Molten bath of glass kiln

A glass furnace and melting pool technology, applied in glass furnace equipment, glass production, glass manufacturing equipment and other directions, can solve problems such as adverse effects on production quality and easy occurrence of crystallization, so as to avoid glass crystallization and improve product quality. , reduce the effect of long stay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

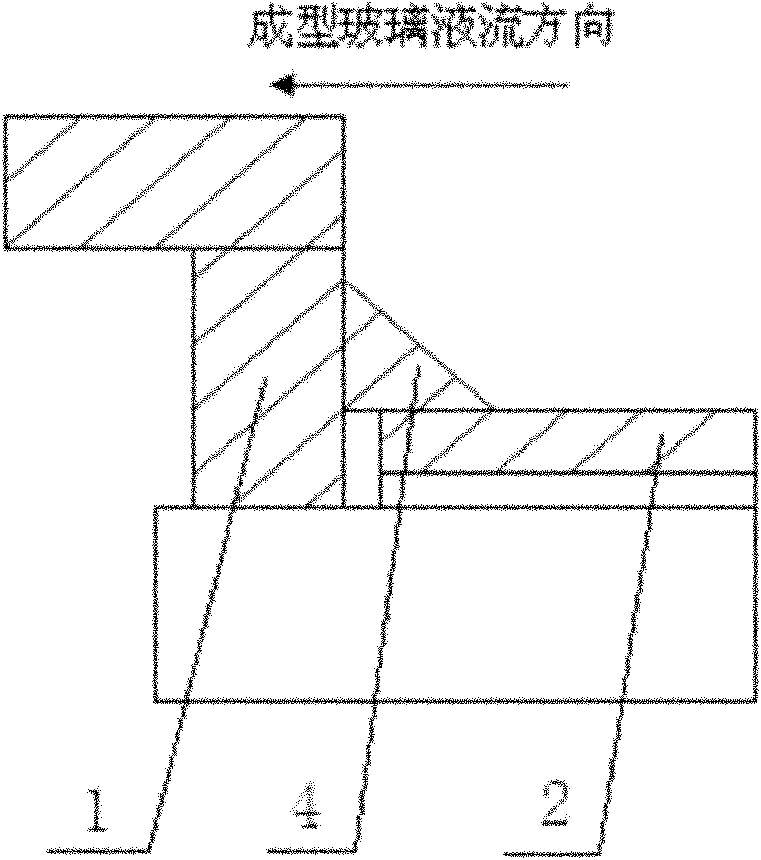

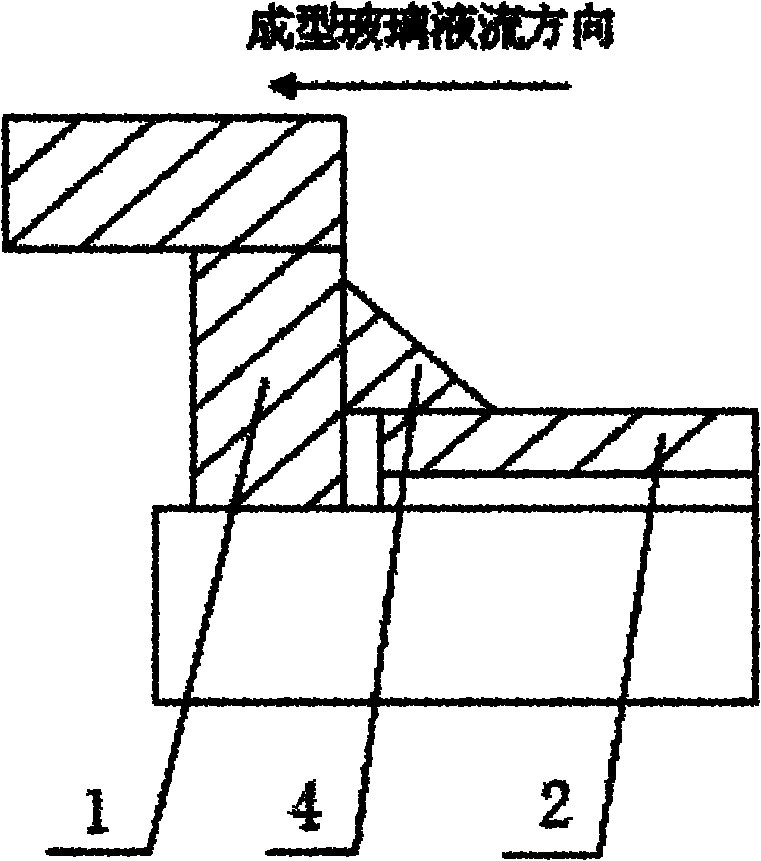

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings.

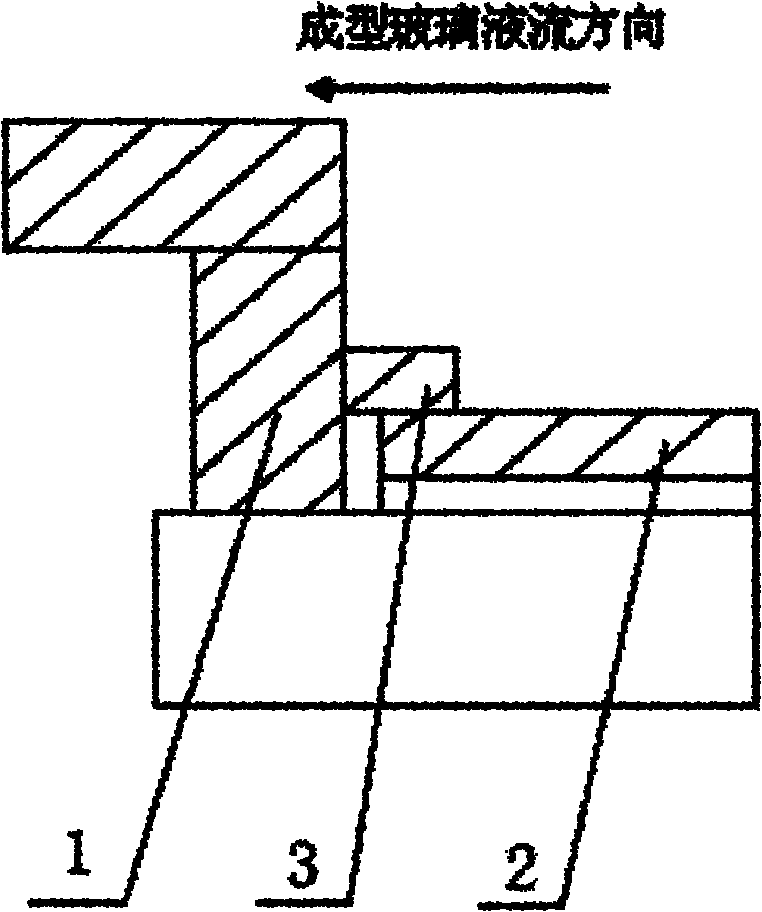

[0013] Such as figure 2 As shown, a melting pool of a glass furnace in the present invention comprises a pool wall 1 and a pool bottom 2. The pool wall 1 and the pool bottom 2 form a right-angled corner, and a right-angled triangular brick 4 is arranged at the right-angled corner, and a right-angled triangular brick 4 The two right-angled sides of the tank are attached to the pool wall 1 and the pool bottom 2 respectively, and the two ends of the hypotenuse are in close contact with the pool bottom 2 and the pool wall 1 respectively.

[0014] The hypotenuse of the right-angled triangular brick 4 forms an angle of 30-60°, preferably 45°, with the pool bottom 2 .

[0015] The length of each right-angled side of the right-angled triangular brick 4 can be determined according to the size of the molten pool and the amount of molten glass, preferably 150-300 mm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com