Preparation method of metal bipolar plate of proton exchange membrane fuel cell

A metal bipolar plate and proton exchange membrane technology, applied in fuel cell parts, fuel cells, circuits, etc., can solve the problems of flow channel structure damage, lower product qualification rate, low forming efficiency, etc., to achieve consistent pressure, Solve the effect of easy damage to the mold and uniform pressure transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing a metal bipolar plate of a proton exchange membrane fuel cell, comprising the following steps:

[0033] (1) Depositing a corrosion-resistant coating on the surface of the metal sheet to obtain a corrosion-resistant metal sheet;

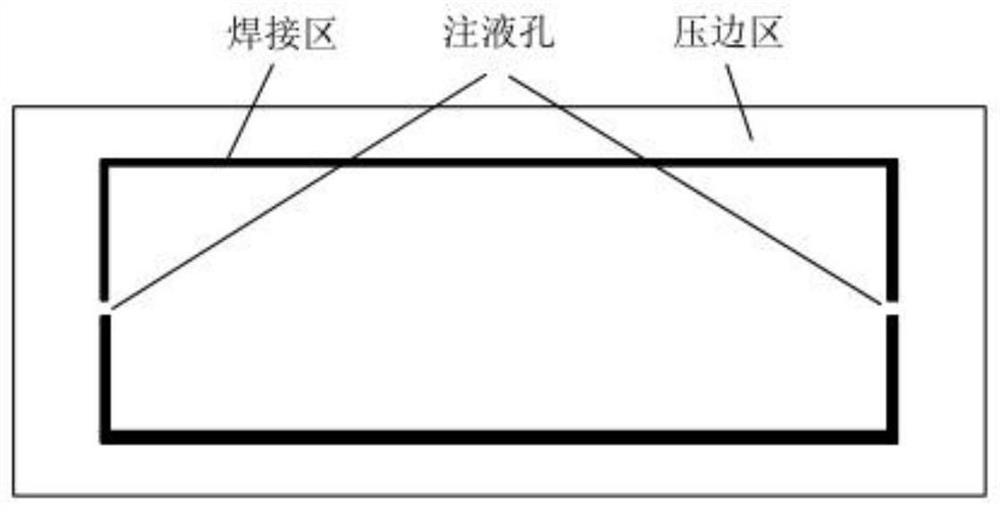

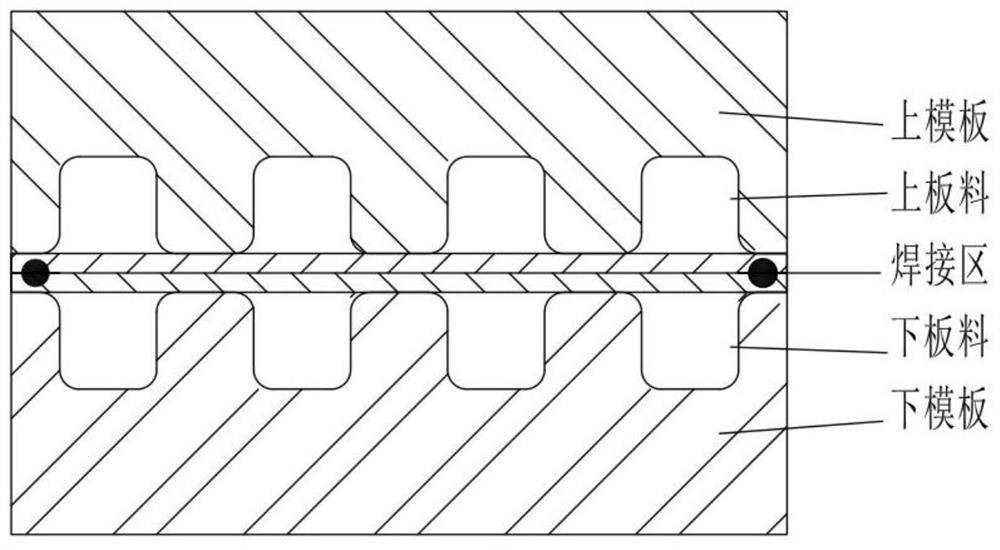

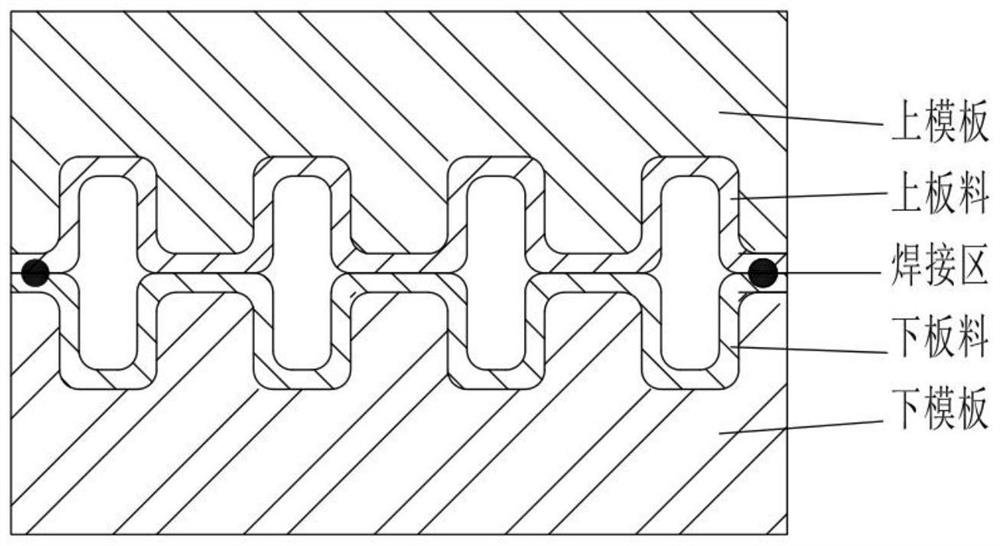

[0034] (2) Two corrosion-resistant metal sheets are superimposed and welded around, and an unwelded area is left on both sides during welding, and the unwelded area is used as a liquid injection hole during hydroforming;

[0035] (3) Place the double-layer metal plate obtained in step (2) in the mold of the hydraulic device, inject high-pressure liquid between the two-layer metal plates through the liquid injection hole, so that the upper and lower plates of the double-layer metal plate form flow channels at the same time structure to obtain a proton exchange membrane fuel cell metal bipolar plate; the proton exchange membrane fuel cell metal bipolar plate includes a cathode plate and an anode plate...

Embodiment 1

[0048] Select a 304 stainless steel sheet with a thickness of 0.1 mm to remove oxides and organic matter on the surface of the substrate. After drying, place it in a vacuum chamber, and then pump the air pressure of the chamber to 2×10 -3 Below Pa.

[0049] A layer of silicon-containing amorphous carbon film (a-C:Si) was prepared on the surface of 304 stainless steel sheet by plasma enhanced chemical vapor deposition (PECVD). 4 As the reaction source gas, SiH 4 The flow rate is 8mL / min, and a layer of silicon-containing amorphous carbon film (a-C:Si) is prepared on the surface of 304 stainless steel sheet; the stainless steel sheet deposited with silicon-containing amorphous carbon film is processed into multiple 550×220mm size sheet.

[0050] The two layers of processed stainless steel sheets are overlapped and placed on the welding fixture, and the sheets are clamped on both sides during the welding process. The YLR SM-200 fiber laser is selected to output single-mode las...

Embodiment 2

[0054] Select a 316L stainless steel sheet with a thickness of 0.1mm to remove oxides and organic matter on the surface of the substrate. After drying, place it in a vacuum chamber, and then pump the air pressure of the chamber to 2×10 -3 Below Pa.

[0055] A layer of silicon-containing amorphous carbon film (a-C:Si) was prepared on the surface of 316L stainless steel sheet by plasma enhanced chemical vapor deposition (PECVD). 4 As the reaction source gas, SiH 4 The flow rate is 8mL / min, and a layer of silicon-containing amorphous carbon film (a-C:Si) is prepared on the surface of 316L stainless steel sheet; the stainless steel sheet deposited with silicon-containing amorphous carbon film is processed into multiple 550×220mm size sheet.

[0056] The two layers of processed stainless steel sheets are overlapped and placed on the welding fixture, and the sheets are clamped on both sides during the welding process. The YLR SM-200 fiber laser is selected to output single-mode l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com