Solvent-free oil pipeline anti-corrosion and anti-drag special coating and preparation method thereof

A solvent-free technology for oil pipelines, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of easy-to-produce lines, difficult construction, and easy fouling of coatings in the air-driven spherical extrusion coating process, and achieve Excellent leveling and drag reduction characteristics, strong construction adaptability, and the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

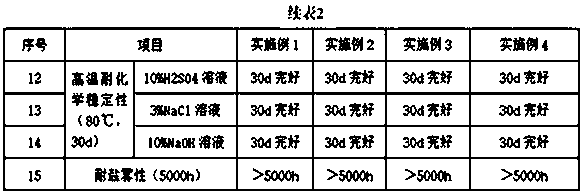

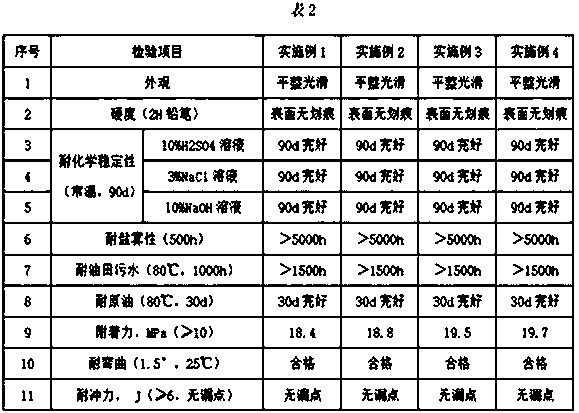

Examples

Embodiment 1

[0035] Embodiment 1. A solvent-free oil pipeline anti-corrosion and drag-reducing special coating is composed as follows:

[0036] Component 1 (i.e. lacquer) prepare raw materials according to the following mass parts: 20 parts of bisphenol A epoxy resin, 10 parts of polyethersulfone modified epoxy resin, 8 parts of aromatic hydrocarbon resin, 8 parts of epoxy reactive diluent , 0.2 parts of dispersant A, 0.3 parts of dispersant B, 0.5 parts of polyethylene wax powder, 5 parts of polytetrafluoroethylene wax powder, 5 parts of potassium hexatitanate whiskers, 0.1 part of phthalocyanine blue, 8 parts of lemon yellow, talc 8 parts of powder, 22 parts of silicon micropowder, 0.6 parts of defoamer, 10 parts of glass fiber powder, and 0.3 parts of leveling agent;

[0037] Component 2 (curing agent) prepare raw materials according to the following mass parts: cashew nut shell oil modified phenalkamine curing agent (CX105X curing agent) 10 parts, resin type modified fatty amine curing...

Embodiment 2

[0048] Embodiment 2. A solvent-free oil pipeline anti-corrosion and drag-reducing special coating is composed as follows:

[0049] Component 1 (i.e. lacquer) prepare raw materials according to the following parts by mass: 25 parts of bisphenol A epoxy resin, 8 parts of polyethersulfone modified epoxy resin, 6 parts of aromatic hydrocarbon resin, 5 parts of epoxy reactive diluent , 0.2 parts of dispersant A, 0.2 parts of dispersant B, 0.8 parts of polyethylene wax powder, 4 parts of polytetrafluoroethylene wax powder, 6 parts of potassium hexatitanate whiskers, 0.3 parts of phthalocyanine blue, 10 parts of lemon yellow, talc 10 parts of powder, 17 parts of silicon micropowder, 1 part of defoamer, 8 parts of glass fiber powder, 0.2 parts of leveling agent;

[0050] Component 2 (curing agent) is prepared according to the following parts by mass: cashew nut shell oil modified phenalkamine curing agent (CX105X curing agent) 30 parts, resin type modified fatty amine curing agent (CK...

Embodiment 3

[0061] Embodiment 3. A solvent-free oil pipeline anti-corrosion and drag-reducing special coating is composed as follows:

[0062] Component 1 (i.e. lacquer) prepare raw materials according to the following parts by mass: 30 parts of bisphenol A epoxy resin, 6 parts of polyethersulfone modified epoxy resin, 6 parts of aromatic hydrocarbon resin, 5 parts of epoxy reactive diluent , 0.5 parts of dispersant A, 0.2 parts of dispersant B, 1 part of polyethylene wax powder, 3.5 parts of polytetrafluoroethylene wax powder, 8 parts of potassium hexatitanate whiskers, 0.3 parts of phthalocyanine blue, 10 parts of lemon yellow, talc 6 parts of powder, 12 parts of silicon micropowder, 0.8 part of defoamer, 15 parts of glass fiber powder, 0.4 part of leveling agent;

[0063] Component 2 (curing agent) is prepared according to the following parts by mass: cashew nut shell oil modified phenalkamine curing agent (CX105X curing agent) 50 parts, resin type modified fatty amine curing agent (CK...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com