Centrifugal casting duplex-metal composite ring part hot extend-rolling forming technology

A centrifugal casting and forming process technology, applied in metal rolling and other directions, can solve the problems of poor contact surface quality, large equipment investment, material waste, etc., and achieve the effect of good surface quality, accurate external dimensions, and shortened process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

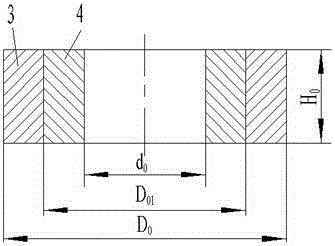

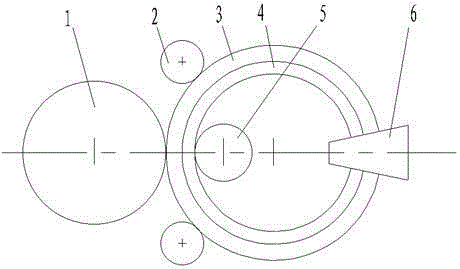

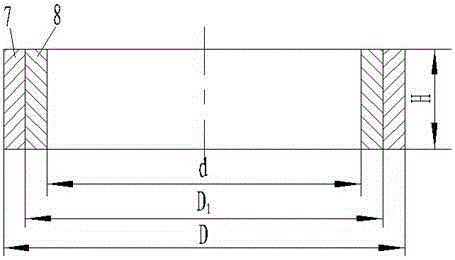

[0016] Such as Figure 1~Figure 3 As shown, a kind of centrifugal casting bimetallic composite ring hot rolling and expanding forming process described in the present invention is carried out on a radial axial ring rolling machine. The outer layer material of the bimetallic composite ring blank is 40Cr steel, and the inner layer material is It is Q345B steel; the outer diameter of the ring billet is D 0 =1500mm, ring blank inner diameter d 0 =1295mm, ring blank height H 0 =92.5mm, the diameter of the joint surface of the inner and outer layers D 01 =1450mm; the size of the bimetallic composite ring after hot rolling and expanding is: the outer diameter of the ring D=1855mm, the inner diameter of the ring d=1708mm, the height of the ring H=92mm, the diameter of the joint surface of the inner and outer layers D 1 =1815mm; The process steps of hot rolling and expanding are:

[0017] (1) if figure 1 As shown, the bimetal composite ring billet obtained by the centrifugal casti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com