Metal part additive manufacturing method and corresponding equipment

A technology of additive manufacturing and metal parts, which is applied in the field of direct manufacturing of metal parts based on additive manufacturing technology, which can solve the problems of poor tensile strength of metal parts, low material utilization rate, and low strength of parts, so as to ensure dimensional control High precision, simple and practical structure, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

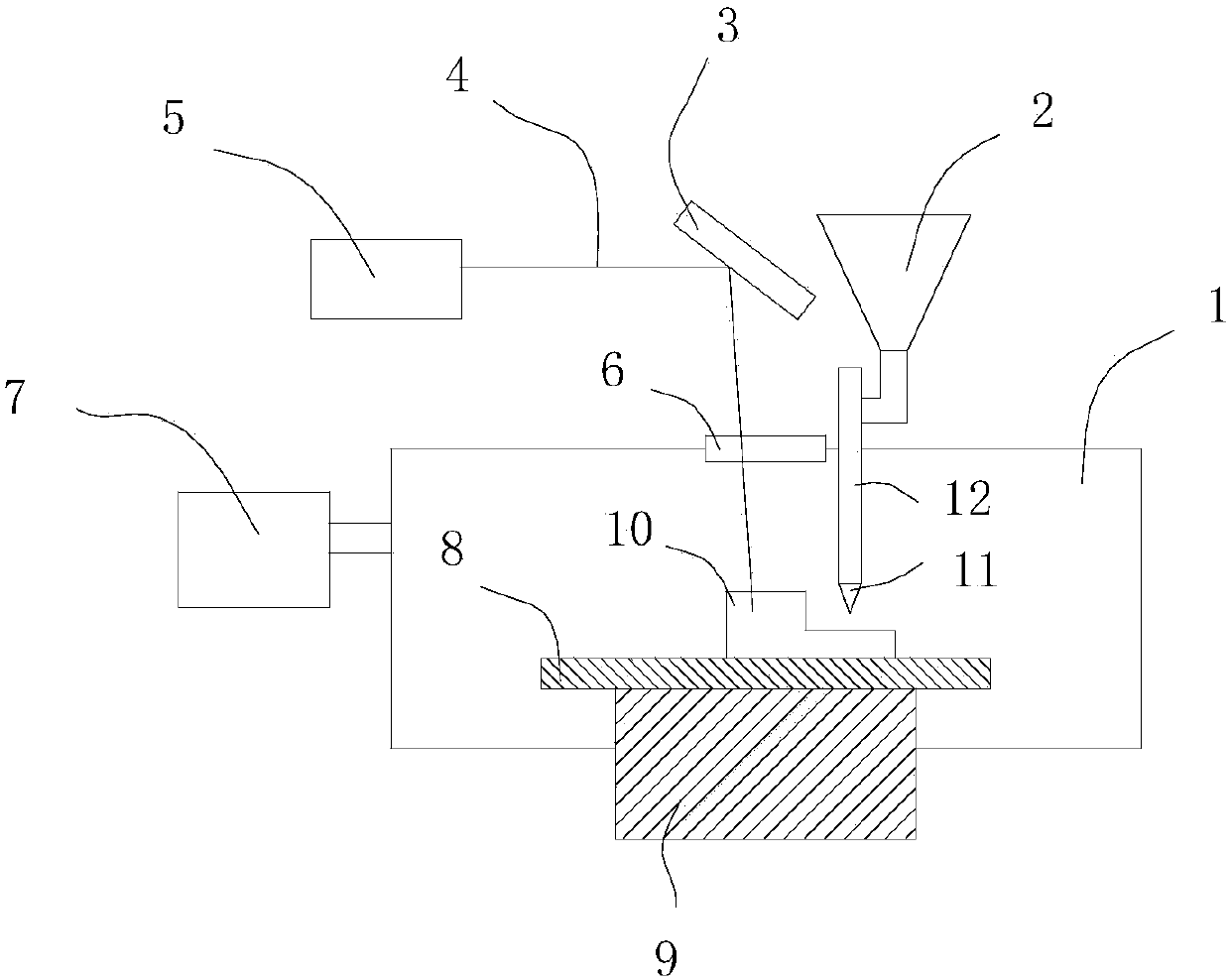

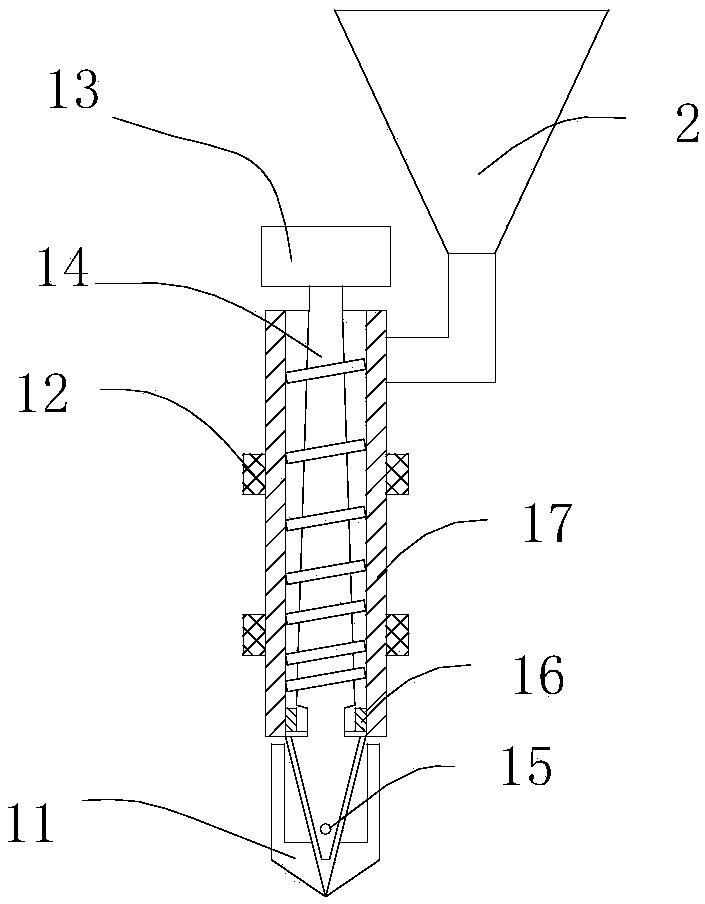

[0026] refer to figure 1, is an additive manufacturing device for metal parts, including a 3D printer with a molding cavity system, a workbench system and a control system, and a feeding system and a laser heating system respectively connected to the control system, wherein the workbench system includes The horizontal platform 8 of the forming part 10 and the lifting mechanism 9 that controls the movement of the horizontal platform 8 up and down, the feeding system includes a feeding funnel 2, a nozzle 11 arranged in the molding cavity 1, and a feeding heating device 12 arranged on the nozzle 11 , the laser heating system includes a laser 5 arranged outside the molding cavity system, and a scanning system 3 for reflecting the laser beam 4 generated by the laser 5 onto the molding part 10 . The molding cavity 1 of the 3D printer is provided with a vacuum-filled protective gas device 7, which can provide a relatively closed environment for 3D printing and sintering. In order to...

Embodiment 2

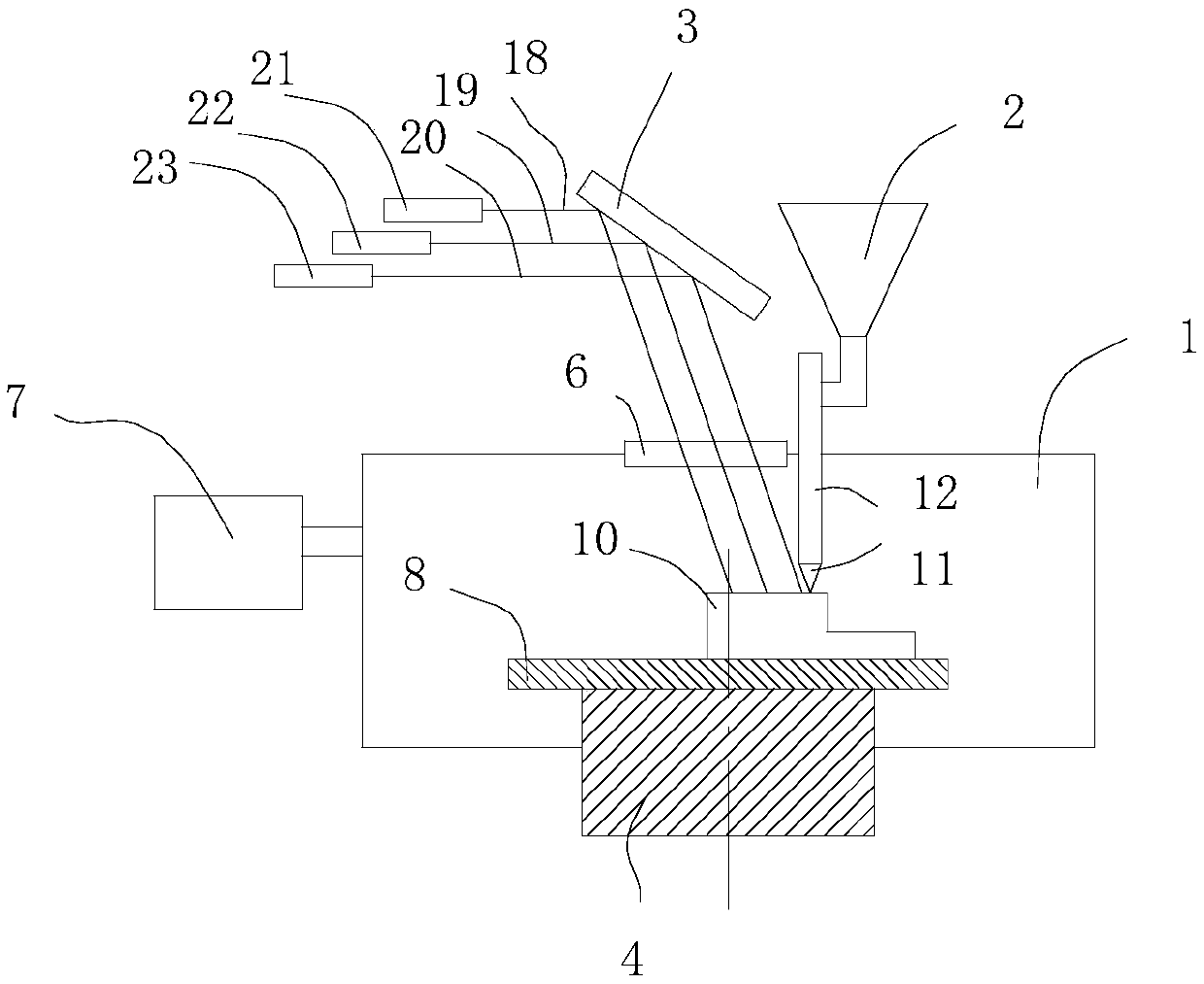

[0035] refer to image 3 , is another metal parts additive manufacturing device, including a 3D printer with a molding cavity system, a workbench system and a control system, and a feeding system and a laser heating system respectively connected to the control system, wherein the workbench system includes The horizontal platform 8 for accommodating the molding parts 10 and the lifting mechanism 9 for controlling the movement of the horizontal platform 8 up and down, the feeding system includes the feeding funnel 2, the nozzle 11 arranged in the molding cavity 1, and the feeding heating device arranged on the nozzle 11 12. The laser heating system includes a preheating laser 21, a degreasing laser 22, and a sintering laser 23 arranged outside the molding cavity system, and a preheating laser beam 18 generated by the preheating laser 21, degreasing laser 22, and sintering laser 23, The degreasing laser beam 19 and the sintering laser beam 20 are respectively reflected to the sca...

Embodiment 3

[0043] refer to Figure 4 , an additive manufacturing device for metal parts, including a 3D printer with a molding cavity system, a workbench system and a control system, and a feeding system and a gas heating system respectively connected to the control system, wherein the workbench system includes a container The horizontal platform 8 of the molding part 10 and the lifting mechanism 9 that controls the movement of the horizontal platform 8 up and down, the feeding system includes a feeding funnel 2, a nozzle 11 arranged in the molding cavity 1, a feeding heating device 12 arranged on the nozzle 11, The gas heating system includes a gas heat source 24 arranged outside the molding cavity system, a gas passage 27 extending into the molding chamber 1 , and a shroud 28 arranged above the molding part 10 and communicating with the gas passage 27 . In order to facilitate the gas channel 27 to enter the molding cavity 1 , a furnace cavity protection device 25 is provided on the mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com