Automobile door internal plate understructure

A technology for automobile doors and door openings, which is applied to the sealing of vehicle components, doors, and engines, etc. It can solve problems affecting strength and appearance, easy to slide down, and ripples, etc., to improve appearance quality, ensure sealing effect, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

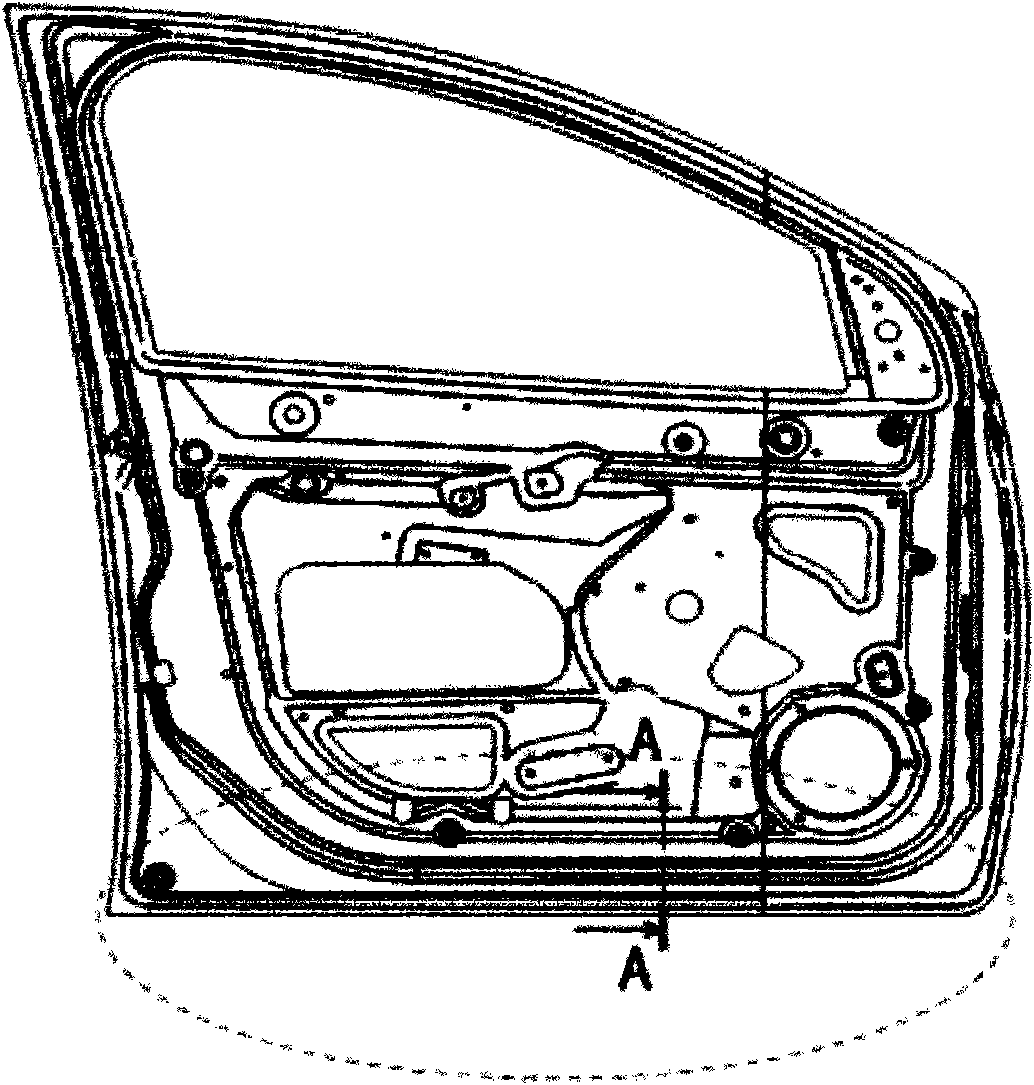

[0031] Combine below Figure 6 , the present invention is further described:

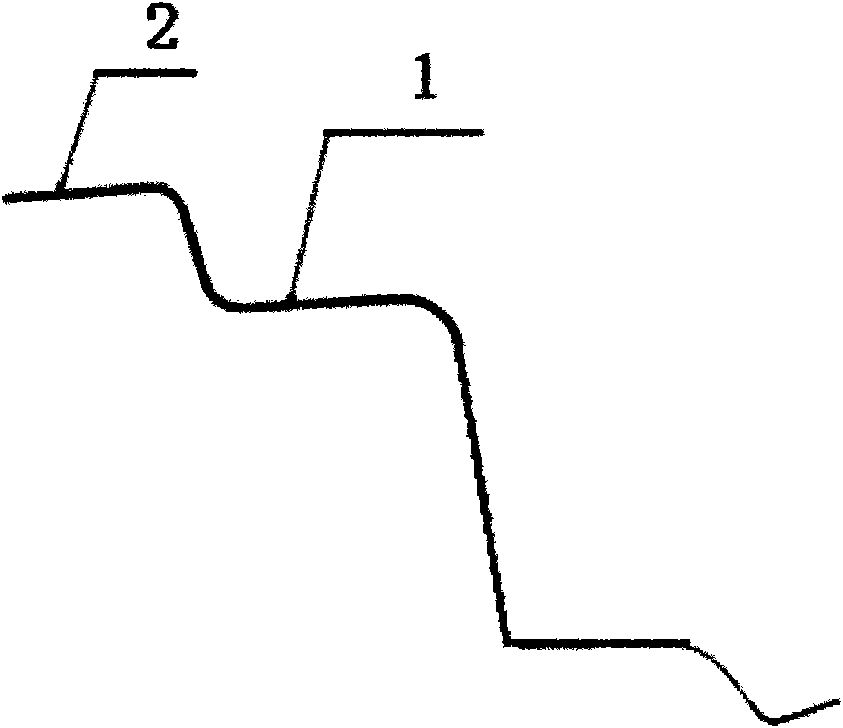

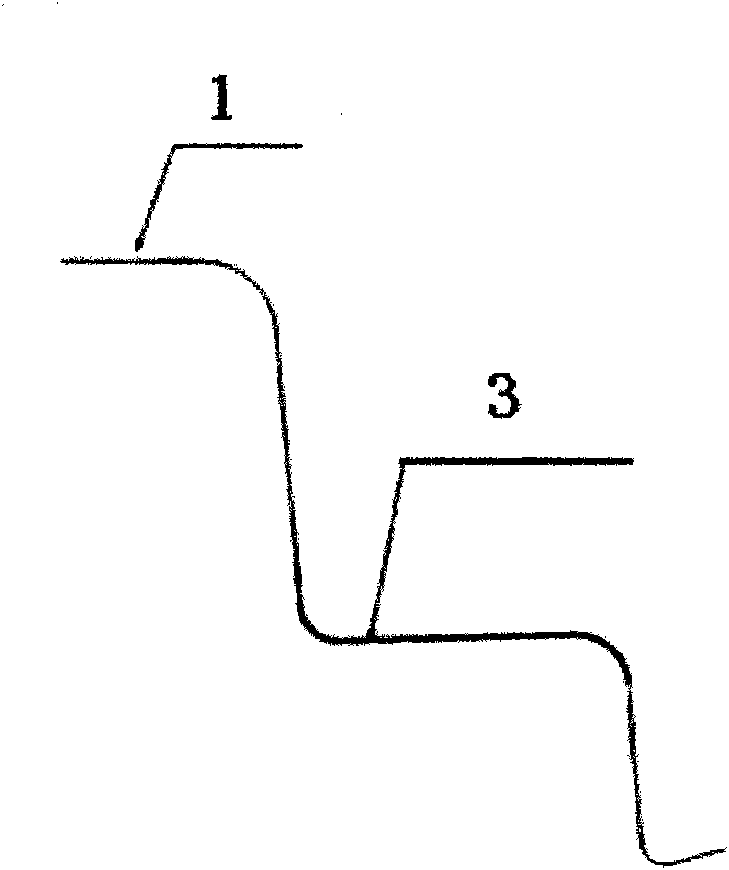

[0032] A lower structure of an inner panel of an automobile door, comprising a door opening sealing area 1, a side wall sealing area 3 and an edge-wrapping flange area 4, and a step 2 is added between the side wall sealing area 3 and the edge-wrapping flange area 4, and the step 2 A draining hole 5 is set through the root of the upper and lower rounded corners, and the draining hole 5 is completed by positive punching.

[0033] The condition for setting the step 2 is: when the width of the side sealing area 3 exceeds 20 mm, and the depth between the side sealing area 3 and the flange area 4 exceeds 15 mm, the drain hole 6 at the lower part of the door inner panel adopts side Punching is completed, which increases the cost of the mold. Therefore, this step 2 needs to be provided. In addition, in order to meet the draining effect of the painting process, the distance between the door inner panel an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com