Patents

Literature

37results about How to "Increase weld width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

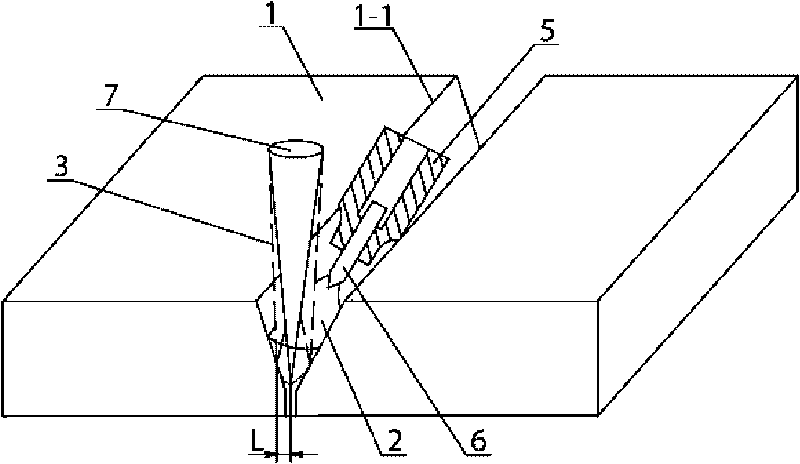

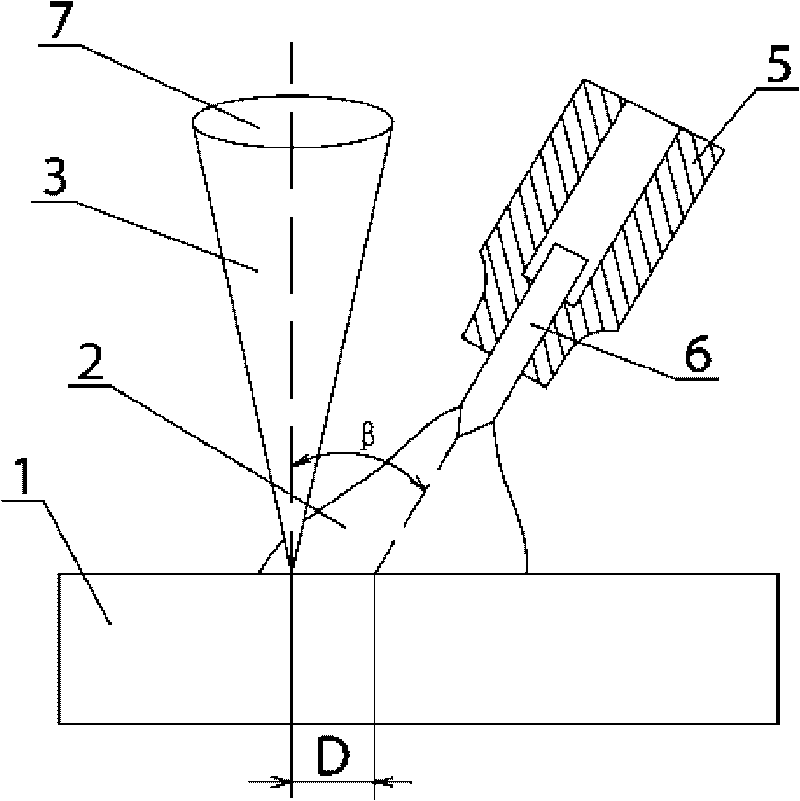

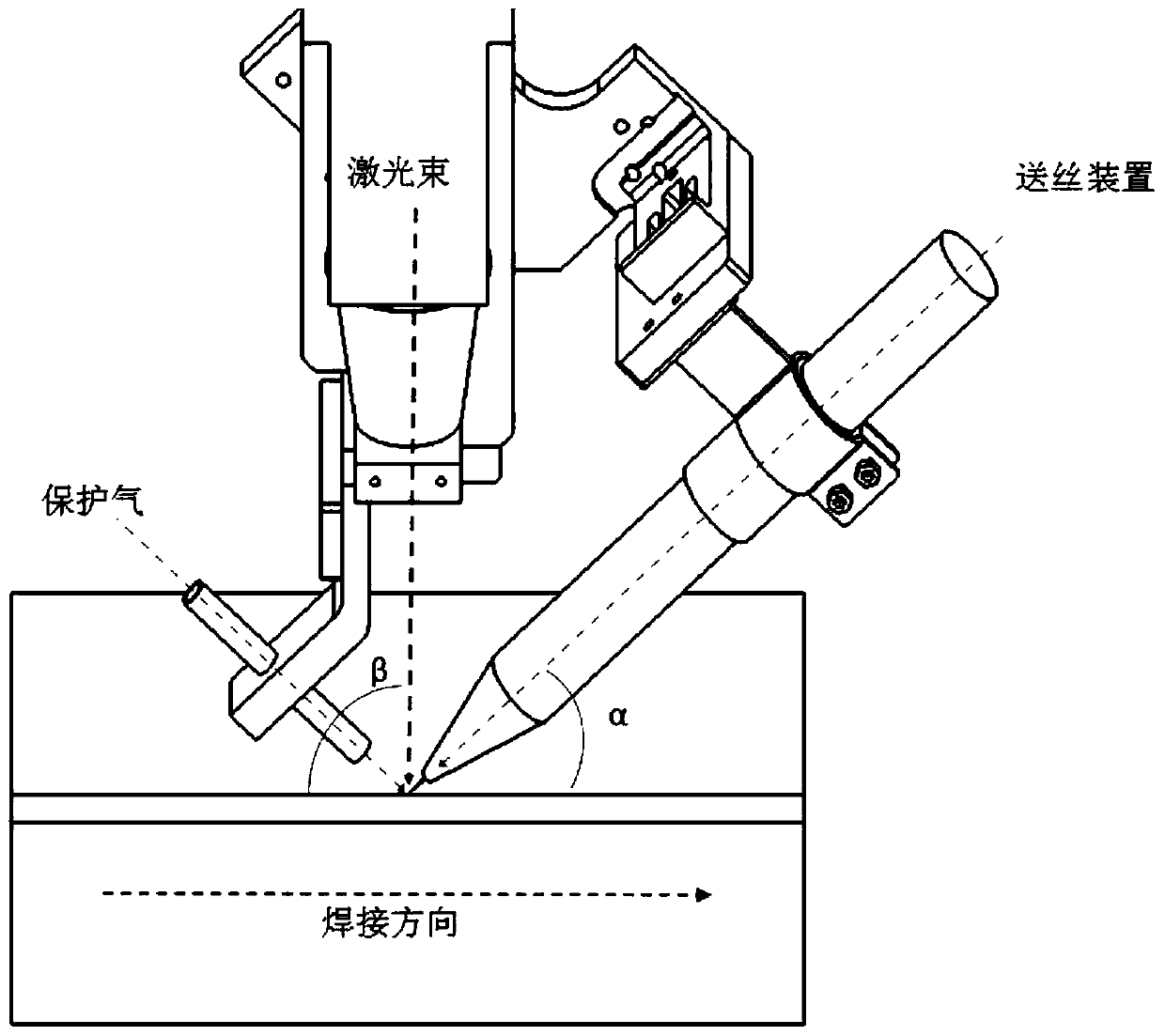

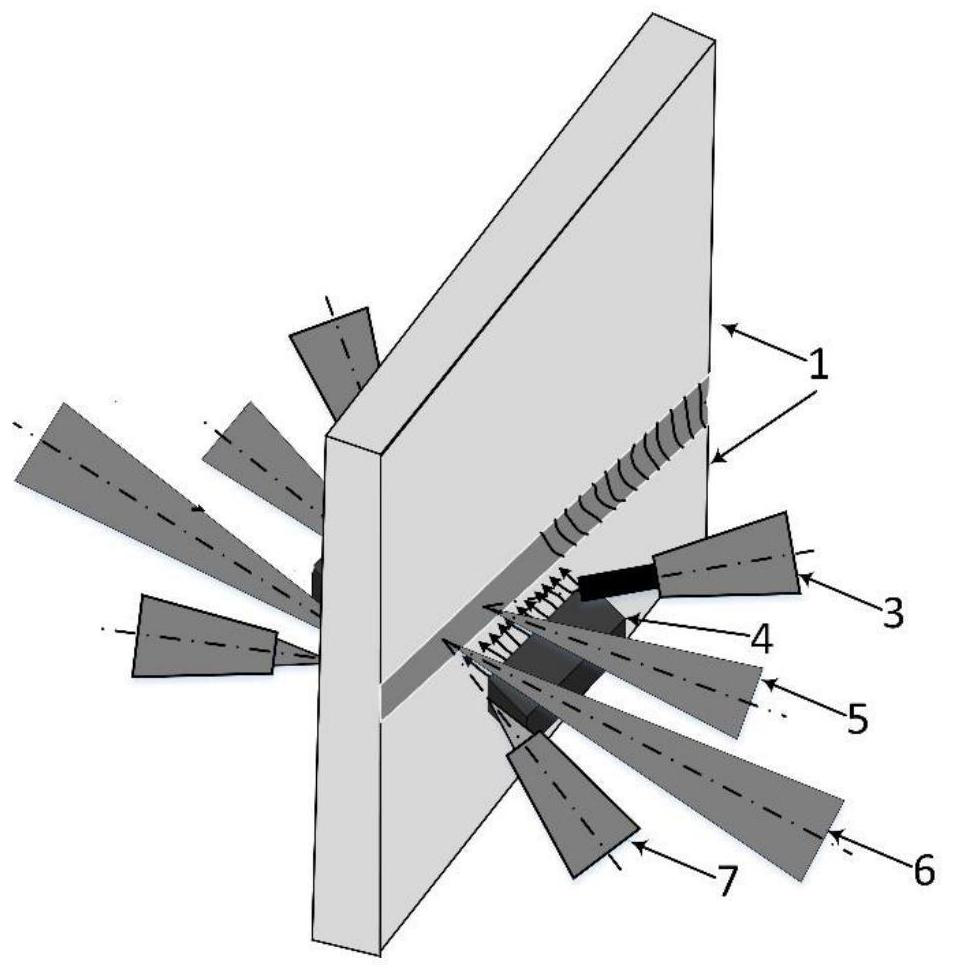

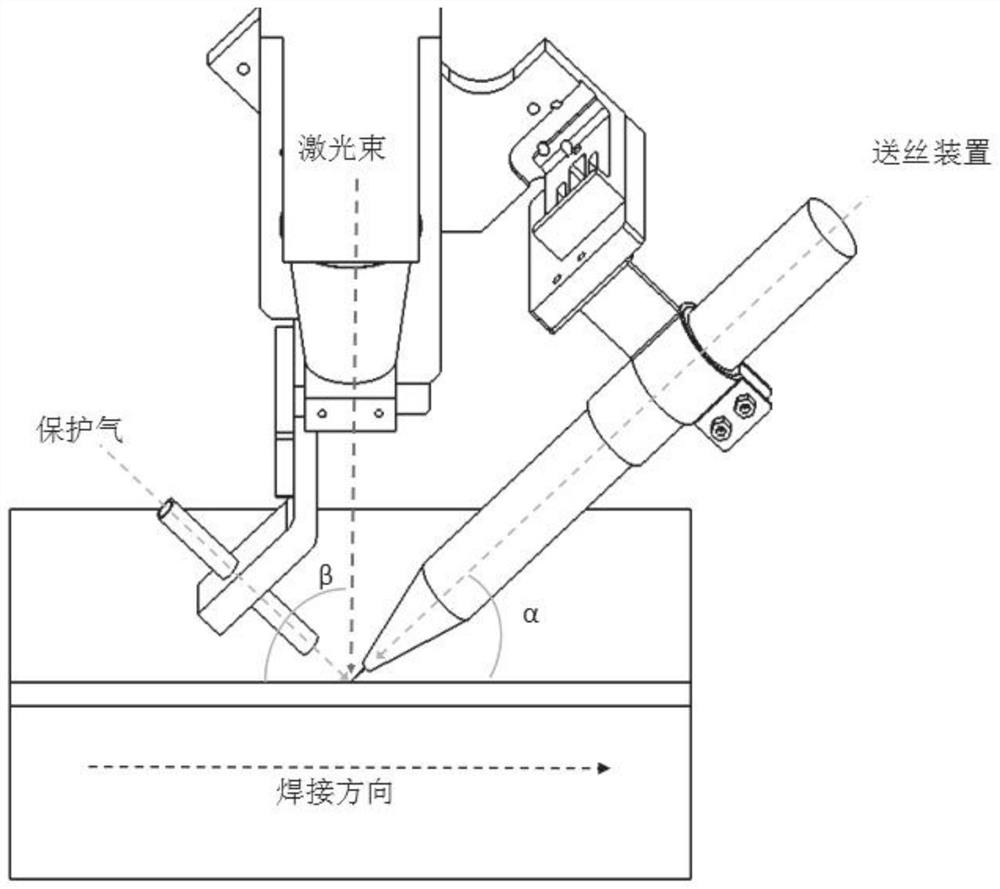

Method for realizing swing welding with laser-GMA electric arc hybrid welding device

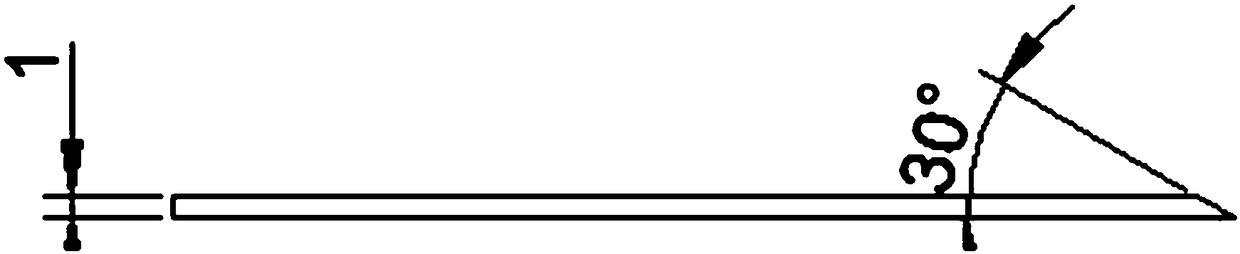

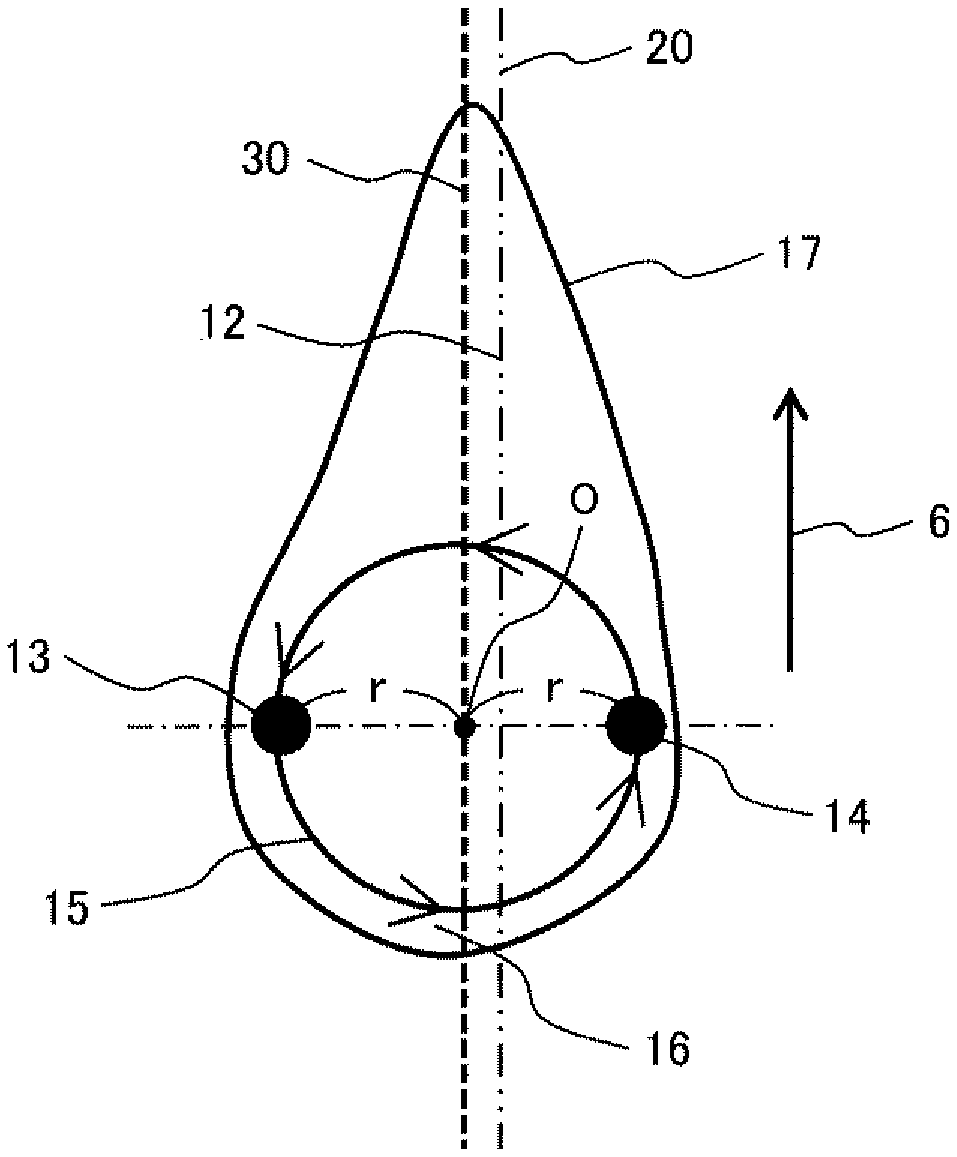

The invention discloses a method for realizing swing welding with a laser-GMA electric arc hybrid welding device, relating to a laser-melting electrode gas metal arc welding hybrid welding method. The method solves the problem that the defects such as incomplete fusion, gas hole and included slag, and the like, are easily existed between a side wall and a layer when welding a moderate plate and a thick plate with the laser-GMA electric arc hybrid welding device. The method comprises the following steps of: 1. chamfering; 2. clamping a work piece to be welded; 3. ensuring the positions of an electric arc and a laser beam, wherein the laser beam is perpendicularly irradiated to the surface of the work piece to be welded, an included angle between the electric arc and the laser beam is 15-60 DEG C, and the distance between the laser beam and the sharp end of a GMA electric arc welding wire is 2-6mm; 4. setting a welding technology parameter; and 5. performing the welding, wherein an electric arc welding gun is kept to be immovable when welding, and a laser beam-focused wielding gun swinging welds in the shape of 'S'. The method is used for butt welding of a thick plate more than 10mm in national defense and civil use fields of shipbuilding, petroleum pipe lines, high-pressure vessels, fighting vehicles and nuclear devices, etc.

Owner:HARBIN INST OF TECH

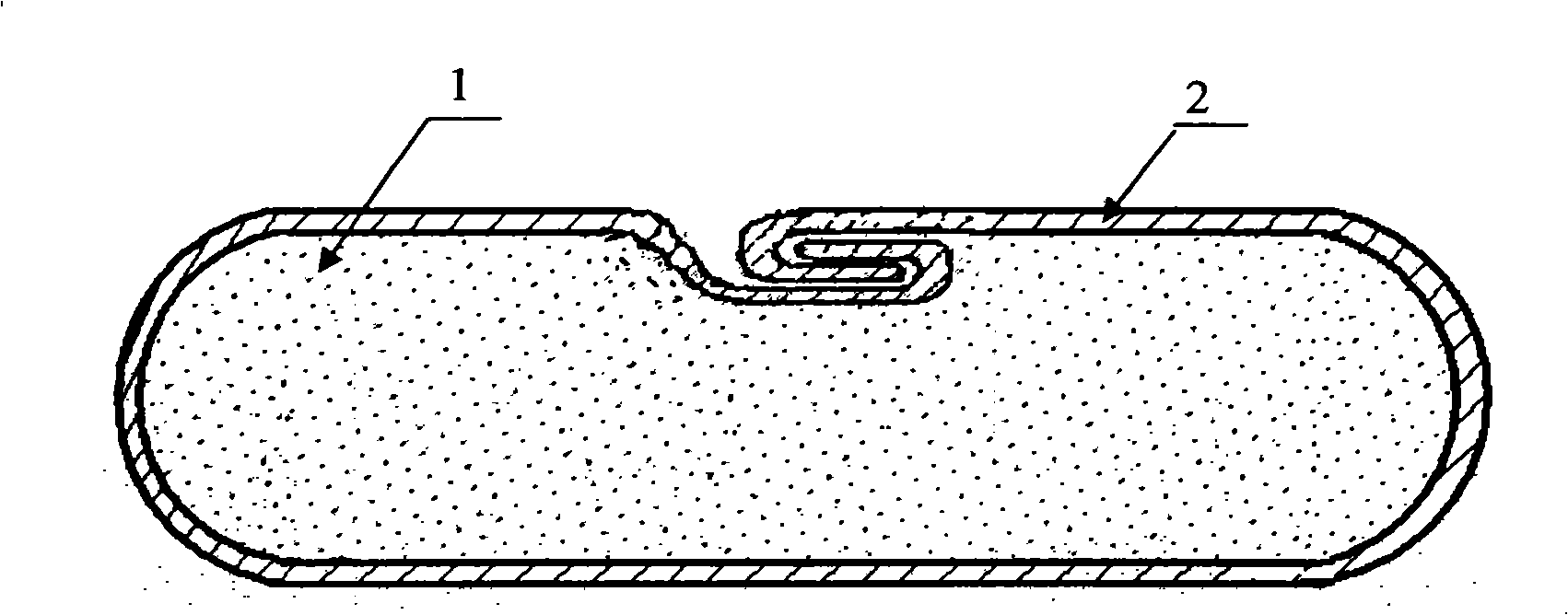

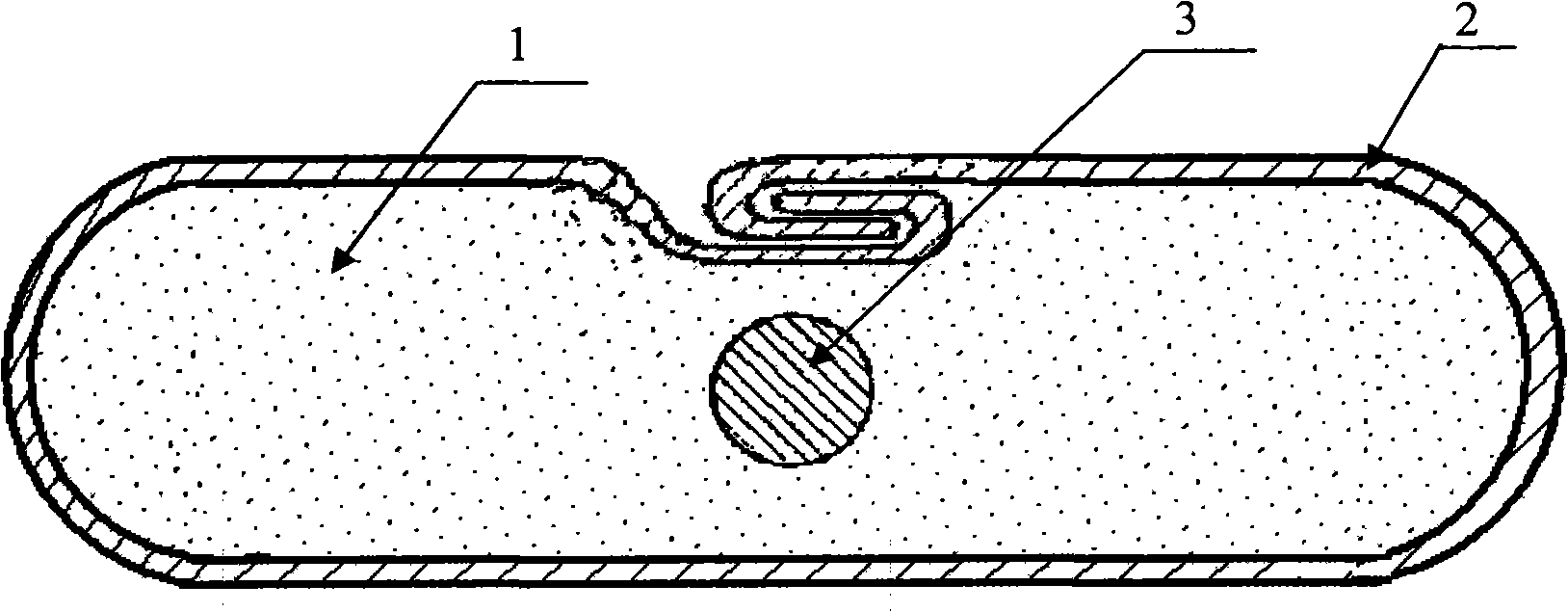

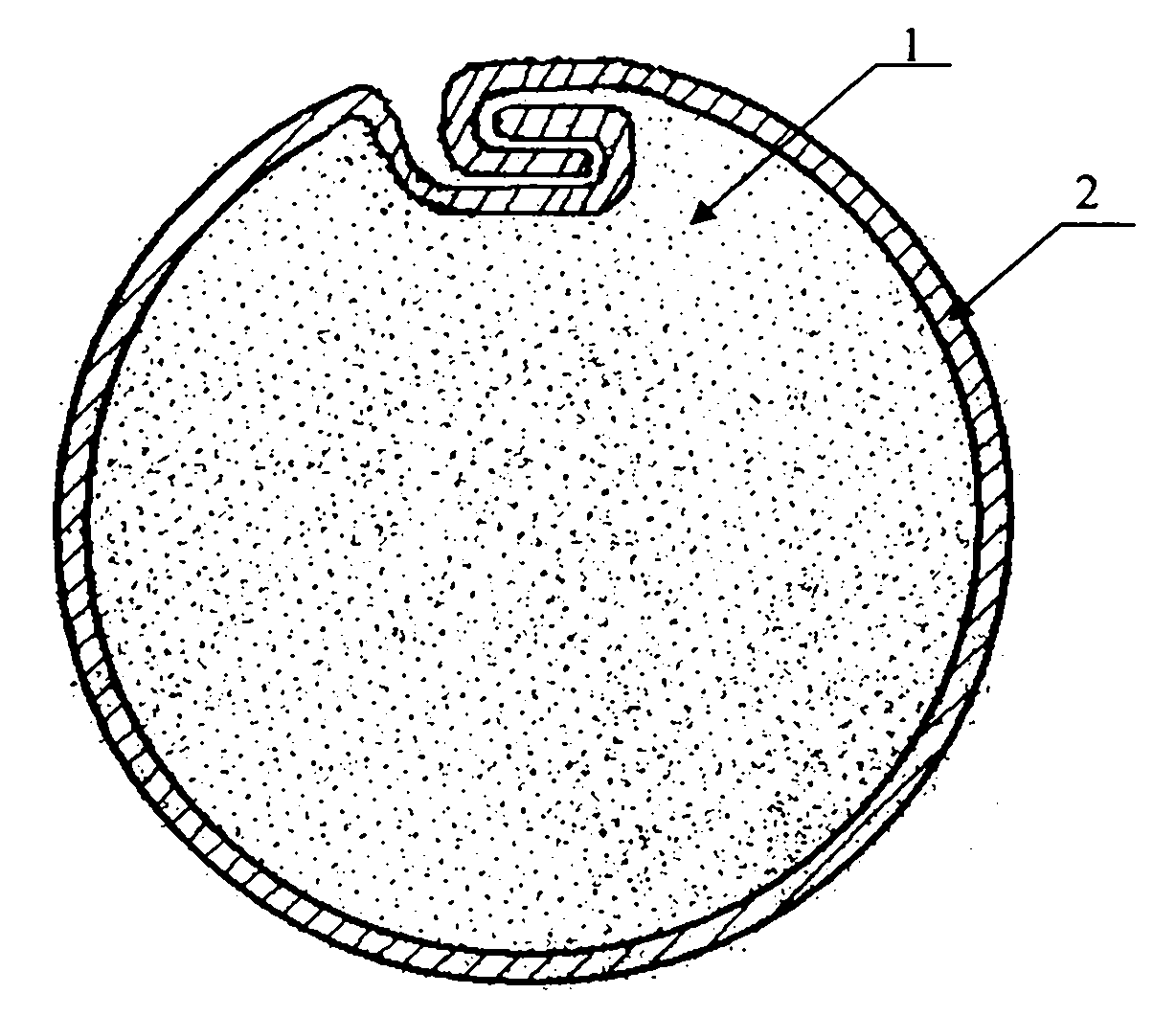

Flux-cored steel belt for build-up welding and preparation method thereof

InactiveCN101306493AIncrease varietyIncrease weld widthWelding/cutting media/materialsSoldering mediaHigh carbonFerrosilicon

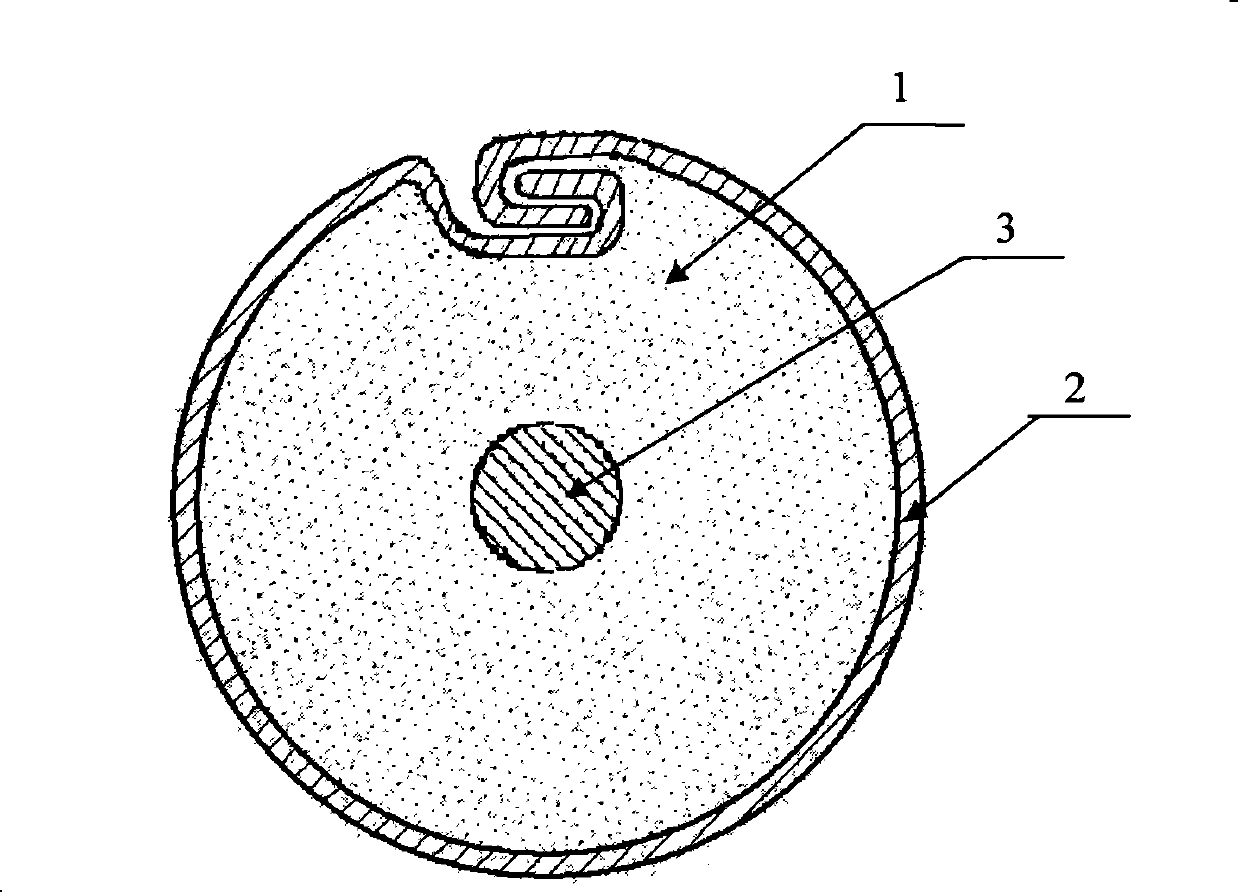

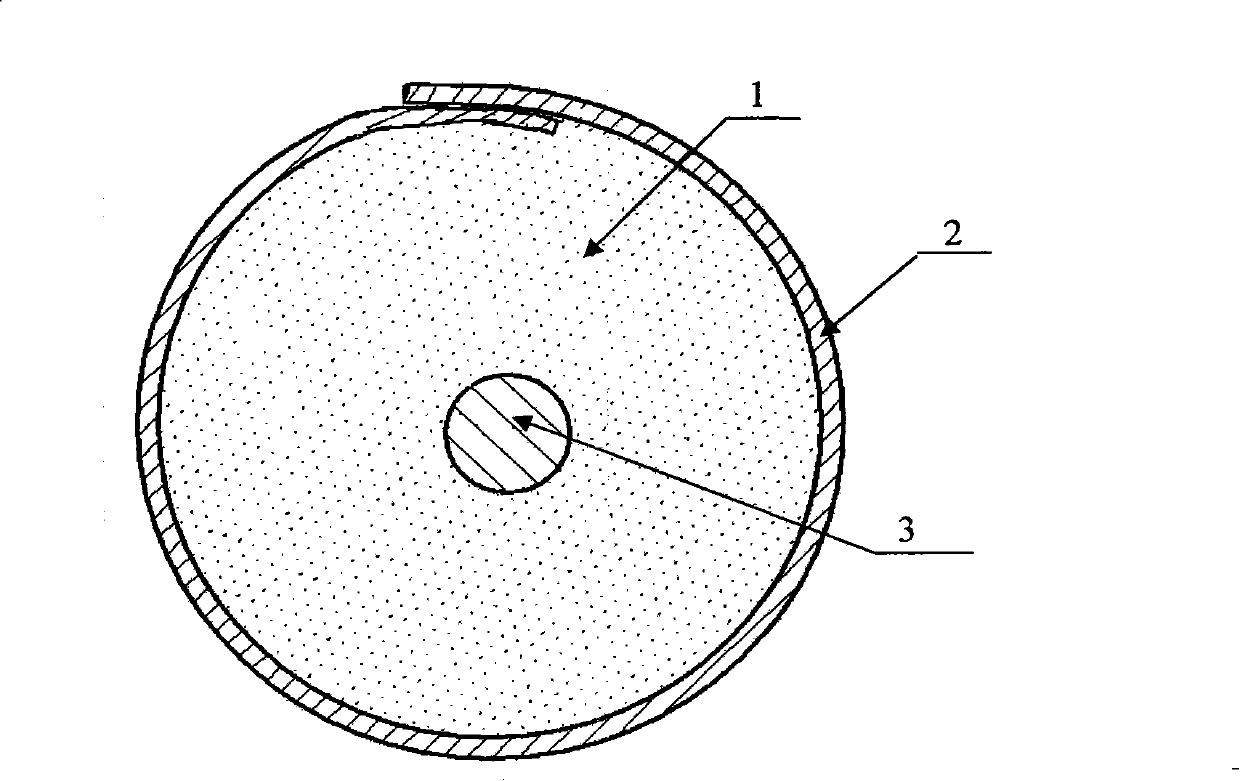

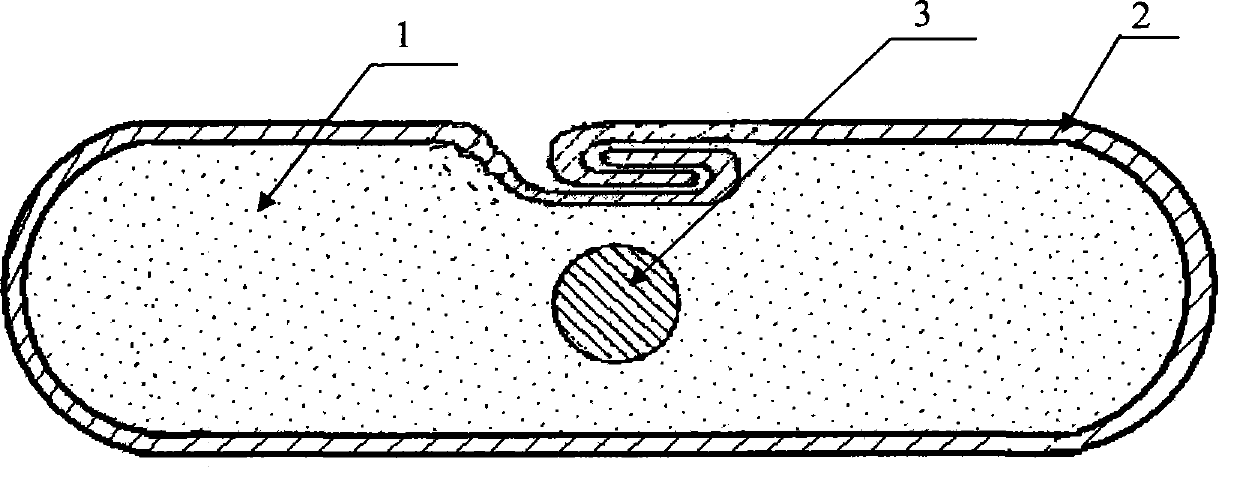

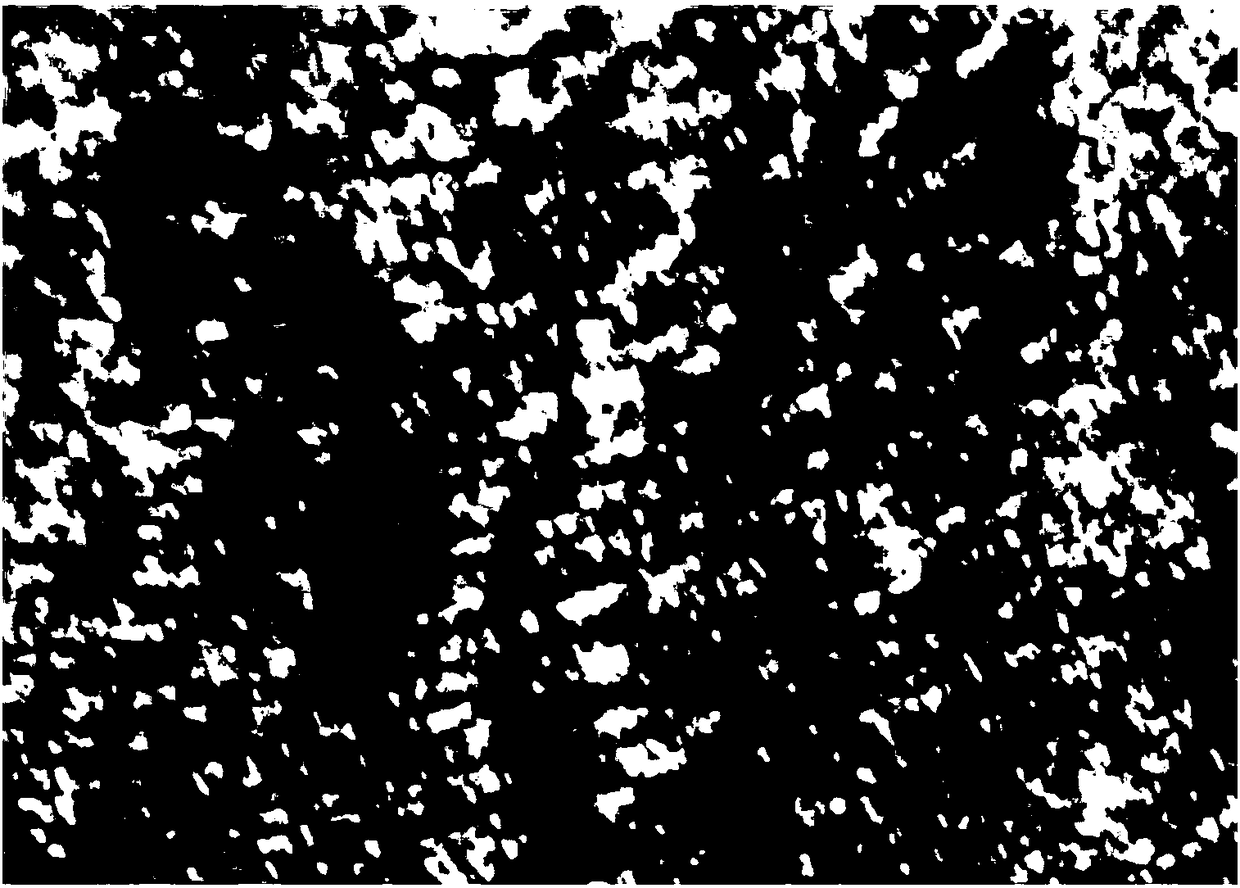

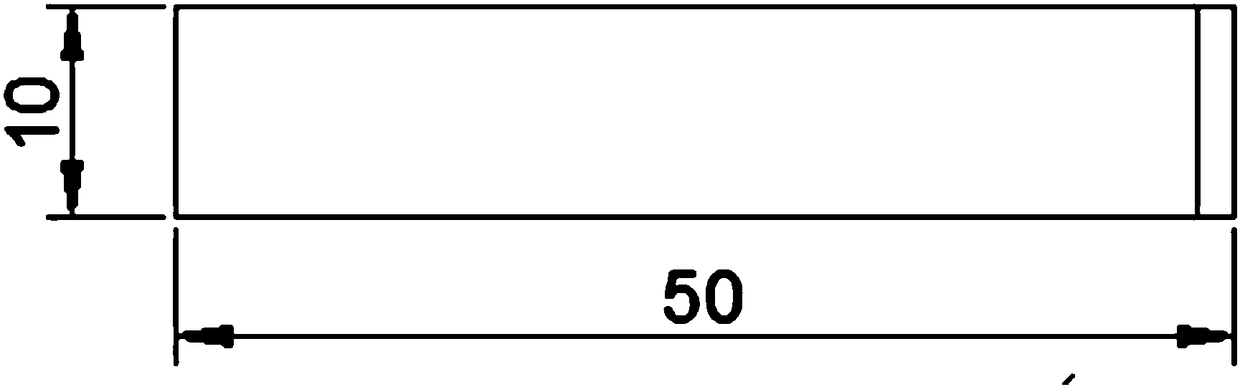

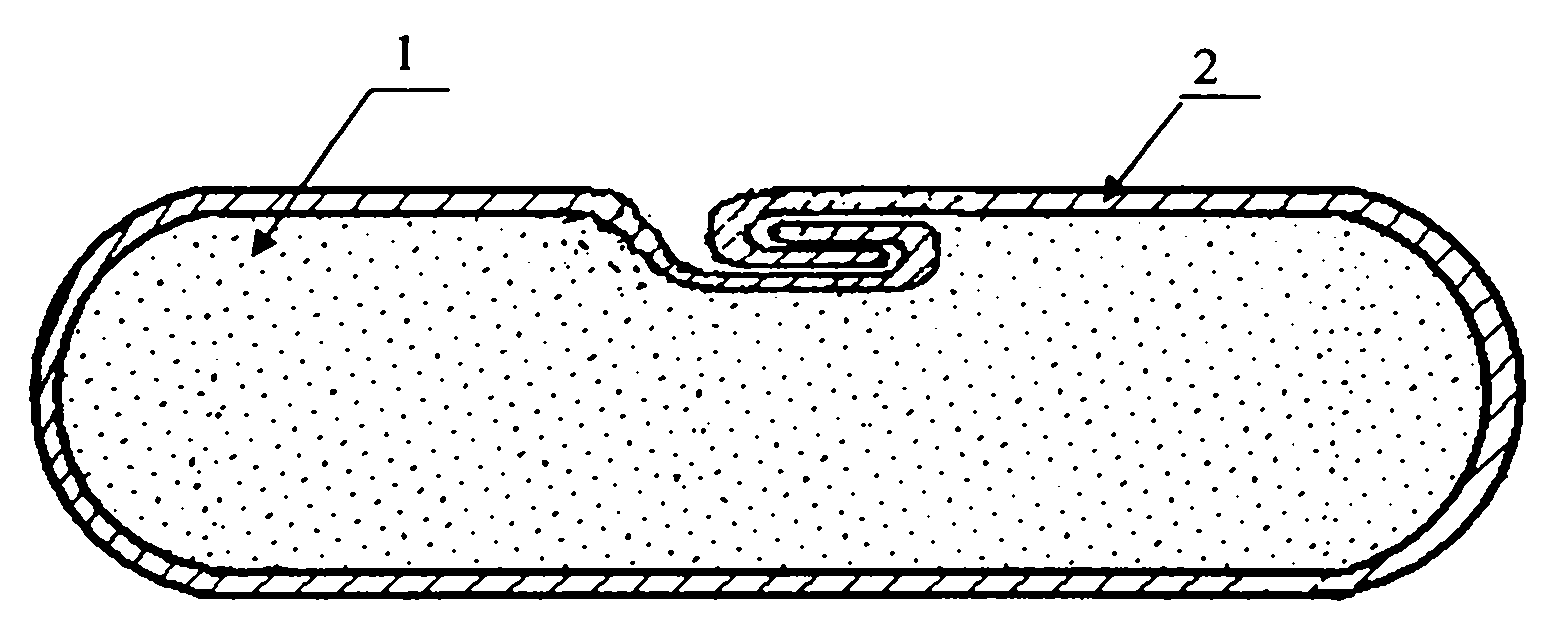

The invention discloses a resurfacing welding used drug cored steel strap and the preparation method. The steel strap is prepared from a mild steel strap and drug powder enwrapped therein, the shape of the steel strap is a tube with the longitudinal cross-section to be in a long and flat shape or in a similar rectangle shape, the longitudinal length can be determined randomly, and the transverse sides of the steel strap are connected in a seam manner or a related joint manner; the drug powder is uniformly filled in the tube rolled from the steel strap, wherein the particle diameter of the drug powder is smaller than 120 Mum, the components include (by weight) 45-70 parts of high carbon ferrochrome, 5-35 parts of ferrovanadium, 1-8 parts of No.75 ferrosilicon, 1-10 parts of high carbon ferromanganese, 2-16 parts of ferroboron, 1-8 parts of ferrotitanium, 0-5 parts of ferroniobium, 2-8 parts of ferromolybdenum, 0-10 parts of graphite, 0-5 parts of fluorite and 0-6 parts of potassium titanate. The drug cored steel strap adopting the invention can efficiently improve the abrasion resistance of the metal on the resurfacing welding layer and the stability of the electric arc, and can be coiled into coils, thereby being suitable for continuous automatic resurfacing welding.

Owner:SHANDONG UNIV

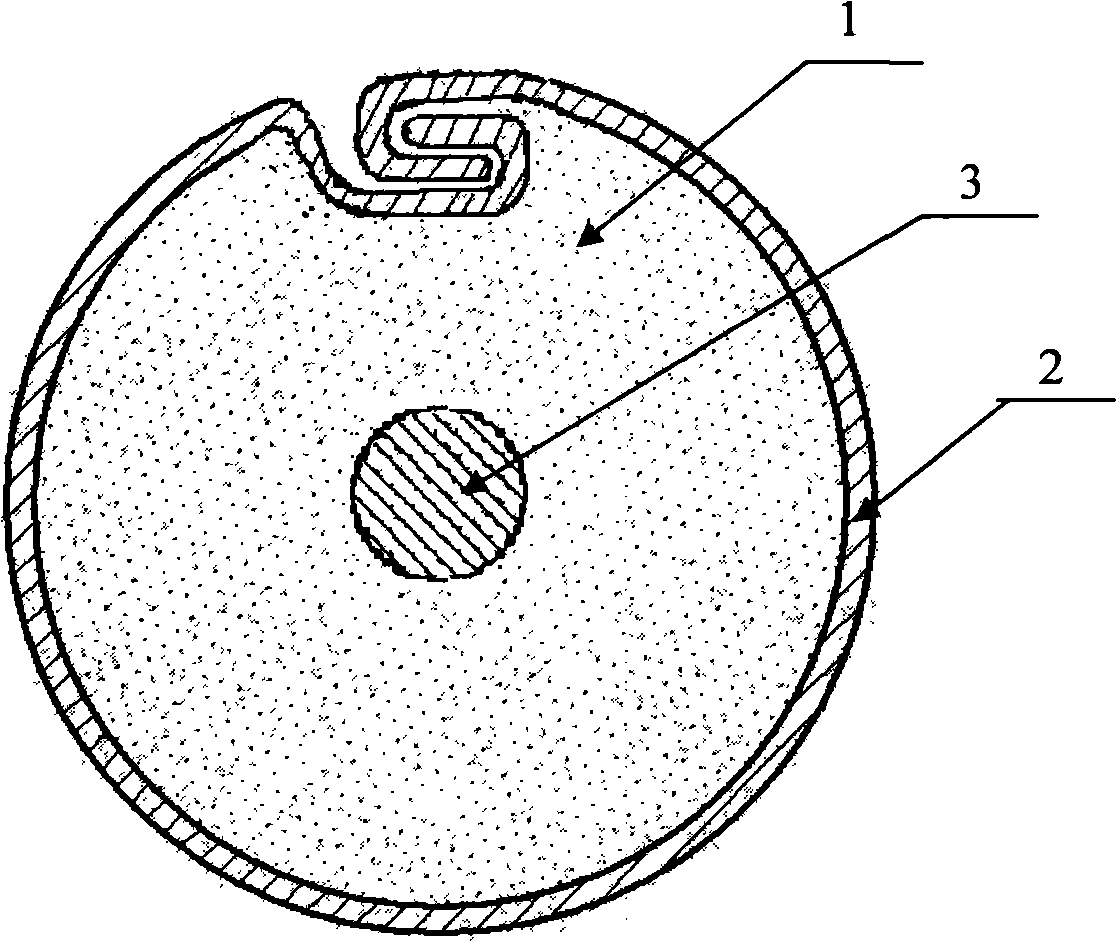

Cored welding strip applied in resurfacing welding and preparation method thereof

InactiveCN101596653AImprove wear resistanceImprove stabilityWelding/cutting media/materialsSoldering mediaSteel beltDrug powder

The invention discloses a novel resurfacing welding cored welding strip which consists of a steel tube circled by steel strips and drug powder wrapped in the steel tube, the steel strips comprises an upper steel strip and a lower steel strip which can be purchased in the market. The shape of the steel tube circled by steel strips is that the longitudinal cross section is long flat form or rectangle-like shape, the longitudinal length is determined at will, and the steel tube can be cut out at will or winded into a tray according to requirements. The transverse edges of the upper steel strip and the lower steel strip are connected at the upper steel strip side in a related joint form, and the drug powder is filled in the steel tube circled by the steel strips evenly with the filling rate being 20-80%. According to the different types of resurfacing metals, the content of alloy element in the resurfacing welding cored welding strip is different. The cored welding strip has simple production equipment and technique, and low production cost, thus overcoming the defect that alloy welding filament used for filament resurfacing welding is difficult to produce and the problems of large investment on production equipment, high production cost and expensive price in cored welding filament production.

Owner:SHANDONG UNIV

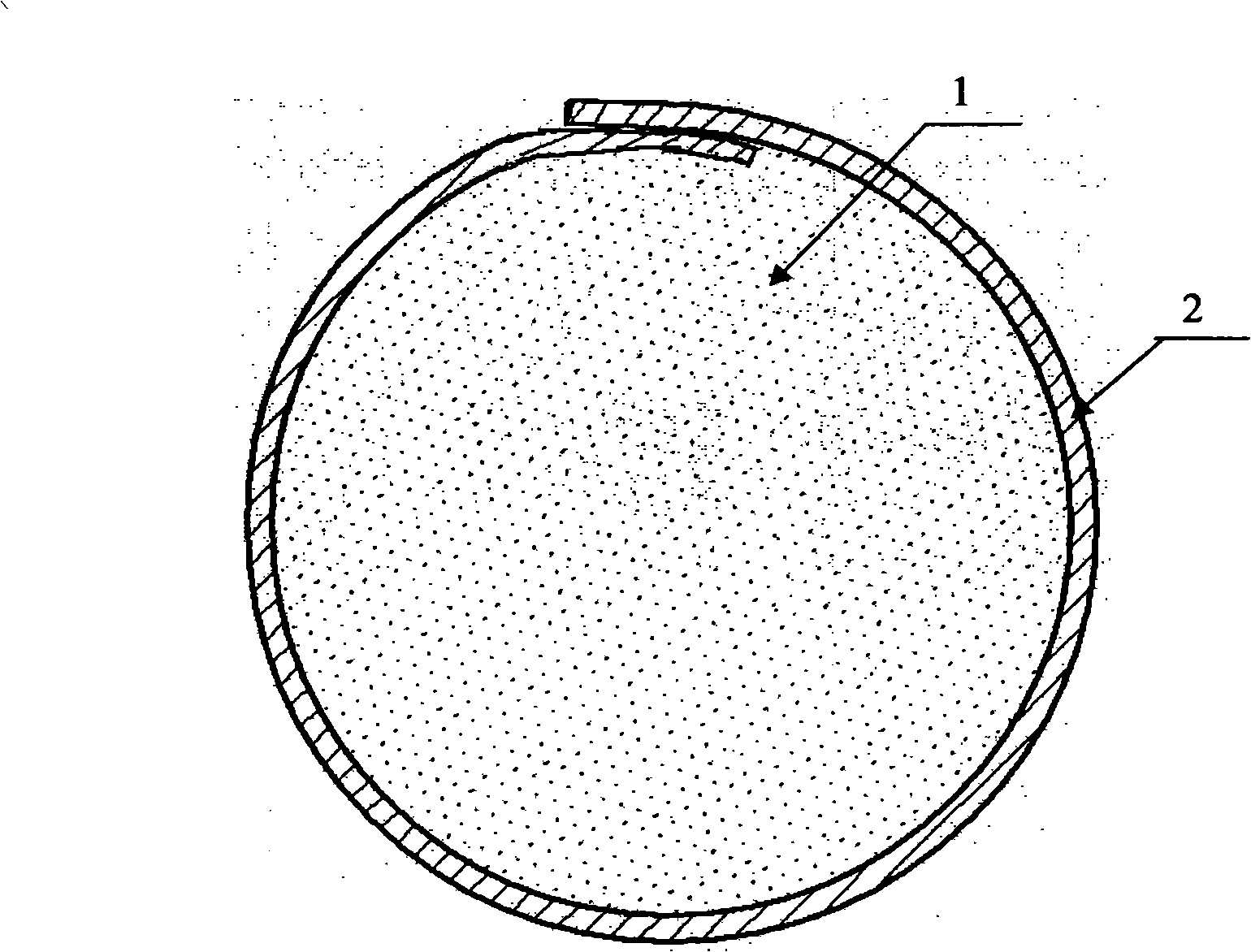

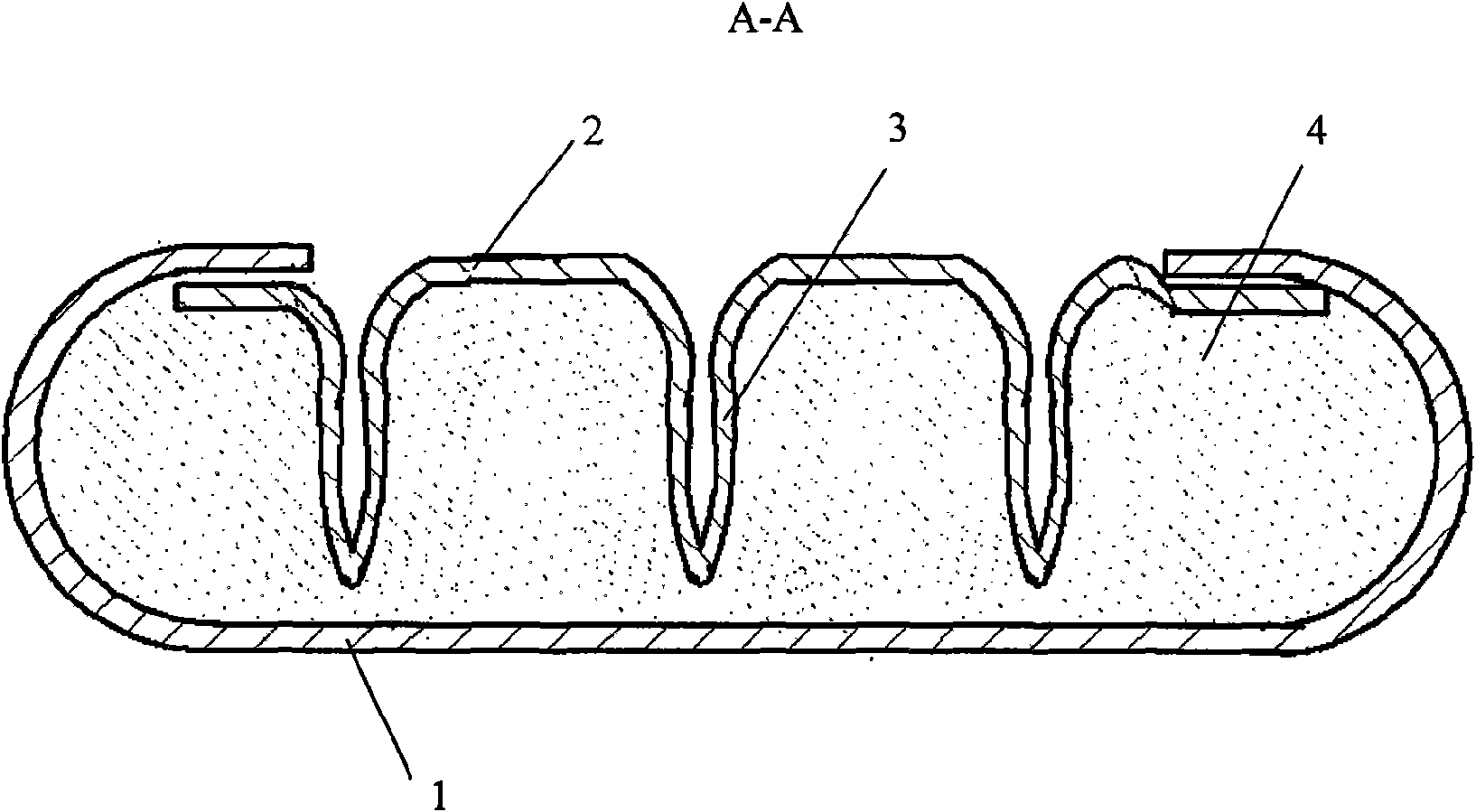

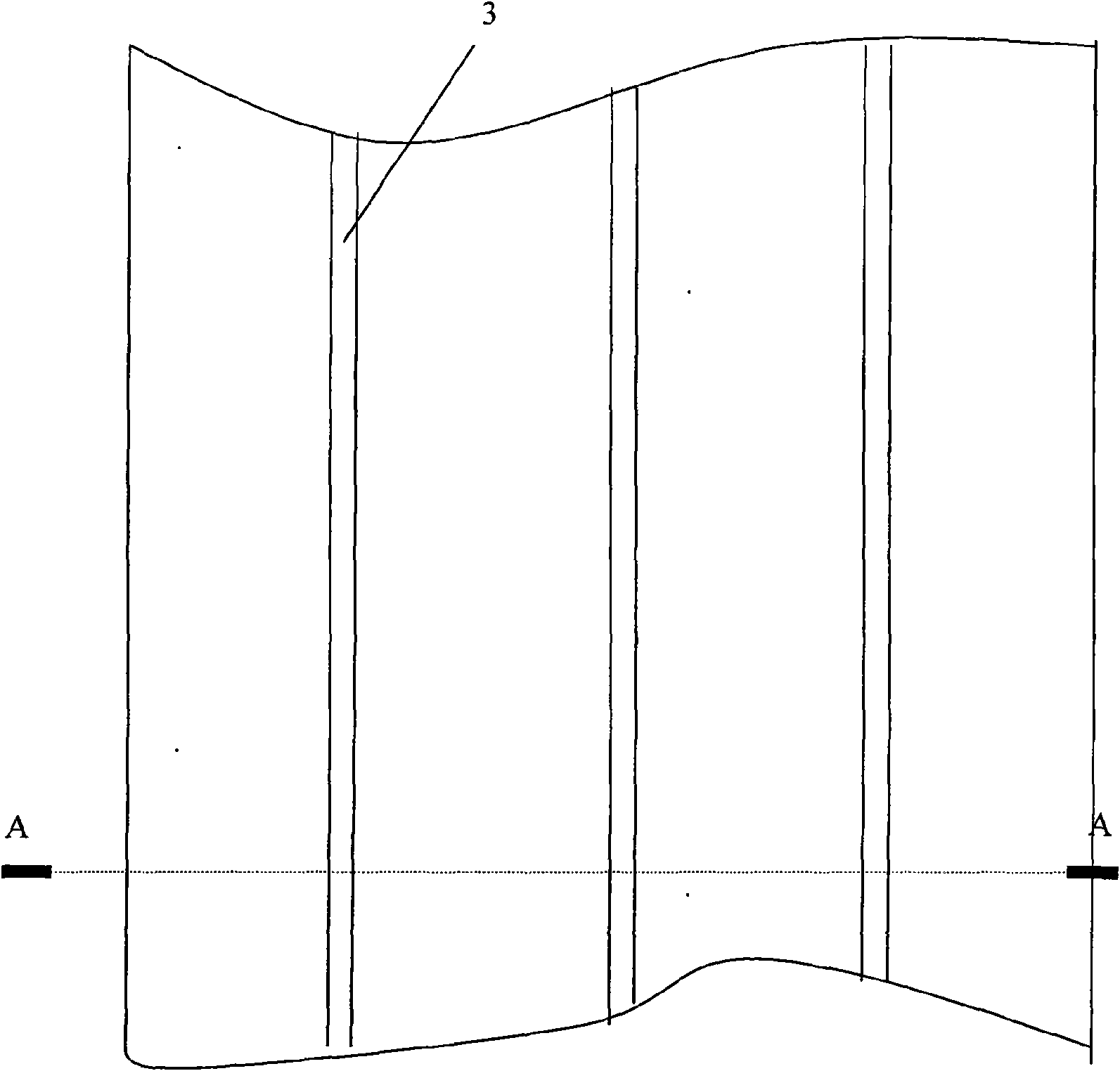

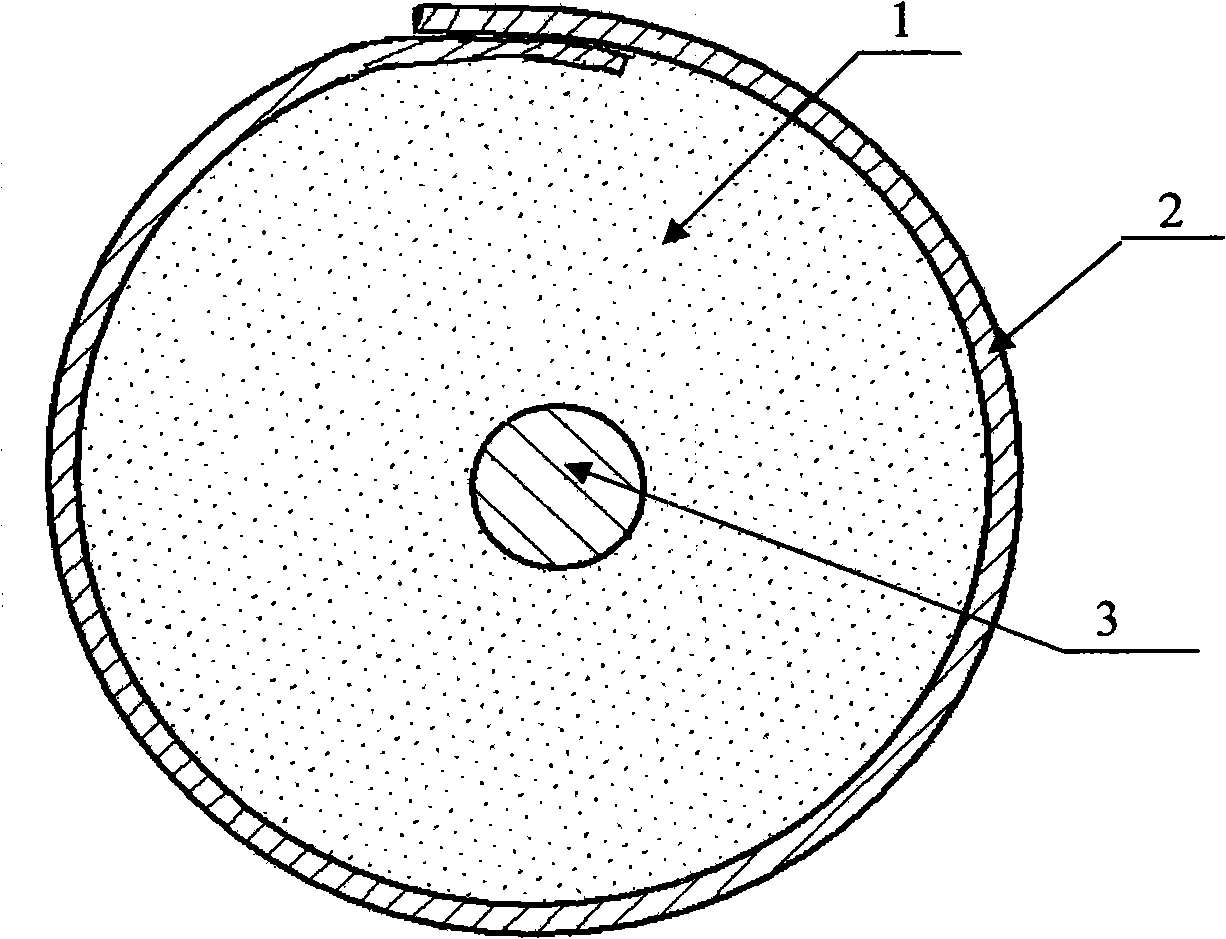

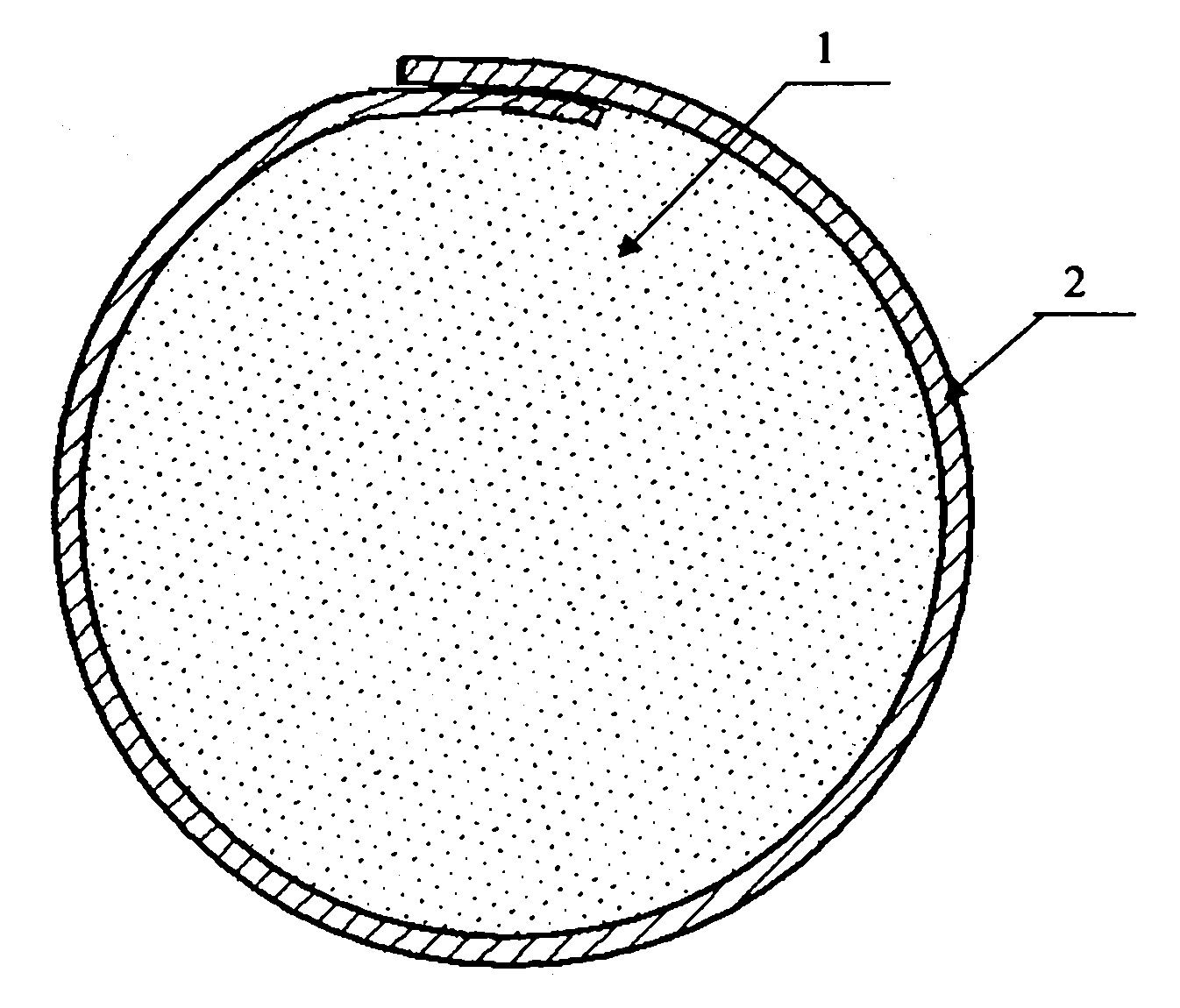

Flux-cored steel belt containing steel wire for surfacing and preparation method thereof

InactiveCN101310913AStable meltingEvenly meltedWelding/cutting media/materialsSoldering mediaMetallurgySteel belt

The invention discloses a flux-cored steel-belt that contains steel wires and is used for surfacing and a preparation method thereof. The flux-cored steel-belt is produced from low-carbon steel belts and powder and a steel wire enwrapped therein. The shape of the steel belts is a tube, of which the vertical cross section is in a long flat shape or a rectangle-like shape and the horizontal sides are connected in a closing form or a lapping form. The powder is evenly filled in the tube rolled from the steel belts and the steel wire which is arranged vertically along the tube, has the same length with the tube and positioned at the geometric center of the vertical cross section of the flux-cored steel-belt is clamped in the middle of the powder. Through the adjustment of clamping the steel wire and the powder flux-cored steel-belt of the invention, the variety of steel belts used for surfacing is added, thus reducing cost. The flux-cored steel-belt can be wound into a disk-like shape, thus being suitable for continuous automatic surfacing, leading the application field of strip surfacing to expand, increasing the stability of electric arc and reducing the technical requirements against welding equipment.

Owner:SHANDONG UNIV

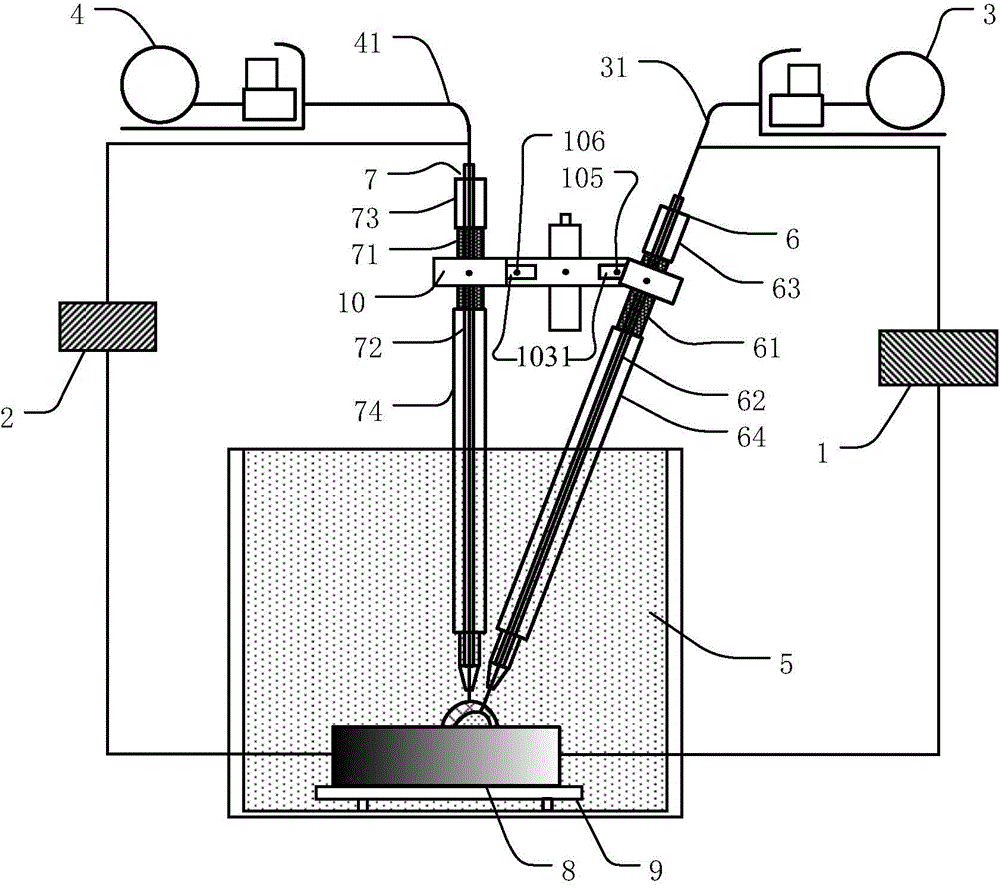

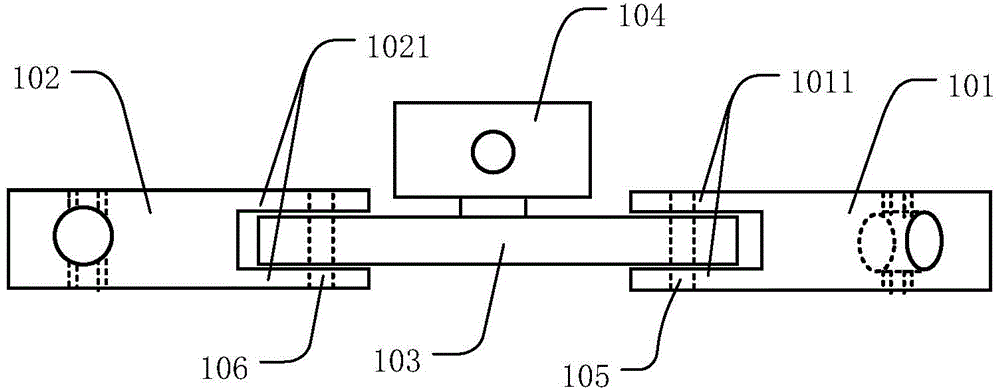

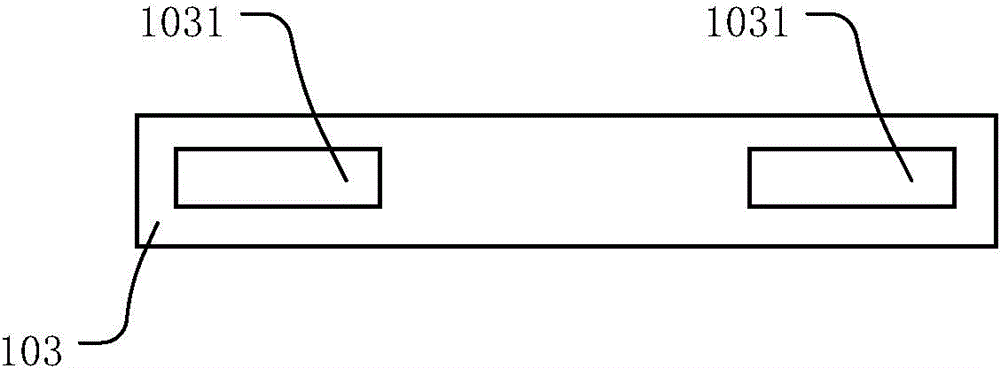

Double-wire underwater wet welding device and method

InactiveCN104400181AStable combustionIndependently adjustable welding parametersElectrode supporting devicesElectric arcBase metal

The invention relates to a double-wire underwater wet welding device and a double-wire underwater wet welding method. The welding device comprises a master welding gun power supply, a slave welding gun power supply, a master wire conveyor, a slave wire conveyor, a master welding gun and a slave welding gun, wherein the master welding gun and the slave welding gun are respectively connected to the master welding gun power supply and a slave welding gun power supply, a master welding wire and a slave welding wire are respectively conveyed to the end parts of the master and slave welding guns through the master and slave wire conveyors, the master welding gun and the slave welding gun are respectively arranged to form a certain angle with a workpiece to be welded, and a certain distance is kept between the front end of the master welding gun and the front end of the slave welding gun. According to the double-wire underwater wet welding device and method, the two welding wires in the master and slave welding guns are heated mutually, and the energy of electric arc is fully used, so that the deposition rate is greatly improved, and the problem that the underwater wet welding molten bath and the base metal cannot be fully fused is overcome.

Owner:HARBIN INST OF TECH AT WEIHAI

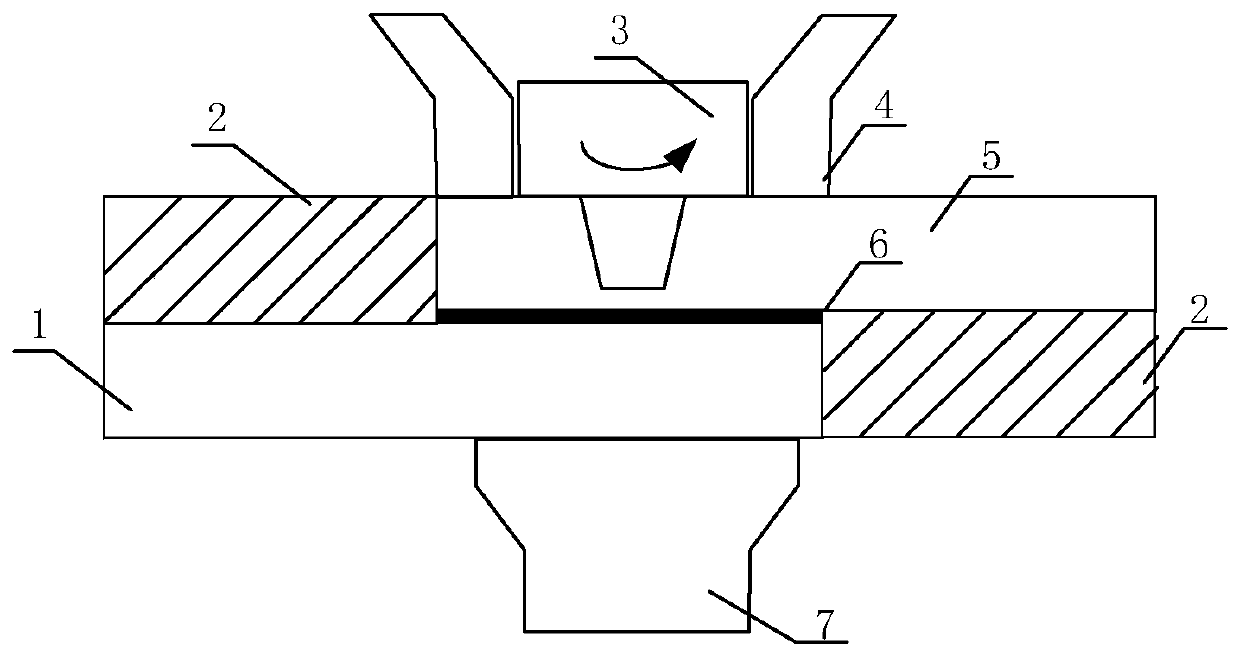

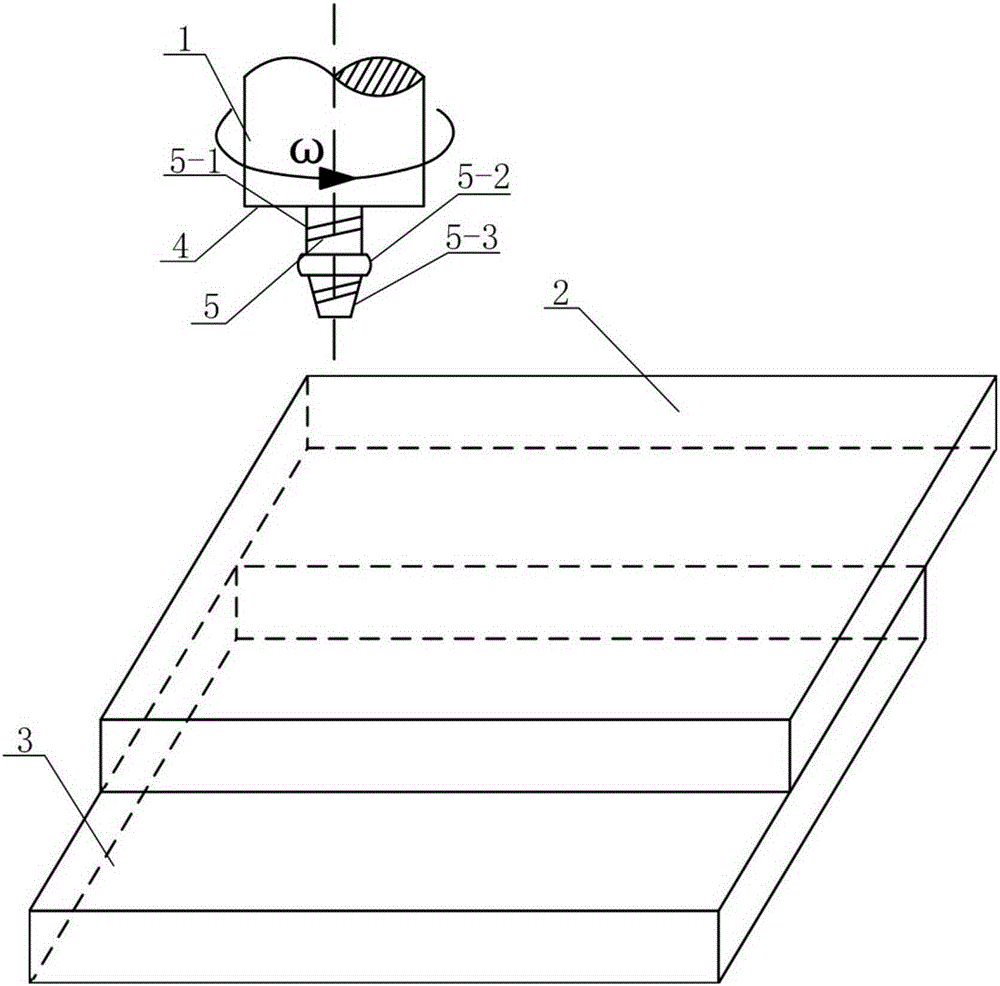

Friction stir and ultrasonic compound welding method of light alloy and resin-based composite

ActiveCN110653479AImprove shear resistanceEasy to moveWelding/soldering/cutting articlesNon-electric welding apparatusInter layerCarbon nanotube

The invention relates to a friction stir and ultrasonic compound welding method of light alloy and a resin-based composite. The method comprises the steps that firstly, the surface, making contact with the resin-based composite, in the light alloy is subjected to mechanical processing or electrochemical processing; secondly the light alloy serves as an upper plate, the resin-based composite servesa lower plate, a carbon nano tube composite thin film serves as a middle layer, and the upper plate, the lower plate and the middle layer are placed on a worktable and fixed; thirdly, an ultrasonic system is connected; fourthly, a stirring head is rotated and carries out downward pricking; fifthly, the ultrasonic system is started; and sixthly, after the shaft shoulder of the stirring head and the upper plate are in contact, the stirring head stays for 3 to 120 s, and then, the stirring head moves in the welding seam direction at the speed of 5 to 1000 mm / min until welding is finished. The welding seam width can be increased, the microcosmic mechanical interlocking capacity in the joint is increased, and the joint anti-shearing and stretching property can be improved.

Owner:SHENYANG AEROSPACE UNIVERSITY

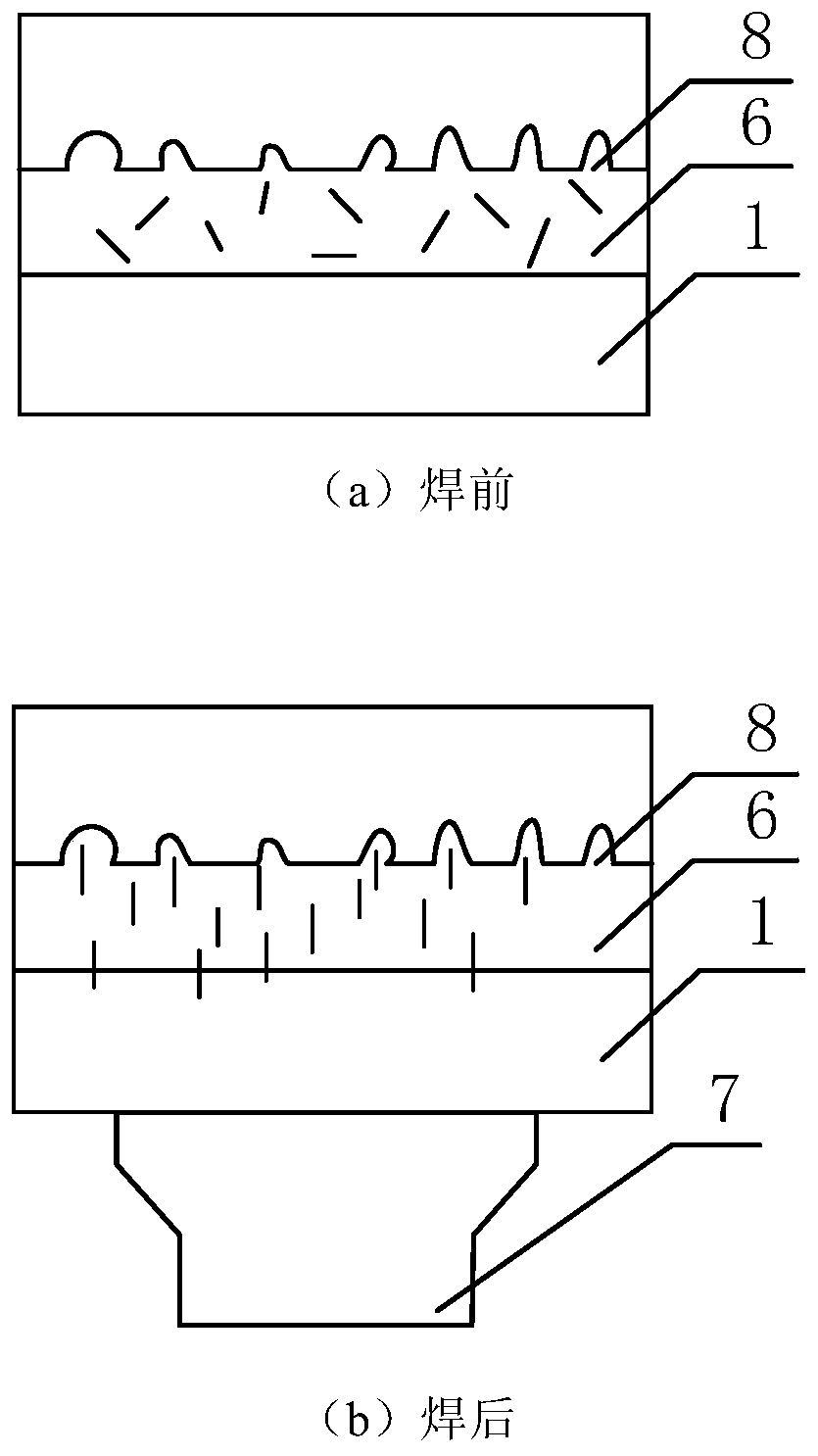

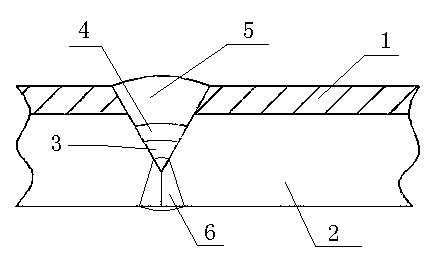

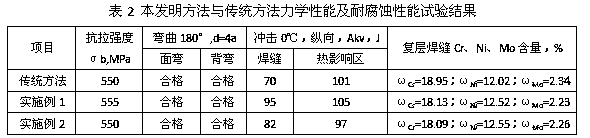

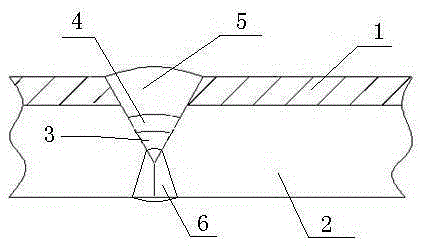

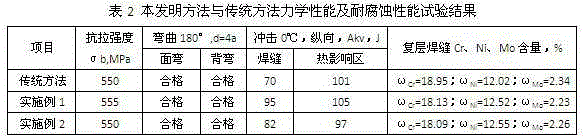

High-efficiency welding method of stainless steel composite board

InactiveCN103862183AWeld depth is smallIncrease weld widthArc welding apparatusMetal working apparatusElectricitySlag

The invention relates to the field of composite board welding methods, in particular to a high-efficiency welding method of a stainless steel composite board. The high-efficiency welding method of the stainless steel composite board comprises the following steps: processing grooves; cleaning and pairing the grooves; welding a base layer on the side of a composite layer; welding the composite layer; welding a base layer on a back surface. The high-efficiency welding method of the stainless steel composite board has the beneficial effects that since electroslag welding with wire electrodes is adopted for welding the composite layer and electrode wires with content of Cr and Ni which is close to the content of Cr and Ni of composite materials, low-carbon weld metal with excellent corrosion resistance is guaranteed to be obtained; since the electroslag welding with wire electrodes has the characteristics of small weld depth and large weld width, welding passes can be effectively reduced, the reduction of the welding passes means the simplification of the welding process, the welding efficiency is improved and the probability of occurrence of defects such as incomplete fusion and slag inclusion is also greatly reduced; since the base layer of the back surface is welded by adopting 450A-500A large-current submerged-arc welding, the weld penetration of base metal can be effectively guaranteed, the defect of incomplete fusion is precluded from occurring and the welding efficiency can be greatly improved.

Owner:JIGANG GRP

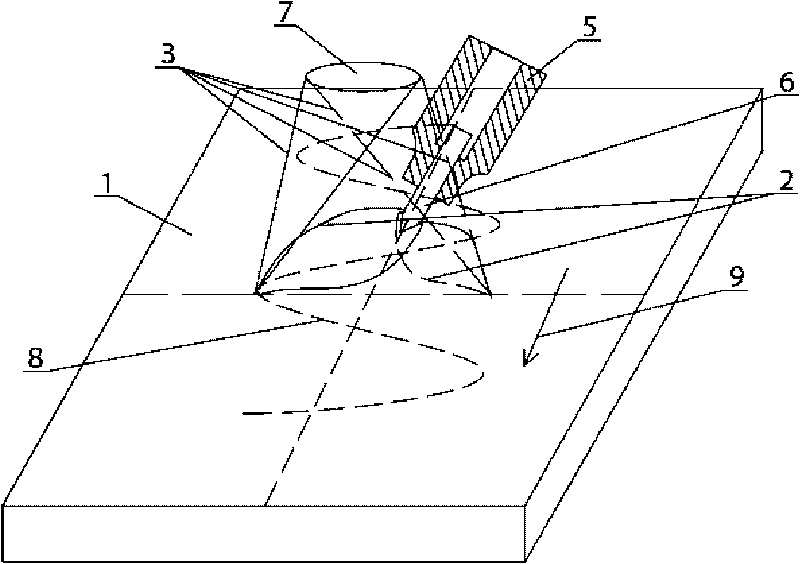

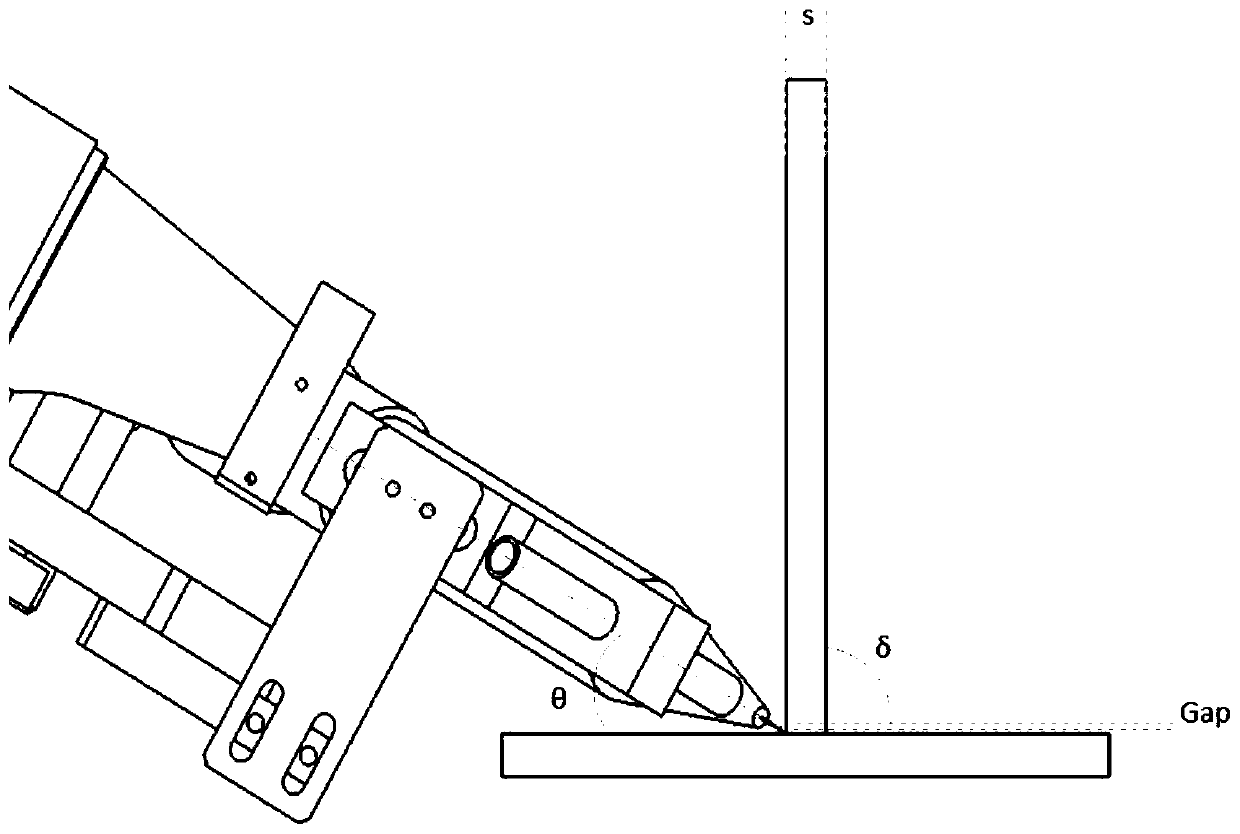

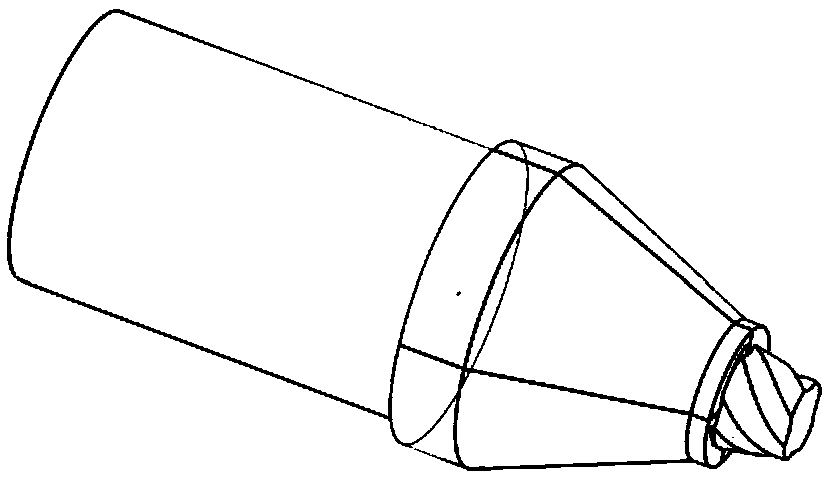

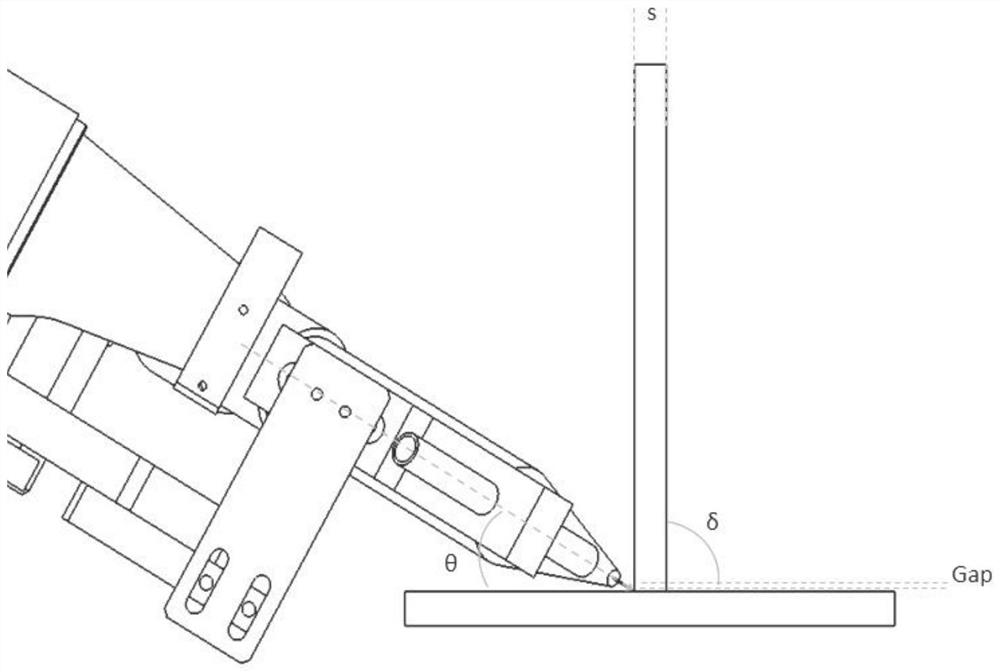

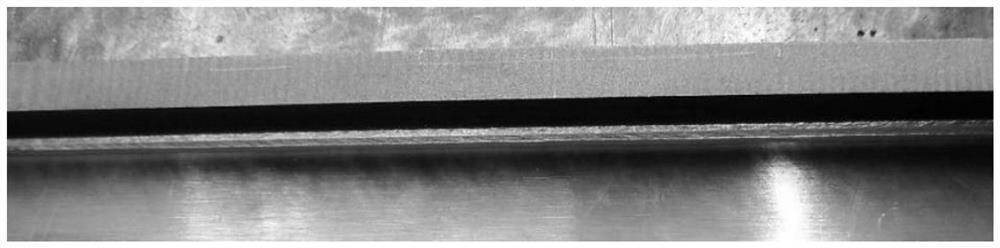

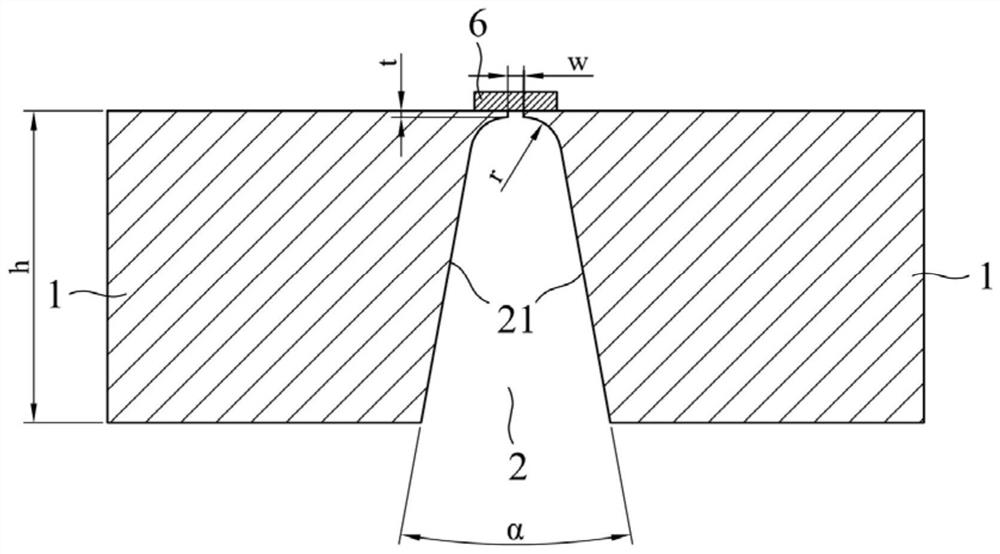

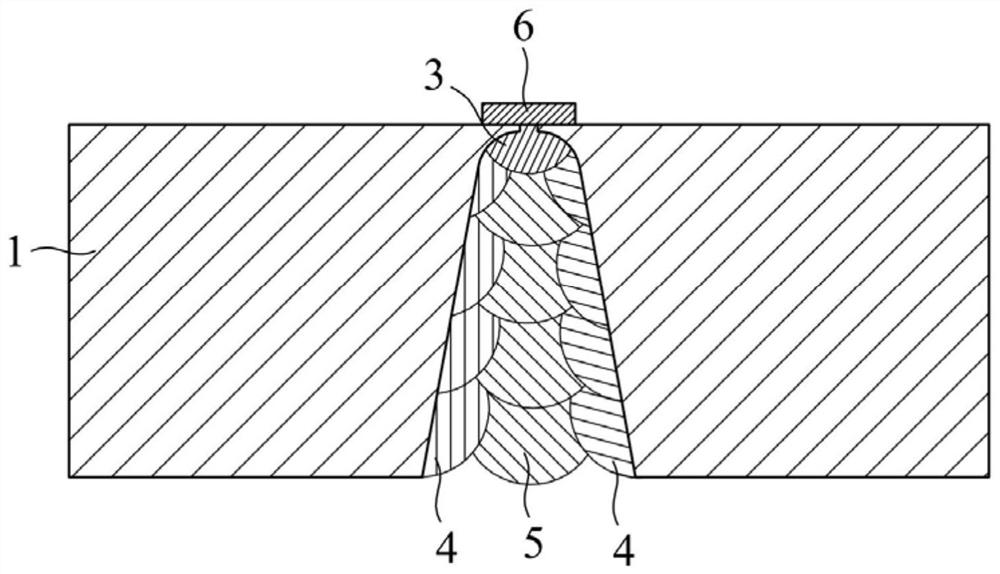

Swinging laser filler wire welding method of medium-thickness plate T-shaped joint fillet welding seam

The invention relates to the technical field of welding, and discloses a swinging laser filler wire welding method of a medium-thickness plate T-shaped joint fillet welding seam. In the medium-thickness plate T-shaped joint fillet welding process, by means of a laser beam which periodically swings in the welding direction and with the assistance of a filler wire, fillet welding seam welding is carried out, wherein the swinging direction is perpendicular to the welding direction. According to the swinging laser filler wire welding method of the medium-thickness plate T-shaped joint fillet welding seam, in the welding process, the laser beam swings periodically in a "I" shape and perpendicular to the welding direction, and a molten pool is uniformly stirred so as to widen the width of the welding seam, so that the large-size, large-penetration, high-efficiency and low-deformation welding process is achieved, and the adaptability of laser welding to plate gaps and the sensitivity of welding throat thermal cracks can be remarkably improved compared with a single laser.

Owner:NANJING ZHONGKE RAYCHAM TECH

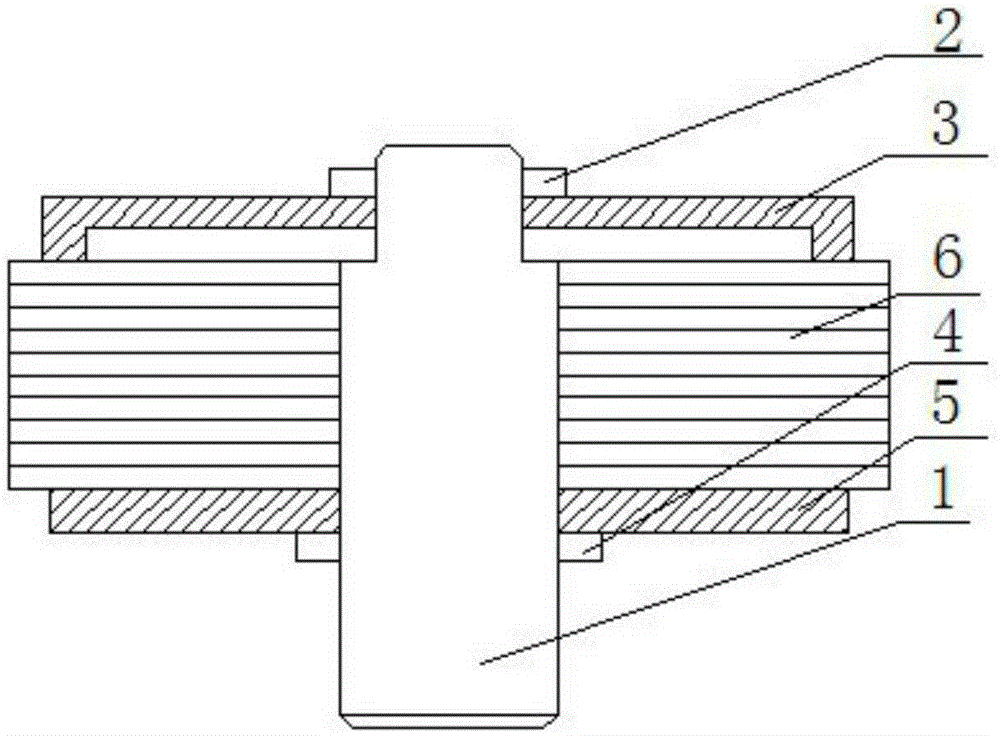

Ultra thin-wall high-temperature alloy lamination laser welding technology and clamp thereof

ActiveCN105397289ASave energyAchieve circumferential continuous weldingLaser beam welding apparatusAlloyStain

The invention discloses an ultra thin-wall high-temperature alloy lamination laser welding technology and a clamp thereof. Through cleaning parts before welding, and after removing oil stain and dirt, the clamp is adopted for assembly positioning so as to ensure tight fit of every two laminations and welding clearance, and then, 40% of the normal welding power is utilized to carry out uniform positioned welding of eight circumferential parts on each tack weld for rotating by 1 degree every time with the positioning radian being 5-8 degrees; a rotary working table rotates the laminations at the rotational indexing of 0.4-0.6 degree as the frequency, carries out welding with the welding parameters of laser power being 80+ / -5 W and welding speed being 800 m / min, and finally carries out laser repairing on non-welded local parts at 90+ / -5 W. With adoption of the ultra thin-wall high-temperature alloy lamination laser welding technology, circumferential continuous welding on the circular end faces of the laminations is realized, the leakproofness of the solder sides of the laminations is ensured, the welding penetration can be better controlled, and the part welding deformation can be prevented.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

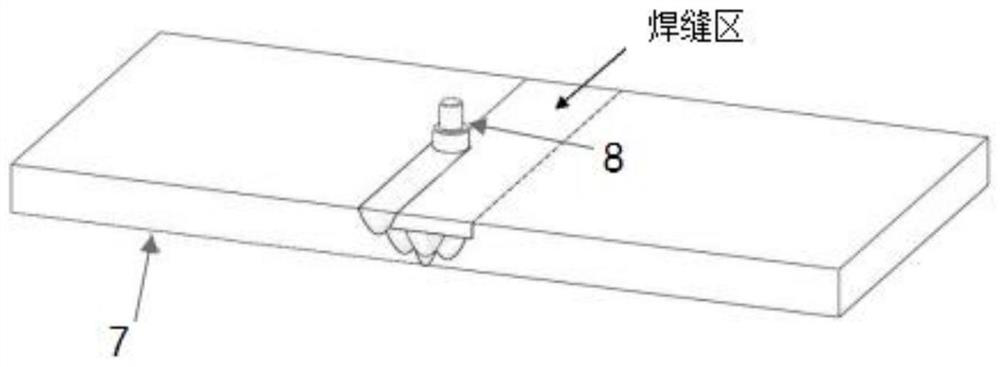

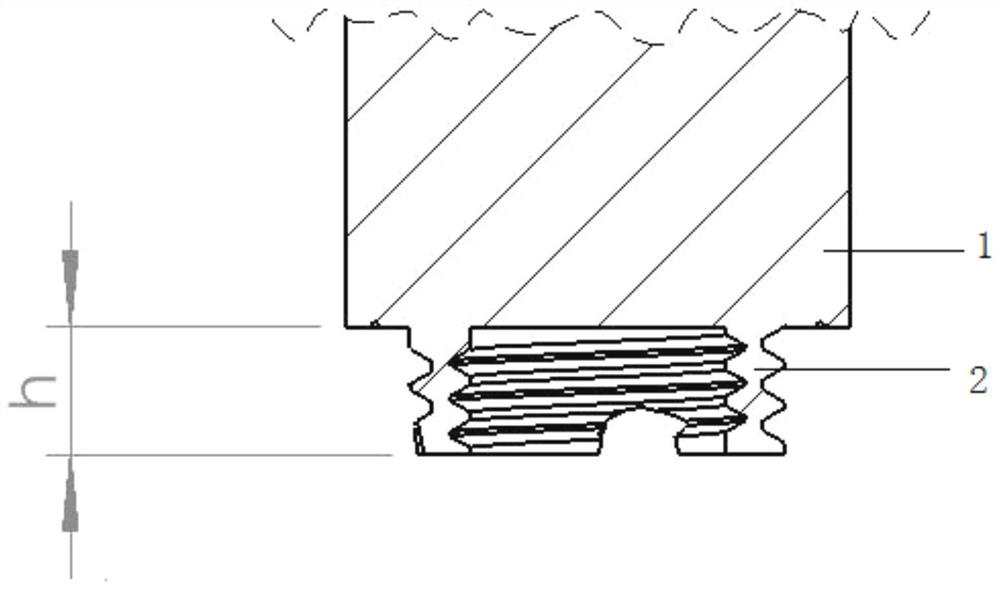

Electronic beam repair welding method for friction stir welding tunnel defects

ActiveCN106180969ALarge weld surface widthAvoid welding deformationArc welding apparatusMetal working apparatusEngineeringMachining

The invention discloses an electronic beam repair welding method for friction stir welding tunnel defects, and relates to repair welding technologies, in particular to a repair welding method for the tunnel defects exposed out of an aluminum alloy friction stir welding liquid cooling assembly after finish machining. The electronic beam repair welding method for the friction stir welding tunnel defects achieves repair welding of the tunnel defects exposed out of the aluminum alloy friction stir welding liquid cooling assembly after finish machining, and therefore deformation of a finish machining structure is avoided, product cost is saved, and the product period is shortened. The electronic beam repair welding method for the friction stir welding tunnel defects comprises cleaning, drying, welding depth h determining, mounting, welding program programming, repair welding and machining. The method can be used for repair welding of the tunnel defects, and the market vacancy is filled; the method is applicable to deformation-free repair welding of the aluminum alloy tunnel defects, and belongs to the technical field of material welding.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

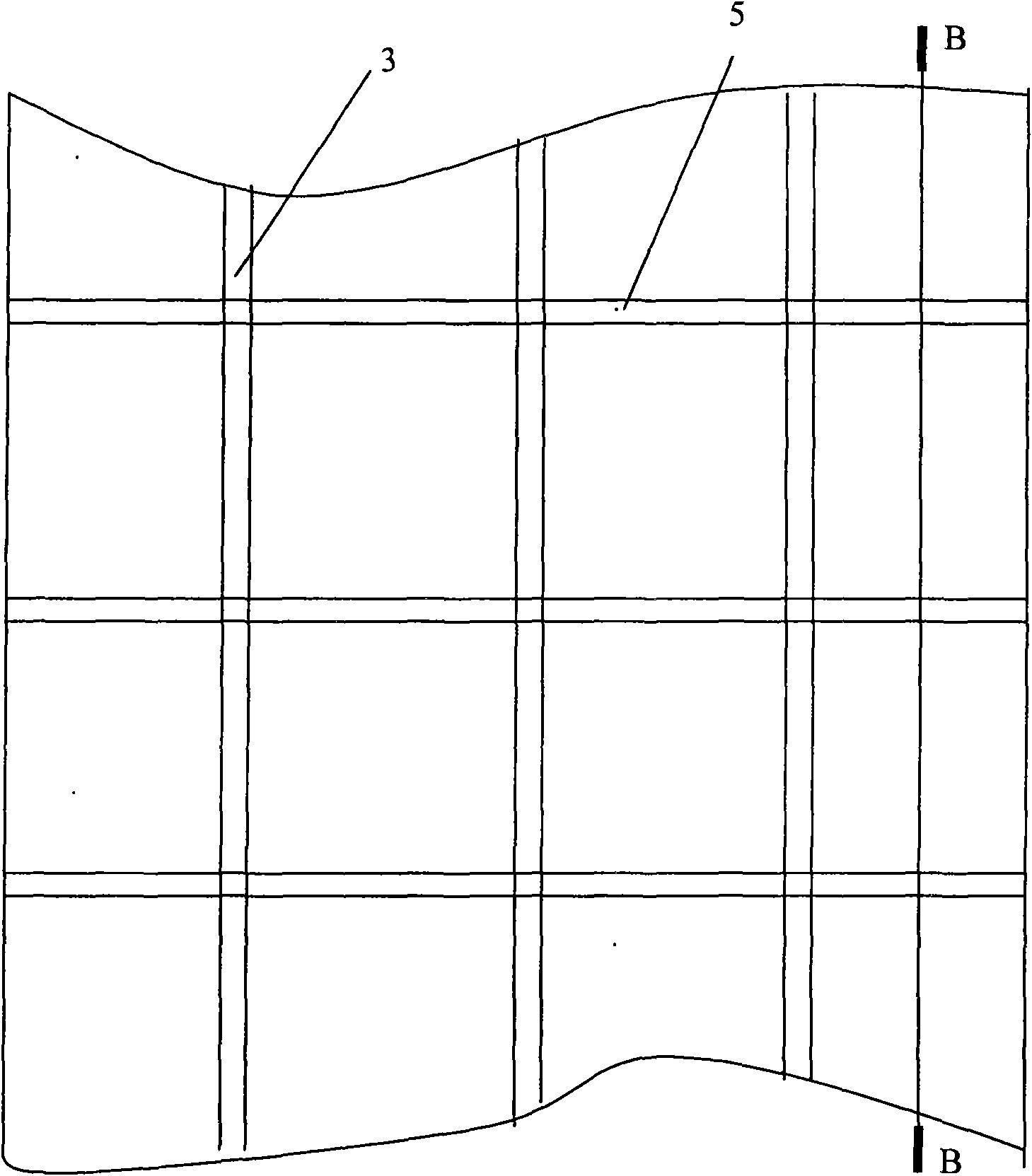

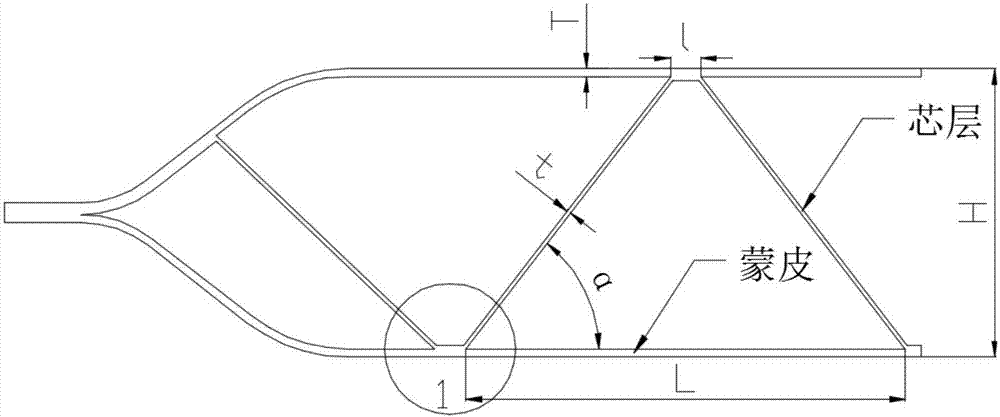

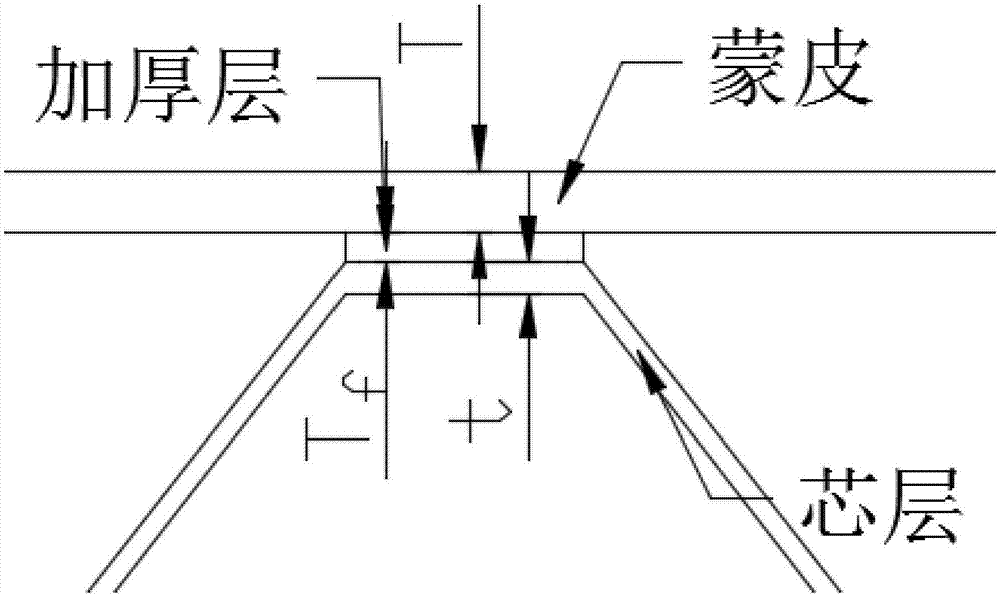

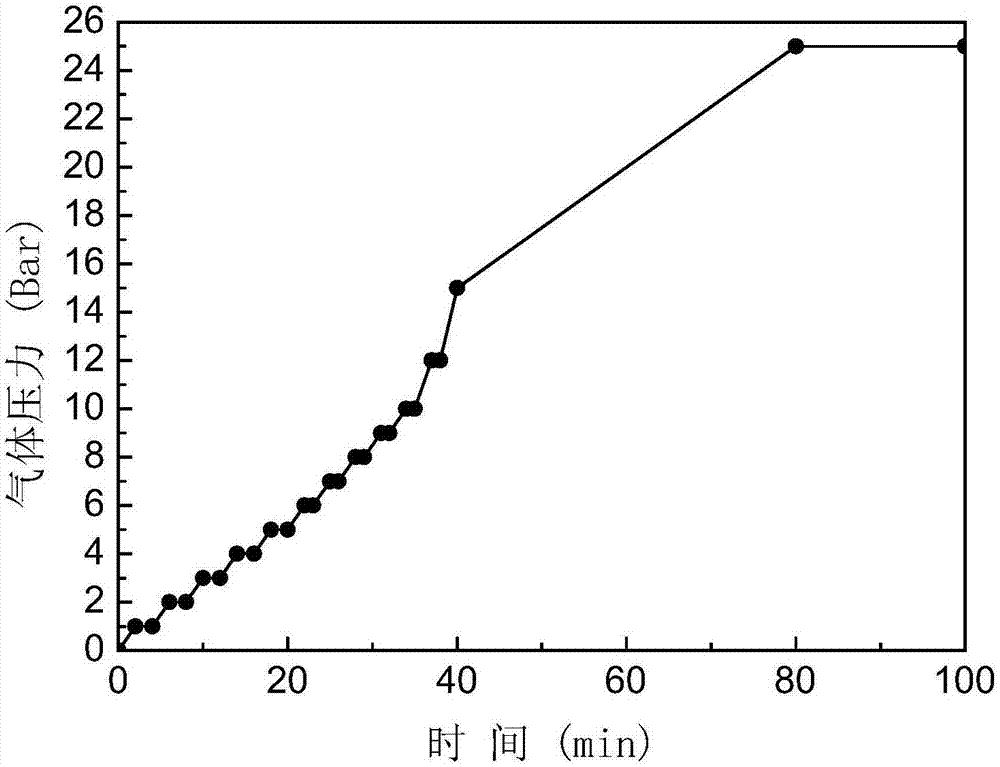

Alloy three-layer structure surface groove control method

The invention relates to a Ti2AlNb alloy laser welding / superplastic forming three-layer structure surface groove control method, belongs to the technical field of three-layer structure superplastic forming, and is suitable for surface groove defect control of superplastic forming three-layer structure parts for aerospace. The method can realize surface groove control of a Ti2AlNb alloy laser welding / superplastic forming three-layer structure, and can control the surface groove depth of the three-layer structure to be not higher than 0.3 mm; and the surface groove control method is suitable for Ti2AlNb alloy laser welding / superplastic forming three-layer structures with different cover-core thickness ratios, different welding line widths and different formed cover-core included angles.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Thick plate laser arc composite double-sided synchronous horizontal welding method and device

ActiveCN114012266AImprove liquidityImprove uniformityLaser beam welding apparatusThick plateEngineering

The invention discloses a thick plate laser arc composite double-sided synchronous horizontal welding method and device. The horizontal welding method comprises the following steps that 1, a welding workpiece is prepared; 2, two laser arc devices are arranged on the two sides of the welding workpiece correspondingly, and the positions are adjusted; 3, welding process parameters are set, a laser arc device is started, and a base layer is welded; and 4, welding process parameters are adjusted, a laser arc device is started, and filling layer welding is performed. The method reduces the porosity of the weld joint, solves the problems of incomplete penetration of the weld joint, incomplete fusion of the side wall, weld joint cracks and the like, and ensures the quality of the weld joint and the welding stability. The horizontal welding device comprises a TIG welding gun, a first laser device, a second laser device, a GMAW welding gun and an air injection assembly.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Laser welding method for narrow space of casing

ActiveCN108015420ASolve welding deformationSolve the test runLaser beam welding apparatusX-rayWelding defect

The invention discloses a laser welding method for narrow space of a casing. The laser welding method comprises the following steps that oil removal treatment is carried out on a section of a joint ofa part and two sides of the joint before welding; a support plate, an outer casing and an inner ring front section are assembled, the inner ring front section and the fixing support plate are positioned, and the matching clearance is ensured to be less than or equal to 0.1mm; a robot optical fiber laser welding device is adopted, and inert gas protection is carried out on the front sides of weldjoints; corresponding welding parameters are controlled, and laser welding is carried out; and after welding is completed, the weld joints of the support plate and the inner ring front section are checked, the appearance of the weld joints is ensured to be in smooth transition with base material, the surfaces of the weld joints are free of cracks, burnthrough, overlaps and welding spatters, an x-ray bar anode coloring inspection is carried out, and no welding defect is found. By the adoption of the laser welding method, the welding heat input quantity and the weld joint forming quality are effectively controlled, welding deformation is reduced, the welding quality and the stability are greatly improved, finally, the problems of welding deformation of the gas inlet casing and testing and repairing cracks are solved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

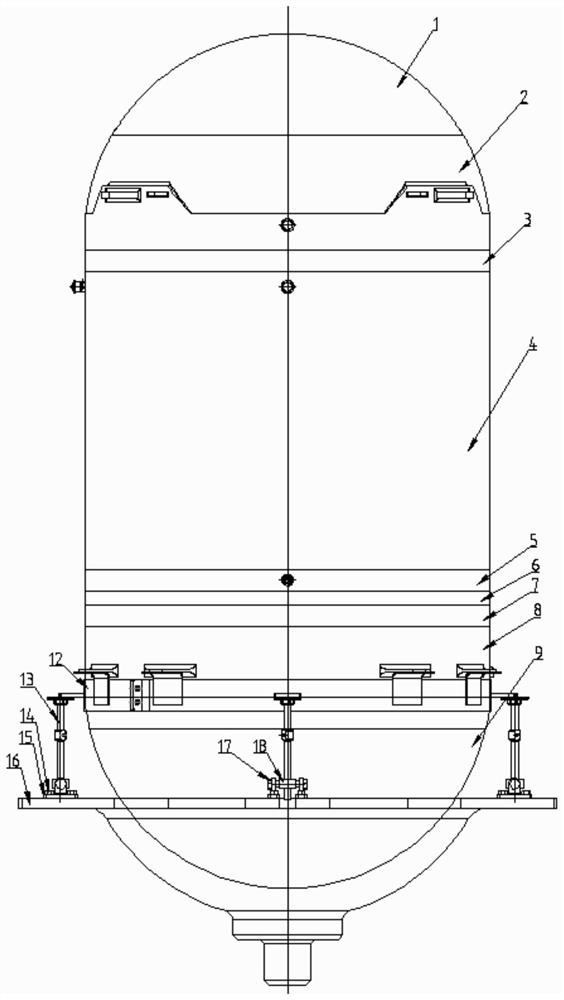

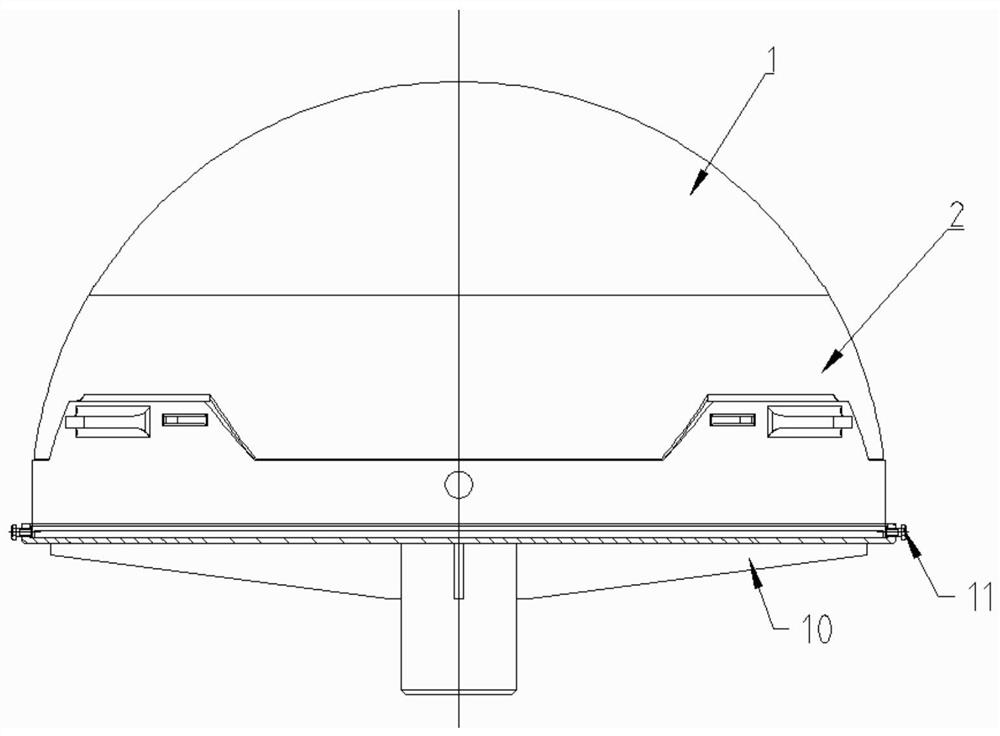

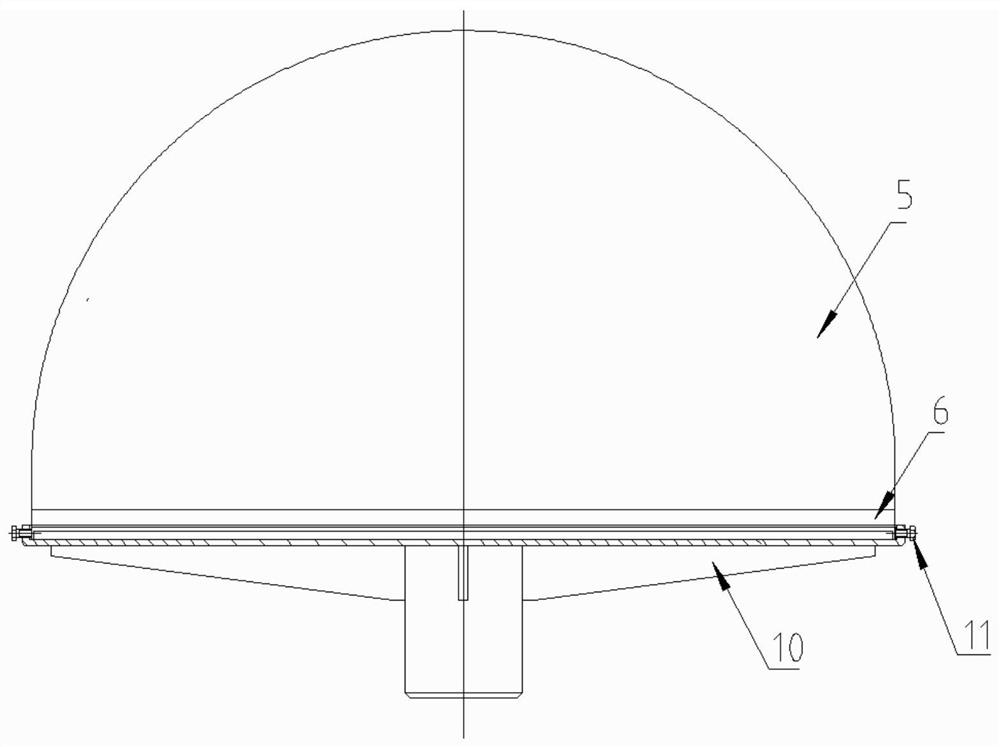

Electron beam welding method for lock butt joint of large-size thin-wall titanium alloy storage tank

ActiveCN112059394AReduce welding distortionEasy to cleanElectron beam welding apparatusButt jointWeld seam

The invention provides an electron beam welding method for a lock butt joint of a large-size thin-wall titanium alloy storage tank. The electron beam welding method comprises the steps that a fuel hemispherical shell and a fuel rear frame are welded; a common-base partition plate and a fixing ring are welded; storage tank workpieces are assembled, clamped and positioned; the storage tank workpieces are positioned and welded; and the storage tank workpieces are welded and formed, wherein during first two welding, a lock is subjected to complete-penetration welding in an electron beam welding mode in a part state, in subsequent welding, all parts are assembled and positioned together and then subjected to electron beam welding, effective penetration of a weld joint is guaranteed, but the complete penetration of the lock cannot be achieved, and splashing on the back is avoided. By adopting an optimized tool and welding process, the effective weld width and the pressure bearing capacity ofthe root of the electron beam welding seam lock of the lock butt joint of the large-size thin-wall titanium alloy storage tank are effectively improved, the phenomena that X-ray inspection air hole defects are extremely likely to occur in a welding seam and the welding seam part is cracked in the hydraulic test process are avoided, the number of rewelding times is reduced, the production efficiency is improved, and the production cost is reduced.

Owner:XIAN SPACE ENGINE CO LTD

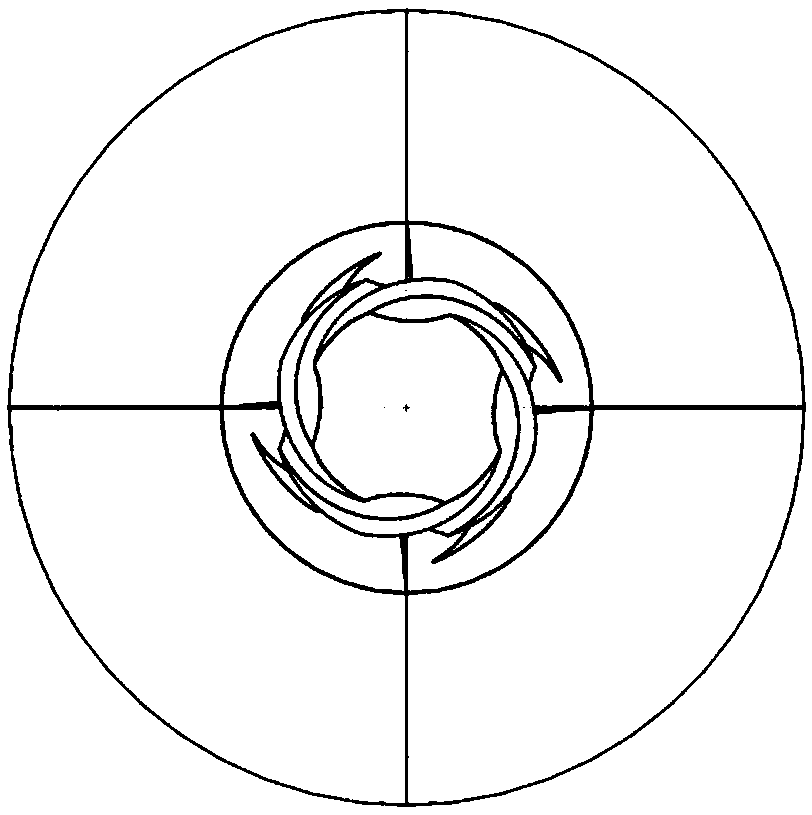

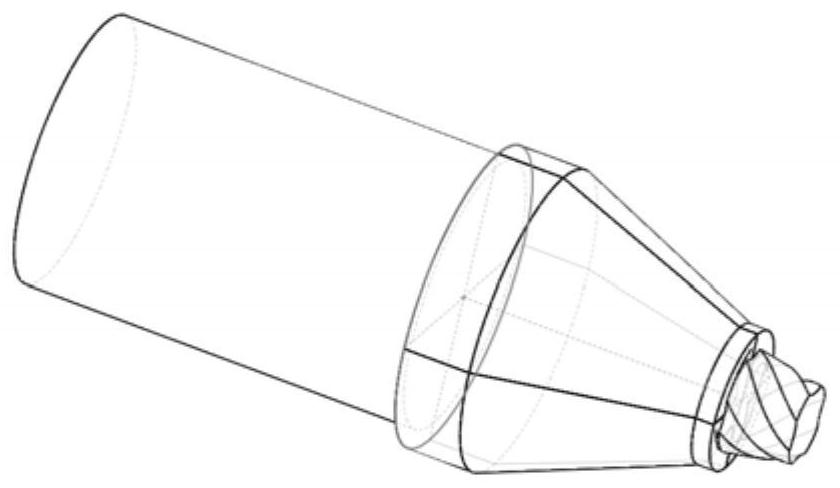

Additive stirring head with small shaft shoulder acting area and high specific surface area stirring needle

ActiveCN114393293ASmall sizeReduce adverse effectsNon-electric welding apparatusLap jointEngineering

The invention discloses an additive stirring head with a small shaft shoulder acting area and a high-specific-surface-area stirring needle, and relates to the technical field of metal welding. Comprising a clamping part, a shaft shoulder and a stirring needle which are sequentially connected, and the ratio of the diameter of the stirring needle to the diameter of the shaft shoulder is 0.6-0.8; the ratio of the volume to the surface area of the stirring needle is 2.5-3.5, a cylindrical first groove is formed in the end, away from the shaft shoulder, of the stirring needle in the axis direction of the stirring needle, and spiral flow guide grooves are formed in the outer circumferential face of the stirring needle and the inner circumferential face of the first groove. The method is used for reducing lap joint passes and can avoid the problem that interfaces of all layers are not welded.

Owner:YANSHAN UNIV

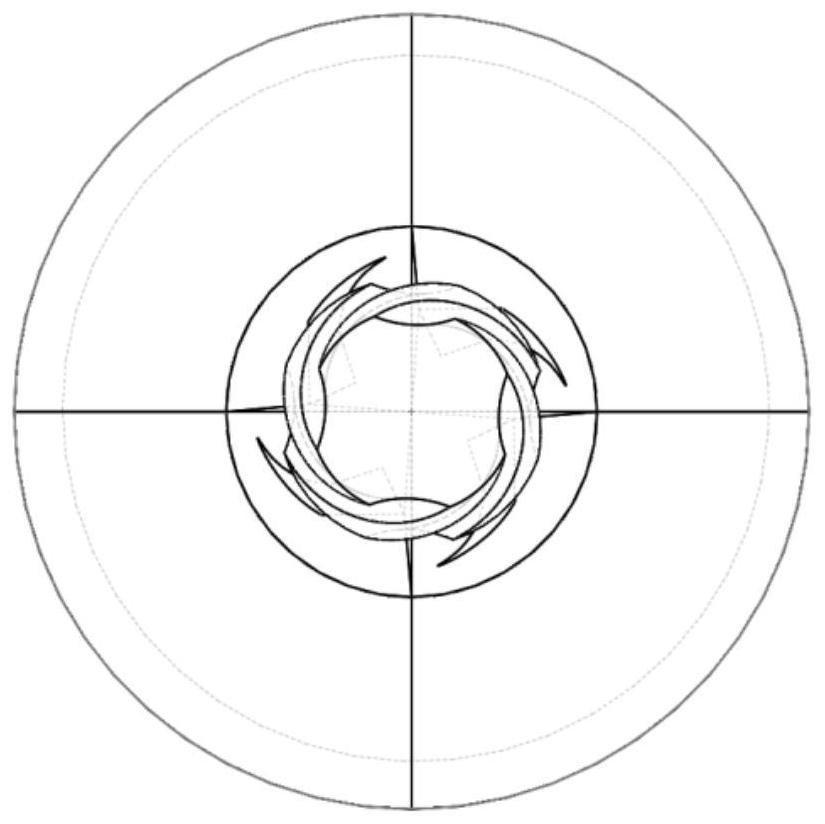

Stirring head for friction stir welding of large gap thin sheet aluminum alloy and welding technology of stirring head

ActiveCN109623127AEffective aggregationSpeed up the flowNon-electric welding apparatusFriction weldingNew energy

The invention relates to the field of thin sheet aluminum alloy welding of a new energy automobile battery box, in particular to a stirring head for friction stir welding of a large gap thin sheet aluminum alloy and a welding technology of the stirring head. The stirring head gathers extruded metal from a shaft shoulder to the shaft shoulder center through shaft shoulder scroll patterns, the gathered metal is conveyed into a gap through spiral grooves in a stirring needle and in cooperation with corresponding technological parameters, and meanwhile, the total metal flow in a weld joint is increased and reduced through the arrangement of large diameter stirring needle to reduce the proportion of the gap in the weld joint, and welding of the large gap thin sheet aluminum alloy is realized finally.

Owner:NANJING UNIV OF SCI & TECH

Oscillating Laser Filler Welding Method for T-joint Fillet Welds of Medium and Heavy Plates

The invention relates to the field of welding technology, and discloses a method for oscillating laser wire-filling welding of a T-shaped joint fillet weld of a medium-thick plate. beam, supplemented by filler wire for fillet welds, where the swing direction is perpendicular to the welding direction. The oscillating laser wire-filling welding method for T-shaped joint fillet welds of medium-thick plates of the present invention, during the welding process, the laser beam swings periodically in the shape of "|" and perpendicular to the welding direction, and evenly stirs the molten pool to widen the width of the weld seam , to achieve a welding process with large size, large penetration, high efficiency, and low deformation. Compared with single laser, it can significantly improve the adaptability of laser welding to plate gaps and the sensitivity of welding throat thermal cracks.

Owner:NANJING ZHONGKE RAYCHAM TECH

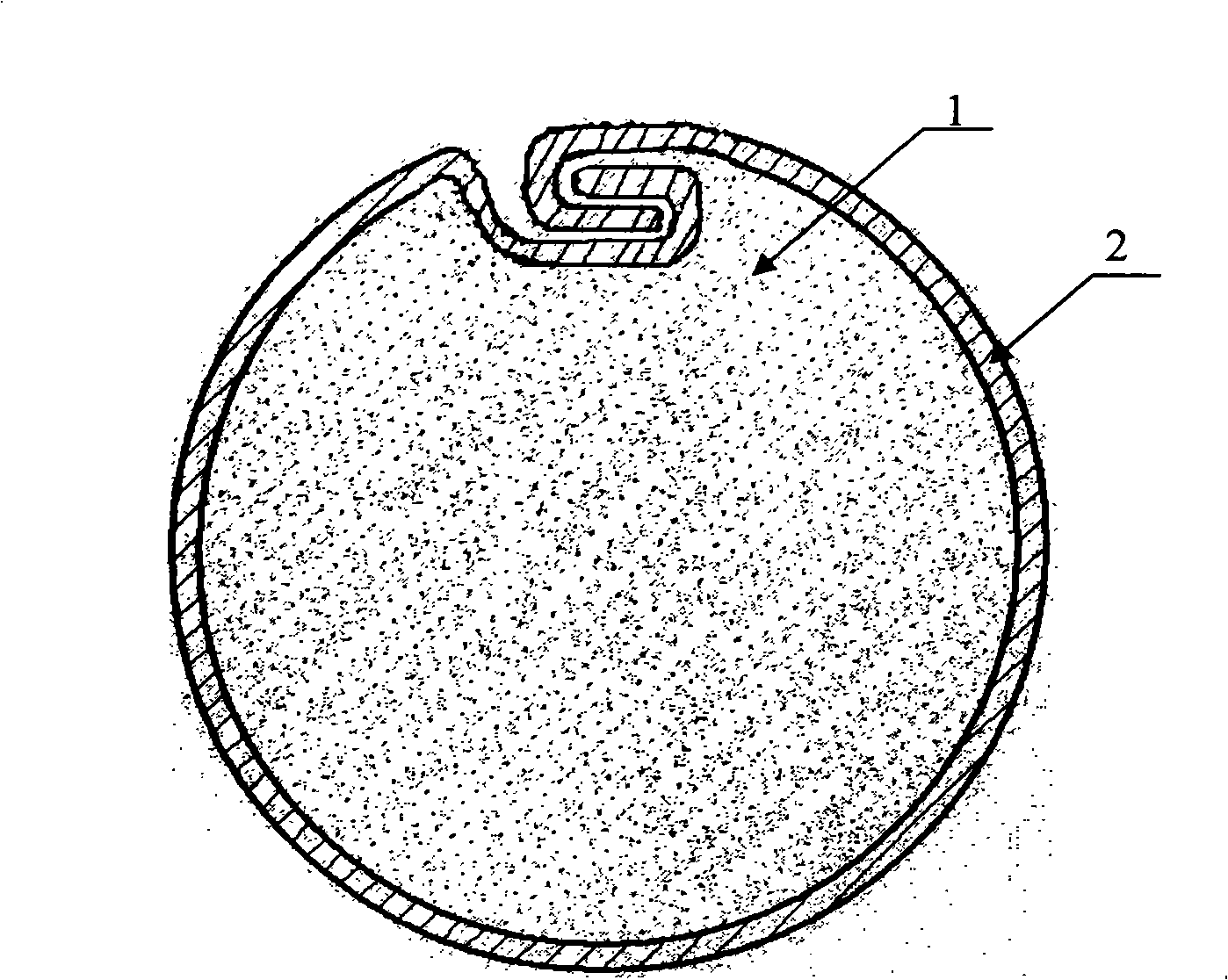

Welding process for overhead welding of plate

InactiveCN111822825AReduce adverse effectsReduce generationWelding accessoriesGas metal arc weldingWelding process

The invention relates to the field of welding, and discloses a welding process for overhead welding of a plate. The welding process includes the steps of machining a groove, wherein the U-shaped groove is formed in a welding butt-joint end of the plate; performing backing welding, wherein a backing welding bead is welded to the root part of the U-shaped groove by gas metal arc welding; and performing filling welding, wherein starting from the root part of the U-shaped groove, straight bead welding is performed on the two side walls of the U-shaped groove by bipulse gas shielded arc welding first to form at least one side wall filling welding bead on each side wall, then weaving welding is performed between the welded side wall filling welding beads by monopulse gas shielded arc welding toform a middle filing welding bead, and finally side wall filling welding beads and middle filling welding beads are welded repeatedly in sequence. By perform straight bead welding on the two side walls of the U-shaped groove by bipulse gas shielded arc welding and performing weaving welding between the side wall filling welding beads by monopulse gas shielded arc welding, the welding beads can beeasily formed, and welding efficiency and quality are improved.

Owner:BEIJING BO TSING TECH CO LTD

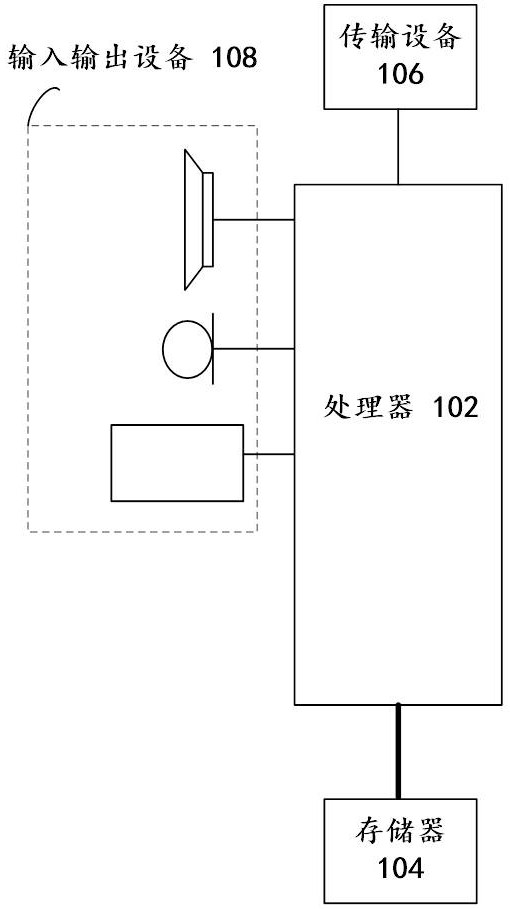

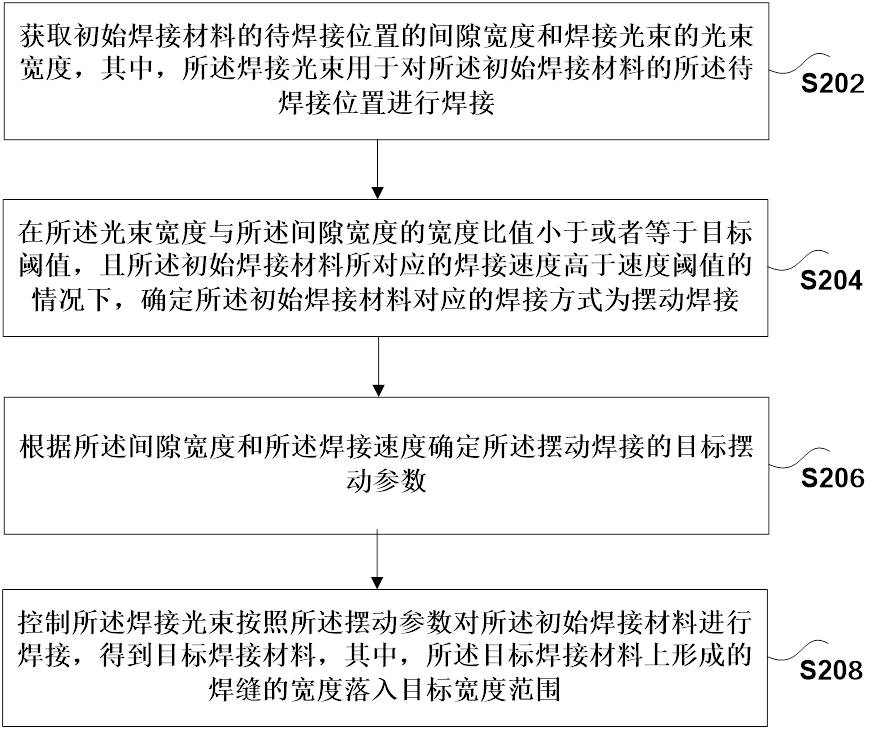

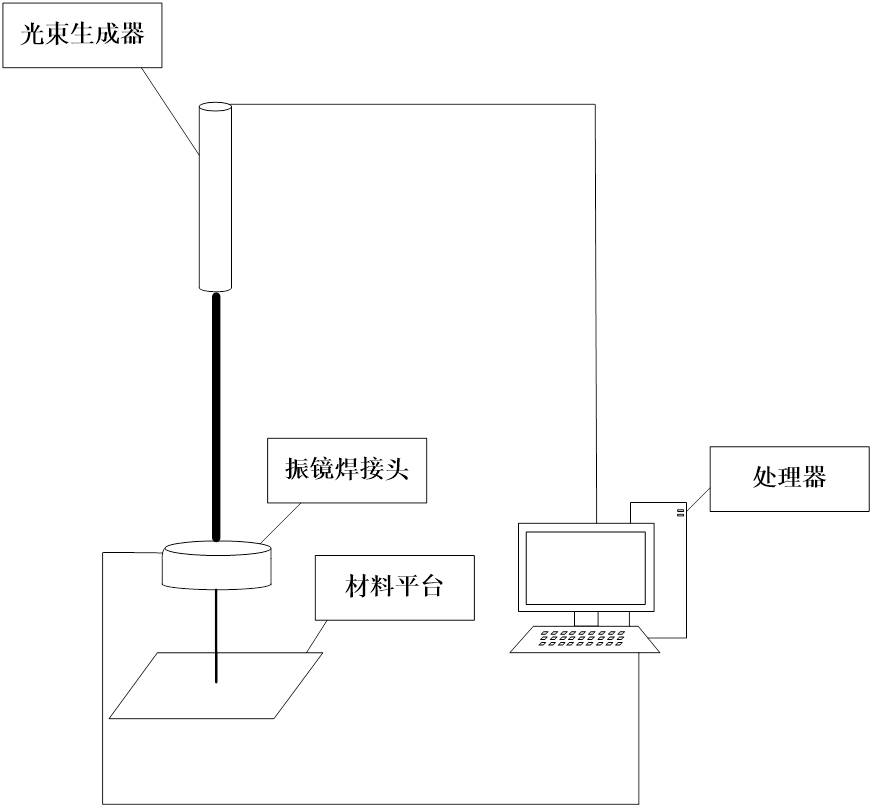

Welding method and device of welding material, storage medium and electronic device

ActiveCN114654120AIncrease weld widthGuaranteed widthLaser beam welding apparatusWeld seamSolder material

The invention discloses a welding method and device for a welding material, a storage medium and an electronic device.The method comprises the steps that the gap width of the to-be-welded position of an initial welding material and the beam width of a welding beam are obtained, and the welding beam is used for welding the to-be-welded position of the initial welding material; under the condition that the width ratio of the light beam width to the gap width is smaller than or equal to a target threshold value and the welding speed corresponding to the initial welding material is higher than a speed threshold value, the welding mode corresponding to the initial welding material is determined to be swing welding; target swing parameters of swing welding are determined according to the gap width and the welding speed; the welding beam is controlled to weld the initial welding material according to the swing parameters, the target welding material is obtained, the width of a welding seam formed in the target welding material falls into the target width range, and by means of the technical scheme, the problems that in the related technology, when high-speed welding is conducted on the material, the welding quality is low are solved.

Owner:WUHAN RAYCUS FIBER LASER TECHNOLOGY CO LTD

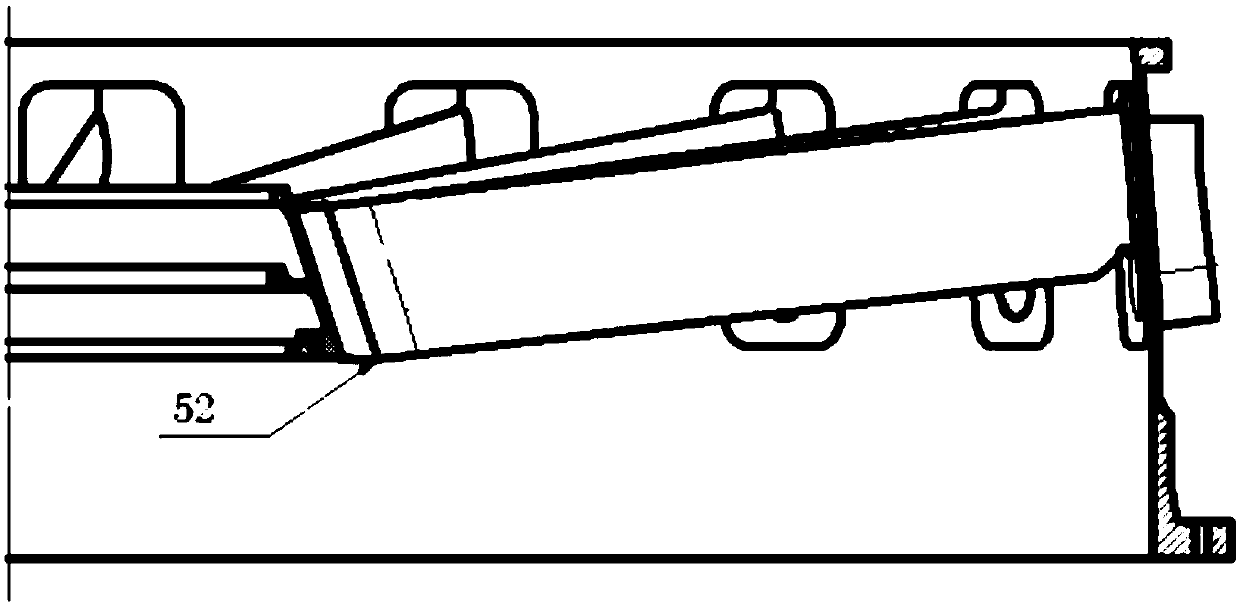

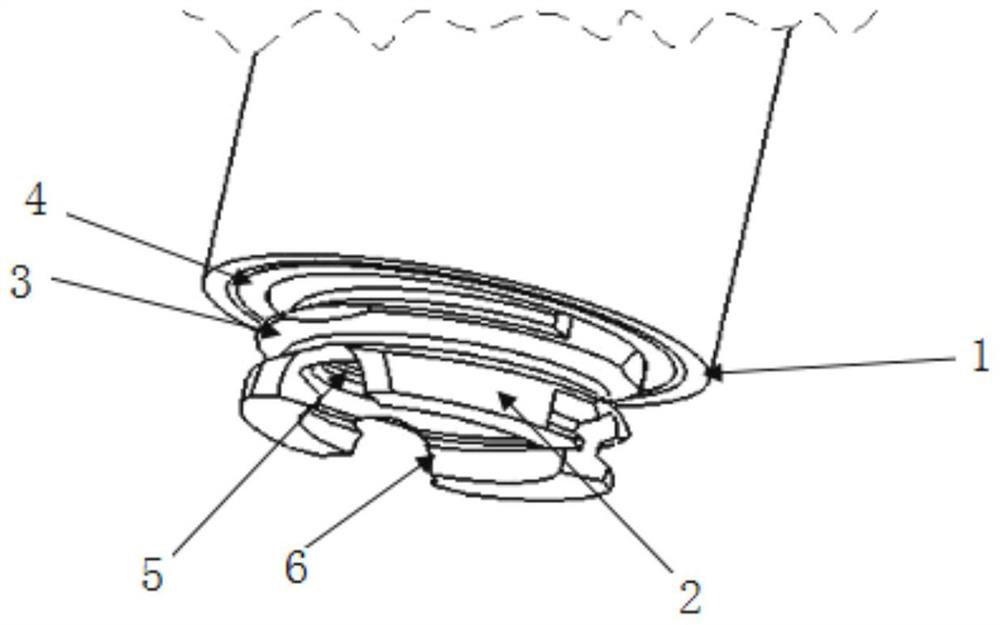

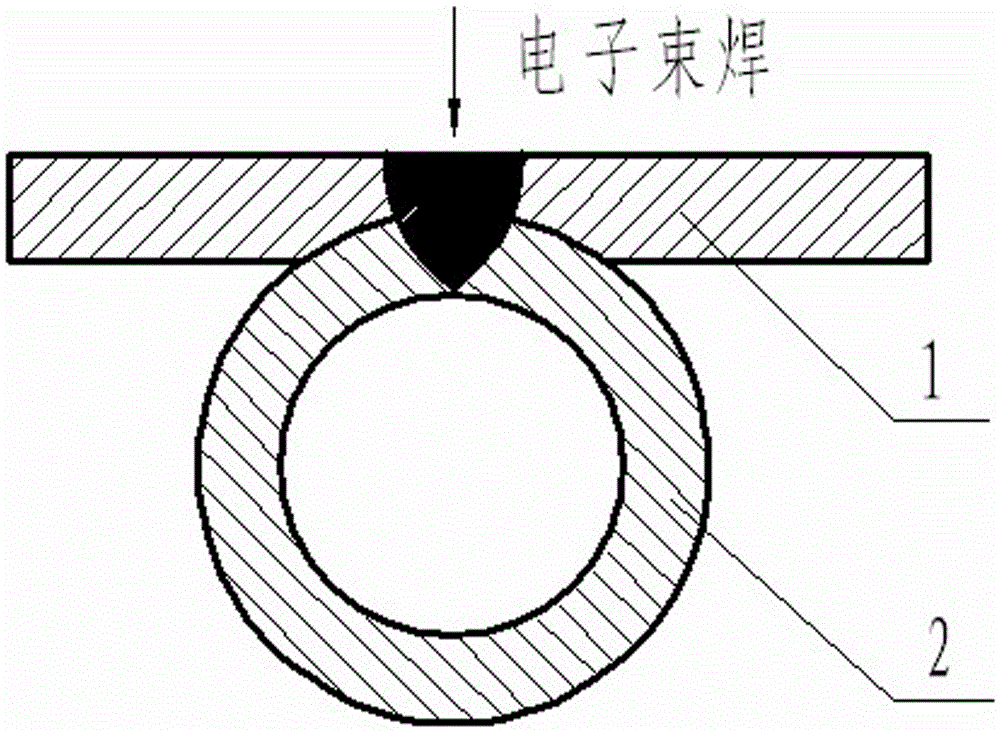

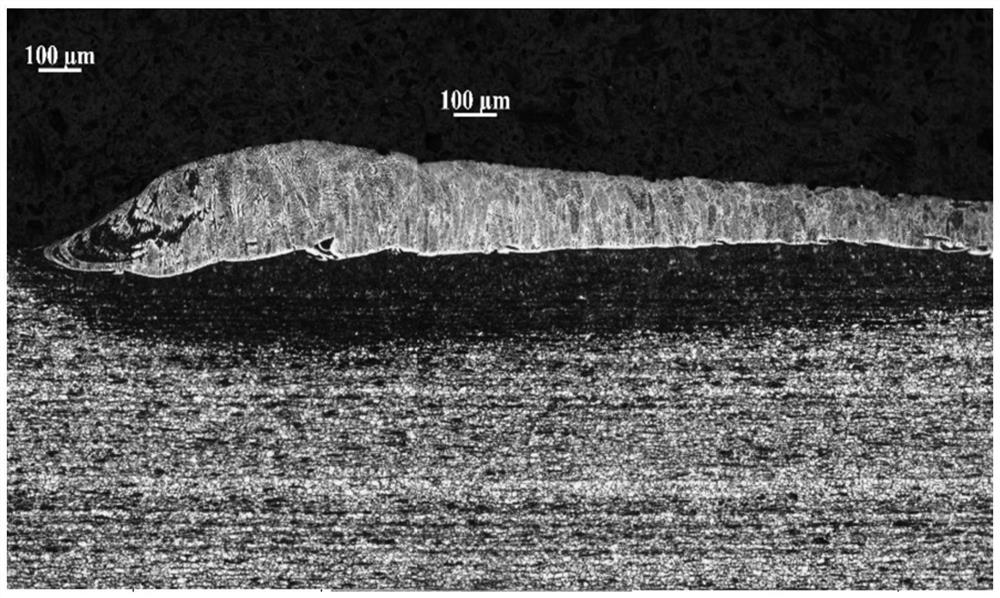

Electron Beam Non-penetrating Welding Method for Feed Components

ActiveCN104227218BIncrease active areaDispersion of the active areaElectron beam welding apparatusIsosceles trapezoidThermal deformation

The invention discloses a non-penetrating welding method of feed components through electron beams. According to the non-penetrating welding method, the needed technological process is simple, efficiency is high, deformation is little, welding seams are regular, welding precision is high, and the product percent of pass can be 100%. The non-penetrating welding method is realized through the technical scheme that in the welding process, scanning waveforms of the electron beams are set to be oval, the scanning amplitude in the X direction is set to be 2 mm to 3 mm, the scanning amplitude in the Y direction is set to be 4 mm to 6 mm, the scanning frequency is set to be 80 Hz to 100 Hz, the acceleration voltage is set to be 50 kV to 60 kV, the beam current is set to be 10 mA to 15 mA, the focus current is set to be 800 mA to 900 mA, any one set of specific values of is selected from the process parameters, the beam slope is set to be in an isosceles trapezoid shape, ascending time and descending time of the electron beams are both set to be 3s to 5s, and the welding seams are welded in a deflection scanning mode; the electron beams penetrate through feed pieces on a sleeve pipe to weld the feed pieces and the sleeve pipe under the feed pieces together. The non-penetrating welding method solves the problems that a conventional welding process is complex, thermal deformation is serious, and burning through and open solder are likely to happen.

Owner:四川泛华航空仪表电器有限公司

Stirring head and its welding process for friction stir welding of aluminum alloy with large gap

ActiveCN109623127BEffective aggregationSpeed up the flowNon-electric welding apparatusFriction weldingNew energy

The invention relates to the field of thin-plate aluminum alloy welding for battery boxes of new energy vehicles, in particular to a stirring head for friction stir welding of large-gap thin-plate aluminum alloys and a welding process thereof. The stirring head extrudes the metal from the shoulder through the vortex pattern of the shoulder and gathers the center of the shoulder, and the gathered metal passes through the spiral groove on the stirring needle and cooperates with the corresponding process parameters to transport the metal to the inside of the gap. Increase or decrease the total amount of metal flow in the weld to reduce the proportion of gaps in the weld, and finally realize the welding of large thin-plate aluminum alloys.

Owner:NANJING UNIV OF SCI & TECH

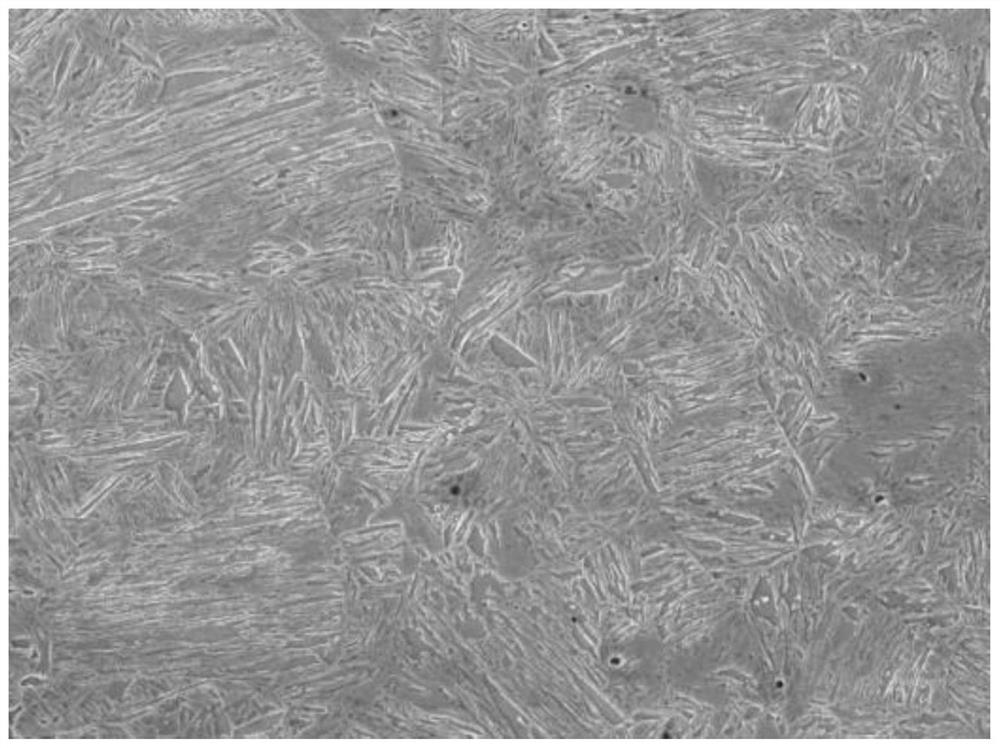

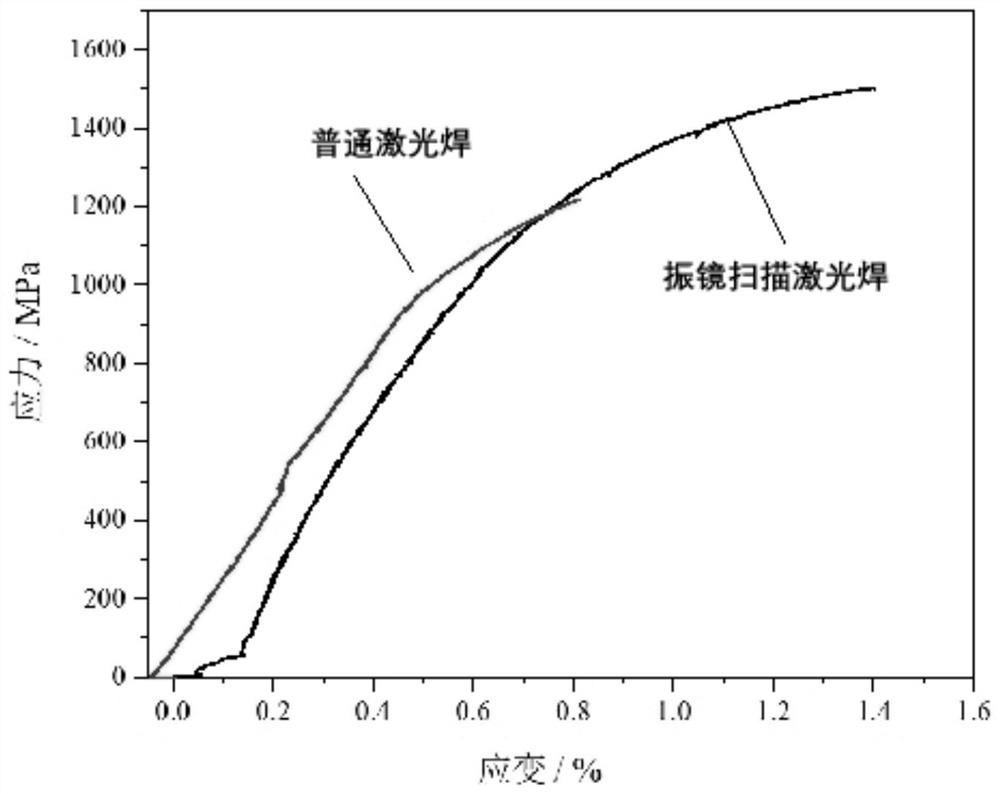

Galvanometer scanning laser welding method based on variable light spots

PendingCN113732499AEvenly dispersedReduce segregationLaser beam welding apparatusLight spotGalvanometer

The invention provides a galvanometer scanning laser welding method based on variable light spots. The galvanometer scanning laser welding method comprises the following steps of fixing two to-be-welded hot forming steel materials in a splicing or overlapping manner, so that the two hot forming steel materials are in close contact; and galvanometer scanning laser welding on a fixed position to be welded, and the position to be welded is melted and solidified to form a welding seam by adjusting the size of a light spot and setting a galvanometer scanning track. Good connection of hot forming steel is achieved, the mechanical property of a welding joint is improved, the proportion of high-temperature ferrite of a welding seam is reduced, the mechanical property of the welding joint is improved, and the problems that in the prior art, equipment cost is increased, alloy components are changed, production efficiency is reduced, production cost is improved, and quality is unstable are solved.

Owner:SHANGHAI TECH UNIV

A high-efficiency welding method for stainless steel clad plates

InactiveCN103862183BWeld depth is smallIncrease weld widthArc welding apparatusMetal working apparatusElectricitySlag

The invention relates to the field of composite board welding methods, in particular to a high-efficiency welding method of a stainless steel composite board. The high-efficiency welding method of the stainless steel composite board comprises the following steps: processing grooves; cleaning and pairing the grooves; welding a base layer on the side of a composite layer; welding the composite layer; welding a base layer on a back surface. The high-efficiency welding method of the stainless steel composite board has the beneficial effects that since electroslag welding with wire electrodes is adopted for welding the composite layer and electrode wires with content of Cr and Ni which is close to the content of Cr and Ni of composite materials, low-carbon weld metal with excellent corrosion resistance is guaranteed to be obtained; since the electroslag welding with wire electrodes has the characteristics of small weld depth and large weld width, welding passes can be effectively reduced, the reduction of the welding passes means the simplification of the welding process, the welding efficiency is improved and the probability of occurrence of defects such as incomplete fusion and slag inclusion is also greatly reduced; since the base layer of the back surface is welded by adopting 450A-500A large-current submerged-arc welding, the weld penetration of base metal can be effectively guaranteed, the defect of incomplete fusion is precluded from occurring and the welding efficiency can be greatly improved.

Owner:JIGANG GRP

Flux-cored steel belt containing steel wire for surfacing and preparation method thereof

InactiveCN101310913BIncrease varietyIncrease weld widthWelding/cutting media/materialsSoldering mediaSteel beltCarbon steel

The invention discloses a flux-cored steel-belt that contains steel wires and is used for surfacing and a preparation method thereof. The flux-cored steel-belt is produced from low-carbon steel belts and powder and a steel wire enwrapped therein. The shape of the steel belts is a tube, of which the vertical cross section is in a long flat shape or a rectangle-like shape and the horizontal sides are connected in a closing form or a lapping form. The powder is evenly filled in the tube rolled from the steel belts and the steel wire which is arranged vertically along the tube, has the same length with the tube and positioned at the geometric center of the vertical cross section of the flux-cored steel-belt is clamped in the middle of the powder. Through the adjustment of clamping the steel wire and the powder flux-cored steel-belt of the invention, the variety of steel belts used for surfacing is added, thus reducing cost. The flux-cored steel-belt can be wound into a disk-like shape, thus being suitable for continuous automatic surfacing, leading the application field of strip surfacing to expand, increasing the stability of electric arc and reducing the technical requirements against welding equipment.

Owner:SHANDONG UNIV

Electron Beam Repair Welding Method for Tunnel Defects in Friction Stir Welding

ActiveCN106180969BLarge weld surface widthAvoid welding deformationArc welding apparatusMetal working apparatusEngineeringMachining

The invention discloses an electronic beam repair welding method for friction stir welding tunnel defects, and relates to repair welding technologies, in particular to a repair welding method for the tunnel defects exposed out of an aluminum alloy friction stir welding liquid cooling assembly after finish machining. The electronic beam repair welding method for the friction stir welding tunnel defects achieves repair welding of the tunnel defects exposed out of the aluminum alloy friction stir welding liquid cooling assembly after finish machining, and therefore deformation of a finish machining structure is avoided, product cost is saved, and the product period is shortened. The electronic beam repair welding method for the friction stir welding tunnel defects comprises cleaning, drying, welding depth h determining, mounting, welding program programming, repair welding and machining. The method can be used for repair welding of the tunnel defects, and the market vacancy is filled; the method is applicable to deformation-free repair welding of the aluminum alloy tunnel defects, and belongs to the technical field of material welding.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

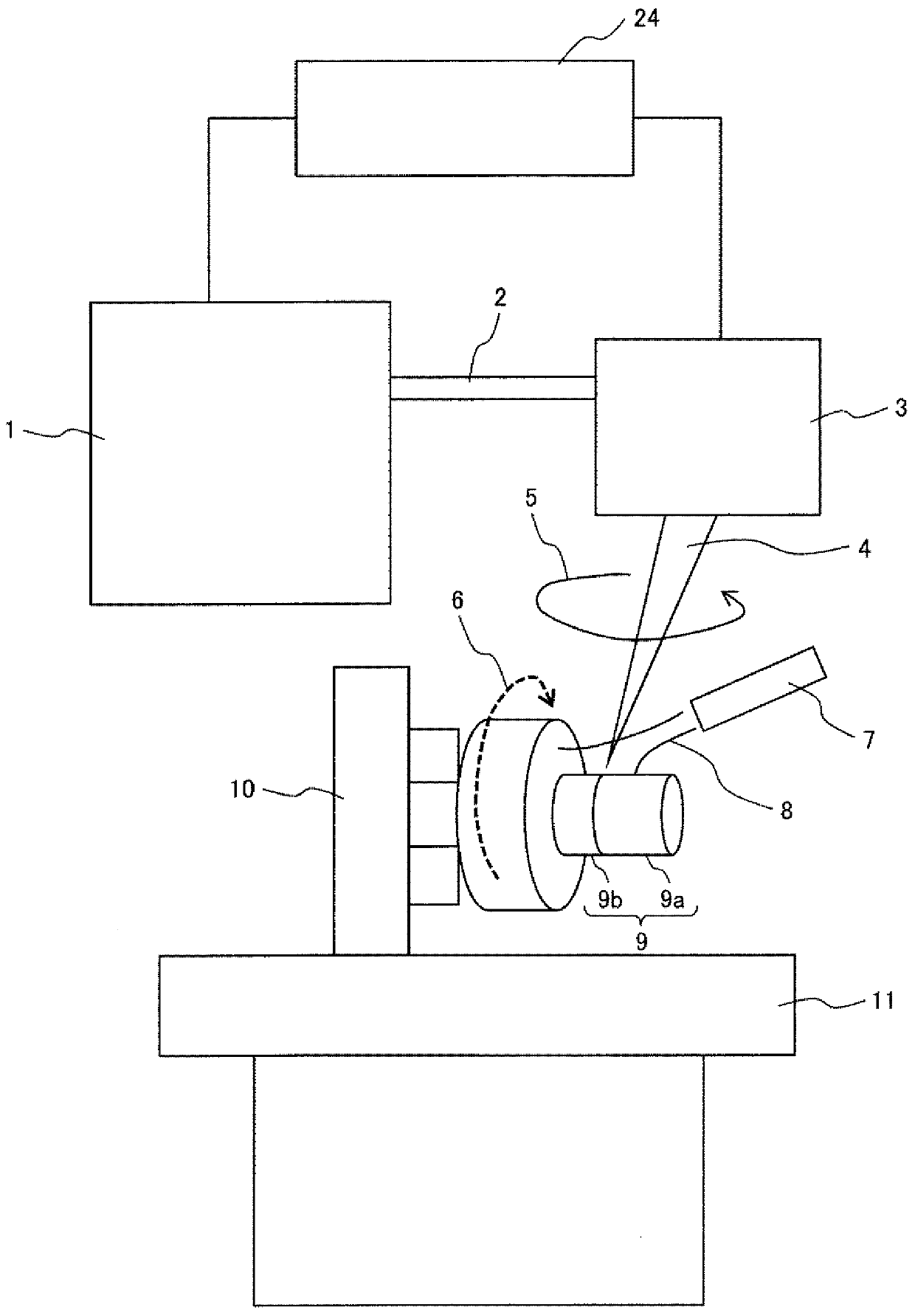

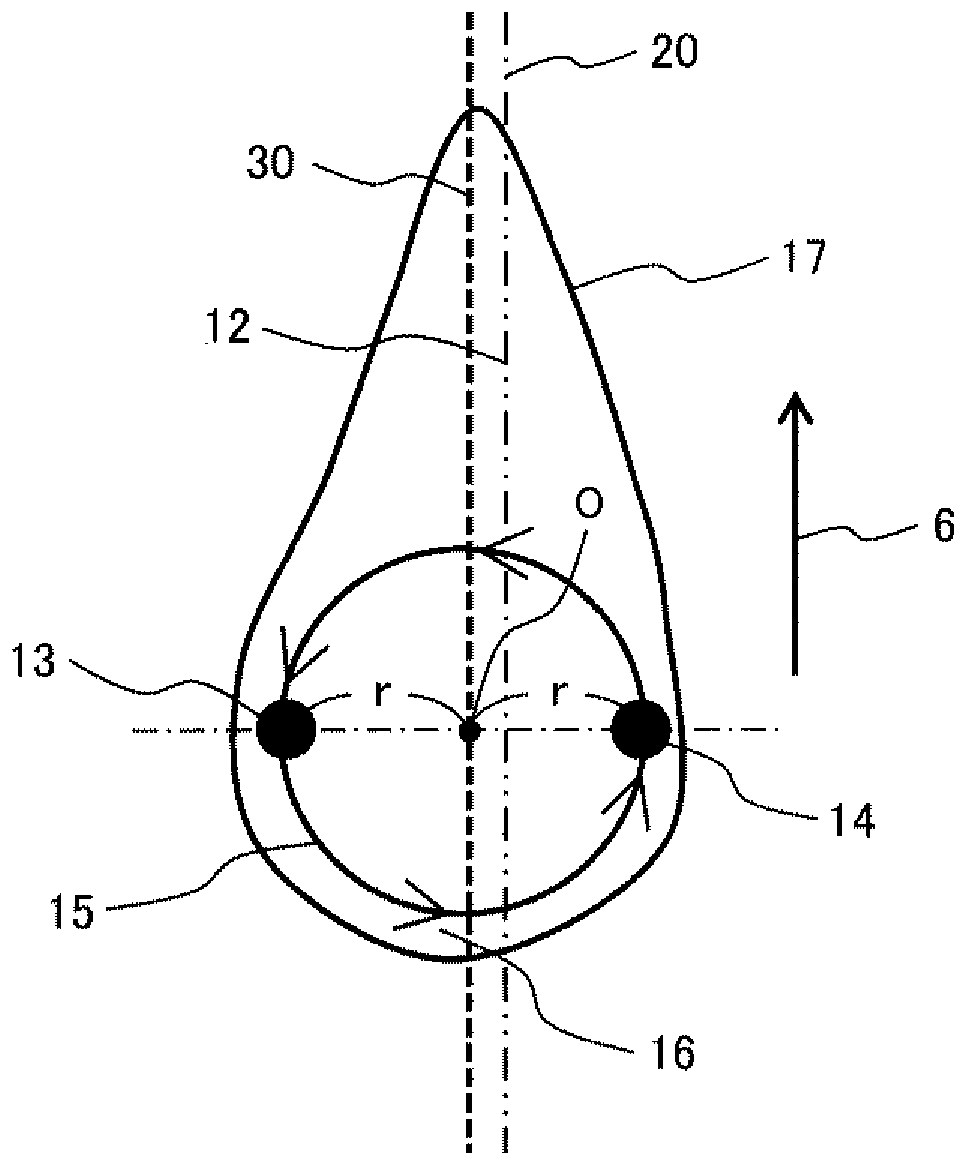

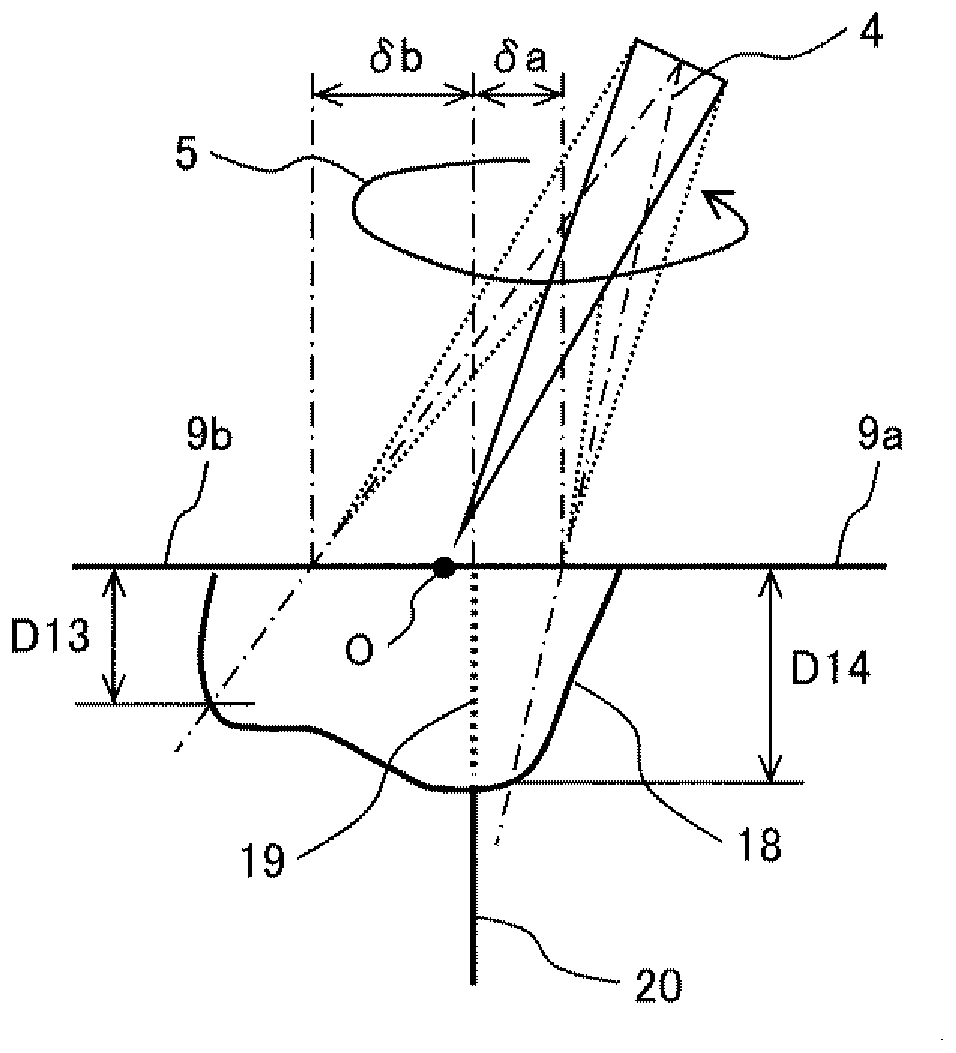

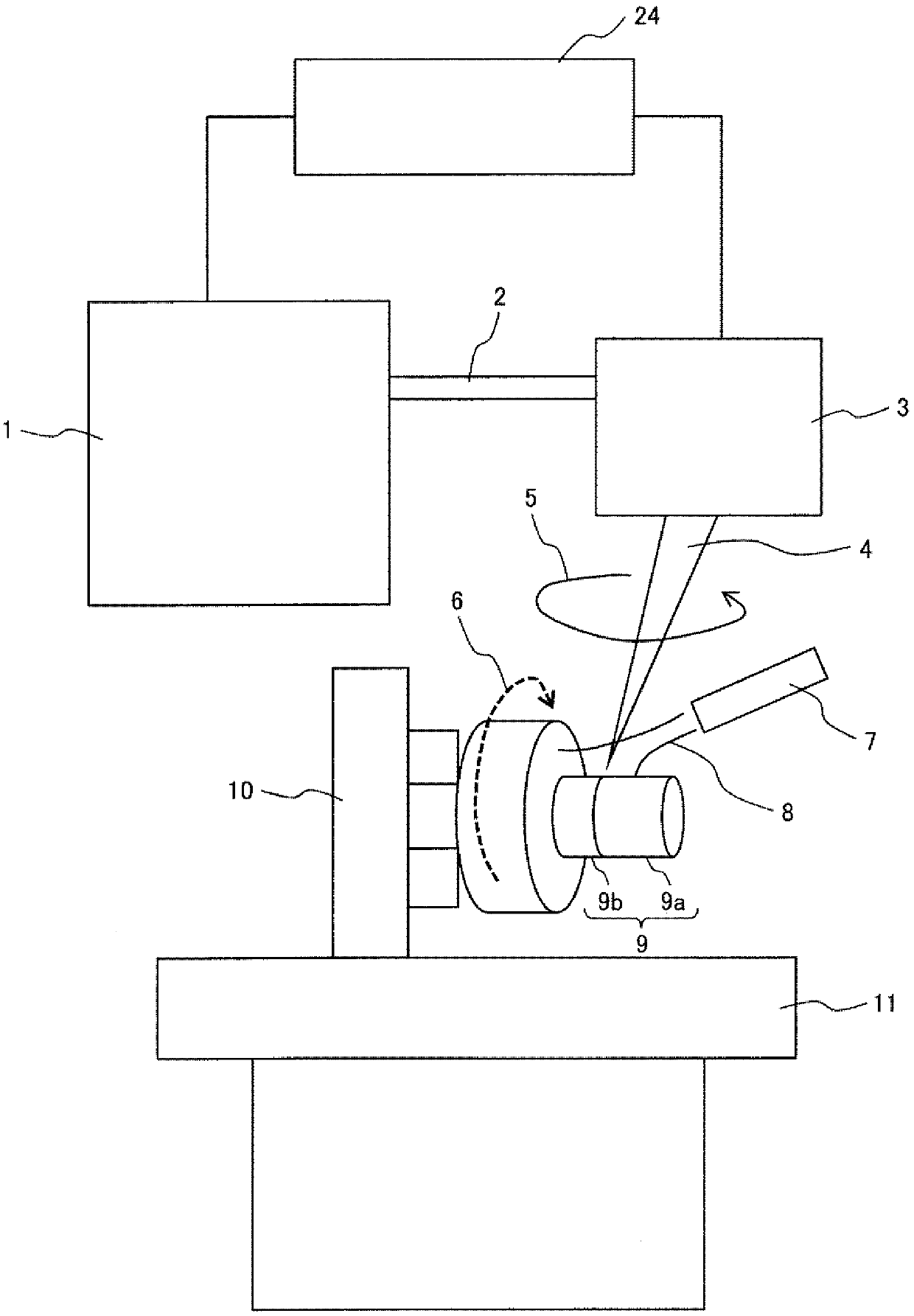

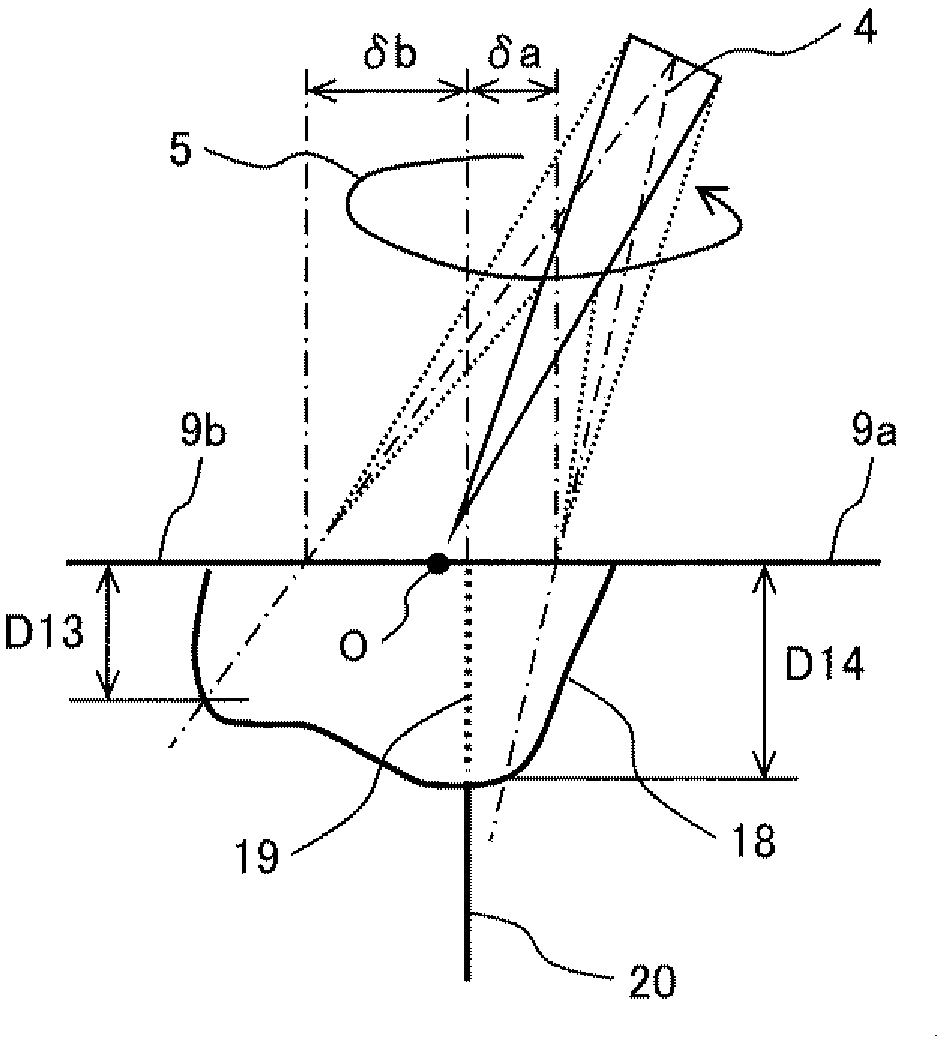

Laser welding method, high-pressure fuel supply pump and fuel injection valve

ActiveCN107708913BIncrease weld widthIncrease Target Position MarginVehicle componentsMetal working apparatusEngineeringIrradiation laser

An object of the present invention is to provide a laser welding method capable of securing an effective welding length when irradiating a laser beam obliquely. In the laser welding method in which the laser beam (4) is oscillated and scanned periodically while the object to be welded (9) is moved, and the surface of the object to be welded (9) is irradiated for welding, the output and scanning of the laser (4) are controlled. Welding is performed in such a manner that at least one of the speed and the scanning trajectory makes the heat input amounts on the left and right sides of the welding progress direction substantially different.

Owner:HITACHI ASTEMO LTD

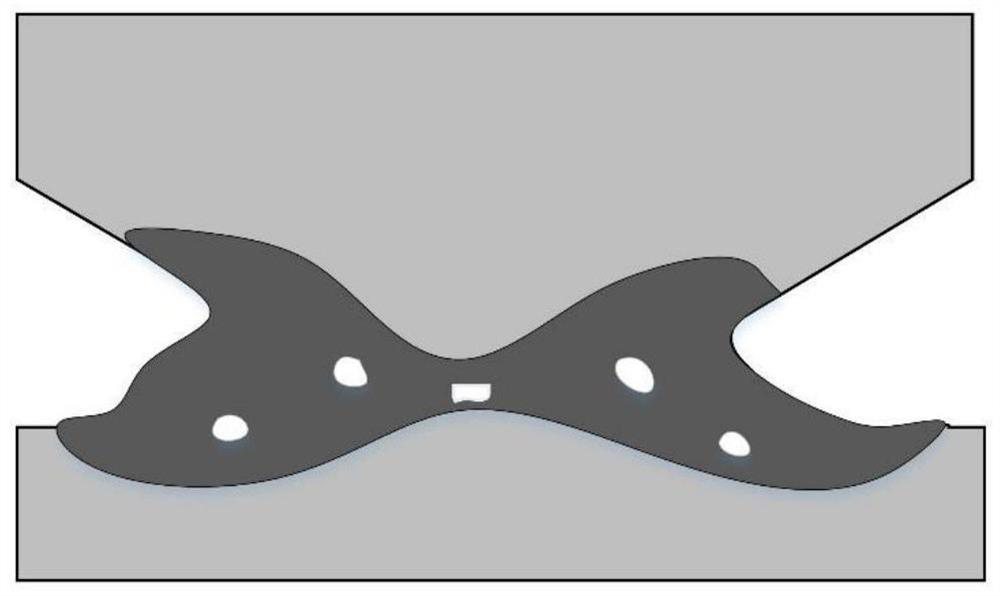

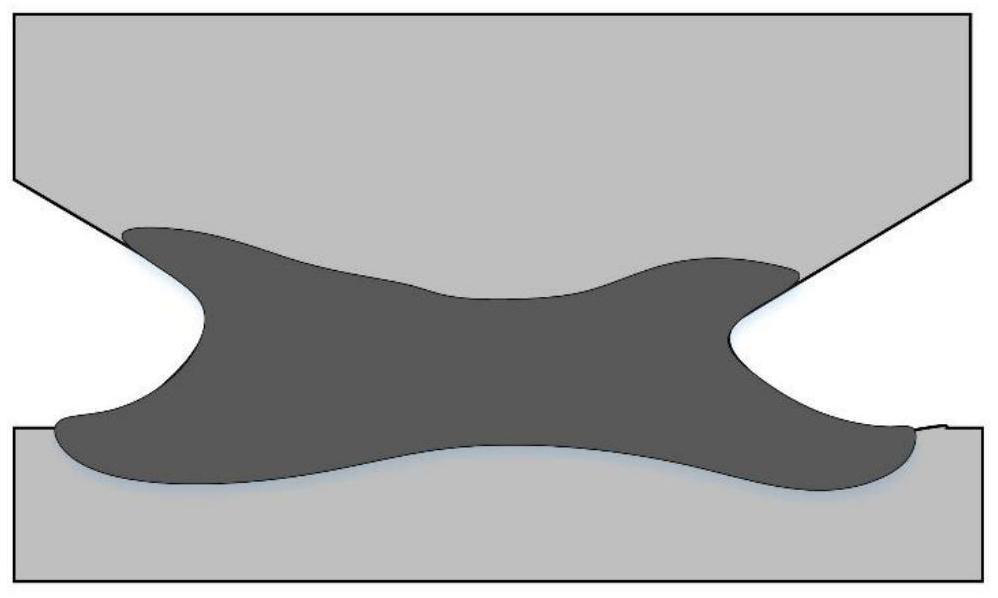

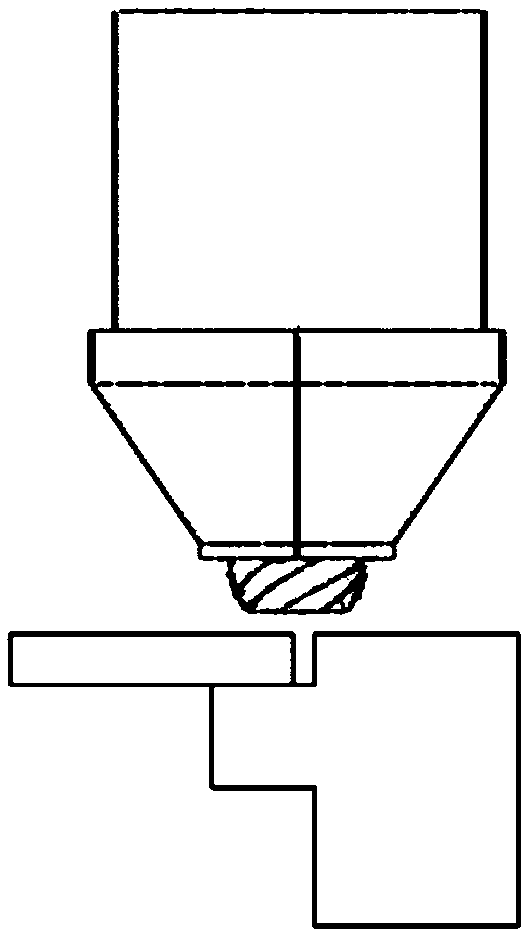

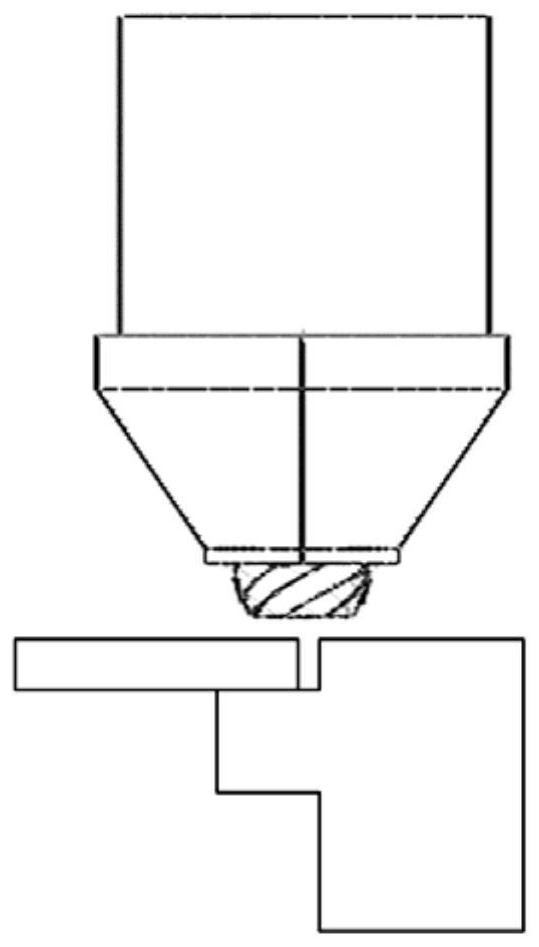

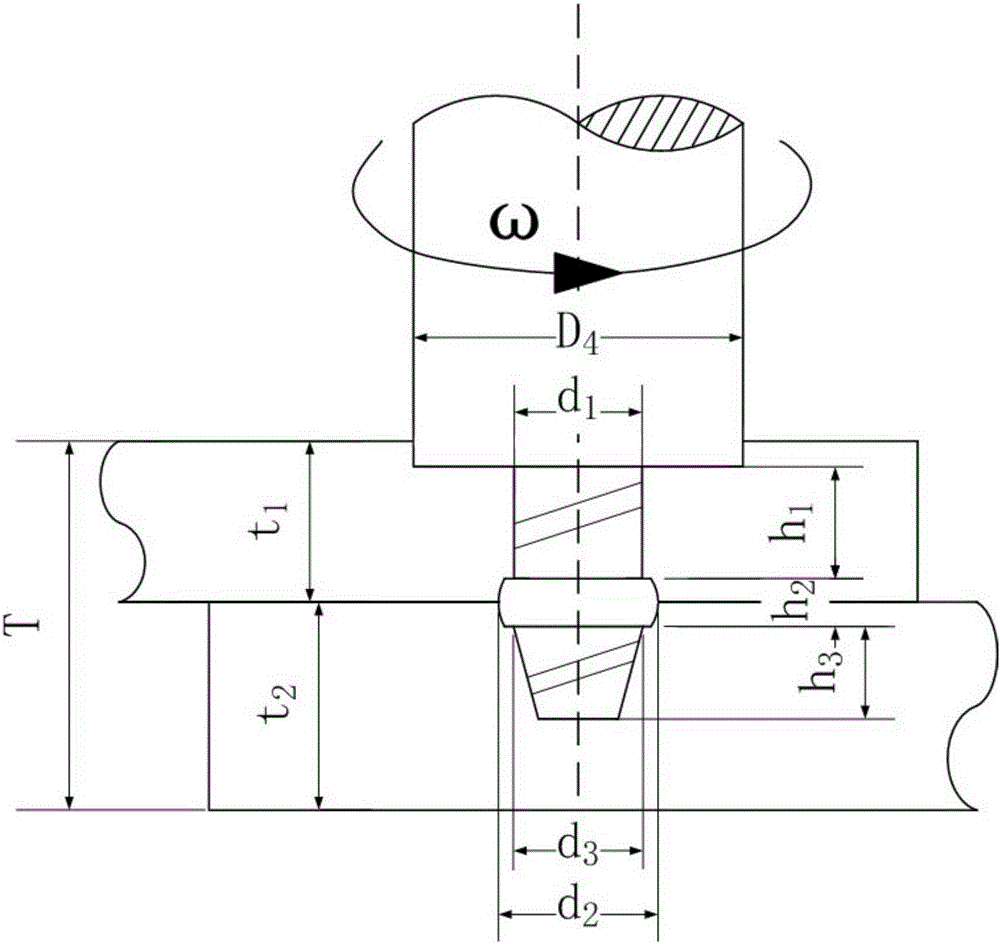

A friction stir lap welding method for reducing the size of interface defects

InactiveCN104400215BIncrease weld widthImprove carrying capacityNon-electric welding apparatusEngineeringMechanical property

The invention discloses a stirring head for friction stir overlap welding for reducing the size of an interface defect and a welding method thereof, relates to the stirring head for the friction stir overlap welding and the welding method thereof, and aims to solve the problem that the effective bearing capacity, the effective overlap width and the mechanical property of a joint are effectively reduced by an advancing side Hook defect and a retreating side cold overlap defect in the existing friction stir overlap welding joint. The stirring head for the friction stir overlap welding consists of a shaft shoulder and a stirring pin, wherein the stirring pin is formed by connecting an upper cylinder, a middle dome and a lower circular truncated cone in sequence. The welding method comprises the following steps: I, determining the size of the stirring head; II, determining the length of the stirring pin; III, fixing a welded workpiece; IV, pressing the middle dome of the stirring pin to the overlap interface of two welded workpieces; V, performing friction stir welding. In the welding process, the original overlap interface is stirred by using the middle dome, so that the size of the interface defect is effectively reduced, and the overlap area is also effectively increased to improve the mechanical property of the joint.

Owner:HARBIN INST OF TECH

Laser welding method, pump for supplying high-pressure fuel, and fuel injection valve

ActiveCN107708913AIncrease weld widthIncrease Target Position MarginVehicle componentsMetal working apparatusEngineeringHigh pressure

The purpose of the present invention is to provide a laser welding method with which it is possible to ensure an effective welding length when irradiating a laser beam at an incline. A laser welding method for performing welding by periodically scanning a laser 4 in an oscillating manner and directing the laser 4 on the surface of an object to be welded 9 while the object to be welded 9 is causedto move, wherein at least one of the output, scanning speed, and scanning path of the laser 4 is controlled, and the amount of input heat on both left and right sides along the direction in which welding proceeds is caused to vary substantially, to perform welding.

Owner:HITACHI ASTEMO LTD

Flux-cored steel belt for build-up welding and preparation method thereof

InactiveCN101306493BIncrease varietyIncrease weld widthWelding/cutting media/materialsSoldering mediaFerroniobiumFerrosilicon

The invention discloses a resurfacing welding used drug cored steel strap and the preparation method. The steel strap is prepared from a mild steel strap and drug powder enwrapped therein, the shape of the steel strap is a tube with the longitudinal cross-section to be in a long and flat shape or in a similar rectangle shape, the longitudinal length can be determined randomly, and the transverse sides of the steel strap are connected in a seam manner or a related joint manner; the drug powder is uniformly filled in the tube rolled from the steel strap, wherein the particle diameter of the drug powder is smaller than 120 Mum, the components include (by weight) 45-70 parts of high carbon ferrochrome, 5-35 parts of ferrovanadium, 1-8 parts of No.75 ferrosilicon, 1-10 parts of high carbon ferromanganese, 2-16 parts of ferroboron, 1-8 parts of ferrotitanium, 0-5 parts of ferroniobium, 2-8 parts of ferromolybdenum, 0-10 parts of graphite, 0-5 parts of fluorite and 0-6 parts of potassium titanate. The drug cored steel strap adopting the invention can efficiently improve the abrasion resistance of the metal on the resurfacing welding layer and the stability of the electric arc, and can becoiled into coils, thereby being suitable for continuous automatic resurfacing welding.

Owner:SHANDONG UNIV

Method of welding steam turbine nozzle by electron beam

ActiveCN100443236CIncrease weld widthIncrease output powerOther manufacturing equipments/toolsElectron beam welding apparatusEngineeringTurbine

The invention relates to a method for using electron beam to weld ejection of turbine, wherein it comprises: 1, casting ejector room; 2, washing the surface of ejector room; 3, fixing the ejector room in the work bench; 4, using electron welding machine to weld the ejector in vacuum room, while the data should be matched; 5, cooling welded ejector and thermally treating, cooling and welding two semi rings. The invention can welding at single surface and form at two surfaces, without back root cleaning, with high welding quality, high efficiency and reduced producing period.

Owner:HARBIN TURBINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com