Directional freezing styloid or single-crystal nickel-base high-temperature alloy repairing or coating method

A nickel-based superalloy, directional solidification technology, applied in metal material coating technology, coating, metal processing equipment, etc., can solve the problems of high thermal crack sensitivity, large heat accumulation, thermal cracks and other problems of nickel-based superalloy, Achieve the effects of avoiding thermal cracks, small thermal influence, and fine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

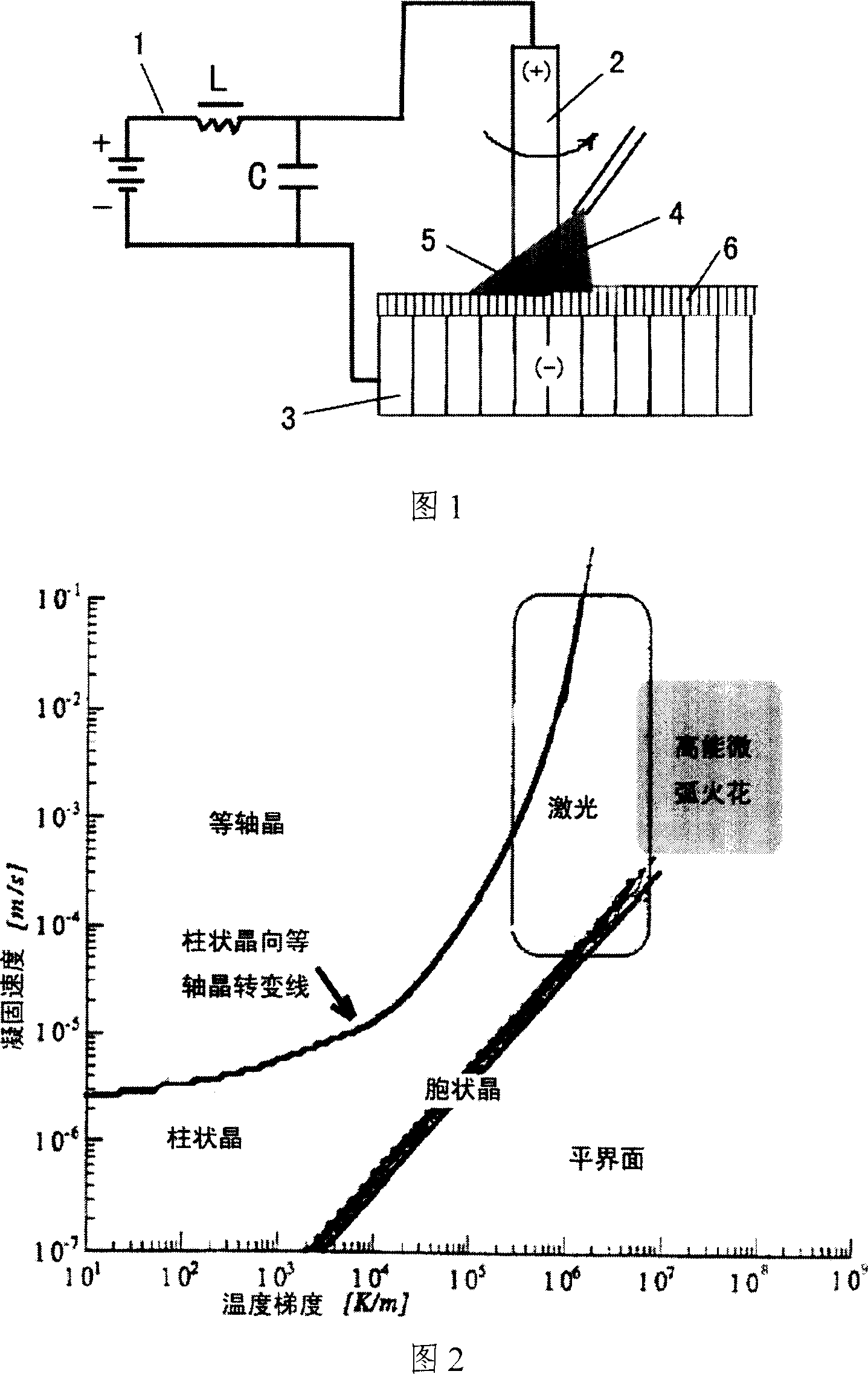

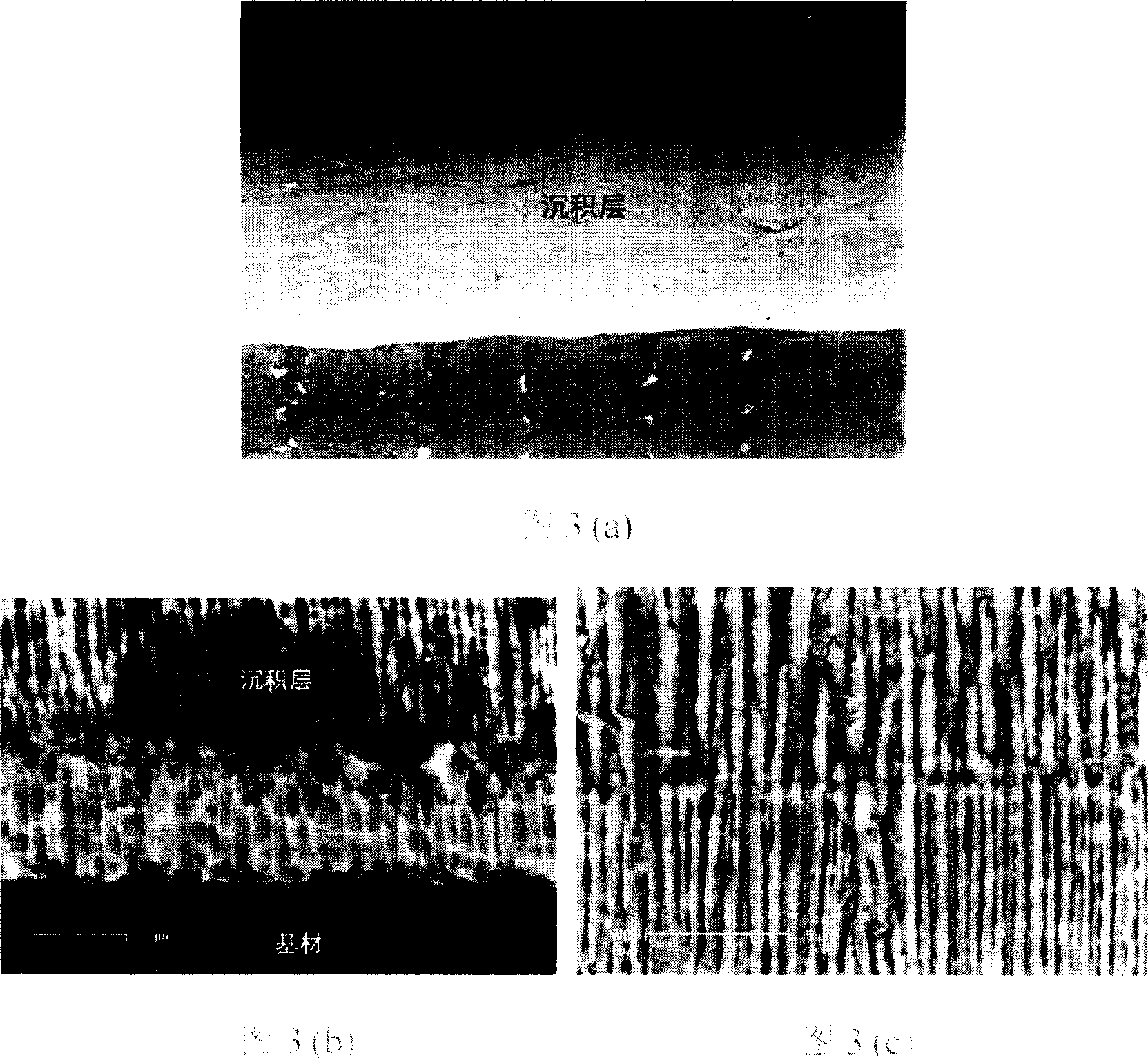

[0027] The repair of directionally solidified nickel-based superalloy materials uses the ultra-high temperature gradient generated in the thin melt formed by high-energy micro-arc sparks, and the characteristics of epitaxial growth of the microstructure from the substrate when the thin melt solidifies to directionally solidify nickel The base alloy material is used as the substrate, and high-energy micro-arc spark continuous deposition is performed on the preferred crystal plane (001).

[0028]During deposition, the usual high-energy micro-arc spark deposition method is used: the repair material is IN738 rod (anode), with a diameter of 4mm, the substrate is directionally solidified DZ125 alloy (cathode), and epitaxial deposition is carried out on its preferred crystal plane (001) . As shown in Figure 1, under the action of a 1500W high-energy micro-arc spark generator 1 (in this embodiment, when depositing, the power is 960W, the frequency is 300Hz, and the anode speed is 3000...

Embodiment 2

[0030] The difference from Example 1 is:

[0031] The coating of single crystal nickel-based superalloy materials utilizes the ultra-high temperature gradient generated in the thin melt formed by high-energy micro-arc sparks, and the characteristics of epitaxial growth of the microstructure from the substrate when the thin melt solidifies. The nickel-based alloy material is used as the substrate, and high-energy micro-arc spark continuous deposition is performed on the preferred crystal plane (001).

[0032] During deposition, the usual high-energy micro-arc spark deposition method is adopted: the coating material is NiCrAlY rod as the anode, the diameter is 6mm, the substrate is a single crystal DD6 alloy (cathode), and epitaxial deposition is carried out on its preferred crystal plane (001) . Under the action of a 3000W high-energy micro-arc spark generator 1 (in this embodiment, during deposition, the power is 1920W, the frequency is 400Hz, and the anode speed is 1500 rpm)...

Embodiment 3

[0034] The difference from Example 1 is:

[0035] The repair of directionally solidified nickel-based superalloy materials uses the ultra-high temperature gradient generated in the thin melt formed by high-energy micro-arc sparks, and the characteristics of epitaxial growth of the microstructure from the substrate when the thin melt solidifies to directionally solidify nickel The base superalloy material is used as the substrate, and high-energy micro-arc spark continuous deposition is performed on the preferred crystal plane (001).

[0036] During deposition, the usual high-energy micro-arc spark deposition method is adopted: the coating material is DZ4 rod as the anode, the diameter is 4mm, the substrate is directionally solidified DZ4 alloy, and epitaxial deposition is carried out on its preferred crystal plane (001). A 1500W high-energy micro-arc spark generator is used. During deposition, the power is 200W, the frequency is 1000Hz, and the anode speed is 300 rpm. The tip ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com