Heat exchanger

A technology of heat exchanger and heat exchange, applied in heat exchange equipment, heat transfer modification, lighting and heating equipment, etc., can solve the problem of large area of heat exchanger, achieve high heat conduction, improve efficiency, and increase contact surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

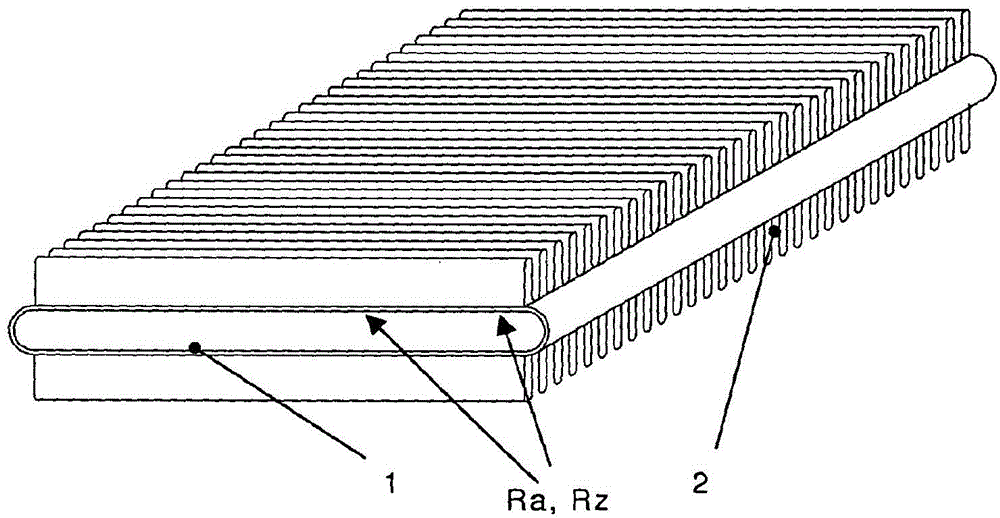

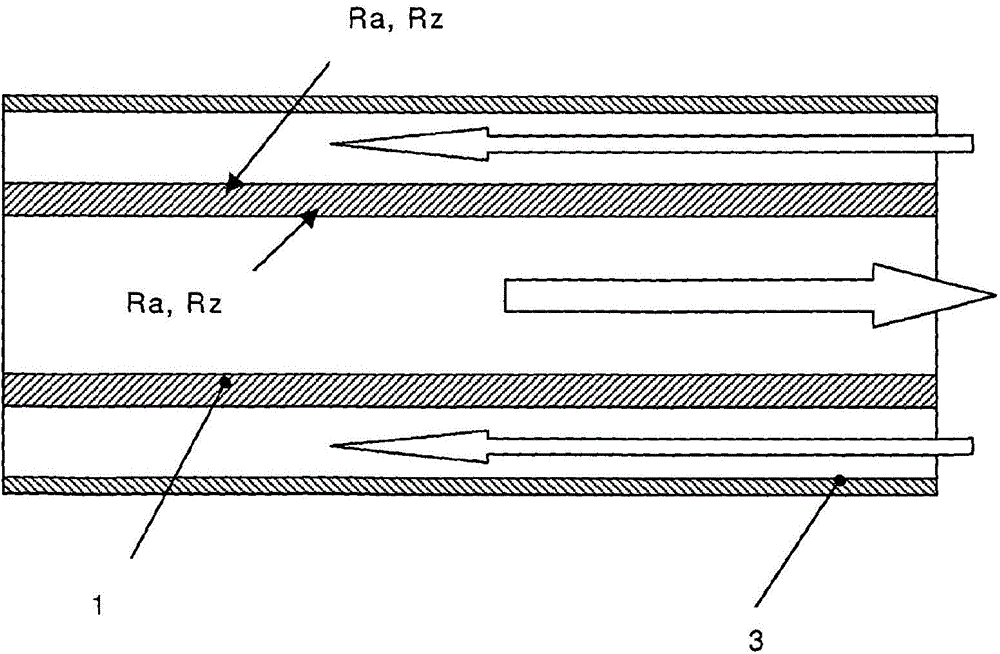

[0029] The heat exchanger of the invention comprises at least one wall separating the material or material flow. In this context, the heat exchanger according to the invention is preferably a heat exchanger for indirect heat transfer, which is characterized in that the material flow is spatially separated by a heat-conducting wall. Such heat exchangers are also referred to as heat recuperators (Rekuperator). The structural form of the heat exchanger (Regenerator) can also be considered.

[0030] According to the invention it is provided that the surface of the partition wall at least locally has an arithmetic mean roughness value Ra of 2 to 20 μm, preferably 10 μm, and / or a roughness height Rz of 10 to 50 μm, preferably 30 μm.

[0031] The commonly used abbreviation Ra represents the arithmetic mean roughness value and implements the standard DIN EN ISO4287:1998. The average roughness value is the arithmetic mean of multiple magnitudes of the roughness profile and describes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com