Hot melt adhesive for bonding cable heat shrinkage bush

A heat-shrinkable sleeve and hot-melt adhesive technology, applied in adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., can solve problems such as product scrapping, self-adhesive hot-melt adhesives, water ingress and leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

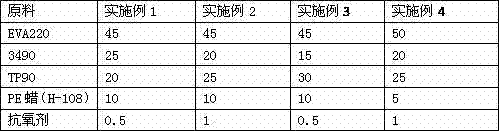

[0021] The invention relates to a hot-melt adhesive for bonding heat-shrinkable sleeves, which is mainly composed of the following raw materials in parts by weight:

[0022] Polyethylene vinyl acetate EVA 40-60 parts

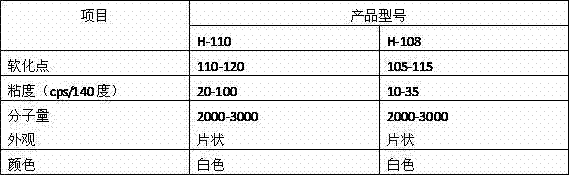

[0023] Modified PE hot melt adhesive 10-25 parts

[0024] Tackifying resin 10-30 parts

[0025] Wax 1-10 parts

[0026] Auxiliary 0-5 parts.

[0027] material selection:

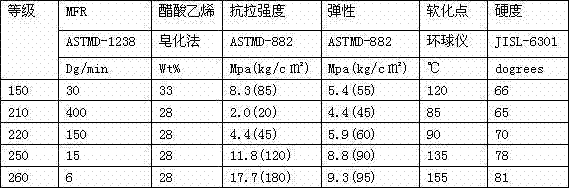

[0028] Grade Selection of Ethylene Polyvinyl Acetate EVA

[0029] EVA resin is widely used. In general, the main products of EVA with a vinyl acetate content below 5% are films, wires and cables, LDPE modifiers, adhesives, etc.; EVA products with a vinyl acetate content of 5% to 10% are elastic films, etc.; EVA with a content of 20~28% is mainly used for hot melt adhesives and coating products; the content of vinyl acetate is 5%~45%, and the main products are films (including agricultural films) and sheets, injection molding and molded products , foam products, hot-melt adhesives, etc.,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com