Motor with good ventilation properties

A technology with good performance, applied in the shape/style/structure of electrical components, electromechanical devices, winding conductors, etc., can solve the problems of poor ventilation and cooling effect, increased ventilation, enhanced convection, etc., to achieve increased ventilation and enhanced convection , Reduce the effect of motor temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

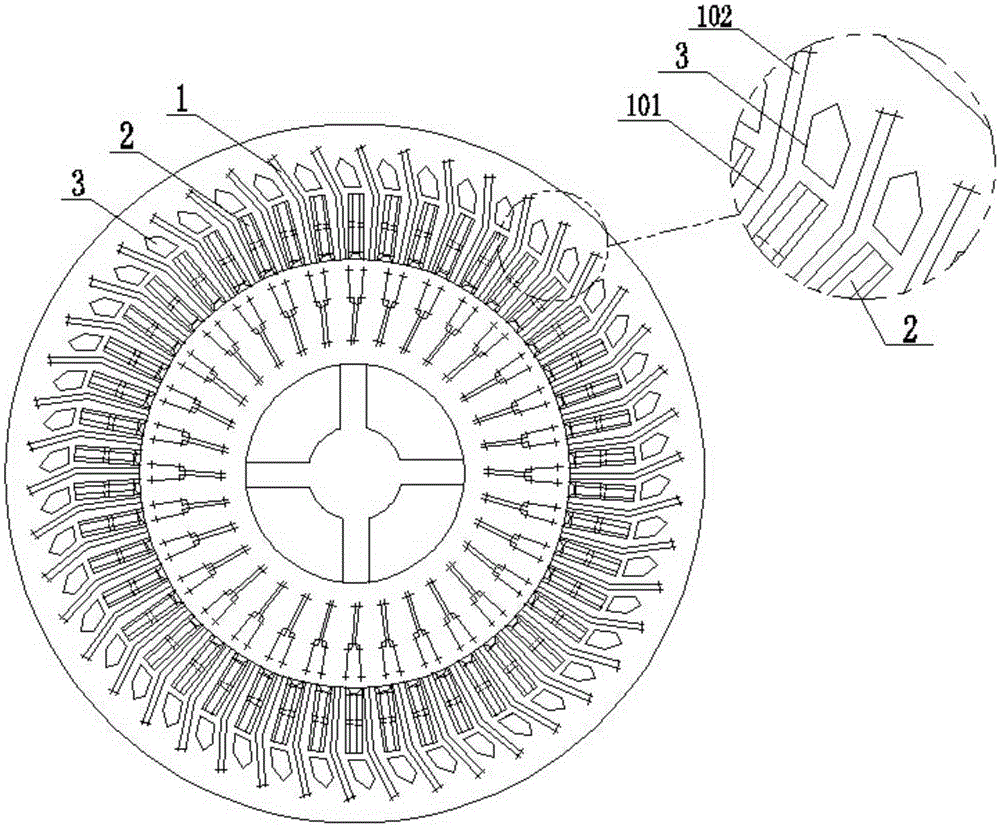

[0011] refer to figure 1 The motor with good ventilation performance includes a motor winding, and a ventilation channel steel 1 is arranged between two adjacent teeth of the motor winding, and the proximal end 101 of the ventilation channel steel 1 is installed on two adjacent teeth of the motor winding. Between two winding teeth 2, the distal end 102 of the ventilation channel steel 1 extends to the outside of the motor winding and deflects counterclockwise to form a ">" shape with the proximal end 101, and the acute angle between the proximal end 101 and the distal end 102 The included angle is 120-165°, and a pentagon 3 is arranged between the far-axis ends 102 of two adjacent ventilation channel steels 1. Except for the bottom surface of the pentagon 3 close to the motor winding, the rest of the sides are counterclockwise. tilt.

[0012] The airflow generated in the motor flows out of the motor along the ventilation grooves formed by two adjacent ventilation channel stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com