Patents

Literature

50results about How to "Change flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

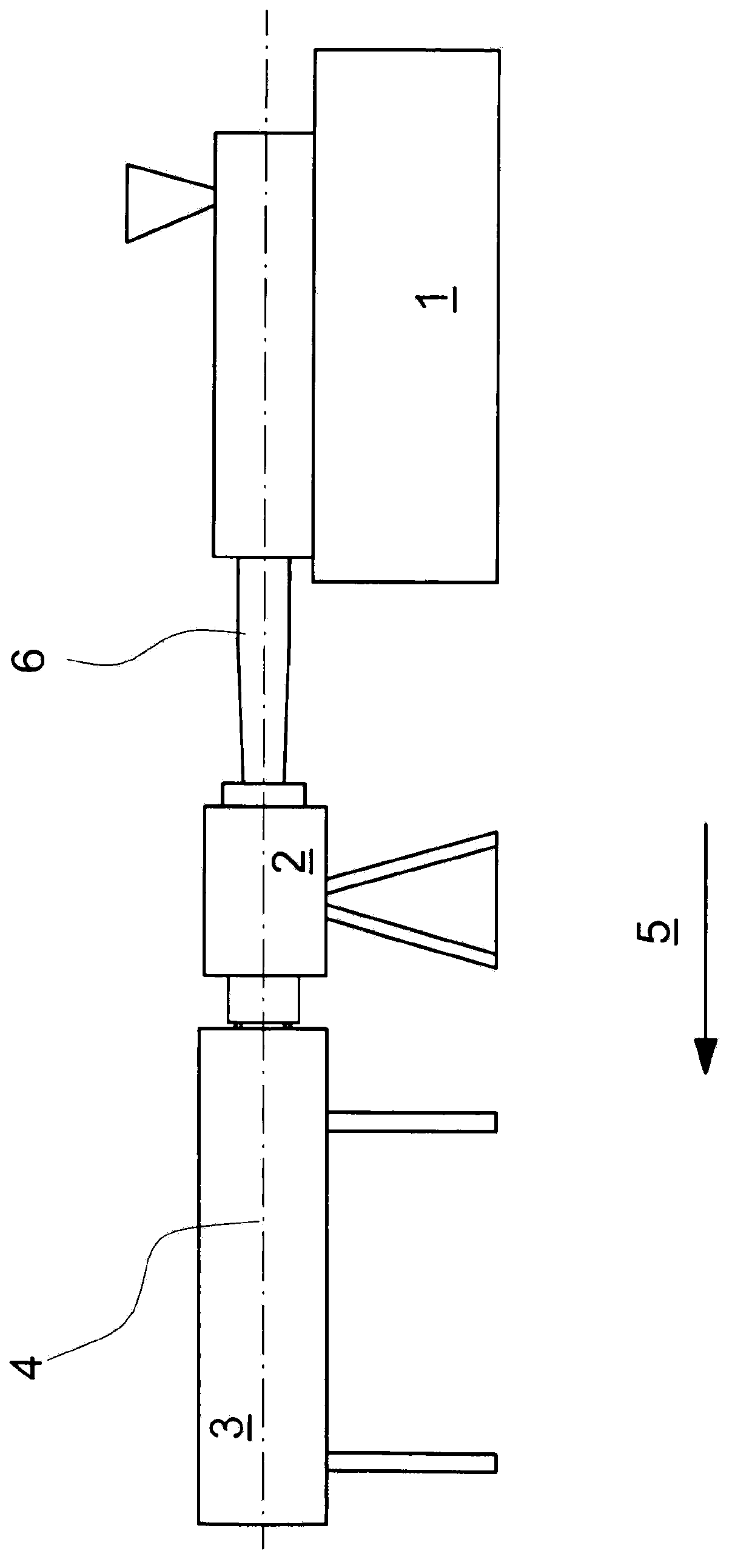

Compressed-air energy-storage system

ActiveCN102213113AIncrease flexibilityChange flowFrom solar energyWind energy with garvitational potential energyPower stationFour-way valve

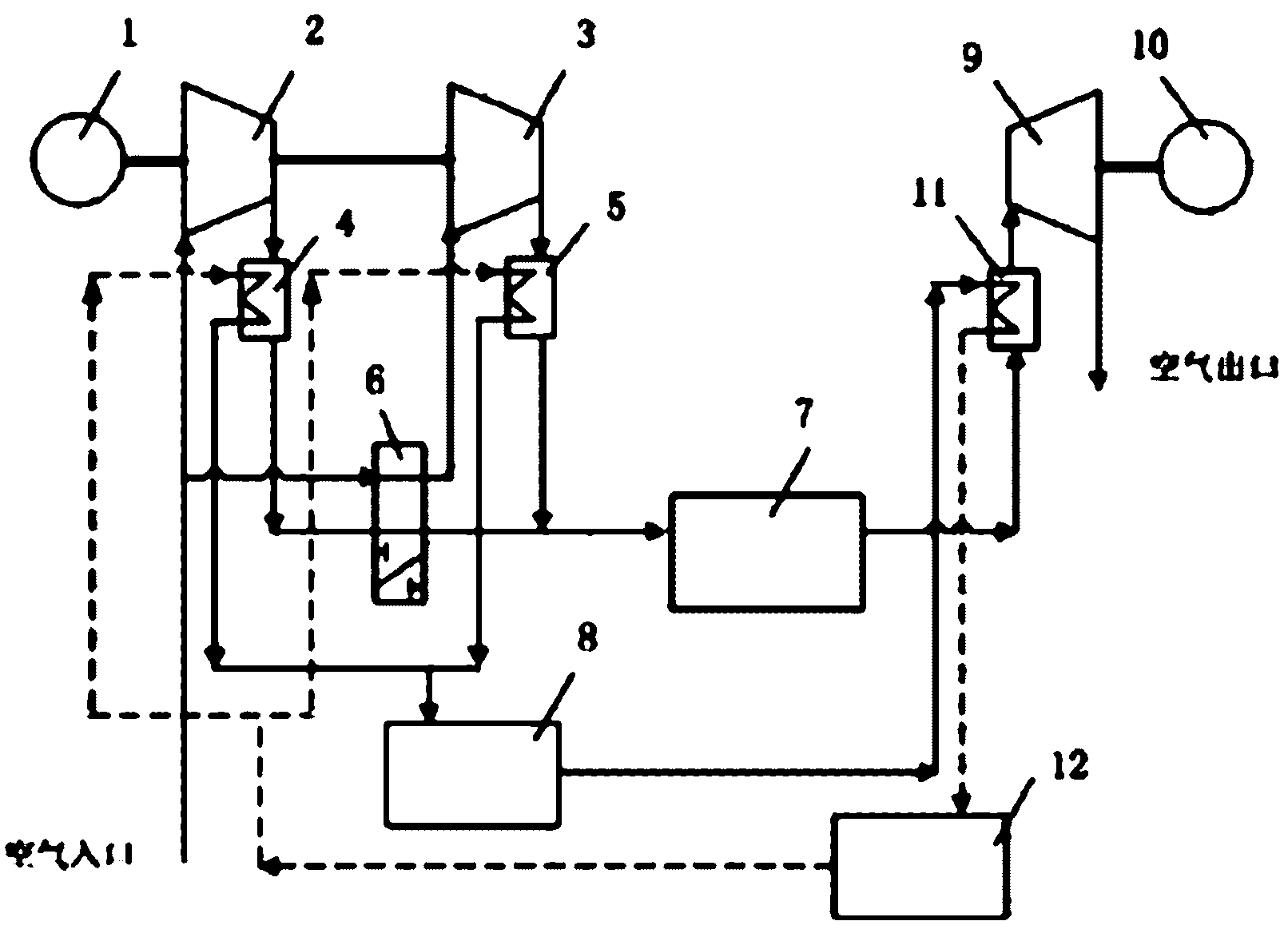

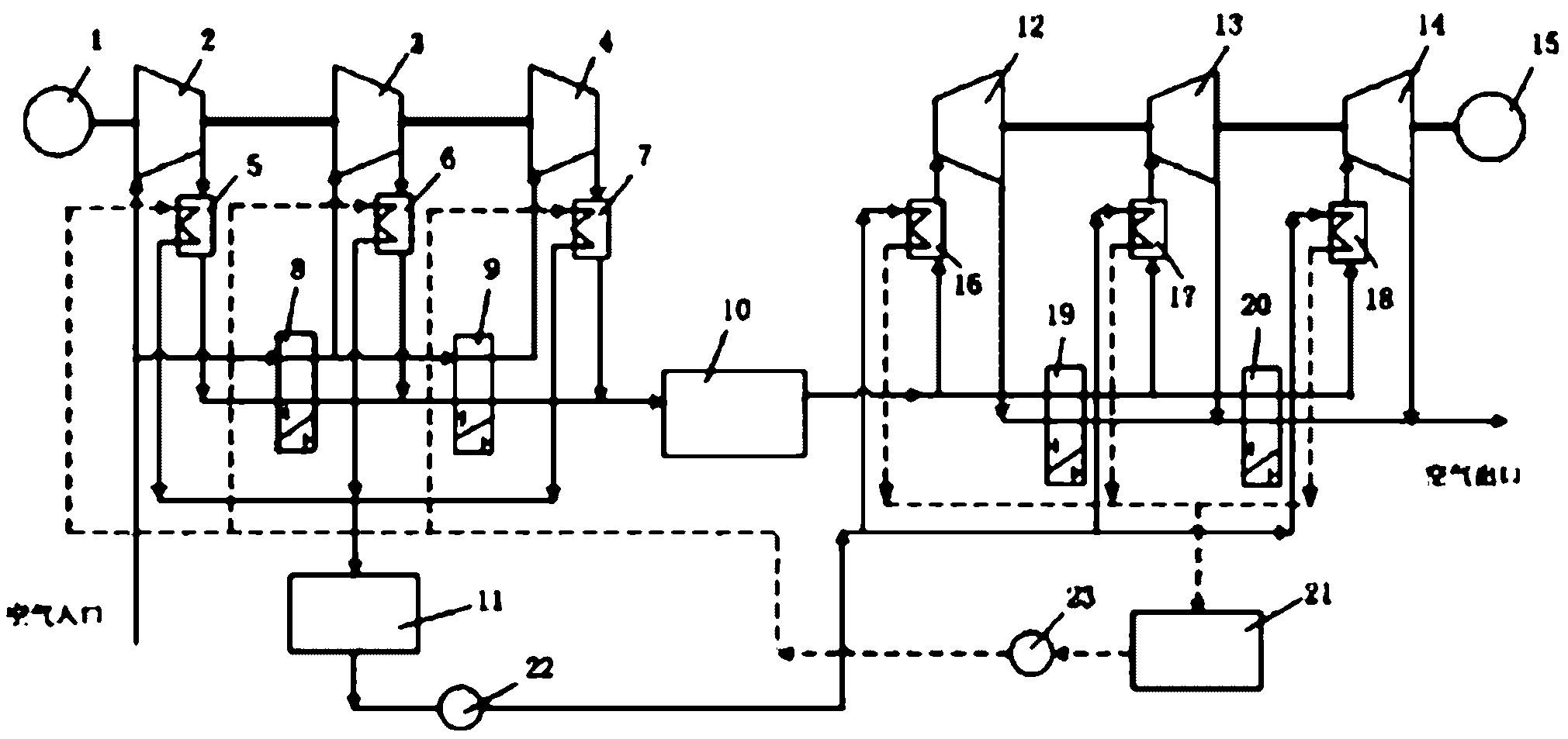

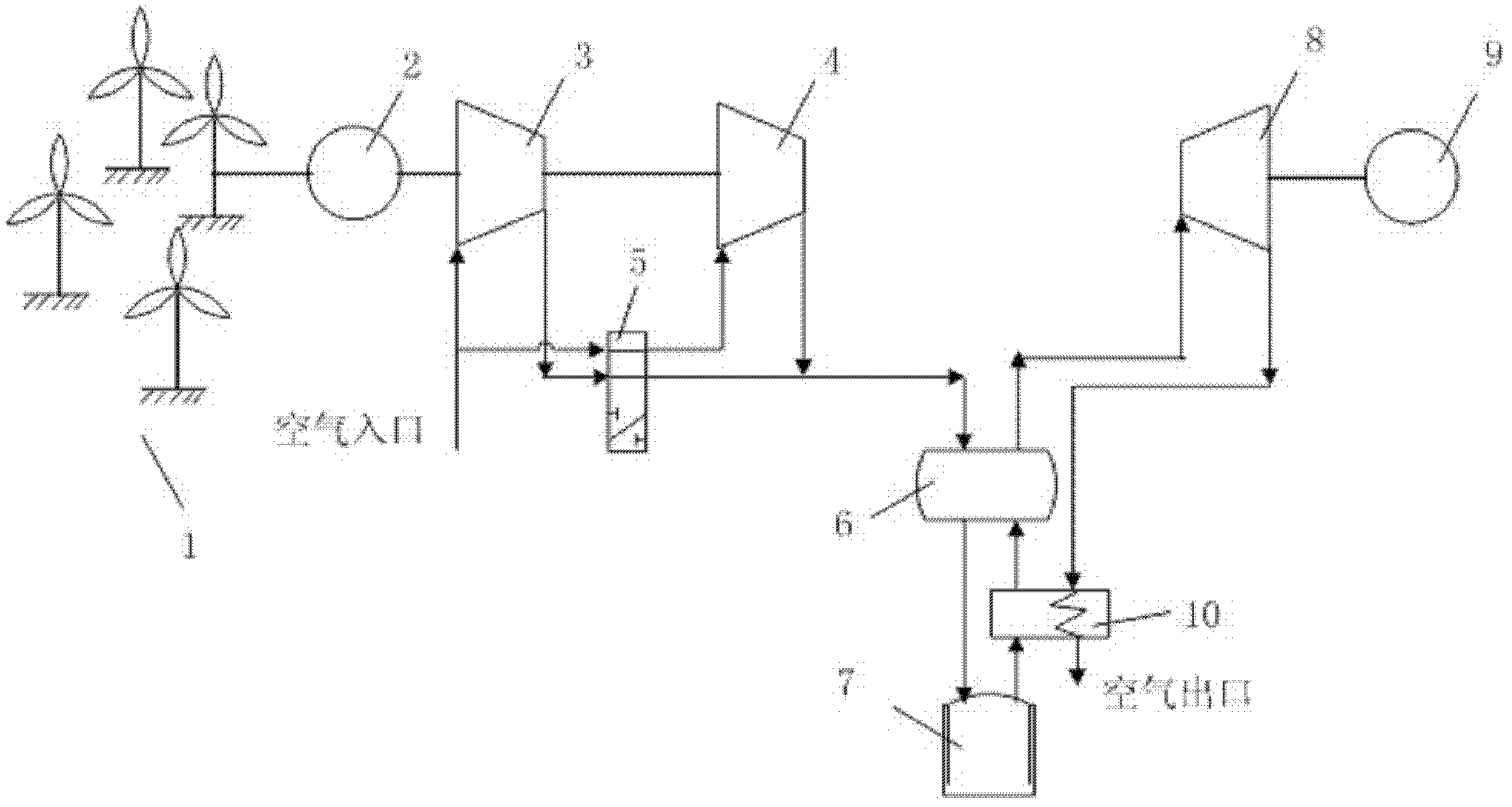

The invention relates to a compressed-air energy-storage system. A three-position four-way valve is arranged in a pipeline of a compression part and an expansion part of the system and the flowing condition of air in the system is changed by utilizing the feature of change of a turn-on state of the three-position four-way valve, thus the variation of the manners of serial-connection and parallel-connection between a gas compressor and a turbine is realized, and the overall working efficiency is increased. With the adoption of the three-position four-way valve, on one hand, the overall flexibility of the compressed-air energy-storage system is improved, so that the operating of the system is more targeted, and the use of the compressed-air energy-storage system matched with various types of power stations is facilitated; and on the other hand, the service condition of turbomachinery is improved, and the optimized configuration of the turbomachinery according to the needs of energy storage and power generation can be realized.

Owner:中科国风科技有限公司

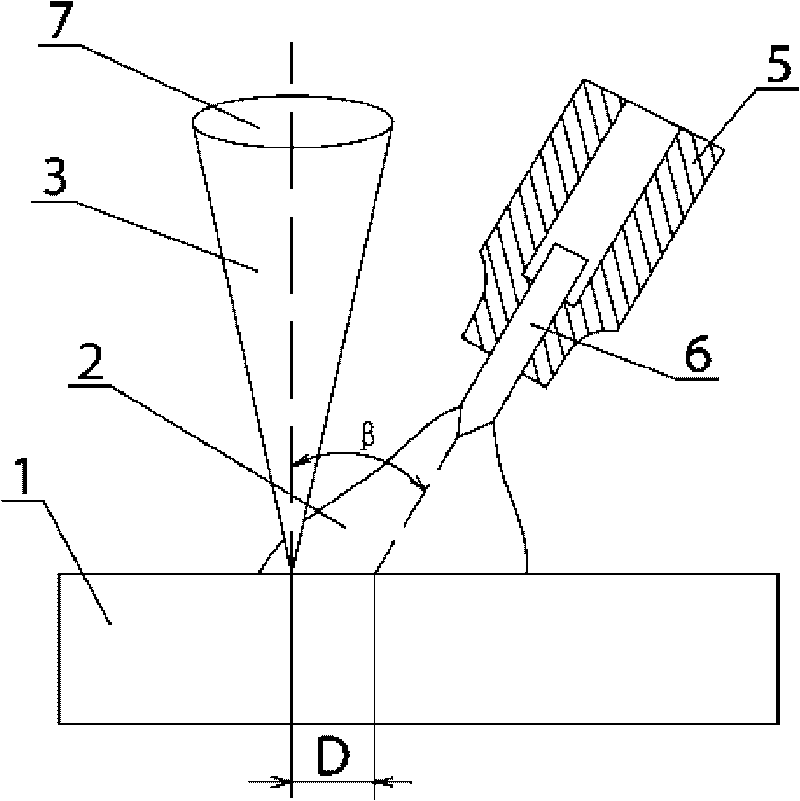

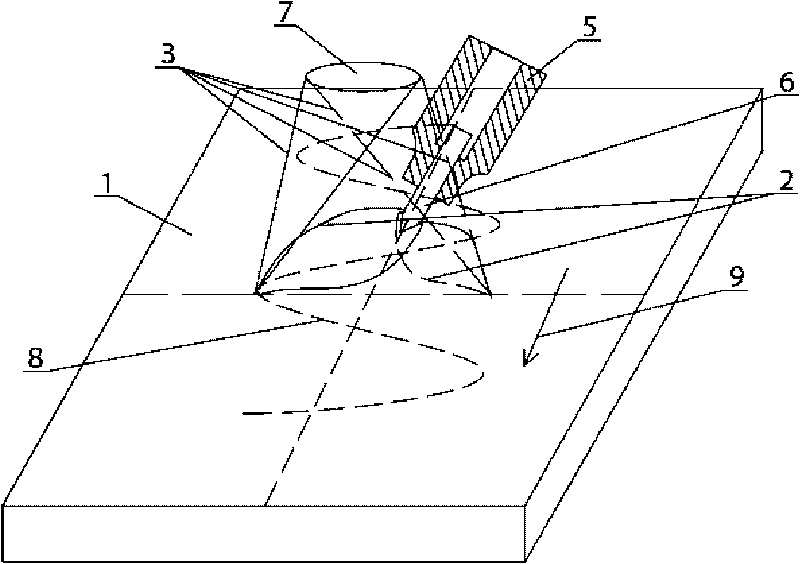

Method for realizing swing welding with laser-GMA electric arc hybrid welding device

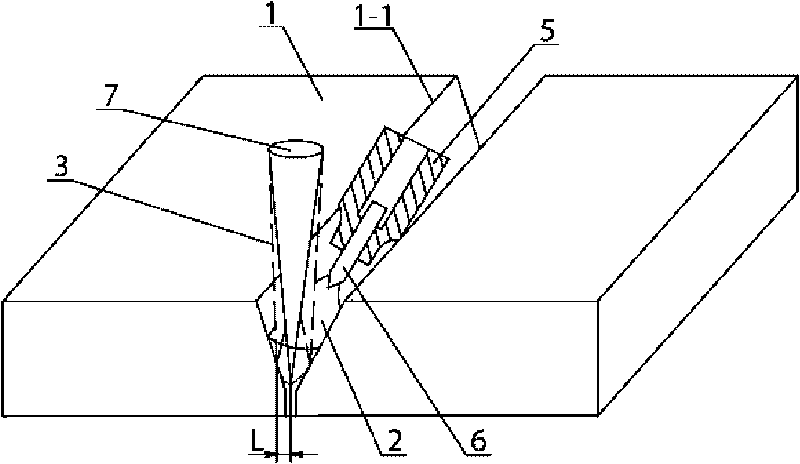

The invention discloses a method for realizing swing welding with a laser-GMA electric arc hybrid welding device, relating to a laser-melting electrode gas metal arc welding hybrid welding method. The method solves the problem that the defects such as incomplete fusion, gas hole and included slag, and the like, are easily existed between a side wall and a layer when welding a moderate plate and a thick plate with the laser-GMA electric arc hybrid welding device. The method comprises the following steps of: 1. chamfering; 2. clamping a work piece to be welded; 3. ensuring the positions of an electric arc and a laser beam, wherein the laser beam is perpendicularly irradiated to the surface of the work piece to be welded, an included angle between the electric arc and the laser beam is 15-60 DEG C, and the distance between the laser beam and the sharp end of a GMA electric arc welding wire is 2-6mm; 4. setting a welding technology parameter; and 5. performing the welding, wherein an electric arc welding gun is kept to be immovable when welding, and a laser beam-focused wielding gun swinging welds in the shape of 'S'. The method is used for butt welding of a thick plate more than 10mm in national defense and civil use fields of shipbuilding, petroleum pipe lines, high-pressure vessels, fighting vehicles and nuclear devices, etc.

Owner:HARBIN INST OF TECH

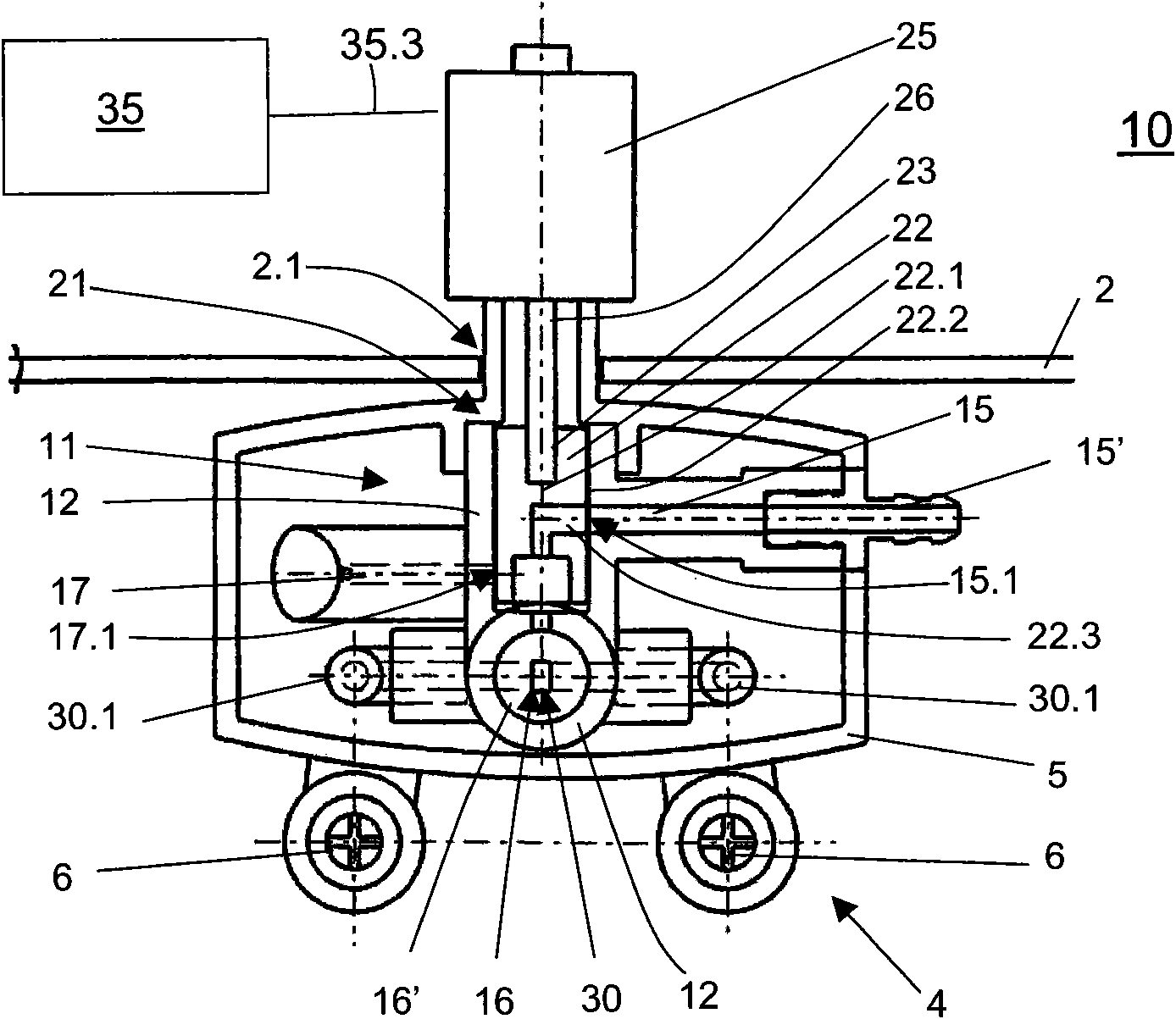

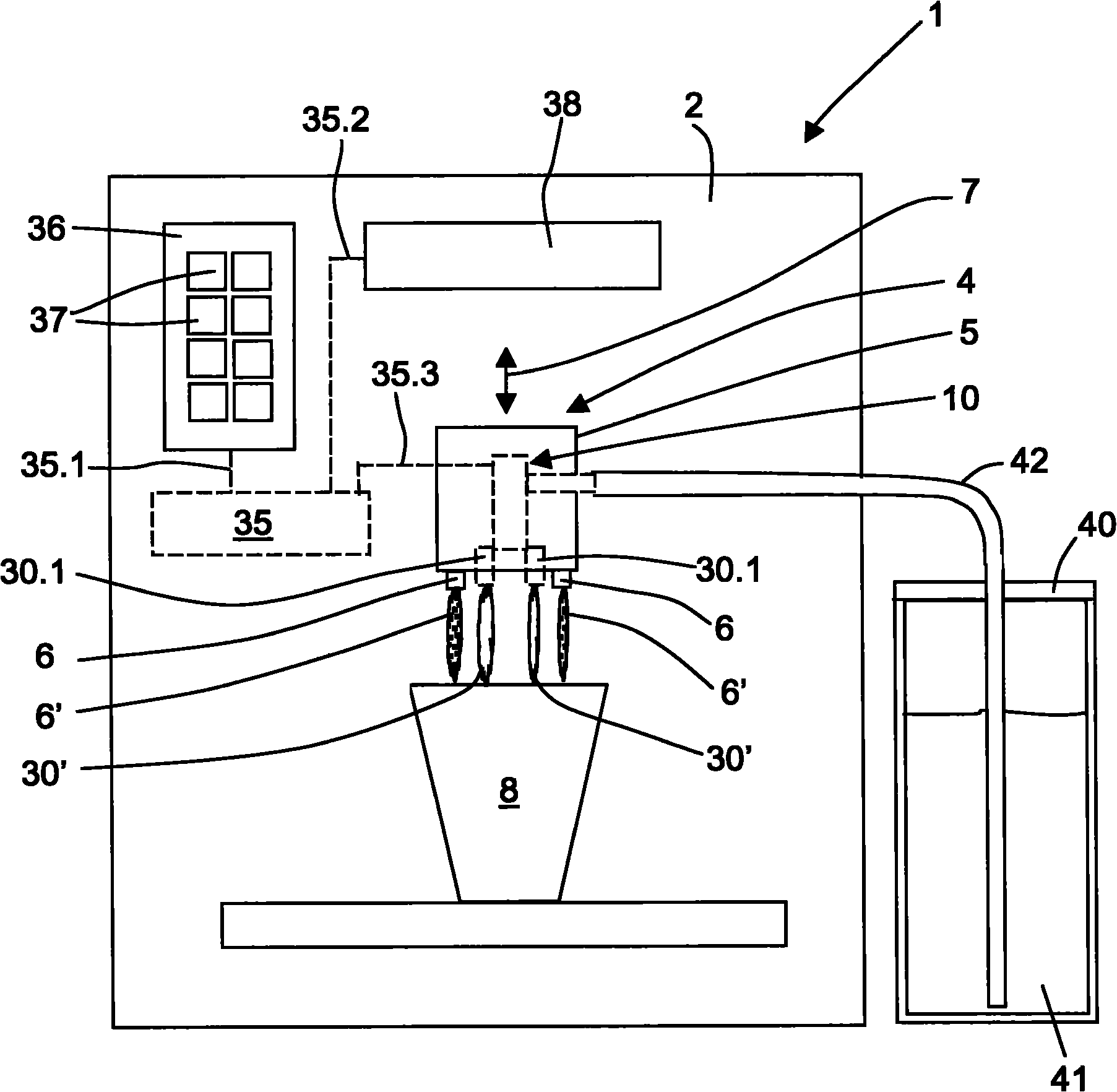

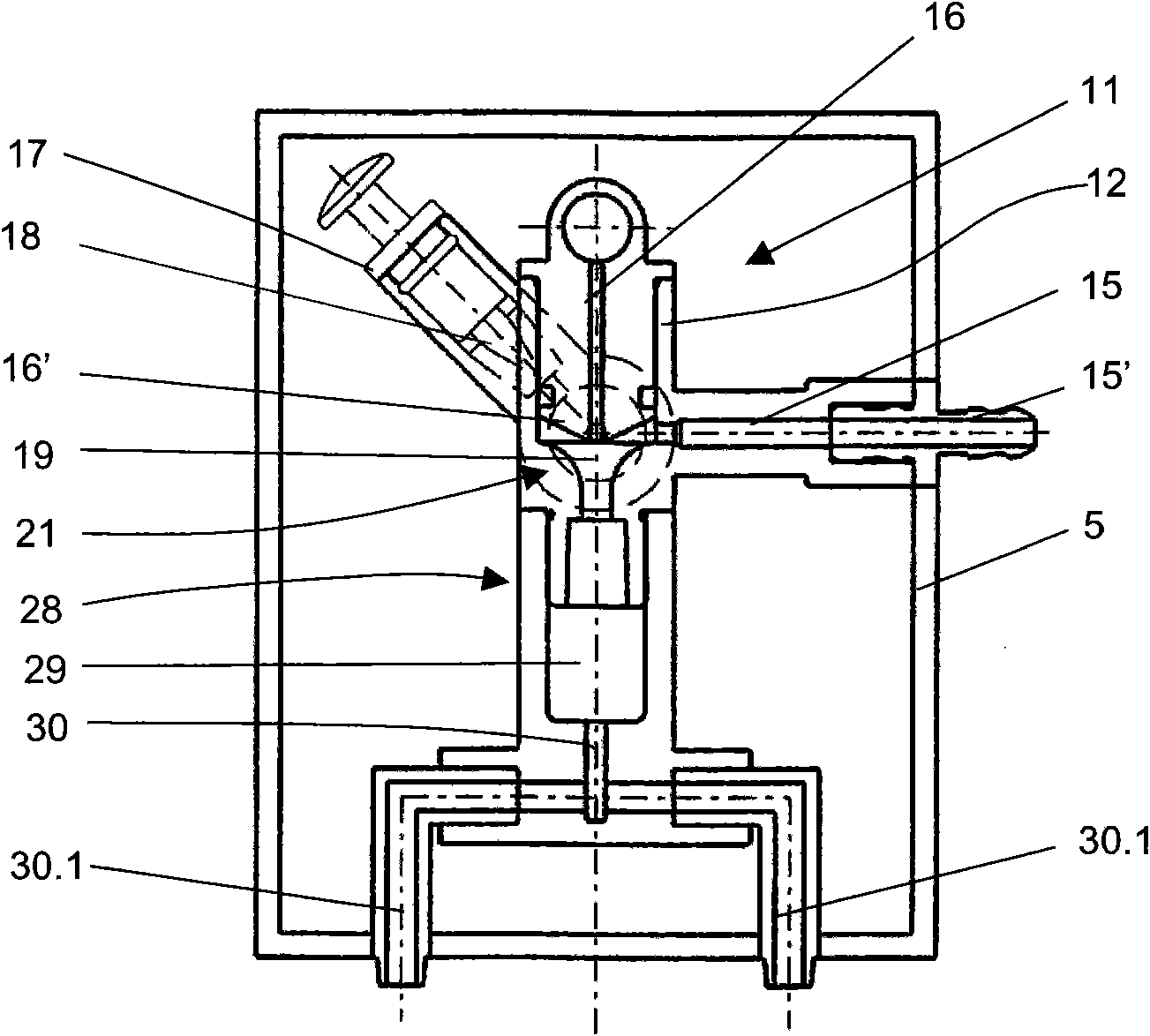

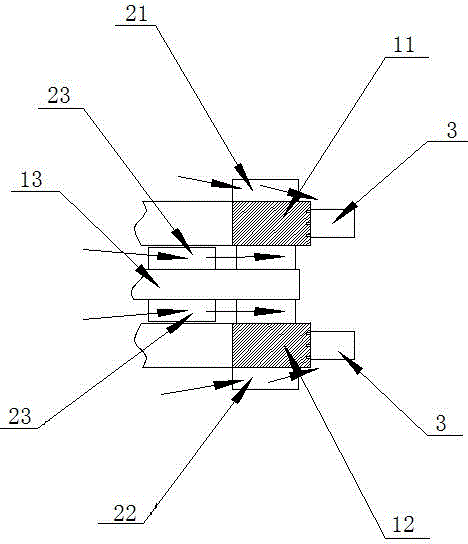

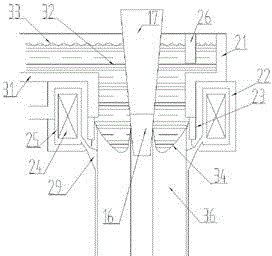

Dispensing device for milk and/or foam and a coffee machine comprising such a dispensing device

A dispensing device for milk and / or milk foam is provided that includes a mixing device for mixing steam, milk and / or air. A mixing device may include a chamber, a first line for the supply of milk into the chamber, a second line for a supply of steam into the chamber, a third line for the supply of air into the chamber, at least one outlet for dispensing the milk and / or the milk foam from the chamber, a valve including an adjustable regulating shaft for regulating the supply of milk and / or air into the chamber. By adjusting the regulating shaft between different predetermined positions at least one flow of milk may be switched on and switched off and / or altered and a flow of air may be switched on and switched off and / or altered. A dispensing device may further include a drive motor for adjusting the regulating shaft of the valve and a control device for controlling the drive motor. The regulating shaft may be movable by controlling the drive motor by means of the control device intorespective predetermined positions.

Owner:JURA ELEKTROAPPARATE AG

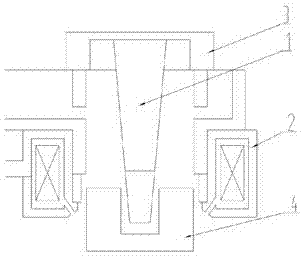

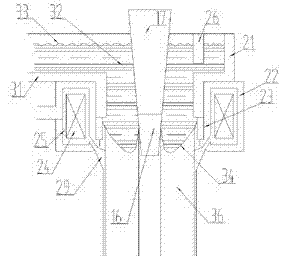

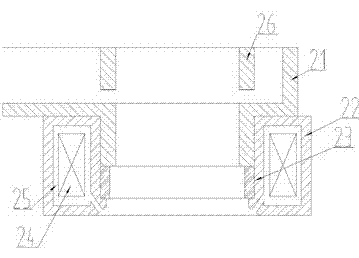

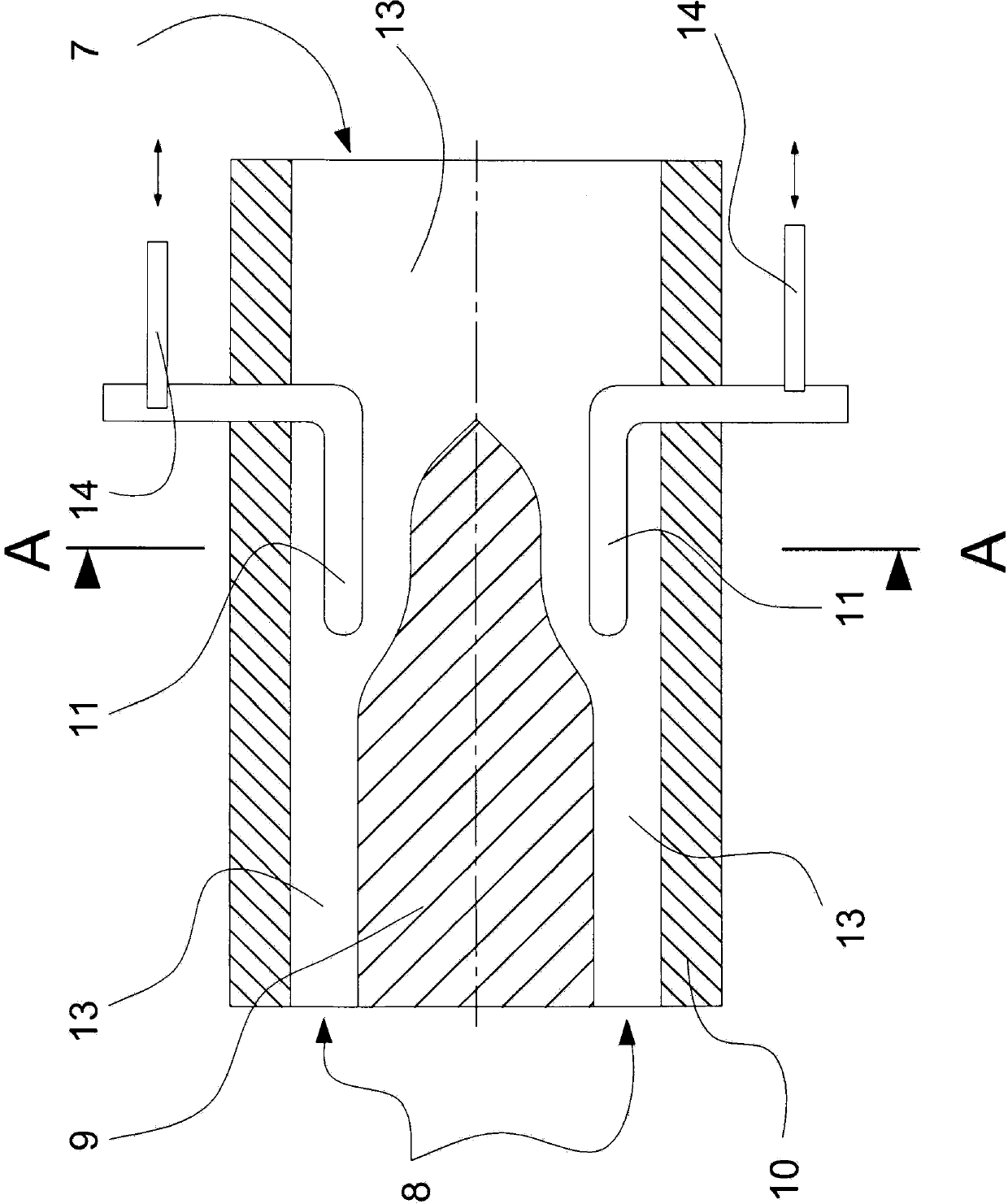

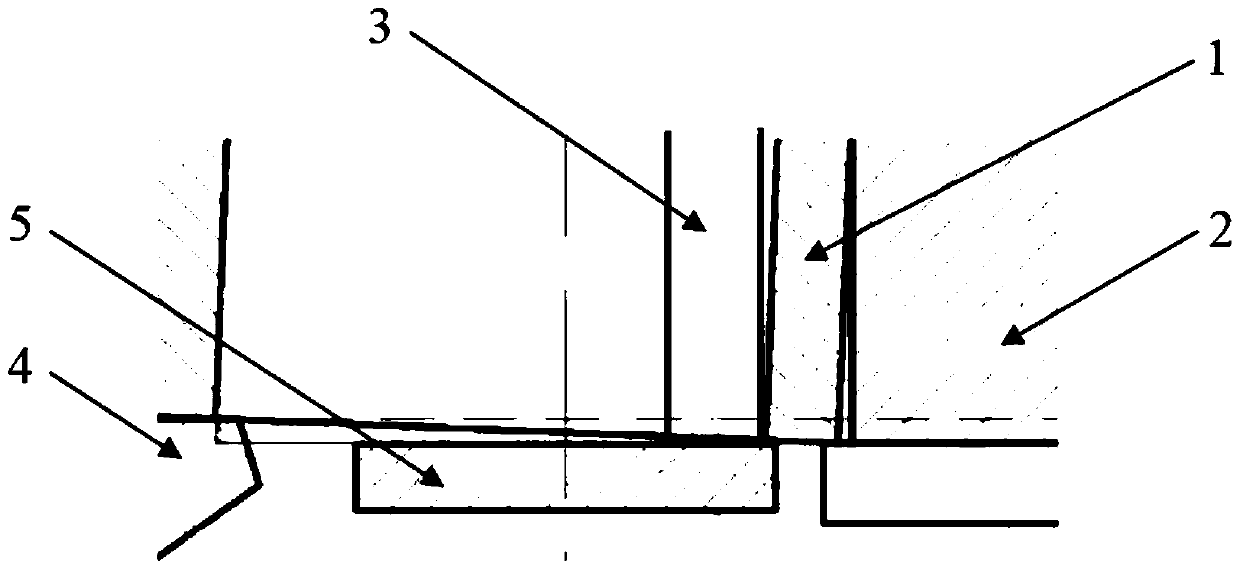

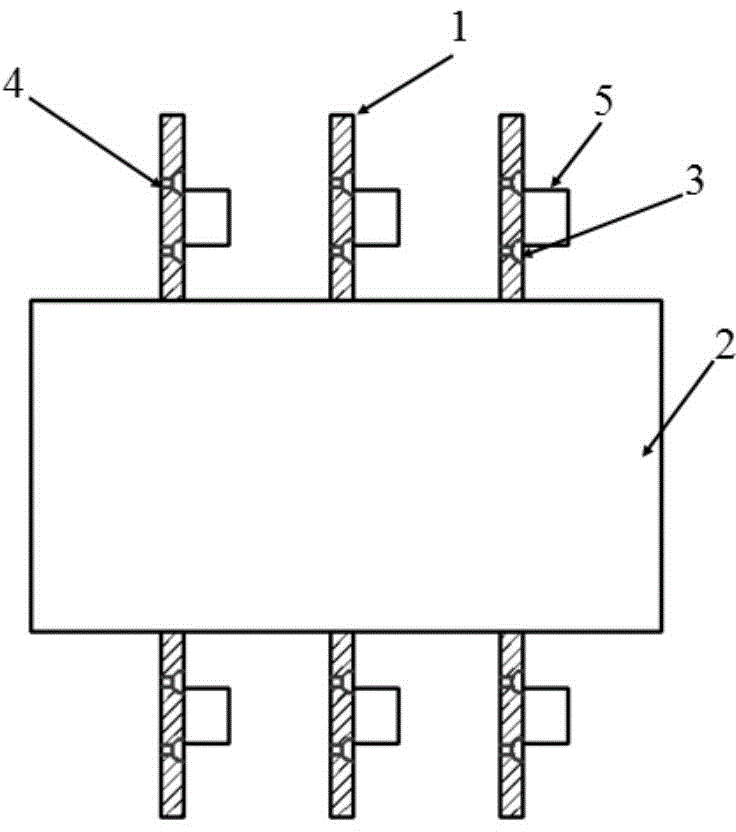

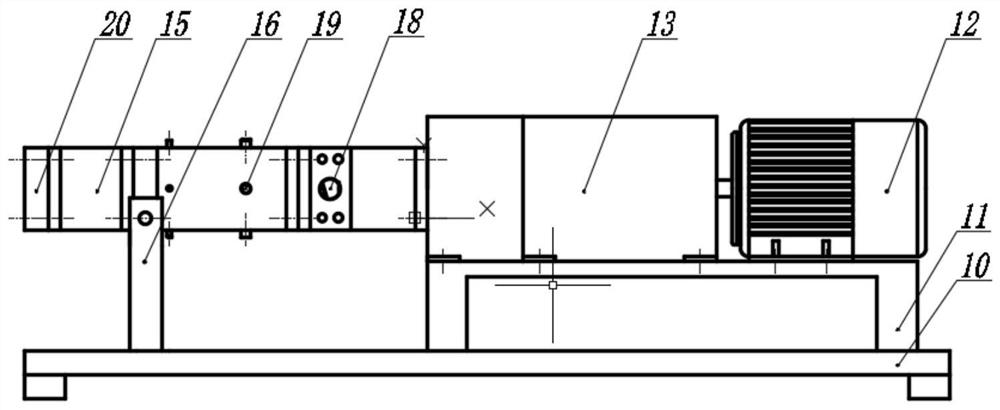

Equipment for producing aluminum alloy hollow casting ingot and method of equipment

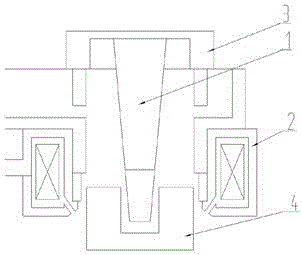

The invention relates to the technical field of aluminum alloys, in particular to equipment for producing an aluminum alloy hollow casting ingot and a method of the equipment. The equipment for producing the aluminum alloy hollow casting ingot comprises a core die, a crystallizer, a bracket and a dummy ingot, wherein the core die is positioned at the center of the crystallizer and is concentric with the crystallizer; the bracket arranged on the crystallizer is used for supporting the core die; the dummy ingot is arranged at the lower part of the core die; a space between the core die and the crystallizer is a die cavity; the core die is designed into a taper with a large upper part and a small lower part; and the size of the taper is 1-30 degrees; a cooling system and a lubricating system are arranged in the core die; a coil is arranged in a water chamber of an aluminum sleeve of the crystallizer; and a shunt and a stop block are arranged on the crystallizer. According to the equipment for producing the aluminum alloy hollow casting ingot and the method for the equipment disclosed by the invention, a friction force between the casting ingot and the die core in the hollow casting process of the aluminum alloy is reduced and the core locking and breakout are avoided.

Owner:NORTHEASTERN UNIV

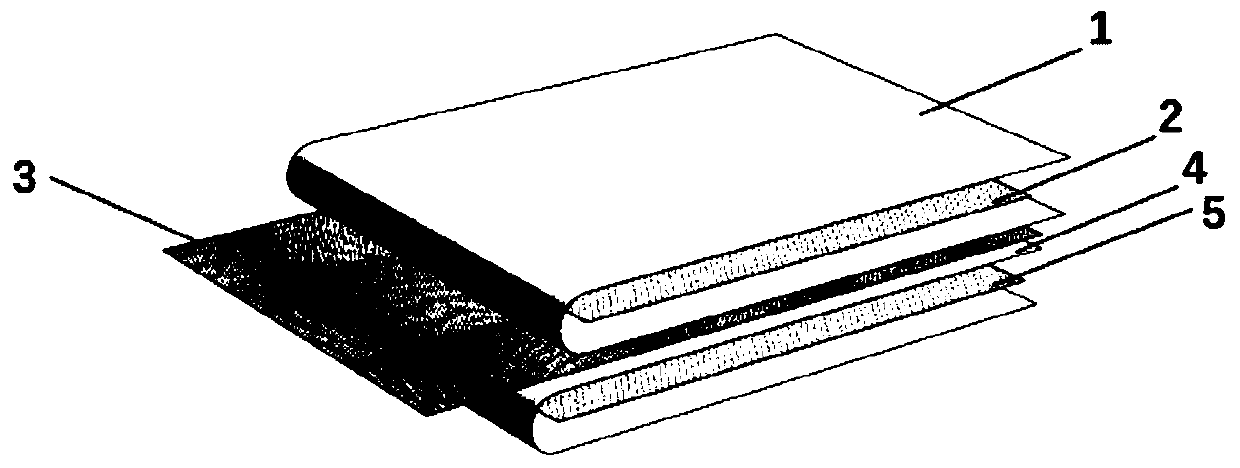

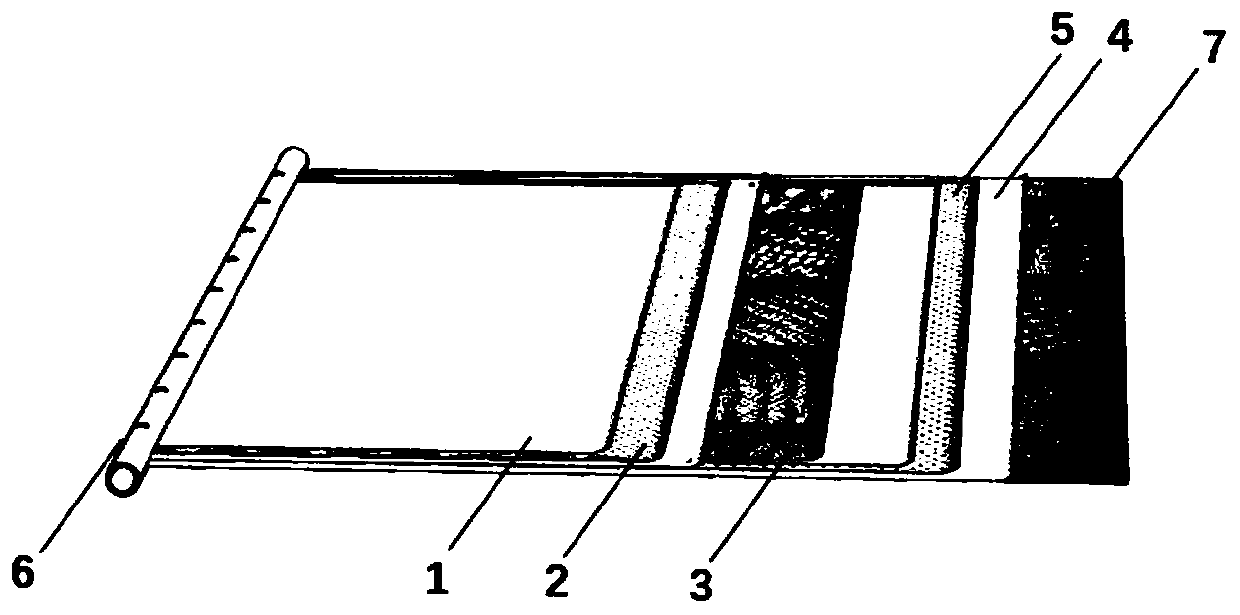

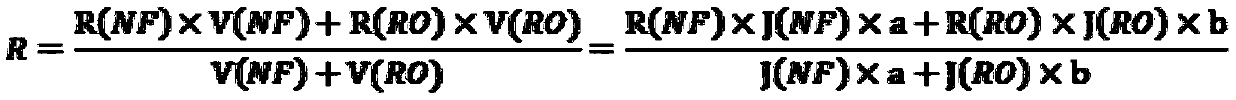

Composite membrane element suitable for water different in quality and manufacturing method

PendingCN110885112AKeep healthyEasy to adjust the lengthSemi-permeable membranesGeneral water supply conservationHigh fluxReverse osmosis

The invention discloses a composite membrane element suitable for water different in quality and a manufacturing method. The element includes a central tube, a reverse osmosis membrane assembly and ananofiltration membrane assembly. The reverse osmosis membrane assembly includes a reverse osmosis membrane, a dense water flow path cloth of the reverse osmosis membrane assembly and a pure water flow path cloth. The nanofiltration membrane assembly includes a nanofiltration membrane, a dense water flow path cloth of the nanofiltration membrane assembly and a pure water flow path cloth. This composite membrane element has a wide range of application, ensures healthy water drinking and no scaling, and has a high flux, the rejection rate of calcium and magnesium ions is higher than that of a single nanofiltration membrane, and the service lifetime of the composite membrane element is effectively prolonged.

Owner:BEIJING ORIGIN WATER FILM TECH

Heat exchanging pipe with reinforced heat transfer elements

ActiveCN103542759AReduce thicknessHigh heat transfer efficiencyTubular elementsHeat transfer efficiencyEngineering

Owner:PETROCHINA CO LTD +1

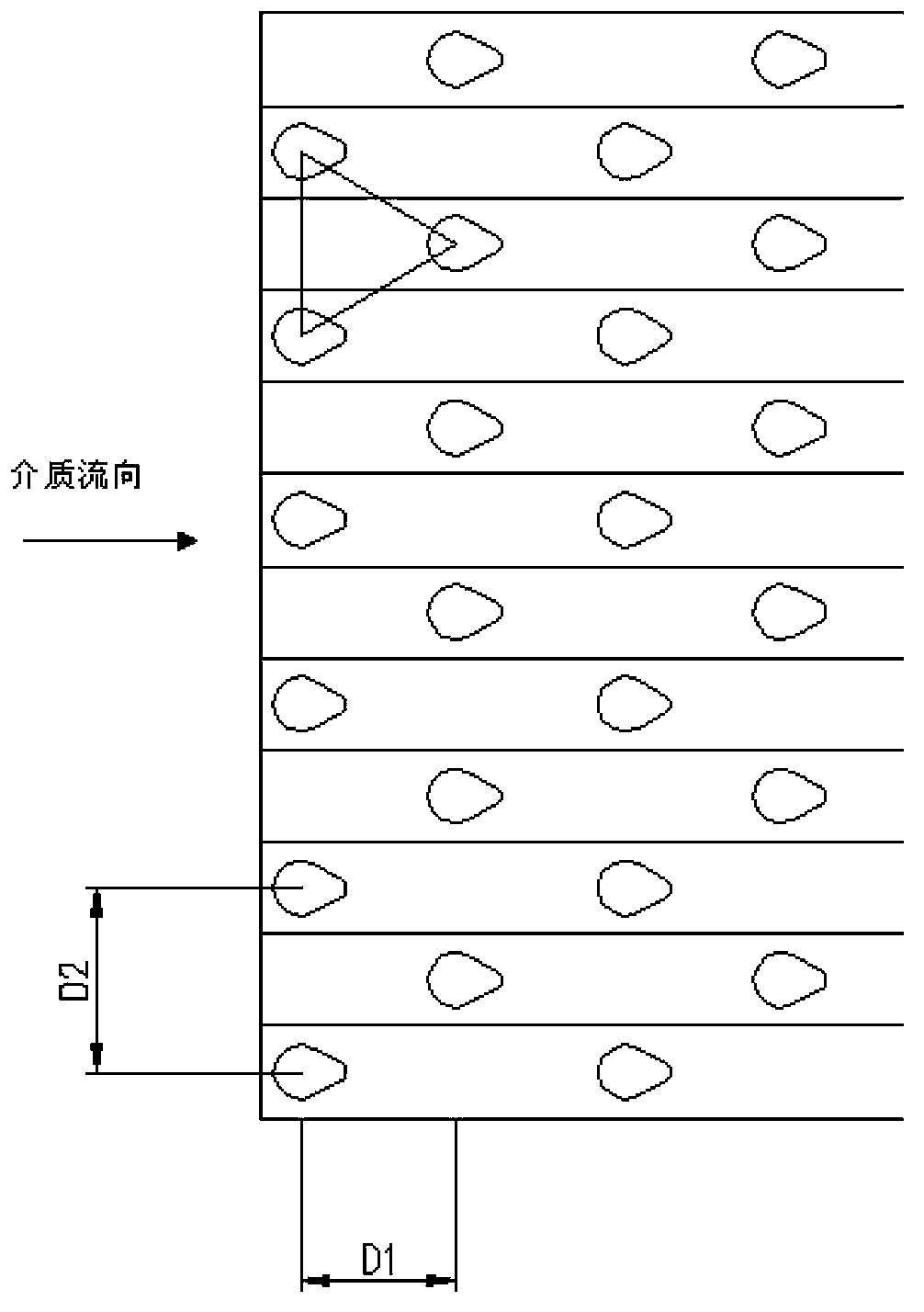

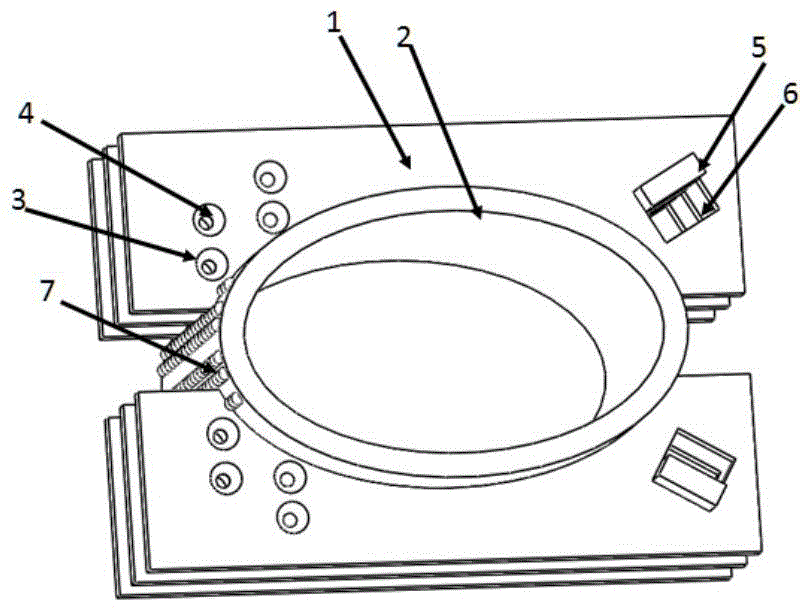

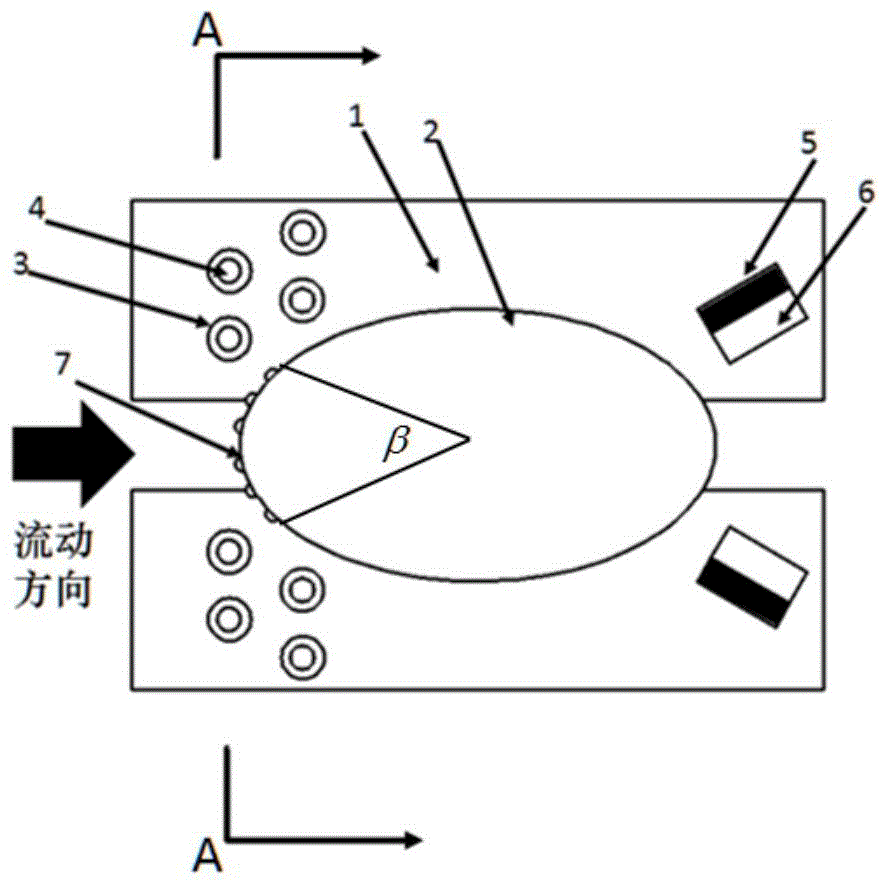

Combined bionic anti-abrasion H-shaped fin elliptical flue gas heat exchange tube

ActiveCN103954161ALow flow resistanceAvoid the formation of large eddy turbulenceCorrosion preventionTubular elementsCHEEK DIMPLESFlue gas

The invention discloses a combined bionic anti-abrasion H-shaped fin elliptical flue gas heat exchange tube which comprises more than two rows of elliptical tubes in the flowing direction of gas and fins arranged on the two sides of the elliptical tubes, wherein a plurality of pairs of semispherical dimples are arranged on the windward sides of the fins; first through holes penetrating through the fins are formed in the bottoms of the semispherical dimples; a plurality of eddy generators are arranged on the leeward sides of the fins; a through hole adjacent to each eddy generator is formed in one side of the eddy generator. According to the flue gas heat exchange tube, the elliptical tubes are used as base tubes, the fins are arranged on the inner two sides of the elliptical tubes, the semispherical dimples and the eddy generators are arranged on the fins, and by the dimples, the flowing resistance can be effectively reduced to avoid the formation of large eddy turbulence in a flow field; in addition, by the novel combined fin structure, the comprehensive heat exchange efficiency can be effectively improved, and tail soot formation and tube abrasion can be greatly reduced.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

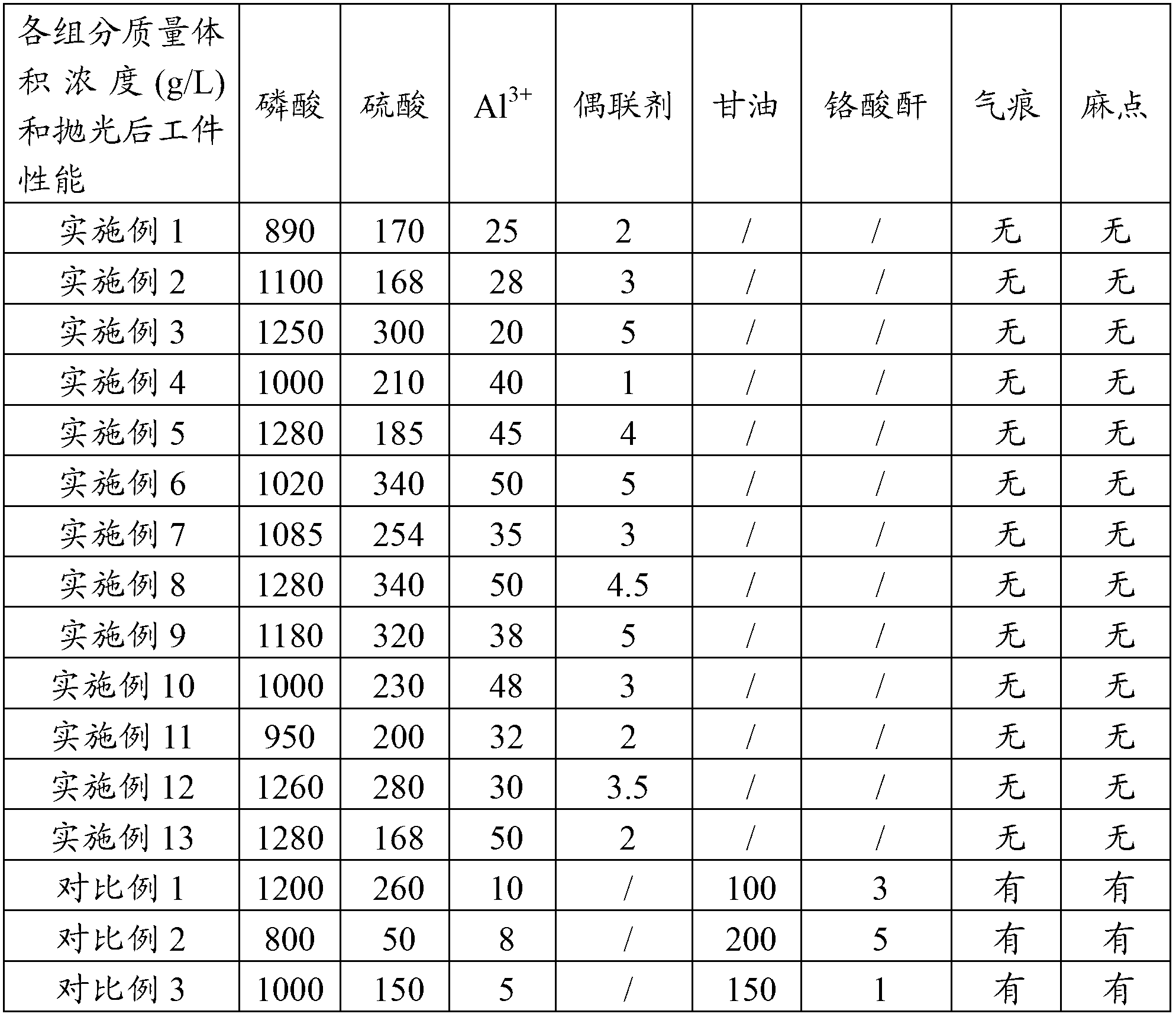

Electrolytic polishing agent

The invention discloses an electrolytic polishing agent which comprises the following aqueous solutions according to massic volume concentration: 890-1280g / L of phosphoric acid, 168-340g / L of sulfuric acid, 20-50g / L of AL<3 plus> and 1-5g / L of a coupling agent. The electrolytic polishing agent is used for regulating the ratio of phosphoric acid to sulfuric acid, and the corrosivity of the polishing agent is also effectively reduced through adding aluminum stearate, so the quality of the electrolyzed workpiece is enabled not to be influenced. The viscosity of the electrolytic polishing agent is increased by adding the coupling agent, the gas flow which is released during the electrolytic process can be changed, and is enabled not to leave gas marks on the workpiece which is electrically polished, so a polished surface can be uniform and complete, and has no defects.

Owner:广州波耳化工科技有限公司

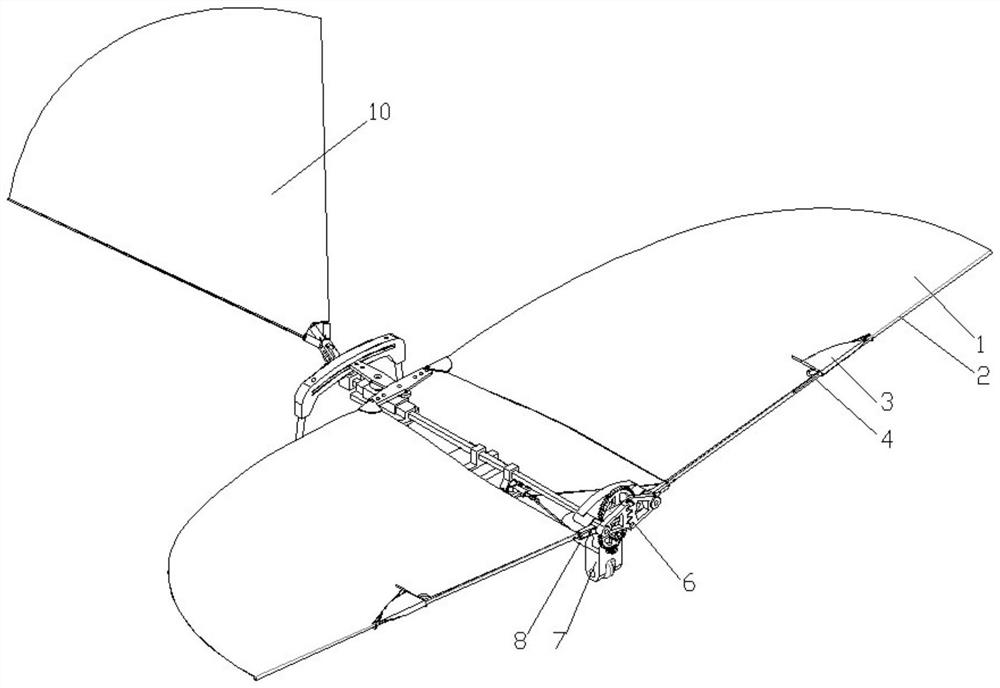

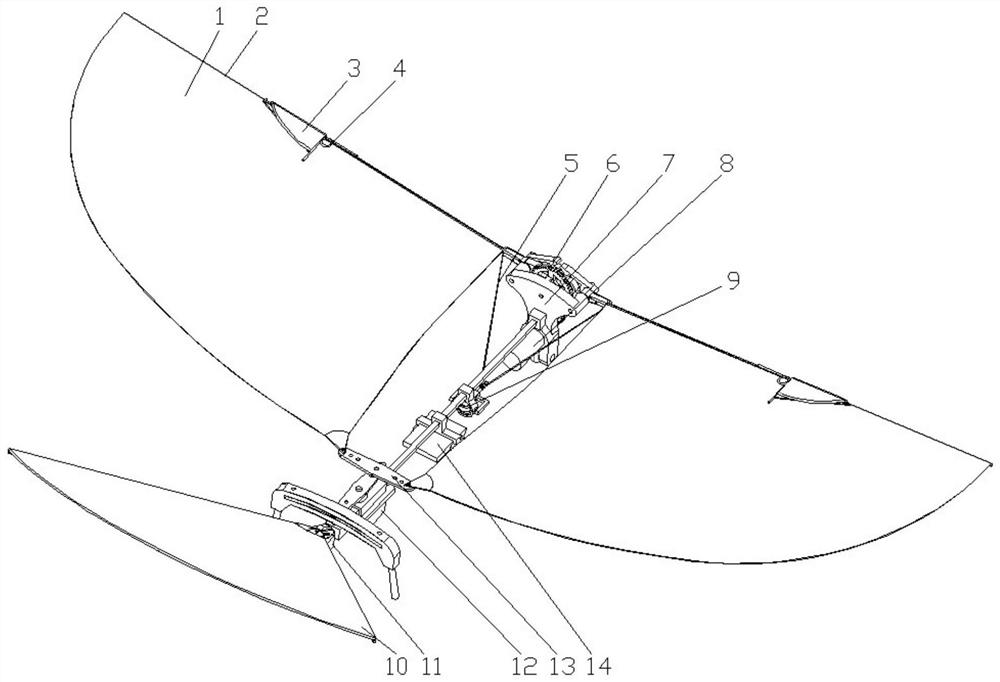

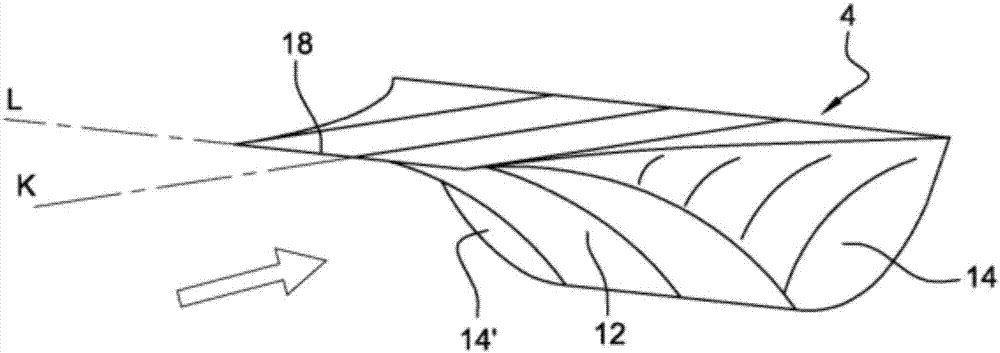

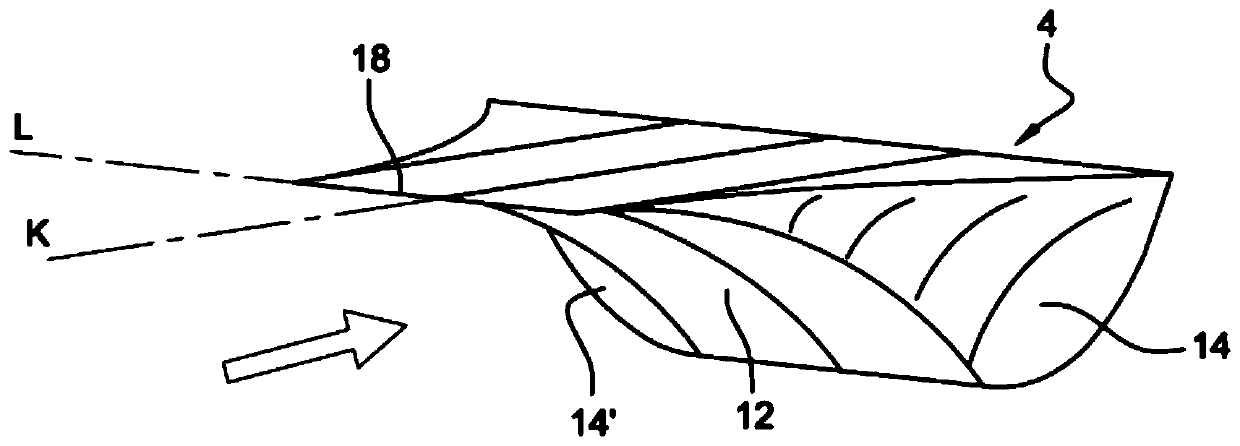

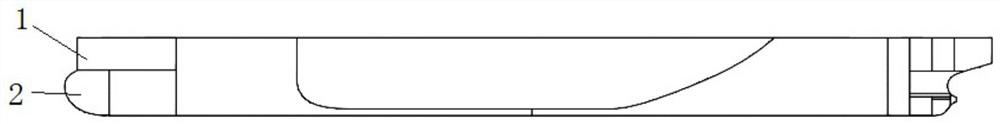

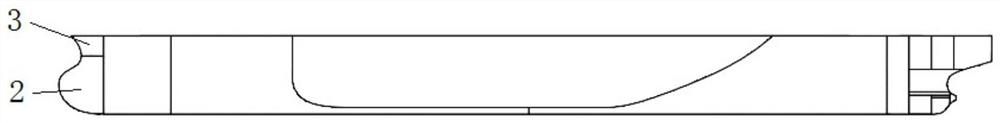

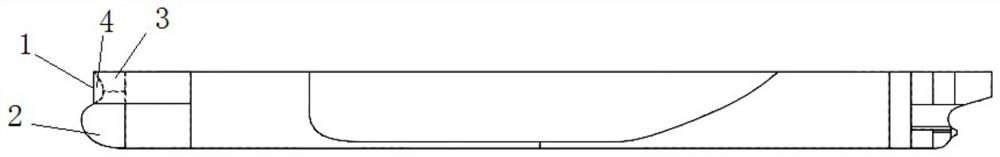

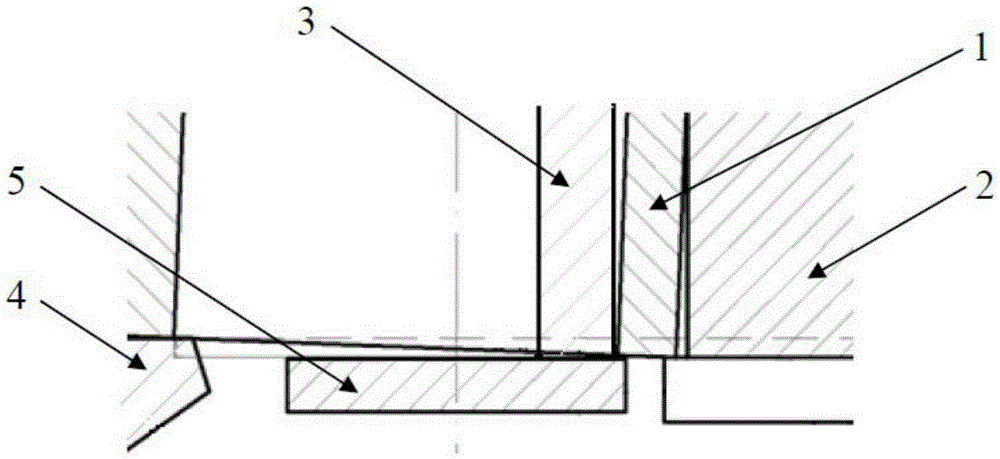

Bionic winglet structure capable of changing streaming of leading edge airfoil surface of flapping-wing aircraft

ActiveCN112977818AImprove aerodynamic performanceOverall stabilityOrnithoptersLeading edgeFlight vehicle

The invention discloses a bionic winglet structure capable of changing streaming of a leading edge airfoil surface of a flapping-wing aircraft, which relates to the field of structures of aircraft wings. The structural characteristics, the movement mode and the aerodynamic performance of the flapping-wing aircraft completely imitating small wing feathers of birds are provided, so that the aerodynamics of the flapping-wing aircraft is effectively improved, and the stall delay effect is achieved by changing the flow around the leading edge airfoil surface; the bionic winglet structure capable of changing the streaming of the leading edge airfoil surface of the flapping-wing aircraft enables the aircraft to take off and land more steadily. The bionic winglet structure comprises a pair of winglets and a winglet control mechanism; the two winglets are symmetrically arranged along the aircraft body and synchronously rotate under the driving of the winglet control mechanism. The flapping-wing aircraft has good aerodynamic performance and streaming characteristic in the flight process, the stall delaying function can be achieved, and due to the special structural design, the weight increased by the mechanism and the rotational inertia increased by wings can be ignored.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

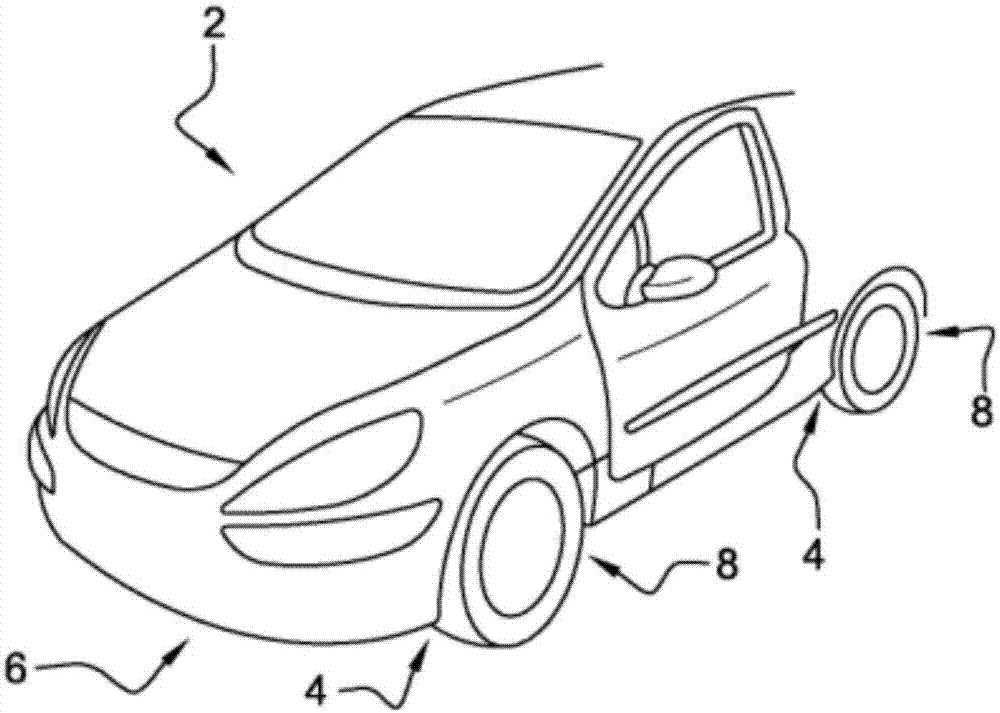

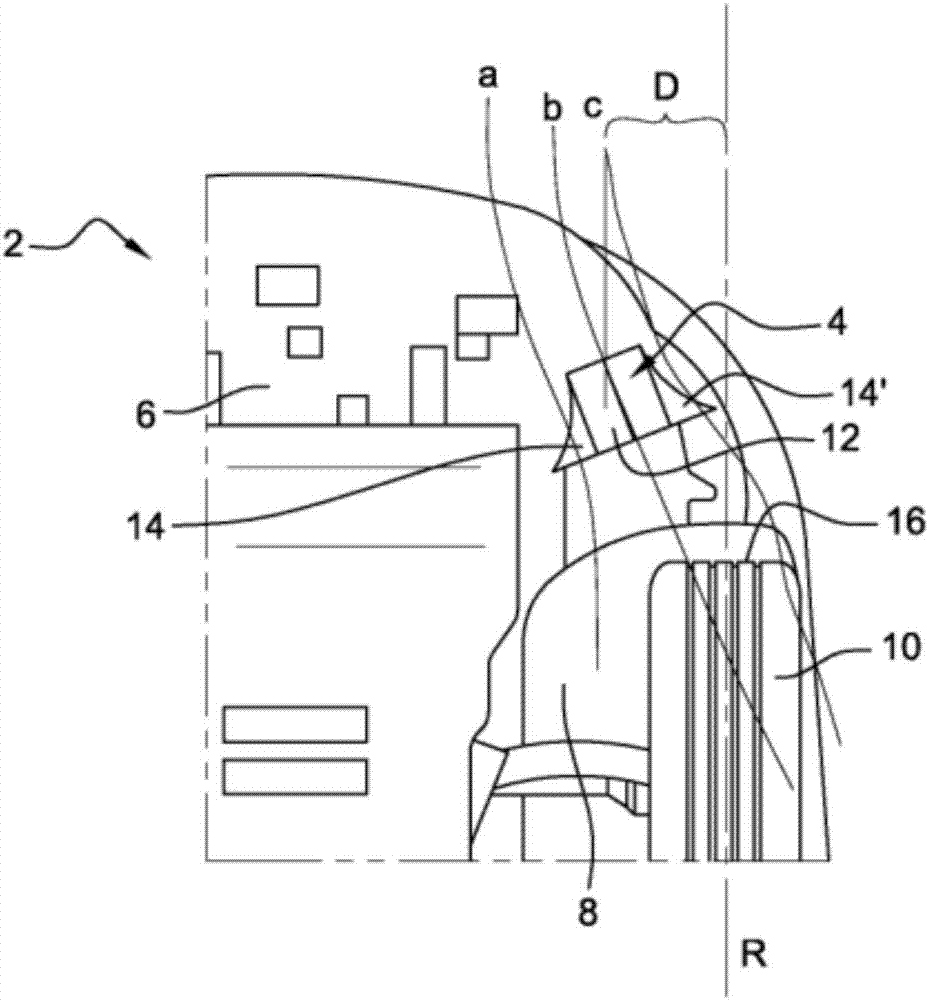

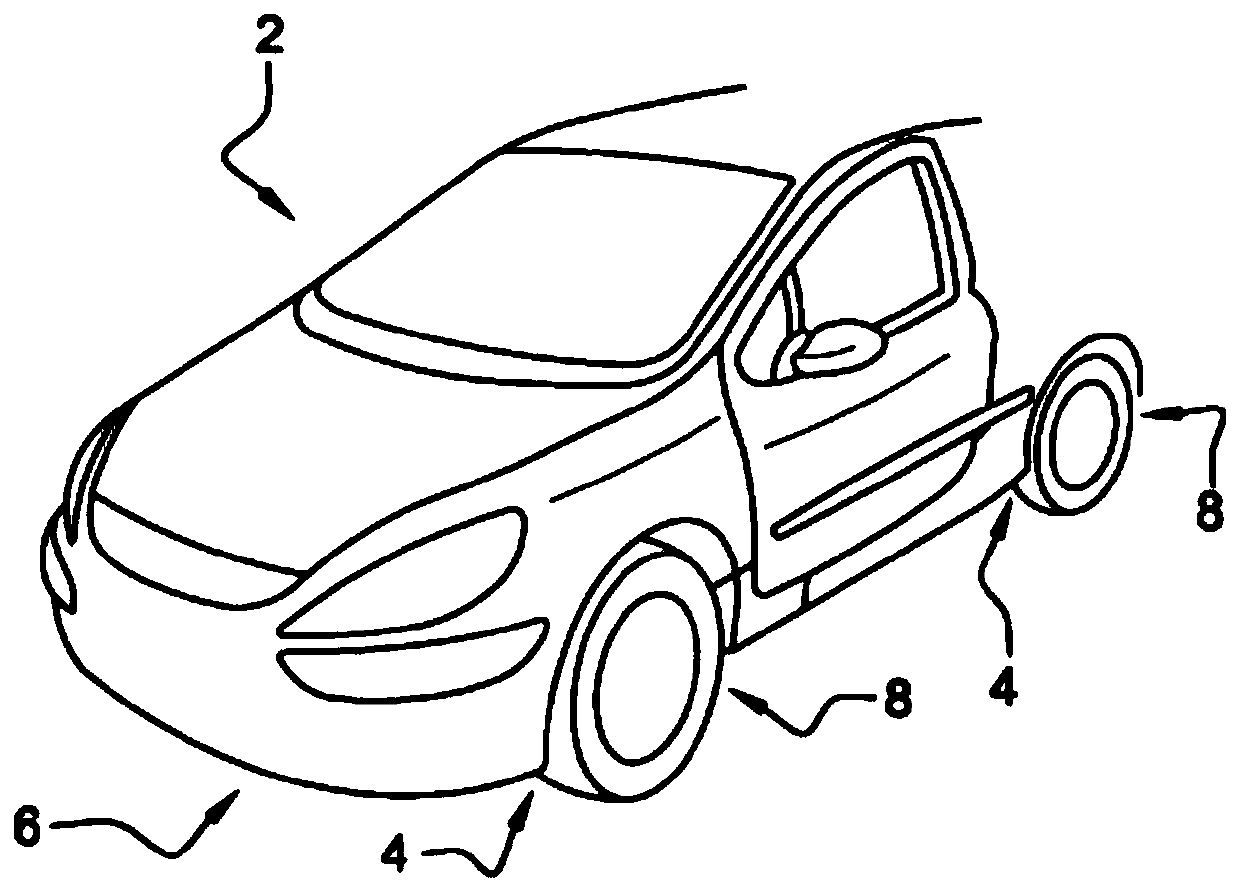

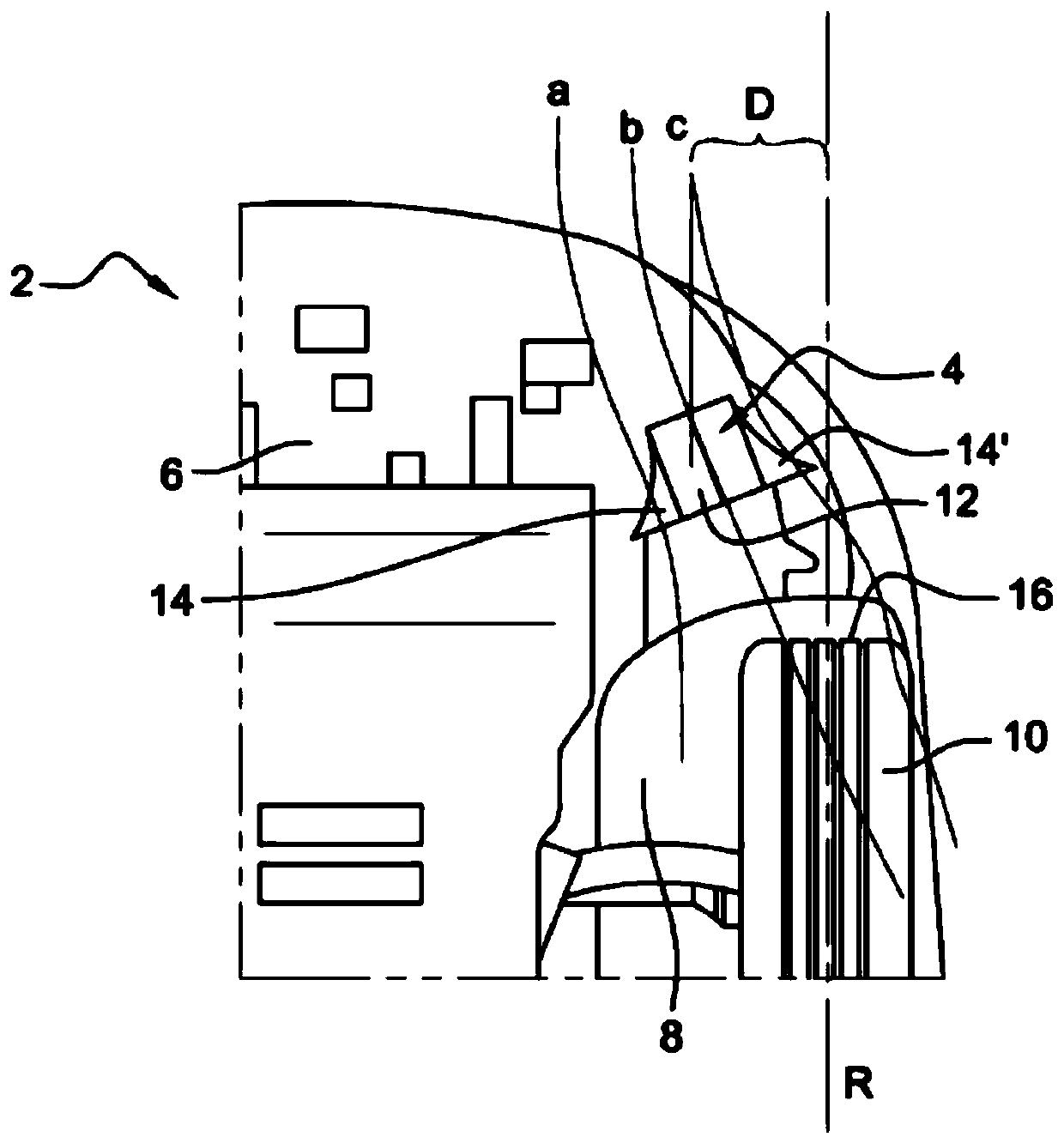

Vehicle with air deflector for wheel

ActiveCN107107971AChange flowExpand volume spaceAerodynamics improvementComponent optimizationAerospace engineeringMotorized vehicle

The invention relates to an air deflector (4) intended to be mounted under a motor vehicle, in front of a wheel of said vehicle, with a view to reduce the aerodynamic drag at said wheel, wherein said air deflector (4) comprises: an angled front surface (12) having a concave profile ; two side surfaces (14; 14') on either side of the front surface (12), respectively; wherein at least one of the two side surfaces (14; 14') has a concave profile. The invention also relates to a vehicle comprising at least one such air deflector (4).

Owner:PEZHO SITROEN AUTOMOBILS SA

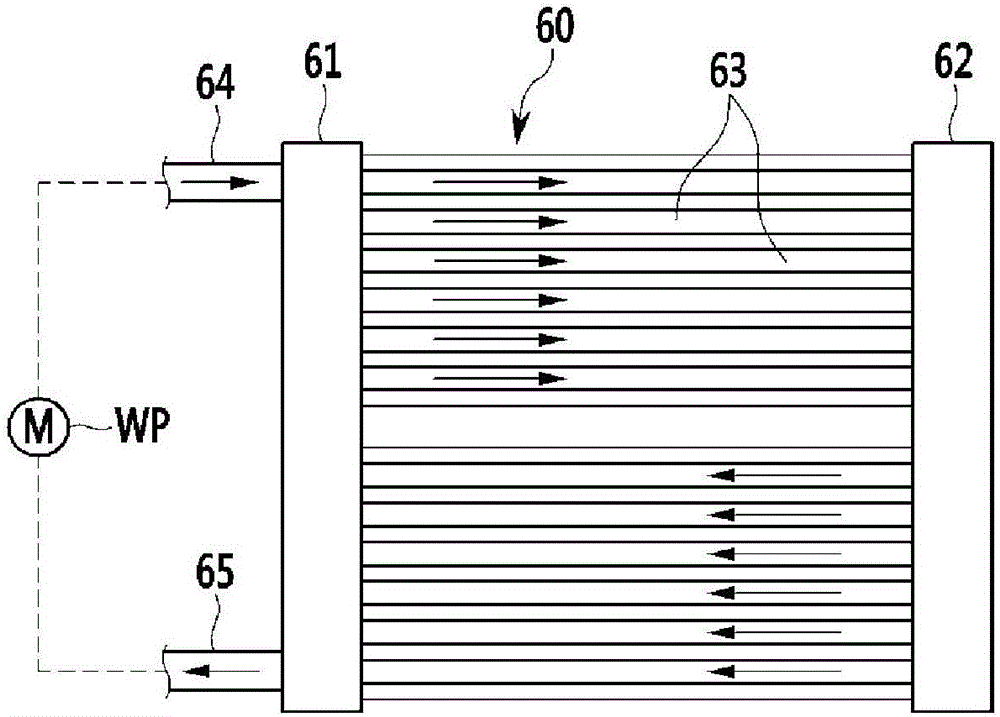

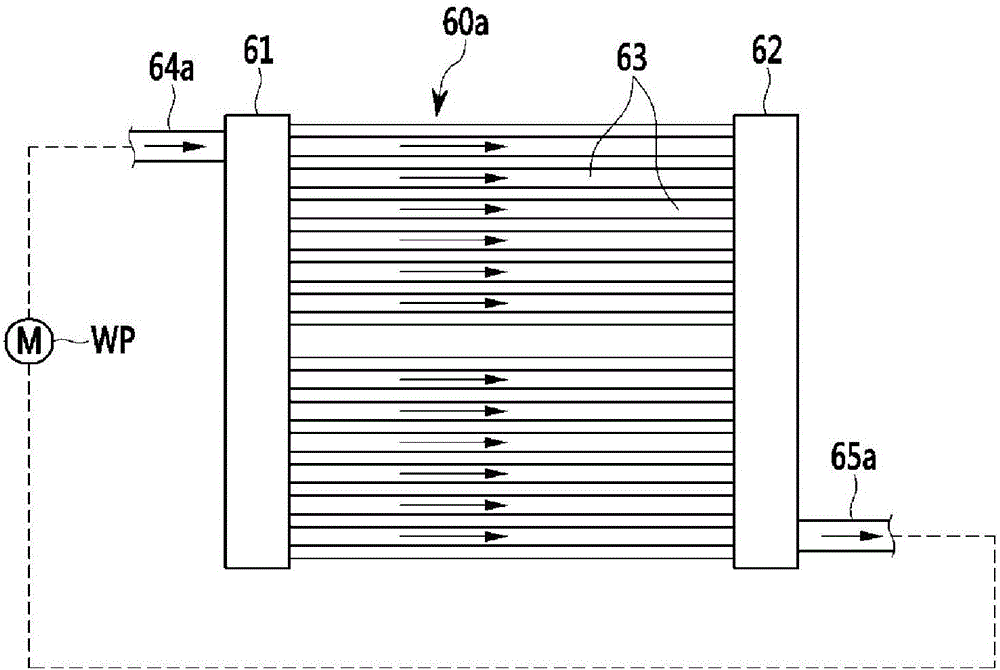

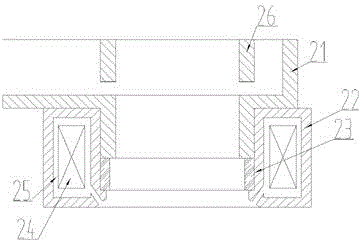

Water-cooling intercooler apparatus

ActiveCN106194397AChange flowReduce power consumptionLiquid coolingCoolant flow controlNuclear engineeringCoolant flow

A water-cooling intercooler apparatus, may include a low-temperature radiator in which coolant flows to cool supercharged air supplied to an engine, wherein the low-temperature radiator is provided with an inlet into which the coolant flows, an outlet from which the coolant discharges, a body portion which is made of a plurality of connecting pipes for the coolant to flow therein, a first coolant tank configured to distribute the coolant to the plurality of connecting pipes, and a second coolant tank configured to collect the coolant; and at least one actuated-valves provided at the first or second coolant tank to open or close an inside of the first or second coolant tank for the coolant to flow in a portion of the plurality of connecting pipes.

Owner:HYUNDAI MOTOR CO LTD

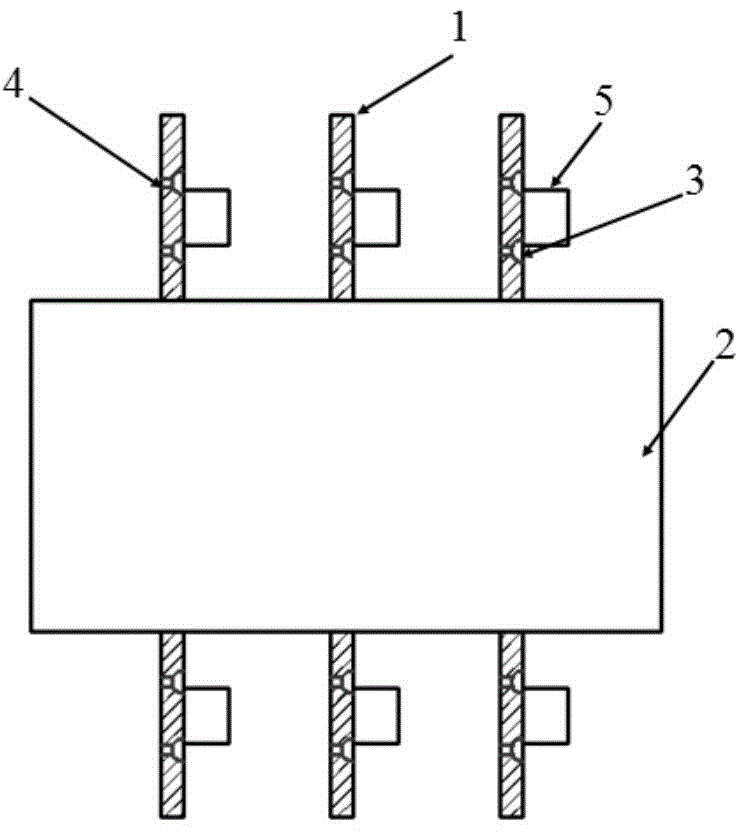

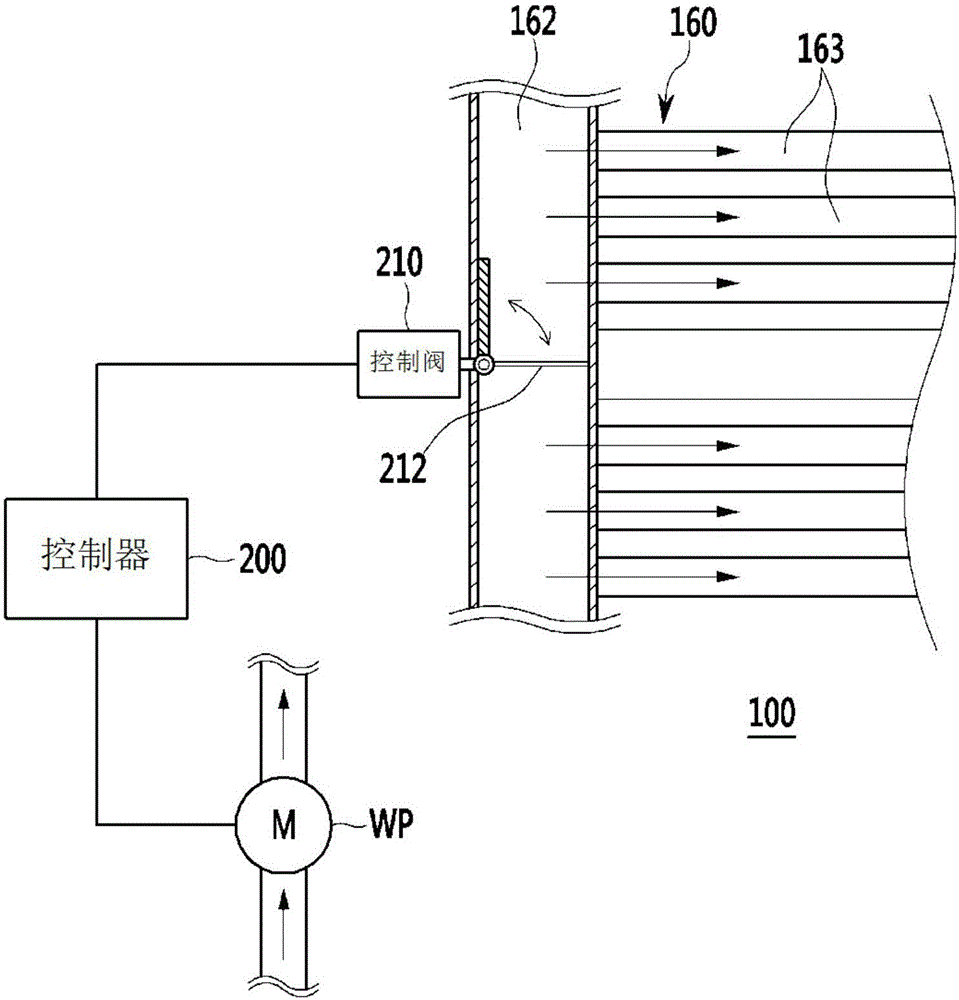

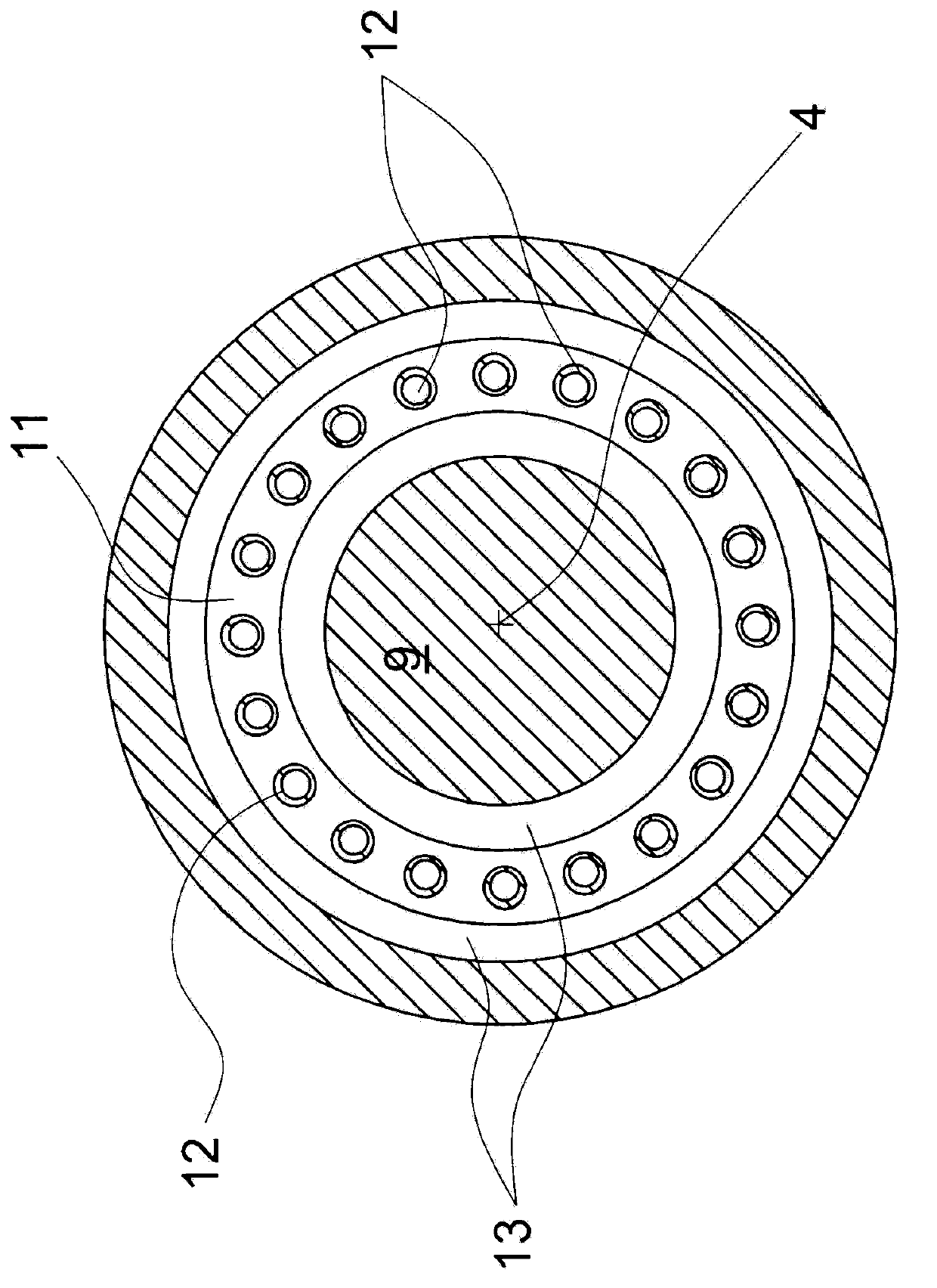

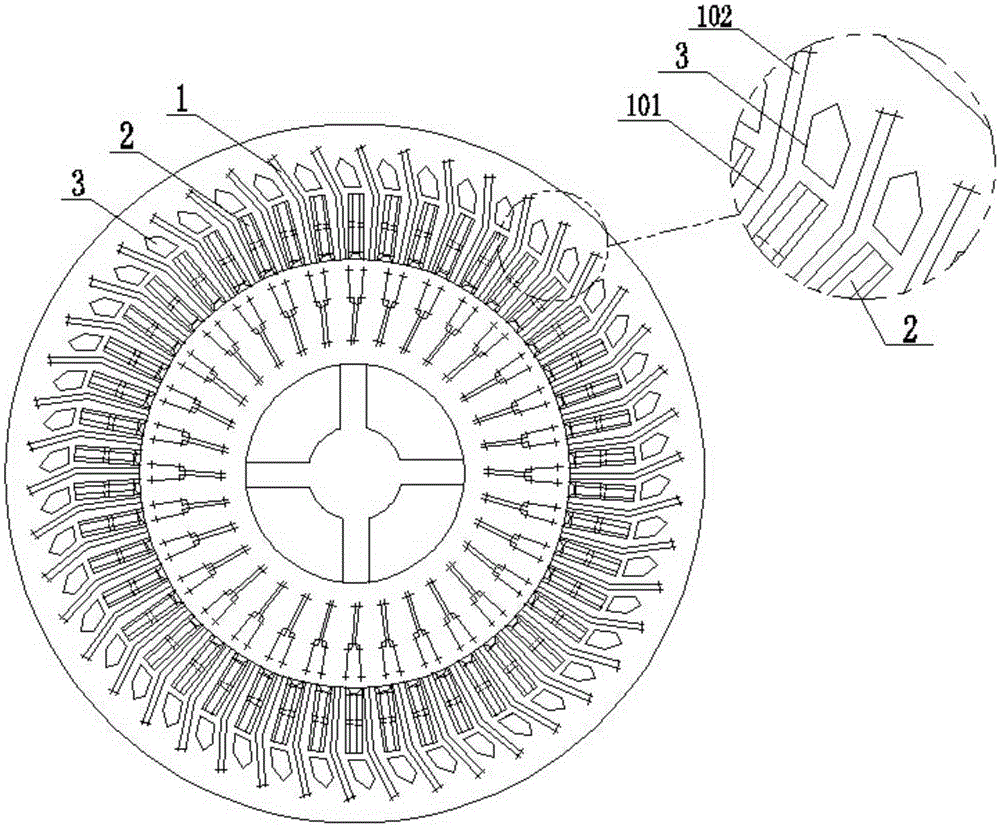

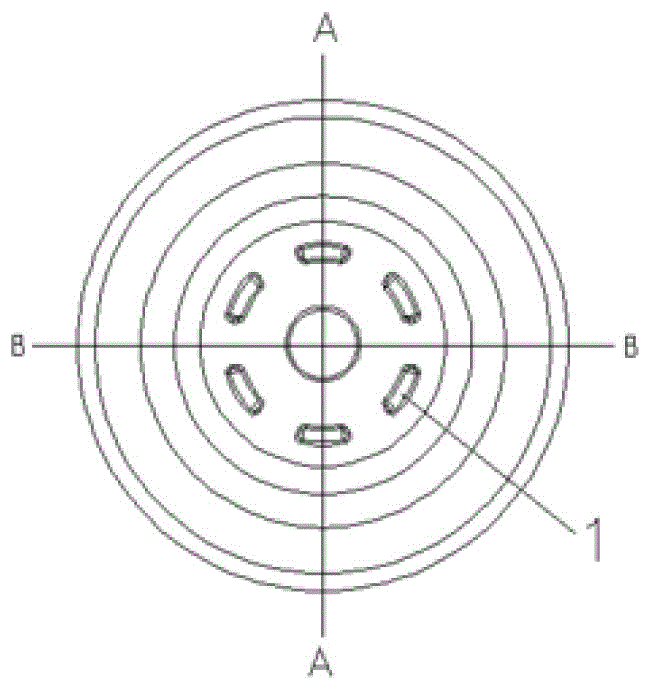

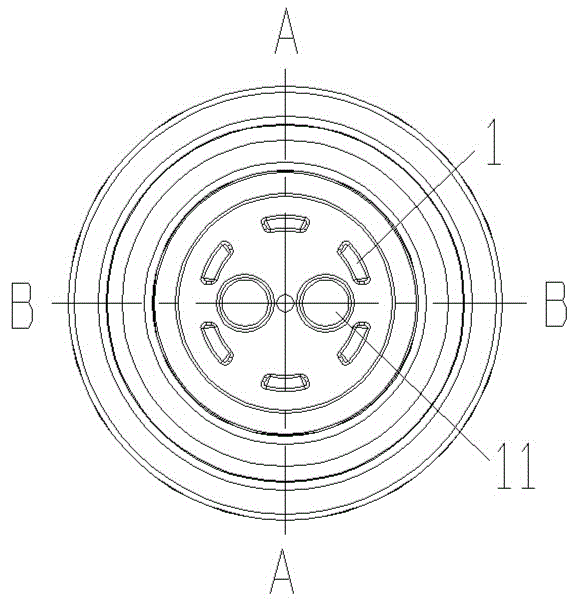

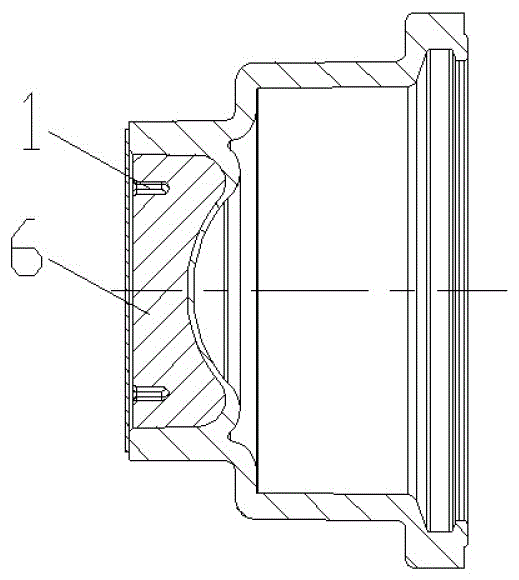

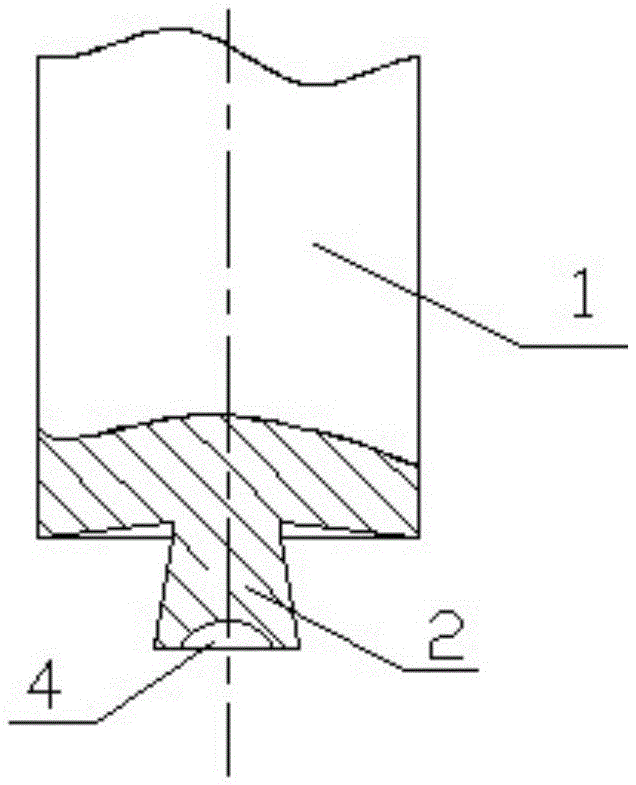

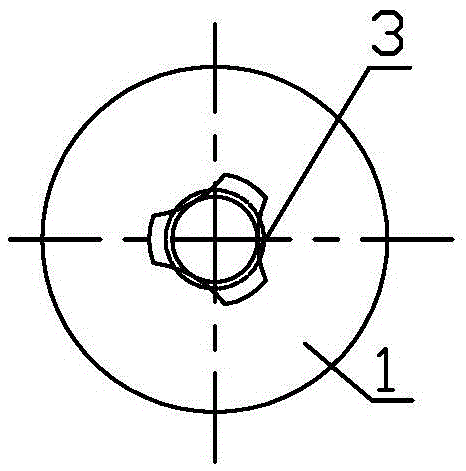

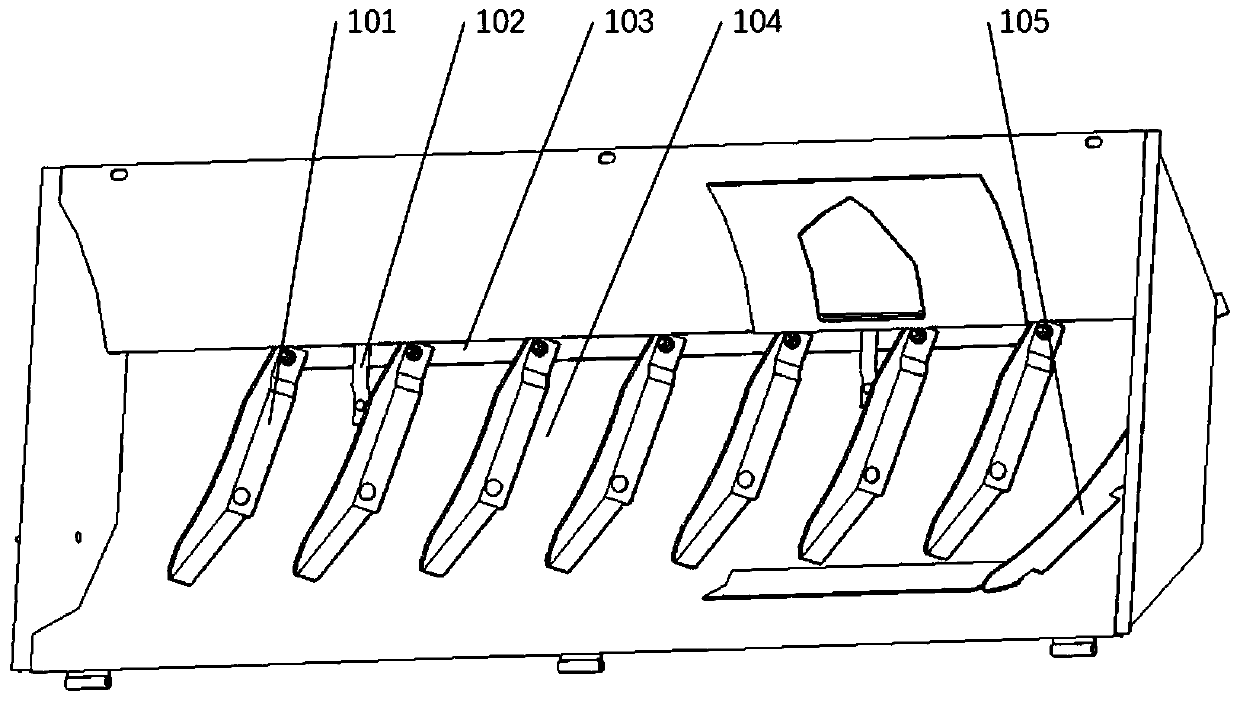

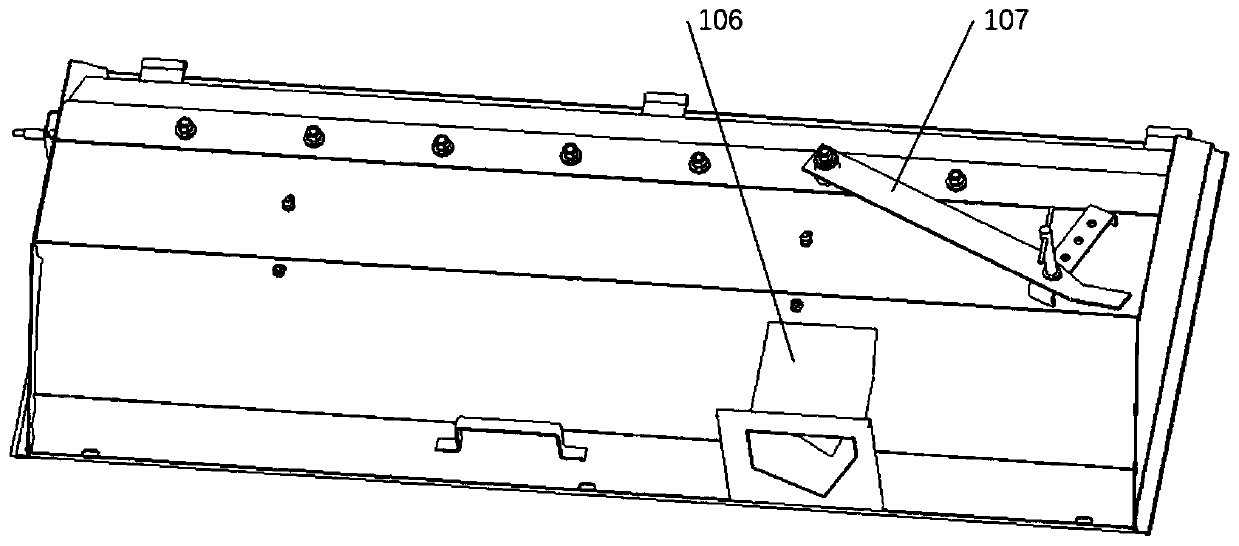

Conical disc rack of disc centrifugal machine

InactiveCN108246523AChange pressure distributionEvenly distributedCentrifugesEngineeringMechanical engineering

The invention discloses a conical disc rack of a disc centrifugal machine. The conical disc rack of the disc centrifugal machine comprises a conical disc rack body, positioning boards, a disc and neutral holes, and is characterized in that the conical disc rack body (1) is conical, the ring diameter of the conical disc rack body is gradually decreased from bottom to top, and the conical disc rackis formed. Materials pass through the neutral holes (4), are separated by the disc (3), and flow out between the positioning boards (2). By controlling the cross section area of a light-phase fluid runner to be gradually increased, the volume in the runner is increased, the inner diameter of the disc and the pressure distribution of fluid in the interval of the disc rack are changed, accordingly flowing of the fluid in the interval of layers of discs is improved, distribution of the fluid in the interval of the layers of discs tends to be uniform, and thus the purpose of improving the separation efficiency is achieved.

Owner:CHANGZHOU UNIV

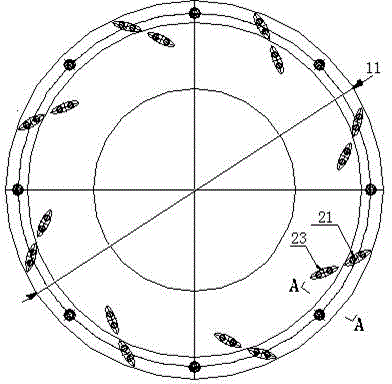

Radiating type collector ring and application thereof

ActiveCN104158350AChange flowAvoid carbon depositsCooling/ventillation arrangementEngineeringCarbon dust

The invention relates to a radiating type collector ring and an application thereof. The radiating type collector ring comprises a collector ring body which sequentially includes an upper collector ring, a collector ring supporting plate and a lower collector ring from top to bottom. The upper surface of the upper collector ring is provided with a plurality of first air guide blades, and the lower surface of the lower collector ring is provided with a plurality of second air guide blades. The included angle between the mounting axis of each first air guide blade and the diameter direction of the upper collector ring at the position is 0-45 degrees. The included angle between the mounting axis of each second air guide blade and the diameter direction of the lower collector ring at the position is 0-45 degrees. When a generator unit is working, the first air guide blades and the second air guide blades make air around the collector ring body move regularly to form strong wind. In the process, the heat on the surface of the collector ring body can be effectively taken away to achieve the purpose of cooling. Moreover, carbon dust produced due to friction between a carbon brush and the collector ring body can be taken away, and carbon powder can be prevented from being attached to and deposited on the surface of the collector ring body to affect insulation.

Owner:重庆华能水电设备制造有限公司

Method and device for controlling the temperature of plastic mass

ActiveCN103419354ARealize targeted temperature adjustment treatmentChange aggregation statusTemperature controlEngineering

A method for controlling the temperature of a polymer melt in an extrusion tool includes flowing the polymer melt via at least one flow channel from an input to an output and around at least one temperature-control element in the at least one flow channel. The temperature control element includes a plurality of temperature control units. The temperature of the polymer melt flowing around the temperature-control element is controlled by individually controlling each of the temperature-control units so as to vary a degree of temperature control of the temperature-control element such that a degree of temperature control is controllable to be the same or different at locations throughout the temperature control-element.

Owner:BATTENFELD CINCINNATI GERMANY GMBH

Isotropic rolling method for cobalt-based high-temperature alloy rectangular ring part

The invention discloses an isotropic rolling method for a cobalt-based high-temperature alloy rectangular ring part. The isotropic rolling method comprises the following steps: firstly, heating a cobalt-based high-temperature alloy bar to a forging temperature, and carrying out upsetting, punching and pre-rolling, thereby forming a rectangular ring blank; secondly, mounting the rectangular ring blank on a ring rolling mill, lifting a conical roller by h=5 to 10 mm such that the rectangular ring blank tilts, and then performing rolling forming to obtain the cobalt-based high-temperature alloy rectangular ring part. According to the method, the mechanical properties of the rectangular ring part in various directions are kept consistent by changing a material flowing direction during rolling, and therefore, the comprehensive mechanical properties of the rectangular ring part are improved. The method is used for producing the cobalt-based high-temperature alloy isotropic rectangular ring parts.

Owner:GUIZHOU ANDA AVIATION FORGING

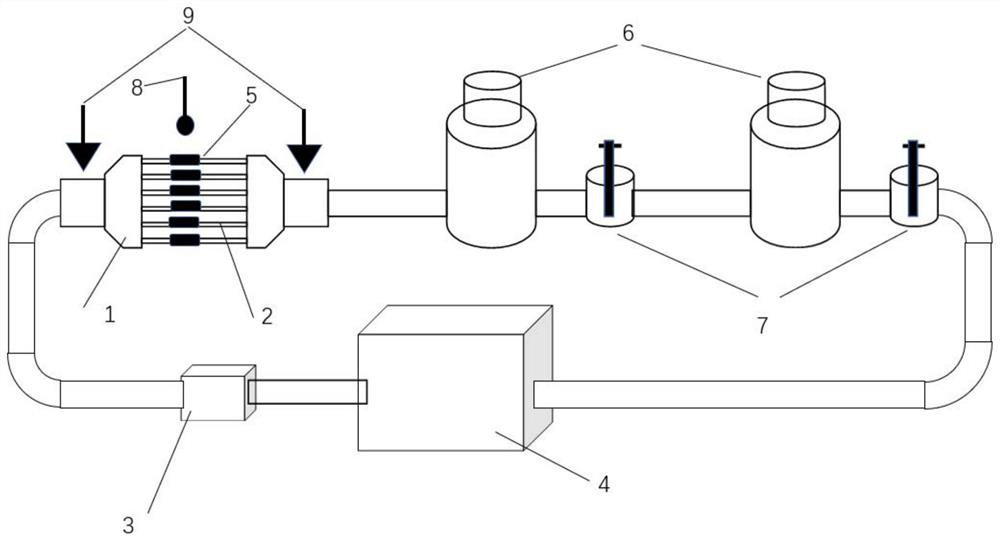

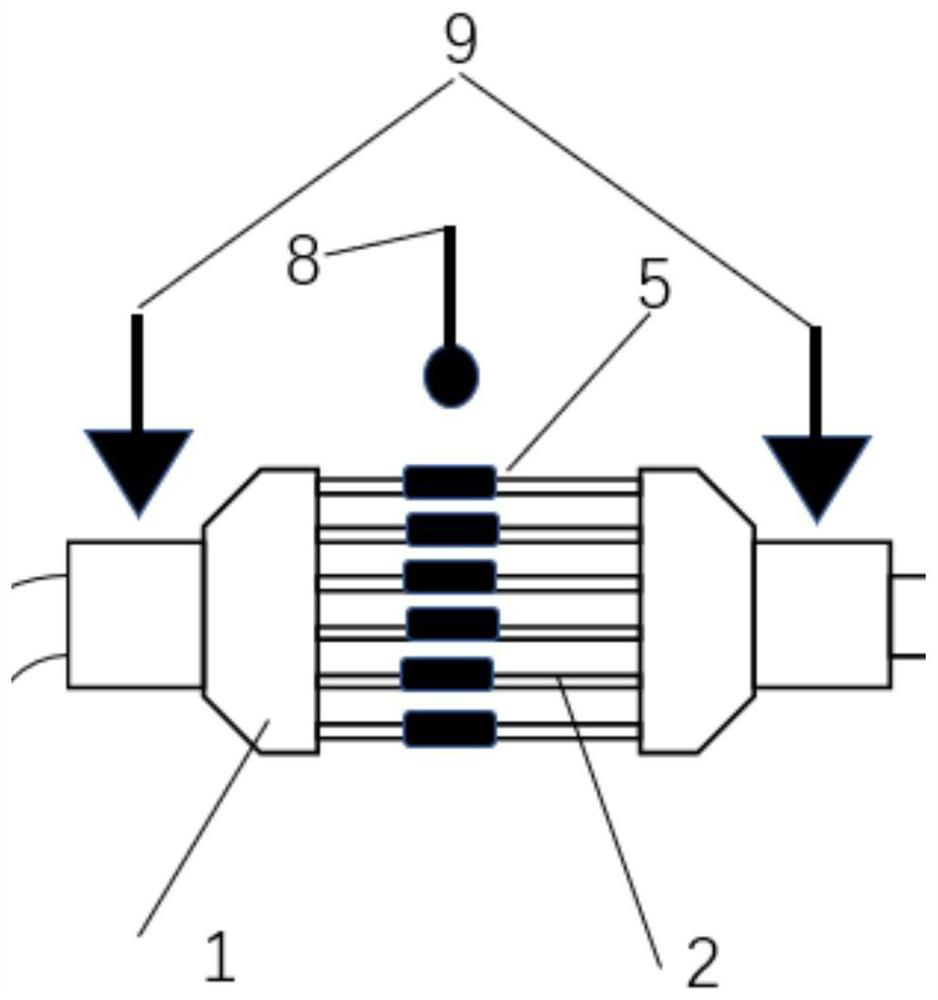

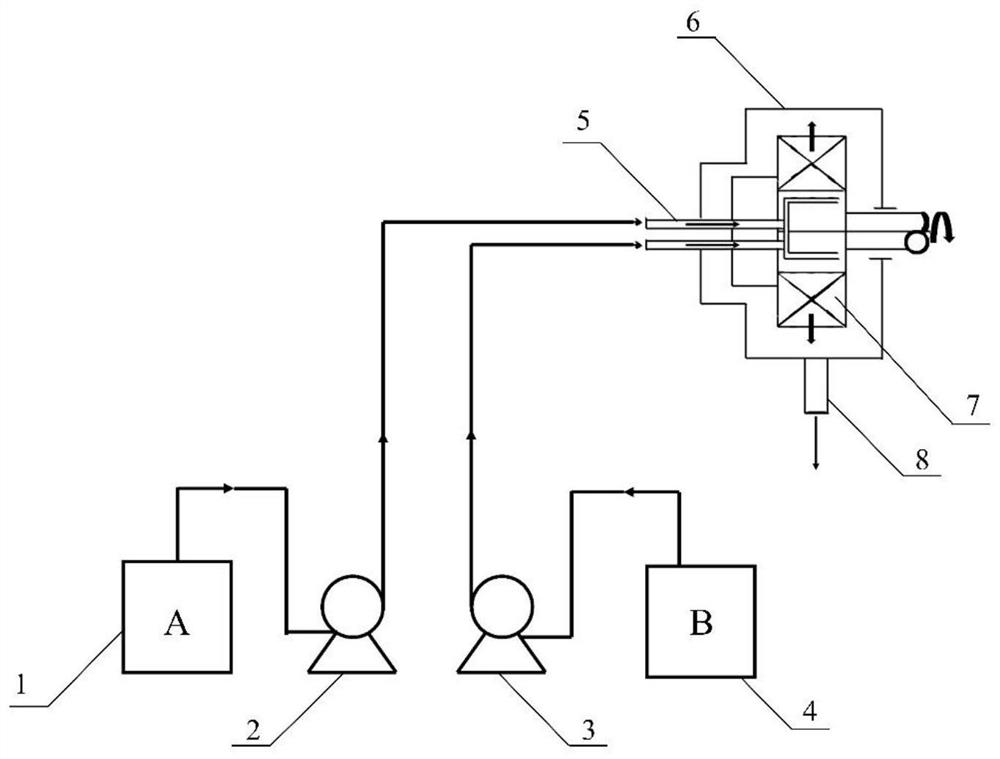

Near-physiological pulsating flow loading device for fatigue test of intravascular stent

PendingCN113654773AThe Science of Fatigue TestingReliable in fatigue testingMachine part testingHuman bodyStent implantation

The invention provides a near-physiological pulsating flow loading device for an intravascular stent fatigue test, and belongs to the technical field of medical instruments, and the near-physiological pulsating flow loading device for the intravascular stent fatigue test comprises a simulated blood vessel which is provided with a detection section for placing a stent to be tested; simulation liquid is suitable for circulating in the simulation blood vessel; a loading device which is internally provided with multiple sections of simulated blood vessels; the detection section of the simulated blood vessel is arranged in the loading device; according to the near-physiological pulsating flow loading device for the fatigue test of the intravascular stent, the pressure and the flow which are similar to the physiological state received after the stent is implanted into the human body are provided. The pulsating pressure enables the simulated blood vessel to generate periodic expansion and contraction deformation, and provides a compression acting force for the stent; the pulsating flow provides pulsating fluid shear force for the stent. The device more accurately simulates the real state of the intravascular stent in the blood vessel of the human body, and solves the near-physiological pulsation loading problem in the fatigue test of the intravascular stent.

Owner:BEIHANG UNIV

Motor with good ventilation properties

InactiveCN105391213AImprove liquidityReduce temperature riseWindings conductor shape/form/constructionEddy currentPrism

The present invention provides a motor with good ventilation properties. The motor comprises a motor winding. Each two adjacent teeth of the motor winding are provided with a ventilation channel. The technical points of the ventilation channel are that: a near shaft of the ventilation channel is arranged between two adjacent teeth of the motor winding, the remote shaft is extended to the outside of the motor winding, and deflected to one side to form a ''>'' type with the near shaft, and a prism are arranged between two adjacent shafts of the ventilation channel. According to the motor with good ventilation properties disclosed by the present invention, the ''>'' type formed by reverse deflection of the remote shaft and the near shaft of the ventilation channel is used to change a flow direction of the gas inside the motor, so that ventilation of the gas inside the motor is improved, convection is enhanced, and an effective cooling purpose is reached; and the prism is further added between the remote shaft of the ventilation channel to change flow condition of the fluid, thereby reducing eddy current losses, and enabling a flow form of the fluid to be better.

Owner:HARBIN UNIV OF SCI & TECH

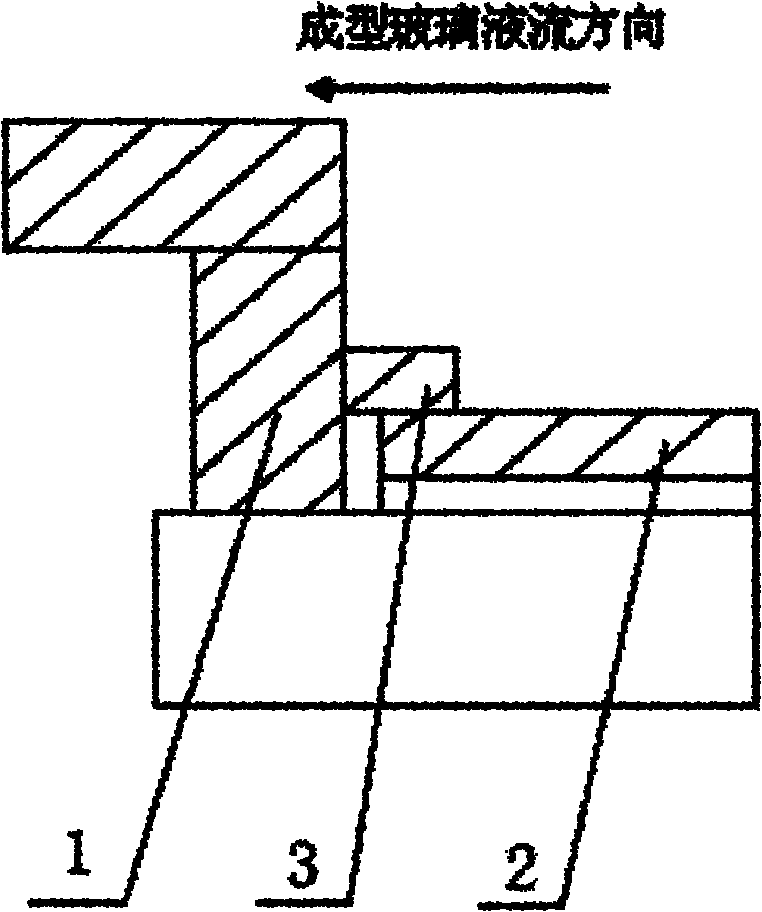

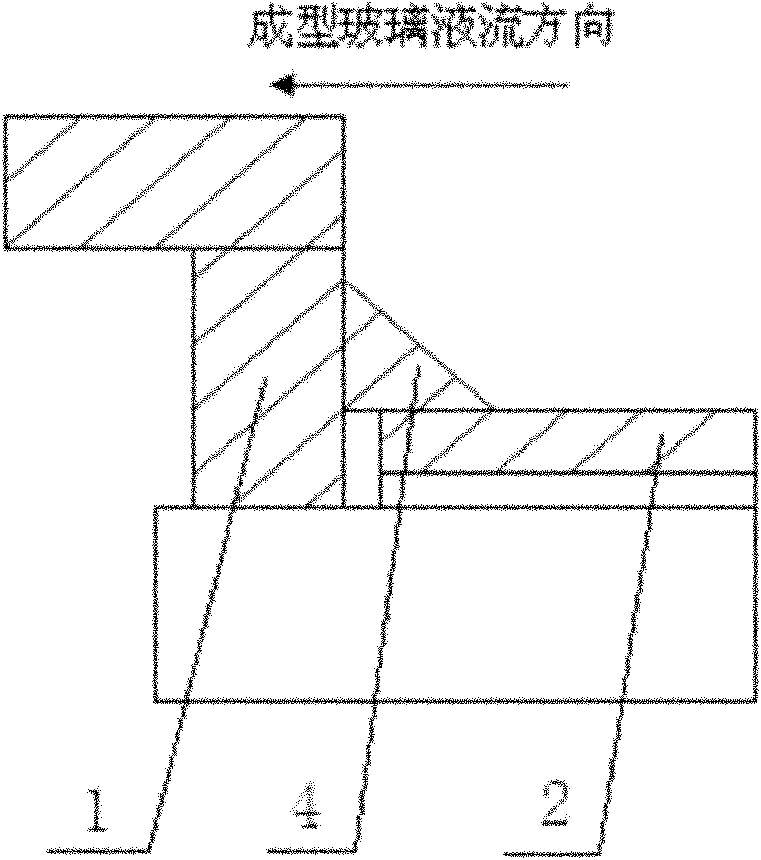

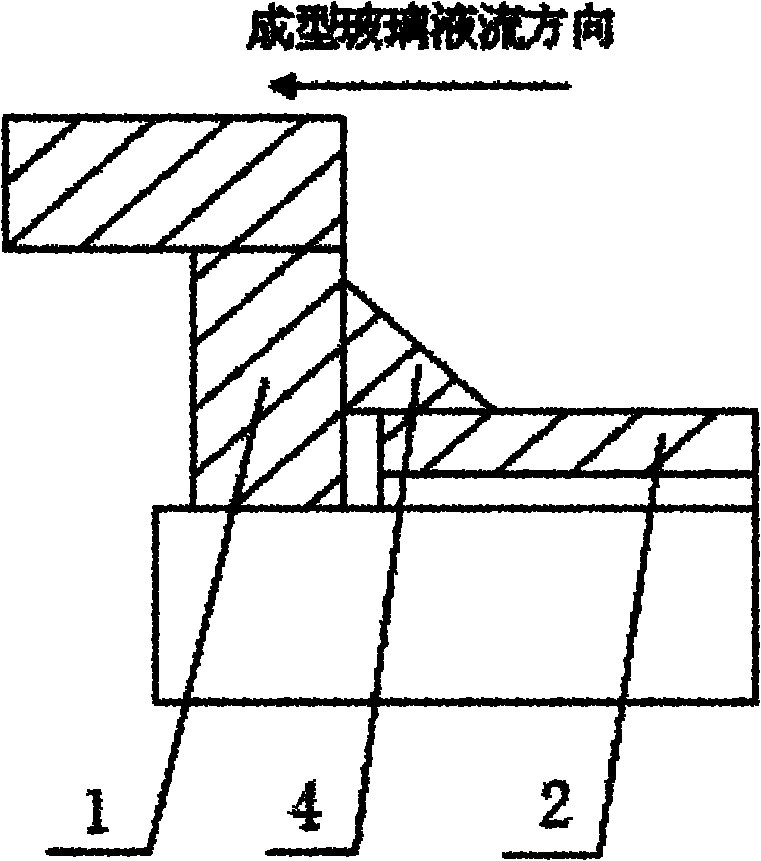

Molten bath of glass kiln

InactiveCN102140006AInhibit devitrificationReduce crystallization defectsGlass furnace apparatusGlass productionMelting tankDevitrification

The invention discloses a molten bath of a glass kiln, which comprises a bath wall and a bath bottom; a right-angle corner is formed between the bath wall and the bath bottom; a right angled triangle brick is arranged at the right-angle corner; two right-angle sides of the right angled triangle brick are respectively clung to the bath wall and the bath bottom; and both ends of an inclined edge are respectively and closely contacted with the bath bottom and the bath wall. The molten bath has the advantages of effectively changing glass liquid flow and reducing the retention time of glass liquid at the corner so as to lead glass liquid not to have the time element of devitrification, thereby avoiding the occurrence of glass devitrification phenomenon, substantially reducing the defect of glass devitrification, improving product quality and increasing finished product ratio.

Owner:HUAERRUN GLASS IND

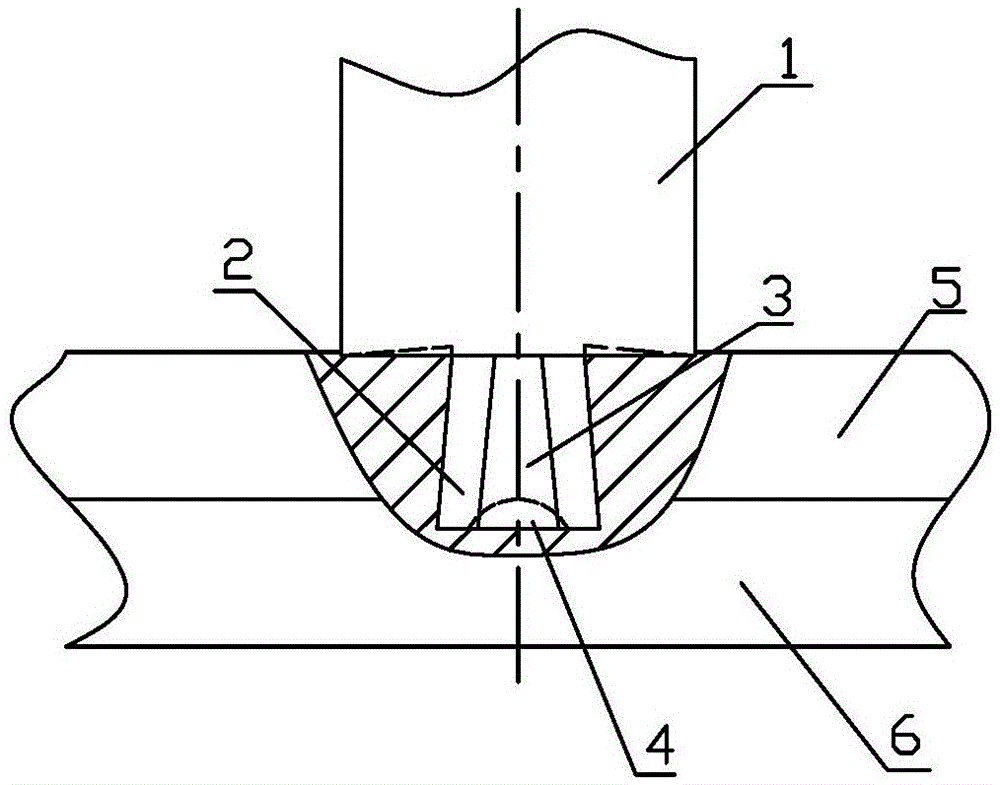

Transfusion plastic bottle double-color combined cover and injection mold thereof

InactiveCN106514971ASmall volumeReduce usagePharmaceutical containersMedical packagingInjection molding processEngineering

The invention relates to a transfusion plastic bottle double-color combined cover and an exhaust structure of an injection mold thereof, aims to solve the technical problem that air trapping is caused by disorderly flowing of an elastomer body in an injection molding process of the double-color combined cover, and belongs to the technical field of injection molding of medical transfusion plastic bottle double-color combined covers. The transfusion plastic bottle double-color combined cover is characterized in that a central shaft is used as a circle center of the upper part of the elastomer body, a plurality of water stopping grooves which are equally distributed uniformly are formed in a position near the periphery of the elastomer body, reinforcing ribs which are connected with a combined cover body are placed among the water stopping grooves, and space between each water stopping groove and a liquid isolating film and space between each water stopping groove and the inner side wall of an upper cavity are filled with an elastomer body (TPE) material; and in the injection mold of the double-color combined cover, an insert is in sleeve connection with a heat nozzle sleeve, water stopping ribs are placed on a surface, which is connected with the elastomer body, of the insert, the overall dimension of each water stopping rib is matched with the dimensional of a cavity of the corresponding water stopping groove in the elastomer body, and the water stopping ribs and the water stopping grooves not only guide the injection molding elastomer body material to flow orderly, but also guide air in the upper cavity to be discharged from air discharge grooves of an inner side surface and an outer side surface of the insert of the injection mold.

Owner:SHANGHAI PACIFIC ENTERPRISES CO LTD

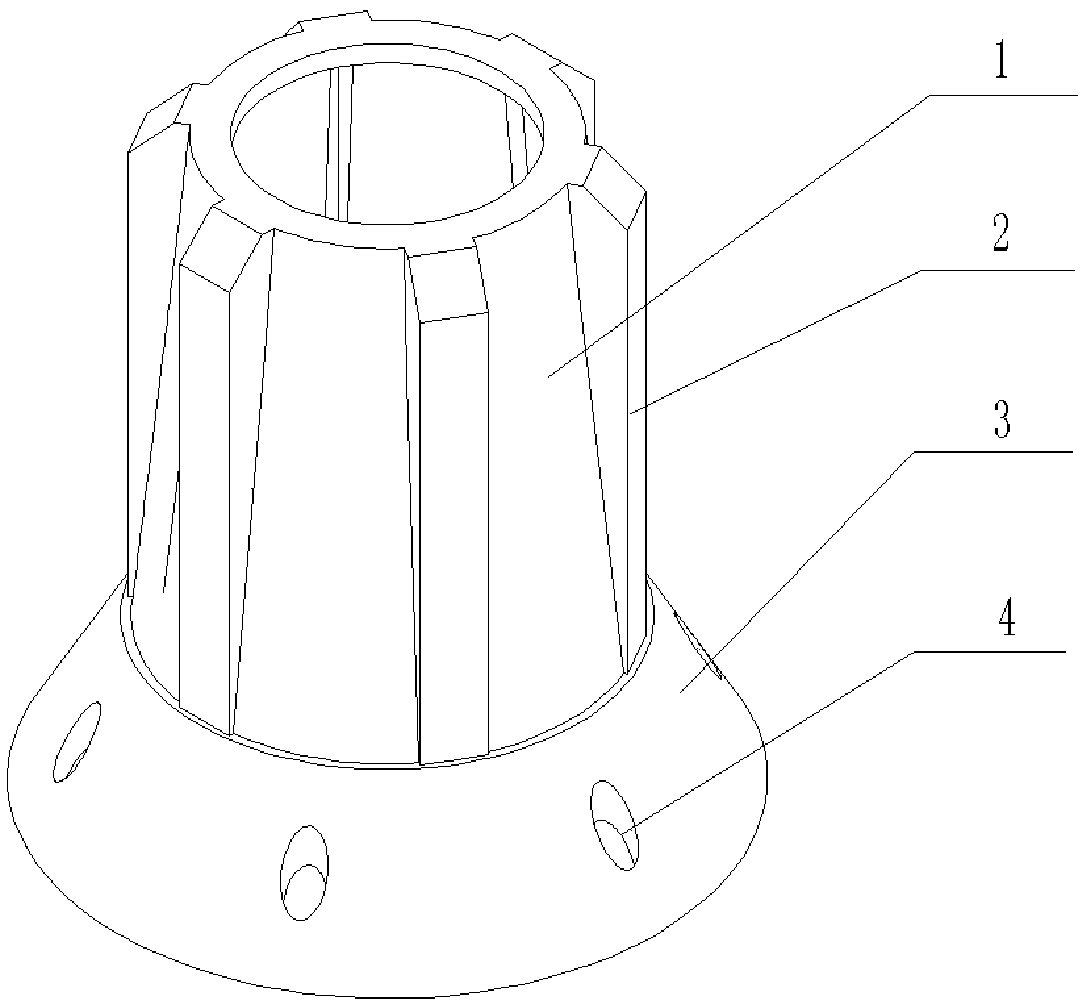

A friction stir welding tool for lap joints

InactiveCN103521912BStrengthening Strength CoefficientReduce vertical movementNon-electric welding apparatusLap jointEngineering

The invention discloses a friction stir welding tool for an overlap joint. The friction stir welding tool is composed of a shaft shoulder and a stirring needle. The stirring needle is shaped like a frustum, the small bottom of the frustum is connected with the shaft shoulder, the end face of the large bottom of the frustum is provided with a round concave hole, and the outer surface of the frustum is provided with three arc-shaped grooves distributed in the circumferential direction. Meanwhile, the invention further discloses the stirring needle and the structures and the sizes of all parts of the shaft shoulder. When a stirring tool designed through the friction stir welding tool is adopted for carrying out friction stir overlap welding, the stirring needle of the frustum shape generates oblique upward thrust on plasticized metal around the overlap face, so that the perpendicular motion of the plasticized metal is reduced, and the perpendicular moving tendency of the overlap face is reduced. Moreover, as the concave hole and the grooves in the side face are formed in the bottom of the stirring needle, material flow in weld zones is improved, the overlap face is broken completely, and the weld metal can be mixed fully. Accordingly, the size of the hook-like defect in a weld joint obtained through welding of the tool is greatly reduced, and the strength coefficient of the joint is remarkably improved.

Owner:TIANJIN UNIV

A combined bionic anti-wear h-fin elliptical flue gas heat exchange tube

ActiveCN103954161BReduce tail dust accumulationReduce washoutCorrosion preventionTubular elementsFlue gasWear resistant

The invention discloses a combined bionic anti-abrasion H-shaped fin elliptical flue gas heat exchange tube which comprises more than two rows of elliptical tubes in the flowing direction of gas and fins arranged on the two sides of the elliptical tubes, wherein a plurality of pairs of semispherical dimples are arranged on the windward sides of the fins; first through holes penetrating through the fins are formed in the bottoms of the semispherical dimples; a plurality of eddy generators are arranged on the leeward sides of the fins; a through hole adjacent to each eddy generator is formed in one side of the eddy generator. According to the flue gas heat exchange tube, the elliptical tubes are used as base tubes, the fins are arranged on the inner two sides of the elliptical tubes, the semispherical dimples and the eddy generators are arranged on the fins, and by the dimples, the flowing resistance can be effectively reduced to avoid the formation of large eddy turbulence in a flow field; in addition, by the novel combined fin structure, the comprehensive heat exchange efficiency can be effectively improved, and tail soot formation and tube abrasion can be greatly reduced.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

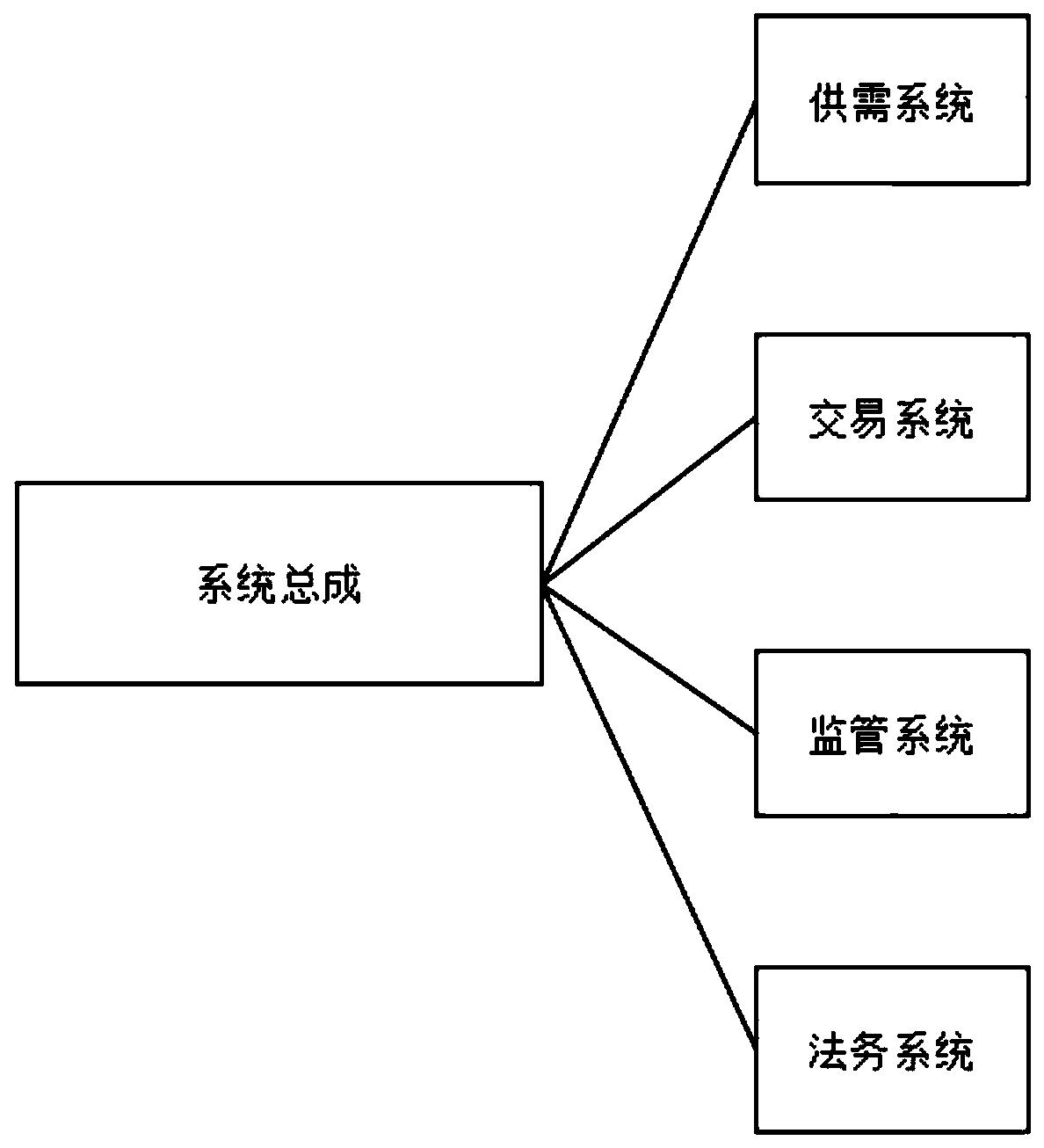

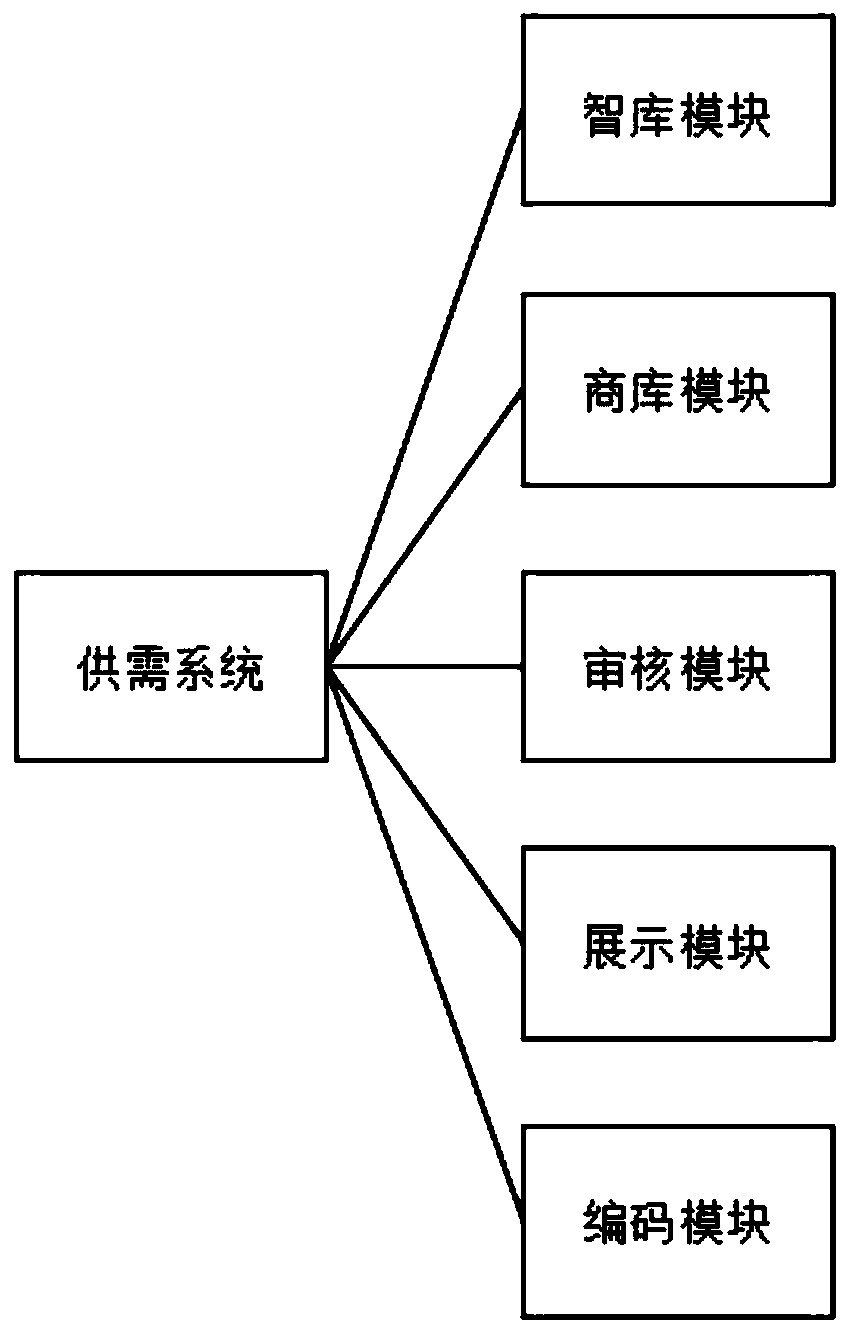

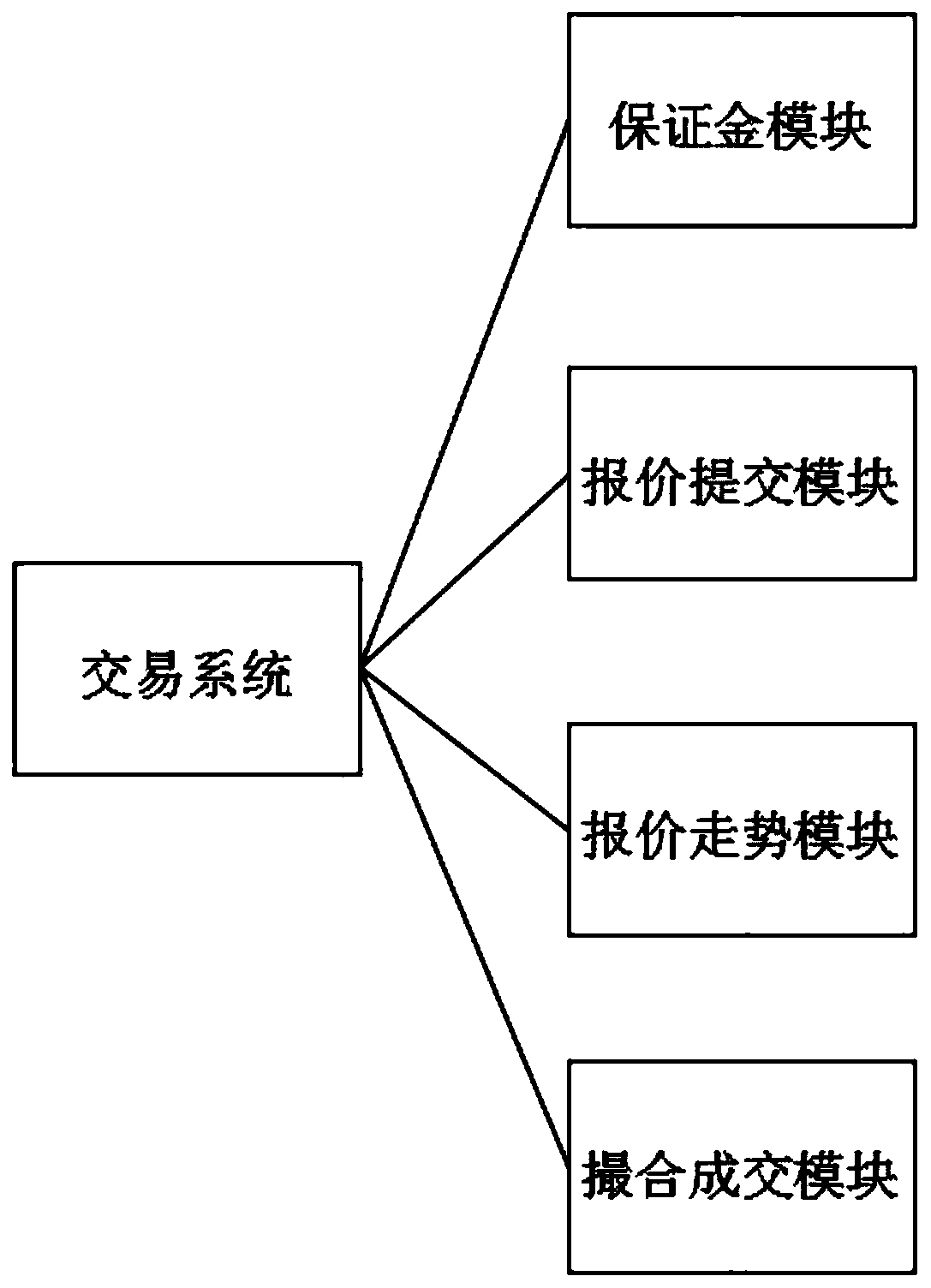

Human resource capital transaction management system

PendingCN110659874ASolve the contradiction between supply and demandPromote rapid growthFinanceOffice automationTransaction management systemManagement system

The invention discloses a human resource capital transaction management system, which comprises a system assembly. The system assembly comprises a supply and demand system, a transaction system, a supervision system and a legal affair system. Compared with the prior art, the system has the advantages that the contradiction between supply and demand of talents is macroscopically and effectively solved; from the aspect of talents, the talents depend on a platform and exist in an independent capital form, and the talents can flow as required; from the aspect of an employment unit, the expected value created by a traditional unit using talents is changed into the value directly achieved by solving the actual problem through the talents, the irregular behavior that the employment unit excavatesthe talents everywhere to grab the talents is changed, and the talents are more direct, more effective and lower in cost; from the aspect of talent service, a talent resource capital platform is established, a stage is provided for talents to play a role and achieve value, and the talents can play a role more advantageously; from the aspect of resource benefits, the talent utilization rate is increased, the labor cost is reduced, and an opportunity is provided for talent value change.

Owner:SHANDONG TAISHAN ZHIKU ECONOMIC DEV CO LTD

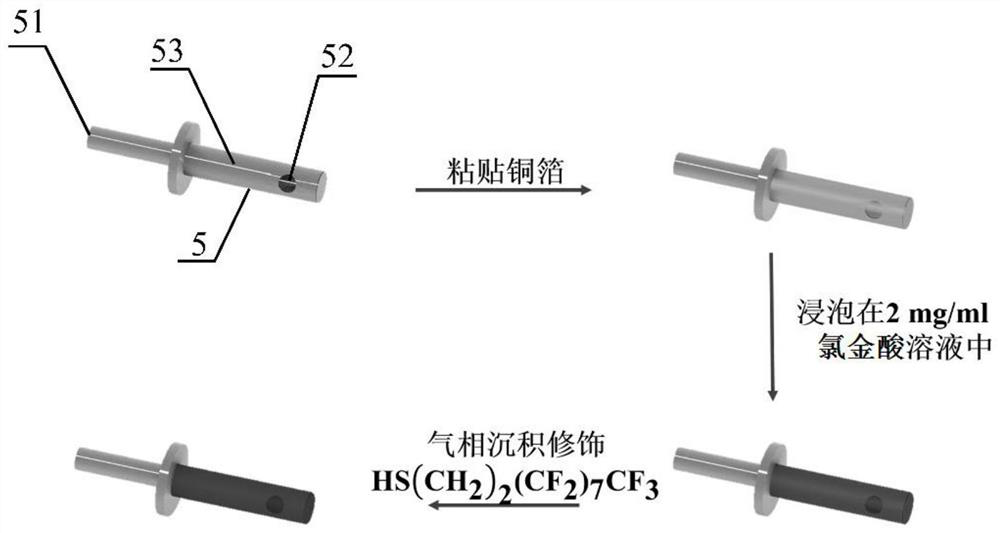

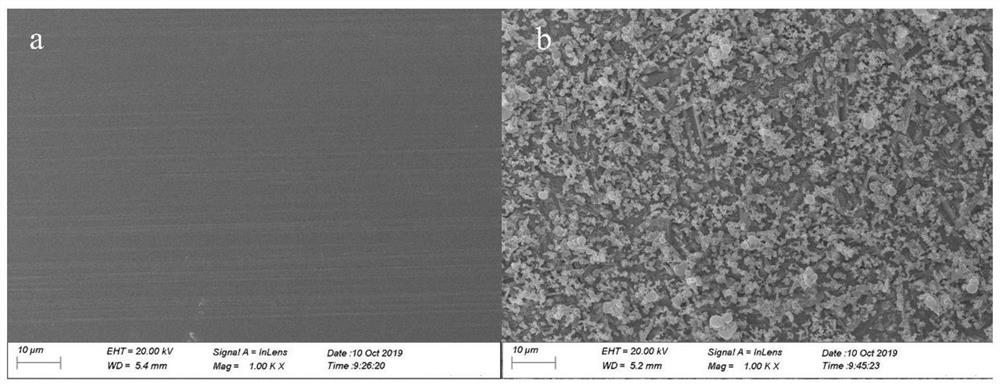

Method for enhancing mixing performance of rotating packed bed based on liquid distributor with super-hydrophobic surface

ActiveCN111659311AWell mixedImprove the mixing effectTransportation and packagingPretreated surfacesSuperhydrophobeEngineering

The invention discloses a method for enhancing the mixing performance of a rotating packed bed based on a liquid distributor with a super-hydrophobic surface. The rotating packed bed is suitable for asystem containing liquid in raw materials. The surface of the liquid distributor of the rotating packed bed is modified with a super-hydrophobic coating so that the liquid distributor has the super-hydrophobic surface, raw materials are not adhered to the surface of the liquid distributor after flowing out of an outlet of the liquid distributor and continuously flow into the rotating packed bed,and the mixing effect of the rotating packed bed on the raw materials is enhanced. It is known that the wettability of the solid surface can influence the flowing condition of liquid in the rotating packed bed, the surface of the liquid distributor is modified with the super-hydrophobic coating so that the liquidity of the liquid in the rotating packed bed is improved, and the mixing effect of therotating packed bed on the liquid is further improved. The rotating packed bed is expected to be applied to chemical preparation and laboratory microminiature experiments in the field of biological medicine.

Owner:BEIJING UNIV OF CHEM TECH

Vehicles with air deflectors for wheels

ActiveCN107107971BChange flowExpand volume spaceAerodynamics improvementComponent optimizationAerodynamic dragClassical mechanics

Owner:PEZHO SITROEN AUTOMOBILS SA

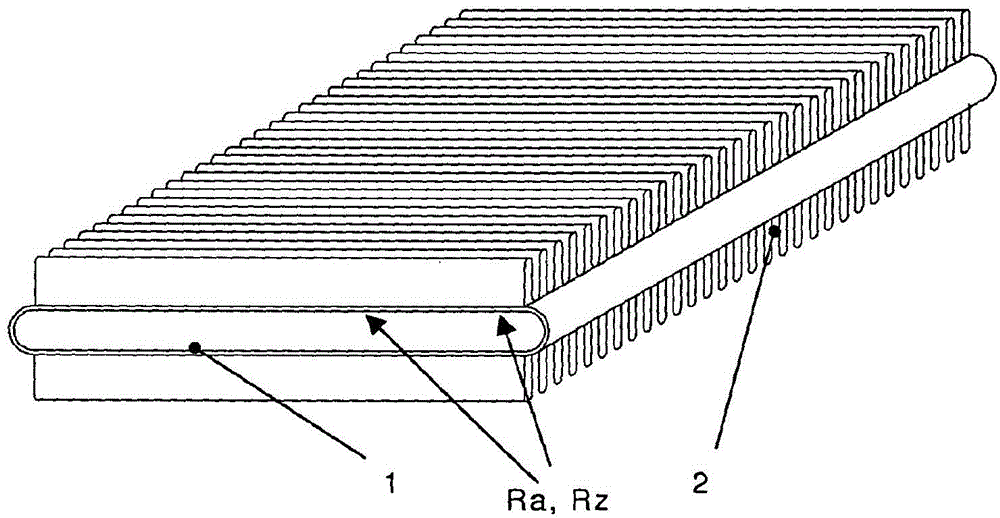

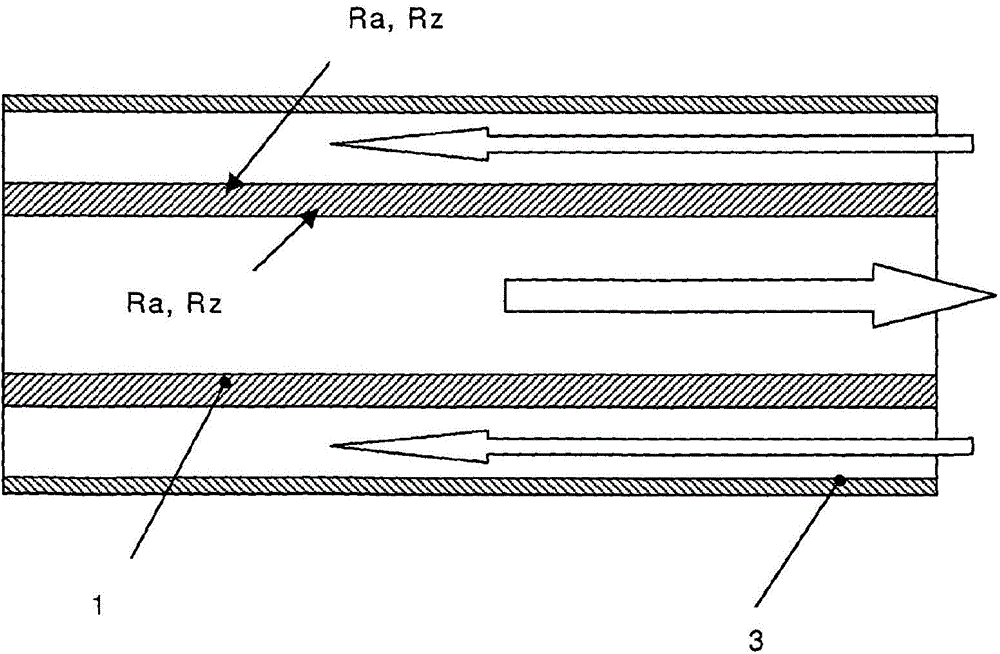

Heat exchanger

The invention relates to a heat exchanger for exchanging heat between a first material or material flow and a second material or material flow, comprising at least one wall that separates the materials or material flows, wherein the surface of the wall has an arithmetic mean roughness Ra of 2 to 20 [mu]m, preferably 10 [mu]m, or a roughness depth Rz of 10 to 50 [mu]m, preferably 30 [mu]m.

Owner:WICKEDER WESTFALENSTAHL

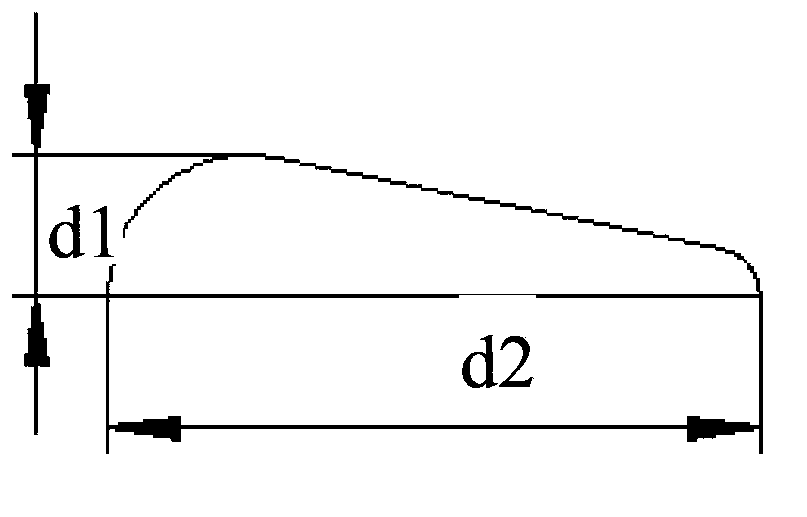

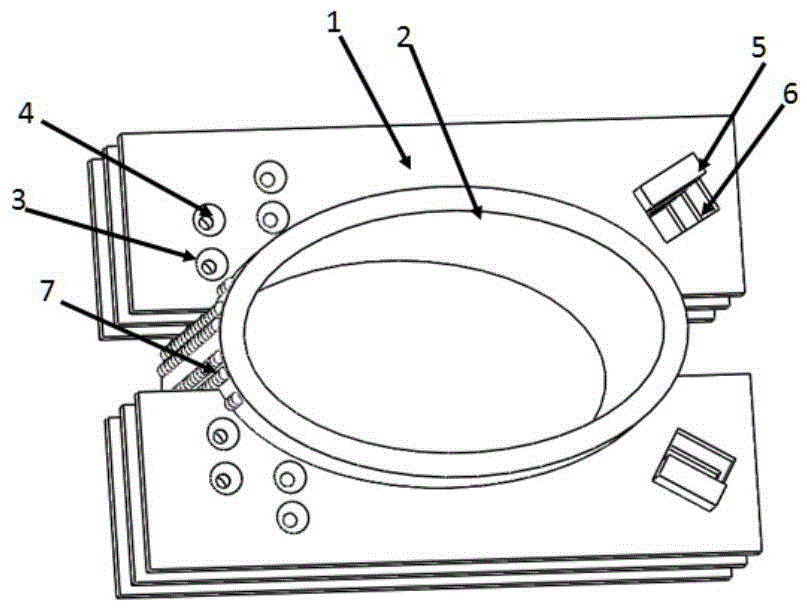

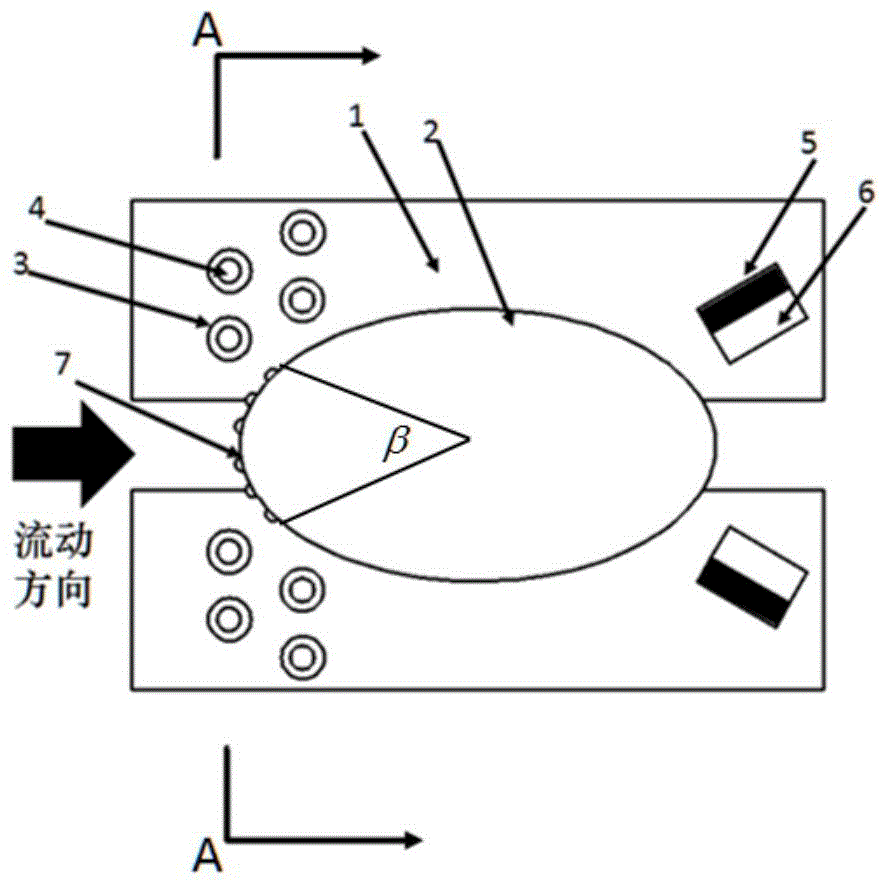

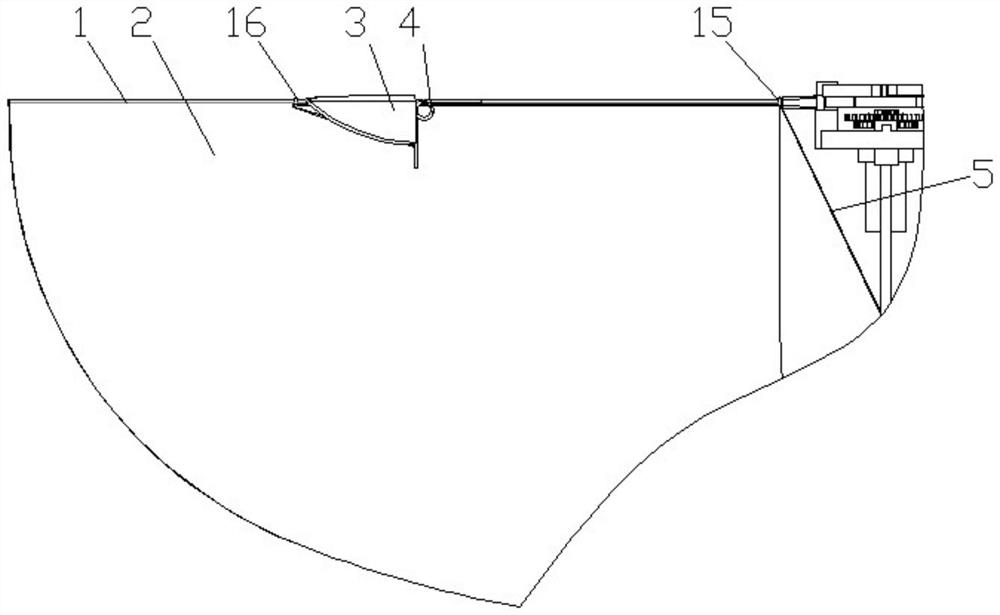

A shark fin bow structure and its bulbous bow hull shape

ActiveCN109895938BChange flowReduce the degree of expansionWatercraft hull designHydrodynamic/hydrostatic featuresWater flowMechanical engineering

The invention provides a shark fin bow structure, which includes an upper part and a lower part, the lower part is a bulbous nose; the front end of the upper part is perpendicular to the sea level, extends upwards to the bow surface of the hull, connects downwards to the bulbous nose, and connects to the bulbous nose backwards. Hull smooth connection. Because the structure of the present invention has the same narrow front end as the bow of the hull, it can change the flow of the water flow in the original bulbous depression, slow down the expansion of the streamline, and effectively reduce the wave-breaking resistance during the ship's navigation without affecting the bulbous bow. The reduction of wave-making resistance can solve the problem of increased resistance of the hypertrophy bulbous bow ship when sailing at medium and low speeds.

Owner:WUHAN UNIV OF TECH

Rolling method for rectangular isotropous stainless steel ring piece

The invention discloses a rolling method for a rectangular isotropous stainless steel ring piece. The rolling method includes the steps that firstly, a stainless steel rod is heated to the forging temperature to be upset, punched and pre-rolled, and a rectangular ring blank is manufactured; and secondly, the rectangular ring blank is put into a ring rolling machine, a conic roller is lifted up by 5 mm to 10 mm, the rectangular ring blank is inclined, then rolling forming is conducted, and the rectangular stainless steel ring piece is obtained. By the adoption of the method, the flowing direction of materials in the rolling process is changed, and isotropous mechanical performance of the rectangular ring piece is kept the same, so that the comprehensive mechanical performance of the rectangular ring piece is improved. The method is used for producing the rectangular isotropous stainless steel ring piece.

Owner:GUIZHOU ANDA AVIATION FORGING

Equipment for producing aluminum alloy hollow casting ingot and method of equipment

The invention relates to the technical field of aluminum alloys, in particular to equipment for producing an aluminum alloy hollow casting ingot and a method of the equipment. The equipment for producing the aluminum alloy hollow casting ingot comprises a core die, a crystallizer, a bracket and a dummy ingot, wherein the core die is positioned at the center of the crystallizer and is concentric with the crystallizer; the bracket arranged on the crystallizer is used for supporting the core die; the dummy ingot is arranged at the lower part of the core die; a space between the core die and the crystallizer is a die cavity; the core die is designed into a taper with a large upper part and a small lower part; and the size of the taper is 1-30 degrees; a cooling system and a lubricating system are arranged in the core die; a coil is arranged in a water chamber of an aluminum sleeve of the crystallizer; and a shunt and a stop block are arranged on the crystallizer. According to the equipment for producing the aluminum alloy hollow casting ingot and the method for the equipment disclosed by the invention, a friction force between the casting ingot and the die core in the hollow casting process of the aluminum alloy is reduced and the core locking and breakout are avoided.

Owner:NORTHEASTERN UNIV LIAONING

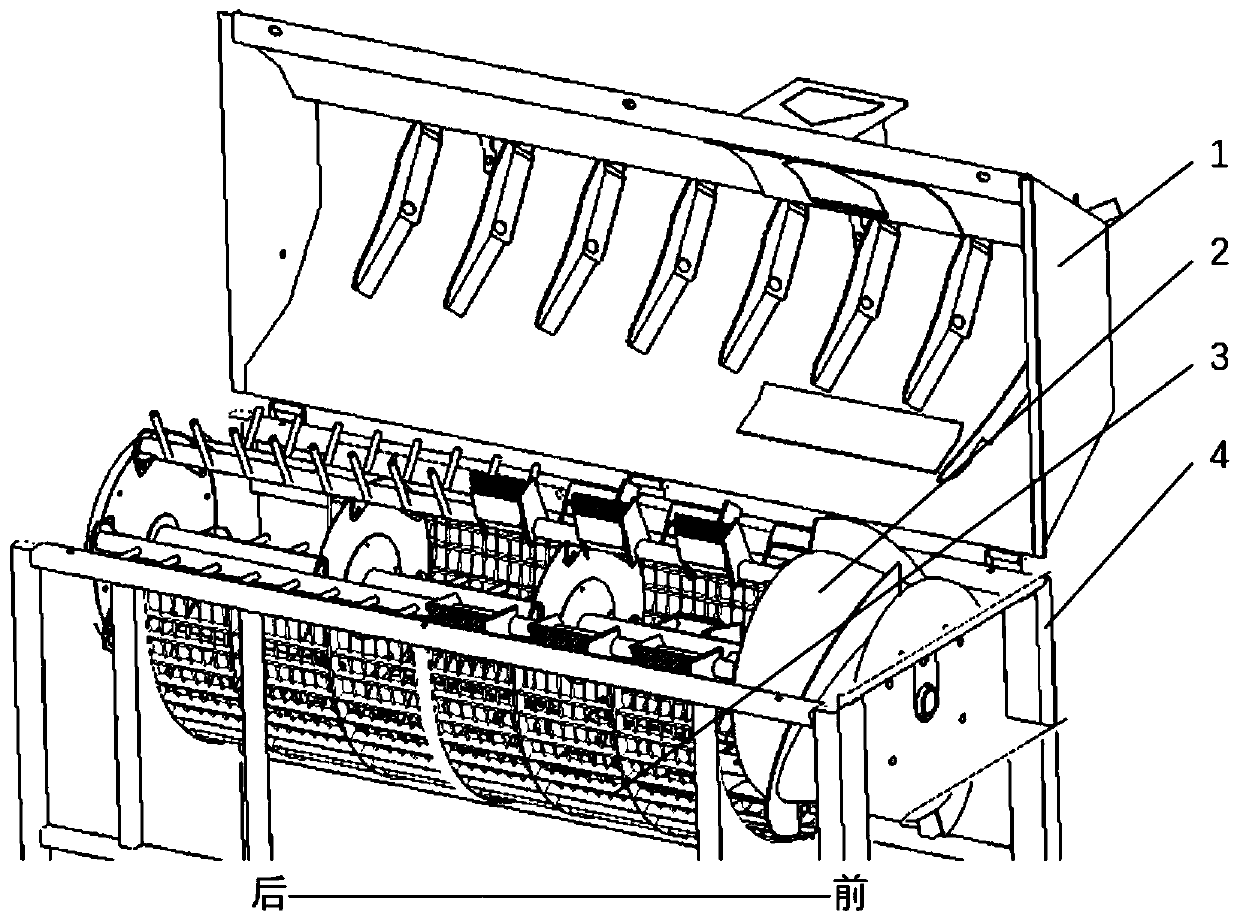

Small-scale threshing and separating device suitable for rice and oilseed rape in hilly and mountainous areas

PendingCN111165189AImprove cleaning rateReduced grain loss rateThreshersAgricultural engineeringEnvironmental geology

The invention provides a small-scale threshing and separating device suitable for rice and oilseed rape in hilly and mountainous areas. The small-scale threshing and separating device suitable for therice and the oilseed rape in the hilly and mountainous areas comprises an open roller, a top cover located above the open roller, and a grid-type concave screen located below the open roller; and theopen roller comprises a roller shaft, a feeding head, a plurality of toothed bars and a plurality of wheels, the feeding head and the wheels are sequentially installed on the roller shaft in a crop feeding direction from front to rear, a plurality of rounds of adjusting holes are formed in the wheels, the toothed bars are installed on the wheels through the adjusting holes, the toothed bars are evenly distributed in a peripheral direction with an axis of the roller shaft as a center, and a plurality of rasp bar board tooth groups and spike tooth groups are sequentially arranged on the toothedbars in the crop feeding direction. The small-scale threshing and separating device suitable for the rice and the oilseed rape in the hilly and mountainous areas can be suitable for threshing and separating of the oilseed rape and the rice in the hilly and mountainous areas, and has the advantages of being low in threshing loss ratio and high in cleaning ratio.

Owner:JIANGSU UNIV

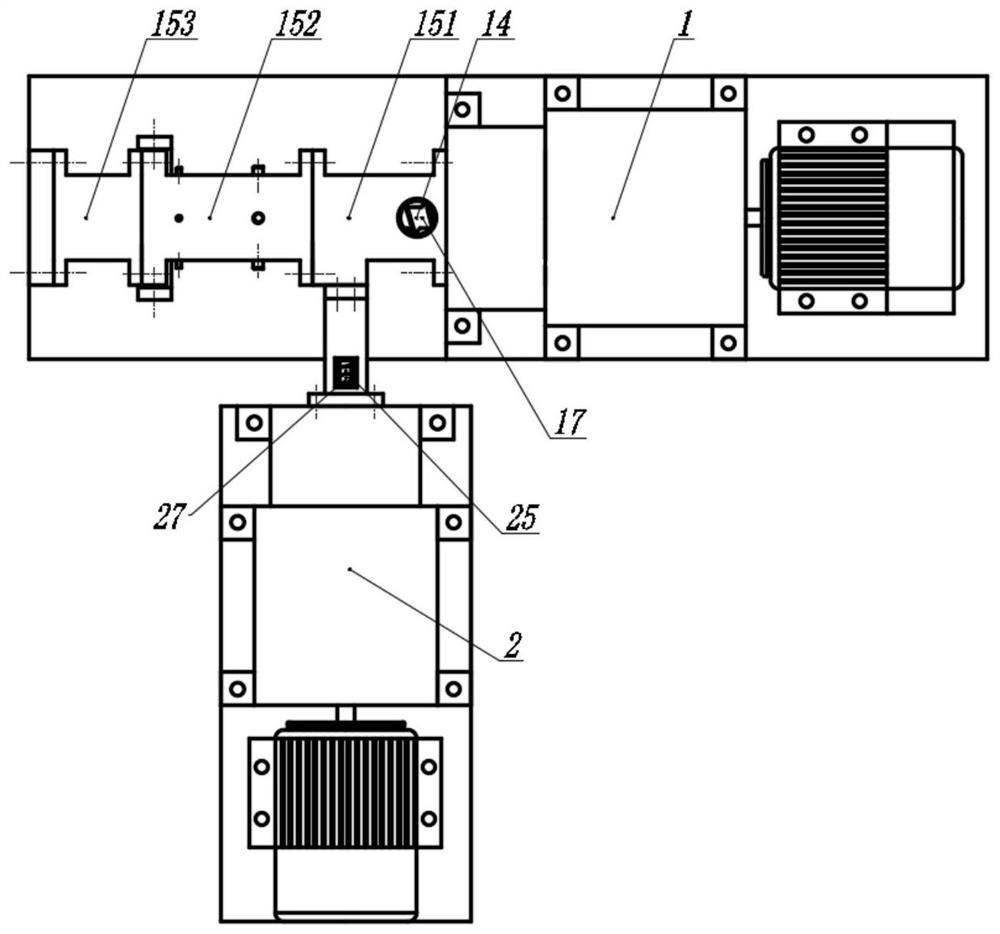

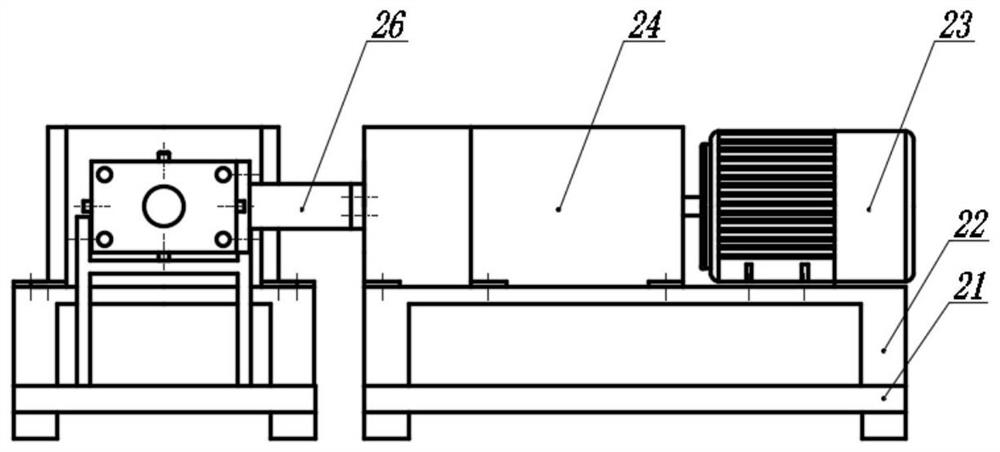

Rubber mixing and extruding device

The invention discloses a rubber mixing and extruding device which comprises a main extruder and an auxiliary extruder, the main extruder and the auxiliary extruder are in right-angle butt joint, and the main extruder fully mixes a rubber compound with a vulcanizing agent and an accelerant or sulfur-containing rubber master batch which are uniformly compacted by the auxiliary extruder and then mixes the rubber compound at a low temperature; the main screw is composed of a main mandrel and a main screw head, and the auxiliary screw is composed of an auxiliary mandrel and an auxiliary screw head. The feeding section and the mixing section are of single-head thread structures with the same thread section and are large in thread pitch, the compaction section is of a single-head thread structure with the small thread pitch, the transmission pressurization section and the transmission pressure reduction section are each of a gradual change type thread structure, the depth of a thread groove of the mixing section is small, two-way threads are machined on the surface of the mixing section, and the reverse mixing section is of a double-head two-way thread structure. The spiral groove depth of the reverse mixing section is deeper than that of the mixing section; the main extruder compacts materials through the small-pitch compaction section, the auxiliary extruder is pressurized and compacted through the flow channel with the flow decreasing gradually, and the mixing effect is enhanced through the combination mode of the gradually-changed threads of the transmission pressurization section, the pin and the internal threads of the machine barrel.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com