Special material for stainless steel substrate composite coating for thin valve plate and preparation method of special material

A composite coating and stainless steel technology, applied in the coating, metal material coating process, heating inorganic powder coating, etc., can solve the problems of coating material oxidation decomposition, poor coating adhesion, thin coating thickness, etc. Achieve the effect of increased coating thickness, not easy to fall off, and sufficient plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific examples according to the technical solutions of the present invention, but the present invention is not limited to the following examples.

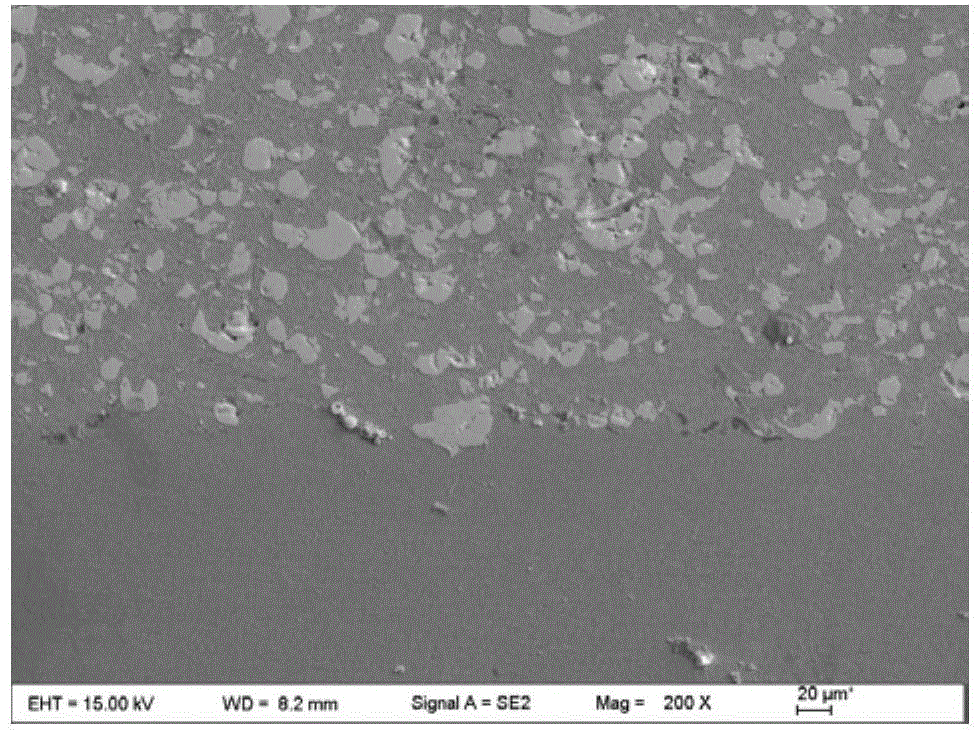

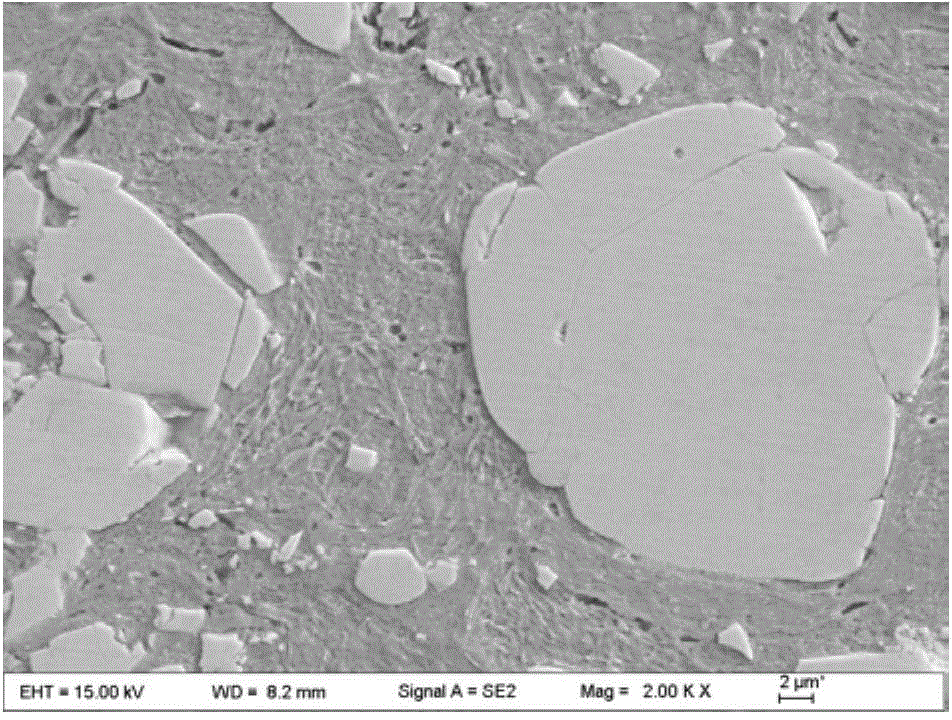

[0025] 316L stainless steel powder is selected as the binder phase of the composite coating and mixed with WC hard phase particles.

[0026] Among them: the content of each element in the composite coating is respectively: the content of each element in the composite coating is respectively: Cr8~9wt%, Ni 5~6wt%, Mo 1~2wt%, W 42~43wt%, C 2~ 3wt%, the balance is Fe.

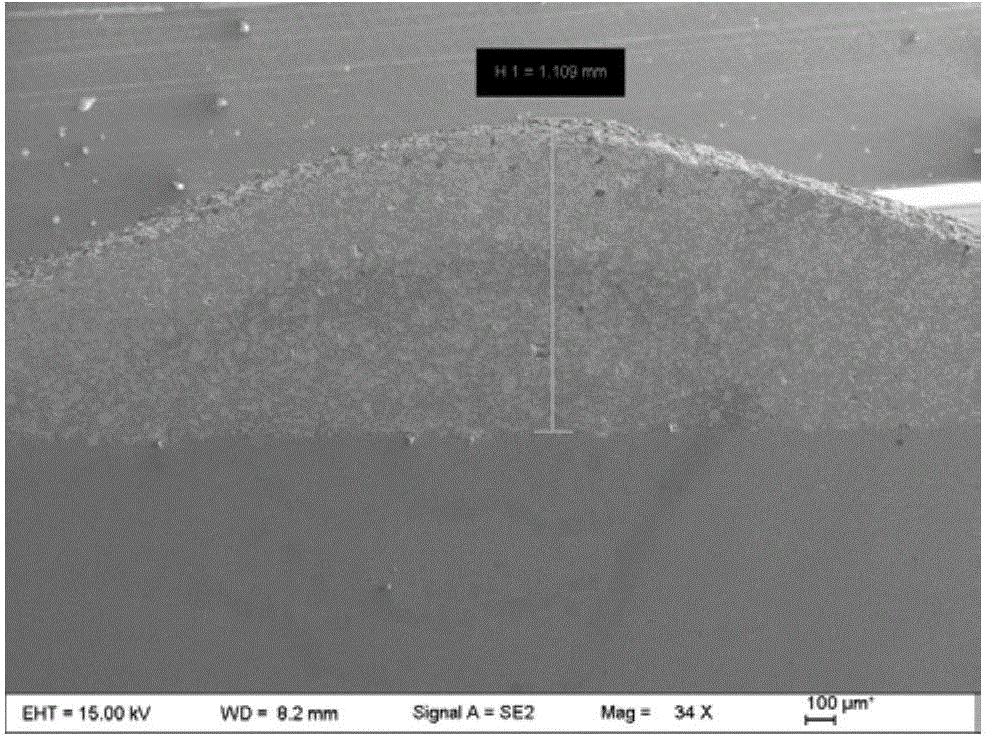

[0027] Mix 316L stainless steel powder and WC hard phase particle powder by ball milling at a volume ratio of 7:3, the ball milling method is planetary ball milling, the ball milling speed is 400r / min, the ball milling time is 3h, and the substrate is made of stainless steel with a large area and thin valve plate, the valve plate area is 297cm 2 , The thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com