Electrolytic polishing agent

An electrolytic polishing and coupling agent technology, which is applied in the field of aluminum alloy polishing agents, can solve the problems of easy stickiness, leaving air marks, unsafe manual operation, etc., and achieve the effects of uniform polishing surface, reduced corrosion, and stable solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

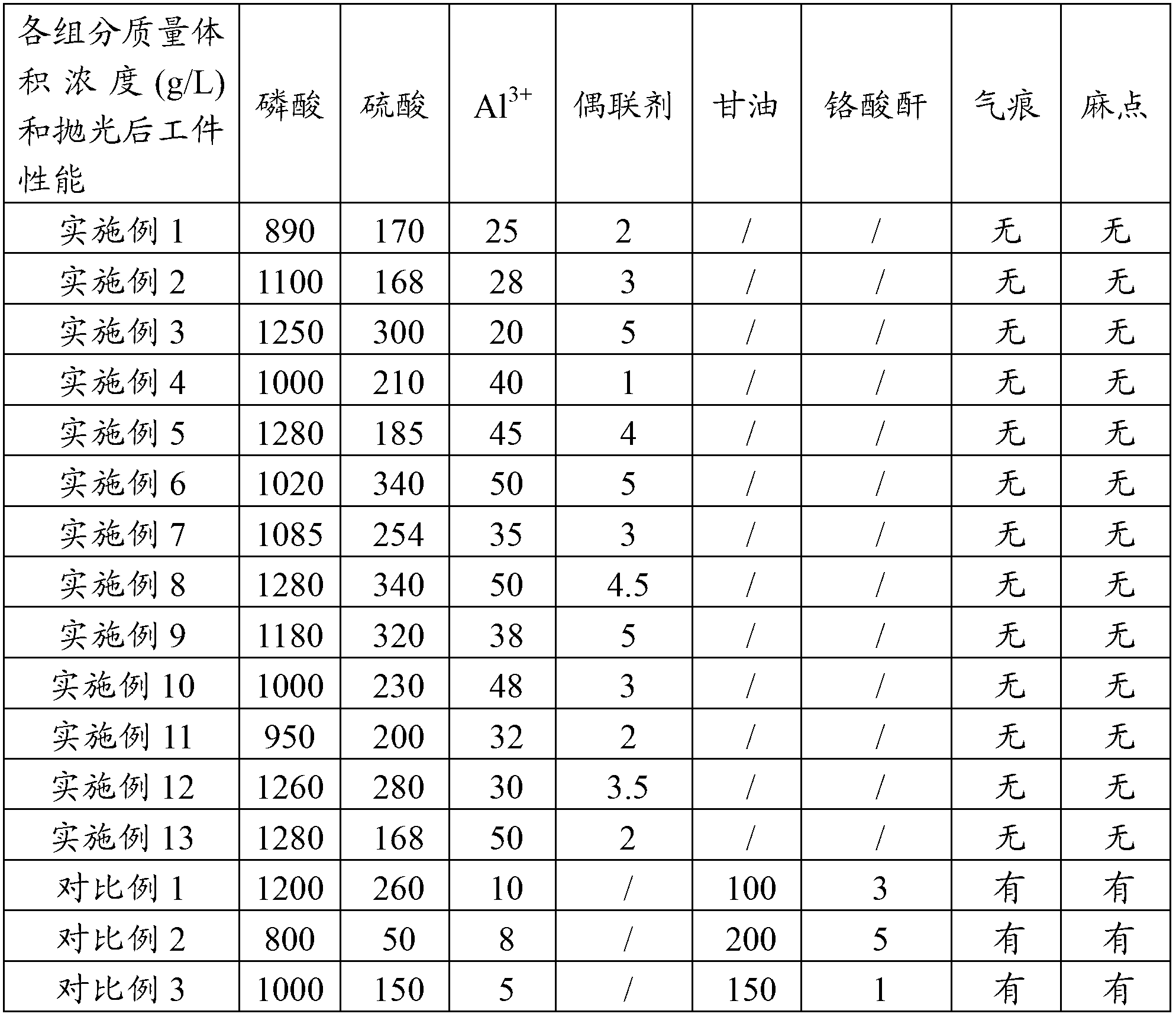

[0016] At normal temperature and pressure, weigh the components specified in Table 1 and add them to water, and stir until the components are completely dissolved, so that the mass volume concentration of each component of the electrolytic polishing agent is shown in Table 1.

[0017] In this example, Al 3+ It is obtained by dissolving aluminum hydroxide, and the coupling agent is titanate and phosphate.

[0018] Pour the prepared electropolishing agent into the electrolytic tank and heat it so that the temperature of the liquid in the electrolytic tank is 80°C. The clamped aluminum alloy workpiece is immersed in the electrolytic tank as an anode, and the clamped lead is immersed in the electrolytic tank as a cathode. Turn on the power supply (voltage: 25 volts, current density: 0.20A / dm 2 ), continue to power on for 350 seconds.

[0019] The electropolished aluminum workpiece was taken out of the electrolytic cell, and whether there were gas marks and pitting above the ope...

Embodiment 2

[0021] The method of Example 1 was repeated for each component specified in Table 1, and the test results are listed in Table 1. In this example, Al 3+ It is obtained by dissolving aluminum sulfate in water, and the coupling agent is titanate.

Embodiment 3

[0023] The method of Example 1 was repeated for each component specified in Table 1, and the test results are listed in Table 1. In this example, Al 3+ It is obtained by dissolving aluminum phosphate in water, and the coupling agent is titanate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com