Nanometer drag reducer for sandstone surface pretreatment and preparation method of nanometer drag reducer

A technology for surface pretreatment and drag reducing agent, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of insufficient hydrophobicity, reducing water injection pressure, restrictions, etc., to facilitate industrial production, reduce construction costs, The effect of simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

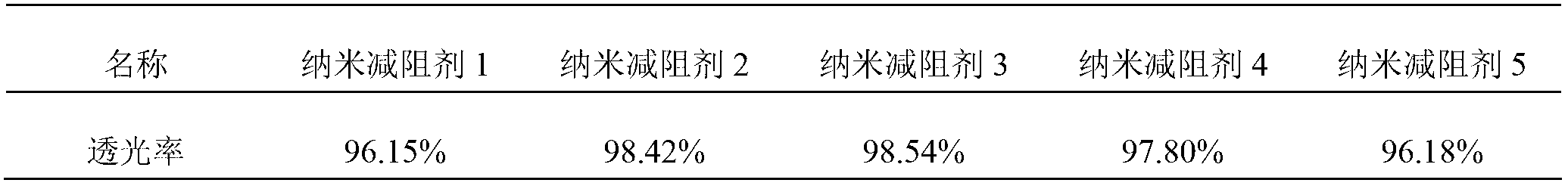

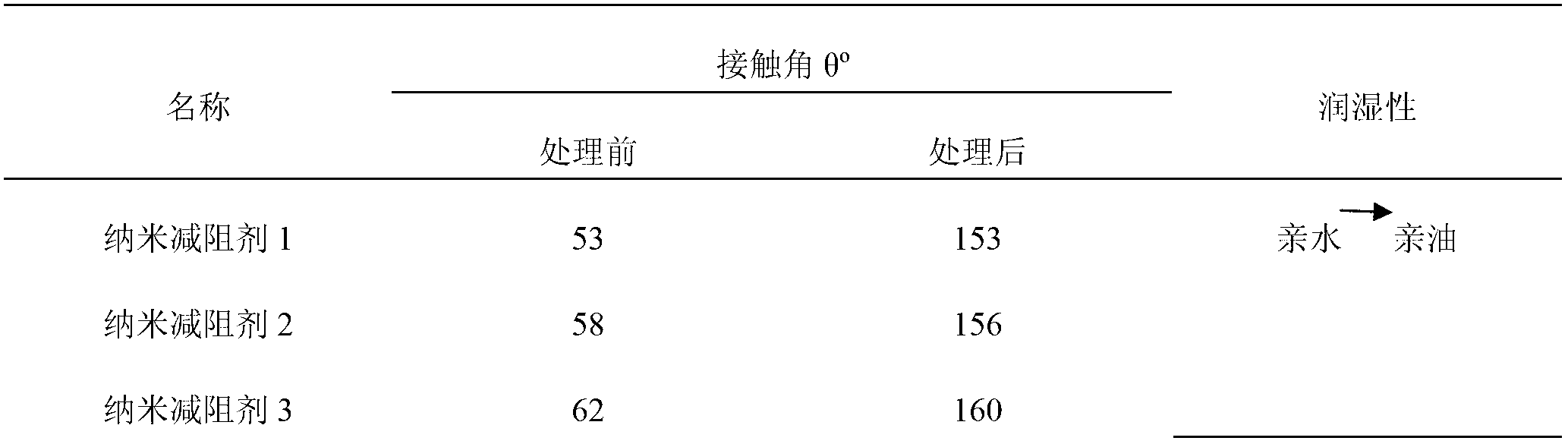

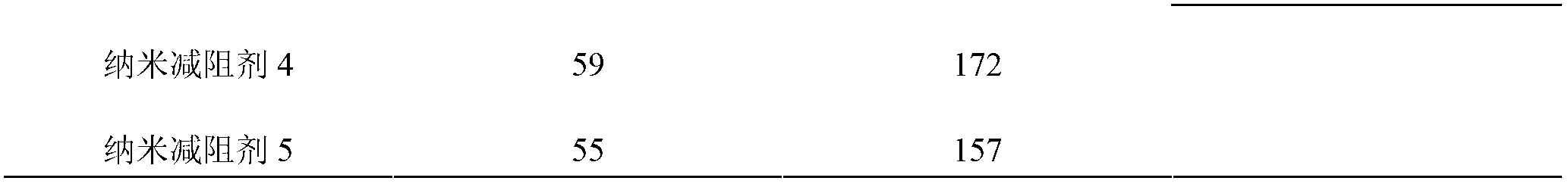

Examples

Embodiment 1

[0020] Pour 125g of surfactant tetradecyl α-olefin sulfonate, OP-1030g, 65g of PO-EO copolymer with molecular weight of 2400, 150g of auxiliary surfactant propylene glycol and 100g of triethanolamine into the mixer, mechanically Stir for 8 minutes, after stirring evenly, slowly add 30g of γ-(2,3 glycidoxy)propyltrimethoxysilane modified nano-silica at a speed of 5000r / min, keep stirring for 10 minutes after all the addition is complete, and then Keep the temperature in a water bath at 60°C for 20 minutes, pour it into a high-pressure homogenizer for dispersion, homogenization and emulsification to obtain 500 g of nano drag reducer 1 for sandstone surface pretreatment.

Embodiment 2

[0022] Pour 60g of surfactant dodecylbenzenesulfonate, OP-1060g, Span-8055g and co-surfactants 160g of isopropanol and 140g of glycerol into the mixer, mechanically stir for 12min at room temperature, and stir evenly Then slowly add 15g of γ-(2,3 glycidoxy) propyltrimethoxysilane modified nano silicon dioxide and 10g of γ-aminopropyl triethoxy silane modified nano silicon dioxide at a speed of 3000r / min. After adding all the silicon oxide, keep stirring for 8 minutes, then keep the temperature in a water bath at 60°C for 20 minutes, pour it into a high-pressure homogenizer for dispersion, homogenization and emulsification to obtain 500 g of nano drag reducer 2 for sandstone surface pretreatment.

Embodiment 3

[0024] Pour surfactant cetyl quaternary ammonium salt 80g, OP-1045g, Tween-8040g and auxiliary surfactant ethylene glycol 130g and glycerol 170g into the mixer, mechanically stir at normal temperature for 10min, after stirring evenly Slowly add 25g of nano-silica modified by N-β (aminoethyl) γ-aminopropyltrimethoxysilane and 10g of nano-silica modified by γ-chloropropyltrimethoxysilane at a speed of 6000r / min, all After the addition, keep stirring for 10 minutes, then keep the temperature in a water bath at 60°C for 30 minutes, pour into a high-pressure homogenizer to disperse, homogenize and emulsify to obtain 500 g of nano drag reducer 3 for sandstone surface pretreatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com