Combined bionic anti-abrasion H-shaped fin elliptical flue gas heat exchange tube

A bionic anti-wear, combined technology, applied in damage protection, tubular components, heat exchange equipment, etc., can solve the problems of increased power consumption, no energy saving, and increased flow resistance of compressors, so as to reduce resistance and prolong service life. , the effect of reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

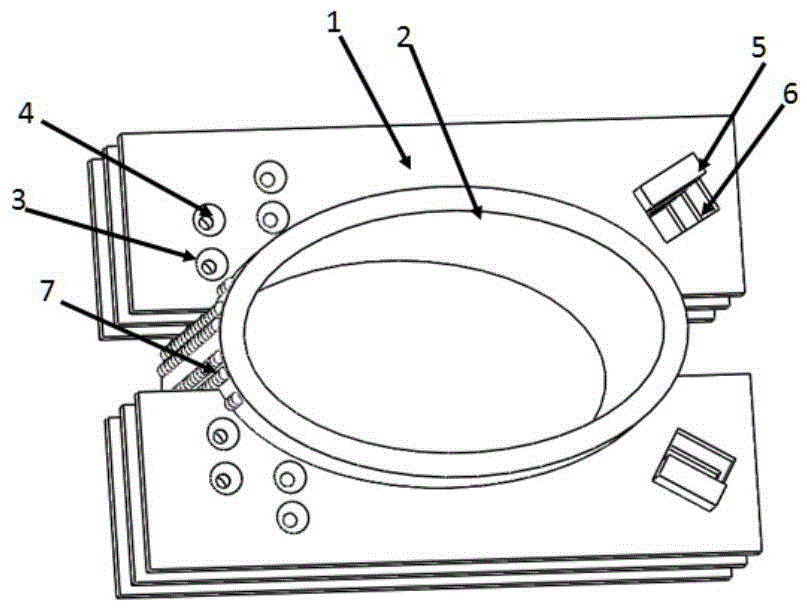

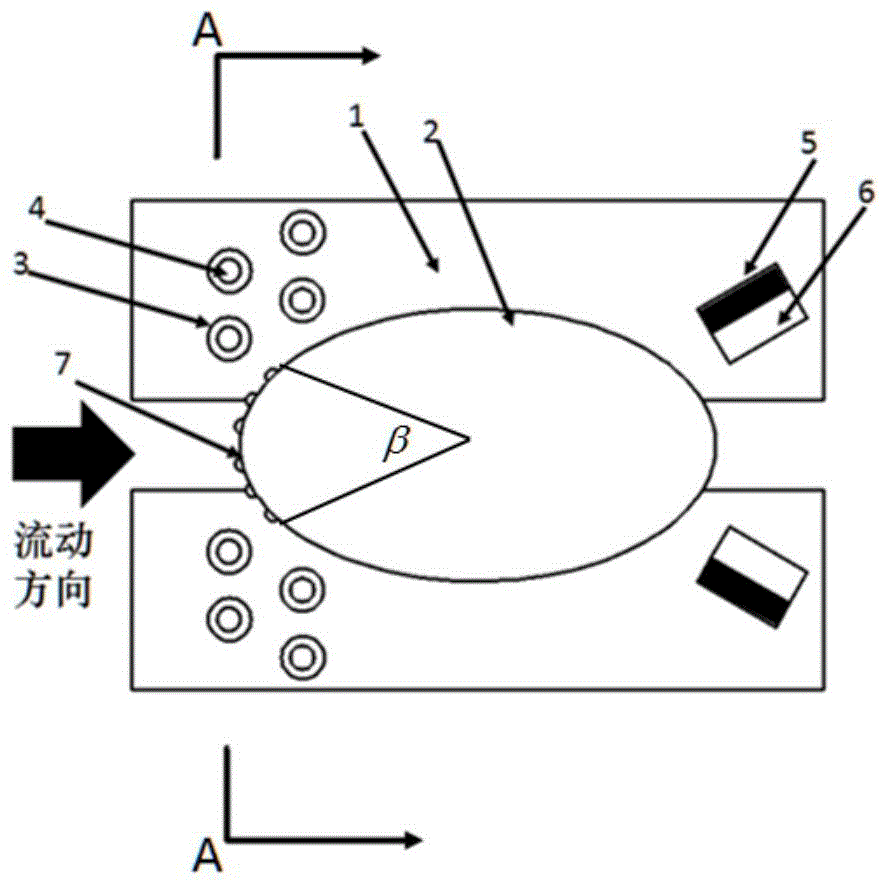

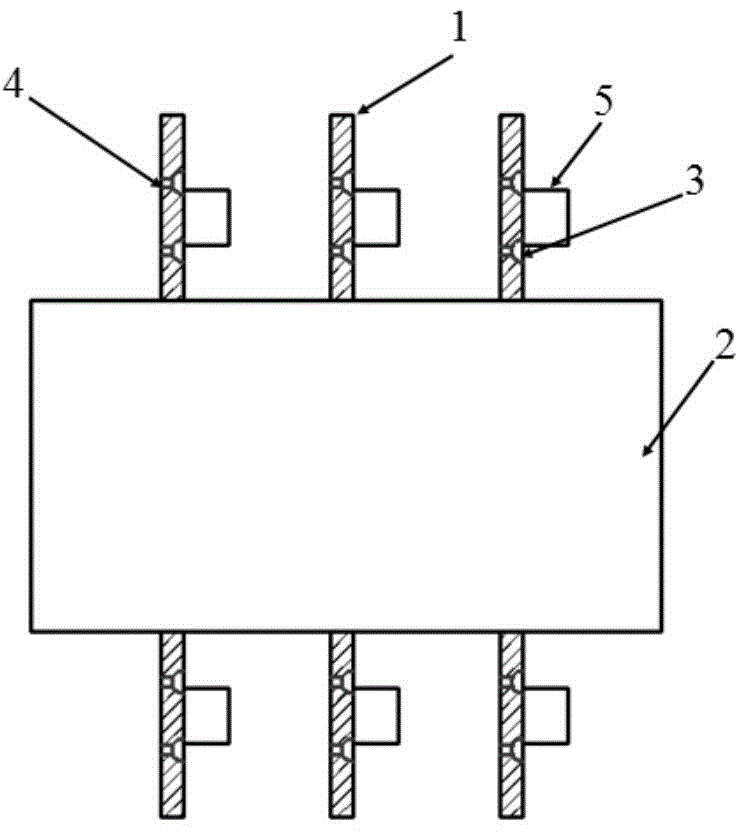

[0037] Considering that the first through hole 4 and the hemispherical cingule 3 can enhance airflow disturbance and reduce resistance; at the same time, considering the complexity and cost of processing and other factors, the present invention uses a mold to process four first through holes 4 and hemispherical Ding cells3.

[0038] The length of the elliptical tube and the length of the minor semi-axis are 64mm and 40mm respectively; the thickness of the fin is 3mm, the length is 76.5mm, the width is 54mm, the width of the slot is 10mm, the radius of the hemispherical cypher is 2mm, and the radius of the first through hole is 1mm, the bottom surface of the hemispherical chrysalis is perforated so that the airflow between the fins can flow together, and it can also enhance heat transfer and reduce the deposition of ash on the heat exchanger. The distance between the centers of the cytospheres on the same fin is 6 mm, and the distance between the centers of cytospheres distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com