Patents

Literature

39results about How to "Fully plastic deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

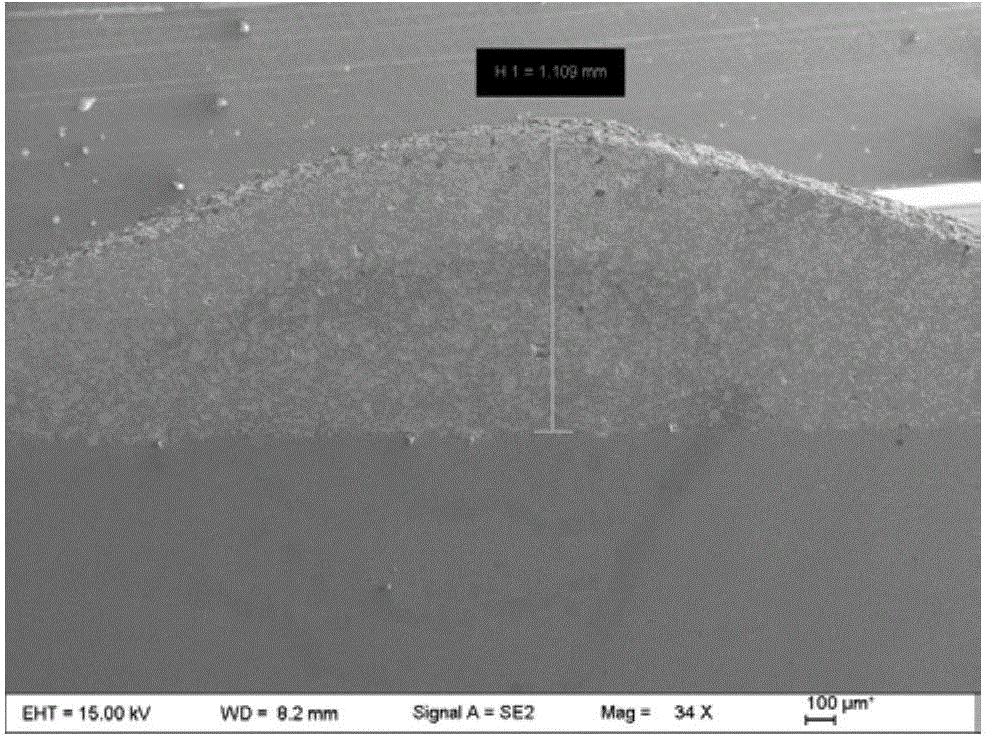

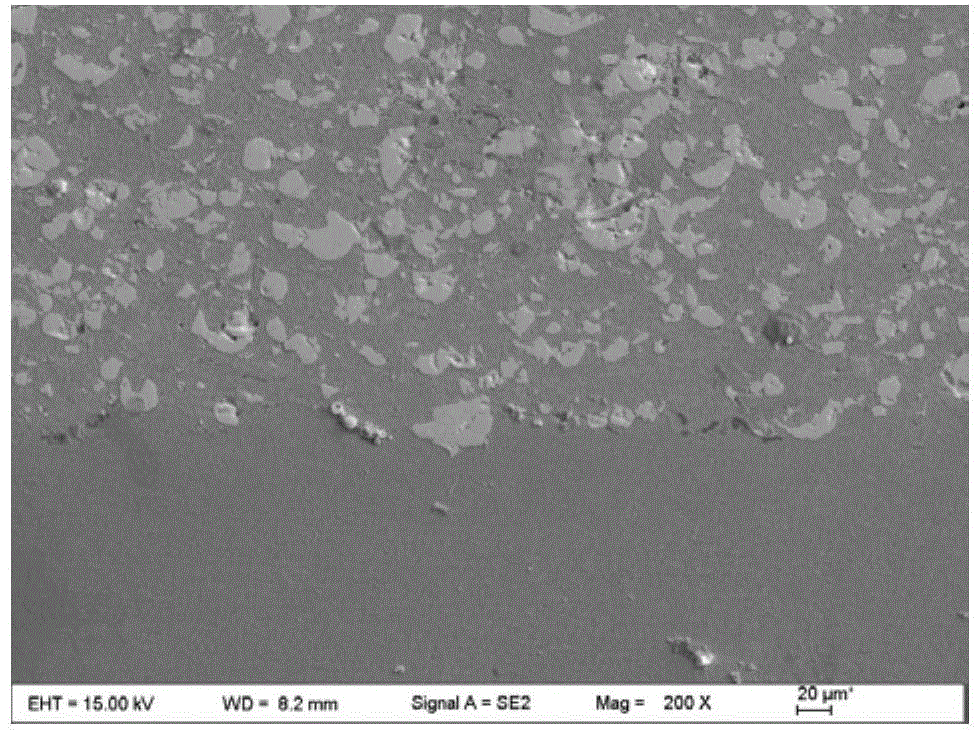

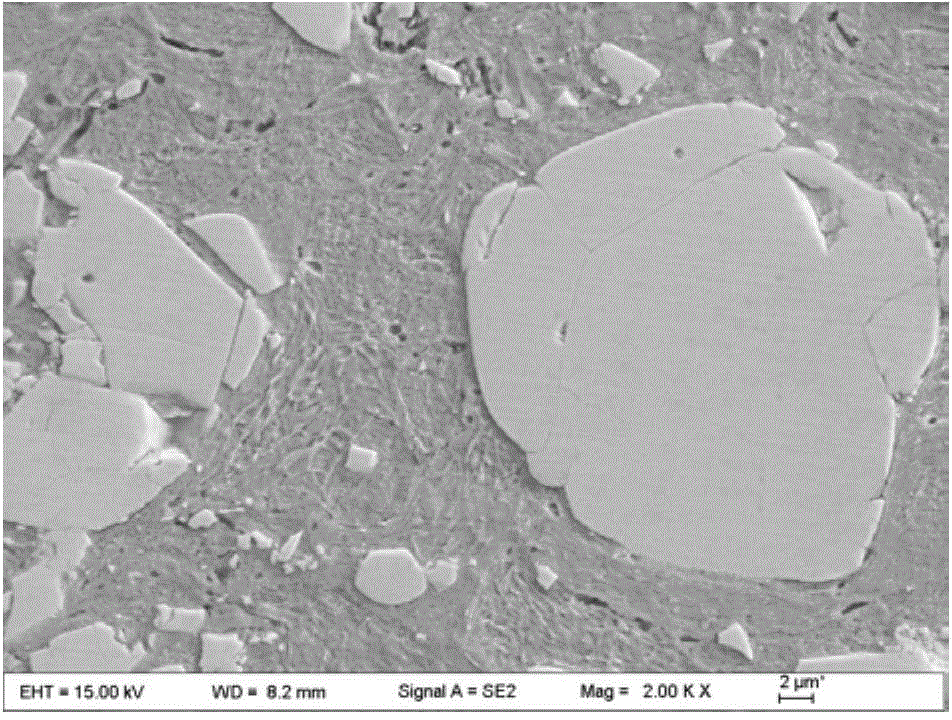

Metal-based/diamond laser composite coating and preparation method thereof

ActiveCN104018156AAvoid easy decompositionInhibition of dissolutionMovable spraying apparatusLaser beam welding apparatusCompound aHardness

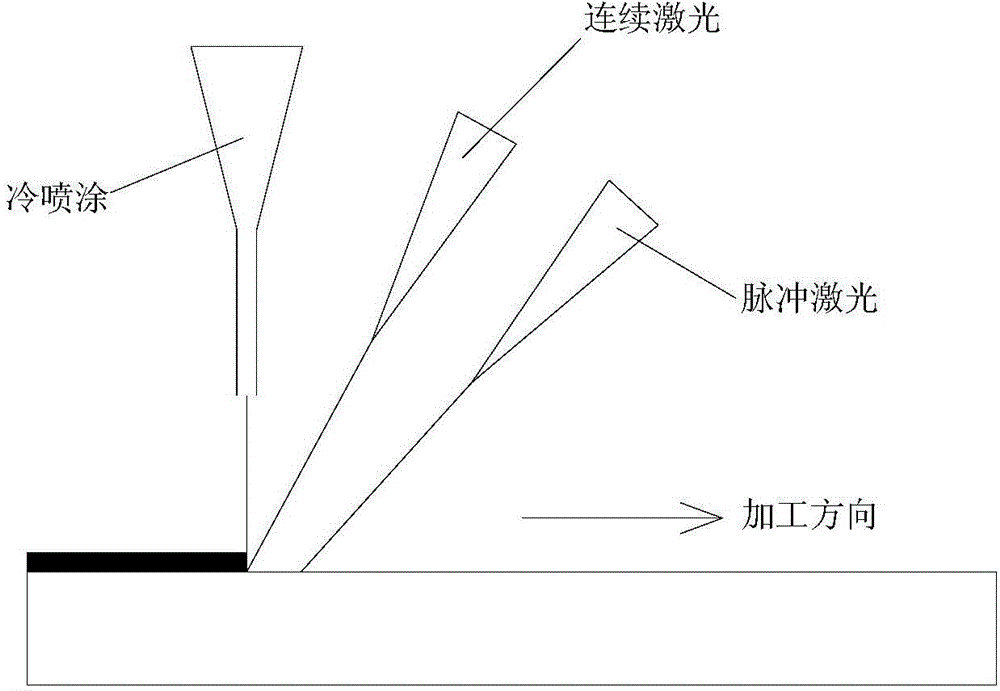

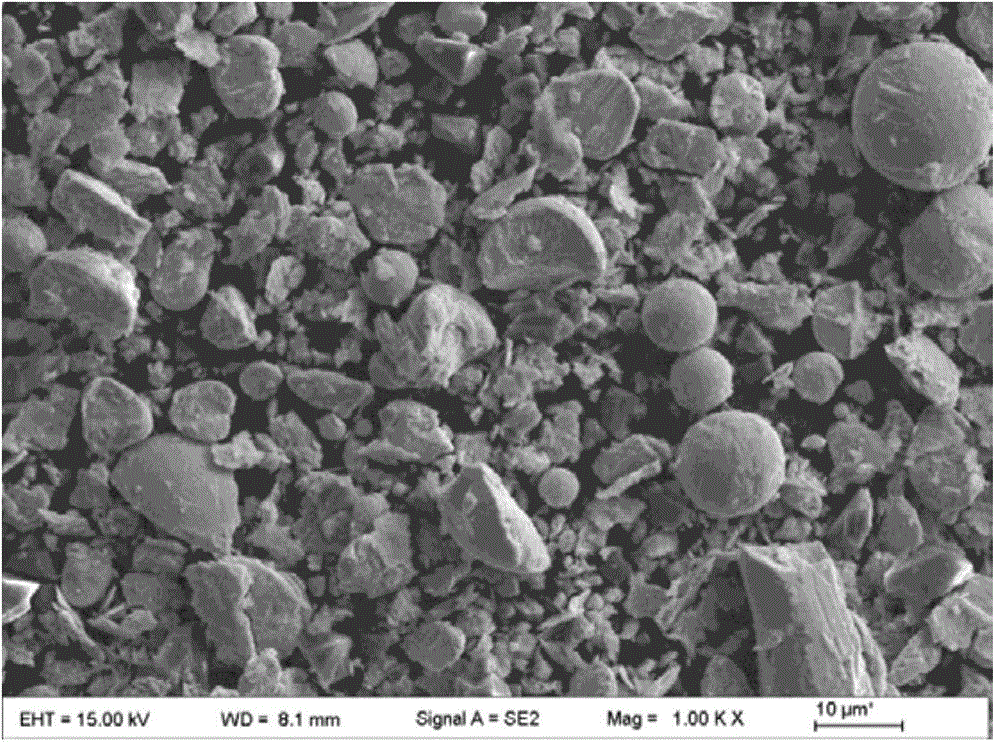

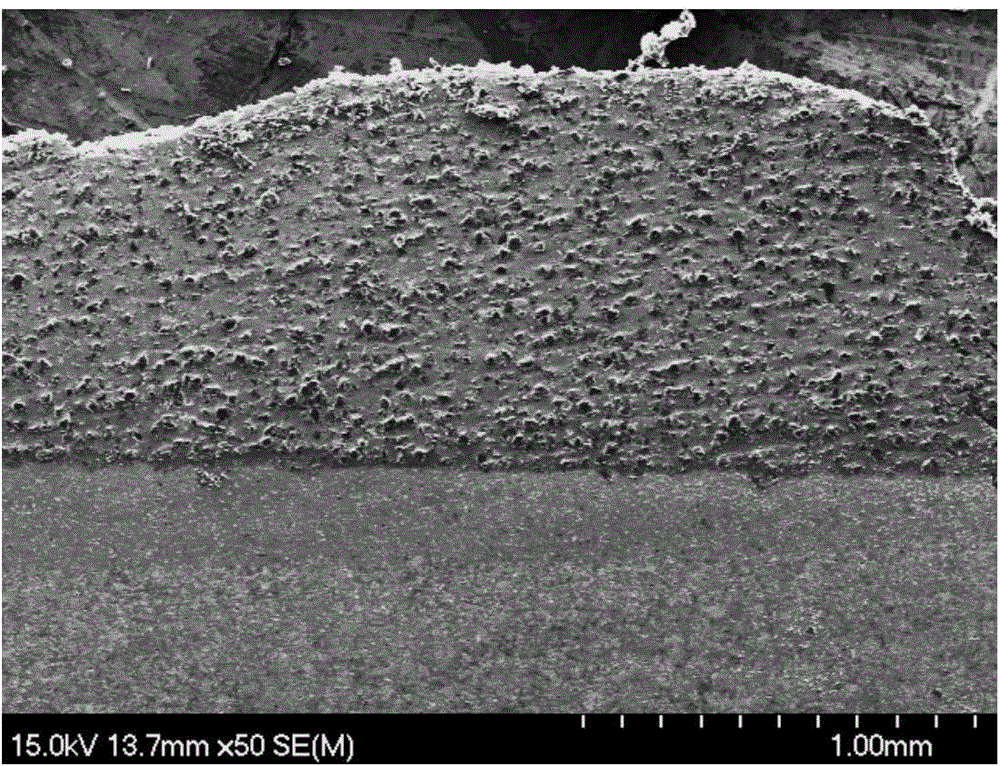

The invention discloses a metal-based diamond laser composite coating and a preparation method thereof. The preparation method comprises the following steps: firstly selecting high-hardness metal powder and diamond powder with proper grain size and shape, uniformly mixing the high-hardness metal powder and the diamond powder by using a ball-milling method, and finally preparing the composite coating on a matrix by using a method of synchronously compounding a laser texturing technology, a laser heat treatment technology and a cold spraying technology. The thickness of the composite coating is over 1mm, and the diamond volume content in the coating is more than 45%. The preparation of the composite coating by using the high-hardness metal powder as the diamond binding phase is realized, and the binding strength of the composite coating and the matrix is improved through the pulse texturing treatment, and finally the stable and high-quality high-hardness metal-based / diamond composite high wear-resisting coating is prepared, and the integration, the automation and the efficiency of the matrix surface treatment and the coating deposition treatment are realized.

Owner:ZHEJIANG UNIV OF TECH +1

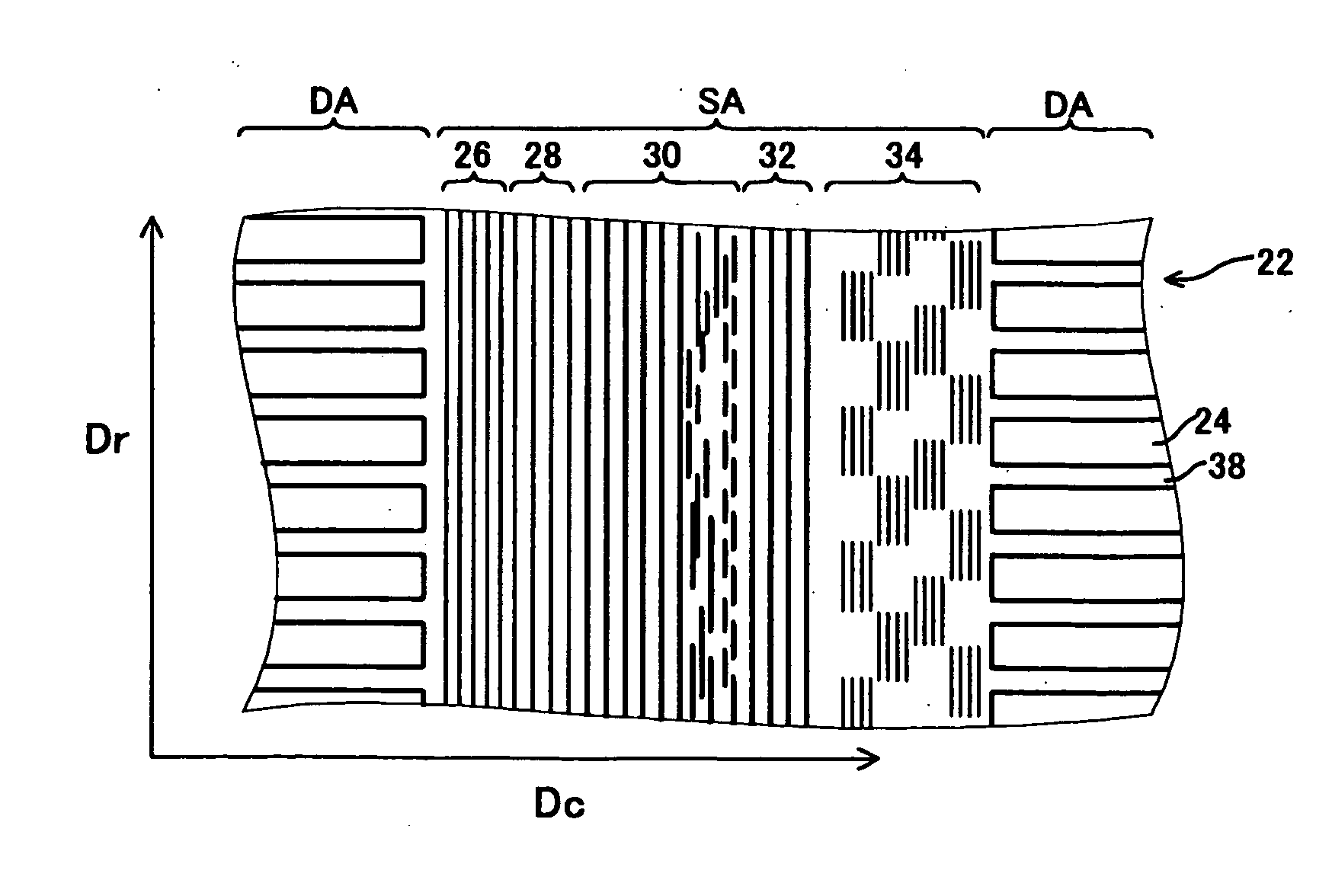

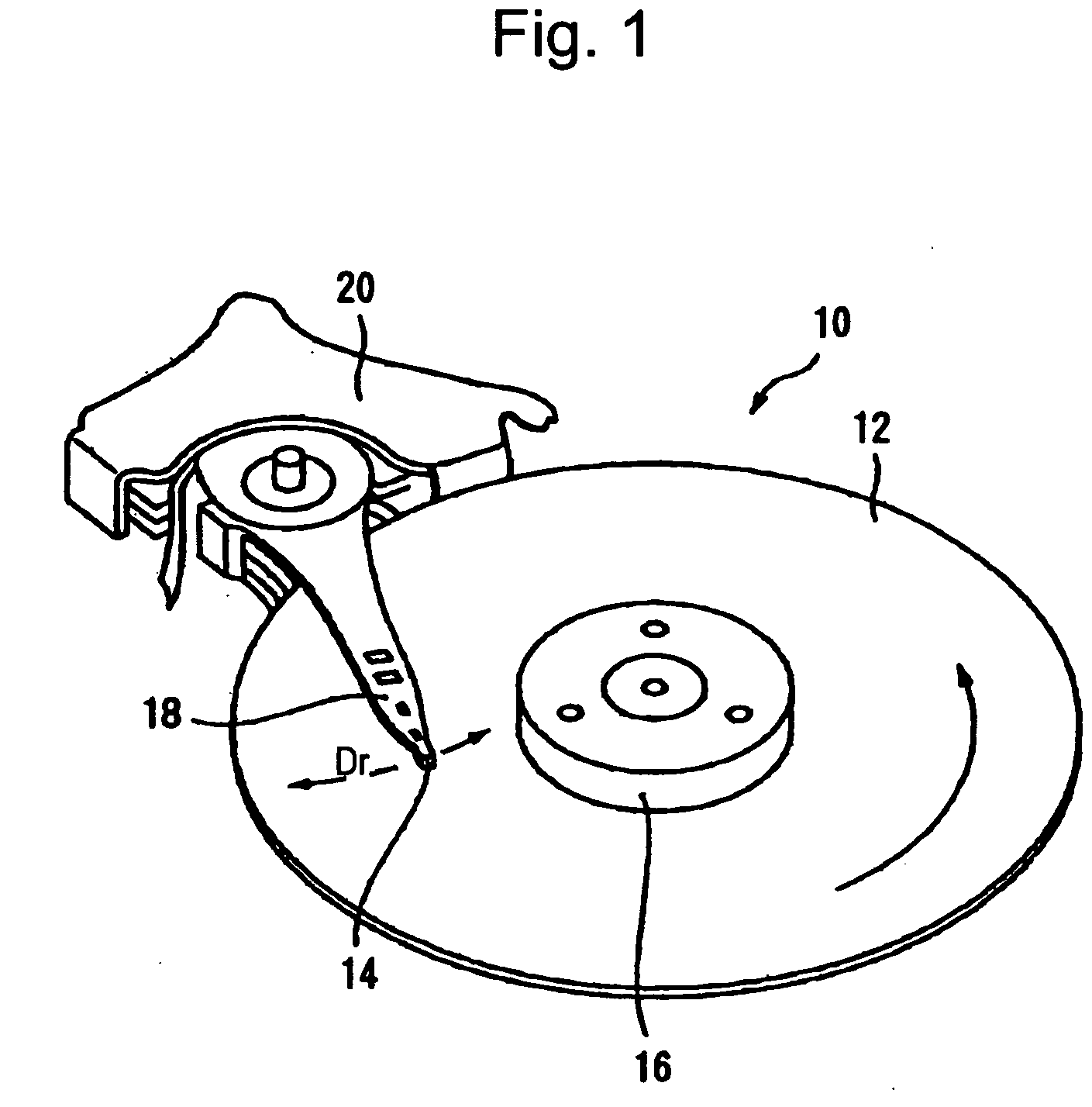

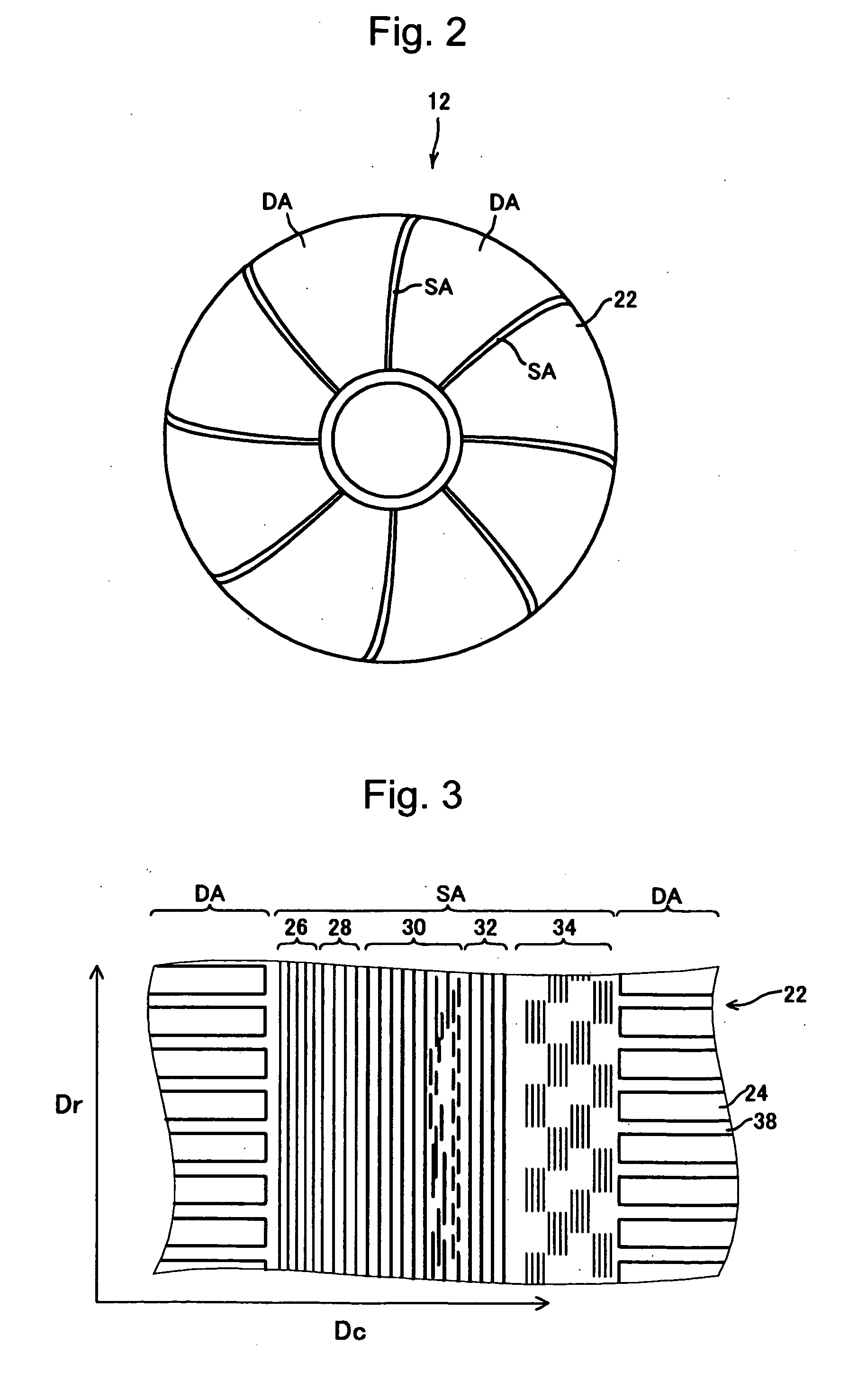

Magnetic recording medium, magnetic recording and reproducing apparatus, stamper, method of manufacturing stamper, and method of manufacturing magnetic recording medium

InactiveUS20060269791A1Pressure acting on the areasFully plastic deformationNanoinformaticsPatterned record carriersRecording layerElectrical and Electronics engineering

A magnetic recording medium which has a recording layer of concavo-convex pattern and has high production efficiency, a magnetic recording and reproducing apparatus which has the magnetic recording medium, a stamper for manufacturing the magnetic recording medium, a method of manufacturing the stamper, and a method of manufacturing the magnetic recording medium are provided. Part of servo areas of the recording layer are formed in an irregular servo concavo-convex pattern in which at least some of either concave portions or convex portions are divided in a radial direction as compared with those of a basic servo concavo-convex pattern, the basic servo concavo-convex pattern having concave portions consisting of concave unit areas corresponding to cell areas for recording either an information on 0 or an information on 1, and convex portions consisting of convex unit areas corresponding to the other cell areas for recording the other information.

Owner:TDK CORPARATION

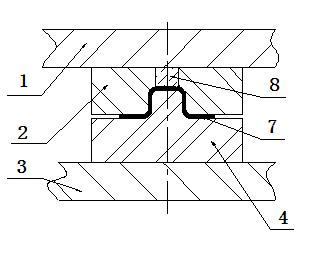

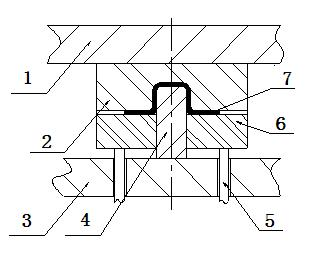

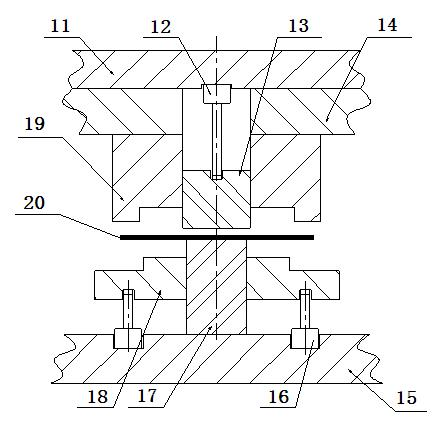

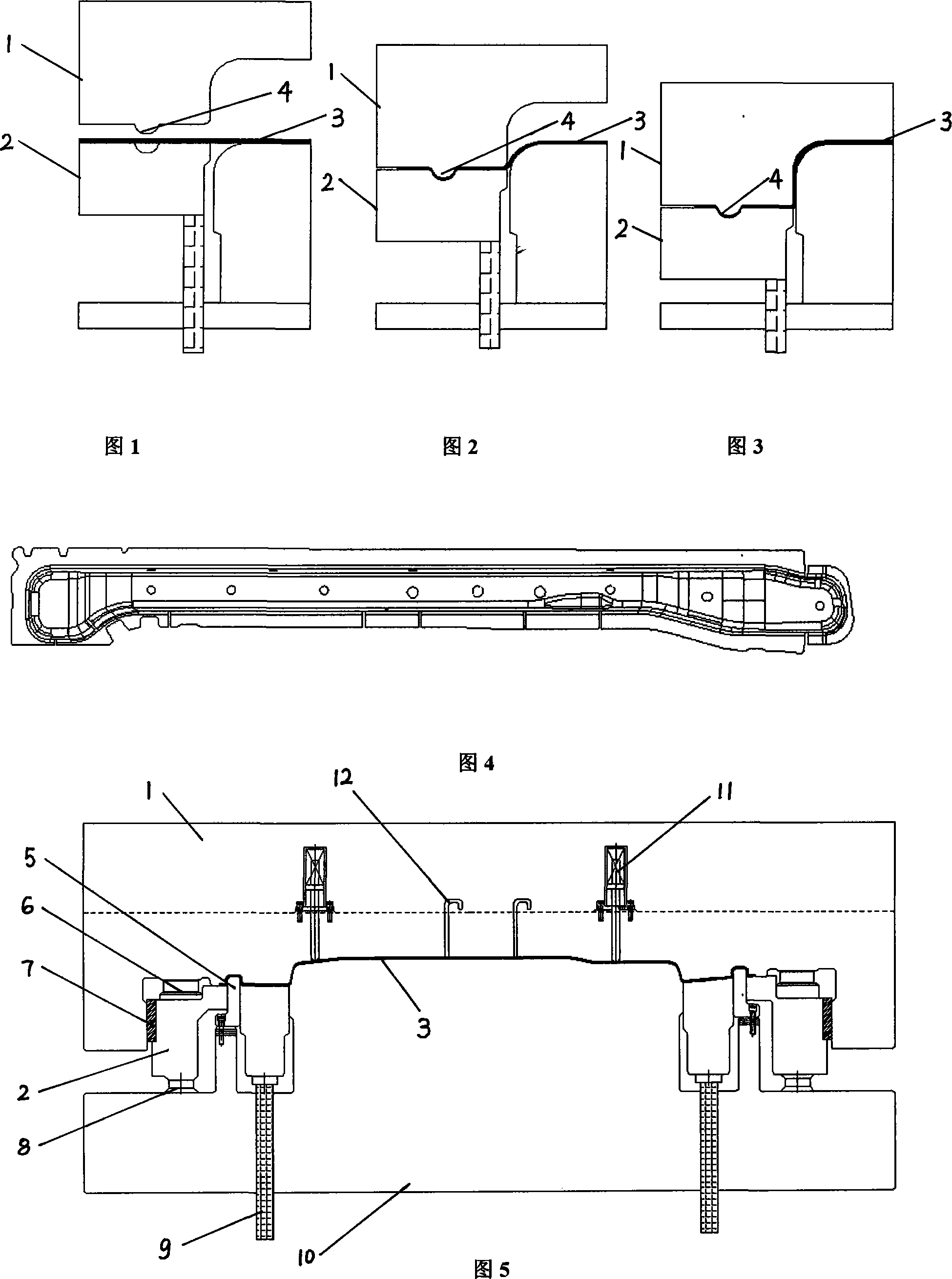

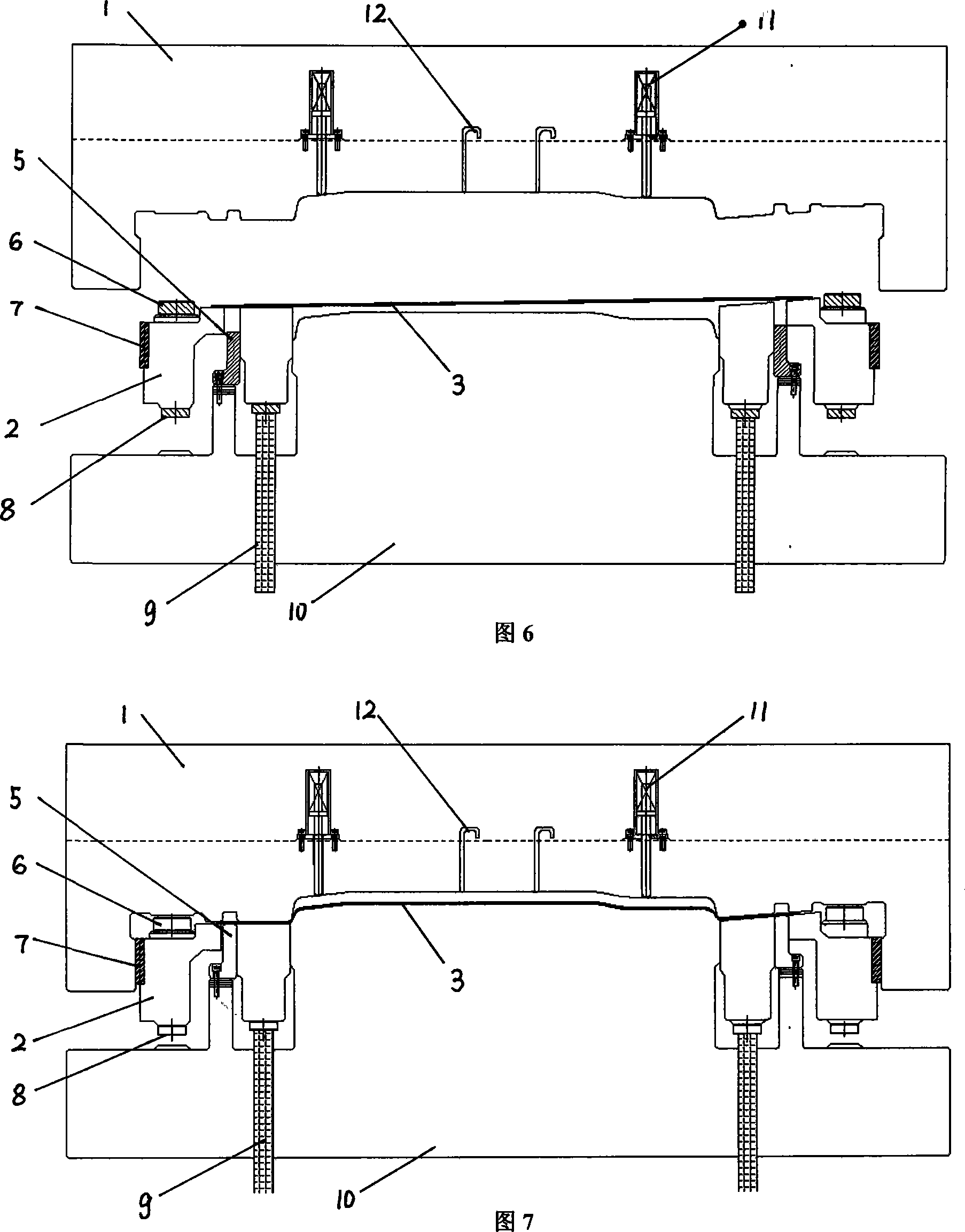

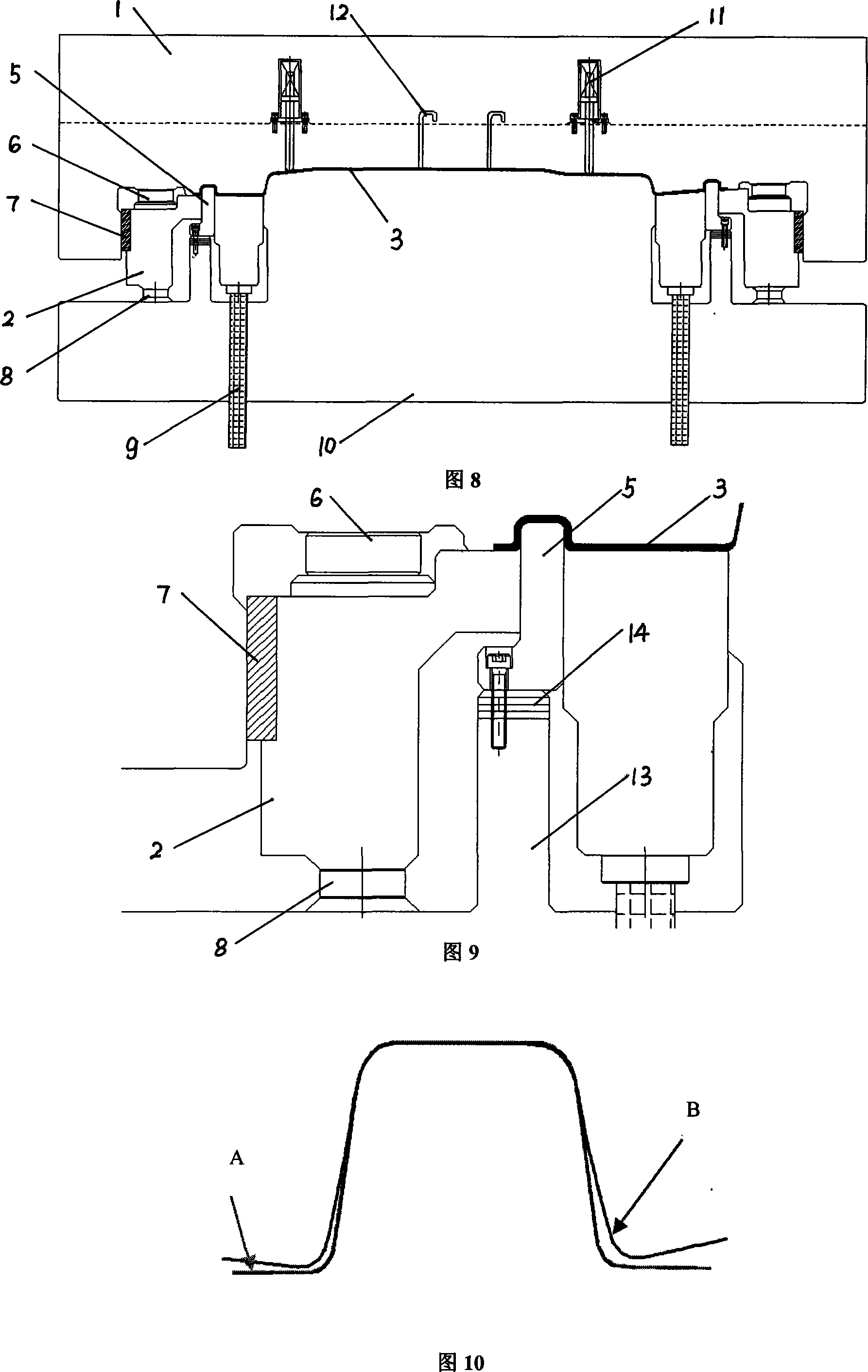

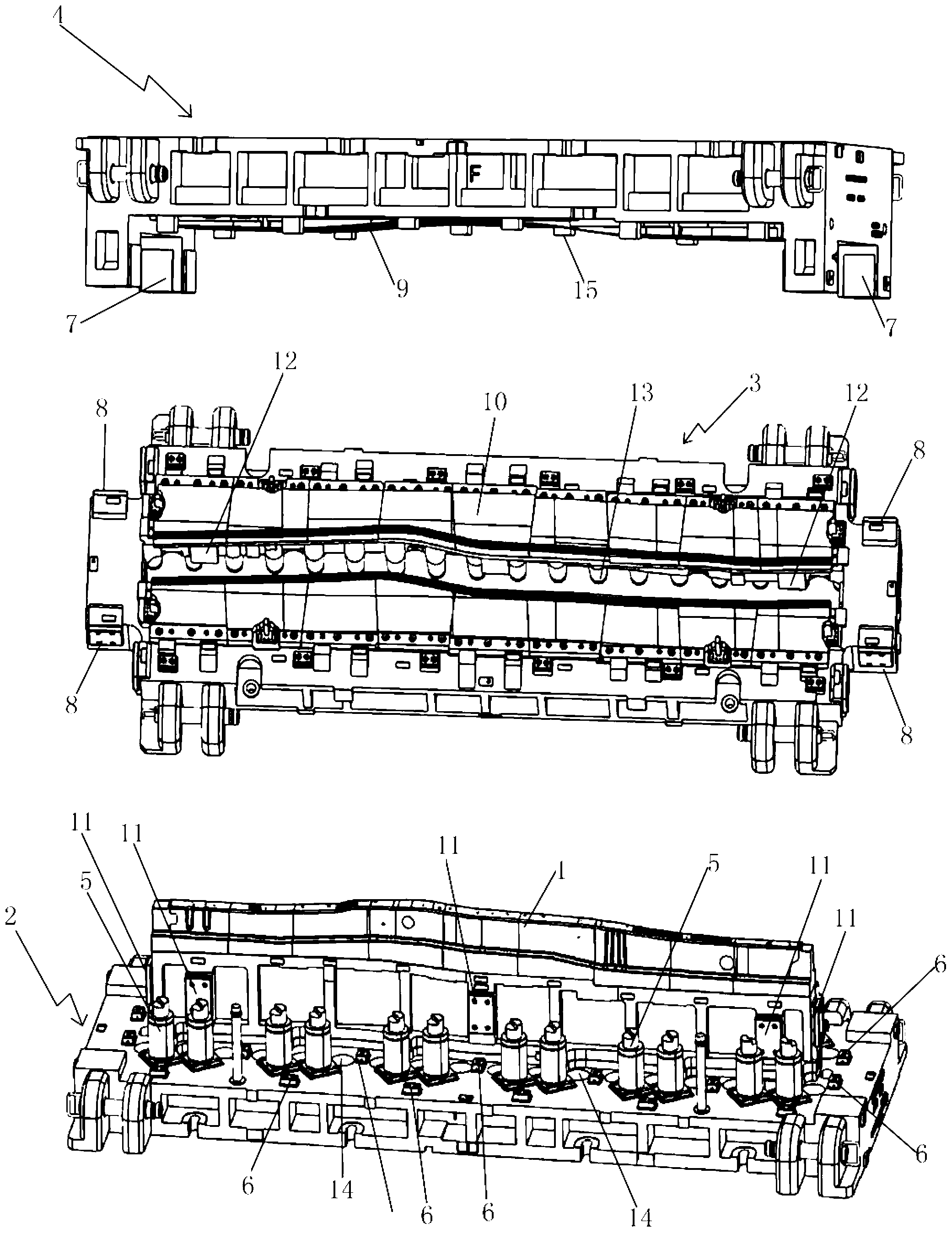

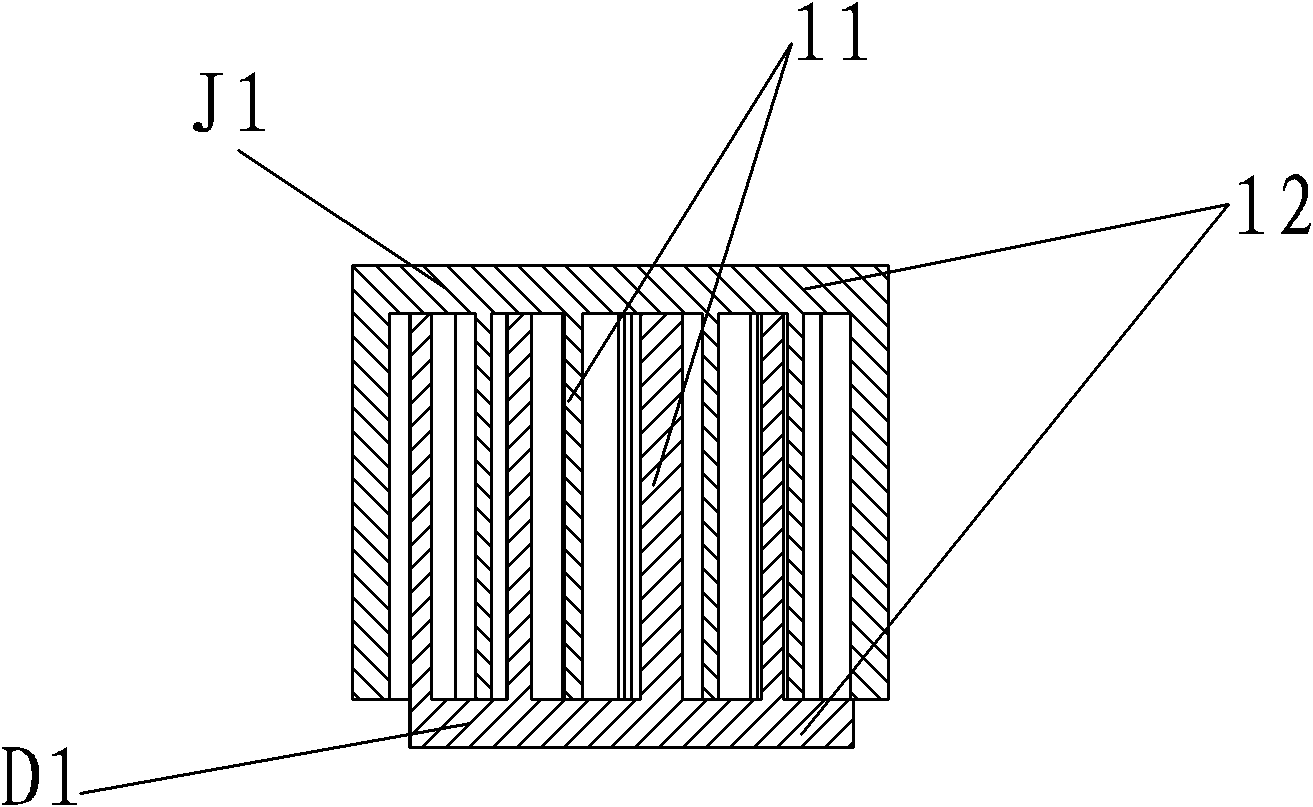

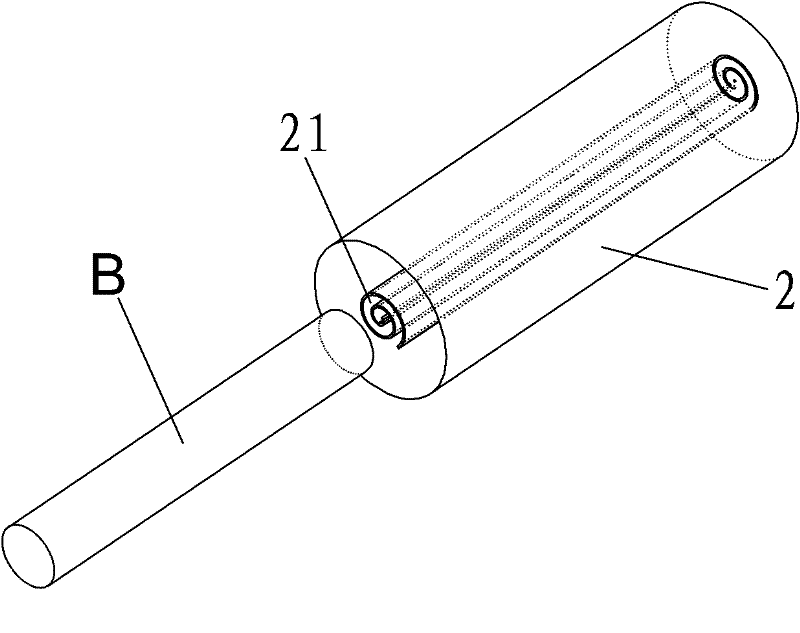

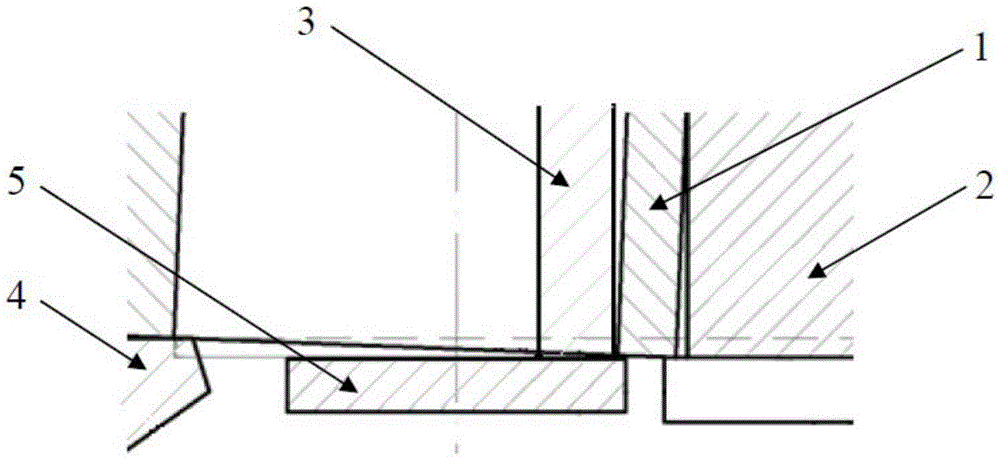

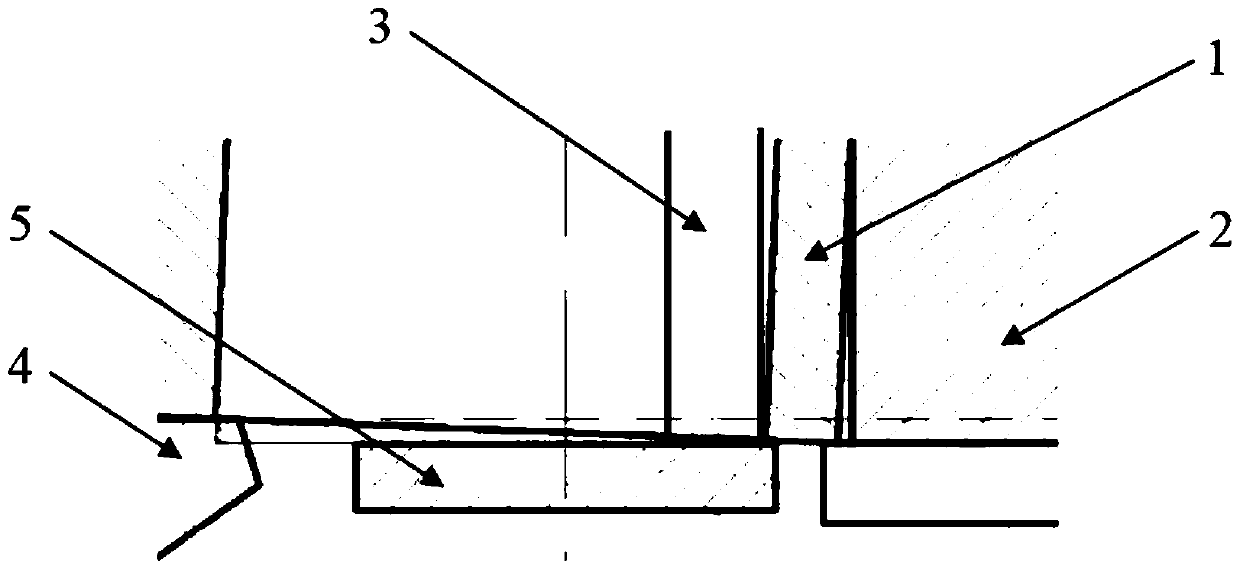

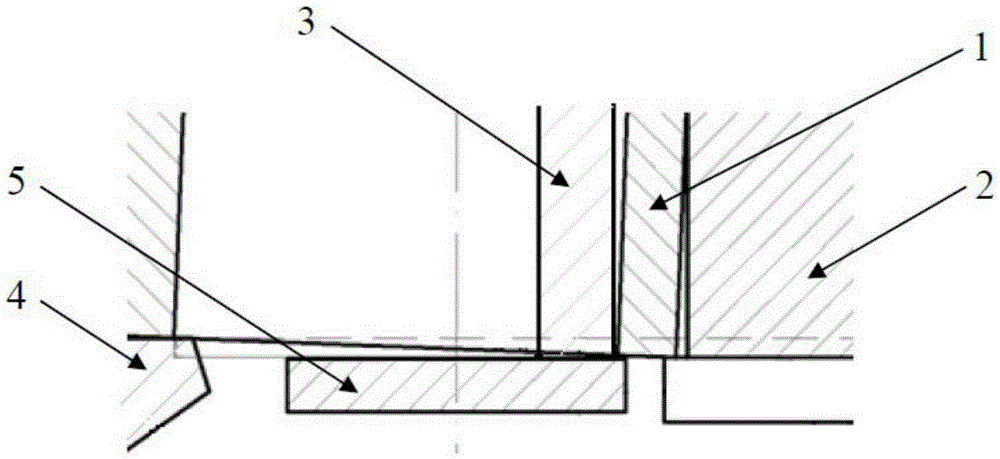

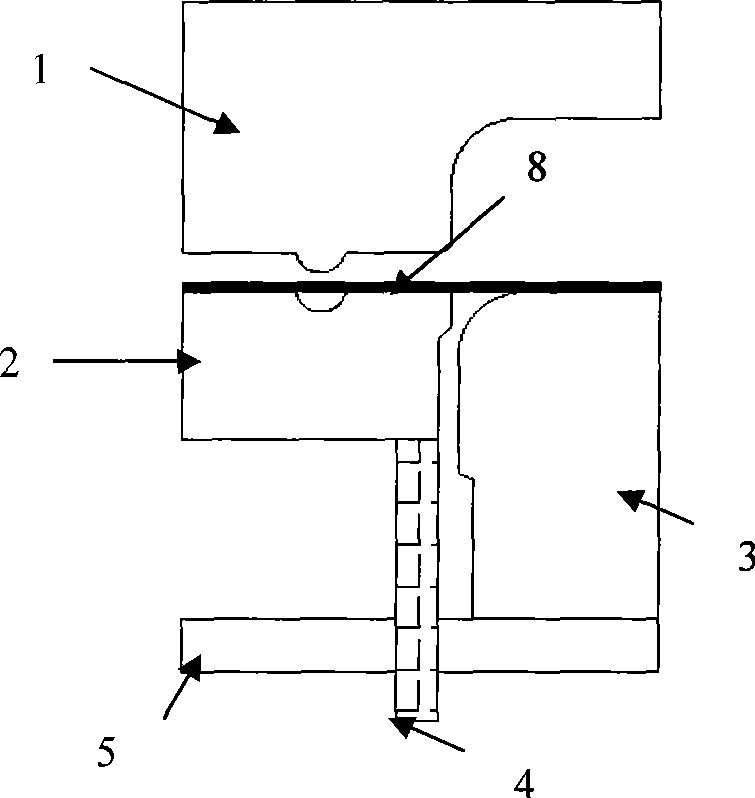

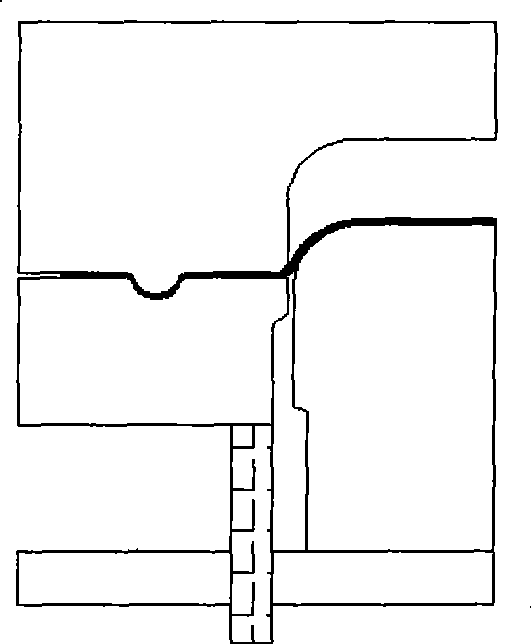

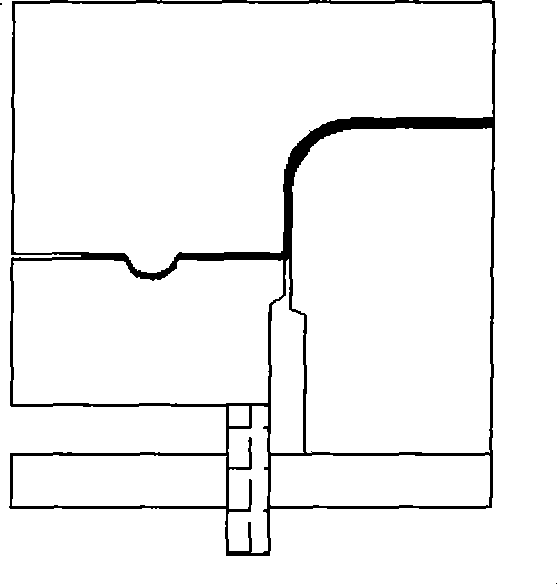

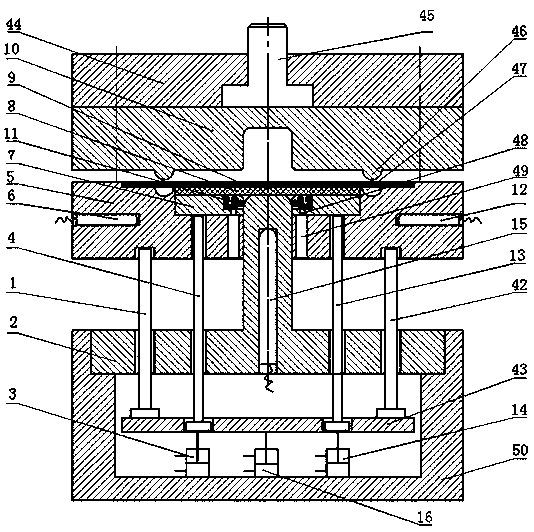

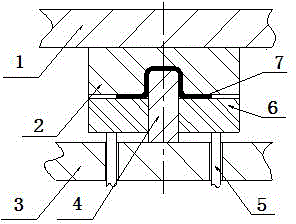

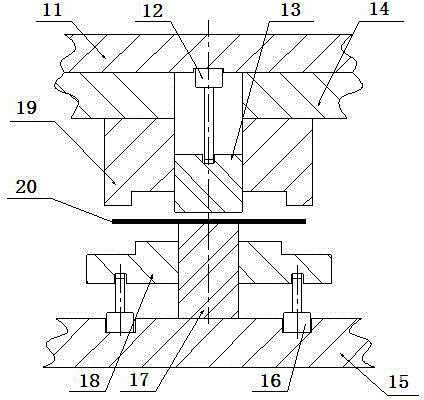

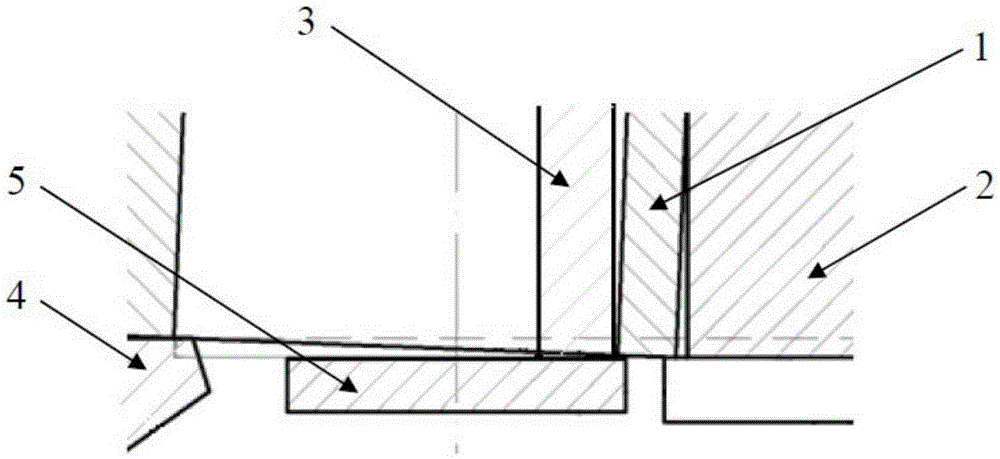

Molding die for processing high-tension plate parts

ActiveCN102310147ASolve molding difficultiesSolve insufficient plastic deformation during moldingShaping toolsEngineeringNitrogen gas

The invention relates to a molding die for processing high-tension plate parts, which comprises an upper die seat (11), a material press core (13), an upper die fixing plate (14), a lower die seat (15), a convex die (17), a material press plate (18) and an upper die knife block (19), wherein the upper die fixing plate (14) is arranged between the upper die seat (11) and the upper die knife block (19), at least one nitrogen spring (12) is arranged between the material press core (3) and the upper die seat (11), at least two nitrogen springs (16) are arranged between the material press plate (18) and the lower die seat (15), a locking unit (21) is manufactured on the material press plate (18) and the upper die knife block (19), a material plate (20) locked between the material press core (13) and the locking unit (21) in molding can be fully stretched for plastic deformation, and the large springback amount after molding is overcome.

Owner:CHERY AUTOMOBILE CO LTD

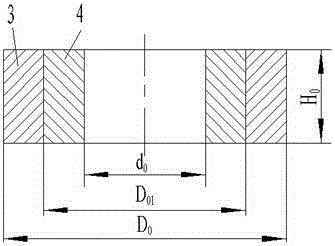

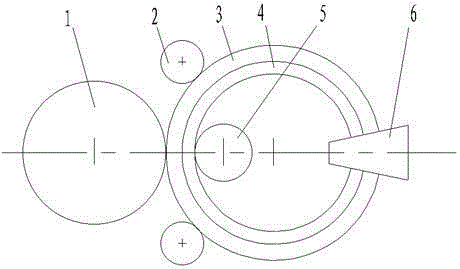

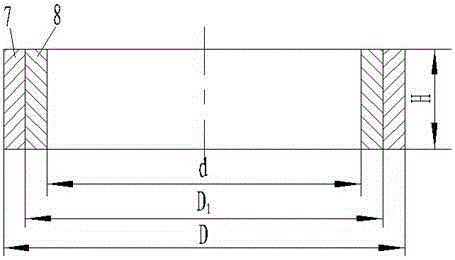

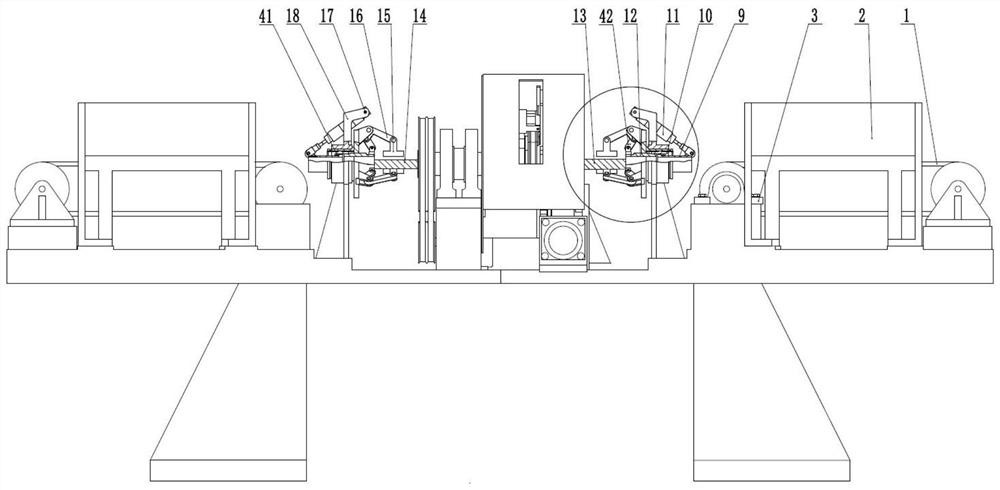

Centrifugal casting duplex-metal composite ring part hot extend-rolling forming technology

InactiveCN105170850AImprove surface qualityPrecise DimensionsMetal rollingUltimate tensile strengthMechanical property

The invention relates to a centrifugal casting duplex-metal composite ring part hot extend-rolling forming technology, and belongs to the technical field of ring part rolling expansion machining. The centrifugal casting duplex-metal composite ring part hot extend-rolling forming technology is characterized by comprising the following steps: (1) isothermal heating is carried out; (2) a heated duplex-metal composite ring blank is placed on a radial and axial direction ring rolling machine; (3) the contact relation between a forming roller and the ring blank is determined; (4) a driving roller drives the duplex-metal composite ring blank and a core roller to perform rotation motion, meanwhile, the core roller does straight line feeding motion in the radial direction of the ring blank, an end face taper roller only keeps the rotary motion rather than conducting axial feeding, and continuous local plastic deformation of wall thickness reduction, diameter enlarging and cross section layout shaping is continuously carried out on the duplex-metal composite ring blank; and (5) when a preset value of the outer diameter of a duplex-metal composite ring part is obtained, a guide roller gives out a signal, the core roller stops feeding, and extend-rolling is finished. The centrifugal casting duplex-metal composite ring part hot extend-rolling forming technology has the beneficial effects that the process procedure is shortened, the device investment is reduced, and energy and materials are saved; and meanwhile, the composite ring part interface plastic deformation is sufficient, the bonding strength is high, the mechanical property is good, and the service life is long.

Owner:定州市金华蓝天汽车零部件有限公司 +1

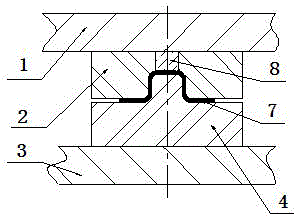

Stretching technology for processing high-tension material parts and stretching mould thereof

The invention requests for protecting a drawing process and a drawing mould for processing parts made of high intension material. The mould comprises an upper mould, a lower mould, an edge pressing coil and an ejector pin. Aiming at overcoming the disadvantage of the structure of the mould, a drawing gluten on the upper mould or the edge pressing coil is changed into an independent process bulging gluten, which is fixed on the two sides of the lower mould. And a groove for the process bulging gluten to pass through is corresponding opened on the edge pressing coil. The height of the process bulging gluten is about larger than that of the binder surface of the edge pressing coil when the edge pressing coil runs to a lower dead point, and the process bulging gluten is controlled to be higher than the binder surface of the edge pressing coil for 10 to 25 mm or so. The lower end of the process bulging gluten is connected with an adjusting gasket. The invention is mainly applied for molding parts of high intension whose tensile strength is more than 600MPa, and makes the plates fully plasticizing deformed in the drawing process of the parts made of high intension material so as to reduce the possibility that the parts are rebounded and twisted, thereby achieving the purpose that the size of the parts is fixed.

Owner:CHANGAN FORD AUTOMOBILE CO LTD +1

Special material for stainless steel substrate composite coating for thin valve plate and preparation method of special material

InactiveCN104561991AMaintain low temperature deposition propertiesAvoid decompositionHeat inorganic powder coatingLow temperature depositionWear resistant

The invention relates to the field of material-surface modification, particularly to a special material for stainless steel substrates composite coating for a thin valve plate and a preparation method of the special material. According to the special material for the stainless steel substrate composite coating for the thin valve plate, stainless steel metal powder is used as a composite coating bonding phase, and the wear resistance is improved through the introduction of hard-phase particles, wherein the stainless steel metal powder is 316L stainless steel powder, the hard-phase particles are WC, and the composite coating comprises the following elements in percentage by weight: 8-9% of Cr, 5-6% of Ni, 1-2% of Mo, 42-43% of W, 2-3% of C, and the balance of Fe. The wear-resistant corrosion-resistant stainless steel substrate composite coating which is disclosed by the invention, is prepared by a method based on cold spraying, the characteristic of low-temperature deposition of the cold spraying is kept, so that undesirable phenomena, such as decomposition, oxidation, phase transition, crystal grain growth and the like, of the coating material, which are caused by high-temperature deposition techniques, such as laser cladding, hot spraying and the like, are avoided.

Owner:瑞安市博业激光应用技术有限公司 +1

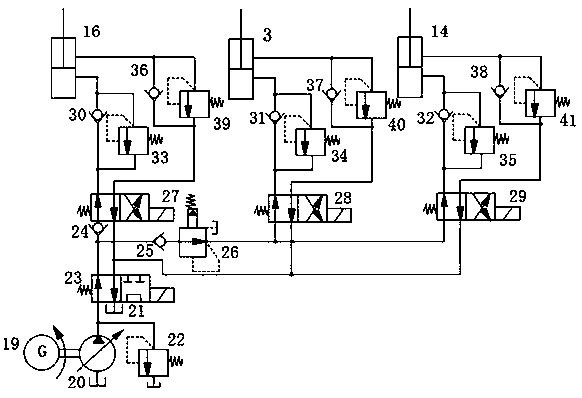

Variable-blank-holding-force beam type drawing die

InactiveCN103240339AReduce reboundResolve distortionShaping toolsInternal stressMechanical engineering

The invention discloses a variable-blank-holding-force beam type drawing die. The variable-blank-holding-force beam type drawing die comprises a concave die base, a protruding die base and a blank holder assembly, wherein the concave die base and the protruding die base are arranged in an up-and-down mode, the blank holder assembly is located between the concave die base and the protruding die base, a protruding die is arranged on the protruding die base, at least two groups of nitrogen spring assemblies are arranged on the front side and the rear side of the protruding die on the protruding die base respectively, tops of nitrogen spring assemblies contact with the lower surface of the blank holder assembly, the protruding die contacts with the blank holder assembly, and the lower surface of the concave die base contacts with the upper surface of the blank holder assembly. By the aid of the variable-blank-holding-force beam type drawing die, arc-shaped springback of cross beam side walls is reduced, the problem of beam distortions is well solved, and the wrinkling phenomena of pressing face materials are reduced, so that a cross beam is shaped and deformed fully, internal stresses of parts are reduced, and the overall springback of parts is reduced.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

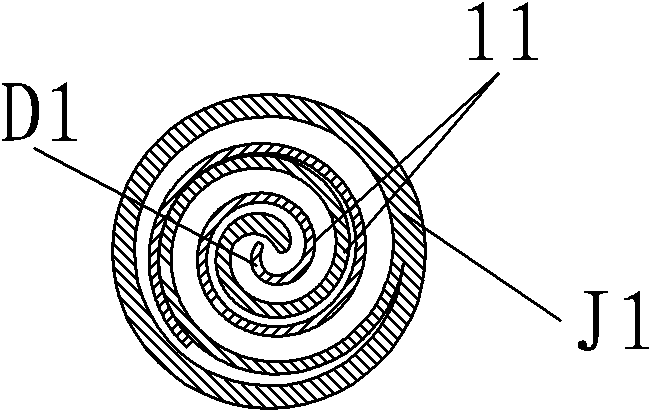

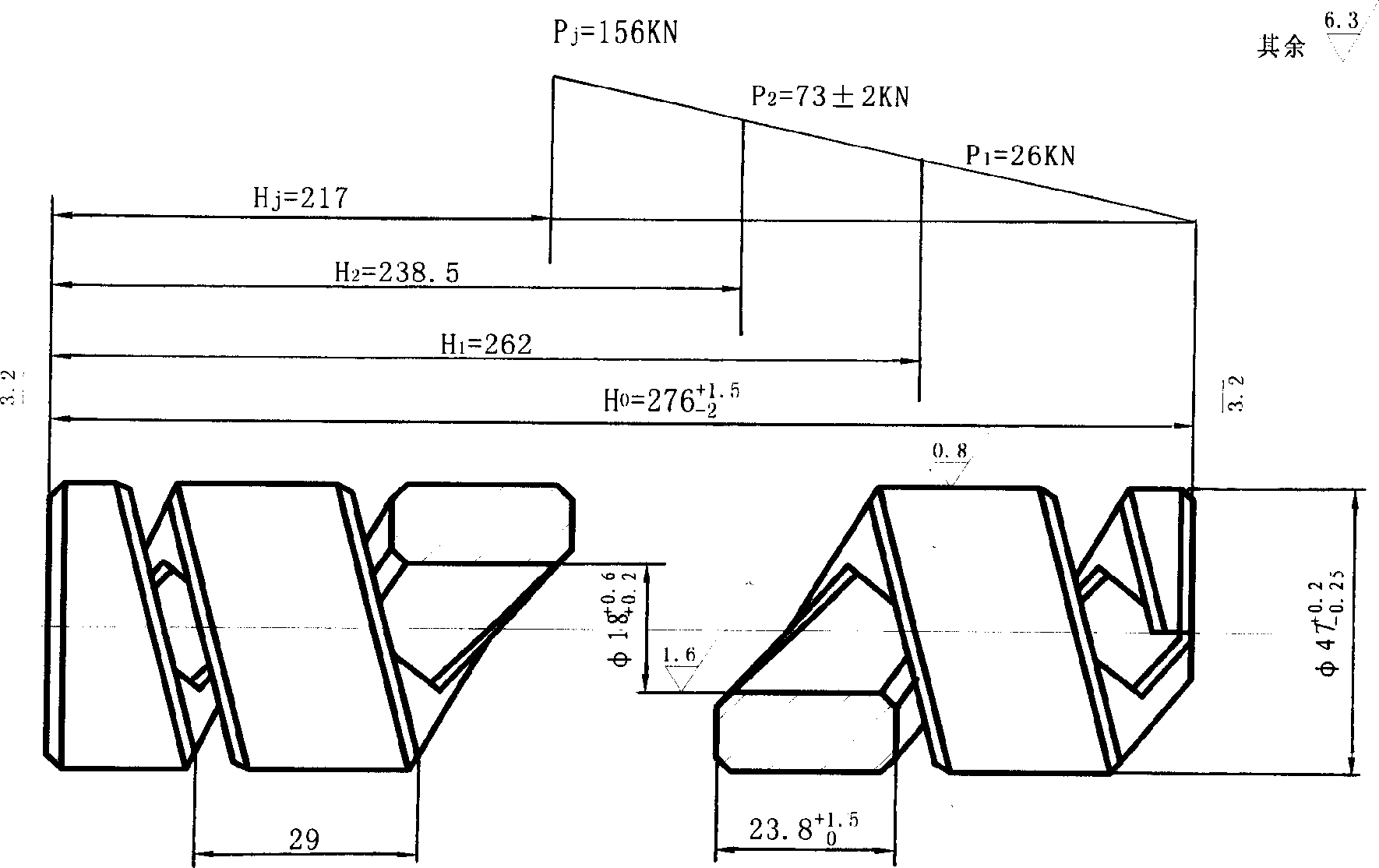

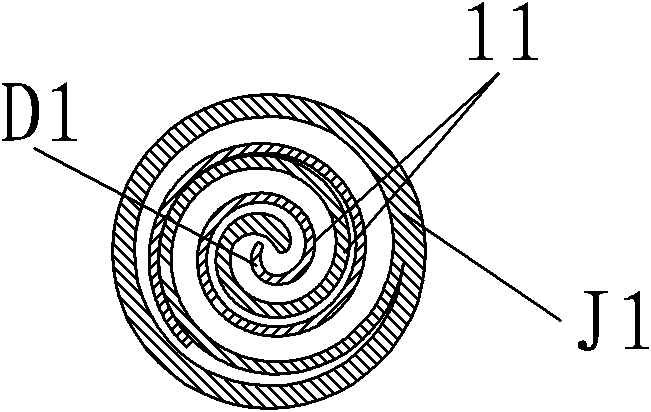

Molding method of scroll and scroll

InactiveCN101961828ADoes not cause swelling problemsFully plastic deformationRotary piston pumpsRotary piston liquid enginesEngineeringScroll compressor

The invention relates to a molding method of a scroll of a scroll compressor, and a scroll processed by the method. The scroll consists of a vortex-type line and a vortex end cap. The method comprises the following steps: 1. molding the vortex-type line according to the structure parameters of the vortex-type line; 2. molding the vortex end cap according to the structure parameters of the vortex end cap; and 3. fixedly installing the vortex-type line and the vortex end cap in a matching mode to obtain the scroll. Due to that the vortex-type line and the vortex end cap are processed respectively as two parts in the invention, and the two parts are finally installed to form the scroll in a matching mode, the processing technique is simple, the production efficiency is high, and the size accuracy can be ensured.

Owner:王少朋

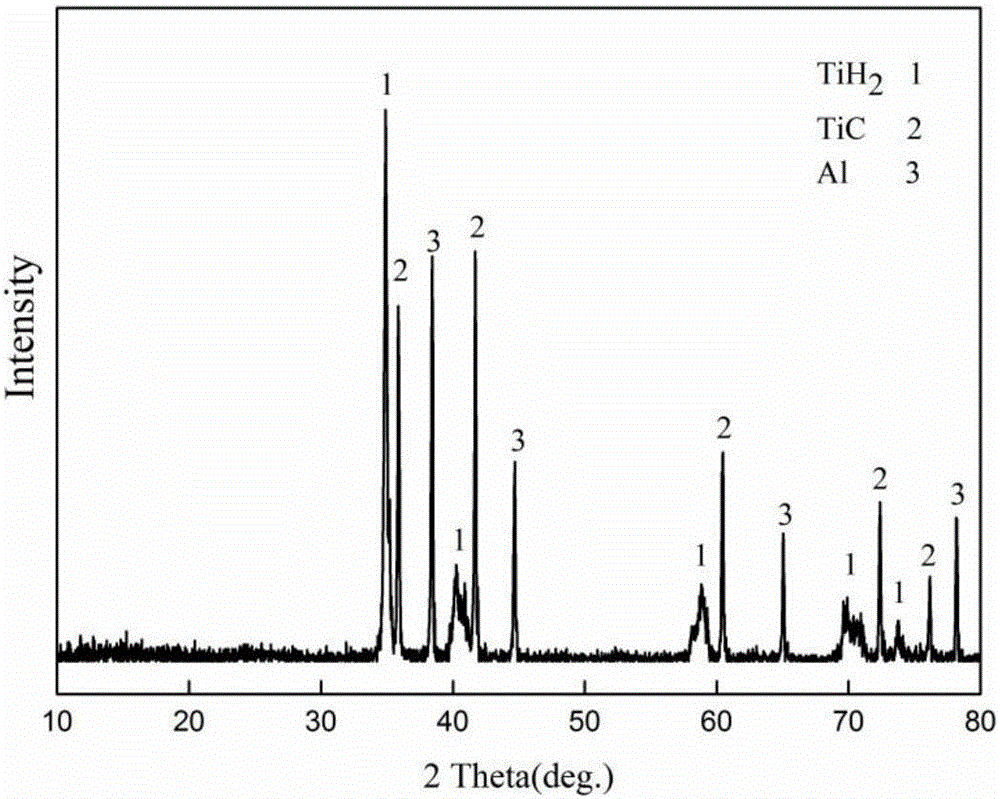

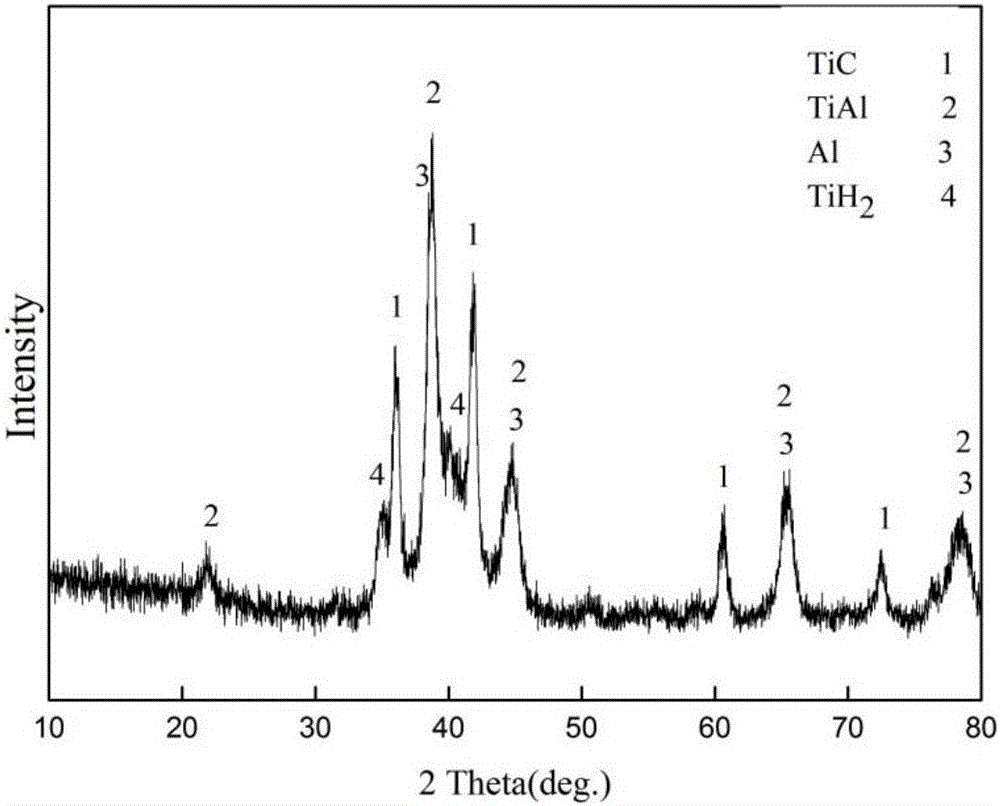

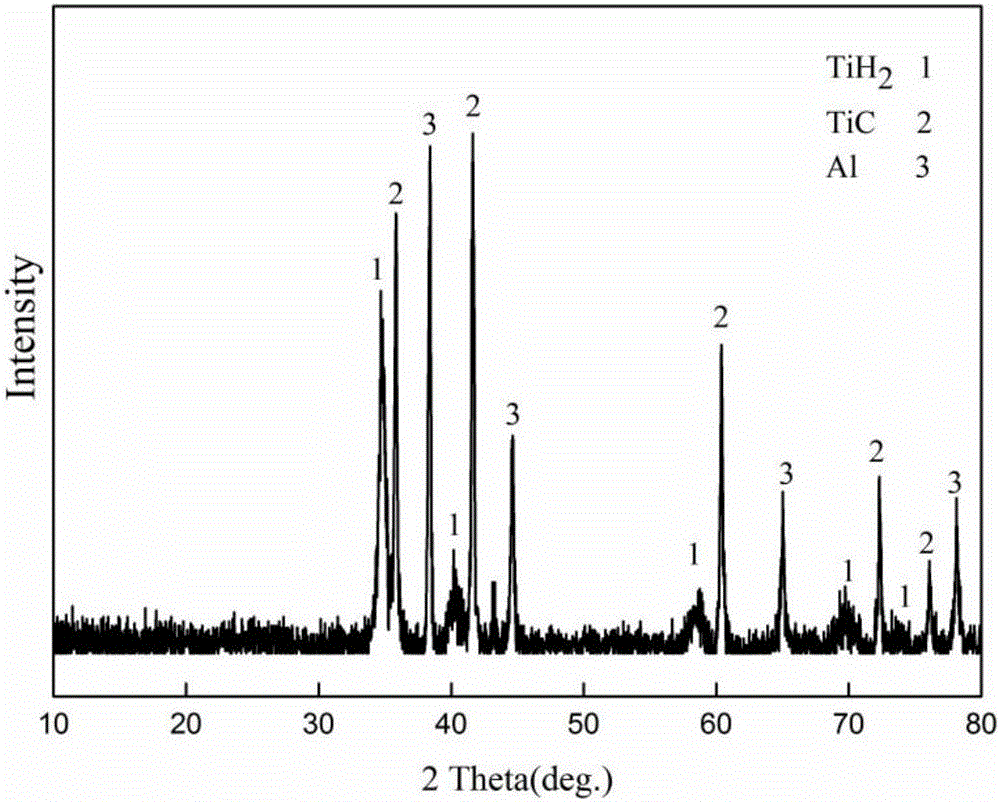

Method for preparing Ti2AlC phase ceramic coating through cold spraying in-situ formation

ActiveCN106048596AShort heating timeFast productionPressure inorganic powder coatingSurface engineeringOrganic solvent

The invention relates to the field of ceramic coating and surface engineering, in particular to a method for preparing a Ti2AlC phase ceramic coating through cold spraying in-situ formation. The preparation method can be applied to an MAX phase material system capable of being synthesized through pressureless sintering and is specifically explained through the preparation method for the Ti2AlC phase ceramic coating. The preparation method comprises the steps that firstly, raw material powder for sintering and preparing the coating is mixed according to the required proportion; secondly, an organic solvent and an adhesive are added into the mixed powder to form slurry through wet ball grinding; thirdly, the slurry is dried into spherical raw material powder through a spray drying granulation method; fourthly, the spherical raw material powder is deposited on a base material where the coating needs to be prepared through a cold gas dynamic spraying device; and fifthly, the deposited base material and the coating are sintered under a vacuum atmosphere, and an in-situ formation MAX phase ceramic coating can be obtained. The method for preparing the MAX phase ceramic coating through cold spraying in-situ formation has the characteristics that the prepared coating is large in thickness and good in quality, the powder deposition speed is high, no MAX phase decomposition reaction occurs in the process, using is convenient, and the method is suitable for large scale application.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

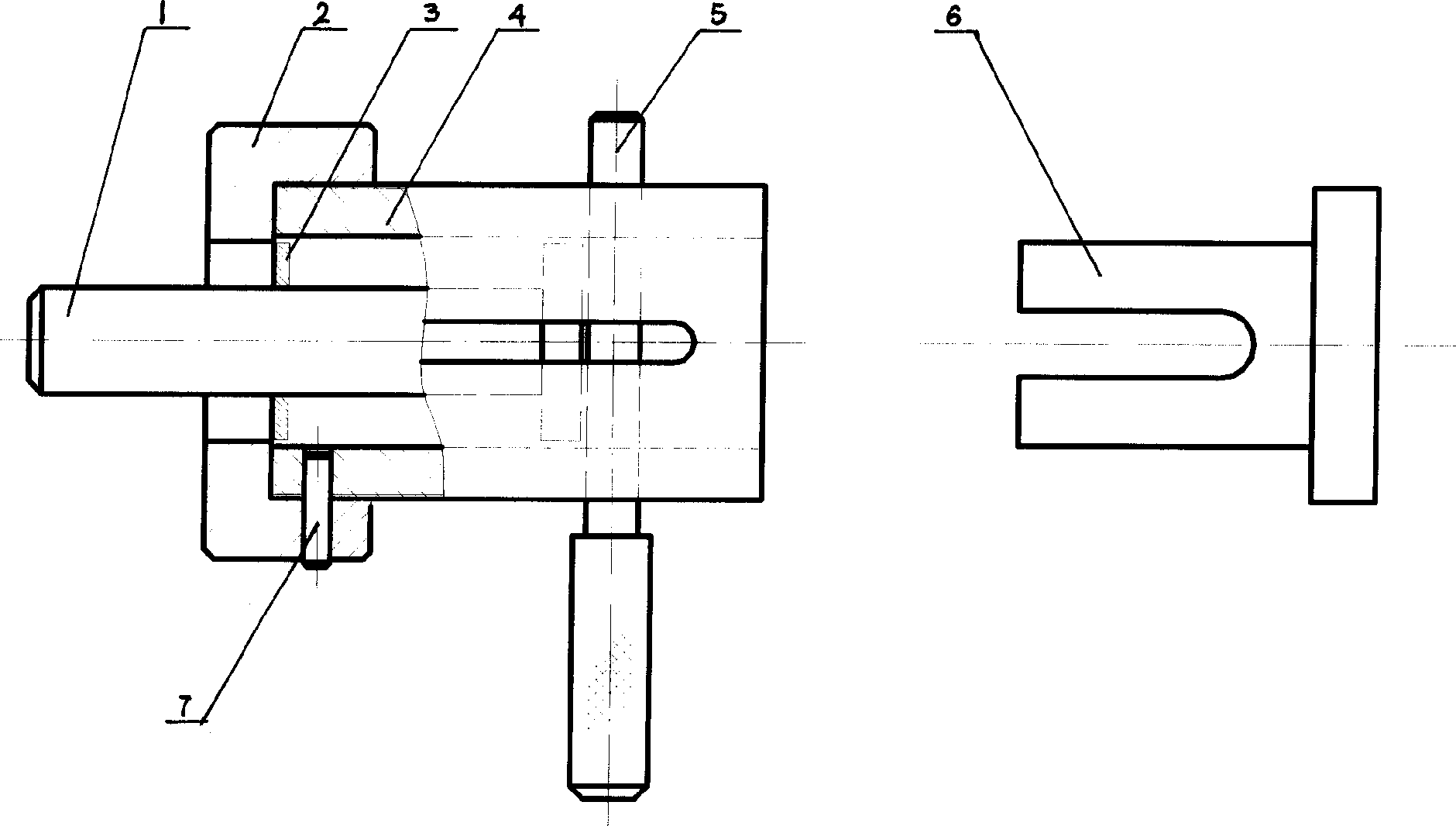

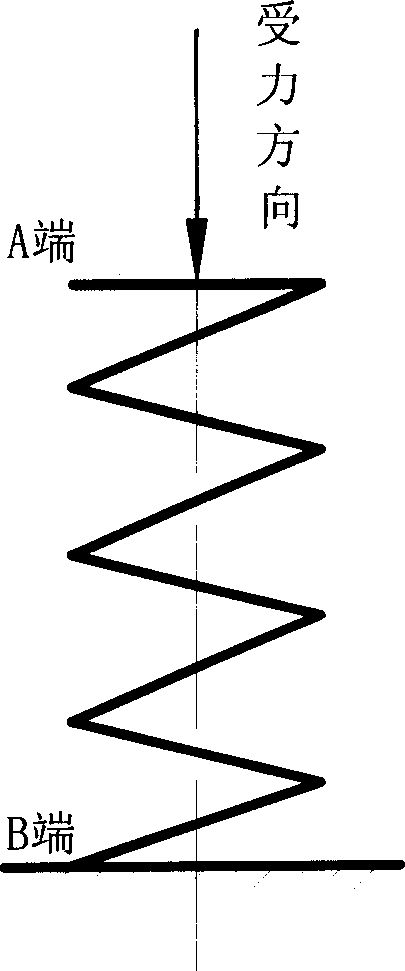

Short-pressure enhancing treatment of sweeping buffer spring

InactiveCN1712548AGuaranteed output characteristicsImprove carrying capacityEngineeringPlastic property

A short pressure reinforcing process of struck buffer elastic spring. The process adopts repeating the way of short pressure reinforcing process when mechanic reinforcing. The elastic spring can be completely plastometric set so that it reaches content force output property and increases endurance life. The process is used for parts with big lead angle and high load which cannot be processed by short pressure and halt.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

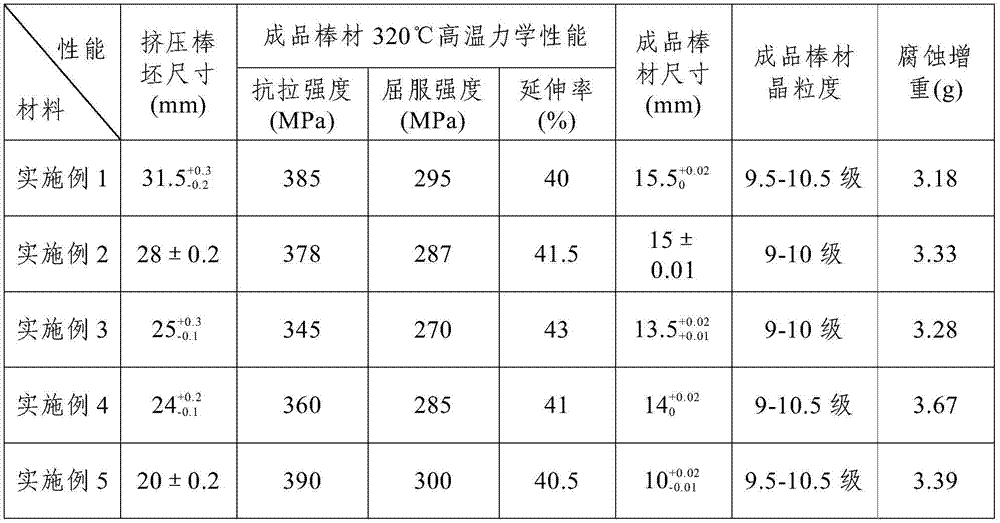

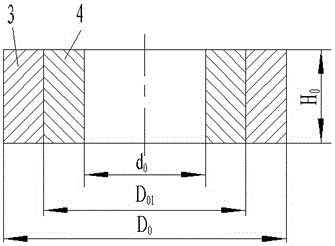

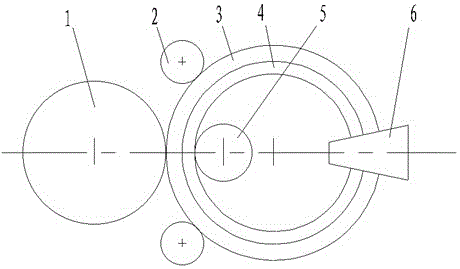

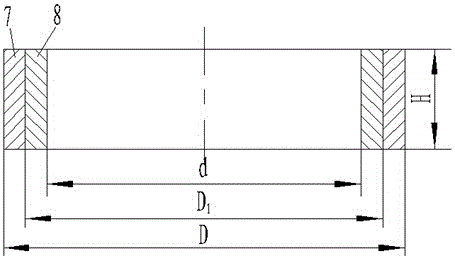

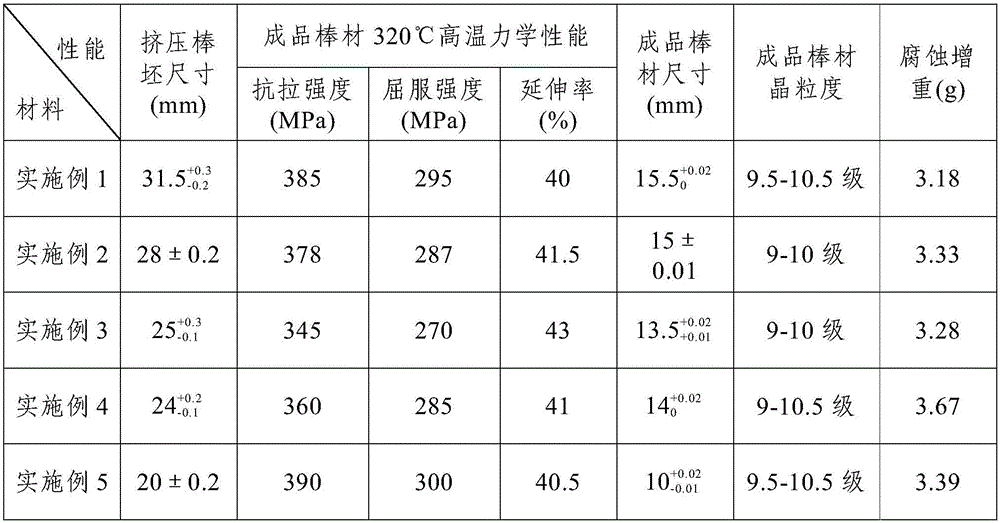

High-quantity hafnium rod manufacturing method

ActiveCN105436232AOvercome scourOvercome uniformity issuesTemperature control deviceMetal rolling arrangementsHafniumOxide coating

The invention discloses a high-quantity hafnium rod manufacturing method. The method includes the steps that a hafnium rod blank is wrapped with a steel pipe, then the steel pipe is wrapped with a copper pipe, and the double-wrapped hafnium rod blank is obtained; secondly, the double-wrapped hafnium rod blank is extruded after the rod blank is heated and the temperature is kept, and the extruded rod blank is obtained; thirdly, the copper pipe and the steel pipe wrapping the extruded rod blank are removed, and then the extruded rod blank is subjected to vacuum annealing treatment; fourthly, under the condition that the extruded rod blank is heated continuously in the atmosphere, the extruded rod blank is rolled through a heat pipe rolling machine; fifthly, oxide coatings are removed, then the extruded rod blank is straightened, ground and polished in sequence, and a semi-finished hafnium rod is obtained; and sixthly, vacuum annealing treatment is conducted, and a finished high-quality hafnium rod is obtained. By the high-quantity hafnium rod manufacturing method, the hafnium rod blank is double-wrapped before being extruded, and the hafnium rod blank is rolled through the heat pipe rolling machine under the condition that the extruded rod blank is heated continuously in the atmosphere, and the hafnium rod with the dimensional deviation ranging from -0.02 mm to 0.02 mm, the ovality smaller than or equal to 0.02 mm and excellent mechanical property and corrosion resistance and of an even structure can be obtained.

Owner:西安诺博尔稀贵金属材料股份有限公司

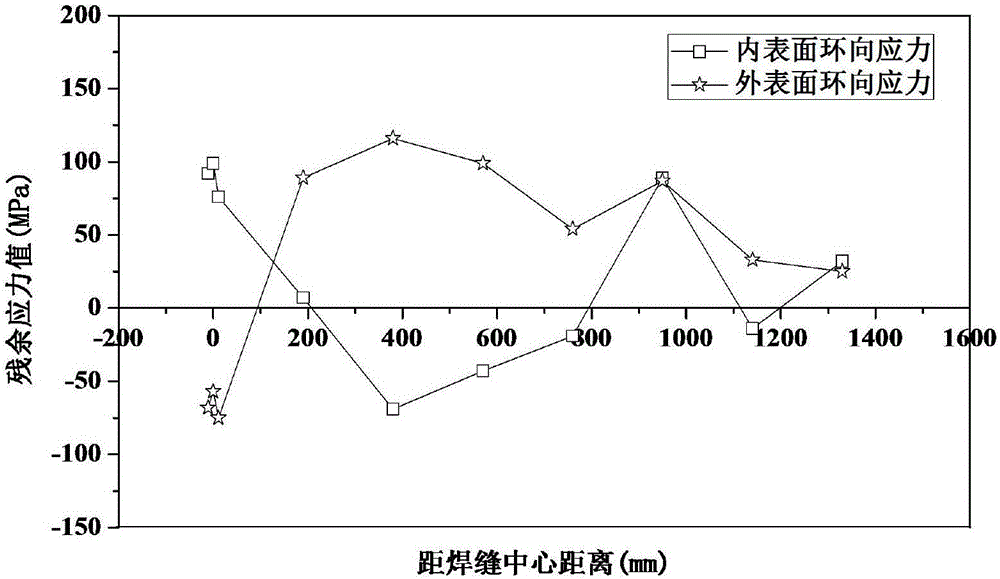

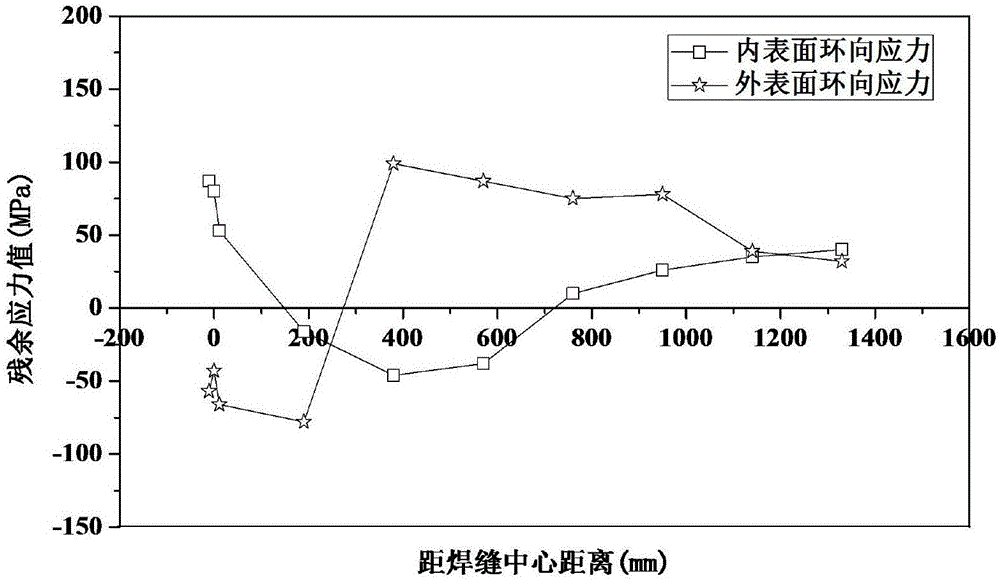

Method for manufacturing X 90 grade pipeline steel large-diameter thick-wall spiral submerged-arc welding pipe

The invention discloses a method for manufacturing an X 90 grade pipeline steel large-diameter thick-wall spiral submerged-arc welding pipe. The method comprises the following working procedures: uncoiling, flattening, edge milling, forming, welding, pipe end expanding, X-ray continuous detection, static hydrostatic testing, weld joint and base metal ultrasonic flaw detection, pipe end chamfering, pipe end shooting and finished product inspection; the welding working procedure comprises inside and outside prewelding, finish inside and outside welding; through reasonably selecting welding parameters, a weld joint and base metal can transit smoothly to reduce or eliminate undercut, and the weld joint has excellent mechanical property and ensures obdurability match of the welding pipe and a welded joint; while the pipe end expanding working procedure is carried out, an automatic spiral submerged-arc welding pipe perimeter measuring device is adopted to measure the perimeter in real time, so that real-time measurement and monitoring on the welding pipe perimeter during the forming process are realized, and precise geometric dimensioning of the welding pipe is ensured.

Owner:BAOJI PETROLEUM STEEL PIPE

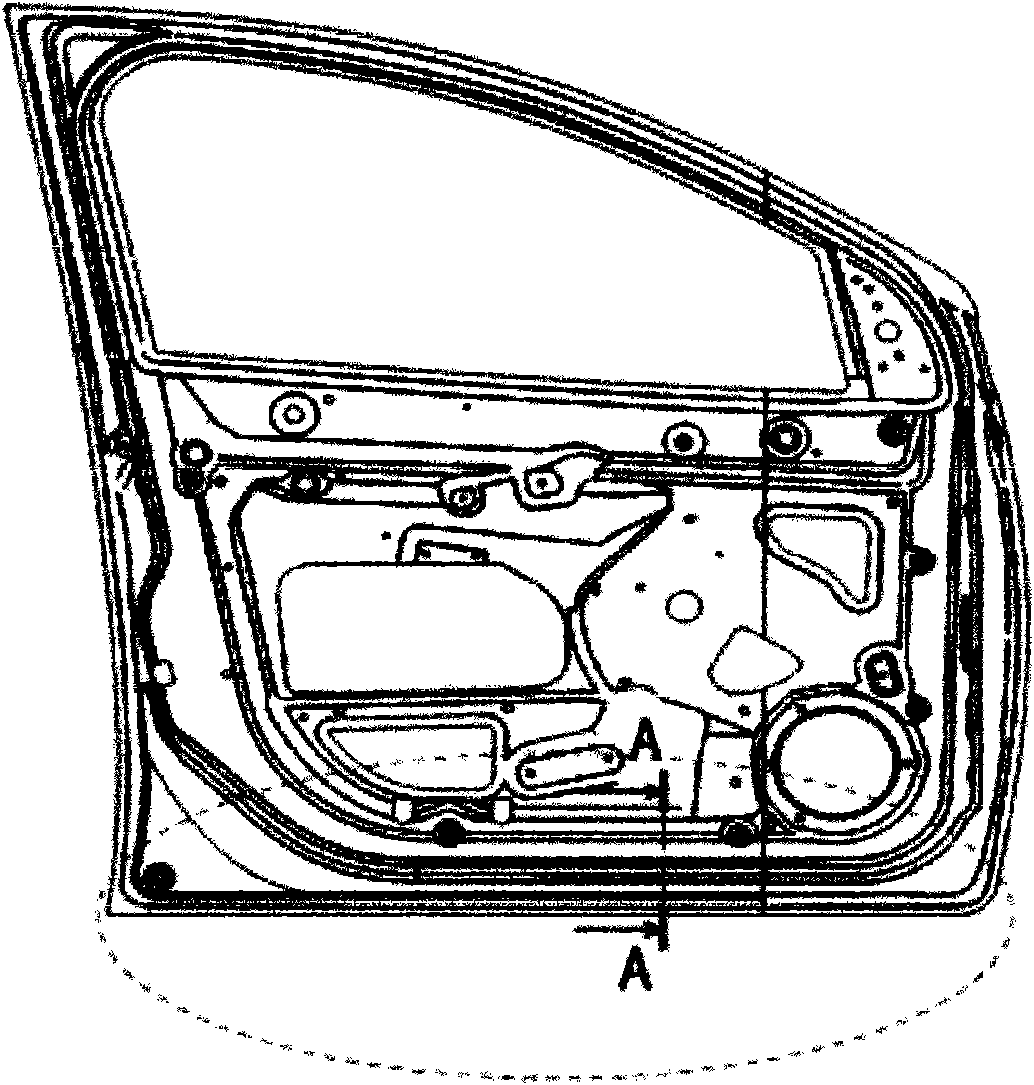

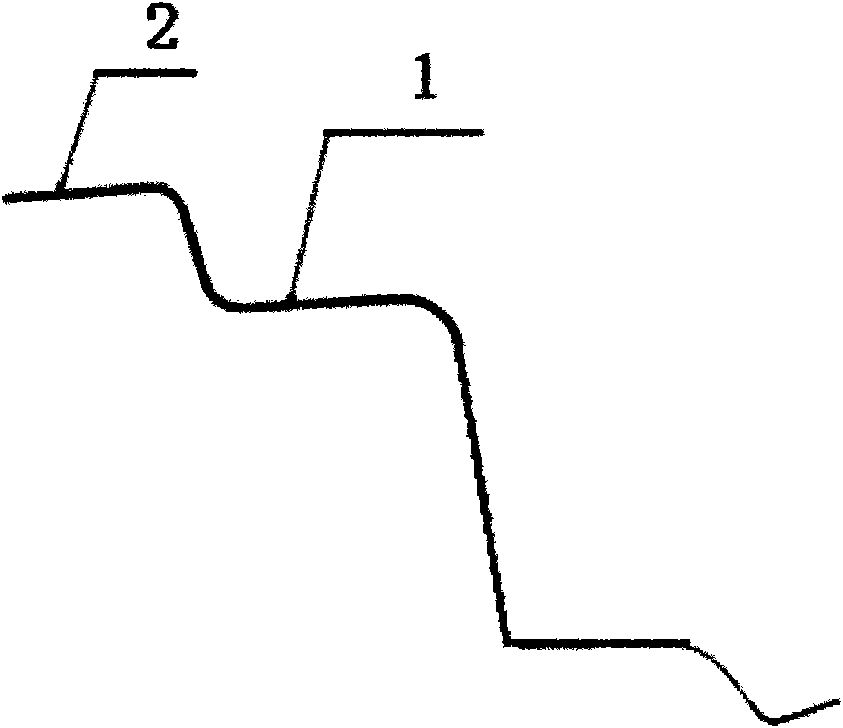

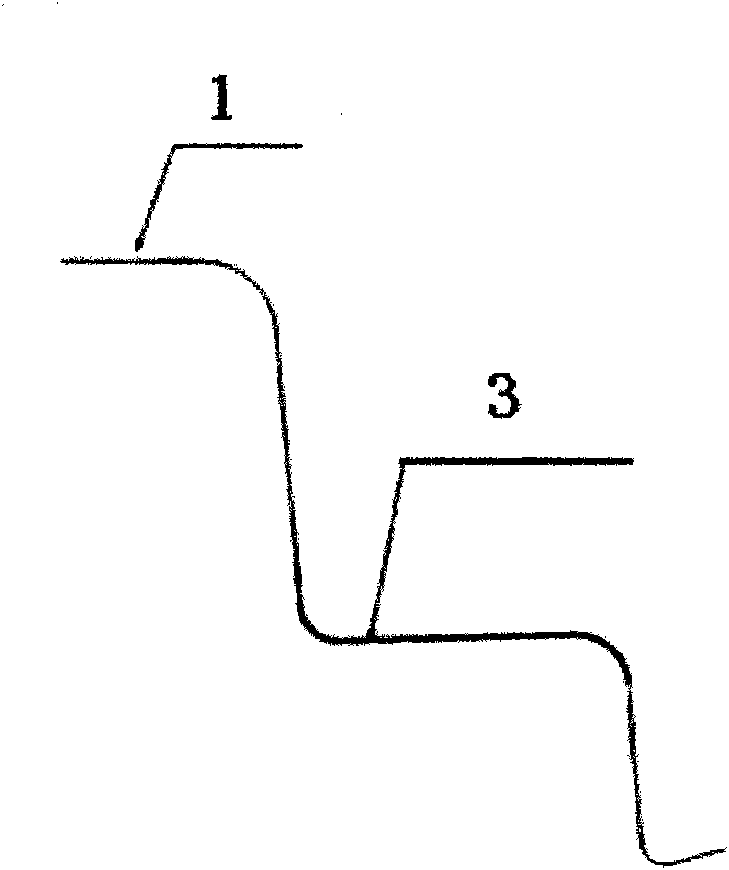

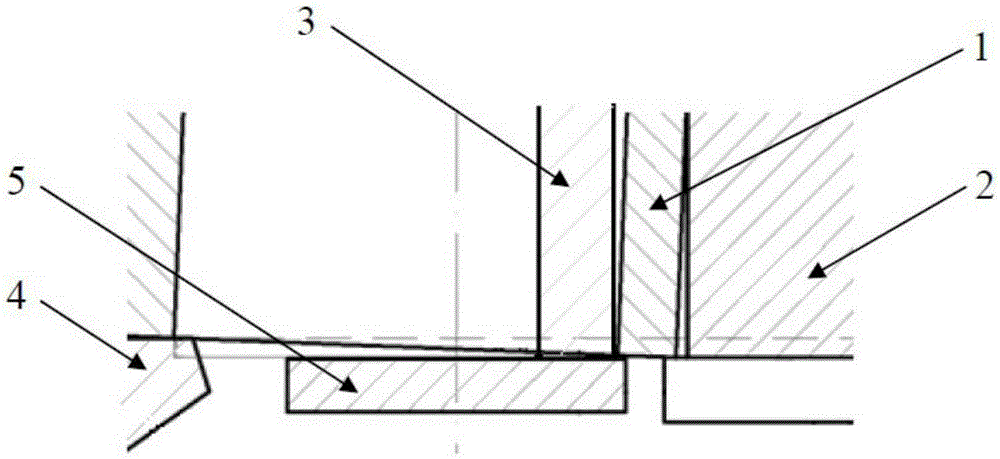

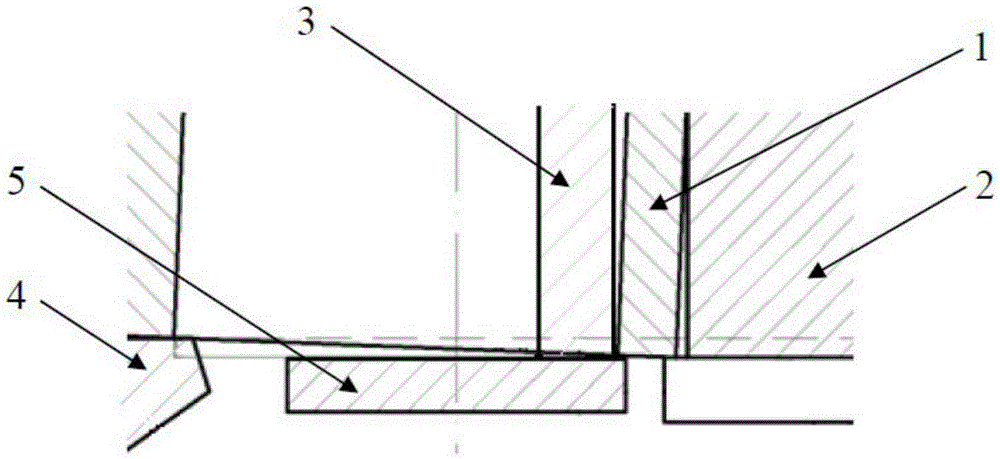

Automobile door internal plate understructure

InactiveCN101982328ALow costImprove appearance qualityEngine sealsVehicle sealing arrangementsPunchingFlange

The invention relates to an automobile door internal plate understructure which comprises a door opening seal region (1), a side wall seal region (3) and a binding flange region (4), wherein a step (2) is additionally arranged between the side wall seal region (3) and the binding flange region (4); the upper and lower round angle roots of the step (2) are provided with a drainage hole (5) in a penetrating mode; and the drainage hole (5) is manufactured by positive punching. The automobile door internal plate understructure has the advantages that the step is additionally arranged between the side wall seal region and the binding flange region, and the step is provided with the drainage hole, thus the traditional wedge mode is changed into a positive punching mode and the mold cost is greatly lowered.

Owner:CHERY AUTOMOBILE CO LTD

Molding method of scroll and scroll

InactiveCN101961828BDoes not cause swelling problemsFully plastic deformationRotary piston pumpsRotary piston liquid enginesEngineeringScroll compressor

Owner:王少朋

Isotropous rolling method for ion-based high-temperature alloy rectangular ring part

The invention discloses an isotropous rolling method for an ion-based high-temperature alloy rectangular ring part. The isotropous rolling method comprises the following steps: firstly, heating an iron-based high temperature alloy rod to a forging temperature, and carrying out upsetting, punching and pre-rolling on the iron-based high temperature alloy rod to prepare rectangular ring blank; filling the rectangular ring blank into ring rolling machine, lifting a tapered roller by a height h being 5mm-10mm for tilting the rectangular ring blank; then, rolling and shaping the rectangular ring blank to obtain the ion-based high-temperature alloy rectangular ring part. According to the method, by changing the flow direction of materials during rolling, isotropous mechanical properties of the rectangular ring part are kept consistent, so that the comprehensive mechanical properties of the rectangular ring part are improved. The method is used for producing the isotropous ion-based high-temperature alloy rectangular ring part.

Owner:GUIZHOU ANDA AVIATION FORGING

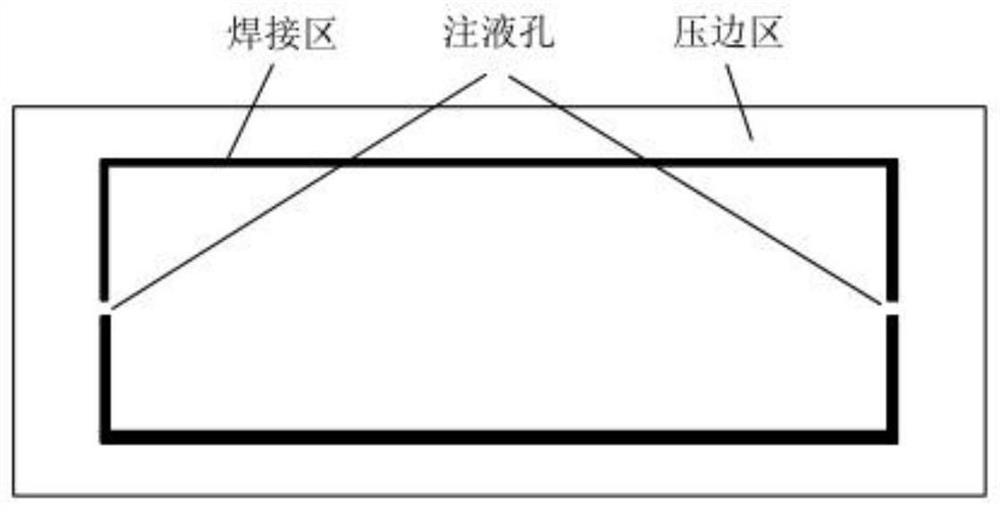

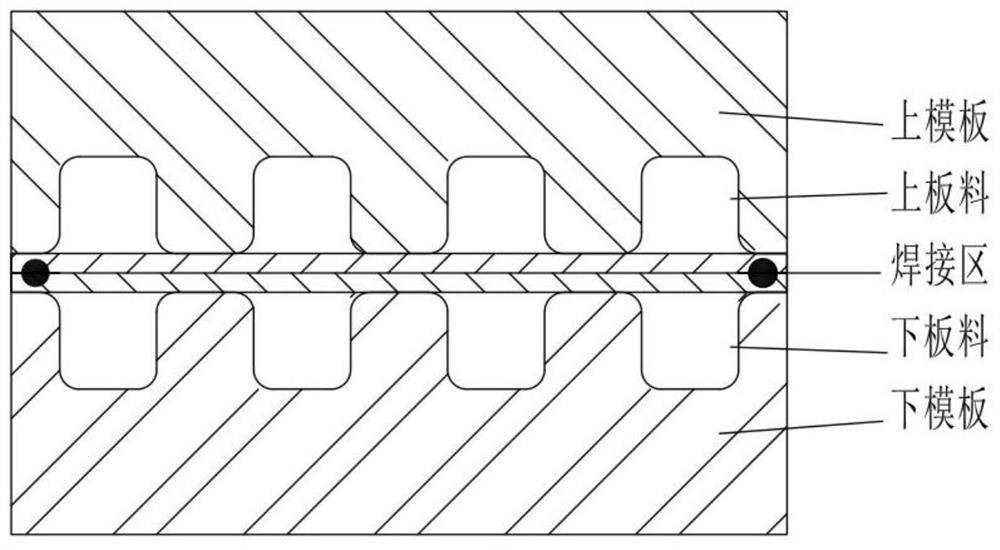

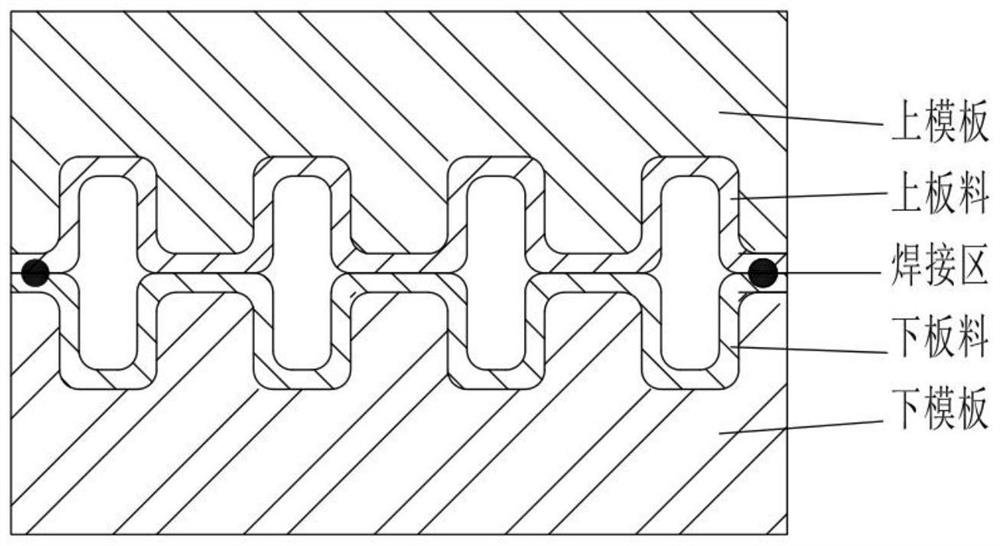

Preparation method of metal bipolar plate of proton exchange membrane fuel cell

ActiveCN112993301AGuaranteed CorrosionEnsure consistencyCollectors/separatorsHydroformingProton exchange membrane fuel cell

The invention relates to the technical field of fuel cells, and provides a preparation method of a metal bipolar plate of a proton exchange membrane fuel cell. According to the invention, the metal bipolar plate is prepared by adopting a method of firstly coating, then welding and finally hydroforming, so that the uniform thickness of the coating can be ensured, and the consistency of corrosion resistance and contact resistance of each part of the bipolar plate is ensured; and when the two layers of metal plates are welded, one non-welding area is reserved on each of the two sides, during hydraulic forming, the non-welding areas serve as liquid injection holes to inject high-pressure liquid between the two layers of metal plates, under the action of hydraulic pressure, the upper layer of metal plate is attached to the cavity wall of an upper mold plate, and the lower layer of metal plate is attached to the cavity wall of a lower mold plate, so a cathode plate and an anode plate are formed at the same time. When the method is adopted for hydraulic forming, the coating cannot be damaged, the formed runner is high in precision, the product percent of pass is high, and simultaneous forming of the cathode plate and the anode plate is achieved for the first time.

Owner:UNIV OF JINAN +1

Isotropic rolling method for cobalt-based high-temperature alloy rectangular ring part

The invention discloses an isotropic rolling method for a cobalt-based high-temperature alloy rectangular ring part. The isotropic rolling method comprises the following steps: firstly, heating a cobalt-based high-temperature alloy bar to a forging temperature, and carrying out upsetting, punching and pre-rolling, thereby forming a rectangular ring blank; secondly, mounting the rectangular ring blank on a ring rolling mill, lifting a conical roller by h=5 to 10 mm such that the rectangular ring blank tilts, and then performing rolling forming to obtain the cobalt-based high-temperature alloy rectangular ring part. According to the method, the mechanical properties of the rectangular ring part in various directions are kept consistent by changing a material flowing direction during rolling, and therefore, the comprehensive mechanical properties of the rectangular ring part are improved. The method is used for producing the cobalt-based high-temperature alloy isotropic rectangular ring parts.

Owner:GUIZHOU ANDA AVIATION FORGING

Rolling method for rectangular isotropous stainless steel ring piece

The invention discloses a rolling method for a rectangular isotropous stainless steel ring piece. The rolling method includes the steps that firstly, a stainless steel rod is heated to the forging temperature to be upset, punched and pre-rolled, and a rectangular ring blank is manufactured; and secondly, the rectangular ring blank is put into a ring rolling machine, a conic roller is lifted up by 5 mm to 10 mm, the rectangular ring blank is inclined, then rolling forming is conducted, and the rectangular stainless steel ring piece is obtained. By the adoption of the method, the flowing direction of materials in the rolling process is changed, and isotropous mechanical performance of the rectangular ring piece is kept the same, so that the comprehensive mechanical performance of the rectangular ring piece is improved. The method is used for producing the rectangular isotropous stainless steel ring piece.

Owner:GUIZHOU ANDA AVIATION FORGING

A Hot Rolling and Expanding Process for Centrifugal Casting Bimetallic Composite Rings

InactiveCN105170850BImprove surface qualityPrecise DimensionsMetal rollingUltimate tensile strengthMechanical property

The invention relates to a centrifugal casting duplex-metal composite ring part hot extend-rolling forming technology, and belongs to the technical field of ring part rolling expansion machining. The centrifugal casting duplex-metal composite ring part hot extend-rolling forming technology is characterized by comprising the following steps: (1) isothermal heating is carried out; (2) a heated duplex-metal composite ring blank is placed on a radial and axial direction ring rolling machine; (3) the contact relation between a forming roller and the ring blank is determined; (4) a driving roller drives the duplex-metal composite ring blank and a core roller to perform rotation motion, meanwhile, the core roller does straight line feeding motion in the radial direction of the ring blank, an end face taper roller only keeps the rotary motion rather than conducting axial feeding, and continuous local plastic deformation of wall thickness reduction, diameter enlarging and cross section layout shaping is continuously carried out on the duplex-metal composite ring blank; and (5) when a preset value of the outer diameter of a duplex-metal composite ring part is obtained, a guide roller gives out a signal, the core roller stops feeding, and extend-rolling is finished. The centrifugal casting duplex-metal composite ring part hot extend-rolling forming technology has the beneficial effects that the process procedure is shortened, the device investment is reduced, and energy and materials are saved; and meanwhile, the composite ring part interface plastic deformation is sufficient, the bonding strength is high, the mechanical property is good, and the service life is long.

Owner:定州市金华蓝天汽车零部件有限公司 +1

A kind of preparation method of high-quality hafnium bar material

ActiveCN105436232BImprove extrusion lubricationImprove uniformityTemperature control deviceMetal rolling arrangementsHafniumOxide coating

The invention discloses a high-quantity hafnium rod manufacturing method. The method includes the steps that a hafnium rod blank is wrapped with a steel pipe, then the steel pipe is wrapped with a copper pipe, and the double-wrapped hafnium rod blank is obtained; secondly, the double-wrapped hafnium rod blank is extruded after the rod blank is heated and the temperature is kept, and the extruded rod blank is obtained; thirdly, the copper pipe and the steel pipe wrapping the extruded rod blank are removed, and then the extruded rod blank is subjected to vacuum annealing treatment; fourthly, under the condition that the extruded rod blank is heated continuously in the atmosphere, the extruded rod blank is rolled through a heat pipe rolling machine; fifthly, oxide coatings are removed, then the extruded rod blank is straightened, ground and polished in sequence, and a semi-finished hafnium rod is obtained; and sixthly, vacuum annealing treatment is conducted, and a finished high-quality hafnium rod is obtained. By the high-quantity hafnium rod manufacturing method, the hafnium rod blank is double-wrapped before being extruded, and the hafnium rod blank is rolled through the heat pipe rolling machine under the condition that the extruded rod blank is heated continuously in the atmosphere, and the hafnium rod with the dimensional deviation ranging from -0.02 mm to 0.02 mm, the ovality smaller than or equal to 0.02 mm and excellent mechanical property and corrosion resistance and of an even structure can be obtained.

Owner:西安诺博尔稀贵金属材料股份有限公司

Method for using balance post rod in drawing process for machining high-tension material asymmetrical component

The invention relates to a method for using a balance mandril in the drawing process for processing an asymmetrical component of a high tension material. The method comprises that: a mould is arranged and locked on a machine while the balance mandril is arranged at one end with smaller stress during mould forming; an upper mould and a sliding block of the machine are locked and move downward, and when the upper mould and plates on a blank holder contact, the height of the balance mandril is adjusted to contact the sliding block of the machine simultaneously; the upper mould contact and press downward the blank holder, the mandril descends along with the action of upward pressure at the same time, and at the moment, the balance mandril supports the action of balanced force and descends together; and the upper mould continuously descends to ensure that the mould moves to a lower dead center and the balance mandril descends to the lowest at the same time so as to press the plates and complete shape curing of the component. The method is mainly suitable for forming plates with more than 600MPa of tensile strength, high tension and left-right asymmetry, can ensure that the plates are subjected to full plastic deformation, and reduce tendency of component rebound and distortion, thereby achieving the aim of size curing of the component.

Owner:CHONGQING PINGWEI AUTOMOBILE TECH CO LTD

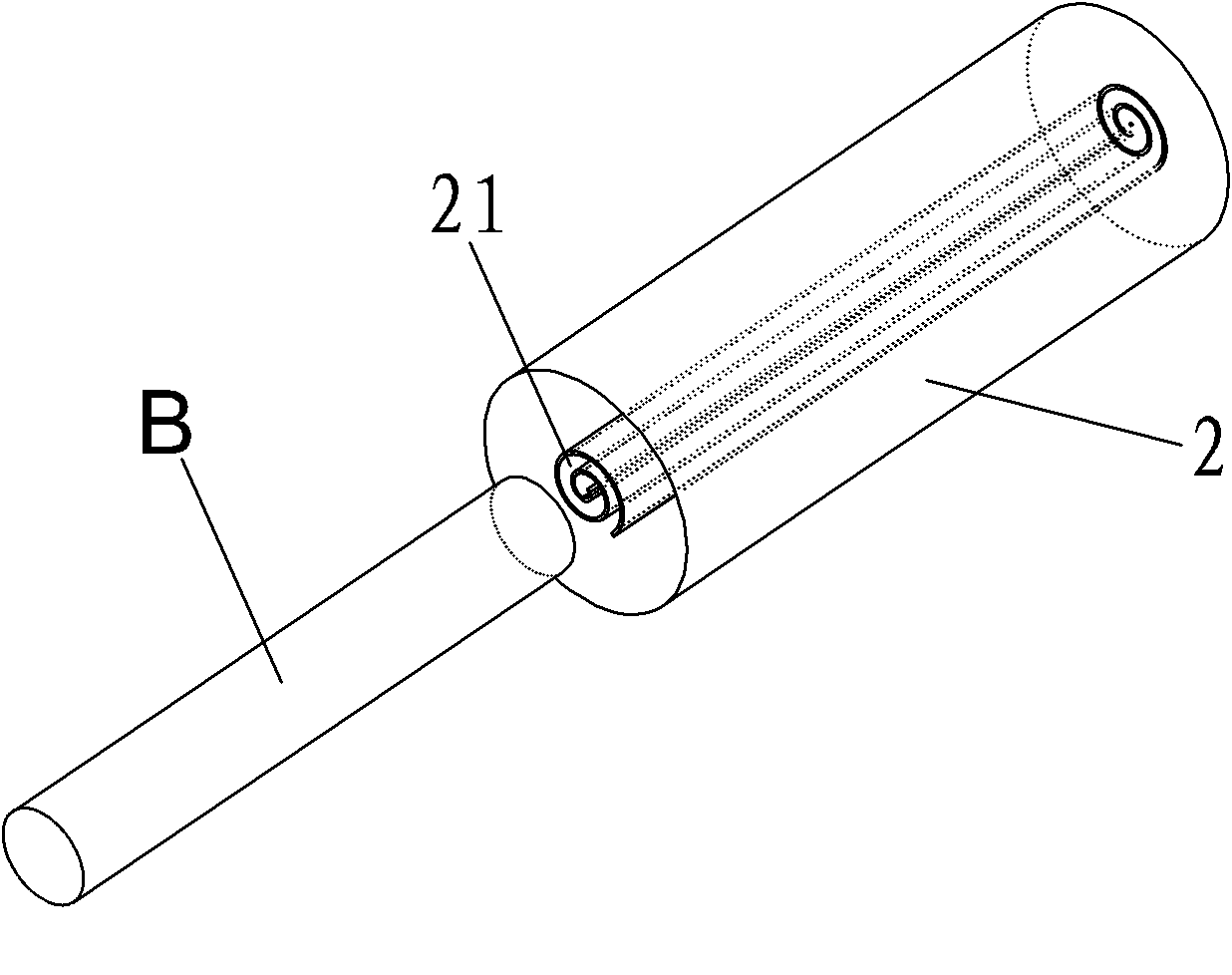

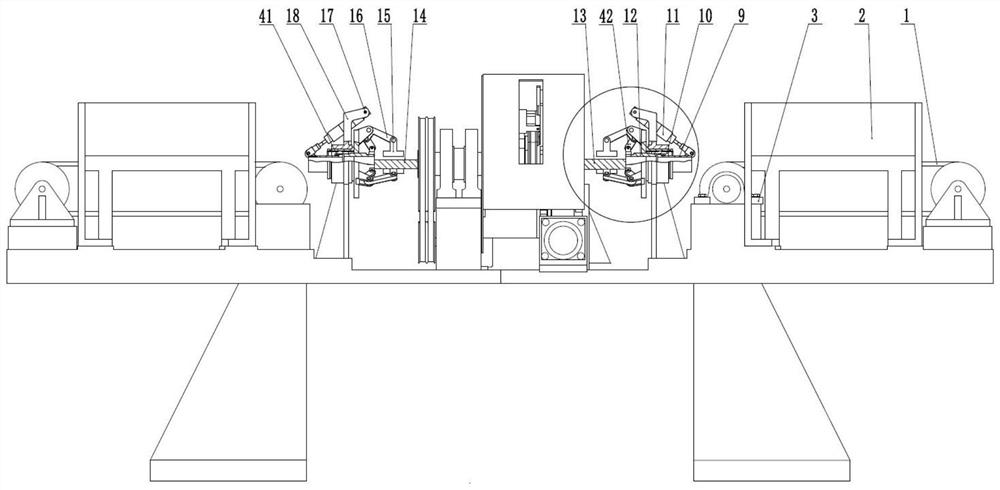

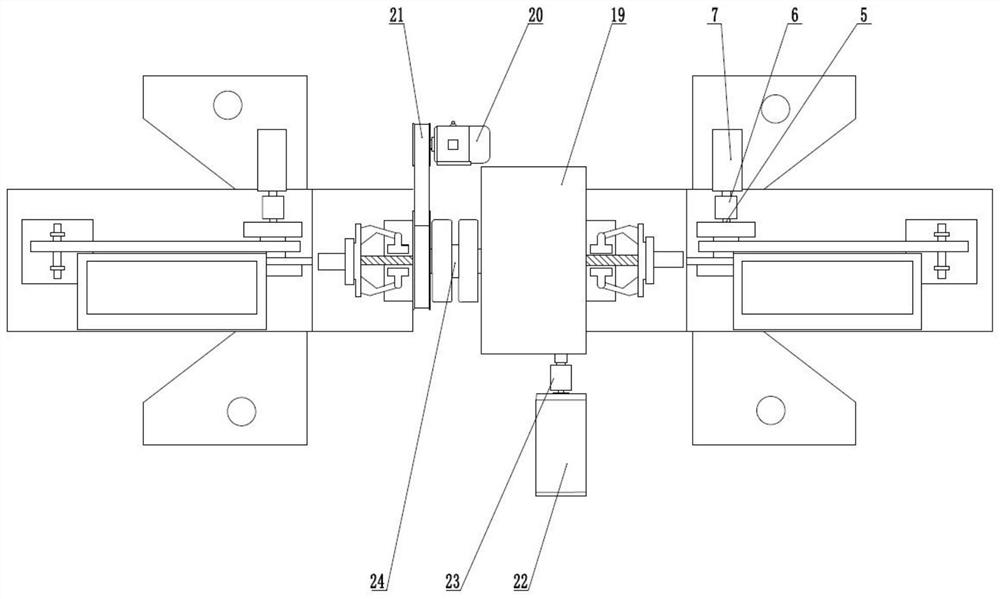

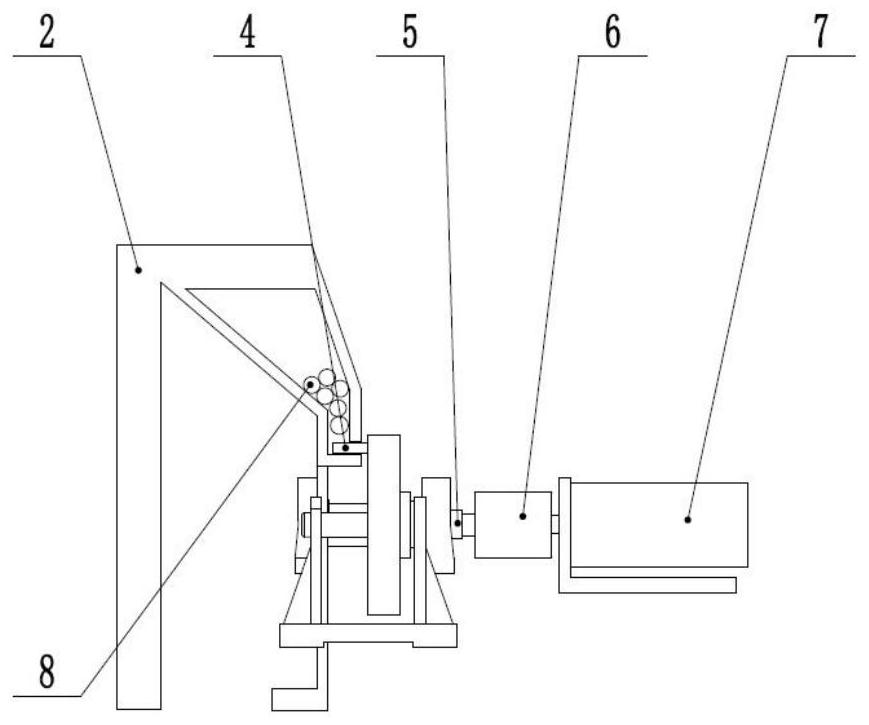

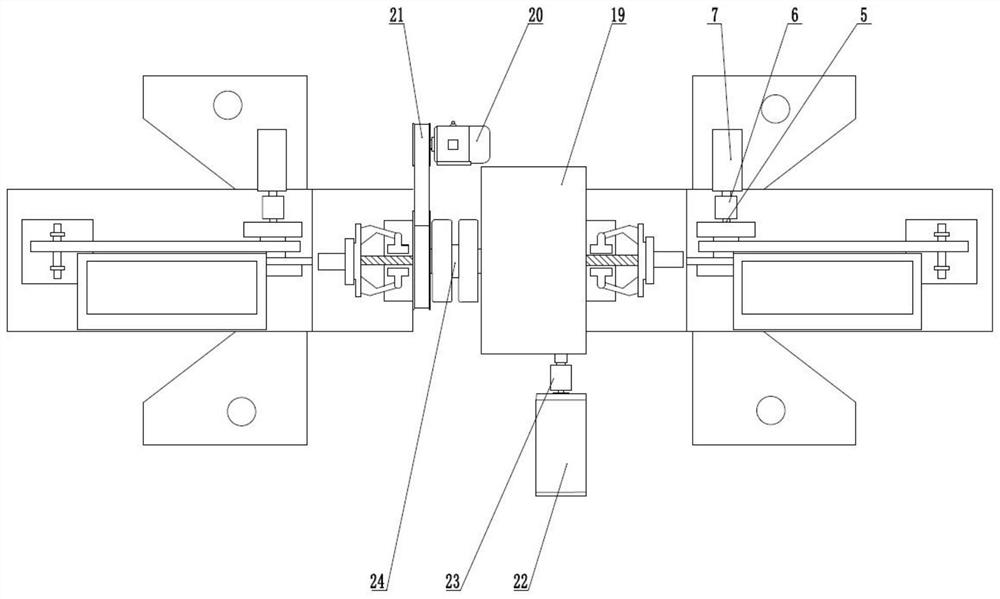

A plastic connection device for round pipes

ActiveCN112571017BShorten the timeReduce deformation speedMetal working apparatusElectric machineGear wheel

A circular pipe plastic connection device, including a feeding mechanism, a fixed clamping mechanism and a circumferential loading mechanism, through a motor and a sprocket, the rotational motion of the motor is converted into a linear feed motion of the sprocket, so that the pipe is placed in a predetermined position , further driven by the cylinder to clamp the pipe in the circumferential direction of the pressing block; driven by the motor, using the precise transmission between the gears to control the movement of the three groups of rolling devices that are opposed to each other, the movement is synchronized, and after repeated and cyclic loading; through the special pipe fixture The unique design and the use of rolling-type local progressive loading greatly improve the product's excellent performance and production efficiency.

Owner:XIAN UNIV OF TECH

Device and method for warm forming of metal and carbon fiber prepreg composite material components

ActiveCN106891511BLarge adjustable restraint resistanceAdjustable restraint with low resistanceHydraulic cylinderFiber

The invention discloses a warm-hot forming device and method for a metal and carbon fiber prepreg composite material component in the field of lightweight composite material forming and processing. An outer blank holder is arranged between a female mold and a male mold. The middle of the outer blank holder is provided with a downwards concave step positioning groove. The top of the step positioning groove can contain a steel plate, and an inner blank holder is placed at the bottom of the step positioning groove. The upper surface of the inner blank holder can contain a carbon fiber prepreg blank. A pushing plate is arranged under the male mold. The top ends of a first outer blank holder pushing rod and a second outer blank holder pushing rod can upwards jack the outer blank holder, and the bottom ends of the first outer blank holder pushing rod and the second outer blank holder pushing rod are fixedly connected to the pushing plate. The top ends of a first inner blank holder pushing rod and a second inner blank holder pushing rod can upwards jack the inner blank holder, and the bottom ends of the first inner blank holder pushing rod and the second inner blank holder pushing rod are each connected with a hydraulic cylinder. A third hydraulic cylinder is connected under the pushing plate. Large adjustable constraint resistance is applied to the steel plate. By means of the adjustable constraint resistance with a small effect on the carbon fiber prepreg blank, two heterogeneous component materials have the mutual matching forming capacities, and warm forming and hot forming are completed in a one-time stamping stroke.

Owner:株洲西康尼克新材料有限公司

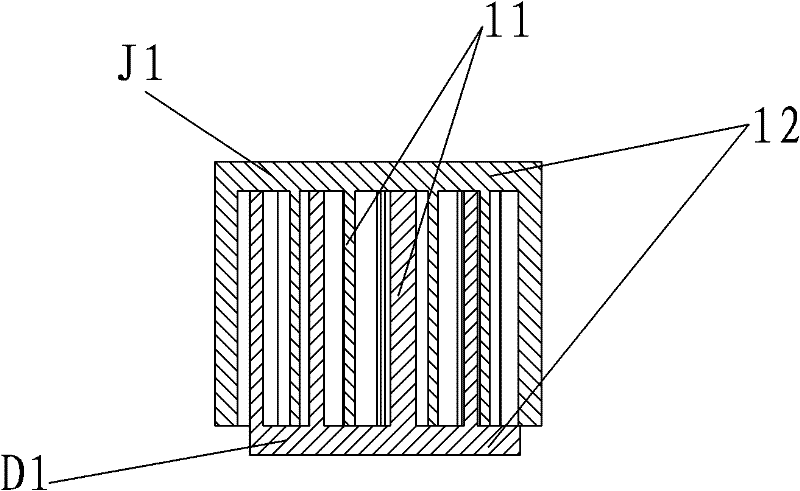

Molding die for processing high-tension plate parts

ActiveCN102310147BOvercoming large reboundFully stretched plastic deformationShaping toolsNitrogenEngineering

The invention relates to a molding die for processing high-tension plate parts, which comprises an upper die seat (11), a material press core (13), an upper die fixing plate (14), a lower die seat (15), a convex die (17), a material press plate (18) and an upper die knife block (19), wherein the upper die fixing plate (14) is arranged between the upper die seat (11) and the upper die knife block (19), at least one nitrogen spring (12) is arranged between the material press core (3) and the upper die seat (11), at least two nitrogen springs (16) are arranged between the material press plate (18) and the lower die seat (15), a locking unit (21) is manufactured on the material press plate (18) and the upper die knife block (19), a material plate (20) locked between the material press core (13) and the locking unit (21) in molding can be fully stretched for plastic deformation, and the large springback amount after molding is overcome.

Owner:CHERY AUTOMOBILE CO LTD

Isotropic rolling method for aluminum alloy rectangular ring

The invention discloses an isotropic rolling method for an aluminum alloy rectangular ring. The isotropic rolling method comprises the following steps: firstly, heating an aluminum alloy bar till a forging temperature, and carrying out upsetting, piercing and pre-rolling to form a rectangular ring blank; secondly, loading the rectangular ring blank on a ring rolling mill, lifting a conical roller by h=5mm-10mm to tilt the rectangular ring blank, and then carrying out rolling forming to obtain the aluminum alloy rectangular ring. Such a method is capable of keeping the mechanical properties of the rectangular ring consistent in all directions by changing a flowing direction of a material during rolling, thereby improving the comprehensive mechanical properties of the rectangular ring. The method is used for producing the isotropic aluminum alloy rectangular rings.

Owner:GUIZHOU ANDA AVIATION FORGING

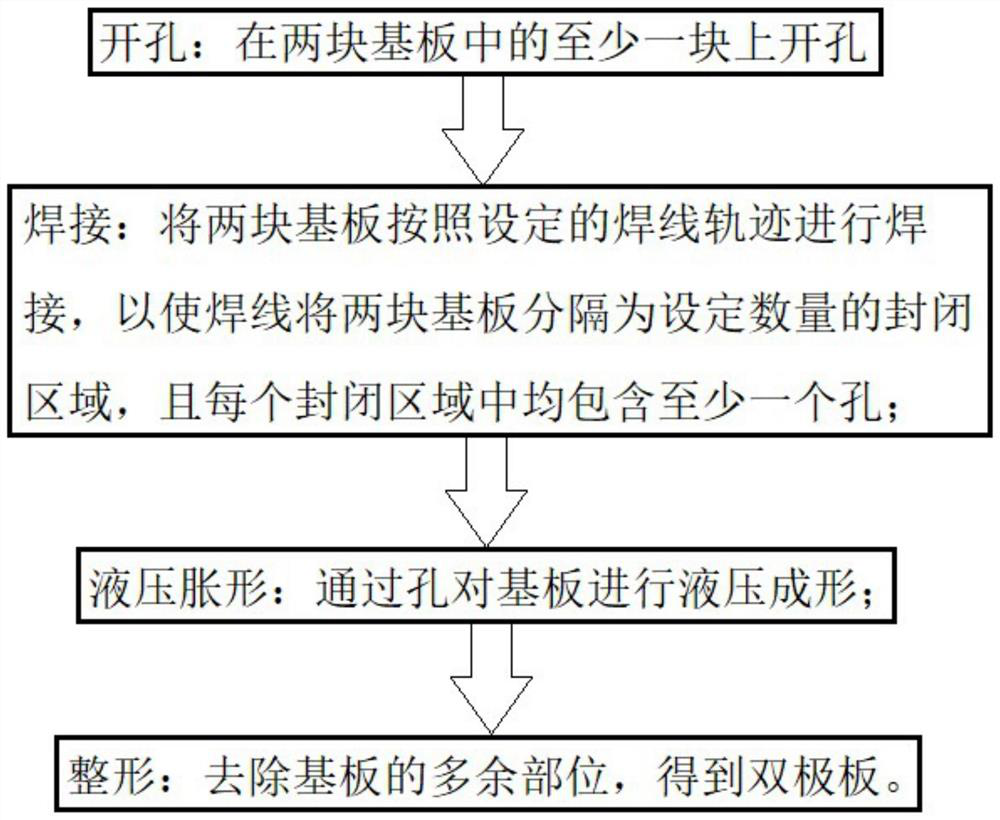

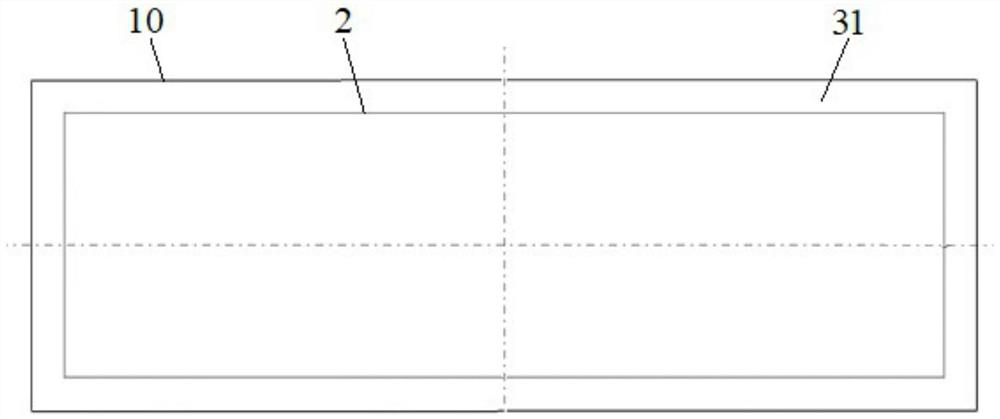

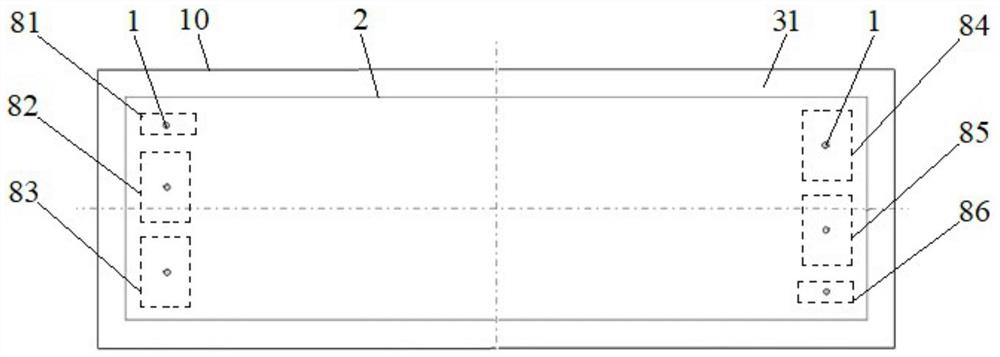

Fuel cell bipolar plate production method

ActiveCN114050288AHydraulic bulging step facilitatesNo deformationFinal product manufactureFuel cellsFuel cellsEngineering

The invention discloses a fuel cell bipolar plate production method, and solves the technical problems of high cost, long period and low bipolar plate forming precision of the existing production method. According to the fuel cell bipolar plate production method, firstly, holes are formed in substrates, and the holes serve as liquid injection holes in a subsequent hydraulic bulging step; the two substrates are welded into a whole according to a set welding track, the welding track completely coincides with a welding line in a bipolar plate, the two substrates are divided into a set number of closed areas by the welding line, and therefore a two-plate three-field structure is formed; and each closed area comprises at least one hole, so that the subsequent hydraulic bulging step can be conveniently carried out. By injecting liquid between the two substrates through the holes, and carrying out hydraulic forming, a flow channel on the bipolar plate and a structure at a fluid inlet and a fluid outlet. are formed. By removing redundant parts of the substrates after hydraulic forming, each fluid inlet / outlet is formed . The integrated forming method is adopted, the production cost is low, the production efficiency is high, and the bipolar plate forming precision is high.

Owner:DONGFENG MOTOR GRP

Rolling method for isotropic high-temperature nickel base alloy rectangular ring

The invention discloses a rolling method for an isotropic high-temperature nickel base alloy rectangular ring. The rolling method comprises the following steps: first, a high-temperature nickel base alloy bar is heated to a forging temperature, and after being upset, punched and pre-rolled, the heated high-temperature nickel base alloy bar is made into a rectangular ring blank; and then, the rectangular ring blank is loaded on a rolling mill, and cone rollers are lifted by h which is 5-10 mm, so that the rectangular ring blank inclines, and next, the inclining rectangular ring blank is rolled to obtain the high-temperature nickel base alloy rectangular ring. According to the rolling method, the mechanical properties of the rectangular ring are enabled to stay the same by changing the flowing direction of a material in rolling, so that the comprehensive mechanical properties of the rectangular ring is improved. The rolling method is used for producing isotropic high-temperature nickel base alloy rectangular rings.

Owner:GUIZHOU ANDA AVIATION FORGING

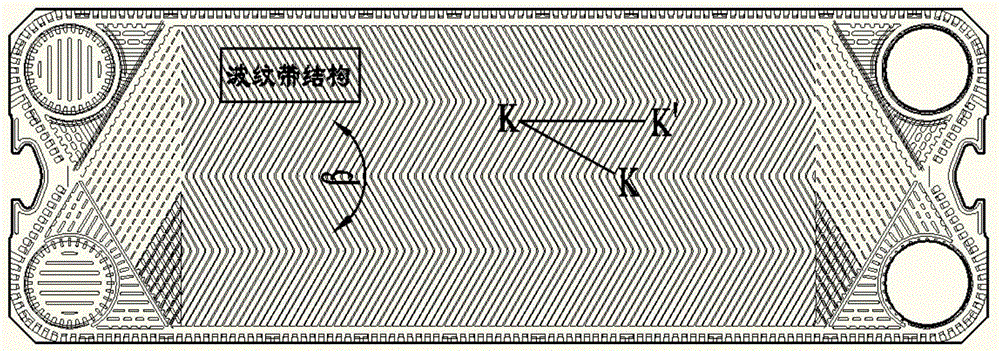

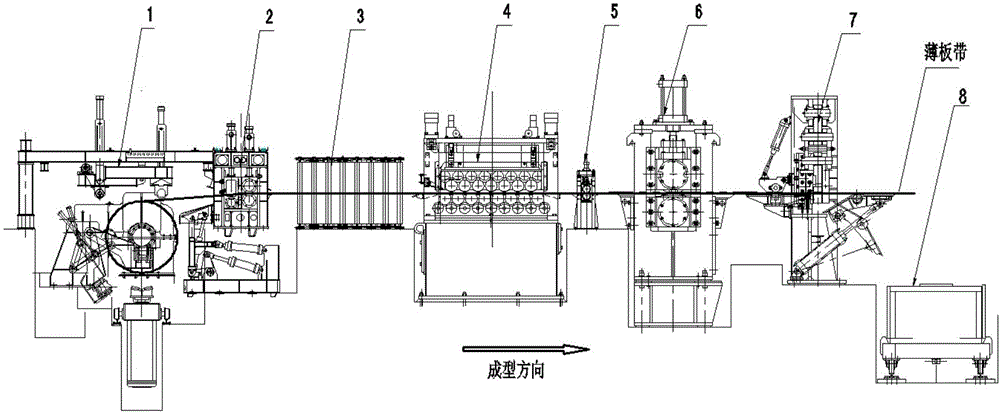

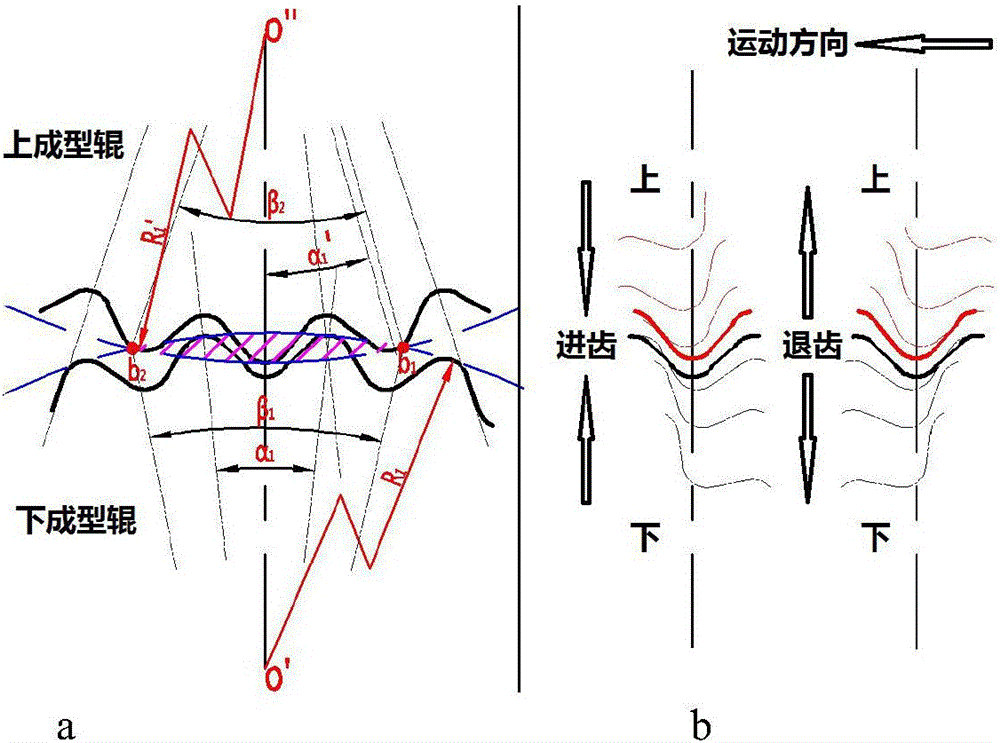

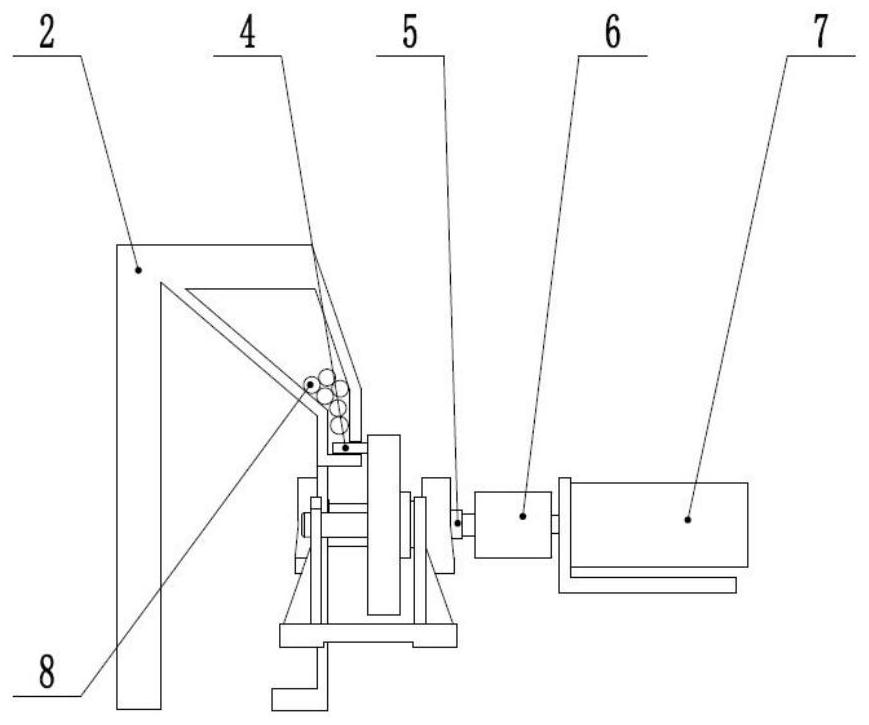

Continuous Roll Forming Method of Stainless Steel Corrugated Plate for Heat Exchanger

ActiveCN104399839BReduce plastic deformationReduce the bend angle γHeat exchange apparatusPlate heat exchangerSheet steel

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Isotropic rolling method for structural steel rectangular ring

The invention discloses an isotropic rolling method for a structural steel rectangular ring. The isotropic rolling method comprises the following steps: firstly, heating a structural steel bar till a forging temperature, and carrying out upsetting, piercing and pre-rolling to form a rectangular ring blank; secondly, loading the rectangular ring blank on a ring rolling mill, lifting a conical roller by h=5mm-10mm to tilt the rectangular ring blank, and then carrying out rolling forming to obtain the structural steel rectangular ring. Such a method is capable of keeping the mechanical properties of the rectangular ring consistent in all directions by changing a flowing direction of the material during rolling, thereby improving the comprehensive mechanical properties of the rectangular ring. The method is used for producing the isotropic structural steel rectangular rings.

Owner:GUIZHOU ANDA AVIATION FORGING

Circular pipe plastic connecting device

ActiveCN112571017AShorten the timeReduce deformation speedMetal working apparatusElectric machineGear wheel

The invention discloses a circular pipe plastic connecting device. The device comprises a feeding mechanism, a fixed clamping mechanism and a circumferential loading mechanism, through a motor and a chain wheel, rotating motion of the motor is converted into linear feeding motion of the chain wheel, so that a pipe is placed at a preset position, and a pressing block is further driven by an air cylinder to circumferentially clamp the pipe; under the driving of the motor, the movement of three groups of opposite rolling devices is controlled by utilizing accurate transmission among gears, the movement is synchronous, and repeated and cyclic loading is carried out for multiple times; and due to the design of a special fixture for the pipe and the adoption of a rolling type local progressive loading manner, the excellent performance and the production efficiency of a product are greatly improved.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com