UV paint in the coating slot, and an infrared-ray heating tube is used for performing radiation heating on UV paint, so that heat loss is reduced; the nickel plate roller is used for transfer-printing patterns onto UVpaint on the raw film, and the UV LED lamp is used for curing the UV paint; and the UV LED lamp is a cold light source, and is free of thermal radiation, the temperature rise of the radiated productsurface is low, thermal harm on products is not caused, and the cooling roller performs cooling on the raw film, so that the integral energy consumption is relatively low.

Owner:珠海市瑞明科技有限公司

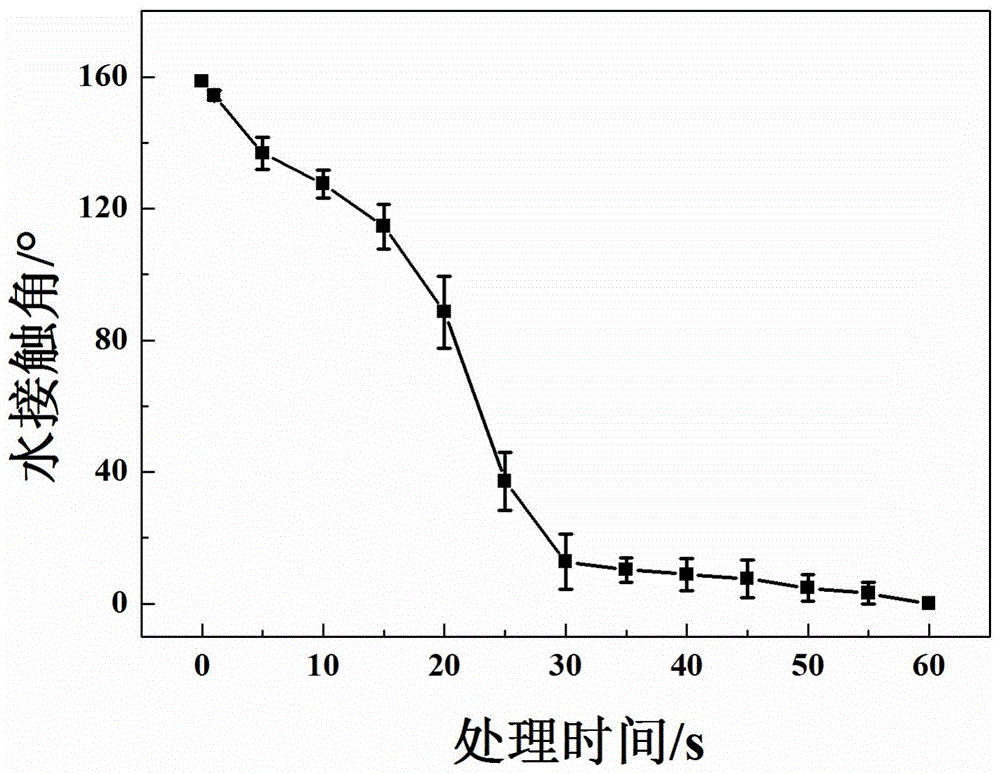

A method for surface modification of metal materials by atmospheric pressure cooling plasma jet

ActiveCN103789716BNo heat damageAchieving surface modificationSolid state diffusion coatingPlasma jetChemical reaction

The invention provides a method for modifying the surface of a metal material by adopting atmospheric-pressure cold plasma jet, and belongs to the technical field of material surface treatment. The method comprises the following steps that: high-energy electrons and particles which are contained in the atmospheric-pressure cold plasma jet generate non-elastic collision with water molecules and oxygen molecules which are contained in an atmospheric environment to generate an oxygen-containing active particle; and the oxygen-containing active particle generates chemical reaction with the surface of the metal material to introduce an oxygen-containing functional group to the surface of the metal material, wherein the cold plasma jet is generated by a cold plasma jet generator with the discharge form of bare electrode corona discharge. The method provided by the invention can realize the modification of a designated-position and large-size metal surface by controlling the size or motion locus of the cold plasma jet without complex vacuum equipment, is low in cost and easily and flexibly operated without pollution on the environment, is a green surface modification method and can be applied to the surface modification of various non-metal materials.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com