Preparation method of glass powder, and glass powder

A technology of glass powder and glass, which is applied in the field of glass powder and glass powder preparation. It can solve the problems of high pressure resistance and weather resistance, poor chemical stability against water, and poor product insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

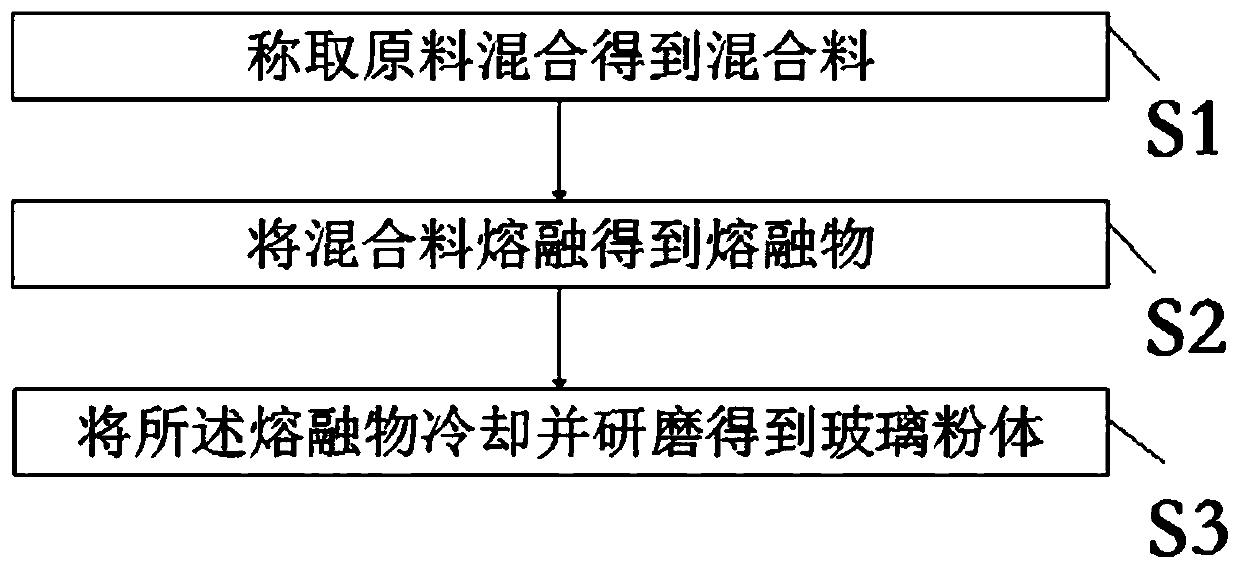

[0031] Such as figure 1 As shown, the method for preparing glass powder according to the embodiment of the present invention includes:

[0032] Step S1, weighing and mixing raw materials to obtain a mixture;

[0033] Step S2, melting the mixture to obtain a melt;

[0034] Step S3, cooling and grinding the melt to obtain glass powder;

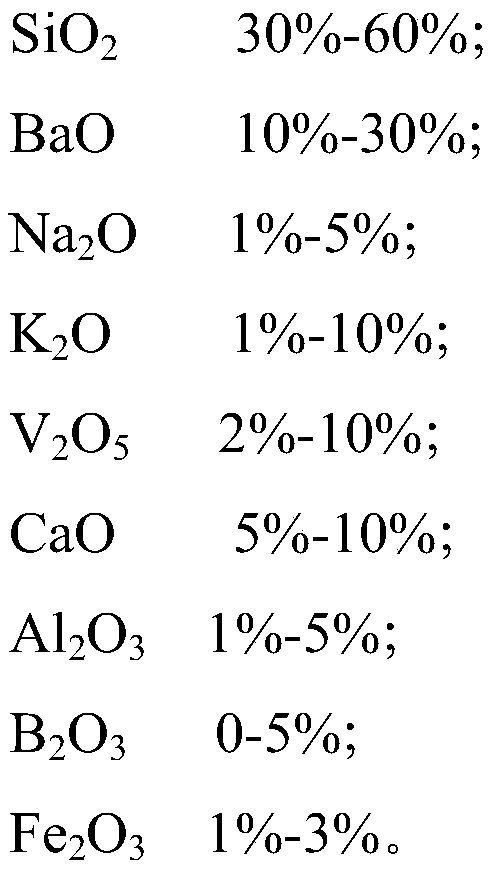

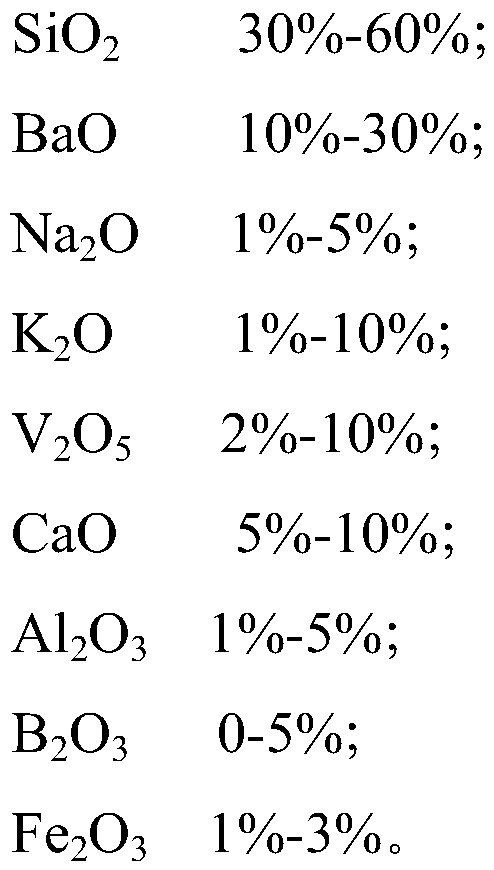

[0035] Wherein, the raw material includes: SiO 2 30%-60%, BaO 10%-30%, Na 2 O 1%-5%, K 2 O 1%-10%, V 2 O 5 2%-10%, CaO 5%-10%, Al 2 O 3 1%-5%, B 2 O 3 0-5% and Fe 2 O 3 1%-3%. In the above method, SiO 2 And BaO are glass forming bodies, SiO 2 The content is between 30%-60%, if SiO 2 The content is less than 30%, it is not easy to form a glass state, if SiO 2 If the content is higher than 60%, the softening temperature of the glass body is too high, and it is not easy to fully infiltrate the metal during the high-temperature sealing process, causing the sealing failure. In addition, SiO 2 It also plays a role in improving the chemical stability of t...

Embodiment 1

[0050] Weigh the raw materials and mix them to obtain a mixture; melt the mixture at 1450°C for 15 hours to obtain a melt; quench the melt with water to form glass fragments, grind and sieve the glass fragments to obtain glass powder; wherein, Raw materials include: SiO 2 30%, BaO 30%, Na 2 O 5%, K 2 O 10%, V 2 O 5 10%, CaO 10%, Al 2 O 3 3%, B 2 O 3 0%, Fe 2 O 3 2% and modifier 0%.

Embodiment 2

[0052] Weigh the raw materials and mix to obtain a mixture; melt the mixture at 1600°C for 8 hours to obtain a melt;

[0053] The molten material is water-cooled, quenched and cooled to form glass cullet, and the glass cullet is ground and sieved to obtain glass powder; wherein the raw materials include: SiO 2 60%, BaO 10%, Na 2 O 1%, K 2 O 10%, V 2 O 5 6%, CaO 5%, Al 2 O 3 1%, B 2 O 3 2%, Fe 2 O 3 3% and modifier 2%, modifier includes SrO and MgO, and the weight ratio of SrO and MgO is 2:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Glass softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com