Compressed-air energy-storage system

A compressed air energy storage and compressor technology, which is applied in wind power generation, energy storage, solar thermal power generation, etc., can solve the problems of reduced operating efficiency, poor application characteristics under variable working conditions, and low efficiency of compressors and turbines, etc. Achieve the effect of improving flexibility, improving work efficiency, and optimizing configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

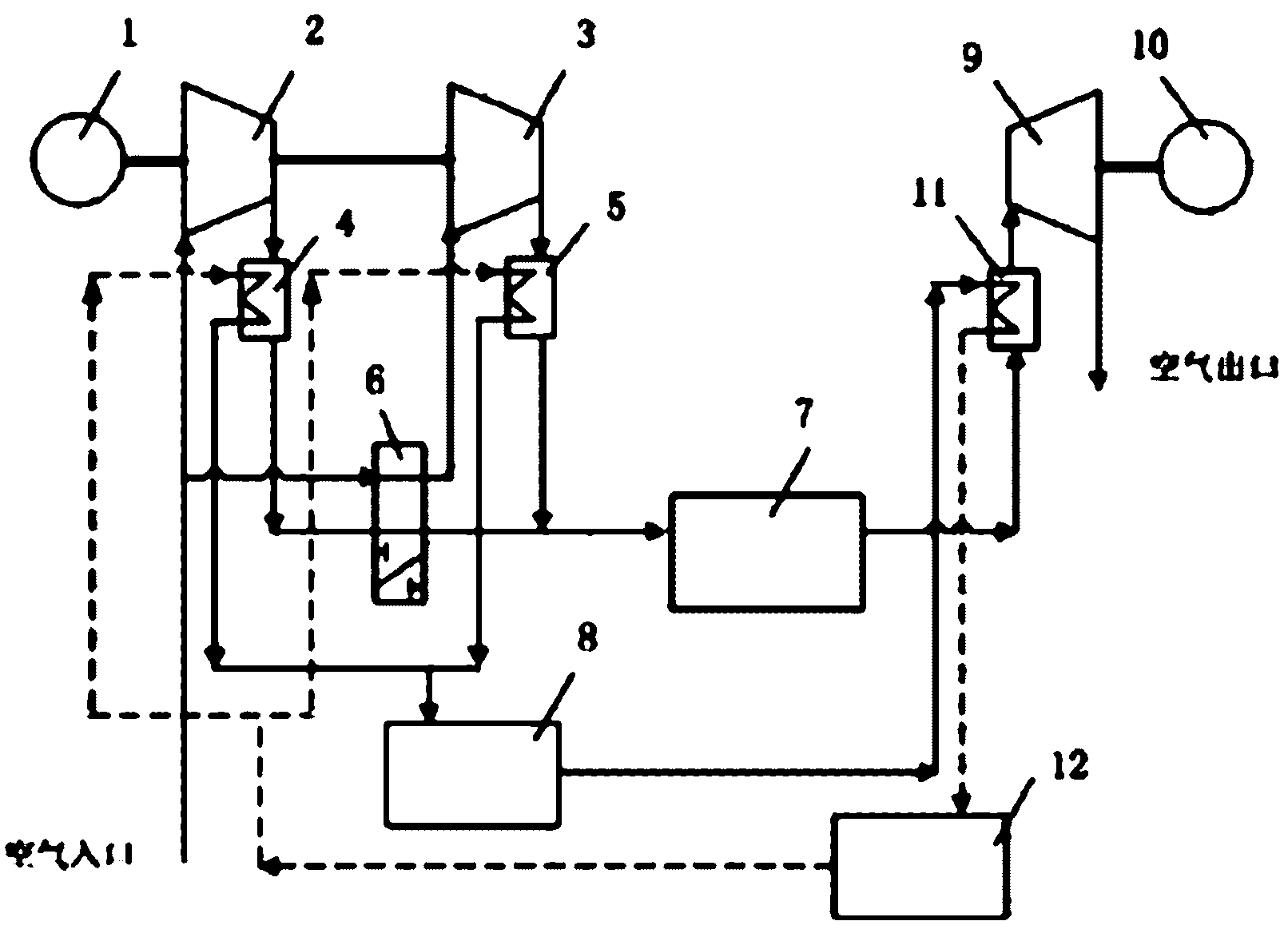

[0032] Such as figure 1 As shown, a compressed air energy storage system includes: an electric motor 1, a low-pressure stage compressor 2, a high-pressure stage compressor 3, a low-pressure stage cooler 4, a high-pressure stage cooler 5, an air storage chamber 7, a thermal storage 8, at least A turbine 9, a generator 10, at least one heat exchanger 11, a cooling medium supply source 12, the electric motor 1 is fixedly connected to the common transmission shaft of the low-pressure compressor 2 and the high-pressure compressor 3, the generator 10 and the turbine The transmission shaft of machine 9 is fixedly connected; the hot-side inlets of low-pressure stage cooler 4 and high-pressure stage cooler 5 are respectively connected with the gas outlets of low-pressure stage compressor 2 and high-pressure stage compressor 3, and the hot-side outlet is connected with gas storage chamber 7 The inlet of the low-pressure stage cooler 4 and the high-pressure stage cooler 5 are connected wit...

Embodiment 2

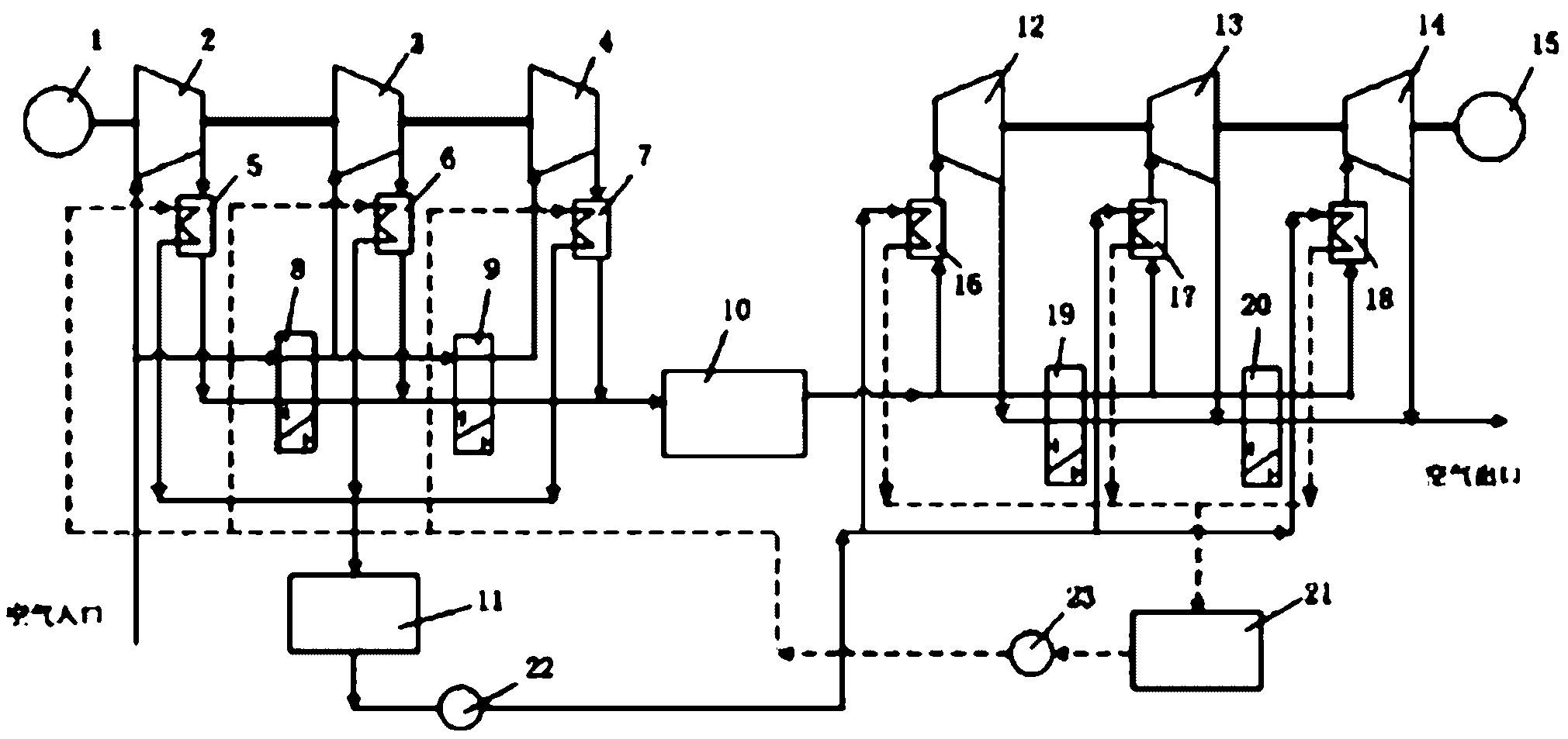

[0035] Fig. 2 is a schematic diagram of the compressed air energy storage system of "Embodiment 2" of the present invention. The compressed air energy storage system includes: electric motor 1, low-pressure compressor 2, medium-pressure compressor 3, high-pressure compressor 4, low-pressure cooler 5, medium-pressure cooler 6, high-pressure cooler 7, three One-position four-way valve Ⅰ8, three-position four-way valve II9, gas storage chamber 10, heat storage 11, high-pressure stage turbine 12, medium-pressure stage turbine 13, low-pressure stage turbine 14, generator 15, high-pressure stage Heat exchanger 16, medium-pressure heat exchanger 17, low-pressure heat exchanger 18, three-position four-way valve III19, three-position four-way valve IV20, cooling medium supply source 21, power pump I22, power pump II23. The difference between this embodiment and Embodiment 1 is that three-stage compression is used in the energy storage stage, and three-stage expansion is used in the exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com