Transfusion plastic bottle double-color combined cover and injection mold thereof

A technology of injection mold and combined cover, which is applied to other household appliances, household appliances, transportation and packaging, etc. It can solve the problems of liquid leakage, elastic body invagination, falling, etc., so as to increase the connection area and reduce the amount of use , enhance the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

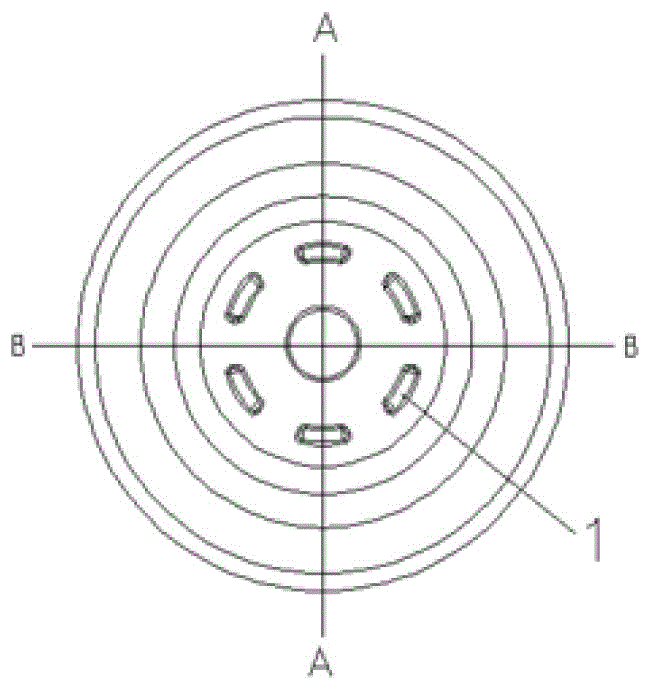

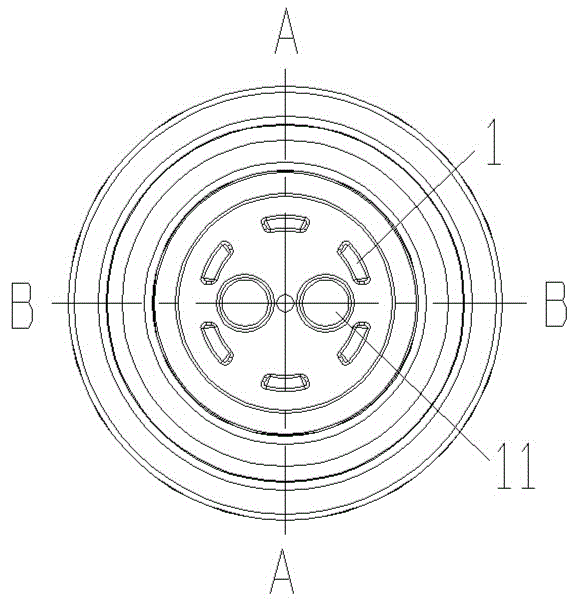

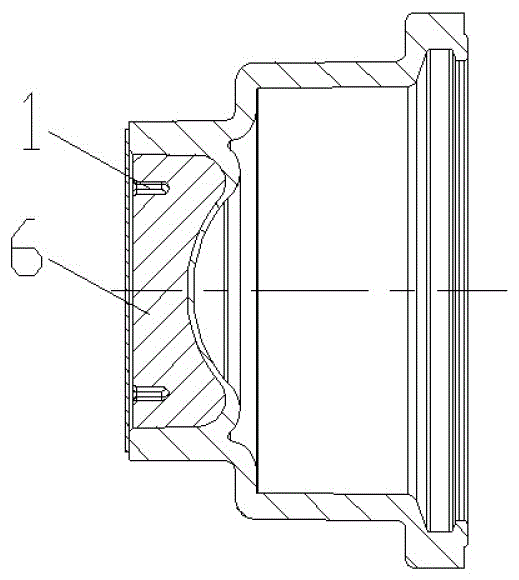

[0016] The embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention. All similar structures and similar changes of the present invention should be included in the scope of protection of the present invention. The commas in all indicate the relationship between and.

[0017] The flow of the elastomer (TPE) body of the two-color combined cover is irregular during the injection molding process, and there is no definite flow direction, which causes the air in the upper cavity of the injection molded elastomer to not be discharged out of the mold smoothly, which affects the flow of the molten material. produce stagnation. The purpose of the present invention is to improve the structure of the two-color combination cap of the transfusion plastic bottle, so as to avoid air trapping due to the disordered flow of the elastomer (TPE) body during th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com